Solinst Levelogger Series, Rainlogger 3001, Leveloader Gold, Barologger 3001 Gold, Levelogger 3001 Gold User Manual

...

User Guide - Software Version 3.2.3

June 5, 2008

Levelogger Series

(Levelogger Gold, Barologger Gold, Levelogger Junior, and Rainlogger)

Levelogger User Guide - Table of Contents

1 Introduction to Solinst Levelogger Series and Software 4

1.1 Level 9

1.1.1 Pressure Calibration 9

1.2 Barologger 9

1.3 Temperature 10

1.4 Total Precipitation 10

1.5 Backwards Compatibility 10

2 System Requirements 11

3 Software Installation 11

3.1 Installing USB Drivers for Software V3.2.3 or Higher 12-15

- USB Installation for Windows 98 12

- USB Installation for Windows 2000 13

- USB Installation for Windows XP (Service Pack 2 or less) 14-15

4 Startup, Configuration and Settings 16

4.1 Communicating with a USB Port 16-17

4.2 Com Port Designation Setup 17

4.3 Data Directory 17

5 Levelogger Settings 18

5.1 Levelogger Information Settings 17-20

- Project ID 18

- Location, input specific site / location information 18

- Altitude 18

- Density Adjustment 19

- Sample Mode 19

- Memory Mode Selection 19

- Linear 19

- Event-based Sample Collection 19

- Schedule Sampling 19

5.2 Setting up Channel Information 20

- For Channel 1: ‘Level’... 21

- Identification 21

- Units 21

- Offset 21

- Range 21

- For Channel 2: ‘Temperature’... 21

5.3 Levelogger Status 22

5.4 Setting up the Levelogger Time 22

5.5 Program Levelogger Settings 22

5.6 Starting and Stopping the Levelogger 22-23

5.7 Saving and Retrieving Levelogger Settings Files 23

6 Rainlogger 24

6.1 Rainlogger Communication Interface 24

- Rainlogger Gauge Connector 24

6.2 Rainlogger Setup 25-26

7 Data Control Window (Downloading and Compensating Data) 27

7.1 Downloading Options 27-29

7.2 Graph Manipulation and Zoom Function 29-30

7.3 Data Compensation 31-32

- Barometric Compensation 32

- Manual Data Adjustment 32

- Density Adjustment 32

- Barometric Efficiency Adjustment 32

Levelogger User Guide - Table of Contents

8 Real Time View Window 33

9 File Export and Print Function 34

10 Installation and Maintenance of Levelogger

35-50

10.1 Installation 35

10.1.1 Free Suspended Installations 36-37

- Suspension Wire Installation 36

- Direct Read Cable Assembly Installation 37

10.1.2 Fixed Installation 37-45

- Open Channel Installations 37-39

- Installation at Weirs 40-41

- Installation in Flumes 41-42

- The California Pipe Method 42

- Orifice Discharge Monitoring 43

- Artesian Monitoring 43-44

- Vacuum/Vapor Monitoring 44-45

10.1.3 Barologger Installation 45

- Barometric Efficiency 45-46

10.1.4 Installation in Extreme Thermal and Marine

Environments 47-48

- Freezing or High Temperature Conditions 47

- Marine or Brackish Installations 48

10

.1.5 References 49

10.2 Levelogger Maintenance 50

11 Manual Barometric Compensation 51-54

12 Diagnostic Utility 54

12.1 Read Levelogger Information 54-55

12.2 Run Self-Test 55

12.3 Read Memory Dump 56

12.4 Create Report 57

13 Firmware Upload Utility 58

14 Trouble Shooting Guide 59-62

14.1 Problems During Installation of Levelogger Gold Software 59

14.2 Error During Software Uninstall Process 59

14.3 Problems During Installation of RS232 to USB Converter 59

14.4 Data Has Been Erased Accidentally 60

14.5 Error Messages During Use of Software 60-62

Appendix

i) 3001 Levelogger Gold Quick Start Guide

ii) 3001 Leveloader Gold User Guide

iii) 3001 Leveloader Gold Quick Start Guide

Levelogger User Guide - Software Version 3.2.3 or Higher

Page 4

1 Introduction to Solinst Levelogger Series and Software

Levelogger Gold Software Version 3.2.3 is intuitive and easy-to-use. It is

designed to support the Levelogger Gold Series of products.

Levelogger Gold

The Levelogger Gold is an absolute (non-vented) data logger, which measures

groundwater and surface water levels and temperature. Water levels are

displayed as temperature compensated pressure readings, and can be

barometrically compensated with the aid of a Barologger Gold.

- Solinst recommends customers use Version 3.2.3 Software using with

V2.000 firmware or higher

Levelogger Gold Technical Specifications

Level Sensor: Piezoresistive Silicon in 316L Stainless Steel

Accuracy (Typical): 0.05% FS

Stability of Readings: Superior, low noise, 6 times better than previously

Resolution: 0.002 to 0.0006% FS

Normalization: Automatic Temp Compensation

Temperature Sensor: Platinum Resistance Temperature Detector

Temp. Sensor Accuracy: ± 0.05°C

Temp. Sensor Resolution: 0.003°C

Temp. Comp. Range: -10 to +40°C

Response Time: < 1 minute

Battery Life: 10 Years - based on one reading/min

Clock Accuracy: ± 1 minute /year

Operating Temperature: -20°C to 80°C

Maximum # Readings: 40,000 of level and temperature

Memory: Superior reliability EEPROM Slate, rollover

and redundant backup of last 1200 readings

Communication: Optical Infra-Red Interface, Serial at 9600 Baud,

Conversion to RS232 or USB Computer Connection

Size: 7/8" x 6" (22 mm x 154 mm)

Weight: 6.3 oz (179 grams)

Backwards Compatibility: Full

Corrosion Resistance: Zirconium Nitride (ZrN) Coating

Other Wetted Materials:

316-L Stainless Steel, Delrin, Viton

Sampling Modes: Linear, Event and User-Selectable with

30 separate line items

Measurement Rates: 0.5 sec to 99 hrs

Barometric Compensation: Software Wizard and one Barologger in local area

(approx. 20 miles/30 km) radius

LT Models

Full Scale

(FS)

Water Fluctuation

Range

Accuracy

(typical)

Resolution

F15, M5 16.4 ft., 5 m 13.1 ft., 4 m ± 0.010 ft., 0.3 cm 0.001% FS

F30, M10 32.8 ft., 10 m 29.5 ft., 9 m ± 0.016 ft., 0.5 cm 0.0006% FS

F60, M20 65.6 ft., 20 m 62.3 ft., 19 m ± 0.032 ft., 1 cm 0.0006% FS

F100, M30 98.4 ft., 30 m 95.1 ft., 29 m ± 0.064 ft., 1.5 cm 0.0006% FS

F300, M100 328.1 ft., 100 m 325 ft., 99 m ± 0.164 ft., 5 cm 0.0006% FS

Note:

This version of software

is not compatible with

older models of the

Levelogger (Silver LT

and LTC, Black LTC and old Rain

Loggers).

To program and use

the old versions, Levelogger

3.1.1 or 2.0.3 Software and

User Guides can still be

accessed at:

www.solinst.com/Downloads/

Levelogger User Guide - Software Version 3.2.3 or Higher

Page 5

Barologger Gold

The Barologger Gold uses algorithms based on air pressure only. It measures

and logs changes in atmospheric pressure, which are then used to compensate

water level readings recorded by a Levelogger Gold, or a Levelogger Junior.

Models

Full Scale

(FS)

Water Fluctuation

Range

Accuracy

(typical)

Resolution

Barologger Air Only ± 0.003 ft., 0.1 cm 0.002% FS

Levelogger User Guide - Software Version 3.2.3 or Higher

Page 6

Levelogger Junior

The Levelogger Junior provides an inexpensive alternative for measuring

groundwater and surface water levels and temperature. The Levelogger Junior

is compatible with all Levelogger Gold accessories.

- Solinst recommends customers use Version 3.2.3 Software with V2.000

firmware or higher

A comparison between Levelogger Gold and Levelogger Junior technical

specifications can be found in the appendix of this User Guide.

3001 Junior - Technical Specifications

Level Sensor: Piezoresistive Silicon in 316L SS

Ranges: F15/M5, F30/M10

Accuracy (typical): 0.1% FS

Resolution: 0.028%, 0.021%

Normalization: Automatic Temp Compensation

Temperature Sensor: Platinum RTD

Accuracy: ± 0.1˚C

Resolution: 0.1˚C

Temp Compensation Range: - 10˚C to 40˚C

Response Time: 3 to 5 minutes

Battery life: 5 Years

Clock Accuracy: ± 1 minute/year

Operating Temperature: - 20˚C to 80˚C

Memory: Non-volatile EEPROM, FRAM back-up

Maximum # Readings 32,000 sets of readings

Communication: Optical Infra-Red to USB or RS232

Size: 7/8” x 5.5” (22 mm x 140 mm)

Weight: 154 g (5.4 oz)

Wetted Materials: 316L Stainless Steel, Delrin®, Viton®

Sampling Mode: Linear, SDI-12, Real Time View

(from 0.5 sec to 99 hrs)

Barometric Compensation: Software Wizard and Barologger Gold

Junior

Models

Full Scale

(FS)

Water Fluctuation

Range

Accuracy

(typical)

Resolution

F15, M5 16.4 ft., 5 m 13.1 ft., 4 m ± 0.010 ft., 0.3 cm 0.001% FS

F30, M10 32.8 ft., 10 m 29.5 ft., 9 m ± 0.016 ft., 0.5 cm 0.0006% FS

Levelogger User Guide - Software Version 3.2.3 or Higher

Page 7

Rainlogger

The Rainlogger is designed for use with most standard tipping-bucket rain

gauges with a reed switch output. It measures rainfall level per sampling period

and a five-minute maximum rainfall. Now users can add precipitation data to

their Levelogger network.

