Page 1

- ENGLISH - Grass trimmer 104L / Brush cutter 107L / 107B

ENGLISH 1

Instruction manual

Original instructions

Caution! Prior to operating the

unit, please read the owner’s manual

carefully, and most importantly, observe

all safety rules.

Observe the maintenance guidelines

closely to ensure the long service life of

your equipment.

Your dealer will be glad to assist you

with any questions.

EC declaration of conformity Î The

EC declaration of conformity on a

separate piece of paper forms part of

these operating instructions.

For USA only:

Emissions Control Warranty Statement

The Environmental Protection Agency and

Solo are pleased to explain the emission

control system on your small non-road

power equipment engine. In the US new

small non- road engines must be

designed, built, and equipped to meet the

Environmental Protection Agency's

standards. Solo must warrant the emission

control system on your small non- road

engine for the period of time listed below

provided there has been no abuse,

neglect, or improper maintenance of your

small non-road engine.

Your emission control system includes

parts such as the carburetor, the ignition

system, and the exhaust system.

Where a warrantable condition exists, Solo

will repair your small non-road power

equipment engine at no cost to you

including diagnosis, parts, and labor.

Manufacturer’s Warranty Coverage

Solo's small non-road power equipment

engines are warranted for a period of two

years. If any emission control related part

on your engine is defective, the part will be

repaired or replaced by Solo.

Contact Information for Authorized Service

Center Locations, Replacement Parts,

Warranty and Technical Information

Warranty repairs must be completed by a

SOLO

Authorized Service Center.

SOLO USA, Inc. 1-800-765-6462

5100 Chestnut Avenue t

techserv@solousa.com

Newport News, VA 23605

Symbols

The following symbols are used in this manual and on the

product:

104L

107L/ B

Thoroughly read these operating

instructions before undertaking any

maintenance, installation and cleaning

steps

Wear ear defenders and a face shield

before starting the engine

Switching off the engine, stop switch on

"STOP"

Wear protective gloves when handling

and working with the equipment

Wear solid shoes, preferably safety shoes

with a good tread

Danger! Failure to comply with the

instructions could cause accidents with

potentially life-threatening injuries

Maintain a minimum distance of 15

metres bystanders

Please note: objects may be thrown out

and high

Please note: power tool may kick back on

contact with a solid object

Never exceed the specified

maximum speed

Never smoke near the power tool or

where the equipment is refuelled!

Keep open flames away from the power

tool and the fuel can

- This equipment produces exhaust fumes

and

- fuel vapours are poisonous;

never start or refuel in enclosed spaces

Fuel mixture: symbol above the fuel

mixture tank cap

Choke flap

:

Cold start position Î choke lever up,

towards this symbol

Operation and warm start Î choke

lever down

---

Model 104L:

Never use metal cutting tools.

Page 2

ENGLISH 2

Index

Page

1. Type plate .................................................................................................................................... 3

2. Safety regulations........................................................................................................................ 3

2.1 Correct use / General safety instructions 3

2.2 Working clothes 4

2.3 Fuelling 4

2.4 When transporting the equipment 4

2.5 Preparing the equipment for starting 5

2.6 Starting 5

2.7 Maintenance and repairs 5

2.8 Working with the machine 6

3. Standard delivery......................................................................................................................... 7

4. Control and function elements ..................................................................................................... 7

5. Preparing the equipment for use .................................................................................................. 8

5.1 Shield installation - model 104L 8

5.2 Fitting the safety end-stop on the loop handle - model 104L 9

5.3 Fitting and replacing the line head - model 104L 9

5.4 Completion - Loop handle - model 107L 10

5.5 Installation - Bike handle - model 107B 10

5.6 Shield installation - model 107L/ B 10

5.7 Assembling and replacing the cutting tool - model 107L/ B 11

5.8 Shoulder strap adjustment - model 107L/ B 13

6. Fuelling............................................................................................................................... ....... 13

6.1 Fuel information 13

6.2 Fuelling 13

7. Starting / Stopping the engine.................................................................................................... 14

7.1 Half throttle start position 14

7.2 Choke and primer 14

7.3 Starting 15

7.4 Turning off the engine: 15

7.5 Engine will not start: 15

8. Using your power tool................................................................................................................ 16

8.1 Scope of Application 16

8.2 Initial use/ start-up behaviour 16

8.3 Correct operating mode 16

8.4 Note on using the nylon line head (available as accessory) 17

9. Parts subject to wear and tear.................................................................................................... 17

10. Operating and maintenance instructions.................................................................................. 17

10.1 General operating and maintenance instructions 17

10.2 Information about the silencer 17

10.3 Sharpening instructions – metal cutting blades - model 107L/ B 18

10.4 Gearbox lubrication - model 107L/ B 18

10.5 Carburettor adjustment 19

10.6 Information about the spark plug 19

10.7 Air Filter Maintenance 20

10.8 Replacing the fuel filter 20

10.9 Shutdown and storage 20

10.10 Scheduled maintenance 21

11. Specification ............................................................................................................................ 22

12. Accessories ............................................................................................................................. 23

13. Guarantee ................................................................................................................................23

In the best interest of continued technological progress we reserve the right to change the design and

configuration of any product without prior notice.

For that reason, no claims can be accepted with reference to text and illustrations in this manual

