Page 1

AWS 924-948

O

WNER’S MANUAL

Page 2

S

olid State Logic

Begbroke, Oxford, England OX5 1RU • +44 (0)1865 842300

320 West 46th Street, 2nd Floor, New York, NY 10036, USA • +1 (1) 212 315 1111

3700 Wilshire Blvd, Suite 720, Los Angeles, CA 90010, USA • +1 (1) 213 249 9229

3-55-14 Sendagaya, Shibuya-Ku, Tokyo 151-0051, Japan • +81 (0)3 5474 1144

7 bis, rue de la Victoire, le Blanc Mesnil, Paris 93150, France • +33 (0)1 48 67 84 85

Via Timavo 34, 20124 Milano, Italy • +39 (0)39 2328 094

Visit SSL at http://www.solidstatelogic.com

82BA1M01B

© Solid State Logic

All Rights reserved under International and Pan-American Copyright Conventions

Solid State Logic, SSL, AWS 900, AWS 900+ SE, AWS 924, AWS 948

and Total Recall are trademarks of Solid State Logic

All other trademarks are the property of their respective owners

No part of this publication may be reproduced in any form or

by any means, whether mechanical or electronic, without the

written permission of Solid State Logic, Oxford, England

Initial release (1A) October 2010

Added console dimensions to Appendices (1A) November 2010

UL clarification of power connection, specifications and termination (1B) January 2011

As research and development is a continual process, Solid State Logic reserves the right

to change the features and specifications described herein without notice or obligation.

E&OE

Page 3

Introduction

IMPORTANT INFORMATION

This section contains definitions, warnings, and practical information necessary to ensure a safe working environment. Please

take time to read this section before installing or using your AWS. Please do not dispose of these instructions.

Graphic Symbols

The following symbols may be used in this section and elsewhere in this manual:

General Hazard (refer to User or Service Instructions for details)

Electrical Hazard

General Safety

• Read these instructions.

• Keep these instructions.

• Heed all warnings.

• Follow all instructions.

• Do not use this apparatus near water.

• Do not expose this apparatus to rain or moisture.

• Clean only with dry cloth.

• Do not block any ventilation openings. Install in accordance with the manufacturer’s instructions.

• Do not install near any heat sources such as radiators, heat registers, stoves or other apparatus (including amplifiers)

that produce heat.

• Ensure that this apparatus is positioned on a secure level surface.

• Ensure that no strain is placed on the cables connecting to this apparatus. Ensure also that such cables are not placed

where they can be stepped on, pinched, pulled or tripped over in any way.

• Refer all servicing to qualified personnel. Servicing is required when the apparatus has been damaged in any way, such

as power-supply cord or plug is damaged, liquid has been spilled or objects have fallen into the apparatus, the apparatus

has been exposed to rain or moisture, does not operate normally or has been dropped.

• Adjustments or alterations to this apparatus may affect the performance such that safety and/or international compliance

standards may no longer be met.

• This apparatus is equipped with a headphone socket – excessive sound pressure from earphones and headphones can

cause hearing loss.

• This apparatus is designed for use solely by engineers and competent operators skilled in the use of professional audio

equipment.

Caution

The AWS console is too heavy for one person to lift. If covers or panels are removed for any reason, sharp

edges may be present on exposed metalwork.

To reduce the risk of fire or electric shock, do not expose this apparatus to rain or moisture.

To reduce the risk of electric shock, do not perform any servicing unless you are qualified to do so.

AWS 924-948 Owner’s Manual Page III

Page 4

Introduction

Page IV AWS 924-948 Owner’s Manual

Power Safety

• This apparatus includes a universal power supply; approved and certified for operation in this apparatus.

• An external disconnect device is required for this apparatus. The appliance coupler is a suitable disconnect device.

• The appliance coupler shall remain readily operable.

• Use only the Solid State Logic provided power cords. Use of any other power cord is not covered by your warranty

and may cause fire or explosion.

• The power cord must be earthed and precautions should be made so that the grounding is not defeated.

• Do not defeat the safety purpose of the polarised or grounding-type plugs fitted to the power cords. A polarised plug

has two blades with one wider than the other. A grounding type plug has two blades and a third grounding prong. The

wide blade or the third prong are provided for your safety. If the provided plug does not fit into your outlet, consult an

electrician for replacement of the obsolete outlet.

• To ensure safe operation of this apparatus, connect only to an ac. power source that contains a protective earthing (PE)

conductor. This apparatus is designed for connection to single phase supplies with the neutral conductor at earth

potential – category TN or TT – and is fitted with a protective fuse in the live conductor only. This apparatus is not

designed for use with live and neutral connections reversed or where the neutral conductor is not at earth potential

(IT supplies). This apparatus should not be connected to a power system that switches open the return (neutral) lead

when the return lead also functions as the protective earth (PE).

• An external over-current protection device is required to protect the wiring to this apparatus which must be installed

according to current wiring regulations. In certain countries this function is supplied by use of a fused plug. In other cases

a fused spur or circuit breaker should be used according to local practice.

The current requirement for this apparatus can be found in Appendix A of this manual.

• If an extension power cable or adaptor is used, ensure that the total power rating of the power cable and/or adaptor is

not exceeded.

• Unplug this apparatus during an electrical storm or when unused for long periods of time.

• Do not operate this apparatus whilst it is covered or boxed in any way.

• To reduce the risk of electric shock, do not perform any servicing unless you are qualified to do so.

• Disconnect the power cord before removing any panels. The power switch alone does not provide adequate isolation

for service access.

• Do not permit anyone to remove panels or covers from this apparatus, other than qualified service personnel.

• Do not permit anyone other than qualified service personnel to operate this apparatus unless all panels and covers are

in place.

Page 5

Introduction

Caution

When installing or servicing any item of SSL equipment with power applied, when cover panels are removed:

H

AZARDOUS CONDITIONS CAN EXIST!

These hazards include: • High energy stored in capacitors

•

High currents available from DC power busses

•

Hot component surfaces

• High voltages

To reduce the risk of fire, replace internal fuses only with identical type and rating.

FCC Notice

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of the

FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment

is used in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in which case the user will be

required to correct the interference at his own expense.

Disposal of WEEE by Users in the European Union

The symbol shown here is on the product or on its packaging, which indicates that this product must not be

disposed of with other waste. Instead, it is the user’s responsibility to dispose of their waste equipment by handing

it over to a designated collection point for recycling of waste electrical and electronic equipment. The separate

collection and recycling of your waste equipment at the time of disposal will help to conserve natural resources

and ensure that it is recycled in a manner that protects human health and the environment. For more information

about where you can drop off your waste equipment for recycling, please contact your local city office, your household waste

disposal service or where you purchased the product.

Standards Conformance

This apparatus fully conforms with the current protection requirements of the European community council

directives on EMC and LVD.

