Page 1

Installation Guide

Page 2

Page 3

Solid State Logic

Digital Broadcast Console

Installation Guide

Version 1.2.0

82S6PC1010C

Page 4

C100 Installation Guide

Solid State Logic

S O U N D

||

V I S I O N

Begbroke, Oxford, England, OX5 1RU • +44 (0)1865 842300

320 West 46th Street, 2nd Floor, New York, NY 10036, USA • +1 (1) 212 315 1111

Suite 401, 5757 Wilshire Blvd, Los Angeles, CA 90036, USA • +1 (1) 323 549 9090

3-55-14 Sendagaya, Shibuya-Ku, Tokyo 151-0051, Japan • +81 (0)3 5474 1144

7 bis, rue de la Victoire, le Blanc Mesnil, Paris 93150, France • +33 (0)1 48 67 84 85

Via Timavo 34, 20124 Milano, Italy • +39 (0)39 2328 094

Visit SSL at URL: http://www.solid-state-logic.com

© Solid State Logic

All Rights reserved under International and Pan-American Copyright Conventions

C100, C200, C300, Centuri, C-SB StageBox, NetBridge, NiTech,

Solid State Logic and SSL are trademarks of Solid State Logic

All other product names and trademarks are the property of their respective owners

No part of this publication may be reproduced in any form or

by any means, whether mechanical or electronic, without the

written permission of Solid State Logic, Oxford, England

As research and development is a continual process, Solid State Logic reserves the right

to change the features and specifications described herein without notice or obligation

E&OE

Page 5

Contents

Introduction 2

1

Safety Considerations 3

2

Safety Warnings 4

E/FCC/WEEE Certification and Directives 5

C

Pre-Installation Information 6

3

Services Provided by SSL 6

Physical/Structural 7

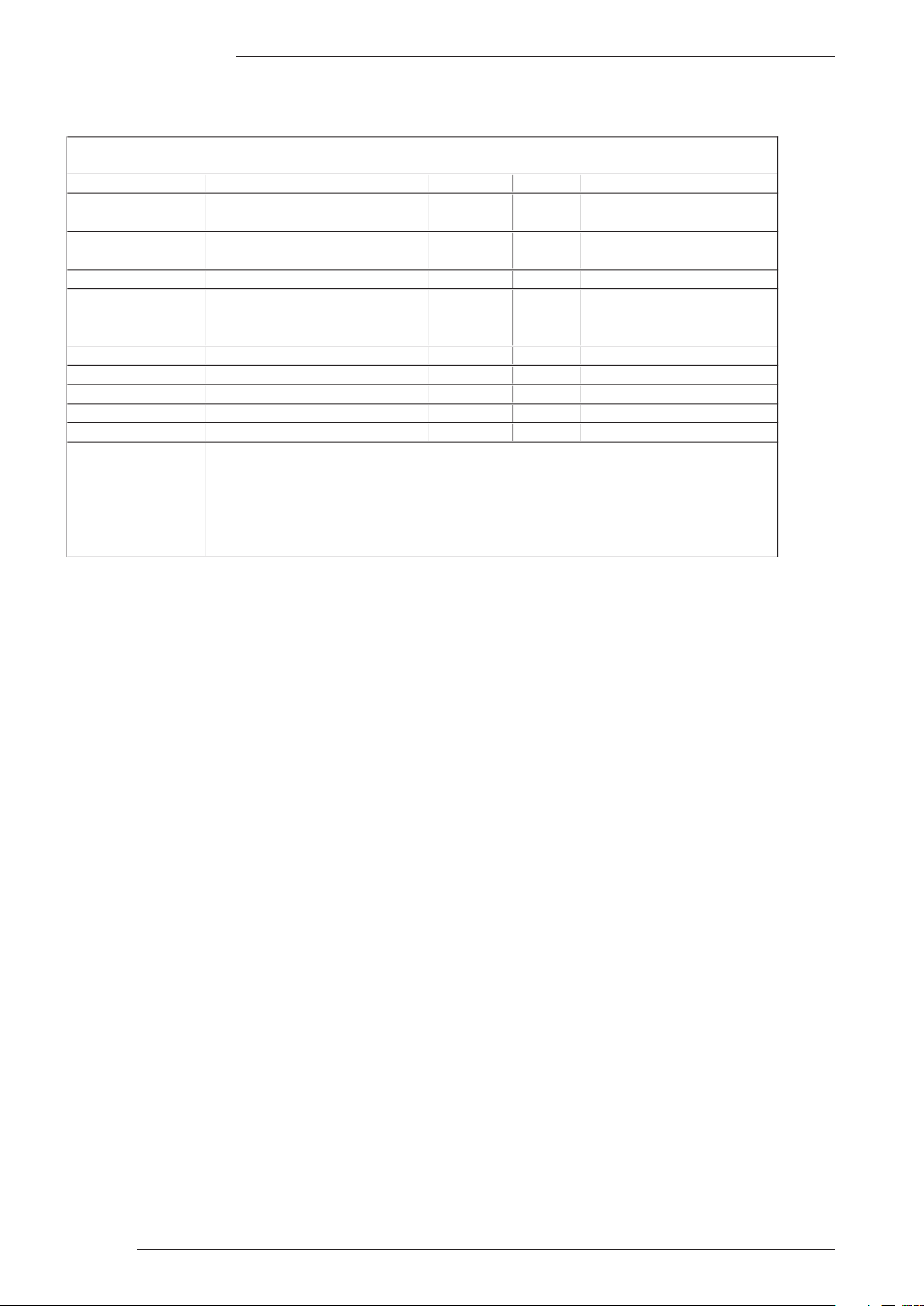

Console Footprint and Side Profile 8

Centuri and Stagebox Side View 10

Technical 11

4 System Components 13

Console Frame 13

The Centuri Processor 15

The Centuri Processor Cards 16

C-SB Stagebox (option) 21

MORSE (option) 21

NetBridge (option) 23

Script Tray (option) 25

Loudspeaker Shelf (option) 25

XGA Video Switcher 25

5 Installation 27

Connections 27

Earth Connection 27

Console Control 29

PSU Status 31

Sync 31

I/O – MicAmp Card 33

I/O – Analogue Card 33

I/O – Digital Card 35

I/O – MADI Card 35

GPI/O Card 37

C-SB Stagebox Wiring 39

Talkback and Oscillator 43

Phasescope and Meter Wiring 45

Appendices

A Equipment Specifications 47

B Connector Details 51

C Connector Pinouts: Console 53

Processor Crate 56

NetBridge 62

D Audio Interfacing 63

E Environmental Specification 65

F Stagebox Installation Requirements 67

G SSL Part Numbers by Description 69

Page 1

Page 6

C100 Installation Guide

Section 1 – Introduction

The object of this manual is to provide purchasers of the C100™ Console and Centuri™ Processor with

information in the following areas:

• Safety considerations

• Installation requirements

• Items supplied: – Main components and optional items

• Installation: – Physical assembly

– Electrical connections and cabling

– System options

• Specifications and Physical dimensions

• Pinouts of standard connectors

The information provided by this manual is relevant to all of the versions of the C100.

The aspects of the C100 which can be customised – frame size, channel layout, meter panel as examples – will be

fully documented in the Custom Specification information for a specific console.

The Custom Specification information, which details the actual console as built, will be found in Section 10 of

the console’s Service Manual.

Page 2

Page 7

ection 2

S

Safety Considerations

Section2 – Safety Considerations

This section contains definitions and warnings, and practical information to ensure a safe working environment.

Please take time to read this section before undertaking any installation work.

Definitions

‘Maintenance’

All maintenance must be carried out by fully trained personnel. Note: it is advisable to observe suitable ESD

precautions when maintenance to any part is undertaken.

‘Non-User Adjustments’

Adjustments or alterations to the equipment may affect the performance such that safety and/or

international compliance standards may no longer be met. Any such adjustments must therefore only be

carried out by fully trained personnel.

‘Users’

This equipment is designed for use solely by engineers and competent operators skilled in the use of

professional audio equipment.

‘Environment’

This product is a class A product intended to form an integrated component part of a professional audio

recording, mixing, TV, radio broadcast or similar studio wherein it will perform to specification providing

that it is installed according to professional practice.

Electrical Safety Warning

When installing or servicing any item of SSL equipment with power applied, when cover panels

are removed, HAZARDOUS CONDITIONS CAN EXIST.

These hazards include: High voltages

High energy stored in capacitors

High currents available from DC power busses

Hot component surfaces.

Any metal jewellery (watches, bracelets, neck-chains and rings) that could inadvertently come

into contact with uninsulated parts should always be removed before reaching inside powered

equipment.

Installation Instructions

Voltage Selection and Fusing

Although the majority of SSL equipment uses auto-ranging power supplies, some sub-systems have userselectable voltage inlets. Always confirm that the input mains voltage range is set correctly before applying

power. Always isolate the mains supply before changing the input range setting.

If it is ever necessary to replace a blown mains-fuse, then always use the correct rating and type of replacement.

If a correctly rated fuse continues to blow, then a fault exists and the cause should be investigated or the unit

returned to SSL for repair/replacement as appropriate.

Details of mains settings and correct fuse ratings can be found in Appendix A of this manual.

Page 3

Page 8

C100 Installation Guide

Safety Earth Connection

Any mains powered item of SSL equipment that is supplied with a 3-core mains lead (whether connectorised or

not) should always have the earth wire connected to the mains supply ground. This is the safety earth and

grounds the exposed metal parts of the racks and cases and should not be removed for any reason.

Mains Supply and Phases

SSL equipment is designed for connection to single-phase supplies with the Neutral conductor at earth potential

category TN – and is fitted with a protective fuse in the Live conductor only. It is not designed for use with

–

Phase (Live) and Neutral connections reversed or where the Neutral conductor is not at earth potential (TT or IT

supplies).

All mains powered assemblies must be connected to the same mains phase. In particular, note that as PSU

redundancy is standard, the two input leads must NOT be connected across different phases.

Mains cables will be coded with either of the following colour schemes:

1 or 2

LIVE: Brown Black

NEUTRAL: Blue White

EARTH: Yellow/Green Green

Mains Isolation and Over-Current Protection

An external disconnect device (switch) is required for this equipment which must be installed according to

current wiring regulations. A detachable power cord, if fitted to this equipment, is a suitable disconnect device;

otherwise an approved disconnect switch is required – the rating of which is defined in the product specification

(Appendix A) and on the equipment itself.

An external over-current protection device is required to protect the wiring to this equipment which must be

installed according to the current wiring regulations. The fusing or breaking-current is defined in the product

specification. In certain countries this function is supplied by use of a fused plug.

Some equipment (specifically units with PSU Redundancy) utilises multiple power sources. This is clearly

marked on the equipment. The finished installation must also be clearly marked to ensure that all sources of

power are removed before servicing begins.

Physical Safety

Most subsystems are too heavy for one person to lift. Take particular care when removing the computer chassis

from the equipment rack.

If the console trim is removed for any reason then there may be sharp edges exposed on the frame metalwork.

Page 4

Page 9

ection 2

S

Safety Considerations

CE Certification

Note that the majority of cables supplied with SSL equipment are fitted with ferrite rings at each end.

his is to comply with current European CE regulations and these ferrites should not be removed.

T

If any of the console metalwork is modified in any way – particularly the addition of holes for custom switches

etc. – this may the adversely affect the CE certification status of the product.

FCC Certification

The equipment which forms a C100/Centuri system has been tested and found to comply with the

limits for a Class A digital device, pursuant to part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is operated in a

commercial environment.

This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications. Operation of

this equipment in a residential area is likely to cause harmful interference in which case the user will be required

to correct the interference at his own expense.

Instructions for Disposal of WEEE by Users in the European Union

The symbol shown here, which is on the product or on its packaging, indicates that this product

must not be disposed of with other waste. Instead, it is the user’s responsibility to dispose of their

waste equipment by handing it over to a designated collection point for recycling of waste

electrical and electronic equipment. The separate collection and recycling of your waste

equipment at the time of disposal will help to conserve natural resources and ensure that it is

recycled in a manner that protects human health and the environment. For more information

about where you can drop off your waste equipment for recycling, please contact your local city

office, your household waste disposal service or where you purchased the product.

Page 5

Page 10

C100 Installation Guide

Section 3 – Pre Installation Information

Physical installation of the console is normally carried out by a specialised transportation company. In some

cases this will have been arranged by the local SSL office, in other cases by the facility.

The cables that run between console and processor can be shipped in advance of the console in a separate kit (the

pre-install kit). These cables should be installed by the facility engineers. Instructions for installing these cables

are found on pages 29 to 31 of this manual.

