Page 1

The Sollatek

PowerBack PB3000S / PB5000S

Inverter With Solar Charger Controller

User Instructions

the power to protect

Important: This manual contains important safety instructions.

Keep this manual handy for reference.

• Before using this product please read all instructions carefully.

• Keep these instructions for future reference.

• All specifications are subject to change without prior notice.

Page 2

Important Safety Warning

WARNING:

This chapter contains important safety and operating

instructions. Read and keep this User Guide for future reference.

General Precautions

1. Before using the unit, read all instructions and cautionary markings on:

(1) The unit (2) the batteries (3) all appropriate sections of this manual.

2. CAUTION --To reduce risk of injury, charge only deep-cycle lead acid type

rechargeable batteries. Other types of batteries may burst, causing personal

injury and damage.

3. Do not expose the unit to rain, snow or liquids of any type. The unit is

designed for indoor use only. Protect the unit from splashing if used in vehicle

applications.

4. Do not disassemble the unit. The maintenance information is only for

service technicians. When service or repair is required, contact your

supplier for further arrangements. Incorrect re-assembly may result in a

risk of electric shock or fire.

5. To reduce risk of electric shock, disconnect all wirings (AC mains, batteries,

solar panel) before attempting any maintenance or cleaning. Turning off the

unit might not eliminate the risk.

6. No terminals or lugs are required for hook-up of the AC wiring. AC wiring

must be no less than 10 AWG gauge copper wire and rated for 75oC or

higher.(Refer to equivalence table on page 10). Battery cables must be rated

for 75oC or higher and should follow the recommendation in the manual.

Crimped and sealed copper ring terminal lugs (refer to INSTALLATION

section) should be used to connect the battery cables to the DC terminals of

the unit. Soldered cable lugs are also acceptable.

7. Be cautious when working with metal tools on, or around batteries. Dropping

a tool and short-circuit the batteries or other electrical parts may result in

sparks and explosion.

8. No AC or DC disconnects are provided as an integral part of this unit.

Both AC and DC disconnects must be provided as part of the system

installation. See INSTALLATION section of this manual.

Page 3

9. No over current protection for the battery supply is provided as an integral part

of this unit. Over current protection of the battery cables must be provided as

part of the system installation. See INSTALLATION section of this manual.

10. GROUNDING INSTRUCTIONS -This battery charger should be connected to

a grounded permanent wiring system. For most installations, the Ground

Lug

should be bonded to the grounding system at one (and only one point) in the

system. All installations should comply with all national and local codes

and

ordinances.

11. The unit must be installed and maintained by qualified staff. Please read the

manual carefully before installations & operations.

12. The unit contains energy source: the batteries and solar. All terminals

and

sockets may be powered even when the unit is not connected to the mains.

Page 4

Table of Content

1.# Overview#.......................................................................................................#1#

1.1# Key#Feature#..................................................................................................#1#

1.2# Product#Outlook#..........................................................................................#2#

1.3# Basic#System#Architecture#...........................................................................#3#

2.# INSTALLA T ION#...............................................................................................#4#

2.1# Unpacking#and#Inspection#...........................................................................#4#

2.2# Remove#bottom#cover#................................................................................#4#

2.3# Placement#...................................................................................................#4#

2.4# Battery#Connection#.....................................................................................#5#

2.5# AC#Connection#............................................................................................#7#

2.6# PV#connection#.............................................................................................#9#

3.# OPERATION#.................................................................................................#11#

3.1# LCD#display#introduction#..........................................................................#11#

3.2# LCD#display#setting:#..................................................................................#15#

3.3# Standby#Charging#Mode#...........................................................................#15#

3.4# Operation#Modes#(after#powered#on)#.....................................................#16#

3.5# Fault#Mode#...............................................................................................#19#

4.# SPECIFICATION#............................................................................................#19#

APPENDIX#A#.....................................................................................................#25#

APPENDIX#B#.....................................................................................................#28#

Page 5

1. Overview

This is a pure sine wave stand-alone inverter/charger system combining the

function of inverter, solar charger and AC charger, and provides a l

ong

run-time uninterruptible power supply. Its comprehensive LCD display

provides system status, and allows users to set output source priority, charger

source priority, charger current and so on.

1.1 Key Feature

• High-frequency switching technology for compact size and light weight

• Pure sine wave output for wide range of applications and harsh

environment

• Build-in solar charger controller with MPPT technology to optimize the

power utilization

• High efficient DC-to-AC conversion minimizing energy loss

• Standby Charging Mode enables battery charging even when the unit is

switched off

• Intelligent cooling fan control

• Input/output isolated design for the maximum operation safety

• LCD displays comprehensive operation status

• Configurable output source priority, charger source priority, charger

current and so on.

• Supports Home Appliances / Office Equipment/ Lighting Equipment/

Motor-based Equipment (such as Fan, Air-Conditioner, Washing

Machines)