- Compatible with Version 3.2.3 Software using V1.000 firmware or higher

Rainlogger Technical Specifications

Battery Life: 10 years (logging two parameters/10 minutes)

Clock Accuracy: ± 1 minute/year

Operating Temperature: -20˚C to 80˚C

Resolution: 0.004 to 0.008" (100 to 200 mm) (dependent on rain gauge type)

Maximum # Readings: 40,000 sets of readings

Memory: Non-volatile EEPROM / FRAM back-up

Communication: Optical infra-red to RS232 or USB

Sampling Mode: Linear

Sampling Rate: 5 minutes to 99 hours

Size: 7/8" x 7" (22 mm x 175 mm)

Weight: 4.8 oz (135 grams)

Materials: Stainless Steel

Levelogger User Guide - Software Version 3.2.3 or Higher

Page 8

Leveloader Gold

The Leveloader Gold is a data transfer device for use with all versions of

Leveloggers. It can be used to download, store, and transfer data from

Levelogger to PC, as well as, save settings files for transfer to a Levelogger.

Also allows real-time viewing of Levelogger readings.

- Compatible with Version 3.2.3 Software or higher using V1.000 firmware

or higher

Software Communication

Leveloggers connect to a laptop or desktop PC with an optical reader cable.

The optical reader cable uses an infrared data reader/port connected to the

Levelogger and an RS232 or USB Com Port to transfer information between

the Levelogger and computer.

Version 3.2.3 Software provides Levelogger Gold users with many convenient

features. Users can view and program Levelogger settings, begin logging

sessions, monitor real-time readings, download data, manage data files, perform

compensations, and save and export files, with this software version.

Levelogger User Guide - Software Version 3.2.3 or Higher

Page 9

1.1 Level

The Levelogger Gold and Levelogger Junior use a high quality piezoresistive silicon

pressure transducer packaged in 316L stainless steel housing. It gives high accuracy

and high stability. The Levelogger Gold body is coated with Zirconium Nitride (ZrN) to

give corrosion resistance. All Leveloggers measure total or absolute pressure. When

the Levelogger is operating in open air, it is recording barometric pressure and

converting that pressure reading to its water level equivalent above the datalogger’s

pressure zero point of 950cm (31.17ft). When submerged, it is recording the

combination of barometric pressure and water pressure. The Levelogger converts the

total pressure reading to its corresponding water level equivalent. Actual water level is

obtained by compensating for barometric pressure. The best method to compensate

for barometric pressure is to employ a Barologger above the water level, somewhere

on site, to obtain records of barometric pressure. The Levelogger Software includes

a Barometric Compensation Wizard, which guides the user through the automated

process of barometric compensation. Manual methods can be employed to determine

the absolute water level using barometric records collected on-site or available from a

local weather station (i.e. Airport). Water level readings from the Levelogger Gold and

Levelogger Junior models are temperature-compensated.

1.1.1 Pr

essure Calibration

The Levelogger Gold and Levelogger Junior are calibrated against a range of set

reference points to an accuracy of 3 decimal places. The units of pressure are in

pounds per square inch. The conversion factor for pounds per square inch relates to

pressure as follows:

1 pound per square inch = 0.0689476 bar

= 0.703070 m

= 6.895 kPa

= 2.31 ft. H

2

0 @ 4°C.

During the calibration procedure, the Levelogger is fully submerged in a highly

accurate water bath. The bath is set to 15°C and allowed to stabilize.

The pressure is then calibrated to six separate pressure points covering the

entire range of pressure for that particular Levelogger to check for any

non-linearity. The process is repeated again at 35°C to check for temperature

effects. Once done, the Levelogger is approved after all specifications for

accuracy, precision, stability and hysteresis have been met.

1.2 Barologger

The Barologger Gold is designed for use in air only. It has a small range and firmware

algorithms based on air pressure rather than water pressure. This makes the

Barologger less accurate if used in water, but more accurate if used as intended, in air.

Using a Barologger is the most accurate and convenient method of obtaining

atmospheric pressure. When programmed with the same sampling parameters as the

Leveloggers on site, a Barologger can avoid barometric data time lags and any errors

introduced due to moisture buildup, kinking or damage to vented cable.

The Barometric Compensation Wizard in the Levelogger Software simplifies the

adjustment of the level measurements for barometric pressure changes, by using the

synchronized data from all Leveloggers on site and the site Barologger.

Levelogger User Guide - Software Version 3.2.3 or Higher

Page 10

1.3 T

emperature

Levelogger Gold and Levelogger Junior, record temperature compensated water

levels. Groundwater and surface water temperature measurements are

particularly important in situations where temperatures may fluctuate

significantly, and when temperature is used in determining liquid level, viscosity

and hydraulic conductivity. Temperature monitoring is vital in the calculation of

certain temperature dependent contaminant reaction rates.

A Platinum Resistance Temperature Detector is used to accurately compensate

for temperature changes within the range of -10 to +40˚C. The Leveloggers

will record temperature in its thermal range of -20 to +80˚C, but outside the

range of -10 to +40˚C compensation will be less accurate. The Levelogger

Gold reacts very quickly to changes in temperature (<1 minute) to give high

accuracy. The thermal response time of the Levelogger Junior is 3-5 minutes.

1.4 Total Pr

ecipitation

The Solinst Rainlogger is designed to count the tips of an external tipping-bucket rain

gauge within a user defined sample interval and output the total rainfall over that

sample interval. The Rainlogger can store 40,000 readings. The Rainlogger is

designed to be compatible with the Solinst Levelogger series of products. The

Rainlogger is programmed and data viewed and exported using the Levelogger

Software from a PC, it can be communicated with using a Leveloader and can be

integrated into an STS Telemetry System.

1.5 Backwards Compatibility

The Levelogger Gold and the Software Versions 3.2.3 or higher are backward

compatible, with limitations. If a Levelogger Gold is to be used with the Leveloader I,

Leveloader II, a Protocol Converter or an STS or RRL Telemetry System, the

data logger must be programmed with the old Levelogger Version 2.03 Software.

Programming Levelogger Gold loggers using Version 2.03 Software limits the

capabilities of the Gold unit, to be the same as the older stainless steel Levelogger units.

If the user has a mix of Levelogger Gold and older units, they can use the Levelogger

Gold Software to program and read all the loggers. They will get the accuracy and

features inherent in the older stainless steel loggers, but will obtain the higher accuracy

and enhanced features and functions of the Levelogger Gold loggers.

Page 11

Levelogger User Guide - Software Version 3.2.3 or Higher

2 System Requirements

The minimal hardware and software requirements for software installation

and operation are:

Communication Port Setting for Levelogger Communications:

3 Software Installation

• Place the Levelogger CD in the CD ROM drive or download the

software from www.solinst.com/Downloads/ and save to hard drive.

• Open Windows Explorer and double click the setup.exe icon.

• At this point Windows will prompt you through the remainder of the

installation process. Figure 3-1 shows the Levelogger Installation

Wizard.

• Restart the computer after installation is completed. Default Directory

is C:\Program Files\Solinst\Levelogger 3-2 (or higher)

FFiigguurree 33--11 SSooffttwwaarree IInnss ttaallllaattiioonn WWiizzaarrdd

Hardware Software

Memory: 32MB or more OS: Windows 98, ME, 2000 or XP

Display: VGA: 800 x600 pixels, 256 colour

Ports: USB or RS232 Serial Port

Bits per second 9600

Data bits 8

Stop bits 1

Flow control None

Levelogger User Guide - Software Version 3.2.3 or Higher

Page 12

3.1 Installing USB Drivers for

Levelogger Software V3.2.3 or Higher

Levelogger Software V3.2.3 or higher, for use with Solinst USB Optical Reader, PC

Interface Cable and Leveloader Gold, comes equipped with USB drivers for:

Windows 98, 2000, XP and Vista.

USB Installation for Windows 98

1) Plug the USB device into the computer, and Windows will automatically

detect the connected device and start the Hardware Installation Wizard.

2) A message may prompt the user that an ‘FTDI USB Drives Disk’ must

be inserted (Figure 3-2). A disk is not needed. Just click ‘OK’.

FFiigguurree 33--22 IInnsseerrtt DDiisskk WWiinnddooww

FFiigguurree 33--33 AAdddd NNeeww HHaarrddwwaarree WWiizzaarrdd WWiinnddooww

3) On the next screen select ‘Display a list of all the drivers in a specific

location, so you can select the driver you want’ (Figure 3-3).

4) On the next screen use the ‘Browse’ function to select the appropriate

driver. The directory should be:

C:\Program Files\Solinst\Levelogger3_2\USB Drivers\win98_XP

Complete and finish the installation. Please note that a system restart may

be required.

Levelogger User Guide - Software Version 3.2.3 or Higher

Page 13

USB Installation for Windows 2000

1) Plug the USB device into the PC and Windows will automatically detect

the connected unit.

FFiigguurree 33--44 FFoo uunndd NNee ww HHaarrddwwaarree PPoopp--uupp WWiinnddooww

FFiigguurree 33--55 FFoo uunndd NNee ww HHaarrddwwaarree WWiizzaarrdd

2) This will start the ‘Found New Hardware Wizard’, click next.

3) In the ‘Install Hardware Device Drivers’ window, select ‘Search for a

suitable driver for my device (recommended)’.

4) In the ‘Locate Driver File’ window (Figure 3-5), select ‘Specify a location’

and click ‘Next’.

5) In the next window point the browser to the USB driver folder located

in the Levelogger 3_2 folder. Default Destination:

C:\ProgramFiles\Solinst\Levelogger3_2\USB Drivers

6) Once the installation completes, a system restart may be required.