AWS 924-948 Owner’s Manual Page V

Page 6

This page is intentionally almost blank

Page VI AWS 924-948 Owner’s Manual

Introduction

Page 7

MANUAL INDEX

Ø switch 3-6

0

dB Function key 3-15

1 / 2 switches 3-6

10db Function key 3-27

48V switch 3-6

80Hz Function Key 3-18

85dB Function Key 3-20

A

A-FADA Analogue Automation 4-5

A2B Function Key 3-18

About tab (Remote) 5-15

AC Function Key 3-19

AFL Function Key 3-20

Air Conditioning 1-1

AL Function Key 3-19

ALF Function Key 3-19

ALL Function key 3-3, 3-15

ALS Function Key 3-19

ALT Function Key 3-20

ALT/EFX SEL 3-9, 3-10

Anl Function key 3-27

AR Function Key 3-19

ARS Function Key 3-19

Attaching the legs 1-3

Audio Connections 1-5

Auto Scan (TR) 6-5

AUTO-M 3-4

Automation (HUI) 4-29

Automation (console) 7-1

AutoTakeover (Automation) 7-14

AWS Remote 5-1

B

balance 3-11

BASS Function Key 3-18

Bass Management 3-18

BMA Function Key 3-18

BMB Function Key 3-18

BMN Function Key 3-18

bus inject 3-23

C

Cable Ducting 1-1

CAL Function Key 3-19

Centre Section 3-15

Chan (TR) 6-5

Channel Banking 4-7

Channel Display 3-12

C

hannel Fader (HUI) 4-11

Channel Modes (948) 2b-3, 3-3

channel output 3-10

Channel Selection 3-12

Channels tab (Remote) 5-11

Chinagraph 3-12

CHOP EFX 3-4, 3-9

CHOP PRE/EFX 3-9, 3-10

CmFb (TR) 6-5

Communications 3-25

Compressor 3-6, 3-21, 3-22

Connectors A-3

Console Setup Menu 3-28

CS (Automation) 7-14

Cubase 4-36

CUE A / B 3-9

CUE F-CH 3-4, 3-11

CUE ST pan pot 3-4, 3-11

Cue 3-9, 3-23

CUT (channel) 3-12

CUT (monitoring) 3-16

CUT (DAW) 4-12

D

D-Type A-3, A-5

DAW Connection 1-7

DAW Controller 4-1

Daw Function key 3-27

DAW Layers 4-3

DAW1 / 2 Function keys 4-3

DF 1 / 2 (A-FADA) Function keys 4-5

Digital Displays 4-13

Digital Performer 4-42

DIM switch 3-16

DIN 5-Pin A-3

Direct Output 3-10

DIRECT PRE/EFX 3-9, 3-10

Downloads 5-15

DOWNMIX 3-16

Dynamics 3-6, 3-22

DynB (TR) 6-5

Introduction

AWS 924-948 Owner’s Manual Page VII

Page 8

Introduction

Page VIII AWS 924-948 Owner’s Manual

L

layers (DAW) 4-3

LF0 Function Key 3-18

LFG Function Key 3-19

LINE pot 3-6

L

NSL Function key 3-15

Logic 4-34

L

ogic Handshaking 4-3

LØ switch 3-6

LRA Function Key 3-17

LS SELECT buttons 3-16

M

Maintenance Ai

Master Control Panel (DAW) 4-8, 4-33

Master Fader 3-21

MCU 4-32

Metering (Centre Section) 3-27

meters (channel) 3-6

METERS Function keys 3-27

MIC pot 3-6

MIDI SysEx 5-1, 7-20

MIDI 1-7, 1-20, A-9

MISC Function key 4-3, 4-5, 7-15

MISC LEVELS switches 3-16

Mix bus 3-11, 3-21

Mix Enabled (Automation) 7-4

Mixes tab (Remote) 5-7, 7-5

Modifier Buttons (HUI) 4-10

Moff (Automation) 7-13

MOM Function Key 3-20

MON SRC buttons 3-16

Monitor Calibration 3-19

MONITOR LEVEL pot 3-16

MONITOR MUTE/SOLO buttons 3-16

Monitor Options Function Keys 3-17

Monitoring 3-16

Motion Control Panel 4-17

N

Navigation Mode (HUI) 4-20

network 1-8

Nuendo 4-37

O

OP switch 3-6

OSC ON 3-19, 3-26

Oscillator 3-26

E

EFX 3-9, 3-10

EFXC Function key 3-9, 3-15

EQ IN switch 3-7

Equalizer 3-7

E

thernet 1-8

Execute (Automation) 7-7

E

XT A / B 3-17

EXT T/B button 3-25

External Source Selectors 3-17

External sources 5-13

Externals tab (Remote) 5-13

F

Fader Links 7-16

fader 3-13, 3-21

FAQ’s 5-15

faults A-13

Filter 3-7

FLIP switch 3-6

Focus Modes 3-1, 4-2

Foldback 3-24

FSM 7-10, 7-12

Function Keys 3-15

FX busses 3-9, 3-23

FX Returns 3-24

G

G-EQ switch 3-7

Grounding 1-1

H

headphones 3-24

HLD Function key 3-27

HPF pot 3-7

HUI 4-9

I

Input configuration 3-6

INS Function Key 3-17

insert (channel) 3-8

INST switch 3-6

Installation 1-1

IP address 1-19

IP switch 3-6

ipMIDI 1-7

ISO Function Key 3-20

J

Join (Automation) 7-8

Page 9

Introduction

AWS 924-948 Owner’s Manual Page IX

P

PAD switch 3-6

PAN switch 3-10

pan 3-11

Patchbay 1-5

P

FL Function Key 3-20

PFM Function Key 3-17

p

hantom power 3-6

PHONES buttons 3-16

PINK ON button 3-19, 3-26

PK Function key 3-27

Plug-In Editor (HUI) 4-21

POST switch 3-9

Power Supply Indicators 3-15

PRE switch 3-10

Pre-Installation Requirements 1-1

Projects 5-1, 5-5

Protection (Automation) 7-10

R

REC/MIX LED 3-9

Record bus 3-11, 3-21

RED LIGHT 3-25

Registration 5-15

Remote Browser 5-1

Remote 1-7

Removing the trim 1-3

RETURN switch 3-3

Revise (Automation) 7-8

RØ switch 3-6

S

S-CUE 3-4

Scan (TR) 6-5

screen 3-2

Scribble Strip 3-12, 4-13

SEL button 3-12, 4-14

Service & Warranty A-11

SET Function key 3-3, 3-15

setup menu 3-28

Shuttle/Scrub Wheel 4-20

SIF Function Key 3-20

Signal Processing Order 3-8

SLATE button 3-25

SLNK Function key 7-19

Snap (Automation) 7-15

Snap Function Key 4-5

SOLO (monitoring) 3-16

SOLO CLEAR button 3-16

SOLO Configuration 3-20

Solo switch 3-12, 4-13

Sonar 4-39

Specifications A-1, A-7

SRA Function Key 3-17

ST Function key 3-3, 3-15

stereo cue 3-9, 3-23

stereo FX Returns 3-24

S

tRt (TR) 6-5

Studio Integration 1-5

S

UM Function Key 3-17

Support 5-15

SysEx 5-1, 7-20

T

talkback 3-25

TB ALL 3-25

TB to Foldback pot 3-25

TFT screen 3-2

Thermal Considerations 1-1

Titles 5-1

TLock (Automation) 7-13

Total Recall 6-1

Total Recall tab (Remote) 5-9, 6-11

TR (Total Recall) 5-9, 6-1

track busses 3-10, 3-23

Trim (Automation) 7-12

TRK Function key 3-3, 3-15

Troubleshooting A-13

Two DAW Layers 4-3

U

Unpacking The Console 1-3

Utility Buttons (HUI) 4-9

V

V-Pots 3-13, 4-8, 4-13, 4-15

VU Function key 3-27

W

Warranty A-11

width (pan) 3-11

Window Buttons (HUI) 4-9

Z

Zoom Mode (HUI) 4-19

Page 10

This page is intentionally almost blank

Page X AWS 924-948 Owner’s Manual

Introduction

Page 11

AWS 924-948 Owner’s Manual Page XI

MANUAL CONTENTS

Important Information III

Graphic Symbols III

General Safety III

Caution III

Power Safety IV

Caution V

FCC Notice V

Disposal of WEEE by Users in the European Union V

Standards Conformance V

Manual Index VII

Manual Contents XI

Reading this Manual XIX

Introduction to the sections XIX

Manual Conventions XIX

Contacting Solid State Logic XIX

Introduction to the AWS XIX

Key Features XX

AWS 924 XX

AWS 948 XX

SECTION 1: INSTALLATION

Section Contents 1-iii

Pre-Installation Requirements 1-1

Console Control Surface 1-1

Power Connections 1-1

Service Access 1-1

Thermal Considerations 1-1

Air Conditioning 1-1

Cable Ducting 1-1

Grounding 1-1

Unpacking The Console 1-3

Attaching the legs 1-3

Removing the trim 1-3

Front Buffer 1-3

End Trim 1-3

Top Trim 1-3

Introduction

Page 12

Studio Integration 1-5

A

udio Connections 1-5

C

onnecting a Patchbay 1-5

A

WS 924 Patchbay layout Example: 1-5

P

atchbay Guidelines 1-6

I

nstrument Inputs (AWS 924 Only) 1-6

Mic Inputs 1-6

AWS948 Patchbay layout Example: 1-6

DAW Connection 1-7

Overview 1-7

Installing the ipMIDI driver and AWS Remote 1-7

Software Installation (Macintosh) 1-7

Software Installation (PC) 1-8

Make and configure the network connection 1-8

Direct Network Connection (Macintosh) 1-8

Direct Network connection (PC) 1-11

Enabling ipMIDI on your AWS 1-12

Finding the console on the AWS Remote application: 1-12

Setting your workstation(s) to communicate via ipMIDI 1-13

Pro Tools 8 1-14

Logic Pro 9 1-15

Preferences/Control Surfaces Setup menu: 1-16

Network trouble shooting: 1-17

Larger networks: 1-18

Assigning the AWS IP Address: 1-19

Using DHCP 1-19

Changing the static IP address 1-19

Using Physical MIDI Ports to Connect your DAW 1-20

SECTION 2A: AWS 924 TUTORIAL

Studio Configurations 2a-1

Smaller systems 2a-1

Larger Systems 2a-1

Focus Modes 2a-2

Channel Strip 2a-3

Input configuration 2a-3

Signal Processing 2a-3

Dynamics 2a-3

Filter and EQ 2a-3

Insert Point 2a-3

Routing 2a-3

Cue, FX and EFX Sends 2a-3

Bus Routing 2a-3

Panning, Width and Balance 2a-4

Level, cuts and solos 2a-4

Page XII AWS 924-948 Owner’s Manual

Introduction

Page 13

AWS 924-948 Owner’s Manual Page XIII

Centre Section 2a-5

A

djusting the Mix and Record busses 2a-5

C

reating a Monitor Mix 2a-5

Creating Foldback Mixes 2a-5

Using the FX Returns 2a-5

Using Talkback 2a-5

‘In-line’ Recording 2a-5

SECTION 2B: AWS 948 TUTORIAL

Focus Modes 2b-1

Channel Modes 2b-3

Basic Tracking Configuration 2b-4

Mono Configuration 2b-4

Stereo Configuration 2b-4

Analogue-style In-Line Tracking Configuration 2b-5

Band Tracking Mode 2b-5

Overdub/Playback Tracking Mode 2b-5

Mixing Configurations 2b-6

Basic Stereo Mixdown 2b-6

Additional Send Mixing 2b-6

Additional Return Mixing 2b-7

Mode Selection 2b-8

Channel Strip 2b-9

Input configuration 2b-9

Signal Processing 2b-9

Dynamics 2b-9

Filter and EQ 2b-9

Inserts 2b-9

Routing 2b-9

Cue and FX Sends 2b-9

Bus Routing 2b-10

Panning, Width and Balance 2b-10

Channel level, cut and solo 2b-10

Centre Section 2b-11

Adjusting the Mix and Record busses 2b-11

Creating a Monitor Mix 2b-11

Creating Foldback Mixes 2b-11

Using the FX Returns 2b-11

Using Talkback 2b-11

Introduction

Page 14

SECTION 3: ANALOGUE OPERATIONS

Section Contents 3-iii

Introduction 3-1

Focus Modes 3-1

The TFT Screen 3-2

Channel Modes (948 only) 3-3

Channel Configuration (AWS 948 only) 3-4

In-line Mix 3-4

In-line Track 3-4

Channel Strip 3-5

Overview 3-5

Input configuration 3-6

Channel Meters 3-6

Dynamics 3-6

Filter 3-7

Equalizer 3-7

Insert Point 3-8

Signal Processing Order 3-8

Cue, FX and EFX Sends 3-9

Direct Output 3-10

Direct Outputs and EFX: 3-10

Track Bus Routing 3-10

Track Busses and EFX: 3-10

REC and MIX Bus Routing 3-11

Panning, Width and Balance 3-11

Scribble Strips 3-12

Channel Display 3-12

Chinagraph Scribble Strip 3-12

Channel Selection 3-12

Cut and Solo Switches 3-12

Level Control 3-13

Centre Section 3-15

Introduction 3-15

Power Supply Indicators 3-15

Function Keys 3-15

Monitoring 3-16

MON MODE buttons [8] 3-16

Monitor Configurations 3-17

External Source Selectors 3-17

Monitor Options 3-17

Monitor Insert 3-18

Bass Management 3-18

Monitor Level Calibration 3-19

Monitor Level Display and Calibrated listening level 3-20

SOLO Configuration 3-20

Page XIV AWS 924-948 Owner’s Manual

Introduction

Page 15

AWS 924-948 Owner’s Manual Page XV

Mix and Rec Bus Controls 3-21

Adjusting a master level 3-21

Assigning Centre Section Dynamics 3-21

Assigning the Stereo Compressor 3-21

Activating bus inserts 3-21

Dynamics Operation 3-22

Compressor/Limiter Section 3-22

Gate/Expander Section 3-22

Track Bus Master Controls 3-23

Cue/FX Send Master Controls 3-23

Cue and FX bus injection 3-23

Foldback Headphone Outputs 3-24

Stereo FX Returns 3-24

Communications 3-25

Communications Setup Options 3-26

Oscillator 3-26

Centre Section Metering 3-27

Console Setup Menu 3-28

Automation 3-28

Talkback 3-29

Monitor section 3-29

Desk Setup 3-29

DAW setup 3-30

Desk settings 3-30

SECTION 4: DAW CONTROL

Section Contents 4-iii

Introduction 4-1

A-FADA 4-1

DAW Controller Features Summary 4-1

Focus Modes 4-2

Configuring DAW Layers 4-3

DAW Layers 4-3

Communication with your DAW 4-4

Logic Handshaking 4-4

A-FADA Analogue Automation 4-5

Snap 4-5

Setup Guidelines 4-6

HUI and MCU common Features 4-7

V-Pots 4-7

The Master Control Panel 4-8

Channel Banking Controls 4-8

Pro Tools HUI Control Guide 4-9

DAW Window Buttons 4-9

DAW Utility Buttons 4-9

Modifier Buttons 4-9

Introduction

Page 16

The Default Button 4-10

Resetting Pans 4-10