• Thorough protections: Input low voltage / Overload / Short circuit / Low

battery alarm / Input over voltage / Over temperature/SCC over current

protection

• Rack design & wall-mounted design for flexible installation

Page 6

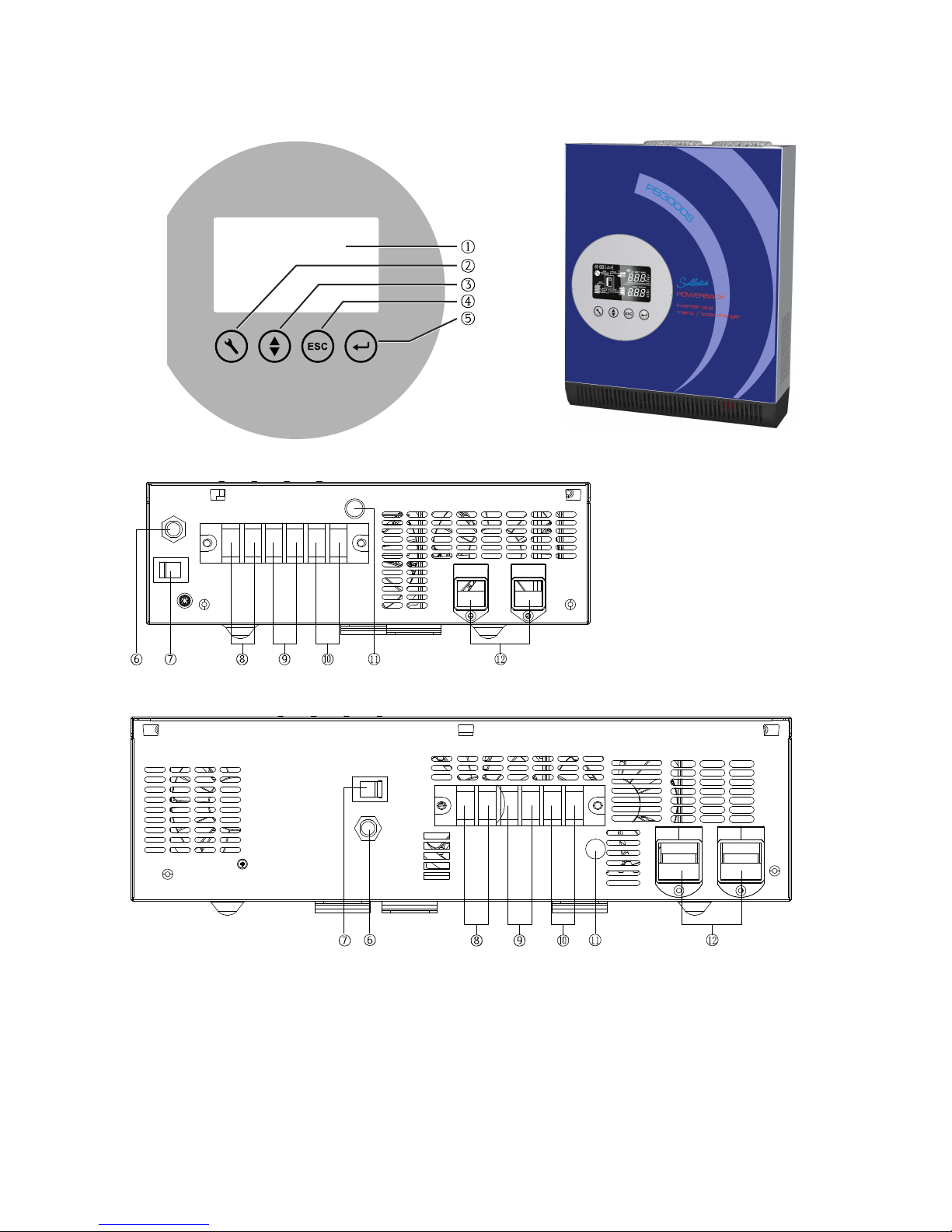

1.2 Product Outlook

3

K rear panel

5

K rear panel

1. LCD display

2. LCD Configuration button: Enter configuration mode, and switch between

setting menus

3. LCD up/down button: Move to previous/next setting option

4. LCD ESC button: Return to main menu

Page 7

5. LCD Enter button: Confirm setting

6. AC input circuit breaker

7. Power ON/OFF switch

8. PV input

9. AC input

10. AC output

11. AC Input & output GND

12. Battery input

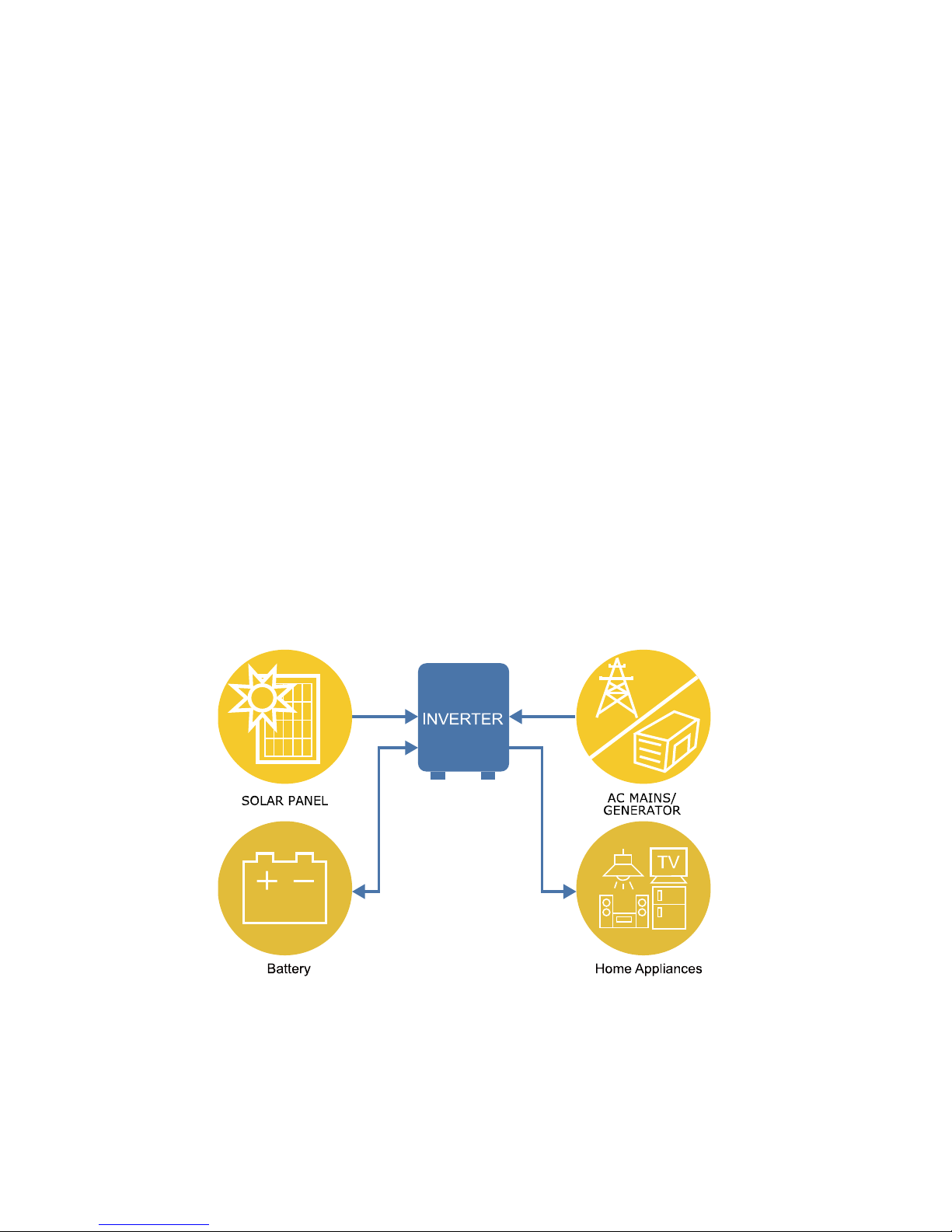

1.3 Basic System Architecture

A typical application diagram for home and office applications is as shown below.

The inverter supports the following power sources as input:

• Generator or AC utility

• PV modules(optional)

• Batteries

And the inverter is capable of supplying various loads such as fluorescent lamp,

fan, TV, refrigerator, air conditioner and so on.

Page 8

2. INSTALLATION

2.1 Unpacking and Inspection

The product package is shipped with the following items. Please call your

supplier or dealer if any items are missing.