Levelogger User Guide - Software Version 3.2.3 or Higher

Page 14

USB Installation for Windows XP (Service Pack 2 or less)

1) Plug the USB device into the computer, and Windows will automatically

detect the connected device. Click ‘Install’ from a list or specific location’,

then click the ‘Next’ Button. Start the Hardware Installation

Wizard (Figure 3-6).

FFiigguurree 33--66 FFoo uunndd NNee ww HHaarrddwwaarree WWiizzaarrdd WWiinnddooww

FFiigguurree 33--77 FFoo uunndd NNee ww HHaarrddwwaarree WWiinnddooww aanndd FFiigg uurree 33--88 BBrroowwssee ffoo rr FFoollddeerr WWiinnddooww

2) Select the installation option, ‘Include this location in the search’ (Figure3-7),

then click the ‘Browse’ Button to search for the appropriate directory:

C:\Program Files\Solinst\Levelogger3_2\USB Drivers\win98_XP

Levelogger User Guide - Software Version 3.2.3 or Higher

Page 15

FFiigguurree 33--99 FFoo uunndd NNee ww HHaarrddwwaarree SSeeaarrcchh WWiinnddooww

FFiigguurree 33--1111 FFoouunndd NNeeww HHaarrddwwaarree CCoommpplleetteedd WWiinnddooww

3) A warning message will then prompt that the software has not passed

the Windows Logo Test. Select ‘Continue Anyway’ (Figures 3-10).

This will complete the installation process. A system restart may

be required.

FFiigguurree 33--1100 HHaarrddwwaarree IInnssttaallllaattiioonn WWiinnddooww

Page 16

Levelogger User Guide - Software Version 3.2.3 or Higher

4 Startup, Configurations and Settings

Startup

To start the Levelogger PC Software, click the icon, or click the Start

button and select:

Programs > Solinst > Levelogger > Levelogger 3.2.3 (or higher).

Communication Port Settings

Note that if using a USB port, plug in the USB cable before starting

the Levelogger Software. Once the user starts the program, they can set up

the parameters for the Software. Choose the Com Port Setting from the

Configuration menu to set up the RS232 or USB communication port for

the computer. Figure 4-1 shows the Application Setting Window.

FFiigguurree 44--11 AApppplliiccaa ttiioonn SSeetttt iinngg WW iinnddooww

In the Com Port Selection field, select the communication port that is

connected to the Levelogger by clicking the drop down list. The program

automatically detects the available Com ports on your computer. If using an

RS232 serial port (9-pin male DB9 Com port), identify the Com port number

and select it in the Com Port Selection window.

Note that you may have to restart your computer after adding a new

USB device, before that port will be detected by the Levelogger Software.

4.1 Communicating with a USB Port

USB port communication requires the installation of USB driver software and

the setting up of a Virtual Com port. If communicating via a USB port, the

user will either:

1) connect a Levelogger Optical Reader or PC Interface Cable to the USB port

2) use a USB to RS232 Adapter

If 1) during the installation of Levelogger V3.2.3 or higher Software, the

virtual com port driver will be installed automatically. The Levelogger

Version 3.2.3 or higher Software Installation Wizard also copies a folder to

the Levelogger 3 folder containing all the Solinst USB drivers. When you

plug in the Solinst USB device, check the com port designation.

Page 17

Levelogger User Guide - Software Version 3.2.3 or Higher

Note:

Do not install generic

drivers that Windows

will locate.

Generic drivers are completely

incompatible with Solinst USB

devices.

If 2) Solinst strongly recommends the use of either Keyspan™ or IO Gear™

USB to RS232 Serial Adapters. These adapters have a sufficiently large buffer

to accommodate the size of data bundle and bit transfer rate of the Levelogger.

Follow the manufacturer's USB Driver and Com port setup installations found

on the CD accompanying the adapter.

If you have installed another brand-name adapter, but cannot communicate

with the Levelogger, in most cases the problem is that the adapter does not

have a large enough internal memory buffer. The minimum buffer size should

be 96 bytes.

4.2 Com Port Designation Set Up:

1) Click Start Settings Control Panel

2) Click Systems to open the System Properties

3) Click the Hardware tab and click ‘Device Manager’

4) Double Click the Ports Icon and select the ‘USB Serial Port’

5) Right click and select Properties

6) Click the ‘Port Settings’ tab and click ‘Advanced’

7) Select the Com Port Number and click ‘OK’

4.3 Data Directory

The program will save data downloaded to the following default directory:

<C:\Program Files\Solinst\Levelogger3.2\Data> unless otherwise specified

in the Default Directory field of the Application Settings Window.

After completing Application Settings, click the OK button to confirm and save

the settings.

Levelogger V3.2.3 or higher Software is based on 3 functional windows:

Levelogger Settings, used to set up, start and stop the Levelogger,

Data Control, used to download, view and compensate data and Real Time

View, used to actively view data as it is being collected by the logger.

Levelogger User Guide - Software Version 3.2.3 or Higher

Page 18

5 Levelogger Settings

After the user starts the Levelogger V3.2.3 or higher Software, the Levelogger

settings window will open.

Click the button to retrieve the current settings from the connected Levelogger.

5.1

Levelogger Information Settings

The Levelogger Information Settings window includes Levelogger

identification, Project ID and Location fields, sampling settings, altitude and

fluid density input fields. The following is a description of each of the fields:

• Project ID, input your own Levelogger identification system.

The Project ID is limited to 32 characters.

• Location, input specific site / location information. The location

is limited to 32 characters.

• Altitude in feet or meters above sea level, at which the logger is actually

deployed, is input in the altitude field. Water column equivalent pressure

decreases with altitude at a rate of approximately 1.2:1000 in the lower

atmosphere below 5000 m. You can compensate for this by entering

an elevation between -1000 ft below sea level and 16,500 ft

(or -300 m and 5000 m) above sea level. The readings will then be

automatically compensated for elevation. See Section 11.1.3 for more

information on how the Levelogger and Barologger adjust for altitude.

FFiigguurree 55--11 LLeevveelloo ggggeerr SSeettttiinnggss WWiinnddooww

Page 19

Levelogger User Guide - Software Version 3.2.3 or Higher

• Sample Mode, allows you to choose the sampling measurement type.

Options are Linear, Event-based and Schedule.

• Memory Mode Selection will be grayed-out if not in Linear Mode

sampling. When using a Levelogger Gold in Linear Mode, there is a

choice of Continuous Logging (wrap around) or Slate Logging.

In Continuous Logging the new log is started at the end of any previous

log and continues logging, eventually recording over the first logged

data. As one of the download options is to ‘Append Data’, Continuous

Logging can be a preferred choice when logging long-term. In Slate

Logging the new log is also started at the end of any previous log, but

will stop recording after 40,000 readings, so that the beginning of the

current log will not be written over.

• Linear refers to a set time interval between collection of readings.

Sample Rate can be any number from 0.5 seconds to 99 hours. The

time unit and number of time unit intervals between each reading are set

up in the Sample rate fields. The Levelogger Gold and Barologger Gold

can store 40,000 readings of level and temperature. The Levelogger

Junior can store 32,000 readings.

• Event-based Sample Collection is the most memory efficient means

of data collection. In Event mode, the Levelogger will activate every

sampling interval defined in Sample rate and check if readings have

changed by the selected percentage (0.1 - 25% of Full Scale) from the

last recorded reading. For Levelogger Gold level is the selected

parameter where change is monitored. The Levelogger will record a

new reading only if the specified change in level has occurred. Note that

the percentage of change for sample collection is set in the Percentage

field beside the Sampling mode and that the threshold change is a

percentage of the Levelogger's Full Scale for that particular parameter.

An important reminder is that, although actual memory usage in stable

water level conditions may be relatively small, battery power

consumption is partially a function of the sample reading rate.

Therefore, a small sample reading interval will consume battery power at

a higher rate whether readings are stored or not. In Event-based sampling

mode, the Levelogger Gold has a total memory of 25,000 readings of level

and temperature.

• Density Adjustment is used to adjust the range of the Levelogger based

on the sample fluid density. The range for the density adjustment is from

0.9 kg/L to 1.1 kg/L. Uncheck the Density Adjustment field to

disable the Density Adjustment function.

Note:

The Levelogger Junior

records using the linear

samlping mode only.

Note:

The battery life of the

Levelogger Gold is 10

Years, based on 1

reading per minute. More rapid

readings will reduce the battery life.

For example, if a Levelogger Gold

is setup in Continuous Mode at a

sampling rate of 1 second, the

battery will be depleted in

approximately 4 months.

Levelogger User Guide - Software Version 3.2.3 or Higher

Page 20

• Schedule Sampling is set by selecting Schedule and clicking the Edit

button in the Levelogger Settings screen to bring up the Schedule Setup

Window. Buttons allow adding and deleting of lines, updating, opening

and saving of *.sci schedule files. The maximum number of line items in

a schedule is 30, each with its own sampling interval of seconds, minutes

or hours and duration of seconds, minutes, hours, days or weeks.

Running totals of the number of readings still available, from the total

possible 40,000, and the run time to date are shown. If the number of

readings selected exceeds 40,000 an error message appears. Schedule

sampling allows the user to select a logarithmic style sampling schedule

adapted to the needs of each application.

FFiigguurree 55--22 LLeevveelloo ggggeerr SScchheedduullee SSeettuupp WWiinnddooww

Levelogger User Guide - Software Version 3.2.3 or Higher

Page 21

5.2 Setting up Channel Information

In the lower portion of the Levelogger Settings window is the window for setting

channel parameters. The software will detect the available channels when the

Levelogger settings are read.

For Channel 1: ‘Level’, you can set the following parameters:

• Identification describes the measurement parameter of the channel and

has already been configured as ‘level’. The level channel monitors water

column equivalent pressure. The Identification field will be the data

column heading and graph line name when viewing the data.