Page 3

Type plate ; Safety regulations

ENGLISH 3

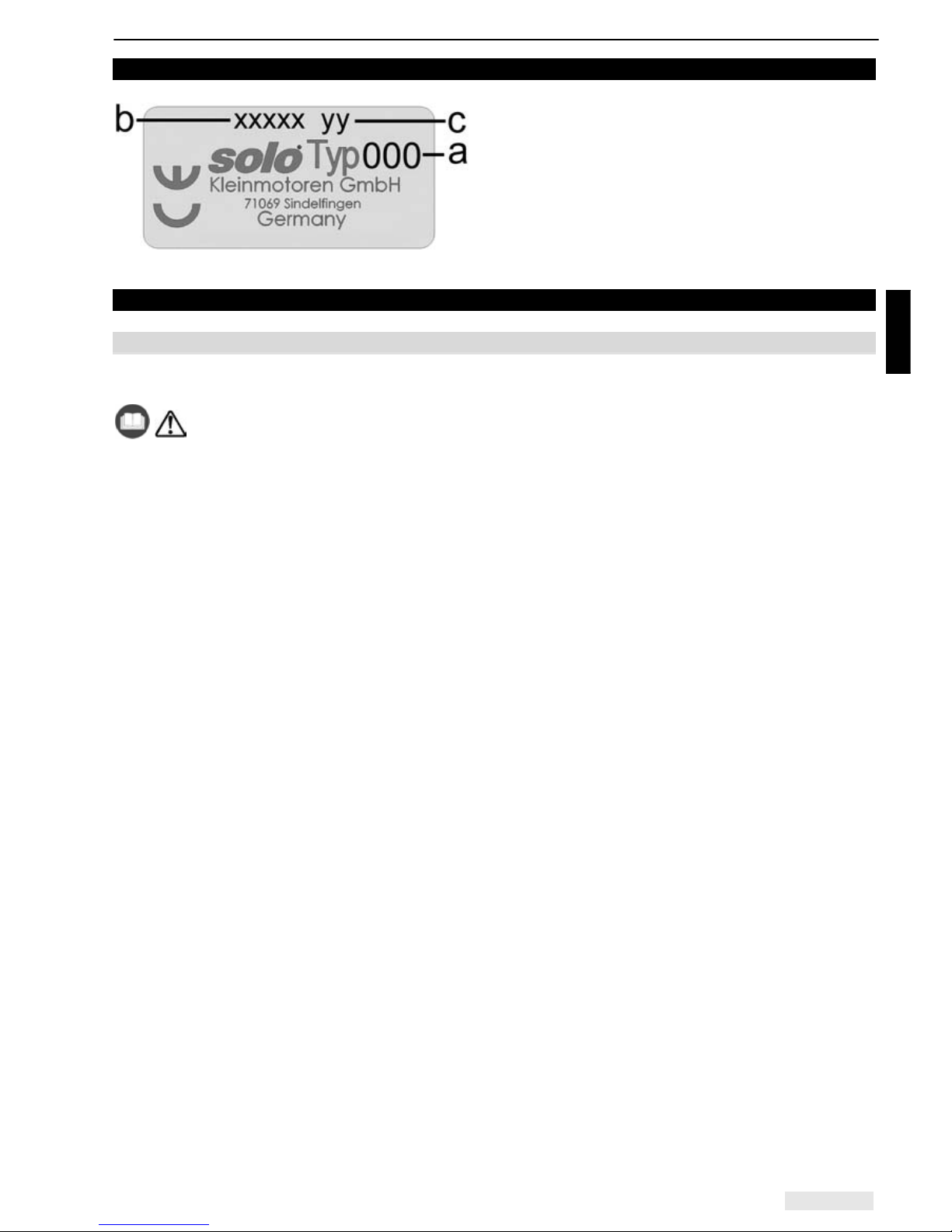

1. Type plate

2. Safety regulations

2.1 Correct use / General safety instructions

The power tool must only be used to cut grass, reeds, weeds and wild growth at ground level. The power

tool must not be used for any other purposes (see chapter 8.1 "Scope of Application").

Read the operating instructions carefully before placing in service and keep them in a safe

place.

Use this power tool with particular caution.

Non-observance of safety instructions can lead to a risk to life. Also observe any regulations from your

professional body. These operating instructions must always be available at the place of work. All

individuals instructed to work with the equipment (including maintenance, care and repair), should read

these instructions.

• You should request and receive instructions from the vendor on the safe operation if you are using this

type of product for the first time.

• Children and young people under 18 years may not work with this power tool, with the exception of

young people over 16 years of age who are being trained under supervision.

• Keep bystanders and animals away from the working area. Maintain a minimum distance of 15 m.

When working near thickets, be aware that children and animals may be hidden there. Immediately

stop the machine and the cutter if any person or animal comes close to the working area. The operator

is responsible for any accidents or damage caused to parties or property.

• This machine may only be passed on or lent to third parties if they are familiar with the safe use of this

product and with these instructions. Always supply the manual with the machine.

• Ensure you are rested and in good health when using this machine.

• Persons under the influence of alcohol or drugs, including prescription drugs, are not allowed to use

this machine, as their ability to quickly react to potential danger may be impaired.

• Never alter, change or modify any safety equipment or functional assemblies on this machine.

• Only use this machine if it is in good, safe condition. Always check the machine prior to use. Risk of

accident!

• Only use those accessories and attachments that have been supplied by the manufacturer and that

are expressly approved for attachment. When using a nylon head, never replace a plastic line with a

steel line. Always use the appropriate contact protection with each cutter.

• Always stop the engine and remove the spark plug cap when changing cutters to prevent unintentional

starting of the engine.

• The reliability and safe operation of your machine depend on the quality of parts used with the

machine. Only use original spare parts. Original spare parts are identical with genuine production parts

and guarantee best quality in material, dimensions, function and safety. Original parts and accessories

are available from your specialist dealer. Your dealer has been supplied with appropriate

documentation to determine the correct parts. Your dealer is frequently supplied with updates about

improvements to the equipment. Please note that the use of non-original parts will void your warranty.

• Always store the machine in a safe place and in such a way that it will not pose any danger. Stop the

engine when the machine is not used.

Persons who disregard safety instructions, operating or maintenance instructions may be liable for any

damage or consequential losses.

a: Type designation

b: Serial number

c: Build year (08 Î 2008)

Page 4

Safety regulations

ENGLISH 4

2.2 Working clothes

To prevent injuries, always wear suitable clothing and safety equipment when working with this power tool.

This clothing should be practically oriented to the application (for example a tight fitting work suit), but

should not be confining.

We recommend:

SOLO forest and countryside work jacket EN 340 Part no: 99303000 + size (2[s] - 6[xxl])

SOLO Outdoor Knee-breeches Part no: 9902095 + size

or SOLO Outdoor dungarees Part no: 9902094 + size

Never wear scarves, ties, jewellery or other items of clothing, which might get caught in the equipment, in

brush or on branches. Safely tie back long hair (use a cap, helmet or similar).

Wear sturdy shoes with a good tread - ideally safety shoes.

We recommend: SOLO leather forest boots Part no: 9930510 + size (36 - 48)

Wear protective gloves with non-slip palms.

We recommend: SOLO Fit Part no: 9939012 + size.

Use ear defenders and/or a visor for protection against flying objects or objects caught up in the

turbulence (protective goggles for example).

We recommend: SOLO face/ear protection pack Part no: 993901002 (one size)

2.3 Fuelling

Petrol is very light and highly flammable. Keep away from open flames and never spill fuel. Do

not smoke at the operating site or at and near the refuelling site!

• Stop the engine prior to refuelling.

• Let the engine cool down before refuelling - fire risk!

• Open the tank lid slowly to allow any excess pressure in the tank to be reduced without the risk of

petrol spraying out.

• Fuel may contain substances similar to solvents. Prevent products made from mineral oil coming into

contact with skin and eyes. Wear protective gloves during filling with fuel. Frequently change and clean

protective clothing.

• Avoid breathing in fuel vapour.

• The refuelling site should be well ventilated.

• Avoid any soil spillage of fuel or oil (protection of the environment). Use a suitable mat.

• Immediately clean any spilled fuel on the machine. Change contaminated clothing without delay.

• Firmly tighten all tank lids. This will reduce the risk of spillage from lids, which have become loose from

engine vibrations.

• Check for petrol leaks. Do not start the machine or work with the machine if there is a petrol leak. Life

threatening risk from burns!

• Store fuel and oil in approved and correctly labelled containers.

2.4 When transporting the equipment

• Always turn off the engine when transporting the machine.

• Never carry or transport the power tool with the engine running.

• Always cover the cutters with blade protectors, when transporting the equipment over longer

distances.

• To prevent fuel running out and associated damages, secure the equipment against tipping over

during vehicle transportation. Check the tank for leaks. It is advisable to drain the tank before

transportation.

• Drain the tank before despatching the equipment.

Page 5

Safety regulations ; (Packaging and disposal)

ENGLISH 5

2.5 Preparing the equipment for starting

Check the complete machine for operational safety.

• The stop switch should function properly.

• The throttle must have freedom of movement and return to the idle position on its own accord.

• The cutters and contact protection must be tightly secured and in perfect condition.

• Ensure the spark plug cap and the ignition cable are connected firmly. A loose connection may cause

a spark, which can ignite any existing fuel:air mixture - fire hazard!

Should the check reveal any irregularities or recognisable damage (also to the frame), incorrect

adjustments or reduced efficiency of the machine, do not commence work. Take the power tool to a

specialised workshop and have it checked.

2.6 Starting

• Start the machine no less than 3 metres from the refuelling location. Never start the machine in an

enclosed space.

• Ensure that you are standing firmly on the ground when starting. Always start on even ground, with a

firm grip on the power tool.

• Only one person at the time may operate this power tool - no other people should be within a radius of

15 m - even when starting.

• Continue with the starting procedure as described in section 7. "Starting/Stopping the engine".