! 1 X Inverter

! 1 X DC red cable

! 1 X DC black cable

! 1 X User’s manual

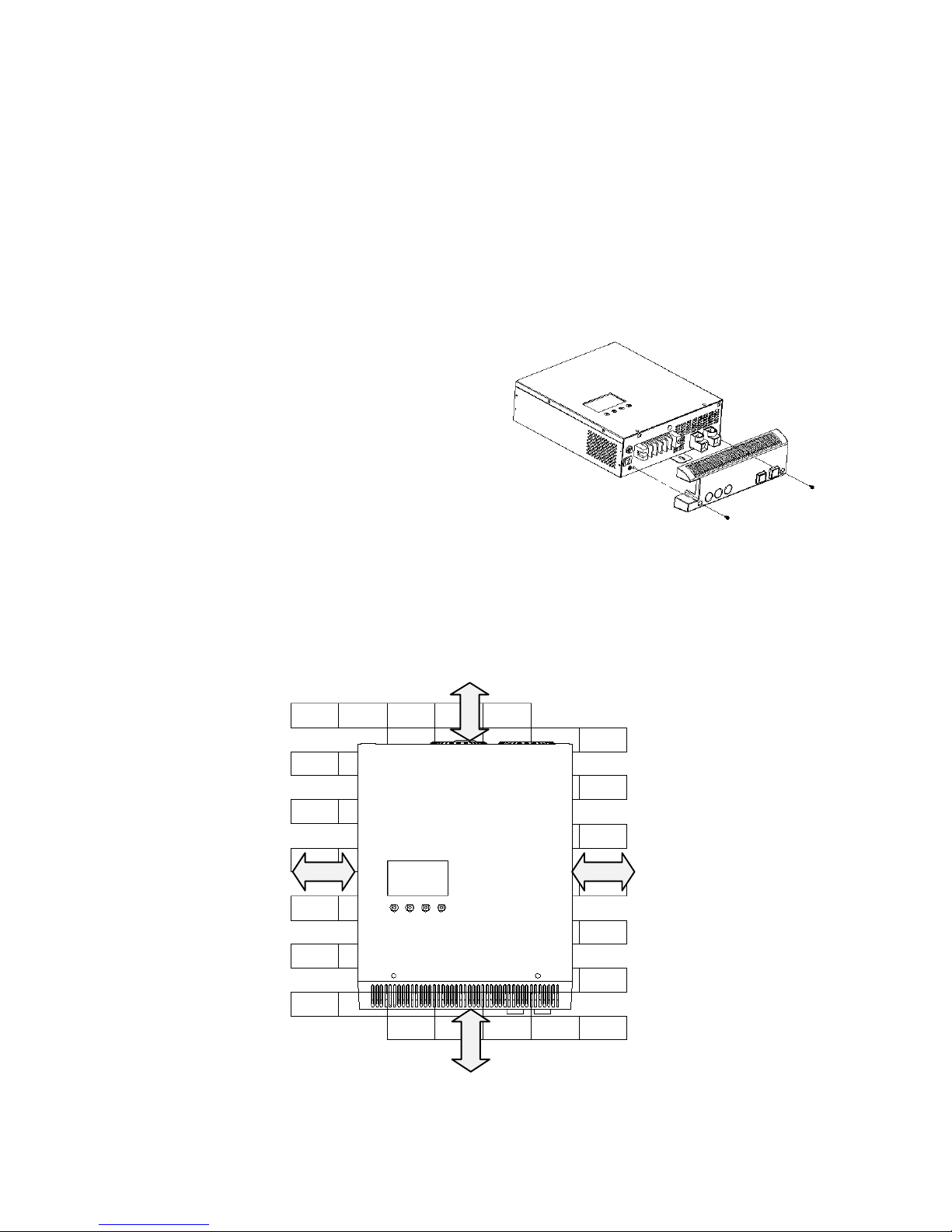

2.2 Remove bottom cover

Please take off bottom cover by removing

below 2 screws before connecting wires.

2.3 Placement

Choosing a location to install, the place should be a firm wall and a well-ventilated

room protected against rain, vapor, moisture and dust. The location should provide

adequate air flow around the Inverter with 30cm minimum clearance on all sides

for proper ventilation.

30cm

30cm

30cm

30cm

Page 9

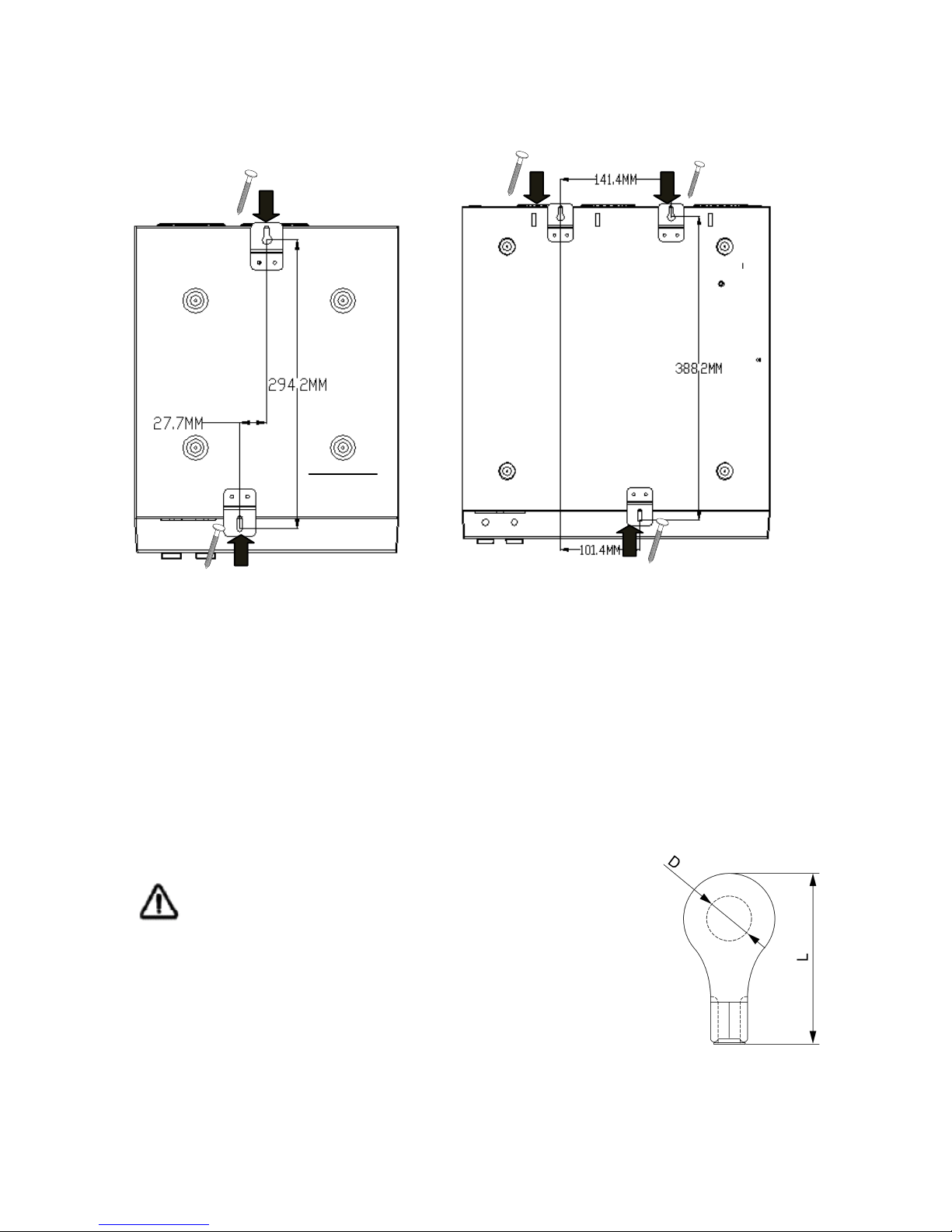

Use screws to mount the inverter to a solid surface. The recommended screw size

is M4*50~65mm.