The Identification is limited to 32 characters.

• Units refers to the channel’s units of measurement. There are three units

of measure available for the user to select: cm, m or ft. When the user

changes the unit, the value of the range and altitude will change

according to the Unit Conversion formula. Note that when a metric unit

is used, the unit of altitude is meters. When feet are the level channel

units, feet are the units of altitude.

• Offset refers to an offset correction, such as the distance between the tip

of the Levelogger and the monitoring well cap or static water level. It is

recommended that the value of 0.00 be used for offset as this keeps all

subsequent readings relative to the tip of the Levelogger. The offset

range for Levelogger Gold, the Levelogger Junior and Barologger Gold

units is -3280 to 16400 ft or -1000 m to 5000 m.

• Range refers to the full scale water fluctuation range capability of your

particular Levelogger model. The full scale reading of any Levelogger

Gold unit is based on its metric range. Therefore, the Levelogger Gold,

which is available in F15 (M5), F30 (M10), F60 (M20), F100 (M30) and

F300 (M100) ranges have actual water level ranges of 16.40 ft

(5 meters), 32.80 ft (10 meters), 65.60 ft (20 meters), 98.40 ft

(30 meters) and 328.0 ft (100 meters), respectively.

For Channel 2:

‘Temperature’, includes the following parameters:

Identification and Units, Reference and Range

• The Temperature channel has been pre-configured by Solinst in °C and

cannot be changed.

Note:

Readings can be

corrected or offset

with respect to a

specific reference elevation or

datum for a much wider spectrum

of numeric Offsets as part of the

Data Compensation Wizard.

Page 22

Levelogger User Guide - Software Version 3.2.3 or Higher

5.3 Levelogger Status

The Levelogger Status Section of the Levelogger Settings Window shows the

Firmware Version of the attached Levelogger, an accurate battery level, the

number of free readings, the current date and time, and the start date and time

of all Leveloggers.

5.4 Setting up the Levelogger Time

The ‘Time Synchronization’ section at the middle right of the Levelogger

Settings window provides the controls for setting the Levelogger clock. The

default setting in the Enable box is off, or unchecked. If you want to

synchronize the Levelogger’s clock, check the Enable box and select the time

and click the synchronize button to set the time in the Levelogger. If you start

the Levelogger without synchronizing the clock and the time difference between

the Levelogger and the PC is more than 3 seconds, the software will give you

a message asking ‘Do you want to synchronize the clock?’. Click ‘Yes’ to

synchronize the clock. It can be very useful to synchronize the clocks of all the

Leveloggers and Barologgers going to one site.

5.5 Pr

ogram Levelogger Settings

At this point you have completed editing the settings for your logging session,

click the button to send all the settings to the Levelogger.

The Levelogger will store all the new settings. Now that the data logger has

been programmed with your new settings, you can move on to Starting the

Levelogger.

5.6 Starting and Stopping the Levelogger

To begin logging, click the button and the Start Levelogger dialog box will open.

FFiigguurree 55--44 SS ttaarrtt LLeevveellooggggeerr WWiinnddooww

Page 23

Levelogger User Guide - Software Version 3.2.3 or Higher

There are two ways to start logging. Choose ‘Now’ to start logging

immediately. The Status field in the Levelogger Status window will state:

Started and will indicate the logger time and the Start time. Free memory

indicates the number of readings remaining at the time of communication.

Choose to start the logging at a later date and/or

time. This Start mode is referred to as Future Start in the Status field. After

confirmation, the starting time is stored in the Levelogger and it will start

collecting readings at the specified time. When the Future Start time is reached,

the Status will change to Started.

After the Levelogger is started, it will begin collecting readings. The Start

icon will change to a Stop icon .

The Levelogger can be stopped at any time before it reaches the maximum

reading capacity. Starting begins a new recording session and clears previously

stored data readings.

It is critical to note that when Leveloggers log data in Slate mode, it means they

will record data until stopped or their memory is full. When the memory fills,

the data logger will Stop recording. For this reason, it is important to

determine, based on your start time and sampling rate, the date and time at

which the memory will be full and the data logger will stop recording.

Levelogger Gold units record in Slate mode if Event or Schedule logging, but in

Linear mode they can be set to Slate or to Continuous logging.

You can stop logging from the Levelogger Settings window, by clicking the

Stop icon .

5.7 Saving and Retrieving Levelogger Settings Files

To store settings as defaults, click the icon. It will store the settings of the

Levelogger into an *.lls file as a series of defaults. The *.lls file will save the

Project ID, Location, Sample Mode, Event Percent, Sample Rate, Altitude,

Density, Channel ID, Unit and Offset.

To retrieve settings from defaults click the icon from an *.lls file. This is

particularly useful if programming several Leveloggers with similar identical

settings. Keep in mind that Project ID and Location identification information

will be identical and should be distinguished from logger to logger or monitoring

point to point.

Page 24

Levelogger User Guide - Software Version 3.2.3 or Higher

6 Rainlogger

The Solinst Rainlogger (Fig 6-1) is designed to count the tips of an external

tipping-bucket rain gauge within a user defined sample interval and output the

total rainfall over that sample interval. The Rainlogger can store

40,000 readings. The Rainlogger is designed to be compatible with the Solinst

Levelogger series of products and is therefore programmed and data is viewed

and exported using the Levelogger Software. It can be communicated with using

a Leveloader Gold and can be integrated into an STS Telemetry system or

PLC/SDADA network.

The Rainlogger can be set up to log rainfall depth at intervals from 5 minutes to

99 hours and also calculates and presents the maximum 5 minute rainfall

intensity within the sampling interval. The waterproof housing is made of

stainless steel. Direct exposure to rainfall should be avoided, and the Rainlogger

should not be submerged.

6.1 Rainlogger Communication Inter

face

The Rainlogger is compatible with Solinst Levelogger Gold accessories. It is

programmed using the Levelogger Gold Software. It connects to a laptop or

desktop PC using a Solinst Optical Reader, or a Direct Read Cable and PC

Interface Cable combination. Stored data can be accessed using a PC or

Leveloader Gold. Settings files can be uploaded to the Leveloader Gold and

used to program the Rainlogger in the field. The Leveloader Gold comes

ready with Optical Reader and PC Interface connections.

The Rainlogger is also able to integrate into a Solinst Telemetry System. It is

connected to a Direct Read Cable, which is then connected to an armored

reader cable to the remote telemetry station.

Rain Gauge Connector

The rain gauge connected to the Rainlogger is supplied by the customer and is

a reed-switch type gauge most commonly known as a tipping-bucket rain

gauge. The rain gauge connector is 3-pin (Fig 6 -2) and connects to the 3-pin

cable supplied with the Rainlogger. Longer cables up to 30m (100 ft) can be

supplied when the Rainlogger is ordered. The connector cable has 3 wires,

however only two, the blue and brown wires, are connected to the tipping

bucket device. As the tipping bucket is just an electrical switch, it does not

matter to which terminal on the tipping bucket the blue or brown wire is

connected. There is no need for a ground or third wire since the Rainlogger is

electrically isolated from any other system. Longer, exposed cables should be

protected from rodents and vandalism by cable armoring or installation within

electrical conduit.

FFiigguurree 66--11 SS oolliinnsstt RRaaiinnlloo ggggeerr

FFiigguurree 66--22

TThhee TTiippppiinngg BBuucckkeett RRaa iinn GGaauuggee

CCoonnnneeccttoorr ooff tthhee RRaaiinnllooggggeerr

3 Pin Rain

Gauge Connector

Page 25

Levelogger User Guide - Software Version 3.2.3 or Higher

6.2 Rainlogger Setup

The Rainlogger is programmed using the Levelogger Settings Window of

the Levelogger Software. The appearance of the Window when in

communication with a Rainlogger is shown in Fig 6-4.

Setting up and Starting a Rainlogger is a quick and simple process.

Identify the logging session and location in the Project ID and Location

fields. The Sample Mode for the Rainlogger is Linear. Input the

Sample Rate from 5 minutes to 99 hours, and input the Unit (mm or in)

you will be using for rainfall measurement.

Channel 1 will provide the total rainfall depth within the sample

interval. It does so by multiplying the number of tips within the interval

by the tipping bucket's calibration factor. The calibration factor is the

amount of rainfall depth (mm, in) per tip. The calibration factor should

be indicated on a label on the tipping bucket device or in the

manufacturer's documentation. Input the calibration factor in mm or

inches in the Rainfall Cal Constant field.

FFiigguurree 66--44 TT hhee LLeevveellooggggeerr SSeettttiinnggss WWiinnddooww ooff tthh ee RRaa iinnllooggggeerr..

Note:

The Rainlogger

must be

programmed at a

specific sample rate in all

applications, as there is no Real

Time View option for the

Rainlogger.

Page 26

Levelogger User Guide - Software Version 3.2.3 or Higher

Channel 2 does not require any setup or user input. The readings in channel

2 are of maximum 5 minute peak intensity within the sampling interval. This

rainfall intensity value is derived by subdividing the sample interval into 5 minute

sub-intervals and temporarily recording the number of tips in each 5 minute

sub-interval. The Peak intensity reading is calculated by multiplying the number

of tips in the 5 minute interval with the largest number of tips by 12 and

presenting peak intensity/hr.

After the user has setup the Rainlogger, click the button to start logging.

A Message Box will pop up to ask for confirmation. When logging, the

logging lamp in the transparent cap on the Rainlogger will flash once every

sampling interval.

FFiigguurree 66--55

RRaaiinnllooggggeerr SSttaarrtt LLooggggiinngg MMeess ssaaggee BBooxx

Page 27

Levelogger User Guide - Software Version 3.2.3 or Higher

7 Data Control Window

(Downloading and Compensating Data)

Click the Data Control Tab from the Main Window, the Data Control window

will appear. From the Data Control window, the user can download data from

a Levelogger or Leveloader, display data in tabular or graphic form perform

data compensations and export.

