Page 1

9 116 104 english 11/2009

116

Instruction manual

Original instructions

Important!

Read this instruction manual carefully before

first operation and strictly observe all safety

regulations!

Electric trimmer

05

Page 2

- ENGLISH - Electric trimmer 116

ENGLISH 2

Instruction manual

Original instructions

Caution! Prior to operating the unit, please

read the owner’s manual carefully, and most

importantly, observe all safety rules.

Observe the maintenance guidelines closely to

ensure the long service life of your equipment.

Your dealer will be glad to assist you with any

questions.

EC declaration of conformity Î The EC

declaration of conformity on a separate piece of

paper forms part of these operating instructions.

Packaging and disposal

Please keep the original packaging in order to

protect the equipment against transport damage in

case you ever need to ship it or transport it. If the

packaging materials are no longer required then

they must be disposed of properly in accordance

with applicable local regulations. Cardboard

packaging materials are raw materials which can

be recycled or reused.

At the end of the equipment’s service life, please

make sure that you dispose of it properly, in

accordance with the official directives and

regulations that apply in your area

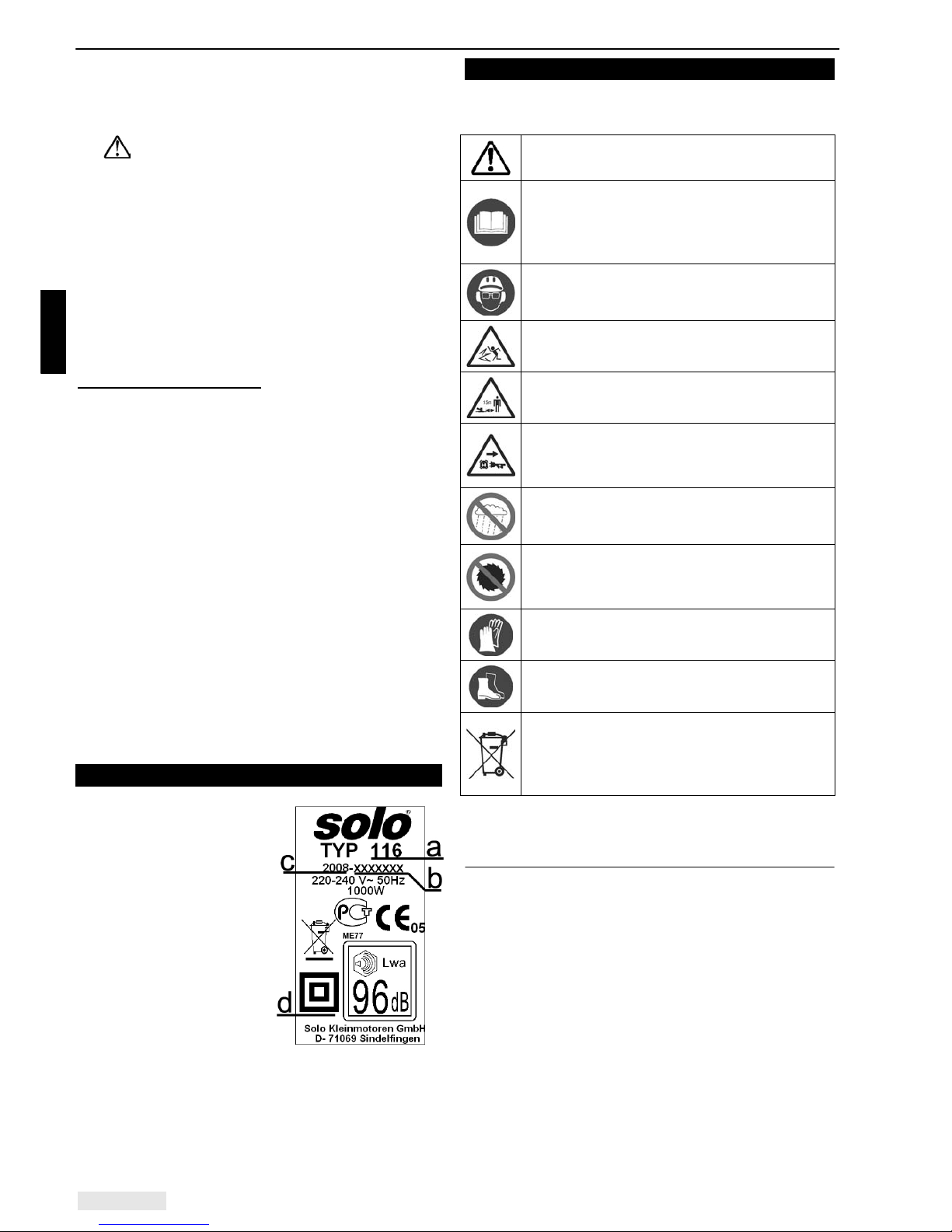

Type plate

a: Type designation

b: Serial number

c: Build year

d: Double-insulated

Symbols

The following symbols are used in this manual and

on the product:

Always handle this power tool with

particular care

Read these operating instructions

carefully before undertaking any

maintenance, installation and cleaning

steps

Wear ear defenders and a face shield

before starting the motor.

Please note: objects may be thrown out

and high

Maintain a minimum distance of 15

metres bystanders

Immediately pull the mains plug from its

socket if the supply cable or extension

cable are damaged

Never use this power tool in the rain

No use of metal cutting blades allowed.

Use only permitted string head cutting

tools for work process.

Wear protective gloves when handling

and working with the equipment

Wear solid shoes, preferably safety shoes

with a good profile

Electrical equipment is unsuitable for

domestic waste. Have the equipment,

accessories and packaging recycled in an