Resetting Faders 4-10

Resetting Sends 4-10

Resetting Plug-ins 4-10

Channel Functions 4-11

DAW Meters 4-11

Status Indicators 4-11

Multi-channel Metering (TDM Systems Only) 4-11

Channel Fader 4-11

Fader Grouping 4-11

Channel Solo and Cut Tile 4-12

Solo Isolate 4-12

Channel SEL Button – Track Arming/Edit/Select 4-13

Record Ready Mode 4-13

Record Safe 4-13

Working with the Channel V-pots 4-14

Setting Sends Pre/Post Fader 4-15

Muting a Send Output 4-15

Flipping Send Levels to the Faders 4-15

Input, Output and Send Routing 4-16

Viewing Input, Output and Send Routing 4-16

Setting Input, Output and Send Routing 4-16

Assigning Signals to Multiple Channels 4-16

Assigning a Channel to Multiple Outputs 4-16

Motion Control Panel 4-17

Transport Controls 4-17

Other useful transport modes 4-17

AWS Footswitch Control 4-18

Zoom, Navigation and Selection Modes 4-19

Navigation Mode (Neither Zoom nor Select lit) 4-19

Zoom Mode (Both Zoom and Select lit) 4-19

Select Mode (Both Zoom and Select Flashing) 4-19

Scrolling Within a Window 4-19

Shuttle/Scrub Wheel 4-20

Numeric Keypad 4-20

Working with Markers/Memory Locations 4-20

HUI Plug-in Control 4-21

Plug-In Editor 4-21

Plug-In Editor Display 4-21

Plug-In Editor Controls 4-21

Paging Buttons 4-21

Selecting DAW Channels to Edit 4-21

Plug-In Display Modes 4-22

Viewing Current Inserts (Insert Mode) 4-22

Assigning a Plug-In or Hardware I/O (Insert Mode) 4-22

Editing Plug-In Parameters (Parameter Mode) 4-23

Selecting a Plug-In to Edit 4-23

Changing Plug-in Parameters 4-23

Hi-Resolution Parameter Display Mode 4-23

Comparing Your Changes 4-23

Bypassing Plug-ins 4-23

V-pot Sensitivity 4-23

Page XVI AWS 924-948 Owner’s Manual

Introduction

Page 17

AWS 924-948 Owner’s Manual Page XVII

Additional HUI Displays 4-25

T

imecode/Bars & Beats/Samples Display 4-25

D

AW Status Display 4-25

Soft Key Display 4-25

1

. Automation Enables 4-25

2

. Automation Modes 4-25

3. Edit Tools Menu 4-26

4. Edit Modes Menu 4-26

5. Status/Group Menu 4-26

6. Function Keys 4-27

7. EDIT Menu 4-27

8. SSL Menu 4-27

HUI Automation 4-29

Automation Enables 4-29

Automation Modes 4-29

Automation Status Display 4-29

Suspending Automation 4-30

Writing Automation (Write to Start, End or All) 4-30

Automating Switches (eg. Cuts) 4-30

Automating Pans and Sends 4-30

Automating Plug-Ins 4-30

Automation Indication for Plug-In Parameters 4-30

MCU (Mackie Control) Emulation 4-31

Mackie Control Emulation Advantages 4-31

Implementation 4-31

DAW Control Function Key Overview 4-33

The Logic Template 4-34

Logic Console Layout 4-34

Transport Function Key Layout 4-35

Logic Control screen 4-35

Nuendo/Cubase Template 4-36

Nuendo Console Layout 4-37

Nuendo Control screen 4-38

The Sonar Template 4-39

Sonar Console Layout 4-40

Sonar Control screen 4-41

Digital Performer Template 4-42

Digital Performer Console Layout 4-42

Digital Performer Control screen 4-43

SECTION 5: PROJECTS AND THE REMOTE BROWSER

Section Contents 5-iii

Introduction 5-1

Working with Projects and Titles 5-1

AWS Remote 5-1

MIDI SysEx data 5-1

Connecting the Remote to the Console 5-3

Introduction

Page 18

The Projects Tab 5-5

C

opying Titles, Total Recall and Mix data between Projects 5-6

R

enaming Projects, Titles, Mixes or Total Recall Setups 5-6

Backing up a Project 5-6

Restoring a Project 5-6

The Mixes Tab 5-7

The Total Recall Tab 5-9

The Channels Tab 5-11

The Externals Tab 5-13

The About Tab 5-15

SECTION 6: TOTAL RECALL

Section Contents 6-iii

Overview 6-1

Accessing Total Recall 6-1

Selecting TR Setups 6-3

Changing the selected setup 6-3

Matching the Console to the TR 6-5

Display Overview 6-5

Correcting controls 6-5

Auto Scan 6-5

The Channel Display 6-6

Setting soft switches 6-6

Copying and Swapping settings between channels 6-6

Centre section displays 6-7

Compressor and Foldback 6-7

Dynamics and Bus Masters 6-7

Stereo Returns 6-7

Additional TR Functions 6-9

Storing setups 6-9

Deleting Setups 6-9

Restoring Legacy MIDI Setups from a Mac or PC 6-9

Total Recall via Logictivity 6-11

Page XVIII AWS 924-948 Owner’s Manual

Introduction

Page 19

AWS 924-948 Owner’s Manual Page XIX

SECTION 7: AUTOMATION

Section Contents 7-iii

Overview 7-1

Key features 7-1

Quick Guides 7-1

A-FADA Analogue Automation 7-1

Working with Projects and Titles 7-2

Automation Management via the Remote 7-3

Operation 7-4

Activating the Automation System 7-4

List Mix Menu 7-4

Changing the selected Mix Pass 7-4

Deleting Mix Passes 7-4

Creating A New Mix Pass 7-5

Join and Revise 7-8

Discard 7-8

Updating a Mix Pass 7-8

Cut Automation 7-9

Selecting Protection 7-10

Summary of fader status and FSM functions: 7-11

Automation Options 7-12

Trim 7-12

TLock 7-13

Motors Off 7-13

Snap Mode 7-14

AutoTakeover 7-14

Copy and Swap 7-14

Deleting Mix Passes from the Console 7-14

Automation Setup Options 7-15

Fader Links 7-16

Viewing Links 7-16

Suspending Links 7-16

Deleting Links 7-16

Pro Tools Setup Notes 7-17

MIDI SysEx Save and Load 7-20

Saving Automation Mix Passes: 7-20

Loading Legacy Mix Passes: 7-20

Introduction

Page 20

APPENDICES

Section Contents Aiii

A: Specifications A-1

1

/4” TRS Jack A-3

DIN 5-Pin 180° A-3

XLR 3-Pin A-3

B: Connector Details A-3

C: Connector Pinouts A-5

Connector Pinouts . . . continued A-6

D: Environmental Specification A-7

E: MIDI Implementation Chart A-9

F: Service & Warranty Information A-11

Introduction A-11

Warranty A-11

Out of Warranty Repairs A-11

Website Support A-11

Out-of-hours Support A-11

G: Troubleshooting A-13

Introduction A-13

Locating Problems A-13

Audio Faults A-13

Control Faults A-14

Replacing Modules A-15

The Channel Strip (629921X1 / 629994X1) A-16

The Channel Fader (629924X1) A-17

The Channel Meter Panel (629923X1 / X2) A-18

Centre Section Cards A-19

Troubleshooting Chart – Channel bays A-20

Troubleshooting Chart – Centre section A-20

H: Glossary Of Terms A-23

I: Link Options A-25

J: Block Diagrams A-26

Page XX AWS 924-948 Owner’s Manual

Introduction

Page 21

AWS 924-948 Owner’s Manual Page XXI

READING THIS MANUAL

Introduction to the sections

Following this section, there is a section describing the console’s installation. The rest of the manual presumes that installation

has been completed. Two tutorials follow next – one for the AWS 924 and one for the AWS 948. There are then detailed

descriptions of the analogue operations (Section 3), DAW operations (Section 4), projects and the Remote (Section5),

Total Recall (Section 6) and the automation system (Section 7).

Manual Conventions

Where the AWS 924 and 948 descriptions differ, the 924 is pictured and described on the left, and the 948 on the right.

Labelling from the control surface, TFT screen or Remote Browser appear in Bold.

Notes and tips are indicated like this.

CONTACTING SOLID STATE LOGIC

If you cannot find the information you need on the pages of this manual, please see the AWS support pages at

http://www.solidstatelogic.com

INTRODUCTION TO THE AWS

Launched in 2004, the AWS (Analogue Workstation System) reinvented the professional production console by combining

classic SSL Superanalogue™ console technology with comprehensive DAW control hardware in a single work surface.

Over 550 consoles later the AWS is now used by leading international recording artists, producers and engineers and has

shaped expectations for session workflow within today’s and indeed tomorrow’s production environments.

Designed for mid scale commercial recording and production facilities, the AWS is available in 24 input (AWS 924) or 48

input (AWS 948) variants within a compact 24 fader frame. Both models deliver pristine SuperAnalogue™ mixing, 24 ultraclean SSL SuperAnalogue mic pre’s, classic SSL dual curve EQ on every channel, two assignable SSL Dynamics, legendary

Stereo Buss Compressor, TotalRecall™ and full 5.1 monitoring. In addition to on board classic SSL Automation, both models

also feature the revolutionary new A-FADA mode where motorised analogue faders follow DAW Automation data.

AWS 924 & 948 also feature Ethernet connectivity for streamlined hardware control of your Digital Audio Workstation,

delivering elegant, ergonomic physical control over your entire studio environment with dedicated heavy duty DAW

transport, V-Pot multifunction encoders with position indicating LED’s, Digital Scribble Strips, DAW fader mode, global

and channel routing control and built-in TFT display for advanced plug-in editing. Project Session Management is kept simple

through SSL’s proprietary Logictivity interface.

The AWS is an SSL SuperAnalogue™ console, featuring the audio performance specifications that have established the

benchmarks by which other manufacturers are measured. Exceptionally low THD, noise floor & crosstalk levels keep your

audio absolutely pristine, while our legendary headroom carries every nuance of your audio and allows engineers to mix

‘hotter’ without distortion.

While the AWS offers a powerful large format analogue console feature set within a compact console design, it also goes

further than any other analogue console by integrating seamlessly into a DAW-based facility by incorporating hands-on

control of important recording, routing, mixing, and editing functions in all major DAW applications including Pro Tools™,

Logic Audio™, Nuendo™, Sonar™ and many others.

Introduction

Page XXI

AWS 9--

Model-specific descriptions are boxed by a thin blue line.

Page 22

Key Features

• Combination of Superanalogue™ console and advanced DAW controller

• SSL SuperAnalogue™ mix bus provides pristine audio foundations

• SSL SuperAnalogue™ mic pre’s provide transparent record path

• Innovative Dual Path Channel with three versatile operating modes (948 only)

• 48 inputs on AWS 948;

o IN-LINE TRACKING = 1 mic + 1 pre-monitor input per channel

o IN-LINE MIX = 2 x mono line inputs per channel

o STEREO MIX = 1 x stereo line input per channel

• Comprehensive metering of all inputs and outputs

• VU and Phase meter with source selector

• A-FADA Mode where motorised analogue faders follow DAW automation

• Versatile 4 band channel EQ, assignable Dynamics and SSL Master Bus Compressor

• 4-Band EQ design with independent E/G curve switching on selected bands

• 5.1 Surround monitoring and Monitor calibration including Bass management

• MIDI over Ethernet multi layer DAW workstation control

• Contigious Digital Scribble Strips for console and DAW data

• Elegant project setup via SSL Logictivity Remote Browser and SD card storage

• SSL’s unique trademarked Total Recall™ system with ‘TR Autoscan’

• Responsible ‘green’ manufacturing and reduced power consumption

• Compact 24 fader frame ideal for small control rooms

AWS 924

The AWS 924 continues the classic design of the AWS 900.

AWS 948

The AWS 948 maintains the same 24 fader footprint as the AWS 924 (and classic AWS 900) and achieves its 48 input count

via a unique Dual Path Channel Strip design where each channel has a single Mic Amp and two line level inputs, a new

Stereo EQ and Stereo Insert. This new channel enables three different operating modes: STEREO MIX, IN LINE MIX and

IN LINE TRACKING. These differing modes offer a wealth of workflow options that enhance today’s versatile production

environments.