FFiigguurree 77--11 DDaattaa CCoonnttrrooll WWiinn ddooww

7.1 Downloading Options

Click the Download icon from the Data Control window to download data

from the Levelogger. There are four options for downloading data. They are:

All Data, Append Data, Partial Download and Recover Previous Log. If the

users select All Data, the program will download all the data from the current

logging session of a Levelogger into a *.lev file. If the users select Append Data,

the program will append the data in the opened *.lev file from the Levelogger.

The opened *.lev file and the attached Levelogger should have the same serial

number and start time, otherwise an error will occur.

• Click the tab

to communicate with a

Levelogger.

• Click the tab

to communicate with a

Leveloader.

• Click the tab

to view the current file

pathway or to open a

specific file.

Note:

The first thing you

should do in this

window is click one

of the following tabs:

Levelogger User Guide - Software Version 3.2.3 or Higher

Page 28

FFiigguurree 77--33 FFiillee WWrriittee EErrrroorr MMeessssaaggee

If the user selects Partial Download, a Partial Download Selection Window will

open. The window shows the time stamp of the last reading in the logging session.

The users can select the number of hours before the data end time. Once the users

click OK, all the data within that time will be downloaded to a *.lev file.

If the user selects the Recover Previous Log, the software will try to recover the

data from the previous log session and download the data to a *lev file.

Once the data is downloaded from a Levelogger, it is automatically saved in a

temporary file.

Click the Save icon to save the data in a specific *.lev file. The default

directory for saved data is in the ‘Data’ folder. However, the default directory

for saved files can be changed by clicking the Configuration tab at the top of the

program window, selecting ‘Application Settings’ and inputting or navigating to

a different folder destination. If an error is experienced in saving your first data

file such as depicted in Fig 7-3, you may not have file writing privileges to the

default directory. It this case, create and set as the default file save folder, a new

Levelogger data folder within the My Documents folder and attempt the file save

procedure again.

FFiigguurree 77--22 PP aarrttiiaall DDoowwnnllooaadd WWiinnddooww

Page 29

Levelogger User Guide - Software Version 3.2.3 or Higher

Click the File Open icon to open a *.lev file. Multiple files can be opened

at the same time and are available for viewing by clicking the File Name Tab on

top of the data table. All the Levelogger settings and the channel information

effective during data collection are shown on the left of the window. Click the

Directory tab on the left of the window to show a directory list of the computer.

Click on the *.lev file from the directory list to open a specific *.lev file.

The Data Control window with the directory list is shown in Fig 7-4.

FFiigguurree 77--44 DDaattaa CCoonnttrrooll WWiinn ddooww wwiitthh DDiirreeccttoorryy LLiisstt

7.2 Graph Manipulation and Zoom Function

To perform the Zoom In function on the graph, click the button.

To perform a Zoom Out function on the graph click the button. Click the

button to undo all the zoom functions.

Click the Graph Option icon to open the Graph Option Dialog. The

Graph Dialog is shown in Figure 7.5.

Page 30

Levelogger User Guide - Software Version 3.2.3 or Higher

FFiigguurree 77--55 LLiinnee OOppttiioonn WWiinnddooww

FFiigguurree 77--66 TT iittllee aanndd AAxxiiss WWiinnddooww

The Line Option is used to adjust the style and colour of the line in the graph

for each channel. The user can also select the shape of the data marker or

remove the data marker.

The Title and Axis Option is used to enter the title of the graph and change the

Y axis label or user selected scale. Check the Best Fit box to enable the software

to determine the best fit scale. If the Best Fit box is not checked, the user has

to enter a maximum and minimum value of the selected channel. The X axis is

logging time.

Page 31

Levelogger User Guide - Software Version 3.2.3 or Higher

FFiigguurree 77--77 CChhaannnneell SSeelleeccttiioonn WWiinnddooww

FFiigguurree 77--88 DDaattaa CCoommppeennssaattiioonn WWiinnddooww FFiillee TTyyppee SSeelleeccttiioonn

The Channel Selection Option is used to control the visibility of each channel

on the graph. A check mark beside the channel name indicates that the channel

is visible on the graph. Click the Select All button to select all the channels.

7.3 Data Compensation

Click the Data Compensation icon to open the Data Compensation

Wizard. The Data Compensation Wizard is shown in Figure 8-8.

In the first window of the wizard, the user identifies the currently opened file

type. There are two file types: Barometric files (data that is retrieved from a

Barologger) and Submerged Levelogger files (data that is retrieved from

Levelogger Gold or Levelogger Junior. After the selection of the file type, click

Next and the Data Compensation selection window will open.

There are four data compensation options available: Barometric

Compensation, Manual Data Adjustment, Density Adjustment and

Barometric Efficiency.

Page 32

Levelogger User Guide - Software Version 3.2.3 or Higher

FFiigguurree 77--99 DDaattaa CCoommppeennssaattiioonn WWiinnddooww -- CCoommppeennssaattiioonn SSeelleeccttiioonn

• Manual Data Adjustment allows the user to enter a manual water

level measurement as a reference datum or field zero, which all

Levelogger water level readings can then be adjusted to. If the reference

datum is above water level (e.g. top of well casing), the datum must be

input as a negative value. If the reference datum is below water level

(e.g. sea level), a positive value is input. The date and time of

measurement of the reference datum must be recorded and input to

complete the adjustment. The program computes a correction factor

based on the time-stamped reference datum, and adjusts all the data in

the selected file after barometric, density, and other data compensations

are performed.

• Density Adjustment corrects the range of the level channel in the data

file based on a user input adjustment of fluid density.

• Barometric Efficiency Adjustment is used to proportionally adjust

Barologger data in relation to a particular Levelogger. Barometric

efficiency is often expressed as a percentage or proportion. The input

field is proportional and has a default value of 1.00. For more

information about Barometric Efficiency, see Section 11.1.3.

The barometric efficiency can be set from 0.01 to 3.00.

The compensated data will be saved in a new *.lev file. The default file

name will be the <Submerged Levelogger file name> with the word

<compensated> added to the file name prefix. Alternatively, the user

can name the compensated file. Do not change or delete the file

extension.

• Barometric Compensation requires the Barometric file and the

submerged Levelogger file and simply involves subtraction of the

barometric reading from the Levelogger reading. If there is an

inconsistency of the time stamp between the Barometric file and the

Submerged Levelogger file, a linear approximation on the barometric

data will be performed.

Page 33

Levelogger User Guide - Software Version 3.2.3 or Higher

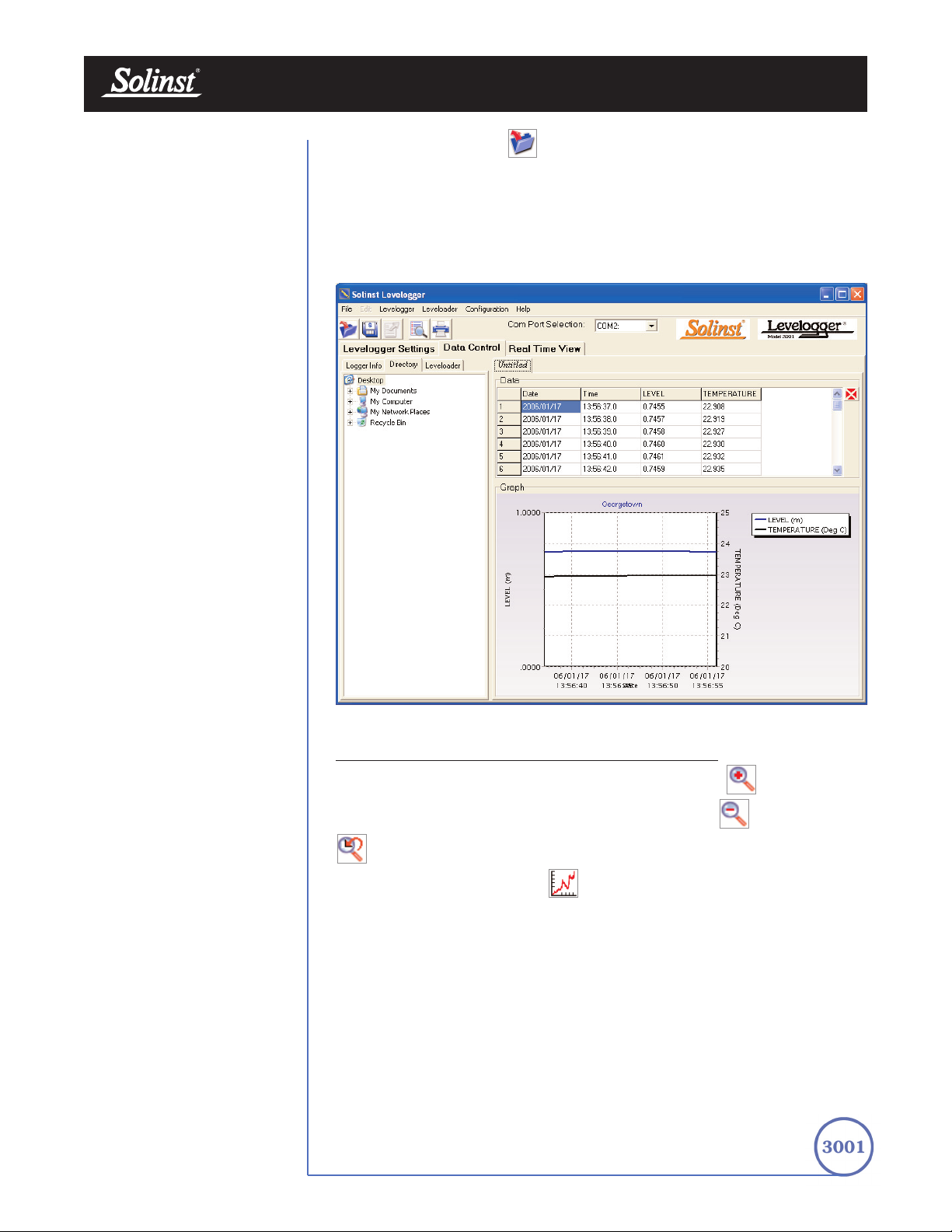

FFiigguurree 88--11 RReeaall TTii mmee VViieeww WWiinnddooww

8 Real Time View Window

Click the Real Time View tab from the main software window and the Current

Readings Window will appear (Fig 8-1). The purpose of this window is to

provide on-screen measurement as data is being recorded by the connected

logger. The data is displayed in tabular and graphical format. All the channel

information and Levelogger settings are displayed in the bottom left window.