##Screws locations of 3K model Screws locations of 5K model

2.4 Battery Connection

CAUTION: For safety operation and regulation compliance, it is requested to

install a separate DC over-current protector or disconnect device between battery

and inverter. Note that some installation requirements may not require a

disconnect device, however, an over-current protection installed is still required.

Please refer to typical amperage in below table as required fuse or breaker size.

WARNING! All wiring must be performed by a

qualified technician

WARNING! Check the polarity before connecting the battery

wires

in order not to damage the inverter.

Page 10

Recommended battery cable & cable terminal size:

Model

Number

Typical

Amperage

Battery

Capacity

Wire

Size

CABLE TERMINAL

Torque

value

Cable

mm

2

Dimensions

D(mm)

L(mm)

PowerBack

PB3000S

110A

200AH

1*4AWG

22

6.4

35

5~ 8 Nm

2*6AWG

28

6.4

35

5~ 8 Nm

PowerBack

PB5000S

100A

200AH

1*4AWG

22

8.4

35

5~ 8 Nm

2*6AWG

28

8.4

35

5~ 8 Nm

Please follow below steps to connect the batteries:

Step 1 - Install a DC Circuit Breaker for positive (+) battery cable. The rating of the

DC Circuit Breaker must be at least

140Amp for POWERBACK PB3000S,

120Amp for POWERBACK PB5000S to

guarantee safe operation without

interruption. Keep the DC Circuit

Breaker off.

Step 2 - Connect a red cable to BAT+

terminal, and a black cable to BAT -

terminal of the inverter.

Knock off below “BAT+” and “BAT-” holes, cross red cable via “BAT+” hole and

cross black cable via “BAT-“ hole.

Step 3 - Connect the above mentioned red cable to the battery’s positive (+)

terminal and black cable to battery’s negative (-) terminal.

Step 4 - After AC input and output wires are connected, switch on the DC Circuit

Breaker.

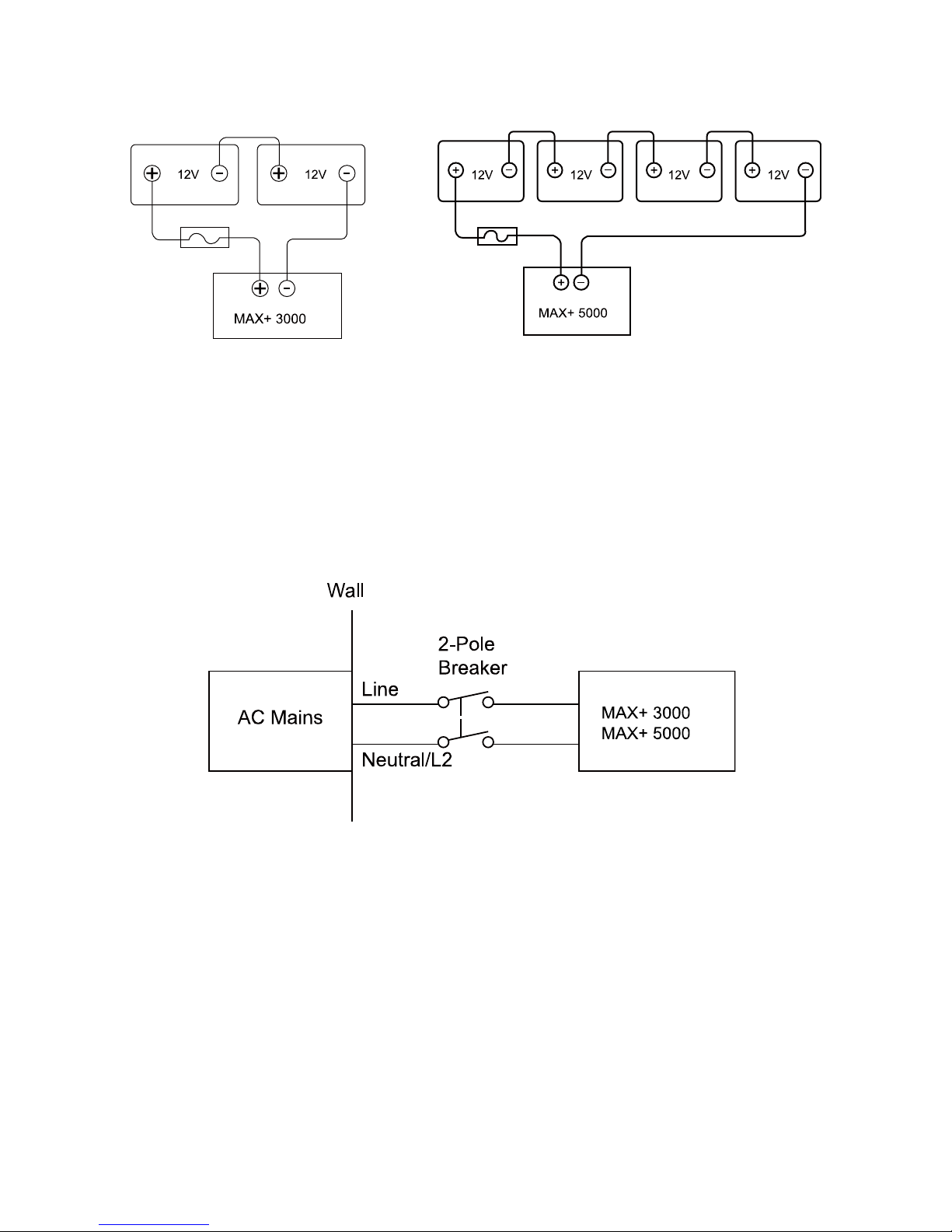

Note: Make sure the battery voltage meets the inverter’s specification:

POWERBACK PB3000S supports 24VDC battery system; POWERBACK

PB5000S supports 48VDC battery system. And use at least 200Ah capacity

battery for POWERBACK PB3000S & POWERBACK PB5000S.

Page 11

2.5 AC Connection

CAUTION: Please install a separate AC breaker between inverter and AC input

power source. This will ensure the inverter can be securely disconnected during

maintenance and fully protected from over current of AC input. The recommended

spec of AC breaker 30A for POWERBACK PB3000S model, 40A for

POWERBACK PB5000S model. Be sure that AC source is switched off before

installing the circuit breaker.

CAUTION: Since the inverter doesn’t have an automatic protection device against

back feed current. We recommends installing an external AC contactor (see the

diagram below). A warning label shall be attached on such AC contractor to

remind the user to disconnect the inverter before accessing the circuit.

The rated voltage and current of the AC contactor shall be no less than the

inverter’s rated voltage and current, and a minimum 1.6mm space clearance shall

be reserved.