Page XXII AWS 924-948 Owner’s Manual

Introduction

Page 23

AWS 924-948

OWNER’S MANUAL

SECTION 1

INSTALLATION

Page 24

This page is intentionally almost blank

AWS Installation

Page 1-ii AWS 924-948 Owner’s Manual

Page 25

SECTION CONTENTS

Section Contents 1-iii

Pre-Installation Requirements 1-1

Console Control Surface 1-1

Power Connections 1-1

Service Access 1-1

Thermal Considerations 1-1

Air Conditioning 1-1

Cable Ducting 1-1

Grounding 1-1

Unpacking the Console 1-3

Attaching the Legs 1-3

Removing the Trim 1-3

Front Buffer 1-3

End Trim 1-3

Top Trim 1-3

Studio Integration 1-5

Audio Connections 1-5

Connecting a Patchbay 1-5

AWS 924 Patchbay Layout Example: 1-5

Patchbay Guidelines 1-6

Instrument Inputs (AWS 924 Only) 1-6

Mic Inputs 1-6

AWS948 Patchbay layout Example: 1-6

DAW Connection 1-7

Overview 1-7

Installing the ipMIDI driver and AWS Remote 1-7

Software Installation (Macintosh) 1-7

Software Installation (PC) 1-8

Make and Configure the Network Connection 1-8

Direct Network Connection (Macintosh) 1-8

Direct Network Connection (PC) 1-11

Enabling ipMIDI on your AWS 1-12

Finding the Console on the AWS Remote Application 1-12

Setting Your Workstation(s) to Communicate via ipMIDI 1-13

Pro Tools 8 1-14

Logic Pro 9 1-15

Preferences/Control Surfaces Setup Menu 1-16

Network Troubleshooting 1-17

Larger Networks 1-18

Assigning the AWS IP Address 1-19

Using DHCP 1-19

Changing the Static IP Address 1-19

Using Physical MIDI Ports to Connect your DAW 1-20

AWS Installation

AWS 924-948 Owner’s Manual Page 1-iii

Page 26

This page is intentionally almost blank

AWS Installation

Page 1-iv AWS 924-948 Owner’s Manual

Page 27

INSTALLATION

PRE-INSTALLATION REQUIREMENTS

Console Control Surface

T

he AWS console is a self contained system; there are no remote power supplies or I/O racks. The frame is not fitted with

cooling fans.

See the appendices for the console footprint diagram.

Power Connections

The console is fitted with auto-sensing power supplies which will function at any voltage from 100 to 230 volts ±10% without

adjustment.

Three IEC mains power-leads are supplied: one with a UK 3-pin fused plug fitted, one with US-style 3-pin mains plug fitted

and one with a european 3-pin plug. Please select the appropriate lead for the local power outlets.

Service Access

Access to all electronic assemblies within the frame is from the front of the console. Note however, that each of the

console’s modules is retained by a screw through its rear panel. It is necessary therefore, to have access to the rear of the

console.

Thermal Considerations

The console is cooled by convection from the front inlet (in the knee panels) to the exit at the top of the rear panels. It is

very important that these ventilation grills are not obstructed in any way.

The heatsink fins on the console rear panels can reach temperatures of approximately 30 degrees Celsius above the

ambient room temperature.

Air Conditioning

It is unlikely that additional air conditioning will be required after installing the AWS (typical dissipation of 450W for the

AWS 924 and 600W for the AWS 948). It is possible however, that when all the studio equipment is taken into

consideration, particularly if additional lighting is being installed, the combined heat output could be sufficient to cause the

temperature to rise to uncomfortable levels. The appendix section contains environmental specifications for SSL equipment.

Cable Ducting

Cable ducting may be required between the console and any outboard racks and the recording areas. If a full remote

patchbay is being provided then the ducting will need to be large enough for sufficient 24-circuit multicore cables to be

accommodated – 12 for the AWS 924 and 15 for the AWS 948.

Grounding

A standard system should not require any additional grounding over and above that provided by a correctly installed mains

supply. The console’s chassis is permanently bonded to mains earth.

The mains input ground wire MUST be connected to the supply earth.

i

Pre Installation

AWS 924-948 Owner’s Manual Page 1-1

Page 28

Pre Installation

Page 1-2 AWS 924-948 Owner’s Manual

Page 29

Unpacking the Console

The AWS consoles are supplied in a wooden crate without the legs fitted. The legs, manuals and anciliaries are located in

a tray at the base of the crate.

The weight of the console is approximately 100kg. It is recommended that at least four people are available before

attempting to manoeuvre the console.

U

sing a large screwdriver or pry-bar carefully open the crate containing the console. The crate is not designed to be reusable

so does not have to be removed intact. Once the top and sides of the crate have been removed there will be sufficient space

for four people to lift the console clear from the base.

The console is shipped with its trim already fitted, avoid using any of the trim as a lifting point. Do not lift the front of the

console by using the buffer alone.

Attaching the Legs

Again, it is recommended that four people are available to perform this operation.

The bolts required to attach the legs can be found in the ancillaries bag in the base of the transit crate. A 6mm hex-key is

provided to secure the leg bolts.

• The console should first be rolled onto its back. Ensure that ample padding is provided – such as blankets or bubblewrap – to support the rear panels (the PSU heatsink fins protrude from the rear of the console, and care must be

taken not to damage them).

• Position the legs on the console beam and attach the M10 bolts using the 6mm hex-key supplied. There are four bolts

per leg.

• Using four people, the console may now be tipped forward onto its feet. Once the console is in position, a limited

amount of adjustment is available to compensate for an uneven floor. Do not unscrew the feet inserts by more than

about 15mm.

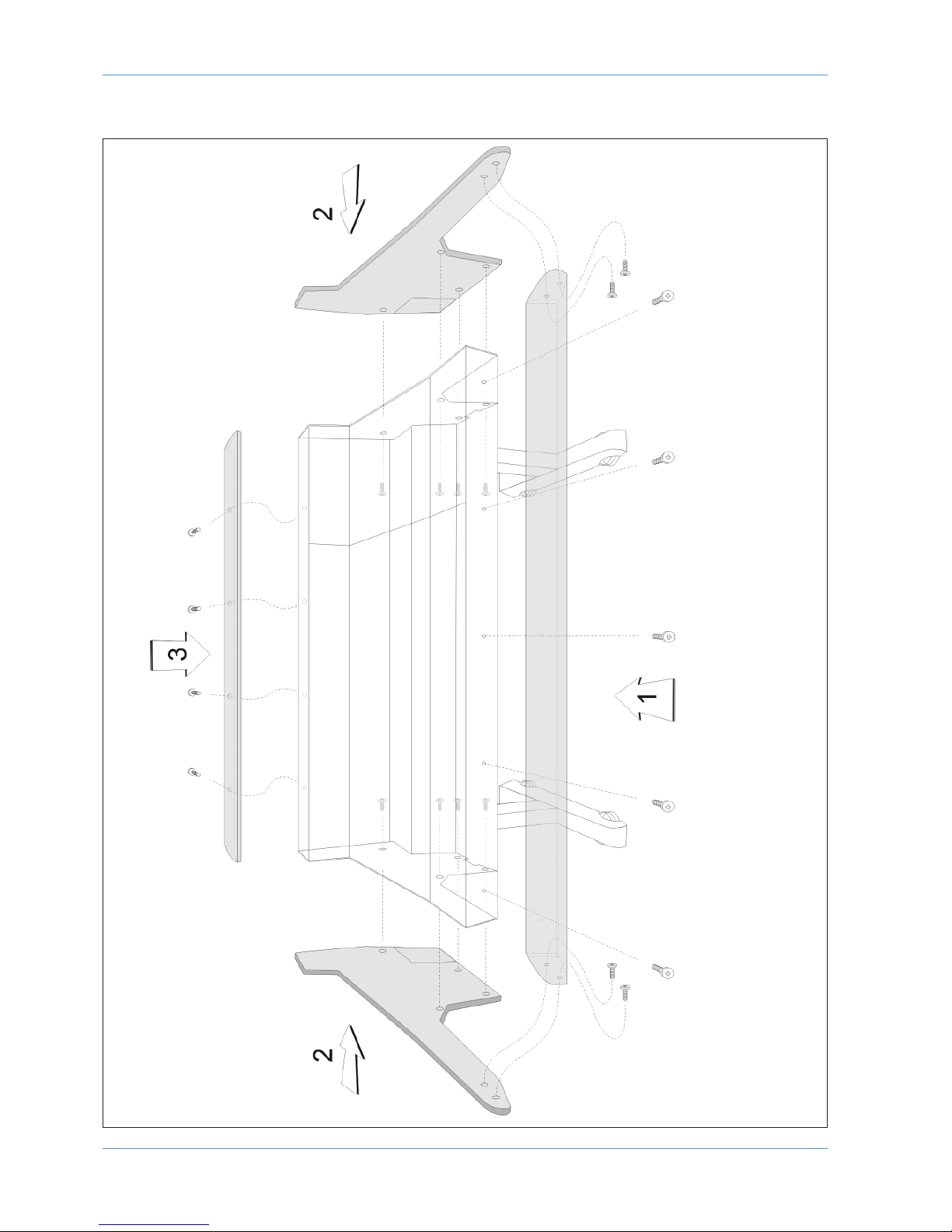

Removing the Trim

If it is necessary to remove the trim panels – to adjoin existing furniture – then please refer to the following information

and the illustration shown on the facing page.

Note that it is not necessary to remove any of the audio modules to gain access to the trim fixing screws.

Front Buffer

The front buffer [1] is secured by nine pan-head screws – five in the front beam and two in each end trim. These are all

visible from beneath the buffer.

End Trim

Each of the end trims [2] is secured by four countersunk Posi-head screws through the profile (one is located in the kneepanel area, two more are found either side of the main beam and the fourth is located on the bottom corner of the outside

profile), as well as two pan-head screws through the front buffer (visible from beneath the buffer).

Top Trim

The top trim [3] is clipped over the front of the meter panels and secured onto the back panels by four M3 screws.