2.7 Maintenance and repairs

Regularly service this machine. Only carry out those maintenance jobs and repairs, which are described in

this manual. A specialised service centre will carry our all other jobs.

• Do not maintain, repair or store the machine near an open flame.

• Before cleaning, maintenance and repair work, always stop the engine first and pull the spark plug

cap. Exceptions: carburettor and idle adjustments.

• For any repairs only use original parts from the manufacturer.

• Do not modify, alter or change the machine as this may impact on the safe operation of the machine

and may lead to accidents and injuries!

Packaging and disposal

Please keep the original packaging in order to protect the equipment against transport damage in case

you ever need to ship it or transport it. If the packaging materials are no longer required then they must be

disposed of properly in accordance with applicable local regulations. Cardboard packaging materials are

raw materials which can be recycled or reused.

At the end of the equipment’s service life, please make sure that you dispose of it properly, in accordance

with the official directives and regulations that apply in your area.

Page 6

Safety regulations

ENGLISH 6

2.8 Working with the machine

• Only use this power tool when it is complete and in a safe condition.

As soon as the engine is running, the power tool generates toxic gases, which may be invisible and

odourless. Never work with the power tool in enclosed spaces. In confined conditions such pits or

excavations, ensure adequate air changes during work.

Do not smoke at the work site and in the immediate vicinity of the power tool. There is an increased

fire hazard!

• Work conscientiously, thoughtfully and calmly, and do not endanger third parties.

- Pay attention to good visibility and lighting conditions.

- Always remain within earshot of other people who can provide help in case of emergency.

- Plan for timely work breaks.

- Pay attention to possible hazards and take appropriate precautions. Be aware that wearing ear

defenders reduces the ability to perceive noise. This includes sounds alerting to danger such as

signals, shouts, etc. that can go unnoticed.

- Exercise caution when the ground is wet or covered in ice and snow, on overhangs, or uneven

terrain. There is an increased risk of slipping!

- Pay attention to the risk of stumbling and obstacles, such as tree roots and stumps, edges, etc. Pay

particular attention to safety when working on slopes.

- Before commencing work, check the working area for stones, broken glass, nails, wire or other solid

objects and remove such debris to prevent them being picked up and thrown out by the cutters.

- Always hold this power tool firmly in both hands, and ensure your safe and solid foothold.

- Always hold the cutters below hip level. Never lift a rotating cutter off the ground.

- Keep all parts of the body away from rotating cutters.

- Use a correct operating mode (see Chapter 8.3 “Correct operating mode ").

- Use the power tool at lowest possible noise and exhaust levels. Only open the throttle when working,

do not let the engine run unnecessarily. Please note that noise also impacts on the environment.

Observe the quiet times that can vary from place to place.

- Never use blunt cutters and avoid uncontrolled contact of the cutter with debris. Otherwise there will

be an increased risk of the equipment kicking, which could throw the entire machine around. As a

result, the operator could be subjected to involuntary movements, which could lead to serious injury

or death.

• Stop the engine if you notice a difference in the operating characteristics of the power tool.

• Due to the centrifugal clutch, the cutters will run on for a short time, even if you release the throttle.

Ensure the cutter has come to a full stop before storing the machine.

• Always stop the engine before any contact with the cutter – even when clearing a blockage or if cutters

have become jammed – wait until the cutter has stopped and remove the spark plug cap.

• Never touch the exhaust or the silencer; as long as they are still hot, there is a risk of burns!

• Never work with a defective or missing silencer. There is a hazard of hearing damage and burning!

First Aid

A first aid box should always be available on-site. Immediately replace any materials you have used:

Note:

Over exposing persons with circulatory problems to vibrations can lead to damage to their nervous system

or blood vessels. The following systems may occur from vibrations to fingers, hands or the wrists:

Numbness, itching, pain, twinges, changes to the colour of the skin or the skin itself. Seek medical advice

if you experience any of these symptoms.

Page 7

Standard delivery; Control and function elements

ENGLISH 7

3. Standard delivery

• Power tool partially assembled; the following components are supplied separately and require assembly

• Handle subject to model and all parts required to complete the assembly

• Shield

• Cutting tool: (model-specific)

• Tools: combination spanner, retaining pin and screw driver

• Instruction manual, the EC declaration of conformity on a separate piece of paper

•

Model 107L, 107B: all assembly components required for assembling the permitted cutting tools

(accessories),

Shoulder strap

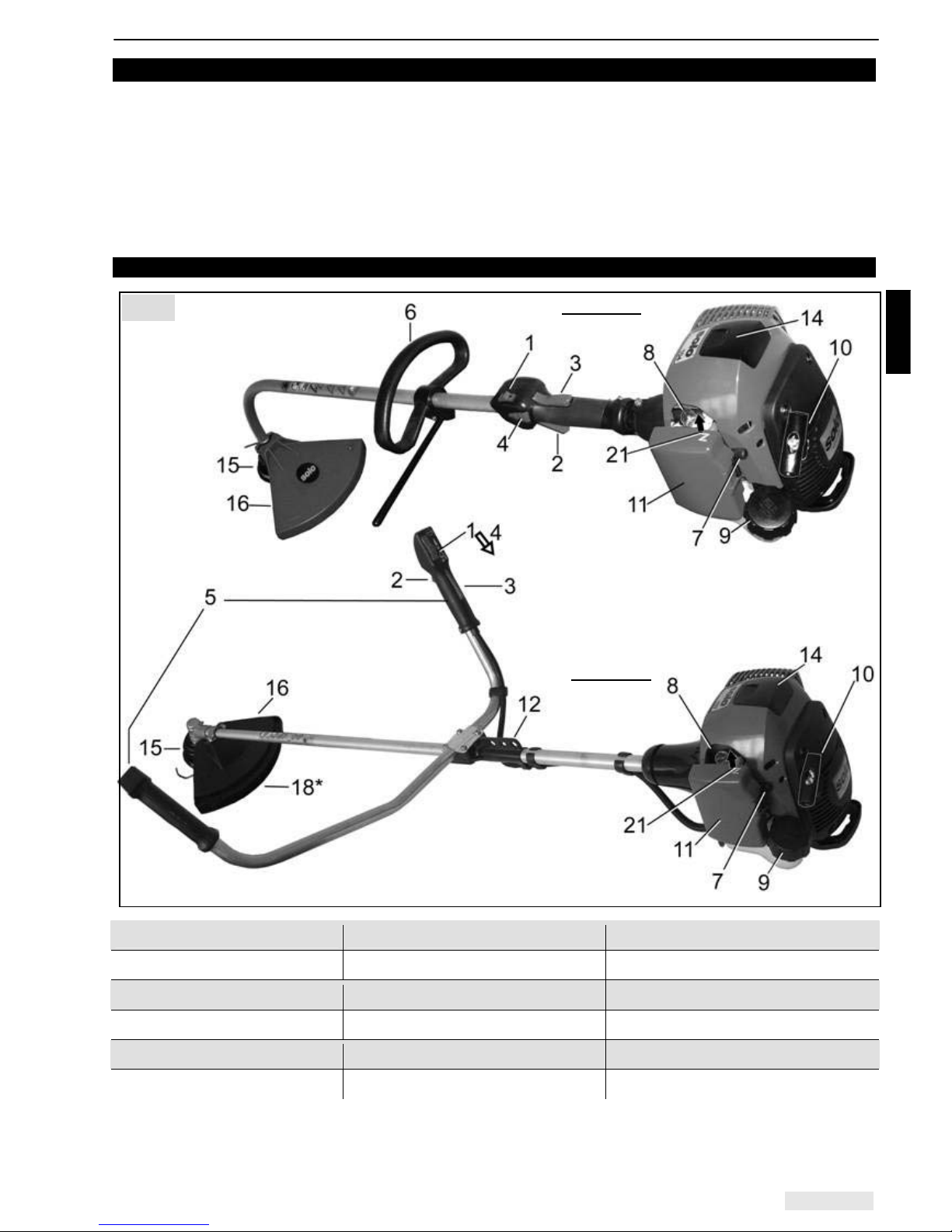

4. Control and function elements

Mod. 104L

Mod. 107B

1 Stop-switch 7 Choke lever 14 Spark plug cap

2 Throttle lever 8 Primer 15 Cutter

3 Gas lever lock 9 Fuel cap 16 Shield

4 Throttle lock 10 Starter grip 18* Protective bar

5* Bicycle handlebar 11 Air filter cover 21 Type plate

6* Loop handle 12* Strap track

*

Depending on the version

Fig. 1

Page 8

Preparing the equipment for use

ENGLISH 8

5. Preparing the equipment for use

For shipping purposes, the power tool is partly disassembled and has to be reassembled prior to use.