A circuit breaker shall be installed between AC mains and the inverter in order to

disconnect the AC mains when needed. Surge protection is built in. For further

protection however, we recommend installing a Sollatek DSP and Sollatek AVS.

Contact us for further information.

Page 12

Please follow the steps below to connect AC wires:

Step 1 - Disconnect the unit from the battery either by turning off the battery circuit

breaker or removing the battery cables from the battery. Note that

turning the unit off does not disconnect the batteries.

Step 2 - Remove bottom cover and knock off “PV”, “IN” & “OUT” holes.

Step 3 - Thread the AC input wires through “IN” hole of bottom cover and AC

output wires through “OUT” hole, then connect the AC input wires to input

terminal, AC output wires to output terminal & AC GND: GND

(green/yellow), Line (brown or black), and neutral (blue) wires.

Legend

B Coil Remote Switch

Q Magneto-Thermal Input Main Switch

T AC Contactor

N/L2 Neutral/L2

L/L1 L1 Line Input

External Distribution

POWERBACK PB3000S/

WARNING! All wiring must be performed by a qualified technician.

WARNING! Operation without a proper grounding connection may

result in electrical shock.

Page 13

Step 4 - Fix the bottom cover with two screws.

The recommended wire gauge and fixing torque are as below,

Model Number

AC Input

Wires Gauge

AC Output

Wires Gauge

AC GND

Wires Gauge

Torque

POWERBACK

PB3000S

12 AWG

12 AWG

12AWG

1.2~1.8 Nm

POWERBACK

PB5000S

10 AWG

10 AWG

10AWG

1.2~1.8 Nm

WARNING! The inverter is designed to be operated alone and is not designed for

parallel connection. Please DO NOT connect the inverter in parallel with any other

equipment.

2.6 PV connection

PV panel selection

PV string is a connection of PV panels whose output voltage and current vary

under different illumination. And just like battery, the PV panel can be connected in

either series or parallel as per needed. Please consult the supplier of PV panel so

that the operational voltage and current fall within the allowed range of the inverter

as set out in the specification.

Page 14

Connect PV strings

CAUTION: As the PV string generates power as long as there is light, a circuit

breaker with 60A rating shall be installed as shown below, so that PV string can be

disconnected when needed (e.g. regular maintenance).

Please follow below step to implement PV module connection:

WARNING! All wiring shall be performed by a qualified technician.

WARNING! Please do not use PV panel which requires one

terminal connected to ground (e.g. thin-film panel).

Step 1 - Disconnect the unit from the battery either by turning off the battery

breaker or removing the battery cables from the battery. Note that turning

the unit off does not disconnect the batteries.

Step 2 - Remove bottom cover & knock off “PV” hole.

Step 3 - Thread the wires through “PV” hole on bottom cover, and then connect

the PV string wires to PV input terminals. Check the polarity of wires

before connecting to terminals.

Step 4 - Fix bottom cover with two screws.

Step 5 - Turn on battery breaker or connect battery cable.

The recommended wire gauge and fixing torque are as below,

Model Number

PV Input Wire Gauge

Torque

POWERBACK PB3000S

10 AWG

1.2~1.8 Nm

POWERBACK PB5000S

10 AWG

1.2~1.8 Nm

60Amps

Page 15

3. OPERATION

After connecting batteries, AC input cables, and loads, the inverter is now ready to

work.

3.1 LCD display introduction

LCD displays the power flow and input/output readings in a visualized graphic

design which allows the user to understand the operation status easily.

Icon

Description

This icon is showed when AC input (from AC mains

or generator) presents.

If unit is on wide mode, “WIDE” will be lighted, else

“NARROW” will be lighted.

This icon is showed when PV (solar) system

presents.

The icon indicates level of remaining battery

capacity

The icon indicates battery flow way.

If unit is on CC & CV charging stages, “FAST” will

be lighted.

The icon indicates output load level. If unit work on

line mode, “BYPASS” will be lighted.

Indicate PV input voltage. PV input current, AC input

voltage, Battery voltage.

Page 16

Indicate output voltage, output frequency, load

percentage, load VA value, load watt value.

The icon indicates unit is on LCD setting mode.

The icon indicates unit is on alarm mode or fault

mode.

When unit is on LCD setting mode, it indicates

program code.

When unit is on fault mode, it indicates the fault

code which can be referred to specific fault event

(please refer to Section “Troubleshooting”).

(2) Setting Menus

After pressing and holding

button for more 2 seconds to enter setting mode,

press button for 1 second to select setting programs, then press button

to select program option, then press button to confirm the selection or

button to exit.

Program

Description

Selectable option & behavior

LCD setting display

01

AC input

voltage range

Wide (default): If selected, acceptable A

C input voltage range will be within

90-280VAC

Narrow: If selected, acceptable AC input

voltage range will be within 170-280VAC

Generator: If selected, acceptable AC

input voltage range will be within

90-280VAC

02

Output

source

priority: To

configure

load power

source

priority

Solar first(default): Solar energy provide

power to the loads as first priority.

If solar energy is not sufficient to power

all connected loads, battery energy will

supply power the load at the same time.

Utility provides power to the loads only

when any below condition happens:

-Solar energy is not available

-Battery voltage drop to either low-leve

l

warning voltage or the setting point in

program 5.

Page 17

Utility first: Utility will provide power to

the loads as first priority.

Solar and battery energy will provide

power to the load only when utility power

is not available.

SbU: Solar energy provides power to the

loads as first priority.

If solar energy is not sufficient to power

all connected loads, battery energy will

supply power the load at the same time.

Utility provides power to the loads only

when battery voltage drop to either

low-level warning voltage or the setting

point in program 5.

03

Charger

source

priority:

To configure

charger

source

priority

Solar first: Solar energy will charge

battery as first priority.

Utility will charge battery only when solar

energy is not available.

Utility first: Utility will charge battery as

first priority.

Solar energy will charge battery only

when utility power is not available.

Solar and Utility(default): Solar energy

and utility will charge battery at the same

time.

Only solar: Solar energy will be the only

charger source no matter utility is

available or not.

04

Setting

voltage point

back to

battery mode

when

selecting

"SBU priority"

or "Solar first"

in program 2.

Options in POWERBACK PB3000S

model:

Full/25.0V/25.5V/26.0V/26.5V/27.0V(def

ault)/

27.5V/28.0V.

Options in POWERBACK PB5000S

model:

Full/50V/51V/52V/53V/54V(default)/55V/

56V.

05

Setting

voltage point

back to utility

source when

selecting

"SBU priority"

or "Solar first"

in program 2.

Options in POWERBACK PB3000S

model:

21.0V/21.5V/22.0V(default)/22.5V/23.0V/

23.5V/

24.0V/24.5V.

Options in POWERBACK PB5000S

model:

42V/43V/44V(default)/45V/46V/47V/48V/

49V.

