Solo 454 - 457, 454, 457 Workshop Manual

BY

MADE IN GERMANY

MADE

SOLO

Workshop Manual

service

service

454 - 457

Edition: 1/99

1.

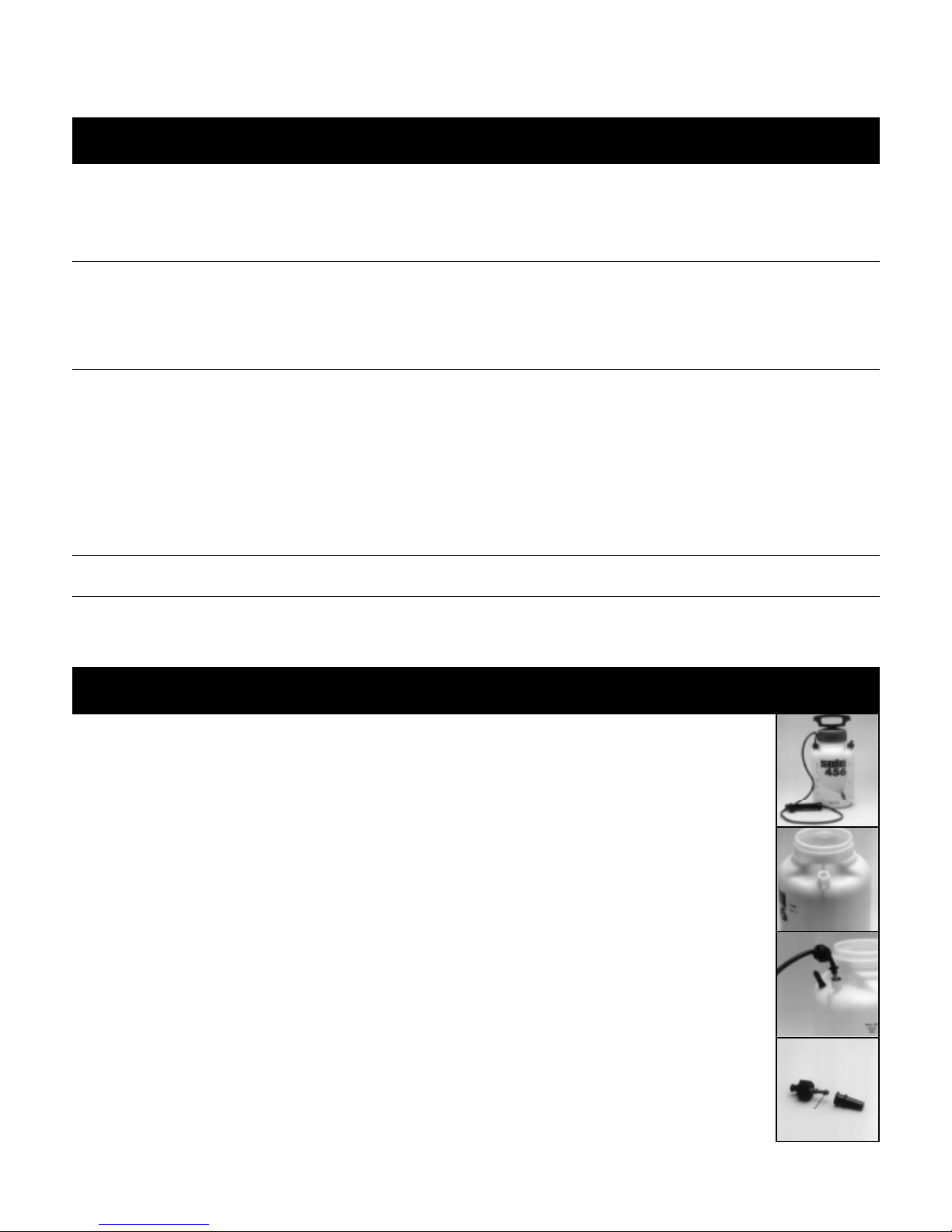

If the sprayer will not hold pressure, fill the sprayer 3”(ca. 8 cm) below the top with water. Replace the cap and

pump 4 times. Filling the sprayer this full makes it very easy to pump up to the maximum pressure. CAUTION: The

bottom of the pressure relief valve is submerged and will discharge water under pressure. Dry off any water on the

outside of the sprayer . (See Figure 1) If you observe water leaking out of the sprayer , check for damage at the site of

the leak.

If the leak is at a connection, try to tighten the screw cap. If that fails, remove the screw cap and check the sealing

surface to make sure that it is flat, smooth and the seal or O-Ring is undamaged. Retighten. (See Figure 2)

When reassembling the connections, especially the hose, make sure the O-Ring is seated before hand-tightening

the screw cap. (See Figure 3)

The pressure relief valve is removed by unscrewing it from the tank. Once removed, the lower housing pulls off to

access the O-Ring on the stem (A). When replacing this O-Ring, make sure it is seated in the recess on the stem.

Lubricate O-Ring with Vaseline Grease on stem before reassembly. (See Figure 4)

Figure 2

Figure 3

Figure 4

A

HANDHELD SPRAYER TROUBLE SHOOTING GUIDE

Figure 1

Note: Always wear rubber gloves, safety goggles and appropriate protective clothing when repairing a sprayer. Once a repair is

completed, fill the unit with clean water, pressurize, and check for leaks. If the sprayer leaks, Do Not Use. Repair leaks and recheck.

2.

3.

4.

PROBLEM CAUSE SOLUTION

Difficulty in Moving • Dirty Cylinder Wall • Remove Piston, Clean and Replace

Pump Handle

• O-Ring on Piston Swollen (Not Cleaned Properly) • Replace O-Ring

• No Lube on Piston/Cylinder • Lubricate with Vaseline Grease

Low Pressure & Resistance • Damaged O-Ring in Pressure Relief Valve • Replace O-Ring

During Pumping

• Worn or Damaged O-Ring onPisto • Replace O-Ring

• Tank Cap Not Tight • Tighten Cap

• No Lube on Piston Cylinder • Lubricate Piston, O-Ring and Cylinder with Vaseline Grease

Leaks From End • Worn or Damaged O-Ring in Shut-Off Valve • Rebuild Shut-Off Valve

of Spray Wand

Leaks From • Worn or Damaged Umbrella Valve • Replace Umbrella Valve

Inside Cylinder at Bottom of Cylinder

Leaks Under Cap • Damaged or Missing Gasket • Replace Gasket

• Screw Cap Not Tight • Tighten Tank Cap

Leaks From Shut-Off Valve • Worn, Damaged or Loose Fittings, Lack of Lubrication• Tighten Fittings and Replace Worn Parts,

Disassemble and Lubricate O-Rings

Leaks From Hose • Worn, Damaged or Loose Fittings • Tighten Fittings and Replace Worn Parts

Pressure Relief • Lack of Lubrication or Contaminated • Clean and Lubricate Pressure Relief Valve

Valve Sticks Relief Valve Assembly

Air Leak - • Tank Cap Not Tight • Tighten Tank Cap

Air Coming Out

Between the Two • Gasket Twisted or Lacking Lubrication • Straighten Gasket and Lubricate with Vaseline Grease

Halves of the

Pump Support • Tank Lip Damaged • Repair or Replace Tank

SPRAYER DISASSEMBLY & REPAIR

2.

-3-

Loading...

Loading...