Only use the power tool after it has been fully assembled.

Ensure that the tank is fully drained before any assembly, disassembly or modification.

Model 104L

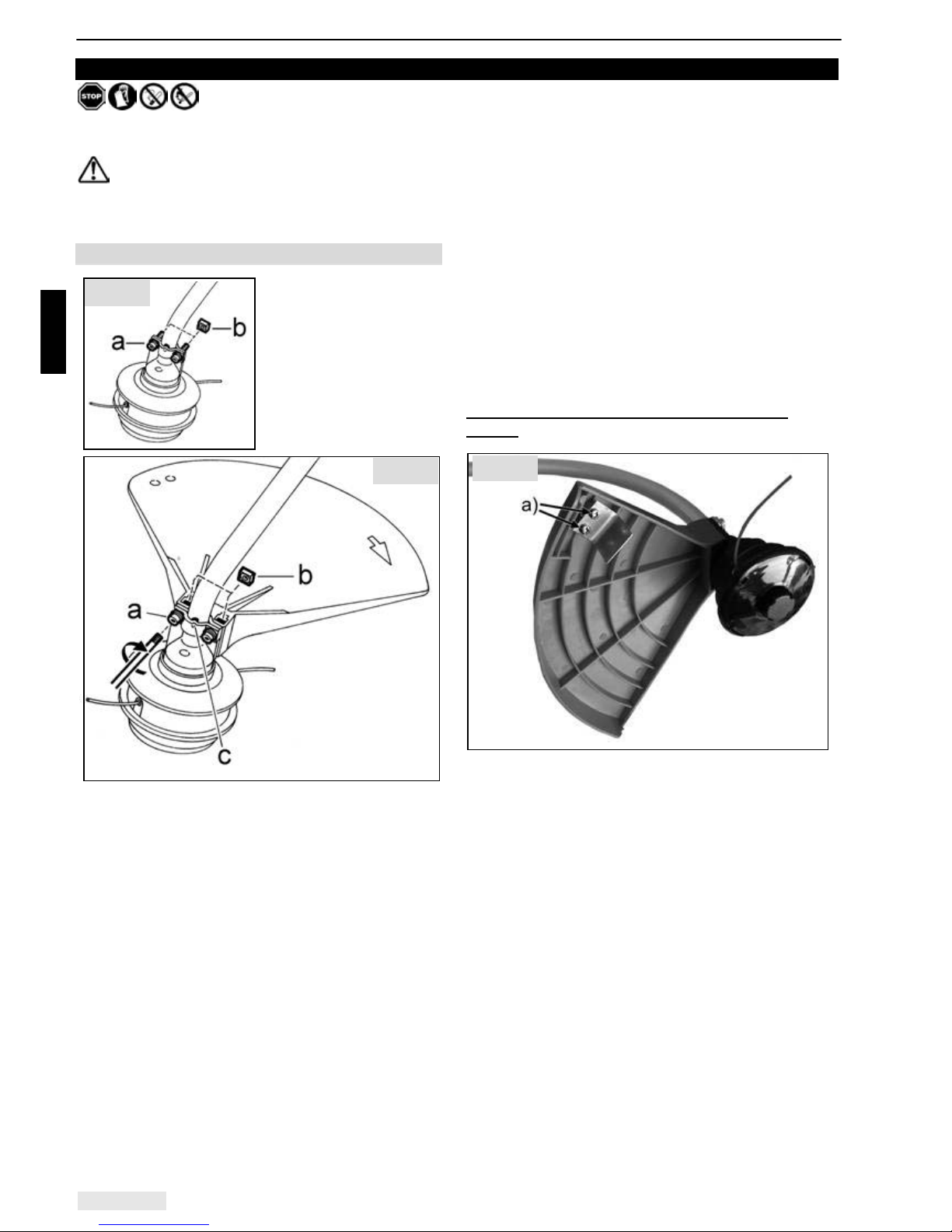

5.1 Shield installation - model 104L

In the pre-assembled

condition, undo both

screws (a) and square

nuts (b).

Leave the remaining

components in their preassembled state.

• Insert square nuts (b) from above on both sides

of the shield.

• Position the shield on the shaft tube so it is

pointing towards the engine.

• Insert fixing screws (a) and tighten evenly.

• Important: The relevant clamp tab (c) must be

fixed in the holes provided on either side of the

shaft tube.

Correct position of the line trimmer on the

shield:

a) The line trimmer must be secured tightly to the

shield using two screws, as shown in the diagram.

Fig. 2a

Fig. 2b

Fig. 2c

Page 9

Preparing the equipment for use

ENGLISH 9

5.2 Fitting the safety end-stop on the loop

handle - model 104L

Always install the safety end-stop (a) on the

operator side of the power tool.

If, during use, you carry the power tool on your r.h.

side, install the safety end-stop in l.h. orientation.

However, if, during use, you carry the power tool

on your l.h. side, install the safety end-stop in r.h.

orientation.

Install the safety end-stop (a) on the loop handle

and secure with the spring clip (b).

The position of the loop handle can be moved

along the shaft tube after loosening screw (c)

(Torx-25), and thus be positioned to suit the height

of the user.

Finally, tighten screw (c), holding the nut opposite

it in place with an open-ended spanner to stop it

turning as well.

In general, before starting work, check the

loop handle and safety end-stop are

seated tightly and correctly.

Model 104L

5.3 Fitting and replacing the line head model 104L

Always switch off the engine, pull the spark

plug cap and wear protective gloves when fitting or

replacing the cutter!

• Carefully place cup washer (a) on drive shaft

(b). Ensure that the edge of the cup washer is

pointing upwards and covers the rim of flange

casing (c).

• Turn the drive shaft with the cup washer until

the hole in the cup washer and the hole in the

flange casing are precisely one above the other.

• Use locking pin (d) to lock the drive shaft.

• Place anti-winding protection (e) (included in

standard delivery of line head) on the cup

washer so the rim of the anti-winding protection

covers the rim of the cup washer.

• Secure line head (f) to drive shaft (clockwise –

standard right-handed thread).

Removing the line head

• Turn the line head until the hole in the cup

washer and the hole in the flange casing are

precisely one above the other and the locking

pin can be inserted.

• Unscrew the line head in an anti-clockwise

direction.

Fig. 3

Fig. 4

Page 10

Preparing the equipment for use

ENGLISH 10

Model 107L/ 107B

5.4 Completion - Loop handle - model 107L

Attach the "loop" handle approximately 5 cm - 30

cm from the strap attachment according to your

preferred working position. The longer side of the

handle serves as a safety barrier and must

therefore always be on the side of the user:

• If you carry the power tool on the right hand

side of your body when working then the longer

side of the handle must face to the left.