First, select a Non-Logged View Rate (middle left). This rate can be set

independently of the logging period of the Levelogger and does not interfere

with any logging taking place in the Levelogger itself. Real Time View readings

can be displayed as a graph or in tabular format. If one channel is not required,

it can be removed by unchecking the check box to the right of the data display.

If not displayed, it is not being recorded. Real Time View readings are being

recorded within the Levelogger Software and prior to closing the window, they

can be saved by exporting the data into a *.csv file, by choosing the file export

option.

To start the current readings, click the Start icon. Immediately the

readings will be displayed.

To take a reading at any specific time, click the button and that reading

will be added to the displayed data. To turn the Real Time View monitoring

off, decide if you want to save the data as described above, and simply click the

Real Time View Tab or the Levelogger Settings Tab.

Note:

Real Time View is

not available with

the Rainlogger.

Page 34

Levelogger User Guide - Software Version 3.2.3 or Higher

FFiigguurree 99--11 PP rriinntt PP rreevv iieeww WWiinnddooww

9 File Export and Print Function

Data can be exported in *.csv (comma separated value) file format by clicking

File > Export > Data. The *.csv file format is supported and can be imported

by most spreadsheet programs. Also, the data graph can be exported to a

*.bmp file or a *.wmf file by clicking File > Export > Graph.

The Logger Settings, data table and data graph can be printed. Click the Print

Preview Icon to open the Print Preview window. Figure 9-1 shows

the print preview of the Logger Settings. The Levelogger Settings are always

on the first page of the document. The data graph is on the second page of the

document and the rest of the document is data table.

Click the Print Icon to open the print dialog and print the document.

Page 35

Levelogger User Guide - Software Version 3.2.3 or Higher

FFiigguurree 1100--11

LLeevveell ooggggeerr TTrraa nnssdduucceerr

MMeeaassuurreemmeenntt LLiinnee aanndd

DDiimmeennssiioonn

10 Installation and Maintenance of Leveloggers

10.1 Installation

Many options exist for installation of the Levelogger, but essentially these

installation methods can be classified into two broad categories: free

suspended or fixed installations.

1. In free suspended installations, the Levelogger is hung via

suspension wire or Direct Read Cable from the well cap, or some

fixed tie-off location, at the well head.

2. In fixed installations the Levelogger is fixed in place by a

compression fitting, a clamping mechanism or simple metal straps.

Prior to commencing the discussion of installation techniques several

general points related to Levelogger installation should be made. First, it

is recommended that the Levelogger be installed in a vertical orientation.

However, inclined or horizontal installation is acceptable. The level

sensor in the Levelogger is indicated by the machined line about the body

of the logger just above the pressure access holes. The pressure

transducer is oriented in a plane normal to the long axis of the body and

detects pressure directed along the plane of the long axis (Fig 10-1).

In vertical orientations, the sensor detects pressure above the pressure

transducer line, where as in non-vertical orientations, the pressure zero

point is proportional to the angle of inclination.

Care should be taken to avoid dropping the Levelogger against a

hard surface. Further, the pressure transducer can be damaged if

the data logger is over-pressurized by submergence greater than its

level range. The Levelogger is warranted to pressures up to 150%

of its full scale level range.

Other important considerations when installing the Levelogger in

pressurized or intermittently pressurized locations such as pressure

vessels, pressurized pipes, pulse flow conditions, drop structures or near

hydraulics works, is to keep in mind the potential effect of water or steam

hammer and hydraulic jump. Water hammer is caused by an abrupt

alteration of flow direction resulting in pressure surges. Steam hammer

occurs when steam enters a cold pipe partially filled with water.

The hammer effect has the potential to significantly increase hydraulic

pressure possibly exposing the pressure sensor to pressures beyond its

maximum rating. Hydraulic jump is a phenomenon that occurs when

water is ‘lifted’ or ‘ramped’ by velocity or flow obstructions. Hydraulic

jump causes turbulence and creates non-representative head conditions

in the water column. Care should be taken to avoid logger installation at

points susceptible to hydraulic jump.

Note:

When using Direct

Read Cables, the

following maximum

lengths apply to the cable

according to which PC

Interface Cable is to be used:

• USB PC Interface Cable:

1,000 ft (300m)

• RS232 PC Interface Cable:

500 ft (150m)

• RS232 PC Interface Booster:

1650 ft (500m)

Measurement Line

Page 36

Diagram 1

Diagram 2

Diagram 3

Diagram 4

Coil 1

Coil 2

Coil 3

Coil 1

Coil 2

Coil 3

Wireline

Coil 3

Coil 1

Coil 2

Wireline

Coil 3

Coil 1

Coil 2

Wireline

FFiigguurree 1100--33 WWiirreelliinnee HHooookk

IInnssttaallllaattiioonn

Levelogger User Guide - Software Version 3.2.3 or Higher

10.1.1 Fr

ee Suspended Installations

Suspension Wire Installation

When installing using a suspension wire, the Levelogger is pre-programmed

and started using the software. It is then deployed using a suspension wire

connected to the installation cap of the Levelogger to the underside of a well

cap. The data is retrieved manually, by withdrawing the Levelogger, removing

the installation cap and attaching an Optical Reader directly to the data logger.

Data is downloaded to a desktop or laptop PC or by using a Leveloader Gold.

Solinst supplies stainless steel suspension wire assemblies including SS stranded

wire and hooks available in a variety of lengths from 50 ft (15 m) to +500 ft

(+150 m). Solinst also supplies a specially designed, tamper-proof, vented,

locking well cap known as the Enviro-Cap™ from which the Levelogger can be

suspended.

This type of installation is applicable to both submerged and barometric record

applications. Follow these steps to install the Levelogger using stranded cabling

and hooks:

1. Loop the cable through the coil 2 of the hook assembly, then wind the

looped strands several times around the hook shaft and pass through coil 1.

2. Pass coil 3 through the Enviro-Cap™ eyelet or Levelogger/Barologger eyelet

and snap coil 3 to the hook shaft.

3. If the Enviro-Cap™ is not used then some secure tie-off point should be used

or installed.

4. If installing a Barologger, ensure the suspension level is above the highest

expected water level.

5. When retrieving data and/or reprogramming the Levelogger, extract it from

the monitoring location, unthread the installation cap, interrogate and

re-suspend the unit rechecking the security of the wireline clamps each time.

FFiigguurree 1100--22

LLoocckkiinngg,, ttaammppeerr--pprrooooff

EEnnvviirr oo--CCaapp SStteepp 11

Tighten

(clockwise)

Loosen

(counterclockwise)

HOLD

HERE

Page 37

Levelogger User Guide - Software Version 3.2.3 or Higher

FFiigguurree 1100--44

DDiirreecctt RReeaadd AAsssseemmbbllyy CCoommppoonneennttss

Direct Read Cable Assembly Installation

When installing using a Direct Read Cable Assembly, the Levelogger can be

deployed before it is programmed and started with the software. The

Levelogger is installed using a Direct Read Cable to a Direct Read Wellhead,

where a PC Interface cable is connected allowing the Levelogger to

communicate with a desktop or laptop PC, or a Leveloader Gold.

The Direct Read Cable system is composed of the ordered length of Direct Read

Cable, the Direct Read Wellhead and the PC Interface Cable. The Direct Read

cable threads to the Levelogger, while the socket at the opposite end of the

Direct Read Cable fits into the specially designed Direct Read Wellhead. The PC

Interface Cable connects to the Direct Read socket at surface and to either a

USB or RS232 port on the PC (Fig.10-4). While use of the Direct Read

Wellhead is recommended and convenient, it is optional as long as a

satisfactorily secure alternative tie-off point is found for the Direct Read Cable.

Follow these steps to install a Direct Read Cable Assembly to the Levelogger:

1. Remove the installation cap from the Levelogger, align and connect the

optical socket (two glass ‘eyes’ using the alignment pin) of the Direct

Read cable to the Levelogger by threading the coupling onto the

Levelogger tightly.

2. The Levelogger and optical socket will fit through the hole in the Direct

Read wellhead. Use the eyelet at the bottom of the wellhead to securely

tie-off the cable and logger. Do not suspend the logger and cable from

the surface socket.

3. Remove the protective cap from the non-optical socket at the wellhead end

of the Direct Read cable, seat the socket in the Direct Read Wellhead and

align and thread it to the round socket of the PC Interface Cable.

4. Connect the USB or RS232 socket of the PC Interface Cable to the

USB or RS232 Com Port on your PC.

5. The plugged hole in the wellhead can be removed to provide an access

port for a water level meter probe.

10.1.2 Fixed Installations

Open Channel Installations

Open channel flow is flow defined as gravity flow in any stream, canal, ditch,

flume, or partially full pipe or tunnel not under pressure. It is different from

closed channel flow in which the closed channel is full and under pressure. This

section provides installation and monitoring advice in such open channels as

natural streams and engineered conduits such as concrete channels as well as

installation recommendations in monitoring water level in flow control structures

such as weirs, flumes, pipes and orifice discharge devices.