Note: Cables for the connection of ancillary functions, Meters, talkback, oscillator and any custom switches etc. are

not supplied by SSL and will need to be provided by the facility. See pages 43–45 for wiring information.

Before the console is installed all building work should be completed and the environment MUST be clean

otherwise the warranty will be rendered invalid.

Before commissioning can take place the following MUST be completed:

• Air Conditioning installed, tested, blown-through and working

• Lighting installed and tested

• Cable Trunking installed

• Wall and floor finishes completed

• Power Distribution installed and tested

• Cables installed and tested

• Monitor loudspeakers installed and working

• Other utilities (telephone, water etc.) available

Services provided by SSL

Commissioning

All C100 systems include on-site commissioning by an SSL engineer. This is usually expected to take from 2 to 4

days depending on system size, configuration and options. Large systems, or consoles split for shipment, may

require an additional 1–2 days of commissioning time.

You will be contacted by your local SSL office or agent shortly before delivery to arrange a commissioning date.

Training

Two days of standard operator training are provided with each C100 system. If required, this is scheduled to take

place immediately following the commissioning period and is usually carried out by the commissioning

engineer. A further day of advanced operator training is available at additional cost.

On-site maintenance training is also available at additional cost. This can be either one day for a basic overview

or two days for more advanced training.

Training should be requested at time of order. For all training, we recommend that no more than five persons

attend each session. If the use of an interpreter is necessary the training period may need to be extended (at

additional cost). Note that travel and subsistence costs are not normally included. Please contact SSL’s Training

Department at: support@solid-state-logic.com.

Warranty

All systems normally include 13 months warranty from date of shipment. This does not include consumable

items such as magnetic media, disks etc. Further details may be found in SSL’s Conditions of Trading (printed

on the reverse of all SSL invoices).

Page 6

Page 11

re Installation Information

Section 3

P

Physical Requirements

onsole Control Surface

C

The console control surface can be specified to have from 8 to 96 channels so the size and weight will vary

considerably. A dimensioned footprint drawing for each specific console control surface can be provided by SSL’s

Project Engineering Department. See page 8 for an example of a 32-channel footprint.

Consoles can be built with split points at any profile (at additional cost). The console can then be split for

shipment to simplify installation into client’s premises. Reassembly will be by SSL engineers.

Refer to Appendix A for weights and power consumption information.

Rack Mounting Equipment – Centuri, NetBridge and Stageboxes

The Centuri Processor is a 15U height chassis into which a range of I/O cards can be fitted. The system’s

processing and DSP resource is also housed in the Centuri rack. The Centuri is therefore fitted with cooling fans

and is expected to be housed in a separate ‘machine’ room.

A 19” equipment rack will need to be provided into which the Centuri Processor can be mounted. Note when

positioning the rack that cards are inserted into the Centuri Processor from both the front and the rear depending

on function. Clearance for access to cards must therefore be provided both in front of and behind the rack (see

page 10 for service clearance diagram).

NetBridge – which is an option – is a 2U high rack mounting unit.

Remotely located stageboxes (C-SBs) – which are also optional – may be specified. These are 14U rack units.

Note. Centuri, NetBridge and stagebox units MUST be supported on shelves and not only by the rack ears.

SSL can supply 39U 800mm deep equipment racks and shelves if requested (at additional cost). Other rack

heights are available to special order.

Acoustic Isolation

Because of the noise generated by cooling fans adequate noise isolation should exist between the machine and

control rooms/recording areas.

Noise figures for individual units are given in Appendix A.

Page 7

Page 12

C100 Installation Guide

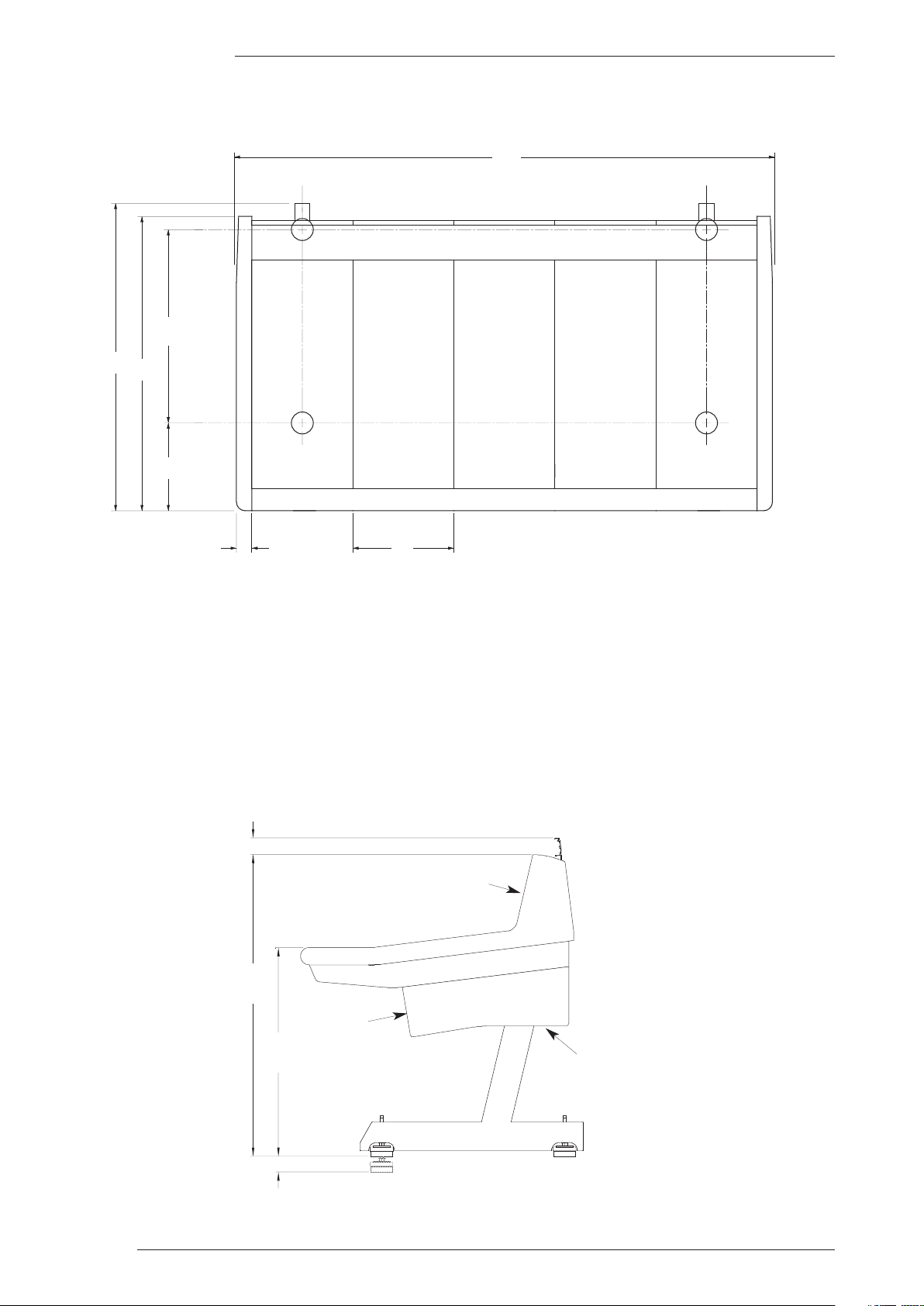

17 24 Master 91618

283

640

956

988

1776

334

25 32

53

32 Channel Footprint

Console legs can be located at any position along console beam. Maximum distance between legs

is 1,336mm (ie. four bays)

Side Profile Showing Service Access

80 min.

Top Trim

Meter

drive

cards

1056

Power

732

supplies

shown raised

Connector

Panels

Page 8

0-45

Page 13

re Installation Information

Section 3

Air Conditioning Requirements

Air conditioning will almost certainly be required for both the Machine and Control rooms in order to maintain

the temperature and humidity to within the required levels.

Power dissipation figures for console control surface and equipment rack are listed in Appendix A.

Appendix E contains the environmental specification for SSL equipment.

Cable Ducting

Cable ducting will be required between the console and the Machine room (as well as to any outboard racks and

the recording areas). The ducting provided should be of sufficient size such that approximately 50mm x 35mm

is available for console surface connection.

The connectors for all control and interface cables are located beneath the console’s Centre Section. The connector

panels are orientated so that cables will route towards the rear of the desk.

The mains input power connector will be located on a separate panel. This panel is usually positioned in a bay

adjacent to the Centre Section nearest to the centre of the console but may vary due to console layout.

P

Cable sets are available in 10, 16, 20, 25, 48 and 80m standard lengths. Sets longer than 16m are at additional cost.

Service Access

Access to all major electronic assemblies within the frame is either from the front or from beneath the console.

The meter LCD panels are retained by finger-screw fastener beneath the top trim. The top trim is designed to

hinge upwards to allow access to these screws. If the console is being built into restricted space – as in some

mobile installations – then always allow a minimum of 80mm clearance above the top trim (see opposite).

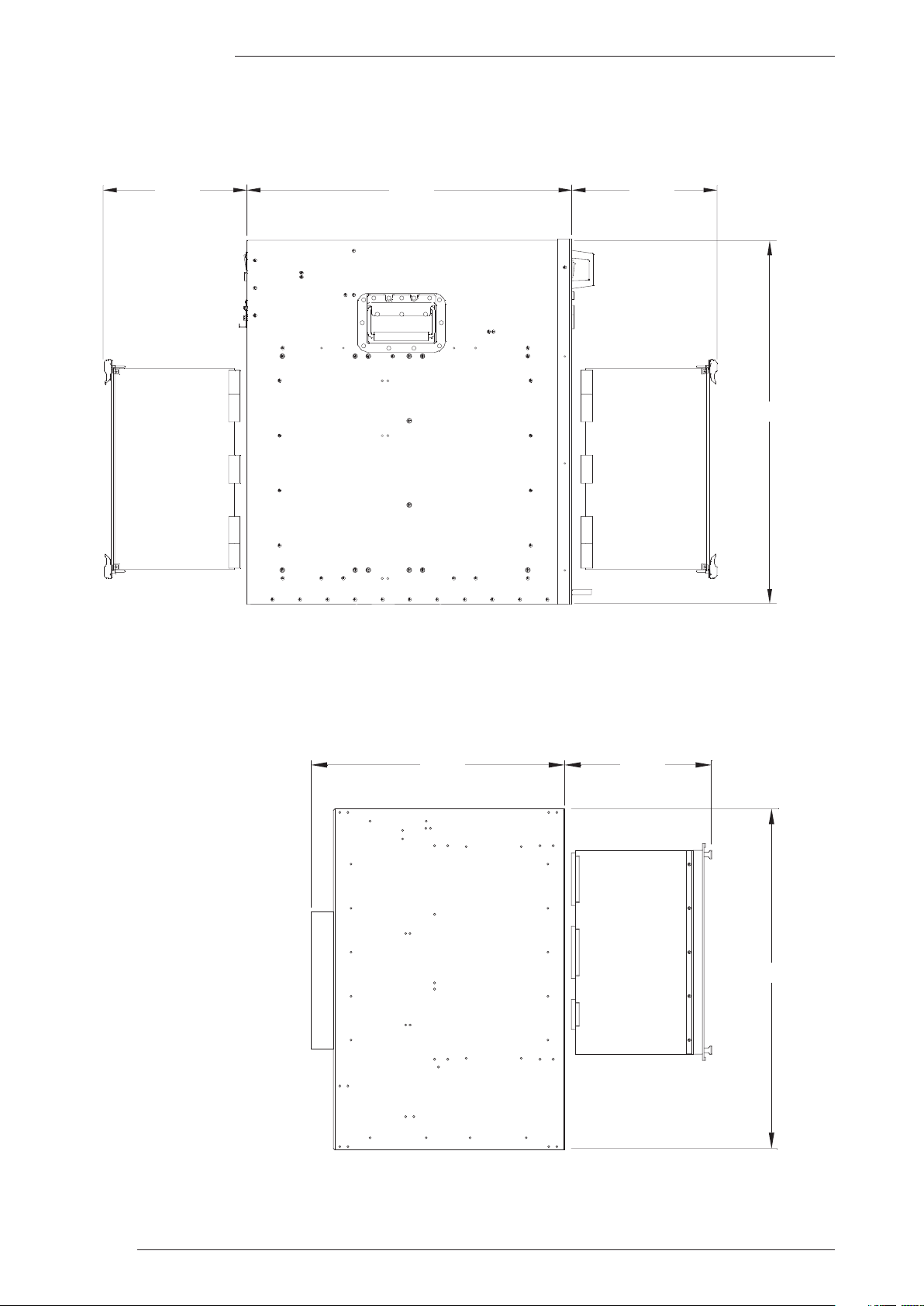

Sufficient clearance must be provided in front of and behind the rack into which the Centuri processor is

installed so that cards can easily be removed. See the drawing on page 10 for minimum clearances.