• If, however, you prefer to carry the power tool

on the left hand side of your body when working

(i.e. if you are left-handed) then the longer side

of the handle must face to the right.

• Initially tighten the screws only lightly.

• Push the handle, in accordance with your body

size, into its optimum position.

• Then tighten the screws.

5.5 Installation - Bike handle - model 107B

• The r.h. side of handle should be fitted as near

as possible to the handle support.

Note: You will have achieved an optimum

adjustment, if the centre of the power tool is at the

centre of your body. Your elbow should be slightly

angled in operating position.

Important: Always lead the power tool with the

bicycle handlebar on the r.h. side of the body!

5.6 Shield installation - model 107L/ B

• Pull anti-vibration piece (a) with the bead

uppermost (towards the engine) over the shaft

tube. For this, the anti-vibration piece can be

bent open at the slot.

• Insert both square nuts (b) from the inside into

the contact shield.

• Secure shield (c) with both screws (d), both

semi-shells (e) and spacers (f) around the antivibration piece on the shaft tube.

• The rectangular recess of the shield must be

seated precisely around protrusion (g) on the

gearbox.

• Tighten screws (d) alternately and evenly.

Please note: No other mounting position is

acceptable for the shield!

Fig. 6

Fig. 5

Fig. 7

Page 11

Preparing the equipment for use

ENGLISH 11

Model 107L / 107B

5.7 Assembling and replacing the cutting tool - model 107L/ B

Always switch off the engine, pull the spark plug cap and wear protective gloves when fitting or replacing

the cutter!

Subject to model version, a line head or metal cutting blade (4-tooth grass cutting blade / 3-tooth brush

cutting blade) is included as the cutting tool in the standard delivery of your power tool.

A) Assembly of the nylon line head

• Fit the anti-winding protection (30) (supplied

with the line head) after the pressure piece (25).

The side of the anti-winding protection labelled

with the number "871" faces the gearbox, so

the edge of the anti-winding protection overlaps

the edge of the bevel gearbox.

• Block the shaft with the pin (29).

• Screw on the line head by hand. Caution: left-

handed thread.

• •Fit the line cutter blade (32) with screw (33)

and washer (34) to the protective bar (31).

• Fit the protective bar (18) with assembled line

trimmer from underneath onto the guard. Bend

the protective bar slightly in the process.

Important:

When using the line head, never

start the power tool without the protective bar

and the line trimmer assembled.

If the length of the line has been adjusted (see

chapter 8.4, "Adjusting the cutting line"), the line

trimmer will automatically cut the ends of the line

to the correct length during operation.

When using metal cutting blades, always

work without the protective bar fitted.

B) Assembling metal cutting blade

• Position the power tool with the output shaft

facing upwards.

• Place the brush cutting blade on the pressure

piece (25). In order to centre the cutting blade,

the shoulder of the pressure piece must be

located exactly in the bore of the cutting blade.

• Fix the pressure washer (26).

• Place the nut protector (27) and turn safety nut

(28) onto the shaft.

Caution! Left hand thread - tighten counter

clockwise.

Take care that all parts are centered.

• Block the shaft with the stop pin (4) and tighten

nut.

It is imperative that the safety nut (28) is

replaced, if it has become loose due to

frequent rem oval and tightening.

Afterwards check that the cutting blade is securely

seated and that it is properly centred.

Fig. 8

Fig. 9

Page 12

Preparing the equipment for use

ENGLISH 12

Model 107L/ 107B

Transport protection for metal cutting blades

(model 107L/ B)

When you first purchase an approved metal

cutting blade which is not supplied together with

the power tool (see chapter 12 "Accessories"), you

will also need to purchase a corresponding

transport protector.

When the metal cutting blades are attached (4tooth grass cutting blade or 3-tooth brush cutting

blade, provided either as standard equipment with

the different models or purchased as accessories),

the transport protector must always be attached to

cover the blades when the device is being stored

or transported, or during work breaks during which

the engine is switched off.

• Position the transport protector with the

corresponding recess at one of the tips of the

metal cutting blade.

• Press the two tabs (a) on the transport protector

together to increase the internal diameter of the

transport protector.

• Lay the transport protector right over the cutting

tool. Position the inner shoulder (b) between the

metal cutting blade and the running disc.

• Open the two tabs again, and in doing so also

position the inner shoulder between the metal

cutting tool and the running disc at tab (c).

When restarting work, take the transport protector

back off by pressing the two tabs (a) together

before starting the engine.

Dismantling the cutting tool

(model 107L/ B)

• With the engine off, turn the cutting tool until the

recess in the cup washer and the hole in the

gearbox casing are precisely one above the

other, and the locking pin can be inserted.

• Unscrew the cutting tool in an anti-clockwise

direction (left-handed thread).

[For metal cutting tools, undo the locking nut

using a suitable tool; for the line head, unscrew

directly by hand.]

Fig. 10

Page 13

Preparing the equipment for use; Fuelling

ENGLISH 13

Model 107L / 107B

5.8 Shoulder strap adjustment

- model 107L/ B

Before commencing work, adjust the shoulder

strap and handle according to the operator’s body

size.

Wear the single shoulder strap over the opposite

shoulder to the side on which you are carrying the

power tool. Once the length of the strap has been

correctly adjusted the strap hook should be over

your hip. Hook the strap hook into the strap

attachment on the power tool.

Balance the power tool and attached cutting blade

so that the cutting tool hovers just above the

ground when your hands are off the attached

power tool.

If the cutting tool hovers more than 30 cm above

the ground, the strap must be secured closer to

the engine.

If the tool lies on the ground, the strap must be

secured further from the engine.

To do this on

model 107L

, undo the two screws

and move the strap holder along the shaft

accordingly

For

model 107B

, hook the strap hook into

another, corresponding fixing hole on the strap rail.

If necessary, the entire bike handle unit with the

strap rail can be slightly moved by undoing the

four screws on the shaft.

As a general principle, check that all screws are

seated tightly before starting work.

(schematic diagram)

6. Fuelling

6.1 Fuel information

A high performance two-stroke engine

operated with a petrol:oil mixture (petrol + oil

= fuel mixture) or with a special fuel mixture for

two-stroke engines available from specialists

powers this machine.

We recommend the proprietary “Aspen 2-takt”

special fuel mixture. Please observe the special

fuel manufacturer’s instructions.

Information on individual mixing of the fuel mixture

Normal or super unleaded petrol can be used for

individual mixing purposes (minimum octane

number 92 RON).

When using a particularly high quality proprietary

2-stroke engine oil such as the “SOLO Profi 2T-

Motoröl” which we supply, we recommend an

oil:petrol mixing ratio of 1:50 (2%).

When using other brands of 2-stroke oil we

recommend a mixing ratio of 1:25 (4%).

Only use proprietary 2-stroke engine oil!

Never store fuel mixture longer than 3 - 4 weeks.

Fuel mixture table

Oil in litres

Petrol in

litres

SOLO 2T

engine oil

2% (50 : 1)

Other two-

stroke oils

4% (25 : 1)

1 0.020 0.040

5 0.100 0.200

10 0.200 0.400

Unsuitable petrol or deviations in the mixing ratio

may lead to serious engine damage!

Avoid direct skin contact with petrol and

avoid inhaling petrol fumes - health hazard!

6.2 Fuelling

While fuelling always follow all safety instructions

and take all safety precautions.

Handle fuel only with the engine turned off.

Carefully clean the area around the filler inlet.