environmentally responsible way.

In the best interest of continued technological

progress we reserve the right to change the design

and configuration of any product without prior

notice.

For that reason, no claims can be accepted with

reference to text and illustrations in this manual.

Page 3

Index ; Safety regulations

ENGLISH 3

Index

Page

1. Safety regulations................................................................................................................................. 3

1.1 Mains supply and extension cable 3

1.2 Correct use / General safety instructions 4

1.3 Working clothes 4

1.4 When transporting the equipment 4

1.5 Before connection to the mains supply 5

1.6 Working with the machine 5

1.7 Maintenance, cleaning and repairs 5

2. Standard delivery.................................................................................................................................. 6

3. Control and function elements............................................................................................................ 6

4. Specification .........................................................................................................................................7

5. Preparing the equipment for use.........................................................................................................8

5.1 Loop handle assembly 8

5.2 Shield installation 8

5.3 Cutter installation 9

5.4 Shoulder strap adjustment 9

5.5 Connection to the mains supply 9

6. Using your trimmer............................................................................................................................. 10

6.1 Scope of Application 10

6.2 Correct trimmer operation 10

6.3 Adjusting the cutting line 10

6.4 Troubleshooting 11

7. Operating and maintenance instructions ......................................................................................... 12

7.1 General operating and maintenance instructions 12

7.2 Gearbox lubrication 12

7.3 Cleaning 12

7.4 Shutdown and storage 12

8. Guarantee ............................................................................................................................................13

9. Parts subject to wear and tear........................................................................................................... 13