Page 9

Page 14

C100 Installation Guide

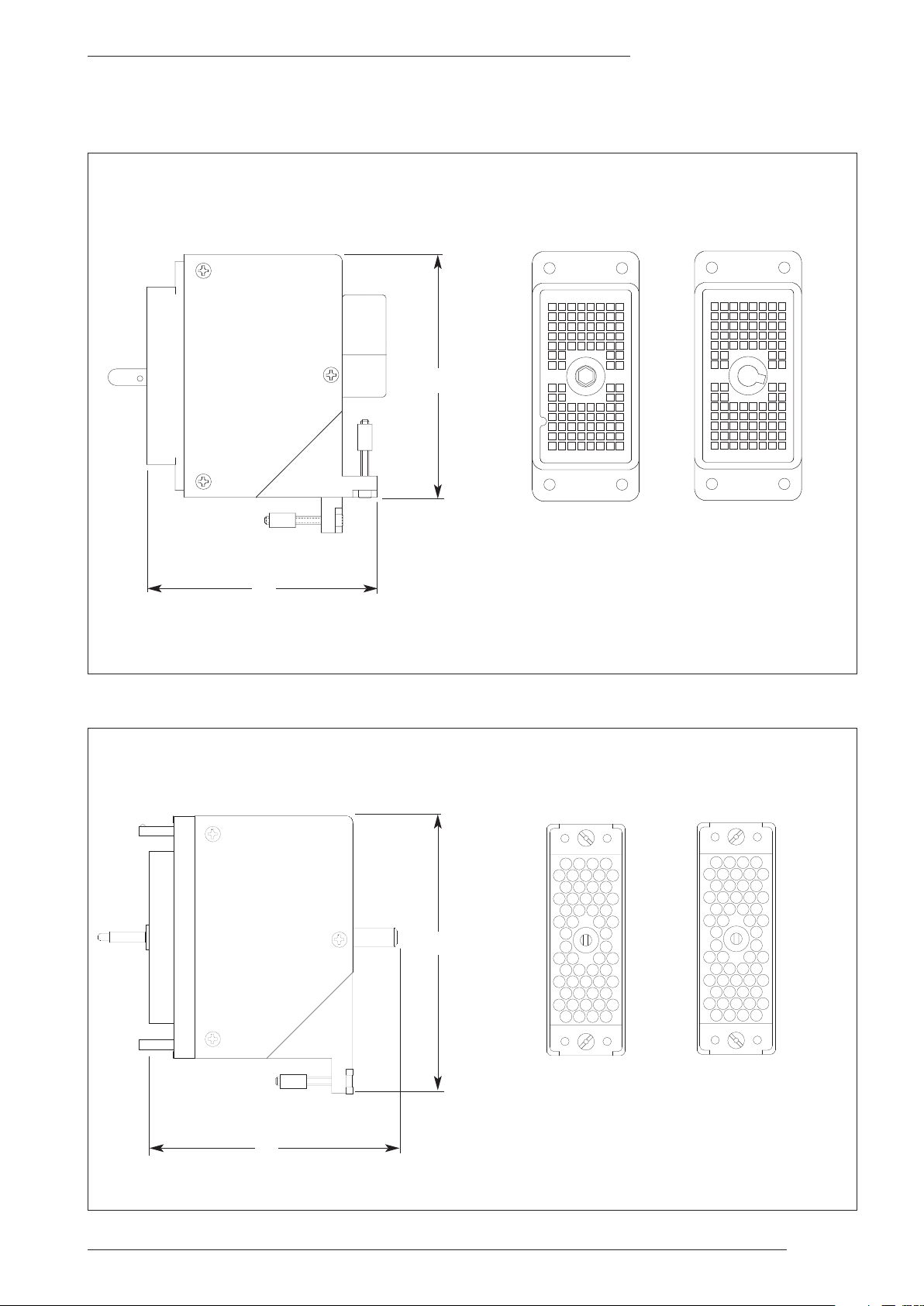

Centuri Processor Crate (side view) Showing Card Access

270

Rear

592 270

15U

Front

C-SB Crate (side view) Showing Card Access

462

270

14U

Page 10

Rear

Front

Dimensions in mm

Page 15

re Installation Information

Section 3

P

Technical Requirements

ideo Sync Source

V

The Centuri Processor requires a feed of video sync. Other sources – MIDI or wordclock etc. – cannot be used as

the sync reference.

he sync required is 75Ω 1V(pk-pk) black-and-burst video. The standard can be either PAL (625 line, 50Hz) ,

T

NTSC (525 line, 59.94Hz or 60Hz). Composite sync may also be used.

Many other studio peripherals (digital recorders, editors and all video picture recorders) will also require a feed

of video sync. Depending on the studio configuration, a suitable video distribution amplifier may also be

required.

Note : The Centuri processor does not provide internal sync generation.

Power Connections – Mains Input Voltage & Current

Both the console control surface and the Centuri processor rack are fitted with auto-sensing power supplies and

will function at any voltage from 90 to 250 volts without adjustment.

The console is supplied with one or more detachable mains leads. These leads are 2m in length and the cable

diameter is 11mm. The free ends of these leads are unterminated for connection to a suitable outlet.

The inrush current present when powering the console can be significant – typically ten times the steady current

– so the use of ‘slow’ or ‘motor ’ rated fuses/circuit-breakers is recommended.

NetBridge (which is a separate 2U unit – see page 23) is fitted with a voltage select switch for 230V or 115V

operation. Confirm that the voltage is correctly set before applying power – see page 23.

See Appendix A for equipment specifications.

Grounding

A standard system should not require any additional grounding over and above that supplied by a correctly

installed mains supply. All rack unit chassis are permanently bonded to mains earth. A permanent mains earth

connection via the mains inlet must be provided.

If, due to the quality of the mains wiring within an installation, it is deemed necessary to improve upon the

mains earthing, chassis ground connection points are provided as follows:

Centuri rack chassis ground can be accessed via a stud located on the rear panel.

Console chassis ground can be accessed via a stud located on the mains power connector panel.

All audio connectors, both analogue and digital, have their screen pins connected directly to the chassis at the

point of entry to comply with AES/EBU grounding and EMC standards.

Page 11

Page 16

C100 Installation Guide

PAN

AFL

PFL

ON

C

LR

MODE

A/B

< >

ATT

D

ELAY

I

NSER T

-20

-18

-15

-12-9-6-3-2-10

ATTACK

RELEASE

samples

fram es

ms

G

ATE/EXPAND

RELEASE

MAKE UP

THRESH OLD

RANG E

-20

-18

-15

-12-9-6-3-2-10

C

OM PRESS OR

RATIO

THRESH OLD

ATTACK

GAIN

CHO P

UOP

MIC

GAIN

GAIN

INPUT

TRIM

BALAN CE

ROU TING

AUX SEN DS

LFHFGAIN

GAINLFLMFQHMF

GAIN

GAIN

HF

EQ

FILTER

ASG

1

PGM

1

7

+

5+

3+1+

1

7-249-16

MO NO L

MO NO R

ALT

M/S

ØL

PGM

2ØRLISTEN

HPF

PAD

48V

S-LIM

ROU TE

TONE

IN P

PRE

MO NOINLISTEN

N-1

PRE

INP

IN

MO NO

TONE

T/B

EXT

2+M4+M

6+M

8+M

IN

IN

HOLD

EXP

S/C

GATE

INDELA Y

S/C

COM P

IN

SLOP E/Q

SLOP E/Q

NOTCH

NOTC H

PAR

PAREQIN

IN

H

FSL OPE

LFS LOPE

17139

5

1

21

AUTO

R

OUTE

C

H

S

ETTINGS

A

/BSET

F

REE

A

SSIGNGROUP

CLEAR

SET

ALLM

ULTIINC

<

Q

SWAP

C

OPY

1

123

4

567

8

9101112131415161718192021222324A1A2A3A4A5A6A7

A8

PGM1

PGM2

dB

∆t

34567

8

123

4

567

8

9101112131415161718192021222324A1A2A3A4A5A6A7

A8

PGM1

PGM2

dB∆t123

4

567

8

9101112131415161718192021222324A1A2A3A4A5A6A7

A8

PGM1

PGM2

dB

∆t

01236912

1

5

1

8

20

24

30

34

4

2

123

4

567

8

9101112131415161718192021222324A1A2A3A4A5A6A7

A8

PGM1

PGM2

dB

∆t

01236912

1

5

1

8

20

24

30

34

4

2

123

4

567

8

9101112131415161718192021222324A1A2A3A4A5A6A7

A8

PGM1

PGM2

dB

∆t

01236912

1

5

1

8

20

24

30

34

4

2

123

4

567

8

9101112131415161718192021222324A1A2A3A4A5A6A7

A8

PGM1

PGM2

dB

∆t

01236912

1

5

1

8

20

24

30

34

4

2

123

4

567

8

9101112131415161718192021222324A1A2A3A4A5A6A7

A8

PGM1

PGM2

dB

∆t

01236912

1

5

1

8

20

24

30

34

4

2

123

4

567

8

9101112131415161718192021222324A1A2A3A4A5A6A7

A8

PGM1

PGM2

dB

∆t

01236912

1

5

1

8

20

24

30

34

4201236912

1

5

1

8

20

24

30

34

4

2

A/B

< >

ATT

A/B

< >

ATT

A/B

< >

ATT

A/B

< >

ATT

A/B

< >

ATT

A/B

< >

ATT

A/B

< >

ATT

PAN

AFL

PFL

ON

C

LR

MODE

PAN

AFL

PFL

ON

C

LR

MODE

PAN

AFL

PFL

ON

C

LR

MODE

PAN

AFL

PFL

ON

C

LR

MODE

PAN

AFL

PFL

ON

C

LR

MODE

PAN

AFL

PFL

ON

C

LR

MODE

PAN

AFL

PFL

ON

C

LR

MODE

10•

5 •

0 •

5 •

10•

20•

30•

40•

50•

••

•

60 •

Protect

reset

layer

enable

o'ride

Remote

sel

0 •

-1 •

-2 •

-3 •

-6 •

-9 •

-12 •

-18 •

-20 •

-30 •

-42 •

SIG •

10 •

5 •

0 •

5 •

10 •

20 •

30 •

40 •

50 •

••

•

60 •

Protect

reset

layer

enable

o'ride

Remote

sel

0 •

-1 •

-2 •

-3 •

-6 •

-9 •

-12 •

-18 •

-20 •

-30 •

-42 •

SIG •

10 •

5 •

0 •

5 •

10 •

20 •

30 •

40 •

50 •

••

•

60 •

Protect

reset

layer

enable

o'ride

Remote

sel

0 •

-1 •

-2 •

-3 •

-6 •

-9 •

-12 •

-18 •

-20 •

-30 •

-42 •

SIG •

10 •

5 •

0 •

5 •

10 •

20 •

30 •

40 •

50 •

••

•

60 •

Protect

reset

layer

enable

o'ride

Remote

sel

0 •

-1 •

-2 •

-3 •

-6 •

-9 •

-12 •

-18 •

-20 •

-30 •

-42 •

SIG •

10 •

5 •

0 •

5 •

10 •

20 •

30 •

40 •

50 •

••

•

60 •

Protect

reset

layer

enable

o'ride

Remote

sel

0 •

-1 •

-2 •

-3 •

-6 •

-9 •

-12 •

-18 •

-20 •

-30 •

-42 •

SIG •

10 •5 •

0 •

5 •

10 •

20 •

30 •

40 •

50 •

••

•

60 •

P

rotect

r

esetlayerenable

o'ride

Remote

sel

0 •

-1 •

-

2 •

-3 •

-

6 •

-9 •

-

12 •

-18 •

-20 •

-

30 •

-42 •

SIG •

10 •5 •

0 •

5 •

10 •

20 •

30 •

40 •

50 •

••

•

60 •

P

rotect

r

esetlayerenable

o'ride

Remote

sel

0 •

-1 •

-

2 •

-3 •

-

6 •

-9 •

-

12 •

-18 •

-20 •

-

30 •

-42 •

SIG •

10 •5 •

0 •

5 •

10 •

20 •

30 •

40 •

50 •

••

•

60 •

P

rotect

r

esetlayerenable

o'ride

Remote

sel

0 •

-1 •

-

2 •

-3 •

-

6 •

-9 •

-

12 •

-18 •

-20 •

-

30 •

-42 •

SIG •

UBus 1

Chan: 17

P

OST PROC

Ins:

CH1Snd

A

lt:None

2

01236912

1

5

1

8

20

24

30

34

4

2

DCart C

Chan: 18

I

NPUT

Ins:

CH1Snd

A

lt:None

EVS 6

Chan: 19

PRE

PROC

Ins:

CH1Snd

A

lt:None

Mic A-1

Chan: 20

P

RE FADER

Ins:

CH1Snd

A

lt:None

Mic A-2

Chan: 21

P

RE FADER

Ins:

CH1Snd

A

lt:None

Mic A-3

Chan: 22

P

RE FADER

Ins:

CH1Snd

A

lt:None

Mic A-4

Chan: 23

P

RE FADER

Ins:

CH1Snd

A

lt:None

Mic A6/7

Chan: 24

P

OST PROC

Ins:

CH1Snd

A

lt:None

181410

6

2

221915

11

7

3

232016

12

8

4

24

ASG 2ASG 3ASG

4

ASG 5ASG

6

ASG 7ASG

8

N-1

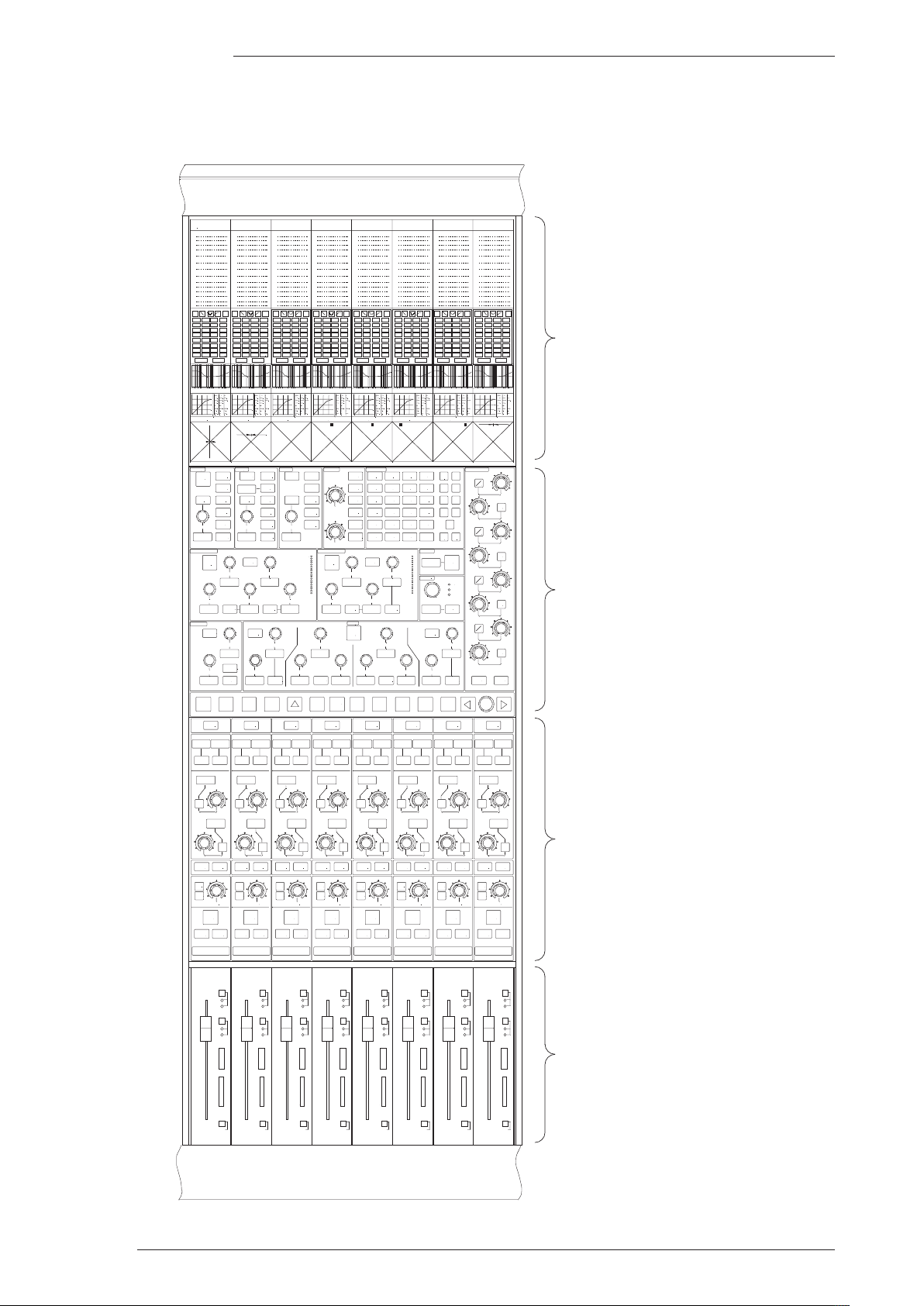

100 Channel Bay Layout

C

LCD Meter panel

Master Channel Tile

Channel Control Tile

Faders (8 individual units)

Page 12

Page 17

Section 4

System Components

Section 4 – System Components

This section gives an overview of the main units in the system. See Appendix A for specifications and

Appendices B and C for connector details and pinouts.

C100 Console

Each console control surface will consist of one Centre Section and can be specified to have from 8 to 96 channel

faders in groups of 8. (Note: a group of 8 faders and controls and its frame is termed a bay). See page 10 for frame

sizes.

Each console channel-bay consists of four sections: Faders, Channel Control, Master Channel and the meters. It

is only necessary to have one Master Channel tile fitted to the console frame as this can be used to access all

channels, although for convenience and additional flexibility additional Channel Masters may be fitted to any

bay.

Only the faders are removable individually, all other panels (termed tiles) are 8 channels wide.

Note that the number of physical faders fitted does not limit the number of processing channels available; this is

determined by the amount of DSP resource fitted to the processor.

The Centre Section may optionally be specified with a 6 or 8-channel LCD phase-scope and has additional space

for mechanical meters. Alternatively, a range of custom meter configurations is possible; these should be detailed

at the time of order.

The console frame may be specified to have 19” wide sections for script space (known as ‘Producer’s’ tables).

These can be fitted with either a full-depth flat table or a shorter table and 7U of equipment racking. A 7.2° corner

section is also available to create angled frames.

Every C100 console is fitted with dual redundant power supplies as standard. Accordingly, there are two

separate mains input connectors beneath the console.

The standard moulded end trims can be substituted by a thin trim panel (approximately 8mm) for installations

where width is limited.

SSL's Project Engineering Department can provide specific console footprint drawings detailing layout, size and

metering options during the specification process.