Place the machine with the fuel inlet pointing

upwards. Unscrew the tank lid and fill the fuel

mixture up to the lower edge of the filler neck. Use

a funnel with filter to prevent tank contamination.

After filling the tank replace the tank lid and tighten

firmly.

Fig. 11

Page 14

Starting / Stopping the engine

ENGLISH 14

7. Starting / Stopping the engine

7.1 Half throttle start position

A) Models with a "loop" handle (104L and 107L)

• Slide the stop switch (1) into the operating

position.

• Grip the handle; the safety locking key (3) is

activated via the grip area, which also enables

throttle lever (2) to be regulated.

• Press throttle lever fully down.

• Press the half throttle lock (4), and let the

throttle lever return, whilst holding the half

throttle lock in.

B) Models with a "bike" handle (107B)

• Grip the handle; the safety locking key (3) is

activated via the grip area, which also enables

throttle lever (2) to be regulated.

• Press throttle lever fully down.

• Whilst holding the throttle lever down, move

stop switch (1) towards "Start"

( ), and

release the throttle lever.

The part throttle stop is cancelled by brief

operation of the throttle control. The stop switch on

the bike handle then jumps to the central position

Î operating position.

7.2 Choke and primer

Adjust choke as follows:

• With a cold engine, position choke lever (7) up

towards "Close"

.

• With a warm engine, position choke lever (7)

down.

When first starting or if the fuel tank has been

completely drained and has been refilled, press

primer (8) several times (at least 5x) until the fuel

is visible in the plastic bulb.

Fig. 14

Fig. 13

Fig. 12

Page 15

Starting / Stopping the engine

ENGLISH 15

7.3 Starting

Observe the safety instructions when starting.

(schematic diagram)

Lay the power tool level and without obstructions

on the ground.

During starting, never stand or kneel on the shaft

tube, otherwise the shaft or the tube might be

damaged.

Take up a safe position, securely hold the machine

and ensure that the cutter does not touch any

objects or the ground.

When the engine is cold:

With the choke lever up (

) start the engine by

pulling the starter handle up in a straight line

several times until the engine is briefly audible

(ignition).

Then immediately move the choke lever down.

Continue to start until the engine runs evenly.

When the engine is warm:

With the choke lever down start the engine by

pulling the starter handle up in a straight line

several times until the engine runs evenly.

If the engine is running in part throttle operation:

,

briefly pull the throttle back to release the half

throttle detent. Release the throttle lever again to

allow the engine to run at idle speed. Now you can

commence working.

The following instructions are aimed at increasing

the service life of the starter rope and of the starter

mechanism:

• Always pull the rope out in a straight line.

• Do not let the rope drag across the edge of the

rope eyelet.

• Do not pull rope all the way out - risk of the rope

breaking.

• Always manually guide the rope back into its

start position with your hand on the starter grip do not let it retract on its own.

A specialist can replace a damaged starter rope.

Note: Under good conditions, the engine will

already start under idling throttle if it is at operating

temperature. (If a part throttle stop is set it will be

cancelled by operation of the throttle control even if

the engine is at standstill.)

Starting with the stop switch in run-position

If the engine will not start under idling throttle, set a

part throttle stop in the way described above.

7.4 Turning off the engine:

Release the throttle and push the stop switch to

”STOP”.

Important: Due to the centrifugal clutch, the cutter

will run on for a short time, even if you release the

throttle. Ensure the cutter has come to a full

standstill before storing the machine.

7.5 Engine will not start:

If the engine fails to start after several attempts,

check whether all adjustments described above

have been correctly carried out, particularly that the

stop switch is not in the "STOP" position. Try

starting once again. The combustion chamber will

be flooded, if the engine still fails to start.

In that case we recommend you proceed as

follows:

Stop switch on "STOP"

• Remove the spark plug cover.

• Pull the spark plug cap off the spark plug.

• Remove the spark plug and dry fuel mixture

from the electrodes.

• Move the throttle lever up to full throttle. Pull the

starter handle several times (with removed

spark plug) to clear the combustion chamber.

• Move the throttle lever down to idling position,

refit the spark plug, the plug cap and the plug

cover.

• Then:

- Position choke lever down ("warm start")

- Slide stop switch into operating position

- Lock the throttle lever at half throttle

- Turn on engine.

Fig. 15

Page 16

Using your power tool

ENGLISH 16

8. Using your power tool

8.1 Scope of Application

Only use power tools equipped with a nylon head

(subject to model) for cutting grass – particularly

suitable around obstacles - and for trimming light

weeds and wild growth near ground level. The

nylon head is particularly suitable for a soft cut,

e.g. for clean trimming around trees and posts.

Use power tools equipped with the grass cutter

blade (accessory 107L / 107B) only for cutting

grass away from obstacles and for cutting stronger

weeds and wild growth near ground level.

Only use power tools fitted with the 3-tooth brush

cutting blade (accessory 107L / 107B) for mowing

grass, light brush, reeds and uncultivated growth

at ground level.

Never use the power tool for any other purpose.

8.2 Initial use/ start-up behaviour

When switching on the engine for the first five

times prior to commencing work, first operate for a

short time in the mid-speed range without any load

until the engine has warmed up a little.

8.3 Correct operating mode

Observe the relevant safety instructions when

using the power tool.

Approach the working area with the power tool set

to idle, and then switch to full throttle. Never leave

the engine running at high speed without applying

a load.

(Diagram: 3-tooth brush cutting blade -

model 107)

Dip the tool from the r.h. side 2/3 into the material

to be trimmed. Then work the power tool like a

scythe, i.e. by moving forward step by step, whilst

cutting from right to left.

Operate the power tool at full throttle to obtain an

optimum cutting result. Never operate with the

clutch in slipping range. Consequential damage

through excess loads or overheating is excluded

from our warranty.

Immediately stop the engine in case of noticeable

vibrations or when material has gathered around

the cutting tool or contact shield. Slow down the

cutting tool by pressing it onto the ground, until it

has come to a complete standstill. Pull the spark

plug cap from the plug, and clean the tool seat of

all grass, roots etc. Check the entire power tool for

perfect condition.

Fig. 16

Page 17

Using your power tool; Parts subject to wear and tear ;Operating and maintenance instructions

ENGLISH 17

8.4 Note on using the nylon line head

(available as accessory)

When using the nylon head, always ensure that

you operate only with the correct length of line.

When the contact shield is fitted, the line will

always be trimmed to the permissible length

automatically (a line trimming blade is fitted into

the shield). There is a high risk of injury, and the

engine is subjected to excessive loads leading to a

risk of damage, if nylon lines are left too long.

Important:

If using the line head, never start

the power tool without having fitted a line

trimmer blade.

Adjusting the cutting line

When using a semi-automatic nylon head:

(schematic diagram)

Whilst the power tool is running without load, but

with rotating nylon head, lightly push the nylon

head several times onto ground with growth cover.

The cutting line will be dispensed in stages. With

each action, approx. 30 mm line will be dispensed.

The line trimming blade will correct any excess

length.

When the cutting line is fully spent, you can

replace it with line available

Ø 2.4 mm under part no. 6900942 (accessory).

9. Parts subject to wear and tear

Various parts are subject to application-specific or

normal wear and must be replaced in good time,

when required. The following parts are subject to

normal wear and are not covered by the

manufacturer's guarantee:

• Air filter

• Fuel filter

• All rubber parts which come into contact with

fuel

• Clutch

• Spark plug

• Starter

• Cutting tools

10. Operating and maintenance instructions

10.1 General operating and maintenance

instructions

The maintenance and the repair of modern

machines as well as their safety-relevant

assemblies require qualified specialised training

and a workshop equipped with special tools and

test equipment. Consequently the manufacturer

recommends that all tasks not described in these

operating instructions be carried out by a

specialised workshop. That specialist has the

required training, experience, and equipment at his

disposal, to provide you with the most costeffective solution for such work. He will provide

additional help in word and deed.