1. Safety regulations

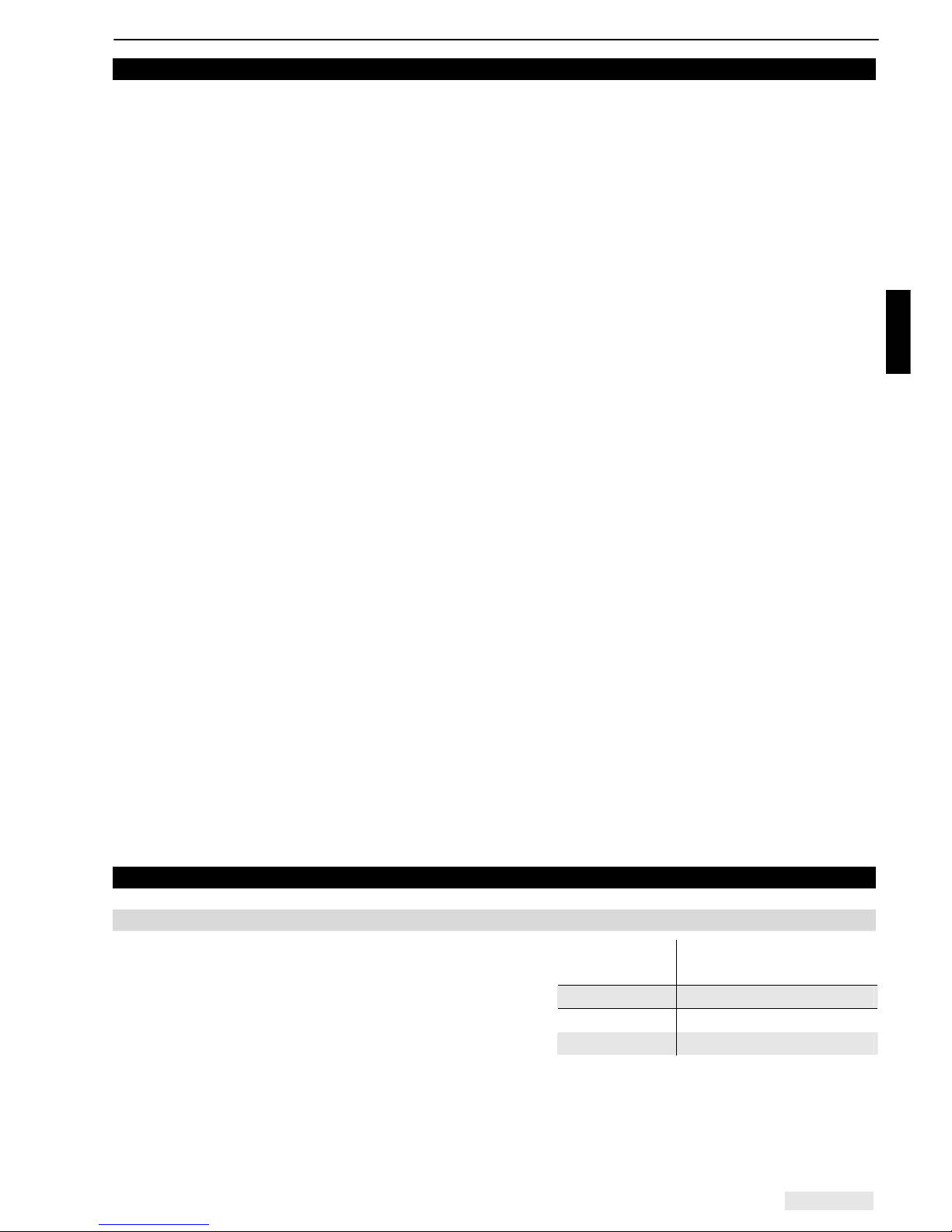

1.1 Mains supply and extension cable

• Only extension cables approved for outdoor use with a

minimum cross-section as shown here are permissible

as mains extension cable.

- DIN 57282/H07 RN-F

- The cable connectors must be made from

rubber or must be covered in rubber.

- When using a cable reel, fully unreel all cable.

• Check whether the mains supply voltage matches the details on the type plate of the power tool.

• The mains socket must be protected at least by a 16 A fuse.

• For your personal safety, we recommend the use of a 30 mA RCD.

Cable length

up to

Minimum cable cross-

section

7 m 1,2 mm

2

15 m 1,6 mm2

30 m 2,0 mm2

Page 4

Safety regulations

ENGLISH 4

1.2 Correct use / General safety instructions

The electric trimmer must only be used to cut grass, reeds, weeds and wild growth at ground level. The

trimmer must not be used for any other purposes (see chapter 6.1 "Scope of Application").

Read the operating instructions carefully before taking this equipment into service and keep

them in a safe place. Use this power tool with particular caution.

Non-observance of safety instructions can lead to a risk to life. Also observe any regulations from your

professional body. These operating instructions must always be available at the place of work. All

individuals instructed to work with the equipment (including maintenance, care and repair), should read

these instructions.

• You should request and receive instructions from the vendor on the safe operation if you are using this

type of product for the first time.

• Never expose this power tool to rain. Never use this equipment in moist or wet conditions.

• Children and young persons under the age of 18 years may not work with this power tool, with the

exception of young people over the age of 16 years who are being trained under supervision.

• Keep bystanders and animals away from the working area. Maintain a minimum distance of 15 m.