Page 13

Page 18

C100 Installation Guide

I

O

I

O

MACHINE

CONTROL

TIME

CODE

CONTROL

SURFACE 1

CONTROL

SURFACE 2

CONTROL

SURFACE 3

9 - 16 1 - 8

25 - 32 17 - 24

9 - 16 1 - 8

25 - 32 17 - 24

AES/EBU IN

AES/EBU OUT

+5V

+3V3

PORT 2

PORT 1

909XB

ROUTING CARD

IN OUT1 OUT2 OUT3 OUT4 EXPANSION

THRU

OUT/

960XA

IN

OUT

1 - 12

13 - 24

25 - 36

37 - 48

49 - 60

1 - 12

13 - 24

25 - 36

37 - 48

49 - 60

GPI

9 - 16 1 - 8

25 - 32 17 - 24

9 - 16 1 - 8

25 - 32 17 - 24

AES/EBU IN

AES/EBU OUT

A

1

A1

ANALOGUE IN

ANALOGUE OUT

A

1

A1

ANALOGUE IN

ANALOGUE OUT

+3.3V

+5V

+5.5V

+15V

-15V

O

I

+3.3V

+5V

+5.5V

+15V

-15V

O

I

SCSI A

S

CSI B

SCSI B

+5V

1

-6

7-12

S

PLIT OUTPUTS

MIC INPUTSA+5V

+

3V3

FLAG 1

FLAG 12

R

ESET

Solid State Logic

O X F O R D • E N G L A N D

+5V

+

3V3

FLAG 1

FLAG 12

R

ESET

Solid State Logic

O X F O R D • E N G L A N D

+5V

+

3V3

FLAG 1

FLAG 12

R

ESET

Solid State Logic

O X F O R D • E N G L A N D

+5V

1

-6

7-12

S

PLIT OUTPUTS

MIC INPUTSA+5V

1

-6

7-12

S

PLIT OUTPUTS

MIC INPUTS

A

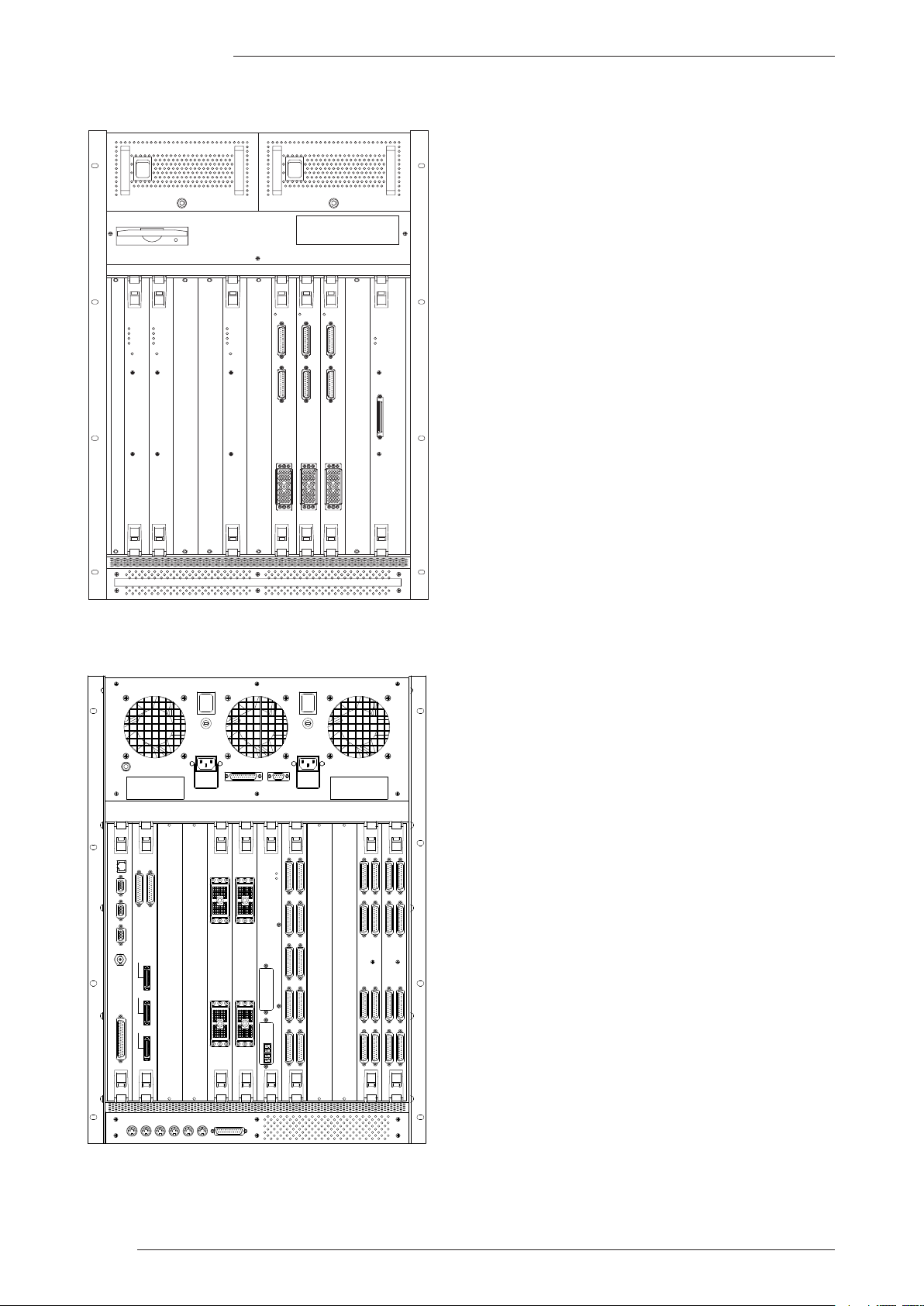

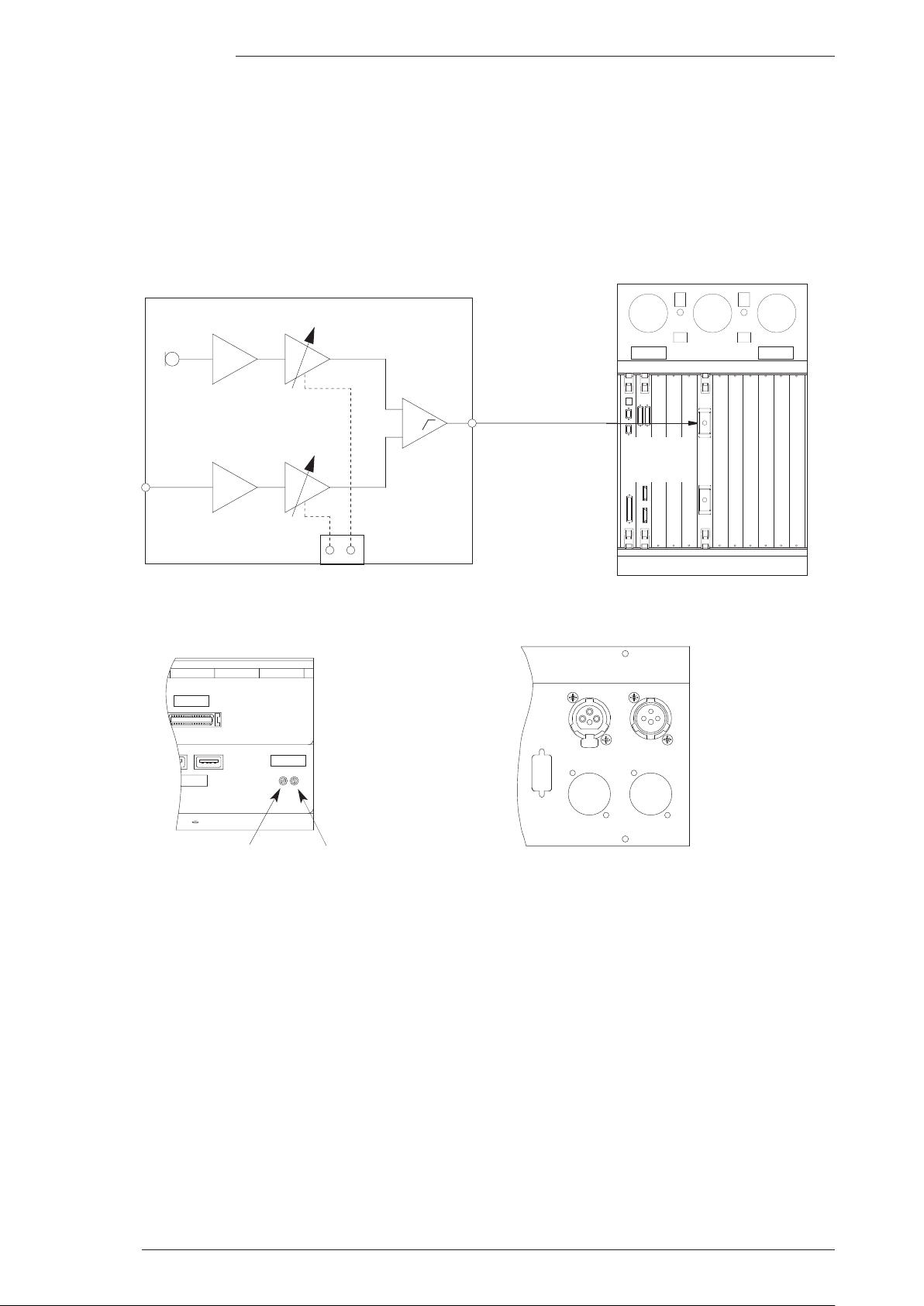

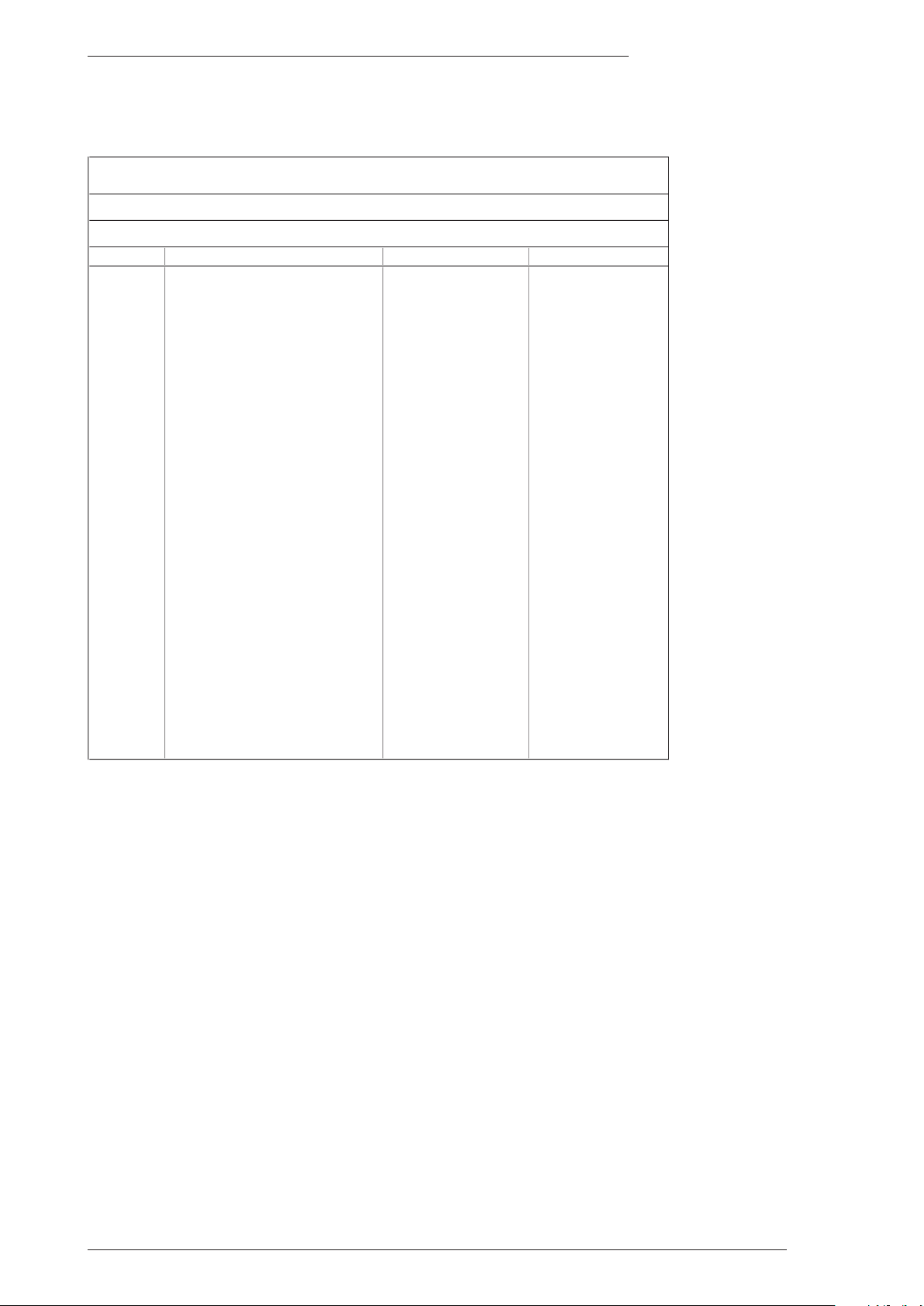

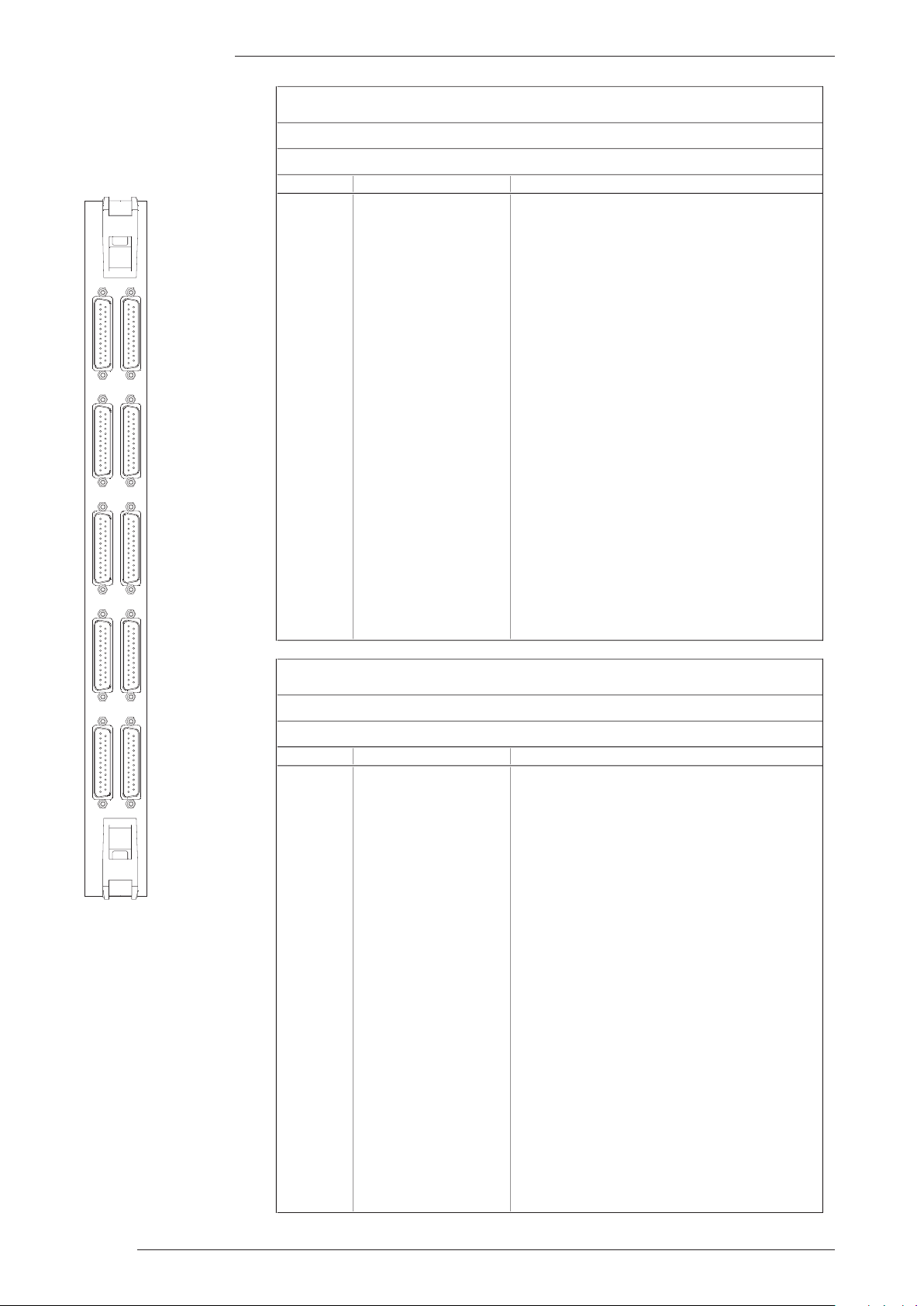

Centuri Processor Crate

(Front View)

ccess to:

A

SUs

P

Removable media drive

DSP cards

System Disk card

I/O Cards (Mic or Digital)

Centuri Processor Crate

(Rear View)

Access to:

CPU card

Front panel card

GPI/O card

Routing/Link card

I/O Cards (Mic, Analogue or Digital)

NB. Cards shown are an example.

Configuration will vary according to

specification.