After a running-in time of app. 5 hours, all

accessible screws and nuts (except the carburettor

adjusting screws) must be checked for tightness

and they must be retightened, if required.

Check the cutter regularly and whenever you

notice any irregularities, or when the cutter/contact

shield becomes blocked. For this, switch off the

engine and wait until the cutter has come to a

complete standstill. Pull the spark plug cap, and

remove grass, debris, etc. from the cutter support.

Immediately replace blunt or damaged tools, even

if they display only small cracks – do a ”ping” test.

It is best to store the equipment in a dry, safe

location with a full fuel tank. There should be no

open flame or similar nearby. When not using the

equipment for longer periods, (longer than four

weeks), see chapter “10.9 Shutdown and storage”.

10.2 Information about the silencer

Your engine appliance has reduced exhaust

emissions which are considerably lower than the

statutory limits. The silencer creates a great deal

of heat during operation as a result. Do not touch

the silencer whilst it is still hot. Discolouration of

the outer silencer housing is quite normal.

Fig. 17

Page 18

Operating and maintenance instructions

ENGLISH 18

Model 107L/ 107B

10.3 Sharpening instructions – metal cutting

blades - model 107L/ B

(Diagram: 3-tooth brush cutting blade)

When the blades become slightly blunt, sharpen

the edges of the cutting tips with a flat file at a 30°

angle.

For the 3-tooth brush cutting blade, file the

edges from both sides; for the 4-tooth grass

cutting blade, file only from one side.

All cutting edges need to be filed back equally, if

the wear and tear is substantial, or if there are

broken-off cutting edges. It is necessary to check

for imbalance and if necessary, to make

corrections by additional filing. The sharpening

angle is 30°.

For the 3-tooth brush cutting blade, your dealer

offers a sharpening jig (part no.: 0080548) to help

with sharpening.

10.4 Gearbox lubrication - model 107L/ B

To lubricate the bevel gear drive, use SOLO

"Special gearbox grease" (part no. 008318025).

Check the grease level weekly and top up, if

required (approx. every 20 - 50 hours).

Remove the filler plug from the side of the gearbox.

If no grease is visible inside, top up with grease

(top-up quantity approx. 5 – 10 g).

Replace and tighten the filler plug.

Please note: Do not overfill with grease, as that

may lead to the gearbox overheating. Never fill the

gearbox casing to the top with grease.

Tip: If required, top up with a maximum of 5g

grease. It is preferable to check more frequently

(e.g. before you start working) whether grease is

still visible.

Your SOLO dealer workshop is happy to help you

in case of doubt.

Fig. 19

Fig. 18

Page 19

Operating and maintenance instructions

ENGLISH 19

10.5 Carburettor adjustment

The carburettor is adjusted at the factory for

optimum performance. Subject to the place of use

(mountains, low-lying areas), the average idling

speed given in the specification can be adjusted

as follows, via the idling end-stop screw "T" (the

use of a rev counter is recommended):

• If the idling speed is too high, turn the idling

end-stop screw "T" anti-clockwise.

• If the idling speed is too low (engine stops)

turn the idling end-stop screw "T" clockwise

until the engine runs smoothly.

With the throttle set to idle, the cutting tool

must not, under any circumstances, rotate!

If the idling speed cannot be set correctly with the

idling end-stop screw "T", request an authorised

service centre to tune the carburettor.

The adjusting screws for the idling mixture "L"

and the full-load mixture "H" must only be

adjusted by an authorised workshop.

The following instructions are for authorised

service shops

Use the D-CUT carburettor key to adjust the idle

mixture screw "L" and the full load mixture screw

"H".

Ask the specialist workshop that is part of our

customer service about standard settings, or visit

our internet portal for dealers at www.part-andmore.org.

Clean the air filter before adjusting the low speed

screw!

Let the engine run warm before adjusting the

engine speed.

The carburettor is tuned for optimum engine

performance. Use a rev counter to tune the

carburettor correctly!

Do not adjust the engine to a higher speed.

Excessive engine speed can lead to major engine

damage!

10.6 Information about the spark plug

Check the spark plug regularly

after 50 hours of operation.

Removing the spark plug:

• Press the top tab of the spark plug cover (16) down

(a), push back (b) and remove.

• Remove the spark plug cap below this.

• Remove spark plug using the combination spanner

and dry thoroughly.

When the spark plug has been removed or the

ignition cable has been pulled out of the plug cap, the

engine must not be moved. There is a risk of fire

through sparks.

Checking the spark plug:

• Clean spark plug with a dry cloth and check

electrodes. There must not be any dirt between the

electrodes. Brush dirt out with a thin paintbrush if

necessary.

• If the electrodes have been heavily worn away,

replace the spark plug immediately – otherwise

after 100 hours run.

• The correct electrode gap is 0.5 mm. If the

electrodes are bent and the electrode gap is

incorrect, replace the spark plug.

• Before starting work, check ignition cable for

perfect connection and insulation.

The permissible spark plug (interference-free, energy

value 240) is available under the following

description:

BOSCH USR 4 AC

Fitting the spark plug:

• Refit the spark plug and tighten using the

combination spanner (recommended torque if

using a torque spanner Î 10 Nm).

• Always push the spark plug cap firmly onto the

spark plug.

• Position spark plug cover (16) on casing and push

on until it clicks back into place.

Fig. 21

Fig. 20

Page 20

Operating and maintenance instructions

ENGLISH 20

10.7 Air Filter Maintenance

Contaminated air filters cause a

reduction in engine performance and increase fuel

consumption with more pollutants in the exhaust

gas. Engines are less likely to start readily with a

contaminated air filter.

As a basic principle therefore, the air filter should

be cleaned as follows before starting work, and

intermittently in very dusty conditions:

Before opening the air filter, close the choke to

prevent dirt entering the carburettor.

• Push tab (a) in, only slightly open air filter lid

(11) and remove by rotating gently back and

forth

• Remove foam filter (c) from the lid and clean

the area around the filter.

• Thoroughly clean air filter casing (d) and air

filter cover (11) on the inside, using a

paintbrush or by carefully blowing on them.

• Clean filter insert (c) by shaking it out or

carefully blowing on it.

If the filter insert is damaged or so contaminated

that it is impossible to clean, replace it with the

original spare part (part no. 20 48 406).

• Insert the new or cleaned foam filter into the air

filter lid.

• Position the air filter cover with both tabs (b)

[inside, opposite tab (a)] in the corresponding

two pockets (b’) of the filter casing.

• Press air filter cover against the filter casing

until tab (a) clicks audibly into place.

10.8 Replacing the fuel filter

We recommend having the fuel filter (34) changed

annually by a specialised service centre.

(schematic diagram)

A trained mechanic can carefully remove the fuel

filter via a wire loop through the fuel tank filler.

Ensure that the thicker part of the fuel hose on the

tank wall is not drawn into the fuel tank.

10.9 Shutdown and storage

Clean the power tool after use.

• Never use aggressive cleaning solutions or

those containing solvents to clean any part of the

engine. Never hose down the engine. For best

results, simply wipe down the entire engine with

a dry or slightly damp cloth.

• Clean leftover cuttings off the blades using a

small brush.

• Ingrained plant remains on the blades can be

removed with the

"SOLO Universal Cleaner"

(part no.: 00 83 116). Leave it to work for a short

time, then residues become soft and partially

dissolve, and can be wiped off with a cloth.