When working near thickets, be aware that children and animals may be hidden there. Immediately

stop the machine and the cutter if any person or animal comes close to the working area. The operator

is responsible for any accidents or damage caused to individuals or property.

• This machine may only be passed on or lent to third parties if they are familiar with the safe use of this

product and with these instructions. Always supply the manual with the machine.

• Ensure you are rested and in good health when using this machine.

• Persons under the influence of alcohol or drugs, including prescription drugs, are not allowed to use

this machine, as their ability to quickly react to potential danger may be impaired.

• Never alter, change or modify any safety equipment or functional assemblies on this machine.

• Only use this machine if it is in good, safe condition. Always check the machine prior to use. Risk of

accident!

• Only use those accessories and attachments that have been supplied by the manufacturer and that

are expressly approved for attachment. When using a nylon head, never replace a plastic line with a

steel line. Always use the appropriate guard with each cutter.

• Before replacing the cutting blades, always first stop the motor and pull the mains plug from its socket

to prevent an accidental starting of the motor.

• The reliability and safe operation of your machine depend on the quality of parts used with the

machine. Only use original spare parts. Original spare parts are identical with genuine production parts

and guarantee best quality in material, dimensions, function and safety. Original parts and accessories

are available from your specialist dealer. Your dealer has been supplied with appropriate

documentation to determine the correct parts. Your dealer is frequently supplied with updates about

improvements to the equipment. Please note that the use of non-original parts will void your warranty.

• Always store the machine in a safe place and in such a way that it will not pose any danger. Stop the

motor when the machine is not used.

Persons who disregard safety instructions, operating or maintenance instructions may be liable for any

damage or consequential losses.

1.3 Working clothes

To prevent injuries, always wear suitable clothing and safety equipment when working with this power tool.

This clothing should be practically oriented to the application (for example a tight fitting work suit), but

should not be confining.

Never wear scarves, ties, jewellery or other items of clothing, which might get caught in the equipment, in

brush or on branches. Safely tie back long hair (use a cap, helmet or similar).

Wear sturdy shoes with a good profile - ideally safety shoes.

Wear protective gloves with non-slip palms.

Use ear defenders and/or a visor for protection against flying objects or objects caught

up in the turbulence (protective goggles for example).

1.4 When transporting the equipment

• Always turn off the motor when transporting the machine.

• Never carry or transport the trimmer with the motor running.

Page 5

Safety regulations

ENGLISH 5

1.5 Before connection to the mains supply

Before taking the power tool into use, check it fully for perfect condition.

• The ON/OFF switch must be able to move freely and must automatically return into the stop position.

• The cutters and guard must be tightly secured and in perfect condition.

• The mains cable, which is part of the equipment, and the extension cable must be in perfect condition.

Should the check reveal any irregularities or recognisable damage (also to the frame) or reduced

efficiency of the machine, do not commence work. Take the power tool to a specialised workshop and

have it checked.

1.6 Working with the machine

• Only use this power tool when it is complete and in a safe condition.

• Work conscientiously, thoughtfully and calmly, and do not endanger third parties.

- Pay attention to good visibility and lighting conditions.

- Always remain within earshot of other people who can provide help in case of emergency.

- Plan for timely work breaks.

- Pay attention to possible hazards and take appropriate precautions. Be aware that wearing ear

defenders reduces the ability to perceive noise. This includes sounds alerting to danger such as

signals, shouts, etc. that can go unnoticed.

- Exercise caution when the ground is wet or covered in ice and snow, on overhangs, or uneven

terrain. There is an increased risk of slipping!

- Pay attention to the risk of stumbling and obstacles, such as tree roots and stumps, edges, etc. Pay

particular attention to safety when working on slopes.

- Before commencing work, check the working area for stones, broken glass, nails, wire or other solid

objects and remove such debris to prevent them being picked up and thrown out by the cutting tool.

- Ensure that, when you start the machine, it contacts neither objects nor the ground.

- Always hold this power tool firmly in both hands, and ensure your safe and firm foothold.

- Always hold the cutters below hip level. Never lift a rotating cutter off the ground.

- Keep all parts of the body away from the rotating cutting tool.

- Always keep the mains supply or extension cable away from the cutting tool.

- Use a correct operating mode (see Chapter 6.2 "Correct trimmer operation").