Page 14

Page 19

Section 4

System Components

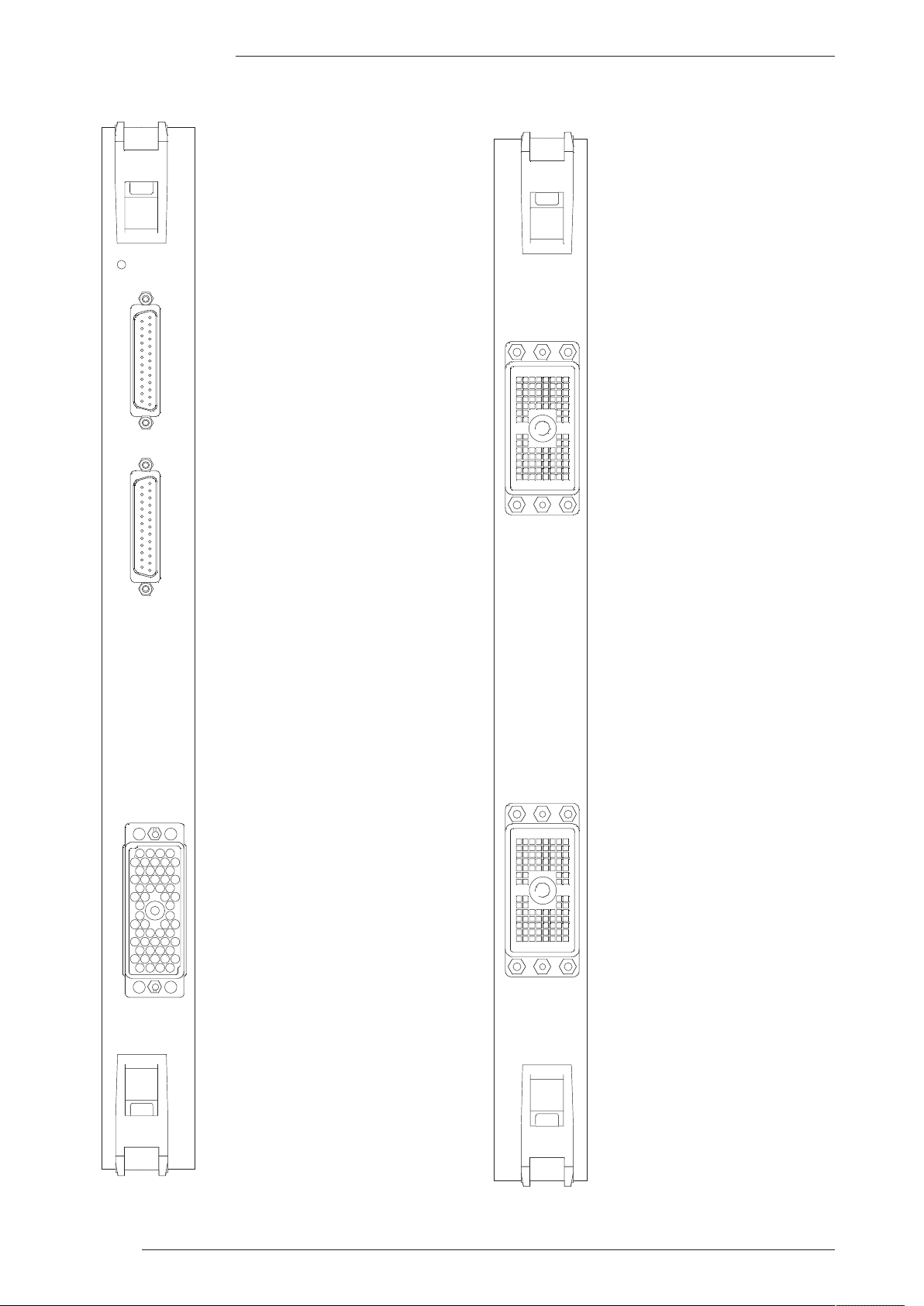

The Centuri Processor

The Centuri processor is a 15U high 600mm deep rack unit. Cards are fitted to the front and rear of the chassis

o space for access is essential. See page 10 for chassis dimensions and minimum service clearance.

s

At the front of the processor are located the plug-in PSU units. One unit is capable of powering the system.

he panel below the power supplies is fitted with either a 250Mb Zip drive or an SD memory card reader. This

T

is used to transfer system software onto the internal hard disk. This panel may also be fitted with the optional

MO drive for project storage.

Below the drives is the front card-cage which has space for 11 plug-in cards, numbered from left to right. The

cards are arranged as follows:

Slots 1–4 Channel DSP cards.

Slot 5 Always fitted with a DSP card for the Centre-Section mixes.

Slot 6 Reserved for future expansion.

1

Slots 7–10 I/O cards – micamp cards (digital/MADI cards to special order only)

.

Slot 11 Always fitted with the system disc card; unless the dual-redundant disc option is specified.

There rear of the processor has space for 12 plug-in cards. Note that these slots are numbered from right to left.

Slots 1–4 Available for I/O cards (analogue, digital and MADI).

Slot 5 Always fitted with the console’s Routing/Link card.

Slot 6 Reserved for the optional GPI/O card.

1

Slots 7–10 I/O cards – analogue, digital and MADI (mic cards to special order only)

.

Slot 11 Always fitted with the Console-Interface card.

Slot 12 Always fitted with the CPU card.

Note that front and rear mounting I/O cards, although functionally identical, are physically different so it is not

possible to exchange cards between back and front after specification.

Below the rear card-cage are connectors for MIDI functions and another labelled ’Expansion’. These are not

implemented in the C100 system.

(1) Specifying rear mounted micamp cards or front mounted digital/MADI cards will extend the order lead time.

Page 15

Page 20

C100 Installation Guide

ETHERNET

VIDEO 3

VIDEO 2

S

YNC

VIDEO 1

SERIAL

+5V

+3V3

FLAG 1

FLAG 12

R

ESET

Solid State Logic

O X F O R D • E N G L A N D

DSP CARD

SCSI A

SCSI B

SCSI B

DISK

CARD

MACHINE

CONTROL

TIME

CODE

CONTROL

SURFACE 1

CONTROL

SURFACE 2

CONTROL

SURFACE 3

+5V

+3V3

PORT 2

PORT 1

ROUTING CARD

1

2

Page 16

DSP

Card

System Disk

Card

CPU

Card

Console

Interface

Card

Routing/Link

Card

Page 21

Section 4

System Components

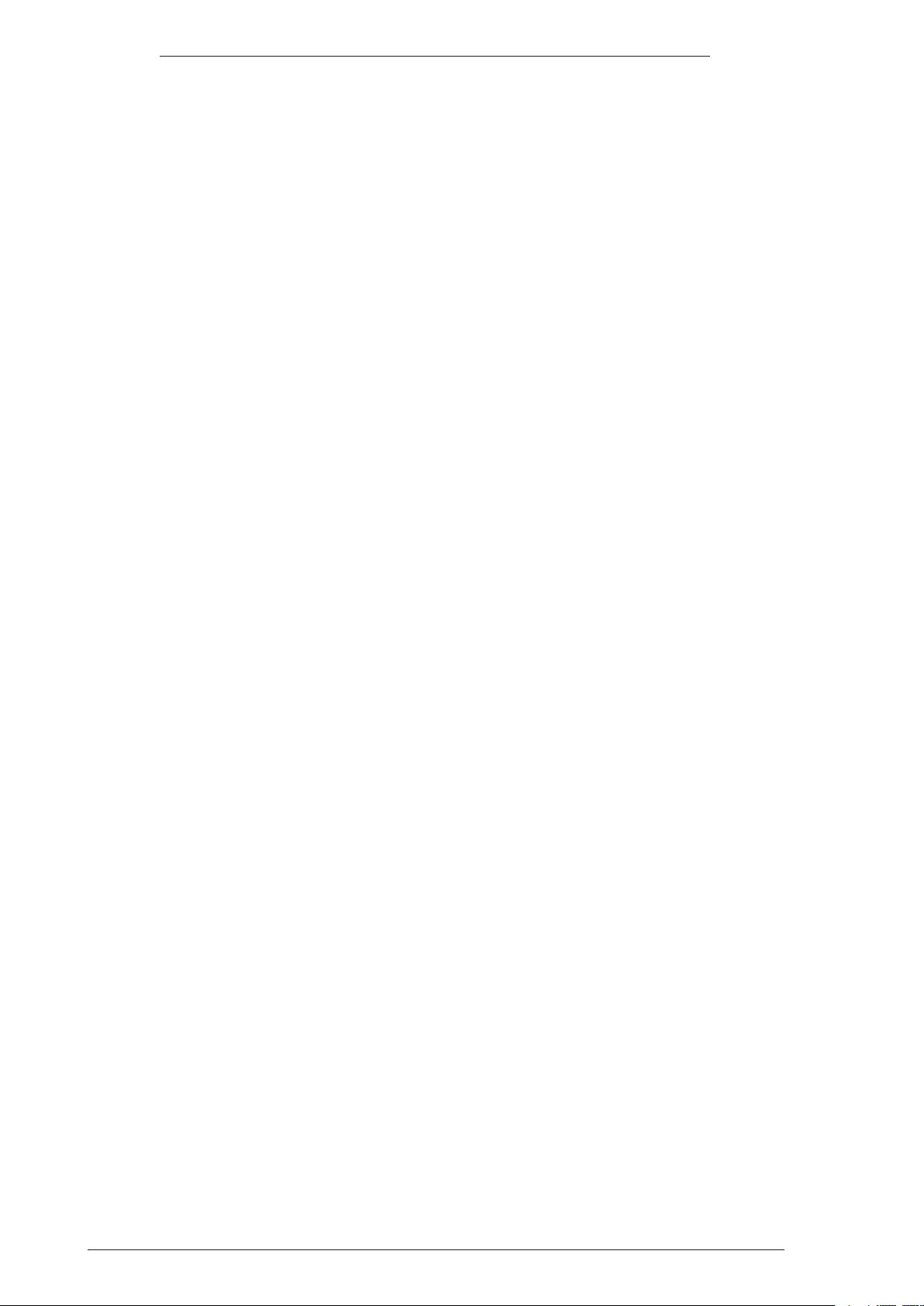

Centuri – DSP Card

The DSP cards supply the signal processing function for the Centuri system. Each card provides 32 channels of

processing. DSP cards are all the same and do not require configuration, they can therefore be fitted into any of

the first 5 slots in the front of the Centuri rack.

For a system to pass any audio, there must a card fitted in slot 5 and a card in slot 1.

Centuri – Disk Card

This is a 1.5 width card which is always fitted in the right-hand slot (slot 11) of the front card-cage. It houses the

system hard-disk. This card is not fitted if the dual redundant disk option is specified. In this case a blank panel

is fitted and the system discs are mounted internally in the space beneath the power supplies. A front panel key

switch is provided to select which disk is in use.

Centuri – CPU Card

The Centuri Processor is always fitted with the CPU card. It must be fitted to the left-most rear slot.

The CPU card is fitted with connectors for the following functions:

Ethernet – 100baseT console network

(1)

Video 1–3 – Display output for the Centre Section monitor.

Sync – Video sync input. Video black & burst is required for system reference.

Serial – 62-pin connector providing eight RS422/RS232 serial ports. An adaptor cable breaking out

to eight off 9-way D-type male connectors, labelled ‘TTY-A’ to ‘TTY-G’, is provided.

TTY-B: --Keyboard (RS422)

TTY-C: --Touchscreen data (RS422)

TTY-G: --Bitpad (RS422)

TTY-E: --Console (RS232) – Connection for data terminal

TTY-A, D, F & H Unused on C100

(1)

The ethernet connection is used for SSL control information, it is not TCP/IP protocol. Do not combine with

proprietary networks. Standard ethernet repeaters can be used.

Centuri – Console Interface Card

The Centuri Processor is always fitted with one Interface card. It must be fitted to the rear of the card-cage next

to the CPU card.

The card provides the connection to the console’s control surface and handles all switch and lamp signals. Of the

three ‘Control Surface’ connectors, only numbers 1 and 2 are used as these contain sufficient capacity for the

largest C100 console.

The ‘Machine Control’ and ‘Timecode’ connectors are not used by C100.

Centuri – Routing/Link Card

The Centuri is always fitted with a Routing/Link card. It must be fitted to the rear card-cage in position 5.

This card has two functions. The first is an internal function to organise the audio routes across the system’s

backplane. The second is to provide access to the optical audio interfaces to the stageboxes and/or MORSE

router (if specified). These optical audio connections are called Fibre Links and there can be from 1 to 4 fitted to

the Routing card. Fibre Links are cost options and should be specified at the time of order. Note that each fibre

link comprises two individual fibre optic connectors – one each for send and for receive.

Fibrelinks are available as either multimode or singlemode versions. The multimode link can be used for cable

lengths of up to 550m and the singlemode version for up to 2km.

If no fibre links are specified then the two cutouts in the front panel will be fitted with blanks.