• To prevent corrosion, we recommend treating

metal cutting tools with the

"SOLO Maintenance

and Care Oil

" (part no.: 00 83 163).

Store the device in a dry, safe location inside a

building (garage, basement, …). There must not be

any open fires or similar nearby. Ensure that the

device cannot be used by unauthorised persons,

especially children.

If not in use for more than four weeks, drain the

fuel tank in a well ventilated location before storing.

Start the engine with an empty fuel tank and drain

the carburettor until the engine stops. Oil residues

from the fuel mixture could otherwise clog the

carburettor jets and make it difficult to start the

device later.

Fig. 23

Fig. 22

Page 21

Operating and maintenance instructions

ENGLISH 21

10.10 Scheduled maintenance

The following information is based on standard operating conditions.

For special conditions, such as prolonged daily use, the recommended

maintenance intervals should be reduced accordingly.

Implement all maintenance jobs regularly. If required, authorise a specialist

service centre to maintain the machine for you. The owner of the machine is

responsible for:

• Any damage caused by a lack of maintenance, incorrect or late

maintenance and repairs

• Consequential losses - including corrosion - from incorrect storage

after the first 5 hours

before starting work

weekly

after every 50 hours

after every 100 hours

as required

before the start of the mowing season,

or once per year

Check idling speed

X

Carburettor

Adjust idling speed

X

Clean

X

Air filter

Replace

X

Check electrode gap and replace spark

plug if required

X X

Spark plug

Replace

X X

Check

X X

Gearbox lubricant

Top up

X X X

Check

X

Sharpen

X

Metal cutting blades

- model 107L/ B only

Replace

X

All accessible screws

(except for adjusting screws)

Retighten

X XX

Controls

(stop switch, throttle lever, half

throttle detent, starter)

Check function

X

Silencer

Visual inspection

X

Visual inspection

X

Complete machine

Clean

X X X

Furthermore, as part of the annual service at an authorised dealer, request the following services:

• Complete check of the entire machine

• Professional cleaning of the engine (fuel tank, cylinder head fins, …)

• Check and, if necessary, replace wearing parts, particularly the annual fuel filter change

• Optimum setting of the carburettor

Page 22

Specification

ENGLISH 22

11. Specification

Gras trimmer / Brush cutter 104L 107L 107B

Engine type SOLO single cylinder two-stroke engine

Engine capacity cm3 25.7

Bore / stroke mm 33 / 30

Engine power kW at rpm 0.7 / 7 500

Max. permissible speed

no load with cutter

Nylon head rpm

Grass cutter blade rpm

8 500 ± 200

---

8 500 ± 200

9 000 ± 200

Medium idling speed rpm 3 000 ± 200

Fuel tank capacity l 0.5

Fuel consumption at max. power

(ISO 7293) kg/h

320

Specific consumption at max. power

(ISO 7293)

g

/

kWh

460

Clutch engagement speed rpm 4 700

Fuel mix ratio:

with SOLO 2T engine oil

with other two-stroke oils

1:50 (2%)

1:25 (4%)

Carburettor All-position diaphragm carburettor with primer and

integrated fuel pump

Air filter Foam filter

Ignition Electronically controlled magneto ignition, maintenance free

--- 1.23 : 1 Gear reduction Î

Max. speed of the cutter rpm

8 500 ± 200 7 300 ± 200

Shaft tube - connectionØ mm

Drive shaft Ø mm

Serration

24

6, flex

M7;

24

7

Star serration 7 teeth

Dimensions Height mm

Width mm

Length mm

34

37

158

30

38

187

50

67

187

Weight kg

w/o shield and cutter

4.9 5.8 6.2

In determining the following values regarding the acceleration of vibrations and sound, the different

operating conditions were weighted in accordance with the current standards.

Weighted effective acceleration a

hv,eq

(DIN ISO 22867)

Handle r.h. side / handle l.h. side

Nylon head m/s

2

Grass cutter blade m/s2

9.3 / 7.4

---

5.7 / 4.8

7.1 / 5.9

4.2 / 4.2

6.3 / 8.3

Sound pressure level L

Peq

(EN ISO 22868)

Nylon head dB(A)

Grass cutter blade dB(A)

92

---

93

94

93

94

Sound power level L

Weq

(EN ISO 22868)

Nylon head dB(A)

Grass cutter blade 4 teeth dB(A)

103

---

103

104

103

104

Page 23

Accessories ; Guarantee

ENGLISH 23

12. Accessories

Via dealers, SOLO offers an extensive range of grass trimmer / brush cutter accessories. Their use is

limited to the particular model to which it is allocated, together with its relevant protection. Orientate

yourself on the following table and check with your dealer.

Model

Accessory Protection Part no.

104L

107L/B

2 nylon head semi-automatic M 10 x 1.25 RE

(grass, even around obstacles, light weeds)

Standard shield +

line trimming blade

69006505 X

2 nylon head semi-automatic M 10 x 1.25 LI

(grass, even around obstacles, light weeds)

Standard shield +

line trimming blade

69006375 X

Replacement line for nylon head 15m, Ø2.4 mm 6900942 X X

Spool of nylon cord 90 m, Ø2,4 mm 0063201 X X

Grass cutter blade 4 teeth, Ø230 mm

(grass, stronger weeds)

Standard shield

without protective bar

6900948 X

Brush blade 3 teeth Ø250 mm

(bushes, reeds, tough grass)

Standard shield

without protective bar

6900947 X

Transport protector for metal cutting blades up to

Ø250 mm

6073534 X

High performance gearbox grease 008318025 X

SOLO 2T engine oil 100 ml 0083103 X X

SOLO 2T engine oil 1 l 0083104 X X

SOLO 2T engine oil, in a metering bottle 1 l 0083105 X X

SOLO face/ear protection pack 993901002 X X

SOLO forest and countryside work jacket EN 340 99303000 + size (2[s] - 6[xxl]) X X

SOLO Outdoor Knee-breeches 9902095 + size X X

SOLO Outdoor dungarees 9902094 + size X X

SOLO leather forest boots 9930510 + size (36 - 48) X X

Gloves SOLO Fit 9939012 + size X X

13. Guarantee

The manufacturer guarantees trouble-free quality and will cover the cost of replacing parts which are found

to be faulty in material or workmanship within the prescribed guarantee period after the date of purchase.

Please note that specific guarantee conditions may vary from country to country. If in doubt, ask your

equipment vendor. He is responsible for guarantee matters.

We hope you will understand that we cannot be liable for damage resulting from the following causes:

• Non-compliance with the operating instructions.

• Neglecting essential maintenance and repair work.

• Damage caused by incorrect carburettor adjustment.

• Wear in normal use.

• Obvious overload by continuously exceeding the maximum performance limit of the product.

• Using non-authorised tools.

• Use of force, incorrect treatment, misuse and accidents.

• Damage from excessive heat due to dirt build-up around the cooling fan housing.

• Attempted adjustments and repairs by unqualified persons.

• Use of unsuitable spare parts or third party parts, if these are the cause of the defect.

• Use of unsuitable or stale fuel.

• Damage caused by using the product in the hire or rental industry.

Normal cleaning, adjustments or maintenance work fall outside the guarantee provisions.

A service centre authorised by the manufacturer must carry out all guarantee work.

Page 24

SOLO

Postfach 60 01 52

D 71050 Sindelfingen

Tel. 07031-301-0

Fax 07031-301-130

info@solo-germany.com

SOLO

P.O.Box 60 01 52

D 71050 Sindelfingen

Germany

Phone+49-7031-301-0

Fax +49-7031-301-149

export@solo-germany.com

Loading...

Loading...