To ensure the integrity of monitoring data, it is vital to choose the monitoring

location with care. In natural channels, choose a location on the stream where

the flow is least turbulent without surcharging, yet representative of the

immediately upstream reach of the channel in slope and bottom surface

roughness. In streams or channels with deep or rapid flow, or of uneven or

slippery bottom materials, take extra care for your personal safety in installing

Levelogger User Guide - Software Version 3.2.3 or Higher

Page 38

equipment. Do not install equipment by attaching to structures that may

interfere with debris flow, threaten the stability of flow at that location or the

security of the equipment. When possible, install the Levelogger in a stilling well

device. The stilling well will protect the logger from floating debris and rock

saltation as well as dampen the effects of surface waves or turbulence. If a stilling

well cannot be used and the logger must be affixed to an anchor structure

instream such as a concrete slab or large stable boulder, consider protecting the

logger from floating debris and rock saltation by placing it inside a short

perforated section of protective 1” dia. pipe. Avoid monitoring in the vicinity of

flow obstacles that can cause hydraulic jump. In pipes, the logger should be

located at least 2 – 4 pipe diameters down and upstream of pipe turns,

junctions, inlets, outlets, turbulent joints or valves. Place the logger upstream of

zones potentially subject to surcharging. Always bear in mind that the logger

does not have to be at the deepest point in the stream or at the bottom of the

pipe, it need only be located in the safest location within the stream/pipe profile

just below the lowest anticipated water line. In this case use an offset value or

the Reference Datum adjustment to compensate the data for the level offset.

This Section discusses flow in open channels determined by one of the following

methods: Area-Velocity, Slope-Hydraulic radius and Hydraulic structure(s).

Using the Area-Velocity method the Levelogger provides readings of the

head of water above the pressure transducer. The practitioner will use the water

depth to determine the cross-sectional area of water, then the water velocity to

ultimately derive flow:

Flow = Area x Velocity

The cross-sectional area of water in natural channels is most commonly

determined by surveying the shape of the channel bottom at the monitoring

station. In circular pipes the wetted area can be determined by using a section

of a circle equation and in other engineered channels, by determining the

channel geometry. Either water head will be related to area by using and

equation, where head is the only variable, or the Head: Area information is

compiled in a Look-up table. The water velocity can be determined in a number

of ways, by estimation taking into account the channel geometry, area and

surface roughness, by spot measurement in which the stream is velocity profiled

both vertically and across its cross-sectional area to develop a rating curve, or

by deployment of a logging velocity meter that can accurately characterize the

velocity over the cross-sectional area. Together the area multiplied by average

velocity to derive flow.

Page 39

Where: Q = Flow rate

K = Constant dependent on units used

A = Cross sectional area of low

R = Hydraulic radius (cross sectional area divided by the

wetted perimeter)

S = Slope of the hydraulic gradient

n = Manning’s roughness coefficient

Q =

KAR

n

2

_

3

1

_

2

S

Hydraulic structures are among the most common and reliable means

of measuring flow. Four types of hydraulic structures and the methods

used to measure them are discussed here: weirs, flumes, pipes and orifice

discharge devices.

Levelogger User Guide - Software Version 3.2.3 or Higher

In the Slope-Hydraulic radius method, techniques like the Manning

formula or variations such as Lanfear and Coll or Chezcy’s equations are

used to estimate flow based on changes to the cross sectional area and

wetted perimeter. The cross sectional area and wetted perimeter must be

predetermined and are proportional to head. The Manning formula:

Page 40

Levelogger User Guide - Software Version 3.2.3 or Higher

Installation at W

eirs

Weirs are very common and reliable flow control and measurement structures.

A wide variety of weir types have been designed and their flow characterized in

discharge equations. The most common weirs are sharp-crested rectangular,

V-notch, trapezoidal (Cipolletti) and compound weirs combining elements of

two or more of these types. Other special weir configurations are designed to

create a specific type of relationship between head and flow rate. The Sutro

weir creates a hydraulic condition where discharge is directly proportional to

head. The approximate linear weir creates a hydraulic condition where the

head: discharge relationship is linear. Other weirs such as the Poebing and

Approximate exponential weir have an exponential relationship between head

and discharge. However, no weir design is more common and better

understood than the rectangular, V-notch or trapezoidal configurations.

From a monitoring point of view it is extremely important to place the pressure

transducer at the appropriate location at the weir. Figure 10-5 illustrates the

appropriate location of the pressure transducer upstream of the weir crest and

the draw-down zone.

3-4 H

2-3 H

Channel Floor

FFiigguurree 1100--55 SShhaarrpp CCrreesstteedd WWeeiirr

The formuli for the three most common weir designs are:

V-Notch: Q = KH

2.5

Rectangular:

a. Suppressed (no end contractions) : Q = KLH

1.5

b. Contracted (with end contractions): Q = K(L - 0.2H) H

1.5

Trapezoidal or Cipolletti: Q = KLH

1.5

Where: Q = Flow rate

H = Head on the weir

L = Crest length of the weir

K = Constant dependent on units

Location of

Measurement Point

Drawdown

Crest

HH

Ventilation

3-4 H

3-4 H

2-3 H

2-3 H

Weir Plate

Channel Floor

Channel Floor

Page 41

Levelogger User Guide - Software Version 3.2.3 or Higher

K values for V-notch weirs for metric of US Customary units vary with the

V-notch angle and can be found in hydraulic texts. K values for the sharpcrested rectangular weirs and the Cipolletti weir, in which the slope of the

trapezoid is 4:1, are provided in Table 10-1

CFS GPM MGD L/s

m3/hr

Unit of L & H

ft ft ft m m

K suppressed & contracted

3.33 1495 2.152 1838 6618

K Cipolletti trapezoidal

3.37 1511 2.176 1859 6692

K California pipe method

8.69 3900 5.62 4680 16900

TTaabbllee 1100--11 CCoonnssttaanntt VVaalluuee ss ffoorr RReeccttaanngguullaarr WWiieerrss

Installation in Flumes

After weirs, flumes are the most common hydraulic control structures and use

flow restriction followed by flow expansion so that flow rate may be determined

by head measurement at a specific point in the flume. In general flumes are

used where weirs are not feasible due to inadequate channel slope or channel

space footprint restrictions. Flumes are grouped into one of three categories

based on the Froude number of flow set up by the flume. The Froude number

is the ratio Inertia : Gravity. If the Froude number is unity, the flume flow is

considered critical. When the Froude number is less than unity, sub-critical

(gravity predominates) and when greater than unity, supercritical (inertia

predominates). Most flumes are designed for critical or supercritical flow.

Critical flow flumes typically use width reduction to set up the critical flow

conditions. Supercritical flow flumes utilize a sloping bed, bed drop and or width

reduction to create supercritical conditions from the converging section,

through the throat to the diverging section. The most common flume types are

Parshall, Trapezoidal, Palmer-Bowlus, Leopold-Lagco, USDA Soil

Conservation Service HS, H and HL flumes as well as Cutthroat, British

rectangular and San Dimas flumes.

As in weirs, the head measuring point(s) in flumes is very specific. Figure 10-6

illustrates the recommended upstream free flow head monitoring point for a

Parshall flume. This point is defined as upstream of the start of the throat, 2/3

the total length of the converging section. The head vs flow rate equation for

free flow via a Parshall flume is:

Where: Q = Flow rate

H = Head measured at point 2/3 A

n = Constant power, dependent on throat width

K = Constant dependent on throat width and units

Q = KH

n

Page 42

Levelogger User Guide - Software Version 3.2.3 or Higher

FFiigguurree 1100--66 PPaarrsshhaallll FFlluu mmee

The Parshall flume is characterized as supercritical by width reduction and drop

in bed. An alternative head measurement is in the throat upstream of the zone

of submerged flow. Care must be taken when using head measurement in the

throat that backwater or surcharging effects in the diverging section during

periods of higher flow do not reach the throat monitoring point.

The California Pipe Method

The California pipe method of flow measurement is for use with circular pipe,

partially filled and horizontal for at least 6 pipe diameters prior to pipe

discharge into air. Water should not enter the horizontal section at an excessive

rate and if flows create near pipe-full conditions, a vent hole should be installed

several pipe diameters upstream of the outfall. To determine pipe discharge

using head at the outfall the California pipe method may be written as:

Where: Q = Flow rate

H = Head of liquid at pipe outlet

d = Pipe diameter

K = Constant dependent on units

Q = Kd

0.6 H1.88

A - Length of converging section

2/3 A

Location of Monitoring Points

Submerged

Flow

Free flow

Levelogger User Guide - Software Version 3.2.3 or Higher

Page 43

Orifice Dischar

ge Monitoring

Discharge through orifices such as in a Hickenbottom perforated riser is a

common water detention and flow control approach. The Hickenbottom device

typically uses a series of circular holes drilled both around the circumference

and along the vertical length of a section of riser pipe connected via an elbow

joint to a lateral discharge pipe. Hickenbottom devices are commonly used to

detain stormwater in ponds, wetlands, ditches, swales or depressions at the

Hickenbottom riser to reduce downstream erosion and prolong the settling

period for suspended solids prior to discharge thereby improving water quality.

Hickenbottom devices enable the practitioner to derive discharge rate by head

measurement outside the structure. Discharge from a Hickenbottom structure

can be calculated as the iteration of individual single orifice discharge equations.

A typical orifice equation is derived from Bernoulli’s equation and can be

written as follows for metric units:

Where: Q = Orifice discharge in m

3

/sec

C = The discharge coefficient (CcCv≈ 0.647), where Cc,

the coefficient of contraction, for a sharp-edged

orifice is ≈ 0.66 and Cv, the coefficient of velocity

through the orifice is ≈ 0.98.