Page 17

Page 22

C100 Installation Guide

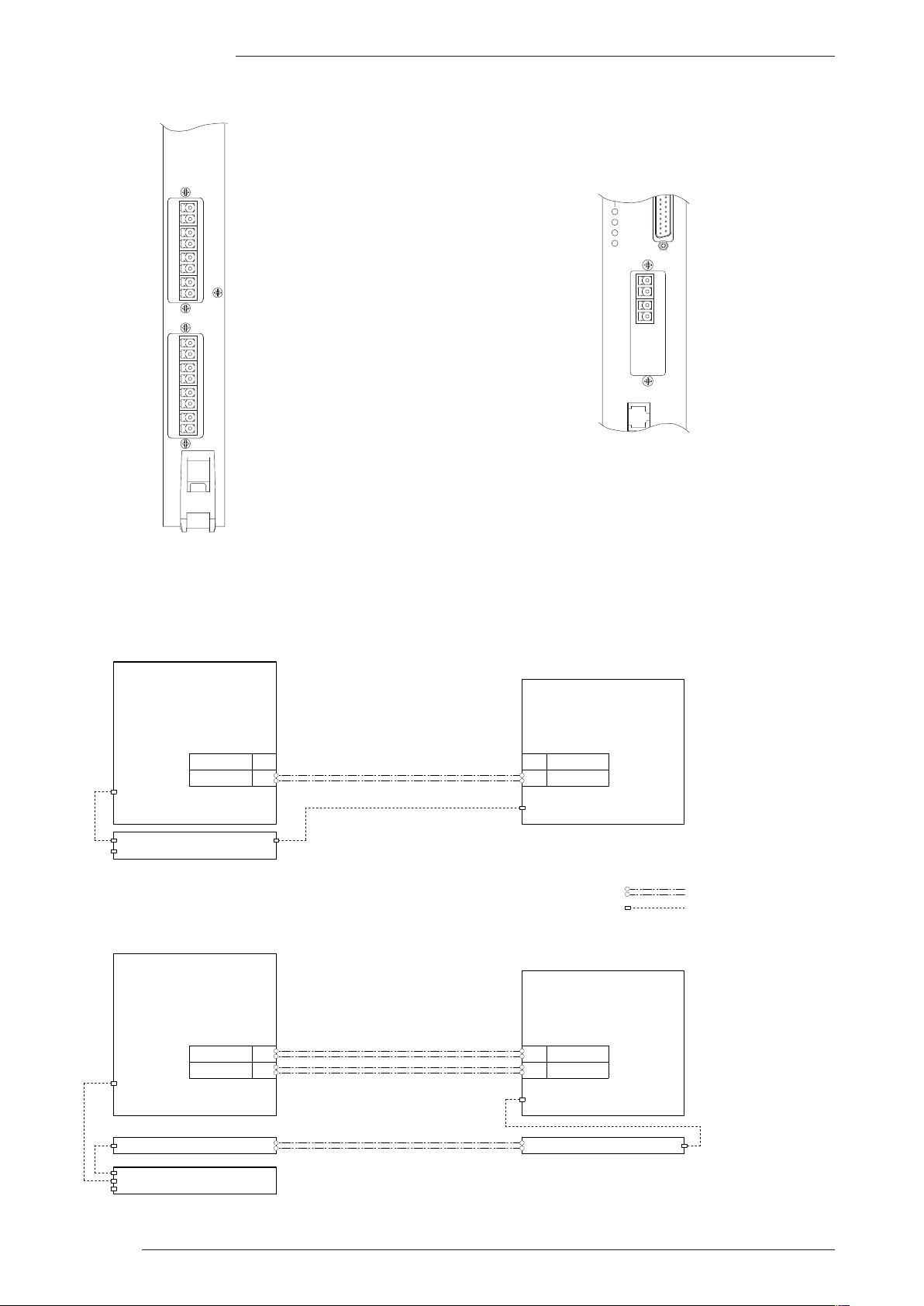

IN

OUT1 - 12

13 - 24

25 - 36

37 - 48

4

9 - 60

1 - 12

13 - 24

25 - 36

37 - 48

4

9 - 60

GPI

9 - 16

1 - 8

25 - 32

17 - 24

AES/EBU IN

9 - 16

1 - 8

25 - 32

17 - 24

AES/EBU OUT

+5V1-6

7-12

SPLIT OUTPUTS

MIC IN

1 - 12

A

A1

A1

ANALOGUE IN

1 - 24

A

NALOGUE OUT

1 - 24

IN

OUT

WORD

SYNCINOUT

AES

S

YNC

Tx

Rx

Tx

Rx

LOCK

A

LOCK

B

M

ADI

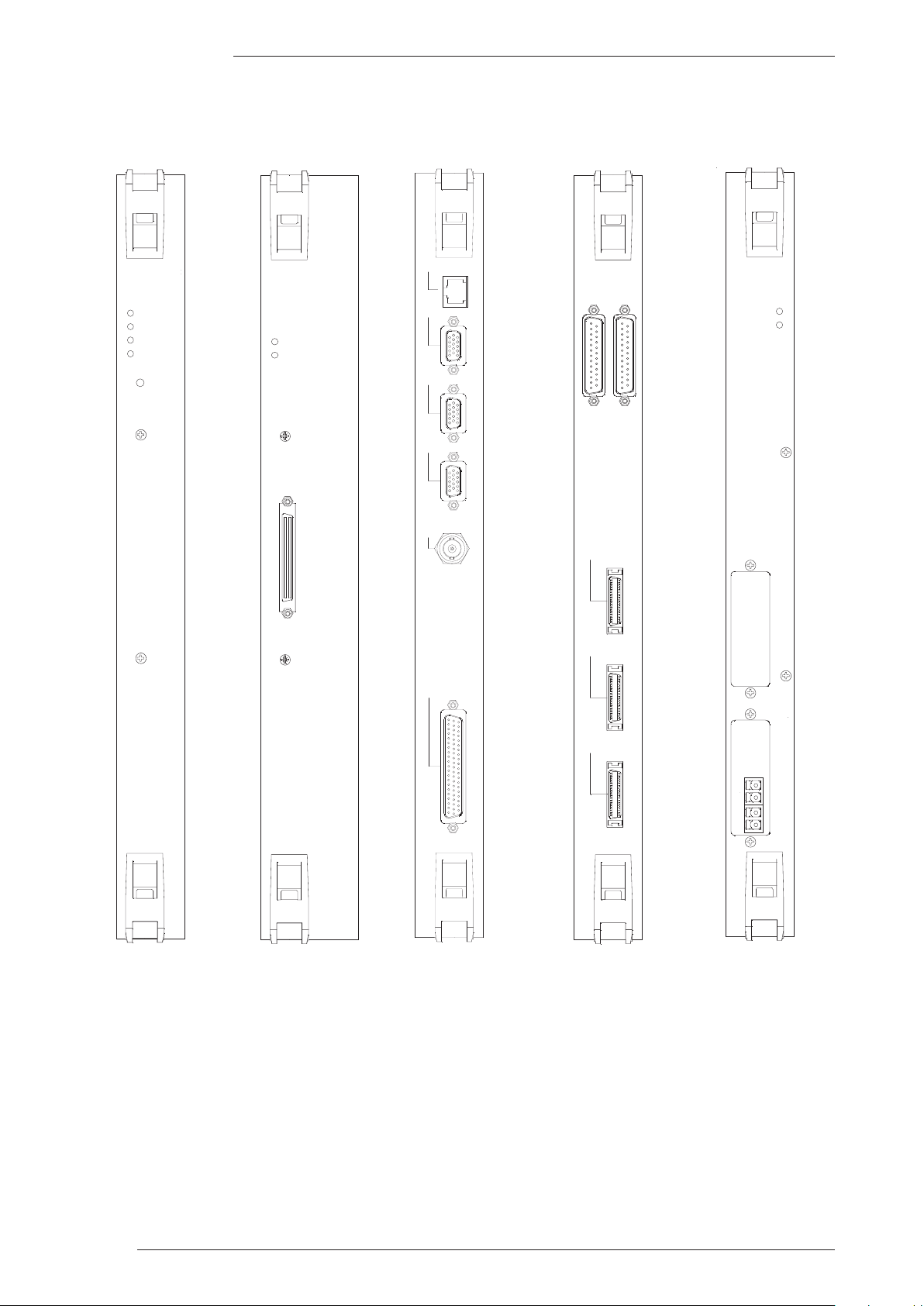

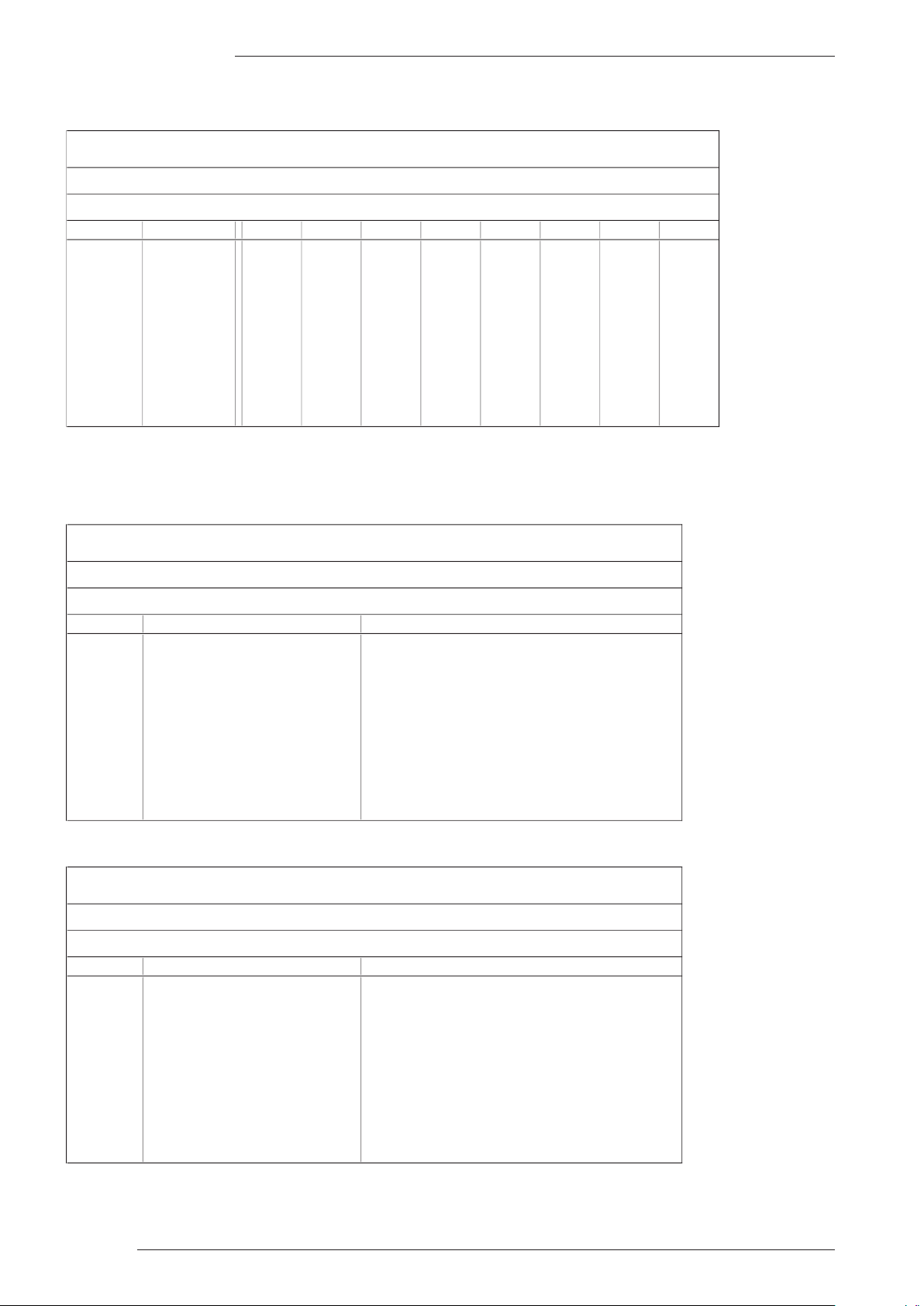

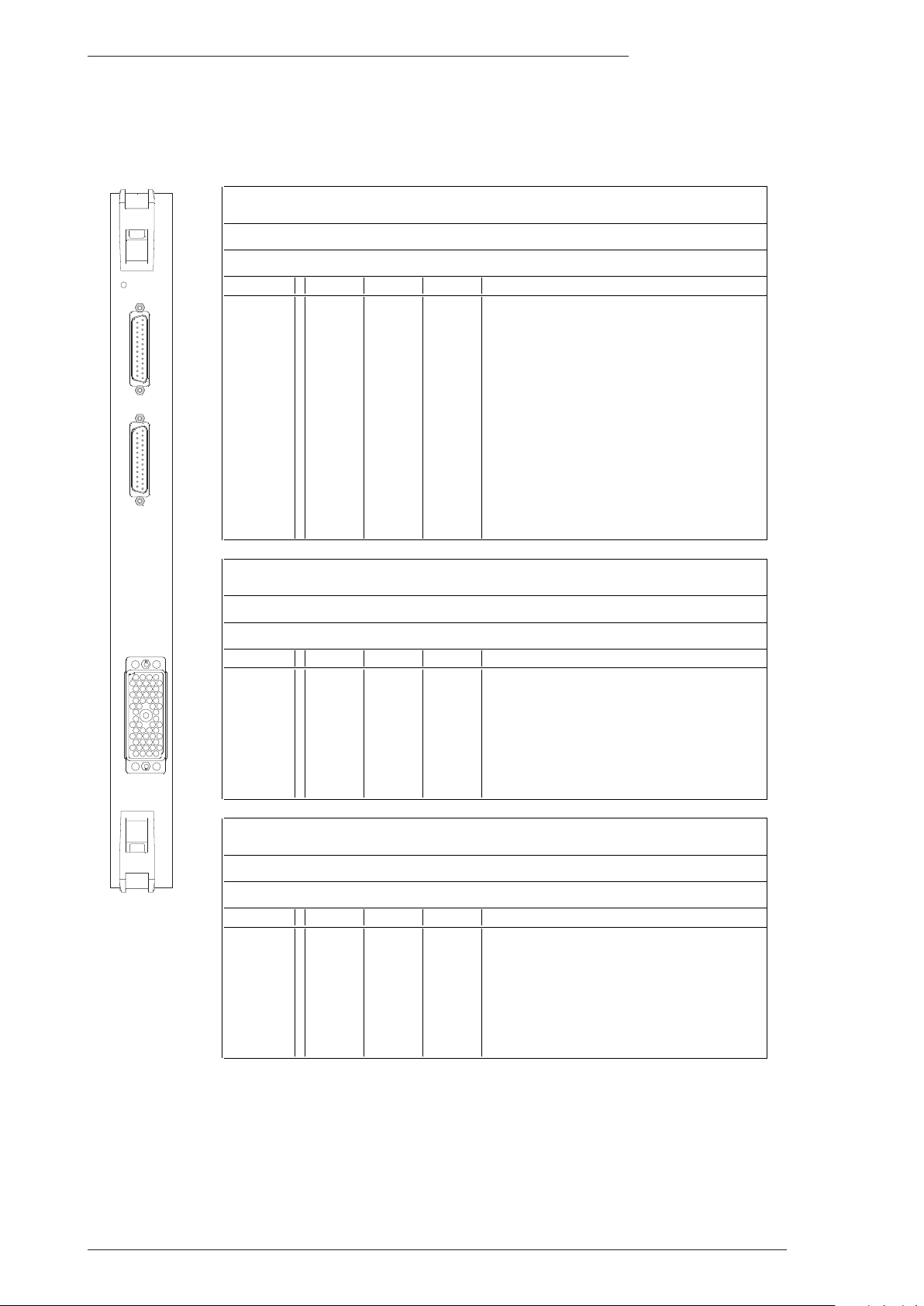

Mic Input

12 Microphone

12 split outputs

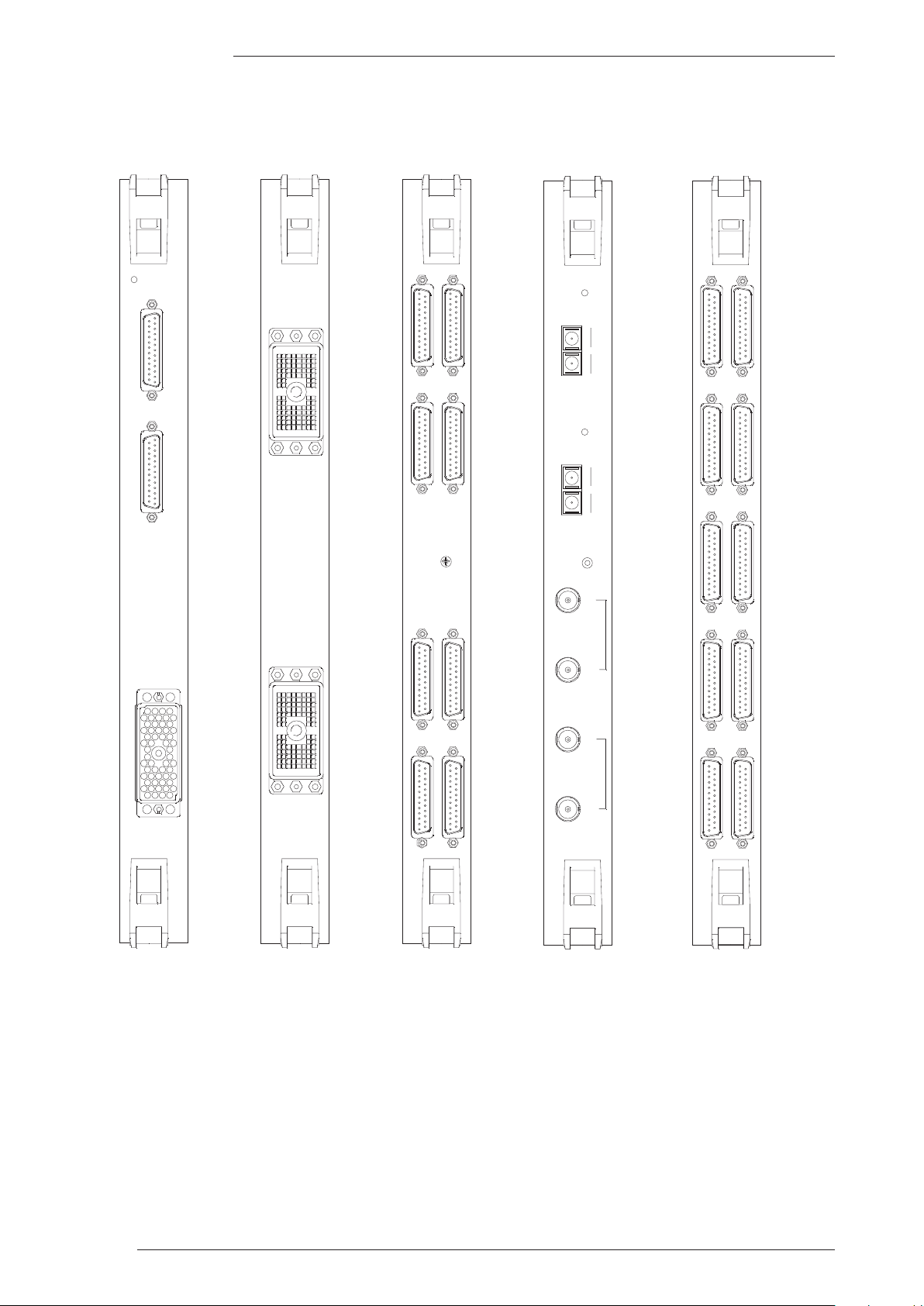

Page 18

Card

inputs

Analogue I/O

Card

24 line level

inputs and

outputs

Digital I/O

Card

64 SRC I/O

(32 AES/EBU pairs)

With 25-pin D-type

connectors

MADI I/O

Card

(Fibre version)

GPI I/O

Card

60 in, 60 out

Page 23

Section 4

Centuri – Micamp Card

The Microphone input card (generally known as the BMA or ‘Broadcast Mic Amp’) provides 12 input channels.

The input is via a female Varicon (EDAC) connector. Mating connectors can be supplied as a cost option.

Each of the mic inputs has a buffered split output. The buffering takes place after the input pad, the RFI filter

and the 25KHz low-pass filter but before the variable gain stage. The split output has a gain of 26dB above the

mic input level (or 6dB with the pad in circuit) but is unaffected by the consoles’ mic gain setting. The split

outputs are available on two female 25-way D-type connectors.

Micamp cards are normally fitted to the front of the Centuri. If more than 48 channels are required then rear

mounting cards can be specified as a special order.

Refer to section C for connector pinouts.

Centuri – Analogue I/O Card

The Analogue card provides 24 channels of balanced line-level input and output. At least one Analogue card will

need to be included if analogue monitor amplifiers are being used. The connectors used are Canon DL96 types.

Mating connector kits and a contact crimp tool can be supplied (as cost options). This card is rear mounting only.

See page 57 for the DL pinout.

System Components

Centuri – Digital I/O Card

The Digital I/O card is available in two versions: 110Ω and 75Ω. Both types provide 64 channels (32 AES/EBU

pairs) of digital input and output. The 110Ω card provides balanced output signals whereas the 75Ω card is

unbalanced for correct matching to co-axial cables. Sample rate conversion is available on every input so the card

can accept input rates from 32kHz to 96kHz. The connectors are all D-25 type females and mating connectors can

be supplied (as a cost option).

A breakout panel is available as an option for the 75Ω card – this converts D-25 connectors to chassis BNC plugs

and comes with 1m connecting looms. These panels should be mounted behind the Centuri rack; they cannot be

remotely located because the linking cables are unbalanced.

Front mounting versions of the digital cards are available to special order only.