Pre Installation

AWS 924-948 Owner’s Manual Page 1-3

Page 30

Pre Installation

Page 1-4 AWS 924-948 Owner’s Manual

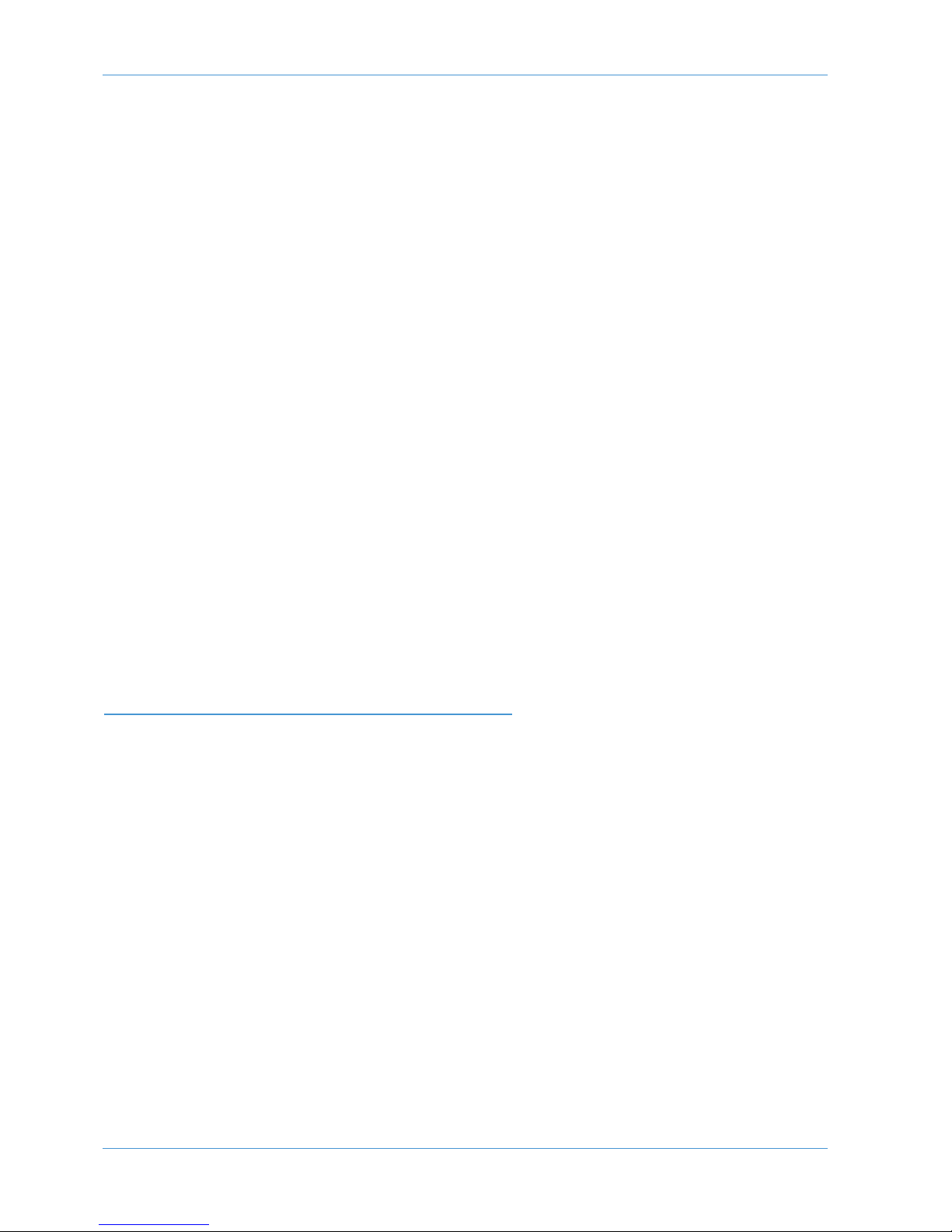

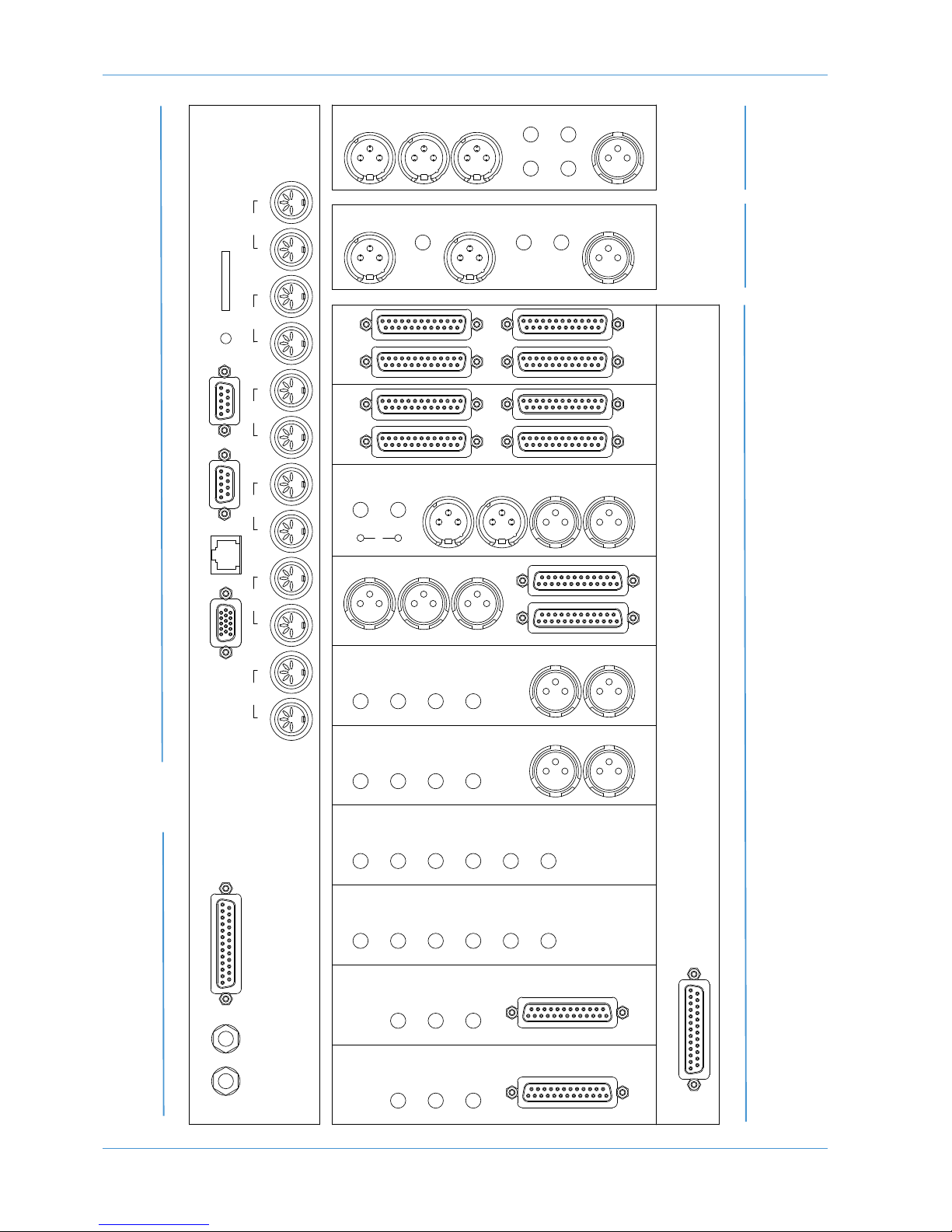

EXT A1 EXT A2

EXT A3 EXT A4

METER

OUT

EXT B

1 - 4

SEND - MON - RET

INSERT

MIC

INST

LINE

SEND

RTN

DIR

T/BACK

MIC OUT

LISTEN

MIC OUT

T/BACK

MIC IN

LISTEN

MIC IN

MINI

AL

MINI

AR

MINI

BL

MINI

BR

OSC

OUT

MON B MON A

SEND

LEFT

RETURN

LEFT

SEND

RIGHT

RETURN

RIGHT

LEFT

OUT

RIGHT

OUT

MIX OUTPUT

SEND

LEFT

RETURN

LEFT

SEND

RIGHT

RETURN

RIGHT

LEFT

OUT

RIGHT

OUT

REC OUTPUT

ECHO

RTN 1L

ECHO

RTN 1R

FX1

OUT

KEY

IN

FB AL

OUT

FB AR

OUT

ECHO

RTN 2L

ECHO

RTN 2R

FX2

OUT

KEY

IN

FB BL

OUT

FB BR

OUT

ECHO

RTN 3L

ECHO

RTN 3R

FX3

OUT

ECHO

RTN 4L

ECHO

RTN 4R

FX4

OUT

8 TRACK

BUS OUT

CUE/FX

BUS OUT

RED LIGHT / TALKBACK / GP I/O

CUE BUS INJECTS

MIC GAIN

DESK

EXT TB

L INSERT R

MIC

LINE

L

LINE

R/MON

SEND

RTN

CH

OUT

VIDEO

OUT

NETWORK SERIAL 2

(DIAGNOSTICS)

SERIAL 1

(X-RACK)

RESET SD-CARD

21

FOOTSWITCH

MIDI 1

INOUT

MIDI 2

INOUT

MIDI 3

INOUT

MIDI 4

INOUT

MIDI 5

INOUT

MIDI 6

INOUT

Stereo

Channels

(AWS 948)

Mono

Channels

(AWS 924)

Master Section

(AWS 924 and 948)

Processor Interface and MIDI

(AWS 924 and 948)

GP IO

(AWS 924 and 948)

Page 31

STUDIO INTEGRATION

Audio Connections

A

ll connections to the AWS – apart from the two headphone jacks – are located on the rear panels of the console. The

headphone sockets are located on the Centre Section knee panel.

The console rear panel is fitted with a label which identifies all the connections on the connector panel, and provides the

pinout for each one (the detail is shown opposite). This information is also provided in the Appendices section of this

manual.

All connections are balanced.

All 25-way D-type connectors use screw pillars that utilise the UNC-440 thread.

See the appendices for the pinouts of all audio connectors.

Connecting a Patchbay

The AWS may, of course, be fully or partially integrated to an external patchbay. 3rd party options are available, and SSL

can provide patchbay solutions as cost options – contact your local SSL distributor for further information.

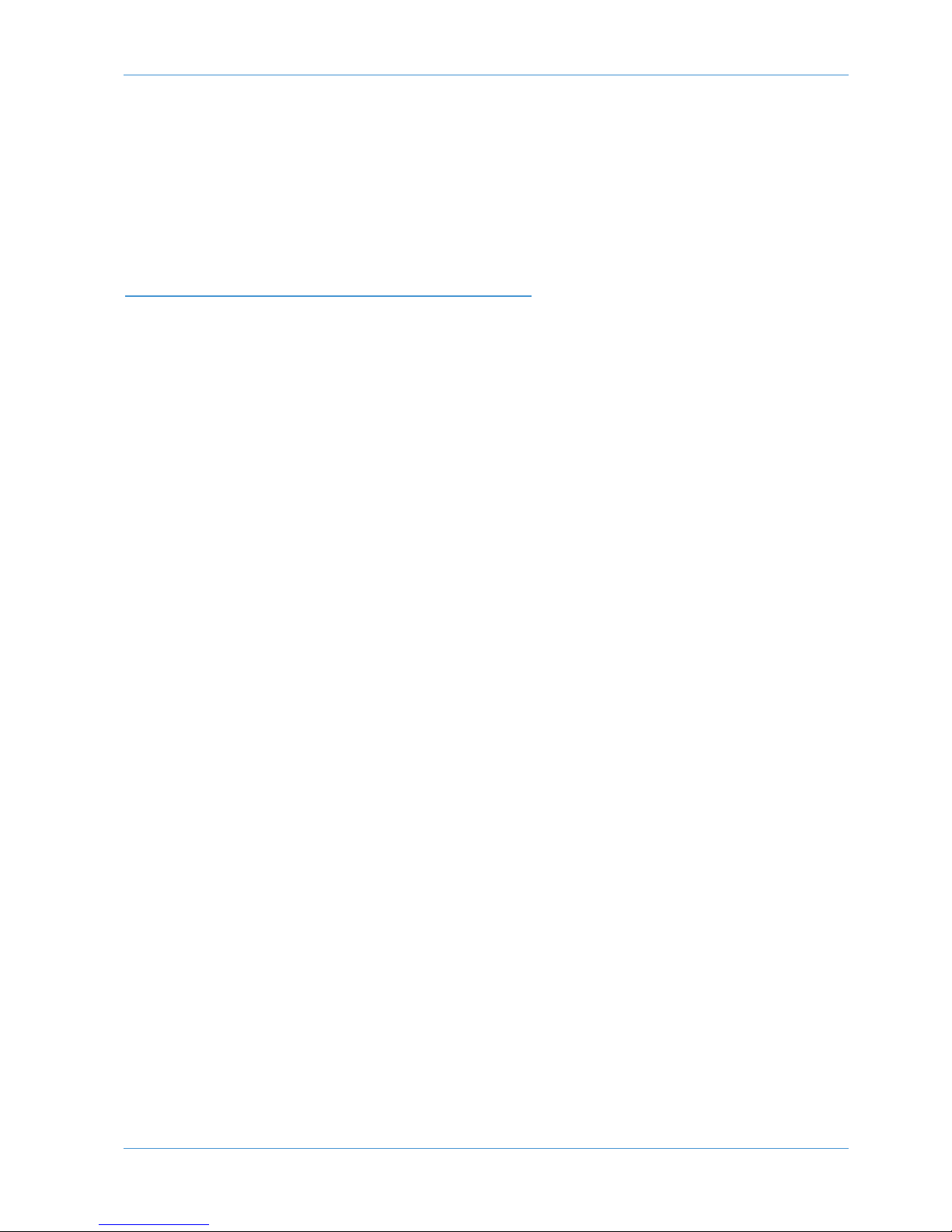

AWS 924 Patchbay Layout Example:

i

Studio Integration

AWS 924-948 Owner’s Manual Page 1-5

Title:

Client:

Sheet:

Revision:

Drawn by:

Date:

21/09/10

GC

AWS 924 Patch layout proposal

Standard Configuration

924 0.1

Solid State Logic

SOUND V SIION

Notes:

1. Patchrow AB is isolated

2. D31 is linked to C33, 35, 37, 39

3. D32 is linked to C34, 36, 38, 40

4. J31 is linked to J32

5. Links at G33–36, G37–40, J33–36,

J37–40, K33–36, K37–40,

Normalling Information:

Fully normalled: AB 1–24, JK 29

No normalling: AB 25–48, GH 33–40, JK 33–40

All other jacks are half-normalled

1

234

FX IN

L

R

CUE A

L

R

CUE B FX SENDS

1234L RLR

ECHO RETURN IN

1

L 1R 2L 2R 3L 3R 4L 4R

FX OUT

1

L 1R 2L 2R 3L 3R 4L 4R

1L 1R 2L 2R 3L 3R 4L 4R

1

L 1R 2L 2R 3L 3R 4L 4R

EXT B IN

STEREO REPLAY

R

EC

INSERT

R

EC

OUTPUT

LRL

RETURN

R

M

IX

INSERT

M

IX

OUTPUT

L

RETURN

R

DIST IN

LR

M

IX DISTRIBUTION OUT

LRL RL RL R

1L 1R 2L 2R 3L 3R 4L 4R

8 TK RECORDER IN

T

RACK BUS OUT

12345678

12345678

EXT A 6TK 4

L R C LFE LS RS

EXT A 6TK 3

L R C LFE LS RS

EXT A 6TK 2

L R C LFE LS RS

EXT A 6TK 1

L R C LFE LS RS

L

R C LFE LS RS

L

R C LFE LS RS

L

R C LFE LS RS

6 TRACK REPLAY 1

L

R C LFE LS RS

6 TRACK REPLAY 2 6 TRACK REPLAY 3 6 TRACK REPLAY 4

MAIN LS B

L

R

MINI BMAIN LS A

AMP IN

L R C LFE LS RS

L

R

MINI A

L

R

AMP INAMP IN

L

R

AMP IN

L

R C LFE LS RS

L R C LFE LS RS

L

R C LFE LS RS

1

7 18 19 20 21 22 23 249 10 11 12 13 14 15 161 2345678 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48

17 18 19 20 21 22 23 249 10 11 12 13 14 15 161 2345678 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48

DIRECT OUTPUTS

9

10 11 12 13 14 15 161 2 3 4 5 6 7 8 17 18 19 20 21 22 23 24

CHANNEL INSERT SENDS

1

7 18 19 20 21 22 23 249 10 11 12 13 14 15 161 2345678 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48

17 18 19 20 21 22 23 249 10 11 12 13 14 15 161 2345678 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48

1

7 18 19 20 21 22 23 249 10 11 12 13 14 15 161 2345678 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48

17 18 19 20 21 22 23 249 10 11 12 13 14 15 161 2345678 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48

17 18 19 20 21 22 23 249 10 11 12 13 14 15 161 2345678 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48

17 18 19 20 21 22 23 249 10 11 12 13 14 15 161 2345678 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48

MIC LINES USER OPTION

9 10 11 12 13 14 15 161 2 3 4 5 6 7 8 17 18 19 20 21 22 23 24 9 10 11 12 13 14 15 161 2 3 4 5 6 7 8 17 18 19 20 21 22 23 24

CHANNEL MIC INPUTS

9 10 11 12 13 14 15 161 2 3 4 5 6 7 8 17 18 19 20 21 22 23 24 9 10 11 12 13 14 15 161 2 3 4 5 6 7 8 17 18 19 20 21 22 23 24

D

AW OUTPUTS

9 10 11 12 13 14 15 161 2 3 4 5 6 7 8 17 18 19 20 21 22 23 24

CHANNEL LINE INPUTS

DAW INPUTS

9 10 11 12 13 14 15 161 2 3 4 5 6 7 8 17 18 19 20 21 22 23 24

CHANNEL INSERT RETURNS

I

N

LSN

O

UT

LSN

O

UT

T/B OSC

17 18 19 20 21 22 23 249 10 11 12 13 14 15 161 2345678 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48

17 18 19 20 21 22 23 249 10 11 12 13 14 15 161 2345678 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48

L

RLR

F/B A OUT F/B B OUT

L

R

AMP A

L

R

AMP B

MONITOR INSERT SEND

Lt Rt

DECODER

MONITOR INSERT RTN

L R C LFE LS RS

Lt Rt

ENCODER

L

R C LFE LS RS

USER OPTION

A

B

C

D

E

F

G

H

J

K

9 10 11 12 13 14 15 161 2 3 4 5 6 7 8 17 18 19 20 21 22 23 24

9 10 11 12 13 14 15 161 2 3 4 5 6 7 8 17 18 19 20 21 22 23 24

9 10 11 12 13 14 15 161 2 3 4 5 6 7 8 17 18 19 20 21 22 23 24

CUE A 12 34

BUS INJECT IN

FXCUE B

Page 32

Patchbay Guidelines

Instrument Inputs (AWS 924 Only)

It is not recommended that the ‘Instrument’ inputs are broken out to a patchbay. These inputs are unbalanced and have a

high input impedance so, to help avoid the pickup of noise and interference, cable lengths should be kept at short as possible.

Line Level Input/Outputs

All other analogue inputs and outputs can be connected via a patchbay. It is recommended that the cable shield is connected

at the console end and disconnected at the patch row to avoid ground loops. Wiring to the installation should normally have

t

he shield connected to the patch row. The shield connection of all jacks should be linked together (note that patch rows

with solid metal front panels will automatically do this) and then linked to a common star point on the patchbay. This

starpoint can then be returned – via a thick grounding cable (6mm sq. or greater) – to the chassis stud on the rear of the

AWS console. This will reduce the risk of earth loops within the installation.

The screen pins of all analogue inputs and outputs – with the exception of the microphone inputs – are connected directly to

the chassis of the AWS924/48.

Mic Inputs

If Microphone inputs are to be connected via a patchbay, the type of patch-row used should be of the insulated variety

where the jack screens are not connected to the main body of the patch-row – there are commercially available patch-rows

that meet this requirement. The ground connection from each microphone must be linked through the patch jacks to the

XLR on the back of the console without interruption.

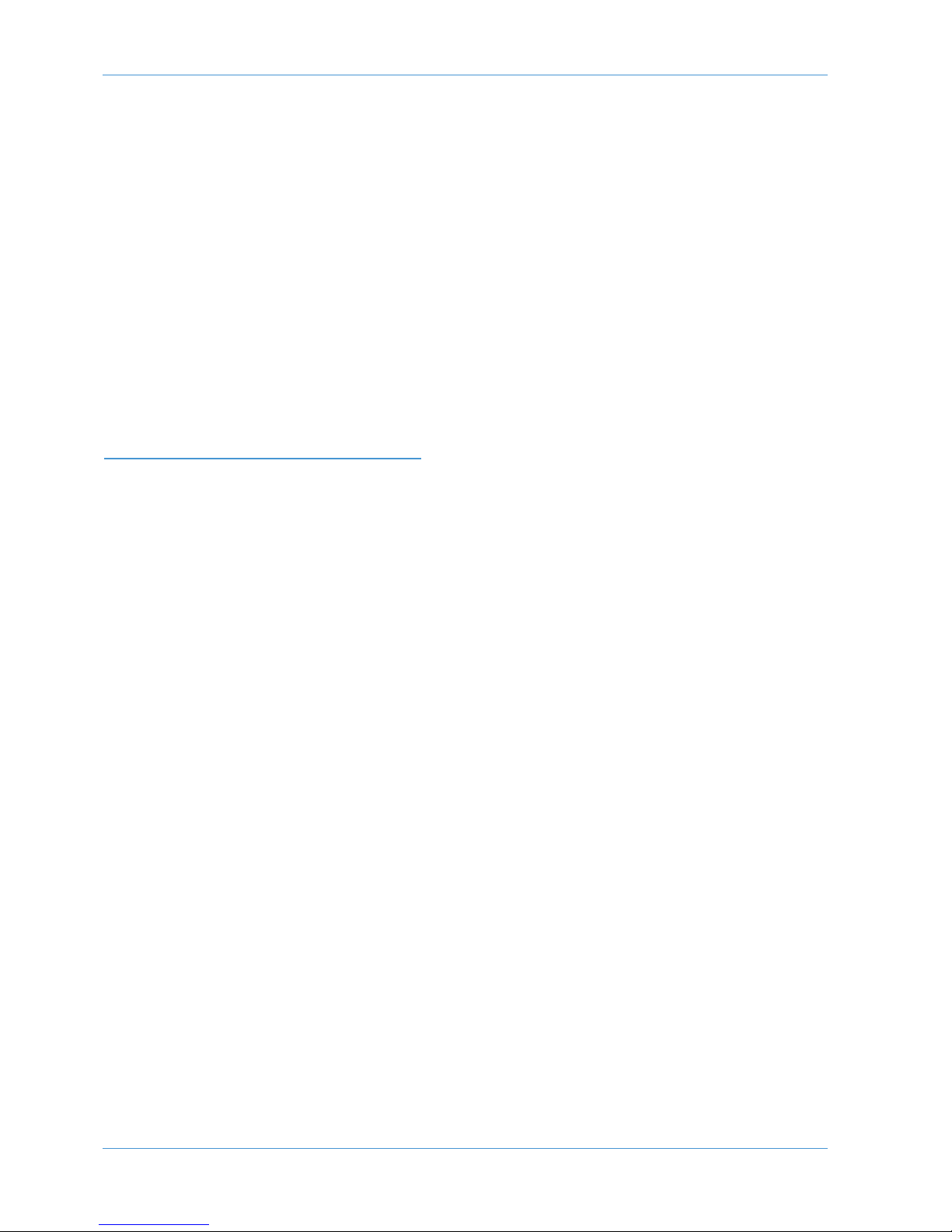

AWS948 Patchbay layout Example:

Studio Integration

Page 1-6 AWS 924-948 Owner’s Manual

Title:

Client:

Sheet:

Revision:

Drawn by:

Date:

14/09/10

GC

AWS 948 Patch layout proposal

Standard Configuration

948 0.1

Solid State Logic

SOUND V SIION

MAIN LS B

L

R

M

INI B

MAIN LS A

AMP IN

L R C LFE LS RS

L

R

M

INI A

LR

AMP INAMP IN

LR

AMP IN

L R C LFE LS RS

L R C LFE LS RS

L R C LFE LS RS

17 18 19 20 21 22 23 249 10 11 12 13 14 15 161 2345678 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48

17 18 19 20 21 22 23 249 10 11 12 13 14 15 161 2345678 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48

17 18 19 20 21 22 23 249 10 11 12 13 14 15 161 2345678 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48

1

7 18 19 20 21 22 23 249 10 11 12 13 14 15 161 2345678 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48

DIRECT OUTPUTS

9 10 11 12 13 14 15 161 2 3 4 5 6 7 8 17 18 19 20 21 22 23 24

CHANNEL INSERT SENDS

17 18 19 20 21 22 23 249 10 11 12 13 14 15 161 2345678 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48

1

7 18 19 20 21 22 23 249 10 11 12 13 14 15 161 2345678 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48

1

7 18 19 20 21 22 23 249 10 11 12 13 14 15 161 2345678 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48

1

7 18 19 20 21 22 23 249 10 11 12 13 14 15 161 2345678 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48

1

7 18 19 20 21 22 23 249 10 11 12 13 14 15 161 2345678 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48

1

7 18 19 20 21 22 23 249 10 11 12 13 14 15 161 2345678 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48

MIC LINES USER OPTION

9

10 11 12 13 14 15 161 2 3 4 5 6 7 8 17 18 19 20 21 22 23 24 9 10 11 12 13 14 15 161 2 3 4 5 6 7 8 17 18 19 20 21 22 23 24

CHANNEL MIC INPUTS

9 10 11 12 13 14 15 161 2 3 4 5 6 7 8 17 18 19 20 21 22 23 24 9 10 11 12 13 14 15 161 2 3 4 5 6 7 8 17 18 19 20 21 22 23 24

DAW OUTPUTS

9 10 11 12 13 14 15 161 2 3 4 5 6 7 8 17 18 19 20 21 22 23 24

CHANNEL LINE INPUTS

DAW INPUTS

9

10 11 12 13 14 15 161 2 3 4 5 6 7 8 17 18 19 20 21 22 23 24

CHANNEL INSERT RETURNS

REC

1234

FX IN

LR

CUE ALRCUE B FX SENDS

IN

LSN

O

UT

L

SN

O

UT

T

/B OSC

1

234L RLR

5L 5R 6L 6R 7L 7R 8L 8R1L 1R 2L 2R 3L 3R 4L 4R 9L 9R 10L 10R 11L 11R 12L 12R 17L 17R 18L 18R 19L 19R 20L 20R13L 13R 14L 14R 15L 15R 16L 16R 21L 21R 22L 22R 23L 23R 24L 24R

5L 5R 6L 6R 7L 7R 8L 8R1L 1R 2L 2R 3L 3R 4L 4R 9L 9R 10L 10R 11L 11R 12L 12R 17L 17R 18L 18R 19L 19R 20L 20R13L 13R 14L 14R 15L 15R 16L 16R 21L 21R 22L 22R 23L 23R 24L 24R

17 18 19 20 21 22 23 249 10 11 12 13 14 15 161 2345678 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48

17 18 19 20 21 22 23 249 10 11 12 13 14 15 161 2345678 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48

EXT A 6TK 4

L

R C LFE LS RS

EXT A 6TK 3

L

R C LFE LS RS

EXT A 6TK 2

L

R C LFE LS RS

EXT A 6TK 1

L

R C LFE LS RS

ECHO RETURN IN

L R C LFE LS RSL R C LFE LS RSL R C LFE LS RS

6 TRACK REPLAY 1

L R C LFE LS RS

6 TRACK REPLAY 2 6 TRACK REPLAY 3 6 TRACK REPLAY 4

INSERT

REC

OUTPUT

LRL

RETURN

R

MIX

INSERT

MIX

OUTPUT

L

RETURN

R

DIST IN

LR

1L 1R 2L 2R 3L 3R 4L 4R

F

X OUT

1

L 1R 2L 2R 3L 3R 4L 4R

L

RLR

F

/B A OUT F/B B OUT

LR

AMP ALRAMP B

C

UE A

1

234

BUS INJECT IN

F

X

C

UE B

MIX DISTRIBUTION OUT

LRL RL RL R

1L 1R 2L 2R 3L 3R 4L 4R

MONITOR INSERT SEND

Lt Rt

DECODER

MONITOR INSERT RTN

L R C LFE LS RS

Lt Rt

ENCODER

L R C LFE LS RS

8 TK RECORDER IN

TRACK BUS OUT

12345678

1 2 3 4 5 6 7 8 1L 1R 2L 2R 3L 3R 4L 4R

1L 1R 2L 2R 3L 3R 4L 4R

EXT B IN

STEREO REPLAY

USER OPTION

33 34 35 36 37 38 39 4025 26 27 28 29 30 31 32 41 42 43 44 45 46 47 48

5L 5R 6L 6R 7L 7R 8L 8R1L 1R 2L 2R 3L 3R 4L 4R 9L 9R 10L 10R 11L 11R 12L 12R 17L 17R 18L 18R 19L 19R 20L 20R13L 13R 14L 14R 15L 15R 16L 16R 21L 21R 22L 22R 23L 23R 24L 24R

A

B

C

D

E

F

G

H

J

K

L

M

Notes:

1. Patchrow AB is isolated

2. K7 is linked to J9, 11, 13, 15

3. K8 is linked to J10, 12, 14, 16

4. L41 is linked to L42

5. Links at J33–36, J37–40,L33–36,

L37–40, M33–36, M37–40,

Normalling Information:

Fully normalled: AB 1–24, LM 29

No normalling: AB 25–48, LK 33–40, LM 33–40

All other jacks are half-normalled

Page 33

DAW CONNECTION

The AWS console communicates with a DAW directly via Ethernet or via three MIDI ports. To use the Ethernet option a

third party ipMIDI software driver must be installed on the DAW computer. Registered owners can download this from

t

he SSL website: www.update.solidstatelogic.com. Using these methods of communication allows the AWS to be

used with a wide variety of DAW applications on a wide variety of platforms. The AWS uses Mackie control or a ‘HUI’

c

ompatible protocol, and so any DAW program that can be configured to use three HUI devices can access the full power

of the AWS.

Please refer to your DAW manual for details on how to configure the DAW application for AWS under Mackie or HUI

control.

Overview

In normal operation the AWS uses an Ethernet connection for DAW control and the SSL AWS Remote for session

management. The next section describes how to download and install the ipMIDI driver and AWS Remote on Macintosh

and PC.

Optionally the AWS can use a standard MIDI connection between the AWS console and your DAW using a multi port MIDI

interface. In this mode only one DAW layer can be configured. The console communicates with the DAW via the MIDI ports

located on the rear of the console – details are provided at the end of this section.

Installing the ipMIDI driver and AWS Remote

Download on to your workstation computer either the AWS923-948_Mac_Support.dmg disk image (Macintosh) or the

AWS923-948_Win_Support.zip file (Windows). These contain the AWS Remote and ipMIDI applications and the latest

version of the installation instructions:

www.update.solidstatelogic.com/support/consoles/aws/downloads.asp

System Requirements for your workstation computer: AWS Remote is a Java application. It will run under Java Version 5

or higher. ipMIDI is compatible with Windows 2000 (maximum 9 MIDI ports), XP, Vista and Windows 7, and Macintosh

OS X 10.4 upwards.

Software Installation (Macintosh)

Mount the AWS924-948_Mac_Support.dmg disk image and open it.

AWS Remote: Double-click on the AWS Remote application to install.

ipMIDI: Double click on the ipMIDI.pkg file to run the installation program. Note that you will be asked to log out and in

again once you have completed the installation. Once you have logged back in open Audio MIDI Setup, select the MIDI tab

and double click on the ipMIDI icon. Set the number of MIDI ports to 10 in the resulting pop-up.

If you are upgrading an older copy of ipMIDI you must uninstall it before running the installer. To uninstall ipMIDI simply

delete: </Library/Audio/MIDI Drivers/ipMIDIDriver.bundle>. You should empty the Trash after deleting the bundle file

before running the installer.

DAW Connection

AWS 924-948 Owner’s Manual Page 1-7

Page 34

Software Installation (PC)

Open the AWS924-948_Win_Support.zip archive.

AWS Remote: Double click on AWS924-948Remote.exe to install the program.

ipMIDI: Run the setupipmidi_1.8.exe application (note that the last part of the name may change depending on the version

you are installing) by double clicking on it. Note that you will have to restart the computer at the end of the setup process.

Once the computer has restarted right click on the ipMIDI icon in the task bar and set the number of MIDI ports to 10 in

the resulting pop-up.

If you are upgrading an older copy of ipMIDI you must uninstall it (using Add/Remove programs) before running the installer.

Make and Configure the Network Connection

The AWS Remote software is designed to communicate with your workstation over Ethernet using the ipMIDI driver to

emulate a multiport MIDI interface. The ipMIDI driver enables your workstation to send and receive MIDI control data via

a network connection. Using Ethernet ensures the fastest possible communication between your workstation computer and

AWS. The standard installation uses an RJ45 crossover network cable (not supplied) to connect the console’s network

connector directly to a separate network port on your workstation computer using the console’s default fixed IP address

of 192.168.1.2. Note that many computer adaptor cards will autosense a direct connection negating the need for a crossover

cable. If you are unsure whether your workstation computer’s network adapter has this functionality, please use a crossover

rather than a pin to pin cable.

It is possible to connect AWS to a larger network which incorporates multiple computers and to enable dynamic (DHCP)

addressing. These configurations need special consideration. Please see the notes at the end of these instructions for details.

Direct Network Connection (Macintosh)

Please note that currently OS X does not allow two ports to be used for IP traffic. As such, the connection to your main

network will not be available while the AWS is connected.

To simplify the process of switching between networks, it is recommended that you create a new network Location for

the AWS in network preferences. Another Location (‘internet’ for example) could be created to enable connection to the

internet. This would use the network settings provided by your Internet Service Provider or network administrator. You

can easily switch between network Locations by going to the Apple Menu and scrolling down to Location.

IP Network

Workstation Computer

N

etwork Connection

N

etwork

AWS Console

Network 1

Network 2

USB

DAW Connection

Page 1-8 AWS 924-948 Owner’s Manual

Page 35

• Using an RJ45 cable, make a direct network connection between the network port on your AWS to a network port

o

n your workstation computer and check that the IP address is set to FIXED in the console’s

SSL > MISC > NET menu.

• Open System Preferences and click on Network. Create a new location by clicking where it says Location, scroll down

to Edit Locations and click the ‘+’ sign. Name the new location AWS.