A = Orifice area in m

2

g = Acceleration due to gravity (9.81 m/sec2)

h = Head in m of water above the orifice

Q = CA(2gh)

0.5

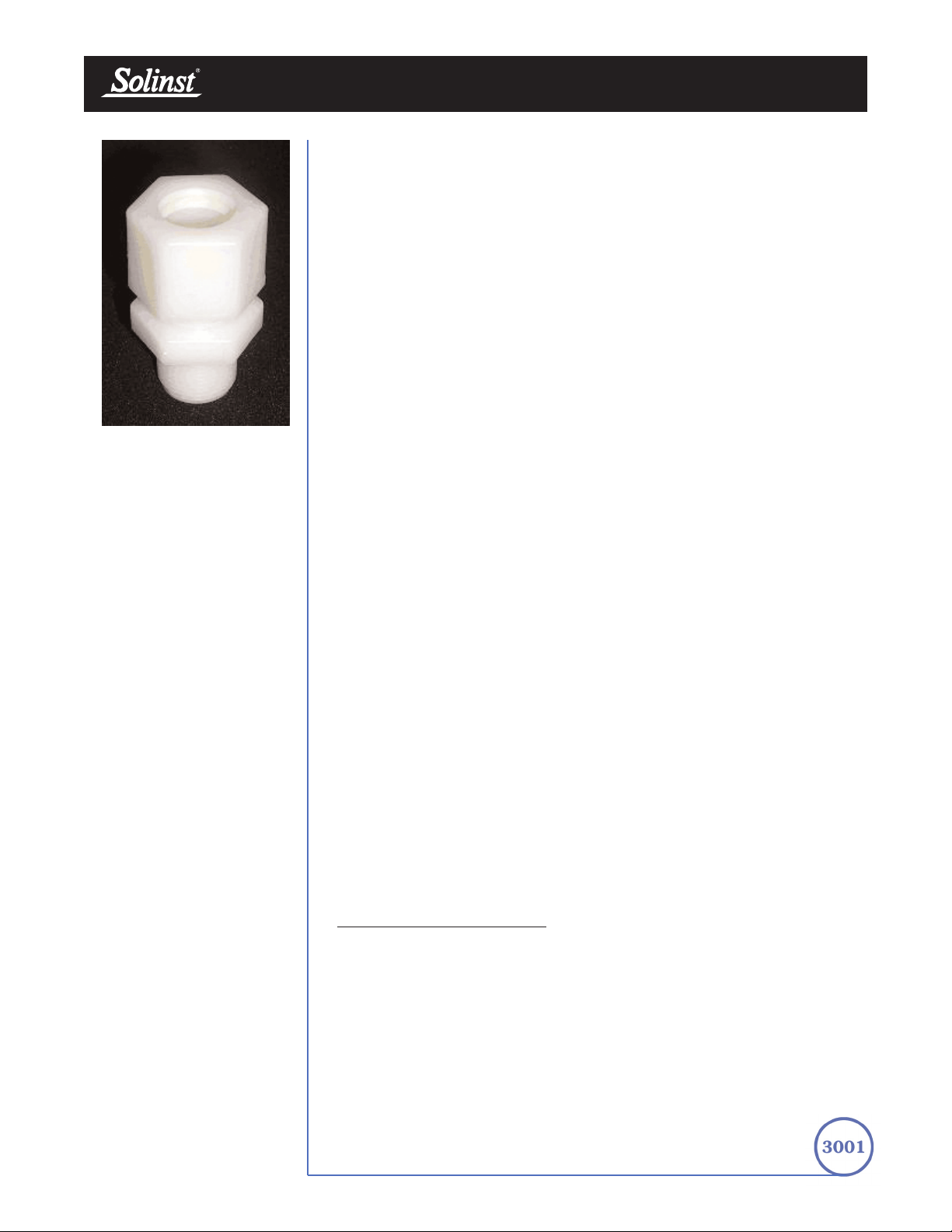

Artesian Monitoring

Monitoring of artesian conditions in which the piezometric surface is above

ground surface or more particularly above the top of well casing elevation using

Leveloggers can be quite straight forward. Three artesian scenarios are

discussed: a) continuous artesian conditions where i) freezing is not a concern,

ii) or where freezing is a concern and b) intermittently artesian conditions.

Continuous artesian conditions infer that the piezometric surface never drops

below the level the ground surface or particularly the top of casing elevation and

the casing is sealed with a sealed wellhead. In this case, where freezing is not a

concern, the Levelogger need only be installed in the wellhead itself by means

of a large compression fitting as illustrated in Figure 10.7. Solinst can supply a

7/8” nylon compression fitting for this purpose. First, a 7/8” NPT hole is

tapped into the wellhead, then the base of the compression fitting is threaded

into the hole and the threads sealed. The collar and ferrule are slid on the

Levelogger just above the transducer measurement line (collar below ferrule),

the logger inserted in the base and the nut slide down over the body of the

logger. The nut is tightened and threads sealed to form a hydraulic seal against

the body of the Levelogger leaving the upper portion of the Levelogger and cap

exposed above the compression fitting. The user can communicate with the

logger simply by removing the logger cap and attaching the Optical reader.

Ensure that the logger and sealed wellhead are enclosed within an outer

protective well cap or enclosure.

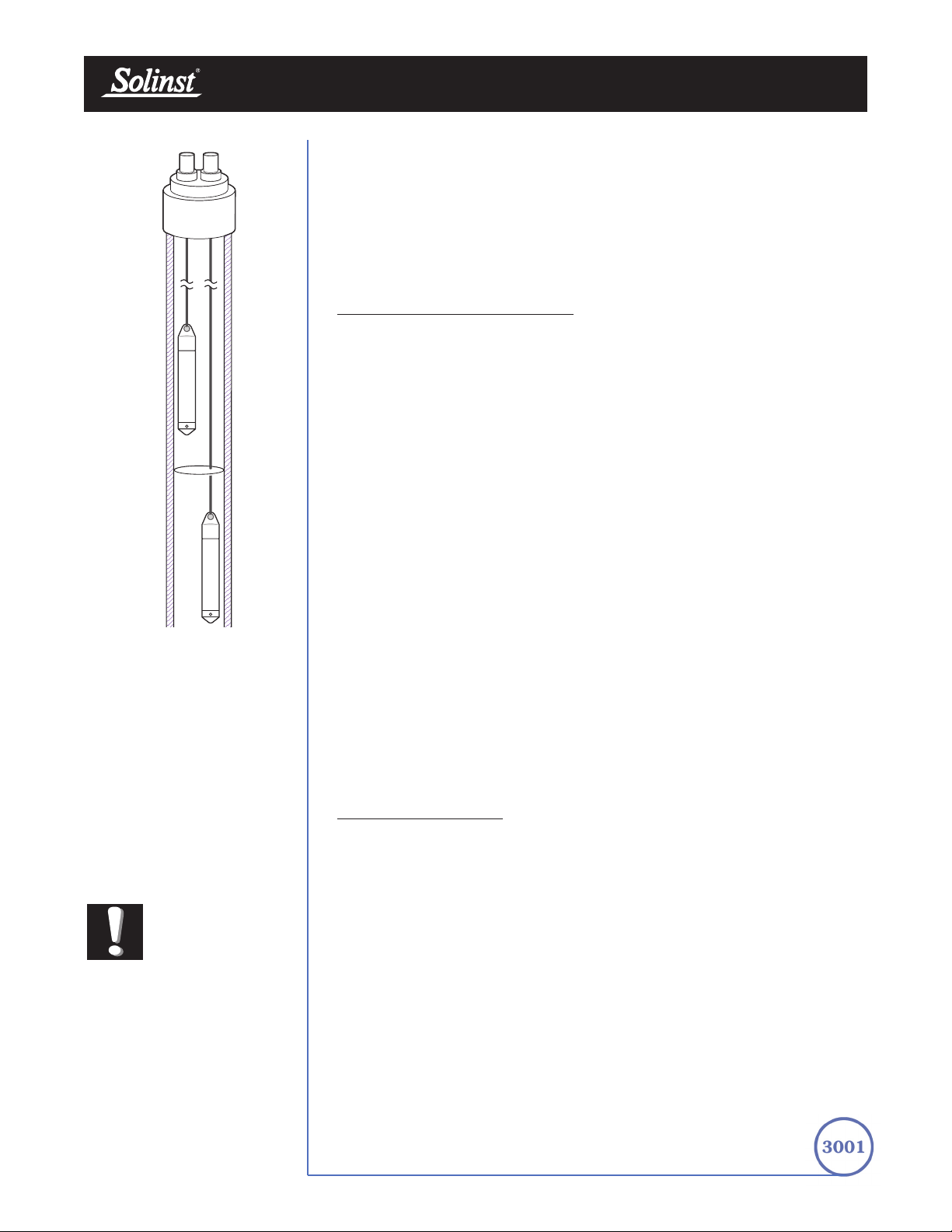

When freezing is a concern in a continuous artesian well, the well is typically

sealed below the frost line with a packer. Again, Solinst can build specially

adapted mechanical packers for this purpose. The special packer is typically

built on 1 – 2” PVC pipe that extends from below the frost line to the wellhead

and is actuated at the wellhead by turning a threaded tube that runs within the

pipe. Direct Read cable for communication with the Levelogger is built into the

packer. The Direct read cable runs through the threaded tube and sealed by use

of a small compression fitting that tightens onto the Direct Read cable. When

installing the Levelogger is threaded to the Direct Read cable and

the Levelogger and packer assembly lowered into the well. When in place, the

packer is actuated, the well sealed and standing water in the well above

the packer is evacuated.