Page 18

06

Max charging

current:

To configure

total charging

current for

solar and

utility

chargers:

(Max.

charging

current=utility

charging

current +solar

charging

current)

Options in POWERBACK PB3000S

model:

20A/30A/40/50A/60A(default)/70A/

80A/90A/100A

Options in POWERBACK PB5000S

model:

20A/30A/40/50A/60A(default)/70A/

80A/90A/105A

07

Max utility

charging

current

Options in POWERBACK PB3000S

model: 0A/2A/10A/20A(default)

Options in POWERBACK PB5000S

model:

0A/2A/10A/25A (default)

08

Auto restart

when

overload

occurs

Restart disable(default):

When unit is overload, unit will release

overload alarm, then turn off output &

release fault alarm, unit won’t restart

again until end-user reduce load & press

unit’s on/off power switch.

Restart enable:

When unit is overload, overload alarm 5

seconds and turn off output for 15

seconds, then restart unit again. The

restart cycle is 5 times.

09

Low DC cut

off voltage

Auto(default):

If setting auto, low DC cut off voltage will

be relate to load percent.

20.0V for 24V model @ >=60%load

21.0V for 24V model @ <60%load

40.0V for 48V model @ >=60%load

42.0V for 48V model @ <60%load

24V model:

20.0V to 24.0V, 0.2V per step;

48V model:

40.0V to 48.0V, 0.4V per step.

Page 19

10

LCD backlight

control

Backlight auto(default):

LCD backlight will be off when no LCD

button is pressed after 1min.

Backlight all on

11

Recover

manufactory

setting

Recover enable:

Return to manufactory default setting.

Recover disable(default)

3.2 LCD display setting:

The default LCD display is:

Line mode

Battery mode

BAT+PV mode

The LCD display content will be changed in turns by pressing button. The

selectable information is switched as below order: PV input voltage, PV input

current, AC input voltage, battery voltage, output voltage, output frequency, load

percentage, load VA value, load watt value. LCD will return to default LCD display

after 1 minute, or press

button return to default LCD display immediately.

3.3 Standby Charging Mode

The battery can be charged without switching on the inverter, and such operation

is called Standby Charging Mode. When AC input cable and battery is connected,

the inverter will enter into Standby Charging Mode and LCD will be turned on with

the following display. But if charger priority setting is only solar, utility won’t charge

battery.

Page 20

If PV string is also connected with enough voltage, the display will be as shown

below to indicate the power flow from PV string. Except only solar setting for

charger priority.

Even if AC input is absent, PV power can still charge the battery and the display

will be as shown below.

3.4 Operation Modes (after powered on)

Press the Power ON/OFF button to power on the inverter and the inverter will

automatically enter into either of the operation mode according to the condition of

AC input and PV input as shown in the table below

Page 21

LINE MODE 1

AC input is present and PV input is absent. Load is supplied by AC input power

directly.

LINE MODE 2

Both AC input and PV input are present. Load is supplied by either AC input or PV

input depending on the priority switch’s setting.

Output source priority setting:

In LINE MODE 2, if priority setting is Solar first or SBU, when PV power is strong

enough to support load, the AC input will not be consumed even though it is

Page 22

present. This is deemed an energy-saving operation.

BACKUP MODE 1

Both AC input and PV input are absent. The backup power to load comes only from

battery. The backup time is determined by the capacity of battery.

BACKUP MODE 2

AC input is absent and PV power is present, if PV power is not enough to support

loads completely. The insufficient power is covered by battery.

The larger the PV power, the less consumption from battery and therefore the

longer backup time.

BACKUP MODE 3

AC input is absent and PV power is present, if PV power is strong enough, it will to not

only support the load but also charge the battery.

Page 23

As long as the PV generates power, the load can be powered continuously without

consuming power from battery.

3.5 Fault Mode

If unit is on fault mode, LCD will show the fault code which can be referred to

specific fault event (please refer to Section “Troubleshooting”).

4. SPECIFICATION

MODEL

POWERBACK

PB3000S

POWERBACK

PB5000S

CAPACITY

2.4KW/3000VA

4.2KW/5000VA

INPUT

Input Voltage Waveform

Pure sine wave (utility or generator)

Nominal Input Voltage

230Vac

Input voltage range

170Vac-280Vac(Normal);

90Vac-280Vac(Generator/Wide)

Max AC Input Voltage

300Vac RMS

Nominal Input Frequency

50Hz / 60Hz (Auto detection)

OUTPUT

Wave from

Pure sine wave (Inverter mode)

Voltage Regulation

(Inverter Mode)

±10% RMS

Output Frequency

50Hz / 60Hz ± 1Hz

Nominal Efficiency

90% (@Inverter mode with normal DC Input; >60% R load);

95% (@Line mode with Rated R load, battery full charged)

Capable of starting electric

motor

1.5HP

2.5HP

Power Factor

0.8

0.84

Over-Load Protection

Tripped off after 5s@≥150% load

Tripped off after 10s@110%~150% load

Transfer Time

(AC to DC)

Normal range : 10ms (typical) 15ms (max)

Generator/wide range: 20ms (typical) 40ms (max)

Power Limitation

POWERBACK PB3000S @ Line mode:

Page 24

AC I/P V

O/P Power

3KVA/2.4KW

90V 180V

280V

POWERBACK PB5000S@ Line mode:

BATTERY

Battery Voltage

24.0Vdc ± 0.6Vdc

48.0Vdc± 1.2Vdc

Battery low alarm voltage

21.0Vdc ± 0.6Vdc (default)

42.0Vdc± 1.2Vdc(default)

Battery low shut-down

voltage

Default:

20.0Vdc ± 0.6Vdc@

load>60%

21.0Vdc± 0.6Vdc@

load<60%

Default:

40.0Vdc ± 1.2Vdc@

load>60%

42.0Vdc± 1.2Vdc@

load<60%

Battery capacity(suggestion)

>=200Ah

AC CHARGER

Charger Current

0A/2A/10A/20A selectable

0A/2A/10A/25A selectable

Boost charger voltage (bat.

Type)

28.4Vdc

56.8Vdc

Floating charger voltage (bat.

Type)

27.4Vdc

54.8Vdc

Over charger Voltage

30.0Vdc

60.0Vdc

SOLAR CHARGER

MODULE

Max. PV Module Charger

current

80A

80A

Max PV panel array

power(base on 250W/8A PV

panel)

2000W

3750W

Max PV mode power rating

to support load

1600W

3200W

MAX. PV Input Current

50A

50A

System DC Voltage

24.0Vdc

48.0Vdc

Page 25

MPPT operating voltage

range

30~80Vdc

60~150Vdc

MPPT optimal work voltage

range

35~70Vdc

70~120Vdc

Max. PV Array Open Circuit

Voltage

80Vdc

150V

AUDIBLE ALARM

Low Battery at Inverter Mode

Beeps 1 time every 2s

Overload

110%~150%load: beep 10 times every 0.5s;

>150% load: beep 5times every 0.5s then fault.