- Please note that noise also impacts on the environment. Observe the quiet times that can vary from

place to place.

• Stop the motor if you notice a difference in the operating characteristics of the trimmer.

• The cutter continues to rotate for a short time after releasing the ON/OFF switch. Ensure that the cutter

has come to a complete standstill before parking the machine.

• Before any contact with the cutter – even when clearing a blockage or jamming of the cutter – switch

OFF the motor, wait until the cutter has come to a complete standstill and pull the mains plug from its

socket.

First Aid

A first aid box should always be available on-site. Immediately replace any materials you have used:

Note:

Over exposing persons with circulatory problems to vibrations can lead to damage to their nervous system

or blood vessels. The following systems may occur from vibrations to fingers, hands or the wrists:

Numbness, itching, pain, twinges, changes to the colour of the skin or the skin itself. Seek medical advice

if you experience any of these symptoms.

1.7 Maintenance, cleaning and repairs

Only carry out those maintenance jobs and repairs, which are described in this manual. A specialised

service centre will carry our all other jobs.

• Before cleaning, maintenance or repairs, always switch OFF the motor and pull the mains supply plug

from its socket.

• For any repairs only use original parts from the manufacturer.

• Never hose down the power tool – not even for cleaning.

Page 6

Standard delivery ; Control and function elements

ENGLISH 6

2. Standard delivery

• Electric trimmer partially assembled; the following components are supplied separately and require

assembly

• Handle and all parts required to complete the assembly

• Shoulder strap

• Guard, Guard bar, line trimmer and all parts required to assemble the shield

• Nylon head cutter with all assembly parts required for fitting the nylon head

• Retaining pin (allen wrench)(for fitting the cutter)

• Instruction manual

• Instruction manual, the EC declaration of conformity on a separate piece of paper

3. Control and function elements

1. Locking button

2. ON/OFF switch

3. Handle on the motor casing (r.h.)

4. Loop handle (l.h.)

5. Safety stop

6. Shoulder strap retainer

7. Guard

8. Fixing part

9. Guard bar

10. Mains cable

Fig. 1

Page 7

Specification

ENGLISH 7

4. Specification

Motor type / Motor power W Electric motor / 1000

Mains voltage / frequency V / Hz 230 AC / 50

Protection class II (double-insulated)

Extension cable (accessory) DIN 57282/H07 RN-F

Rated speed of the cutter

1

/

min

6500 - 7500

Drive shaft – property / diameter mm Flexible / 6,2

Shaft tube – material / diameter Ø mm Aluminium / 25

Gear reduction 1,25 : 1

Standard cutting tool 2-line nylon head; semi-automatic;

square section and twisted line Ø 2.0 mm

Cutting diameter mm 380

Dimensions - Height / Width / Length mm 1750 / 380 / 240

Weight w/o guard and cutting tool kg 4,5

Weighted effective acceleration (EN 786 Appendix D)

Handle r.h. side / handle l.h. side m/s

2

5,88 / 10,6

Sound pressure level LPeg (EN 786 Appendix E) dB(A) 74,3

Sound power level L

Weg

(EN 786 Appendix E)

actual / guaranteed 95% dB(A)

95,85 / 96

Page 8

Preparing the equipment for use

ENGLISH 8

5. Preparing the equipment for use

For shipping purposes, the trimmer is partly

disassembled and has to be reassembled prior to

use.

Only use the trimmer after it has been fully

assembled.

5.1 Loop handle assembly

• Install the safety stop (5) pointing to the left

(viewed from the operator position).

• Initially tighten the screws only lightly.

• Push the handle, in accordance with your body

size, into its optimum position.

• Then tighten the screws.

5.2 Shield installation

Insert both square nuts (18) from below into the

contact protector (19).

Locate the fixing part (20) on the gearbox so, that

the gearbox screw locates in the central hole (21).

Secure the contact protector with both screws (22)

in the outer holes of the fixing part.

Fig. 2

Fig. 3

Fig. 4

Page 9

Preparing the equipment for use

ENGLISH 9

5.3 Cutter installation

• Position thrust piece (23) on gear shaf.

• Rotate the gear shaft with the thrust piece, so

that the recess for retaining pin (allen

wrench)(24) is flush with the recess in winding

protection (25) or the gearbox casing.