• Next, select the Ethernet port which is connected your AWS and configure as shown below:

• If your Macintosh features multiple network ports, you should set the priority of these so that the Ethernet port

connected to your AWS is at the top of the list. To do this, choose Set Service Order from the Actions pop–up menu:

DAW Connection

AWS 924-948 Owner’s Manual Page 1-9

Page 36

• Now drag the port connected to the AWS to the top of the list (in our example this port is Ethernet 2):

• Now click OK then Apply.

• Alternatively, if you have already created a separate Location for your existing network you can simply delete the

unused ports (Airport, Firewire) from the AWS location so that only the network port connected to AWS is

remaining.

DAW Connection

Page 1-10 AWS 924-948 Owner’s Manual

Page 37

Direct Network Connection (PC)

• Double click on Network Connections in Start/Control Panel. Right click on the network adapter connected to your

AWS (likely to be called “Local Area Connection”). Select Properties.

• Select Internet Protocol (TCP/IP) and Properties.

• Next, configure the adapter as shown below:

• Click on OK on both windows to save. Back in your network connection list, right click on your adaptor and ensure

that it is enabled. If it is disabled, the enable option will appear in the list. Click on enable.

DAW Connection

AWS 924-948 Owner’s Manual Page 1-11

Page 38

Enabling ipMIDI on your AWS

In the SSL > MISC > SETUP menu, toggle the ‘MIDI connects via:’ setting to ‘Network’. Your console will now

communicate with your workstation via Ethernet. With ‘MIDI connects via:’ set to ‘MIDI ports’, AWS will communicate with

your workstation via the conventional MIDI connectors on the rear of your console.

You will need to reboot the console after changing this option.

Also in the SSL > MISC > SETUP menu, ensure that the ‘DAW’ option (workstation layer 1) and DAW2 (workstation

layer 2) are set to match your workstation or workstations if you are using the second layer. Please note that you will need

t

o restart the console after making a change to the DAW layer options.

Finding the Console on the AWS Remote Application

Launch AWS Remote on your workstation. If you only have one AWS console on the network, AWS Remote will

automatically locate the console and the message ‘AWS 948-924 SN xxxxx is online’ (where xxxxx is the ID of the

console) will be shown in green text in the bottom left hand corner of the browser:

If you have multiple AWS consoles on the network or the AWS Remote browser did not automatically locate your console

‘No AWS 924-948 connected’ will be shown in red text. In this instance, click on the find icon . If the list is empty,

click on Find, select the console you wish to connect to and click on select.

If your console does not appear in the list, it suggests you have a network related issue. Please follow the steps in the

network trouble shooting section at the end of this document to resolve the issue.

Once you have made this selection, the AWS Remote will automatically connect to the selected console and display the

‘AWS 948-924 SN xxxxx is online’ message. To connect to a different console, click on the find icon and

change your selection.

DAW Connection

Page 1-12 AWS 924-948 Owner’s Manual

Page 39

Setting Your Workstation(s) to Communicate via ipMIDI

The AWS software uses 10 virtual MIDI ports which are pre-assigned as follows:

* Note that MIDI port 4 or ipMiDI port 7 can be used for MTC input, allowing MTC to be connected from systems (such as

RADAR) that do not support the ipMIDI driver. MTC should only be routed to one port at a time.

• Note that there are now two switchable workstation layers allowing independent workstations to be interfaced.

Once configured, you can switch between the two layers using the console’s SSL > DAW menu. Port 7: If your

console is equipped with SSL automation, this port is used to feed SSL automation with MTC.

• Port 8: Used for the import of legacy SysEx TR and SSL automation data saved under earlier software versions.

• Port 9-10: Mapped to the conventional MIDI connectors on the rear of the console allowing connection of a keyboard

or other MIDI device to your DAW via ipMIDI .

To select which DAW is assigned to each layer go to SSL > MISC > SETUP on your console and select the following:

DAW 1: select from Protools HUI / Logic / Logic Handshake / Nuendo / Digital Performer / Sonar

DAW 2: select from Protools HUI / Logic / Logic Handshake / Nuendo / Digital Performer / Sonar / None

After making these changes the console should be restarted.

The MCU protocol supports automatic detection of connected control surfaces. To enable this select Logic Handshake.

Logic will then automatically detect the AWS. If you select Logic Handshake on both layers then Logic will detect 6 control

surfaces, which may not be what you want! The other protocols do not transmit handshaking messages.

To enable control of your workstation via HUI or MCU your workstation(s) must be configured to match the appropriate

layer in the list above. This is done using the MIDI Controller configuration page of your workstation.

The following pages show examples using Pro Tools 8 and Logic Pro 9.

P

ort

L

ayer

A

ssignment

P

ort

L

ayer

A

ssignment

1 1 Faders 1–8 7 – MTC/MMC input *

2 1 Faders 9–16 8 – SysEx

3 1 Faders 17–24 9 – AWS MIDI Port 1

4 2 Faders 1–8 10 – AWS MIDI Port 2

5 2 Faders 9–16

6 2 Faders 17–24

DAW Connection

AWS 924-948 Owner’s Manual Page 1-13

Page 40

Pro Tools 8

In the Setup menu, click on Peripherals and select the MIDI Controllers tab. Using MIDI controllers 1, 2 and 3, select HUI

as the MIDI controller Type and assign the MIDI ports for this layer’s DAW to the two MIDI controllers, as listed in the

table above. If Pro Tools has been assigned to Layer 1, the MIDI Controllers window should look like this:

If you have SSL automation, set the MTC generator port in the Synchronization tab to ipMIDI port 7 (or AWS MIDI port

4 if you are using the console MIDI ports):

Also, set the MMC MIDI port in the Machine Control tab to ipMIDI port 7 (or AWS MIDI port 4 if you are using the

console MIDI ports):

DAW Connection

Page 1-14 AWS 924-948 Owner’s Manual

Page 41

Logic Pro 9

When Logic is assigned to one of the two AWS workstation layers a Mackie Control together with a Mackie Control

Extender must be added to the Logic Pro Preferences/Control Surfaces Setup menu as shown below:

AWS Faders 1-8 are mapped to the Mackie Control ports along with the Master Fader and workstation Control function

switches. AWS Faders 9 -16 and 17-24 are mapped to the Mackie Control Extender ports. The actual ipMIDI ports used

will depend on which layer (or layers) Logic is assigned to. See the list of AWS MIDI port assignments for details. It is

essential that the layout shown is followed. If the physical arrangement is reversed, then the AWS faders will not map

correctly to the on-screen faders in Logic.

If the protocol is set to Logic Handshake, Logic should automatically detect the three virtual controllers which will be

shown in the Logic Setup menu (as shown above), with the appropriate AWS ipMIDI ports assigned. If Logic fails to detect

the control surfaces, then the controllers can be added manually via the New/Install menu and the appropriate MIDI Out

port and Input assigned. As described above, normally only one layer should be set to Logic Handshake.

Full details can be found in the online Logic Pro 8 Control Surfaces Support guide in the Logic Help Menu.

DAW Connection

AWS 924-948 Owner’s Manual Page 1-15

Page 42

Logic’s Click and ports environment layer selects the SUM of all of the ipMIDI input ports as its default MCU control data source.

This may lead to difficulties when using multiple DAW layers. To avoid Logic responding to MIDI messages intended for the

other DAW layer, the Click and Port MIDI port mapping should be changed from SUM to individual direct MIDI port assignment. The example below shows Logic on DAW layer 1:

Preferences/Control Surfaces Setup Menu

If you have SSL automation, set the MMC MIDI port in File/Project Settings/Synchronisation/MIDI to ipMIDI port 7 (or

AWS MIDI port 4 if you are using the console MIDI ports):

For other DAWs, please refer to the program’s manual for details about configuring MIDI controllers.

DAW Connection

Page 1-16 AWS 924-948 Owner’s Manual

Page 43

Network Troubleshooting

Most Ethernet adaptor cards have two LEDs associated with each port. The one indicates that the link is connected and

the other indicates network traffic. Please note that some Macintosh computers do not have external LEDs to indicate

status. Instead the link status is shown in the System Preferences/Network menu.

On your host workstation computer, confirm that the link LED is permanently illuminated. If it is not permanently illuminated,

it suggests you have a cabling error. In this instance please check the following:

• The RJ45 network connector on the console and on your workstation are fully inserted.

• If you are using a pin-pin cable to make a direct connection between your console and workstation, try replacing it

with a crossover cable.

• Try replacing the network cable.

• If you are not using a direct connection between your console and workstation using the default fixed IP address on

the console, please try this simple configuration to rule out issues with external routers and network switches. If the

link LED is illuminated, the next step is to confirm that the activity LED is illuminating periodically to show network

traffic. If it does not illuminate periodically check the following:

• If your workstation is not connected directly to your console using a crossover RJ45 cable and fixed IP addressing,

follow the installation instructions to configure this simple network configuration to rule out issues with any external

routers or network switches.

• Using the fixed default IP address on the console, check that the workstation has basic communications using ‘ping’:

Windows:

Select Run under the Start menu. In the resulting window enter cmd to launch the command prompt. In the

command prompt window type ping 192.168.1.2

Macintosh OSX:

Open a Finder window, select Applications, then Utilities, and double-click on Terminal. In the terminal window

enter ping –c4 192.168.1.2

In both cases your host computer will try to establish communications with your console. In the resultant terminal

text, check that the console responded to every message sent by your workstation.

DAW Connection

AWS 924-948 Owner’s Manual Page 1-17

Page 44

Larger Networks

To ensure minimum latency the ipMIDI driver uses broadcast UDP rather than TCP/IP. This means that:

• The network connection should be as short as possible and should only use routers that can support high data transfer

rates. Problems have been experienced with some domestic routers, particularly when used with Pro Tools.

• Because ipMIDI uses broadcast UDP packets, messages between one computer and AWS will be received by all other

computers on the network, potentially causing problems in installations with more than one AWS. The UDP packets

can be blocked by using a firewall router and connecting the main network to the WAN connector. The firewall can

then be configured to allow all traffic apart from UDP ports 21928 through 21947 which are used by ipMIDI and

(optionally) port 50081 which is used by the AWS Remote application. Most systems can be easily configured with a

direct connection between AWS and the controlling computer.

DAW Connection

Page 1-18 AWS 924-948 Owner’s Manual

Page 45

Assigning the AWS IP Address

When shipped from the factory, the AWS uses a fixed IP address of 192.168.1.2.

Using DHCP

Alternatively, dynamic (DHCP) address can be selected via the SSL > MISC > NET menu. The currently assigned address

is also shown in the MISC > ABOUT > NET menu. If your AWS is connected to the computer via a network switch or

router, it should be assigned a DHCP IP address; otherwise the fixed option should be used. If you have altered the IP

mode, you will need to restart your AWS for the change to take effect. A software restart option is available in the

SSL > MISC > NET menu.

Changing the Static IP Address

The default fixed IP address can be altered using the console diagnostic port. This should only be necessary where the

default address is already in use at an installation.

You will need a PC or Mac running terminal emulator software. Connect your computer’s serial port to the rear of the

console using a 9 way ‘D’ type extension cable. The pin out for the console’s 9 way ‘D’ type serial connector is shown below:

A standard male – female pin-to-pin 9-way D-type lead can be used for serial connection.

Set the terminal as follows: Baud rate 19200, 8 data bits, No parity, No start bit, 1 stop bit, Flow control Xon/Xoff

Press the ‘

Return

’ key (<CR>) and the terminal window should echo a ‘>’ if communication is established.

To set the IP address type the following (note that the spaces are required between the number groups):

ip<CR>