Fault

Beeps continuously

PHYSICAL

Dimension(D*W*H)mm

342*268.2*94.4mm

436.00*394.4*118.3

Net weight

5.7KG

10.3kg

General Specification

Safety Certification

CE

Operating Environment

0°C to 50°C; 5% to 95% non-condensing

Altitude, operational

Elevation: 0~1500 Meters

Storage temperature

-15°C ~ 60°C

Troubleshooting

Problem

Possible Causes

Remedy

No LCD display

1. Battery weak

1. Re-charge battery

2. Battery defective (can't be

charged)

2. Battery replacement

3. Power switch is not

pressed

3. Press and hold power switch

4. Battery polarity reversed,

can’t start up the unit

4. Contact dealer or supplier for service

Mains normal

but works in

inverter mode

1. AC Input is missing

1. Check AC input connection

2. Input protector tripped off

2. Reset the input protector

PV input

normal but

works in

inverter mode

1.PV weak

1.Check PV power or reduce loading

2.PV input is missing

2.Check PV input connection

Page 26

Alarm buzzer

beeps

continuously

1. Overload (fault code: F2)

1. Reduce loading so the loads’ capacity

is no larger than the upper limit

2. Output short-circuited

(fault code: F3)

2. Check wiring or remove abnormal load

3. Inverter over-temperature

(fault code: F5)

3. Check the ventilation at installed

location and make sure the air vent of

inverter is clear

4. Over charging (fault code:

F1)

4. Restart the unit, If the fault persists,

contact dealer or supplier for service.

5. Fan error (fault code: F4)

5. Check if the fan is blocked by

obstacle. if not, contact dealer or

supplier for service

6. DC voltage is under low

DC shut-down point (fault

code: F0)

6. Make sure mains is normal to

recharger the battery

7. Output abnormal (fault

code: F6)

7. Contact dealer or supplier for service

8. Back-EMF, only for

POWERBAC

K

PB3000S/5000model (fault

code: F7)

8. Check the AC Input and output wire

connection

9.SCC output over current

(fault code: F11)

9.Check wiring or remove abnormal load

10.SCC over temp(fault

code: F12)

10. Check the ventilation at installed

location and make sure the air vent of

inverter is clear

11.SCC Output over

voltage(fault code: F13)

11. Restart the unit. If the fault persists,

contact dealer or supplier for service

12.SCC PV input over

voltage (fault code: F14)

12.Check PV input voltage. If the voltage

is normal, contact dealer or supplier

for service

13.SCC Fan Fault (Only for

POWERBACK PB5000S)

(fault code: F15)

13. Check if the fan is blocked by

obstacle. if not, contact dealer or

supplier for service

Back up time is

shortened

1. Overload

1. Reduce the loading

2. Battery voltage is too low

2. Charge battery for 8 hours or more

3. Battery bank is too small

3. Increase battery bank capacity

Note: If the unit fails to operate properly after installation and the setup has been

re-examined thoroughly, use the troubleshooting table to determine the probable

cause and remedy. For unlisted faults, please contact your local dealer or supplier

for service assistances.

Page 27

Alarm Behavior Table

Fault

Code

Protect

Function

Active

Mode

Condition

Warning

(O/P=ON)

Fault

(O/P=OFF)

Restart

Operate

Condition

--

Low DC

Voltage

Alarm

Inv. mode

DC

voltage<Low

DC Alarm

1beep/2s

--

--

--

1

Over

Charge

Protection

Line mode

DC

Voltage>High

DC input

Shut-down

Beep

continuous

--

Manual

--

1

Over

Voltage

Protection

Standby

DC

Voltage>High

DC input

Shut-down

--

Beep

continuously

Auto

DC

Voltage<High

DC input

Shut-down

Recovery

2

Over Load

Protection

Line/

Inv. mode

110%~150%

rated load

1beep/0.5

s,and

continue

for10s

Beep

continuously

Manual

--

>150% rated

load

1beep/0.5

s,and

continue

for 5s

Beep

continuously

Manual

--

3

Output

Short

Circuit

protection

Inv. mode

Output

Voltage<20Vr

ms

--

Beep

continuously

Manual

--

4

Inverter

Fan Fault

Protection

Line/

Inv. mode

Fan Locked

Fan Defected

2beep/2s,

and

continue for

1min

Beep

continuously

Manual

--

5

Inverter

Over

Temp

Protection

Line/

Inv. mode

HEAT SINK

over temp

--

Beep

continuously

Auto

HEAT SINK

Temp≤ 55

6

Output

Abnormal

Inv. mode

(Output

Voltage

<170Vrms and

output current

under 32Arms)

or Output

Voltage

>280Vrms

--

Beep

continuously

Manual

--

7

Bus Over

Protection

Standby/

Line/

Inv. mode

Bus voltage

over/ AC

Input and

output

reconnect

--

Beep

continuously

Manual

--

11

SCC

charger

over

current

SCC

SCC charger

current over

120A

--

Beep

1time/2Seco

nd

Manual

--

Page 28

12

SCC over

temp.

SCC

SCC NTC

Temperature

over 110℃

--

Beep

1time/2Seco

nd

Manual

--

13

SCC

Output

over

voltage

SCC

SCC Output

voltage over

30V(3K)/60V(

5K)

--

Beep

1time/2Seco

nd

Manual

/

Auto

SCC Output

voltage lower

than 24V(3K)/

48V(5K)

14

SCC PV

input over

voltage

SCC

PV Input

voltage over

80V(3K)/150

V(5K)

--

Beep

1time/2Seco

nd

Manual

/

Auto

PV Input

voltage lower

than 70V(3K)/

140V(5K)

15

SCC Fan

Fault(Only

for 5K

SCC)

SCC

SCC Fan lock

--

Beep

1time/2Seco

nd

Manual

--

Note: when SCC Fault, press ENTER Key will clear this fault message.

1) Unit will shut down after alarm for 1min, when unit on both fault mode and

Switch-off mode.

2) Unit will shut down immediately without any alarm, when unit on Switch-

on

mode with low DC input.

Input voltage setting:

(1) Normal “170V~280V”for is for valuable electronic devices. If the utility is

higher or lower than this range, the unit will transfer to inverter mode

automatically.

(2) Wide “90V~280V” for is for home application. If the utility is higher or lower

than this range, the unit will transfer to inverter mode automatically.

(3) Generator, if AC input is connected to a generator, please choose “generator”

as “Input range”.

Page 29

APPENDIX A

How to Select and Configure PV Panels

The following parameters can be found in each PV panel’s specification:

• P

max

: Max output power (W)

• V

oc

: open-circuit voltage (V)

• I

sc

: short-circuit current (A)

• Vmp: max power voltage (V)

• I

mp

: max power current (A)

PV panels can be connected in series or parallel in order to obtain the desired

output voltage and current which meets the inverter’s allowed range.

When connecting PV panels in series, the max voltage and current of the string is

V

string

= V1+V2+V3+V4…

I

string

= I1=I2=I3=I4

When connecting the above PV string in parallel, the max voltage and current of

the total string is

V

total

= V

string1=V string2=V string3=V string4

…

I

total

= I

string1+Istring2+Istring3+Istring4

In either case, the total output power is P

total

= P

panel

X Number of PV panel

The guideline to select and configure PV string is

• P

total

shall be equal or slightly larger than the max. capacity of solar battery

charger (2000W for 3000VA model and 3750W for 5000VA model). Extra

capacity in PV string will not increase the charge capacity but only result in

higher installation cost.