• Insert the retaining pin to lock the gearbox.

• Rotate the complete nylon head (27) with the

additional line winding protection (26) on the

gear shaft against the thrust piece. Please note:

Left-hand thread! Tighten anti-clockwise against

the nylon head.

• Push the protective bar (28) from below onto

the shield. For this, insert the hexagon nuts (29)

into the protective bar, then fit the protective bar

with the three screws (30).

Please Note: When operating with the nylon head,

never start the engine without fitted protection bar

and line trimming blade (31).

Note: When the nylon line length is adjusted (see

chapt. 6.3 "Adjusting the cutting line"), the line

trimmer blade (31) will trim the line automatically to

the correct length.

5.4 Shoulder strap adjustment

Before commencing work, adjust the shoulder

strap and handle according to the operator’s body

size.

Position the single shoulder strap over your l.h.

shoulder, so that, after adjusting the strap length,

the strap hook is located at your r.h. hip.

Balance the trimmer with fitted cutting tool so, that

the cutter hovers just above the ground, without

touching the suspended trimmer with your hands.

If the cutting tool hovers more than 10 cm above

the ground, secure the shoulder strap retainer

nearer to the motor.

If the cutter lies on the ground, secure the shoulder

strap retainer nearer the loop handle.

5.5 Connection to the mains supply

Always secure the extension cable on the cable

retainer (23) on the motor housing.

To isolate the equipment, always pull the mains

plug from its socket, i.e. never pull on the cable to

remove the plug.

Fig. 5

Fig. 7

Page 10

Using your trimmer

ENGLISH 10

6. Using your trimmer

6.1 Scope of Application

Only use trimmers equipped with a nylon head for

cutting grass – particularly suitable around

obstacles - and for trimming light weeds and wild

growth near ground level. The nylon head is

particularly suitable for a soft cut, e.g. for clean

trimming around trees and posts.

6.2 Correct trimmer operation

Observe the relevant safety instructions when

using the trimmer.

Carry the power tool on your r.h. side.

Approach the area to be cleared with the motor

switched OFF; then start the motor before dipping

the cutter into the working area.

With your thumb, initially press the locking button

(1) and then additionally the ON/OFF switch (2)

with your index finger. Then release the locking

button again. Release the ON/OFF switch to

switch the motor OFF again.

Dip the tool from the r.h. side 2/3 into the material

to be trimmed. Then work the trimmer lie a scythe,

i.e. by moving forward step by step, whilst cutting

from right to left.

Immediately switch OFF the motor, if you notice

any unusual vibrations or cuttings have wrapped

themselves around the cutting tool or have jammed

near the guard. Reduce the cutting tool speed by

pushing the cutter down onto the ground, until it

has come to a complete standstill. Pull the mains

plug from its socket and clear the cutting tool of

grass, brush etc. Check the entire power tool for

perfect condition.

When using the nylon head, always ensure that

you operate only with the correct length of line.

When the guard is fitted, the line will always be

trimmed to the permissible length automatically (a

line trimming blade is fitted into the guard bar).

There is a high risk of injury, and the motor is

subjected to excessive loads leading to a risk of

damage, if nylon lines are left too long.

Therefore, when operating with the nylon head, the

guard bar must always be fitted, together with the

integral line trimming blade, to the standard guard.

6.3 Adjusting the cutting line

When using a semi-automatic nylon head:

(schematic diagram)

Several times, tip down the equipment with rotating

nylon head onto covered ground. This dispenses

nylon line in steps. Per release, approx. 30 mm line

length will be dispensed. Excess line lengths will

be trimmed to size by the line trimming blade.

Fig. 8

Fig. 11

Fig. 9

Fig. 10

Page 11

Using your trimmer

ENGLISH 11

6.4 Troubleshooting

Fault Possible cause Remedy

Motor will not start

1. No power supply

2. Cutting tool

jammed/blocked

1a.Check the mains supply and the extension

cable.

1b. Check the mains socket (e. g. different

equipment plugged in).

2. Pull the mains plug and clear the cutting tool.

The cutter does not rotate,

even though the motor is

running.

1. Flexible shaft

broken

2. Flexible shaft

incorrectly assembled

1. Contact your local specialist.

2. Contact your local specialist.

Cutting line will not unreel 1. Line spent

2. Line reel jammed,

line twisted

1. Pull the mains plug and load a new cutting

line.

2. Pull the mains plug, open the nylon head,

rewind the line, clean the reel and reassemble correctly.

Page 12

Operating and maintenance instructions

ENGLISH 12

7. Operating and maintenance instructions

7.1 General operating and maintenance

instructions

The maintenance and the repair of modern

machines as well as their safety-relevant

assemblies require qualified specialised training

and a workshop equipped with special tools and

test equipment. Consequently the manufacturer

recommends that all tasks not described in these

operating instructions be carried out by a

specialised workshop. That specialist has the

required training, experience, and equipment at his

disposal, to provide you with the most costeffective solution for such work. He will provide

additional help in word and deed.

After a running-in time of app. 5 hours, check all

accessible screws and nuts for tightness and

retighten them, if required.

Inspect the cutting tool regularly (short intervals)

and when you notice unusual vibrations or the

cutting area or guard has become

jammed/blocked. For this switch OFF the motor,

and the cutting tool must be at a complete

standstill. Pull the mains plug and remove grass

cuttings, brush etc. from the tool base.

7.2 Gearbox lubrication

To lubricate the bevel gear drive, use SOLO

"Special gearbox grease" (part no. 0083180).

Check the grease level weekly and top up, if

required (approx. every 20 - 50 hours).

Remove the filler plug from the side of the

gearbox. If no grease is visible inside, top up with

grease (top-up quantity approx. 5 – 10 g).

Replace and tighten the filler plug.

Please note: Do not overfill with grease, as that

may lead to the gearbox overheating. Never fill the

gearbox casing to the top with grease.

Tip: If required, top up with a maximum of 5g

grease. It is preferable to check more frequently

(e.g. before you start working) whether grease is

still visible.

Your SOLO dealer workshop is happy to help you

in case of doubt.

7.3 Cleaning

Before cleaning always switch OFF the motor and

pull the mains supply plug from its socket.

Never hose down this power tool.

• Clean cuttings from the cutting area with a handheld brush.

• Only use a dry or slightly damp cloth to clean the

entire machine. Never use solvents or abrasive

cleaning agents. Before connecting the

equipment to the mains supply, the motor casing

and its interior must not be damp.

7.4 Shutdown and storage

Store the equipment in a dry secure location. Open

flames and similar should not be nearby. Prevent

unauthorised access – particularly by children.

Fig. 12

Page 13

Guarantee ; Parts subject to wear and tear

ENGLISH 13

8. Guarantee

The manufacturer guarantees trouble-free quality

and will cover the cost of replacing parts which are

found to be faulty in material or workmanship

within the prescribed guarantee period after the

date of purchase. Please note that specific

guarantee conditions may vary from country to

country. If in doubt, ask your equipment vendor.

He is responsible for guarantee matters.

We hope you will understand that we cannot be

liable for damage resulting from the following

causes:

• Non-compliance with the operating

instructions.

• Neglecting essential maintenance and repair

work.

• Wear in normal use.

• Obvious overload by continuously exceeding

the maximum performance limit of the

product.

• Using non-authorised tools.

• Use of force, incorrect treatment, misuse and

accidents.

• Damage from excessive heat due to dirt buildup around the cooling fan housing.

• Attempted adjustments and repairs by

unqualified persons.

• Use of unsuitable spare parts or third party

parts, if these are the cause of the defect.

• Damage caused by using the product in the

hire or rental industry.

Normal cleaning, adjustments or maintenance

work fall outside the guarantee provisions.

A service centre authorised by the manufacturer

must carry out all guarantee work.

9. Parts subject to wear and tear

Various parts are subject to application-specific or

normal wear and must be replaced in good time,

when required. The following parts are subject to

normal wear and are not covered by the

manufacturer's guarantee:

• Cutting tools

• Lubricants

• Nylon line

Page 14

SOLO

Postfach 60 01 52

D 71050 Sindelfingen

Tel. 07031-301-0

Fax 07031-301-130

info@solo-germany.com

SOLO

P.O.Box 60 01 52

D 71050 Sindelfingen

Germany

Phone+49-7031-301-0

Fax +49-7031-301-149

export@solo-germany.com

Loading...

Loading...