Model

PV panels

installed

Max. PV module to support load

3000VA

2000W

1600W

5000VA

3750W

3200W

Page 30

• Total Vmp of the string shall be within the operating voltage range of solar

battery charger (35~70V for 3000VA model and 70~120V for 5000VA model

are recommended).

Model

PV Operating voltage range

PV Optimize working voltage range

3000VA

30~80Vdc

35~70Vdc

5000VA

60~150Vdc

70~120Vdc

Example 1 - How to connect 3000VA model to PV panels with the following

parameters?

• P

max

: 250W

• V

oc

: 36.6V

• I

sc

: 8.75A

• Vmp: 30.96V

• I

mp

: 8.07A

(1) The max. PV input power for 3000VA model is 2000W,

2000W / 250W = 8⇒ min. 8 PV panels shall be connected.

(2) Best Operating Voltage Range is 35~70V,

70V/30.96V = 2.26 ⇒ max. number of PV panel in series is 2.

(3) Taking (1)~(2) into consideration, the optimized configuration is 2 PV panels

in series as a string and 4 strings in parallel, as shown below.

(4) Check again the Voc and Isc of PV string,

V

oc

of string is 73.2V < 80V (Max. PV Input Voltage) ⇒ OK

I

sc

of string is 4 x 8.75A = 35A < 50A (Max. PV Input Current) ⇒ OK

Page 31

Example 2 - How to connect 5000VA model to PV panels with the following

parameters?

• P

max

: 250W

• V

oc

: 36.6V

• I

sc

: 8.75A

• Vmp: 30.96V

• I

mp

: 8.07A

(1) The max. PV input power for 5000VA model is 3750W,

3750W / 250W = 15⇒min. 15 PV panels shall be connected.

(2) Best Operating Voltage Range is 70~120V,

120V/30.96V = 3.87 ⇒ max. number of PV panel in series is 3.

(3) Taking (1)~(2) into consideration, the optimized configuration is 3 PV panels

in series as a string, and 5 strings in parallel (as shown below).

(4) Check again the Voc and Isc of PV string,

V

oc

of string is 3 x 36.6V = 109.8V < 150V (Max. PV Input Voltage) ⇒ OK

I

sc

of string is 5 x 8.75A = 43.75A < 50A (Max. PV Input Current) ⇒ OK

Page 32

APPENDIX B

HOW TO DETERMINE THE OUTPUT SOURCE PRIORITY SETTING AND

CHARGER SOURCE PRIORITY SETTING?

Please read this document carefully if you intend to manually set the priority setting

of the product. Improper setting might compromise the function and performance of

the product.

The product is designed to accept both utility and solar (PV) power as input source,

and it also provides a function allowing the user to determine the priority between

utility and solar input power. The priority is to be set via LCD and control buttons on

the front panel (please refer to user manual for more details). This document

explains how the product’s behavior will be at each setting and what should be

considered while determine the priority.

A. Output source priority setting

1. Setting Utility as output source priority

1.1 When utility is normal

The loads connected to the product are supplied by utility power only, even when

solar power presents.

1.2 When utility is down

As soon as the utility is down, the inverter enters into “Backup Mode” and checks

both solar power and battery’s status. If solar power is strong enough, it will supply

the loads. If solar power becomes weak, the loads will then be supplied by battery

until it’s too low. The longer the solar power lasts, the less consumption from the

battery and hence the longer backup time.

Advantages

Disadvantages/Risk

backup function won’t be compromised when the utility is

down.

discharging mode.

fully utilized by supporting

the loads, especially when

battery if fully charged.

2. Setting Solar as Priority

2.1 When utility is normal

As long as solar power is strong enough to support the, utility power will not be

consumed even though it’s available. If solar power is not enough, battery will firstly

come up to support the loads, and after battery is low or the setting point in program

5, utility will then take over to support the loads.

If solar is absent, utility will then take over

to support the load too.

Page 33

2.2 When utility is down

The behavior is the same as 1.2.

Advantages

Disadvantages

power.

reducing the consumption

of utility

cycles and therefore battery’s service life will be shorter.

before the battery can fully-charged by utility, the backup

function of the product might be compromised or void.

3. Setting SbU as Priority

3.1 When utility is normal

As long as solar power is strong enough to support the loads, utility power will not

be

consumed even though it’s available. If solar power is not enough, battery will firstly

come up to support the loads, and after battery is low or the setting point in program

5, utility will then take over to support the loads and charge the battery.

2.2 When utility is down

The behavior is the same as 1.2.

Advantages

Disadvantages

power is maximized.

reducing the consumption

of utility

cycles and therefore battery’s service life will be shorter.

before the battery can fully-charged by utility, the backup

function of the product might be compromised or void.

Summary

Whether setting utility as priority or setting solar or SbU as priority is subject to

purpose of installing the product. In the event the product is to be installed in areas

where the utility power is unstable and backup function is much important than

energy saving, utility shall be set as priority.

If the product is to be installed in areas with stable utility power and strong sunlight,

and energy saving is more concerned than backup function, solar power shall be

set as priority or SbU.

B. Charger source priority setting

1. Setting Utility as charger source priority

Utility first: Utility will charge battery as first priority.

Solar energy will charge battery only when utility power is not available.

2. Setting Solar as charger source priority

Solar energy will charge battery as first priority.

Utility will charge battery only when solar energy is not available.

Page 34

3. Setting only Solar as charger source priority.

Solar energy will be the only charger source no matter utility is available or not

.

4. Setting only Solar and Utility as charger source priority.

4.1 When utility is normal

Solar energy and utility will charge battery at the same time.

4.2 When utility is down

Solar energy will charge battery.

Summary

Whether setting which option as charger source priority subject to purpose of

installing the product. In the event the product is to be installed in areas where the

utility power is unstable and backup function is much important than energy saving,

Solar and Utility or Utility shall be set as charger source priority.

If the product is to be installed in areas with stable utility power and strong sunlight,

and energy saving is more concerned than backup function, solar first or only solar

shall be set as priority, and set the maximum utility charging current as small

current as possible (program 7), for example: 2A.

Page 35

Sollatek (UK) Ltd. Sollatek House, Waterside Drive, Langley, Slough SL3 6EZ UK

ISO9001: 2008 accredited company

All weights and dimensions are approximate. Specifications are subject to change

without prior notice. ©Sollatek (UK) Limited 2012. All Rights Reserved. SOLLATEK

and the SOLLATEK device are the trade marks of the Sollatek group of companies.

SOLLATEK UK LTD.

Tel: +44 (1753) 214 500

sales@sollatek.com

www.sollatek.com

PowerBack Instructions Manual Aug 2018

A/W ID: 10910516

MJA 21.08.2018

the power to protect

Loading...

Loading...