Centuri – Madi Card (Copper version)

The MADI I/O card can operate in two ways: either as a 56 channel varispeed I/O multitrack interface (at 48kHz

± 12.5%) or as a 64 channel fixed 48kHz link (station router). In either case a source of sync is required. The sync

source can be AES, Word sync or self clocked from the MADI bitstream. This sync source must be derived from

the same station video reference as used for the CPU card sync input.

The card is fitted with dual MADI connections – MADI A and MADI B. The outputs are duplicates of the MADI

signal so that a safety backup can be made without having to use external distribution. For the inputs, MADI A

has priority but MADI B will take-over if the A signal is lost.

Centuri – Madi Card (Fibre version)

Operates exactly the same as the copper version but the MADI connectors are now singlemode or multimode SC

optical types. The fibre type must be specified at time of order.

Centuri – GPI/O Card

The optional GPI/O card provides 60 GPI inputs and outputs. Inputs (which can trigger many console functions

including channel faders and cuts) are opto-isolated. The outputs are provided by relay closure. Access is via 25pin D-type connectors; inputs are male and outputs are female.

Only one GPI/O card can be fitted to the Centuri rack.

Page 19

Page 24

C100 Installation Guide

+48V

SIG

OVER

LOAD

SELECT

+48V

SIG

OVER

LOAD

SELECT

+48V

SIG

OVER

LOAD

SELECT

+48V

SIG

OVER

LOAD

SELECT

+48V

SIG

OVER

LOAD

SELECT

+48V

SIG

OVER

LOAD

SELECT

+48V

SIG

OVER

LOAD

SELECT

+48V

SIG

OVER

LOAD

SELECT

P

USH

PUSH

PUSH

PUSH

P

USH

PUSH

PUSH

PUSH

PSU 1

ACDCPSU 1

ACDCSTANDBY

ON

SELECT

TERMINAL

NETWORK

LINK

CH1

CH2

CH3

CH4

SELECT

LEVEL

MONITOR

TALKBACK

SELECT

(YES)

(NO)

MENU

Solid State Logic

O X F O R D • E N G L A N D

+48V

SIG

OVER

LOAD

SELECT

+48V

SIG

OVER

LOAD

SELECT

+48V

SIG

OVER

LOAD

SELECT

+48V

SIG

OVER

LOAD

SELECT

+48V

SIG

OVER

LOAD

SELECT

+48V

SIG

OVER

LOAD

SELECT

+48V

SIG

OVER

LOAD

SELECT

+48V

SIG

OVER

LOAD

SELECT

P

USH

PUSH

PUSH

PUSH

P

USH

PUSH

PUSH

PUSH

+48V

SIG

OVER

LOAD

SELECT

+48V

SIG

OVER

LOAD

SELECT

+48V

SIG

OVER

LOAD

SELECT

+48V

SIG

OVER

LOAD

SELECT

+48V

SIG

OVER

LOAD

SELECT

+48V

SIG

OVER

LOAD

SELECT

+48V

SIG

OVER

LOAD

SELECT

+48V

SIG

OVER

LOAD

SELECT

P

USH

PUSH

PUSH

PUSH

P

USH

PUSH

PUSH

PUSH

+48V

SIG

OVER

LOAD

SELECT

+48V

SIG

OVER

LOAD

SELECT

+48V

SIG

OVER

LOAD

SELECT

+48V

SIG

OVER

LOAD

SELECT

+48V

SIG

OVER

LOAD

SELECT

+48V

SIG

OVER

LOAD

SELECT

+48V

SIG

OVER

LOAD

SELECT

+48V

SIG

OVER

LOAD

SELECT

P

USH

PUSH

PUSH

PUSH

P

USH

PUSH

PUSH

PUSH

+48V

SIG

OVER

LOAD

SELECT

+48V

SIG

OVER

LOAD

SELECT

+48V

SIG

OVER

LOAD

SELECT

+48V

SIG

OVER

LOAD

SELECT

+48V

SIG

OVER

LOAD

SELECT

+48V

SIG

OVER

LOAD

SELECT

+48V

SIG

OVER

LOAD

SELECT

+48V

SIG

OVER

LOAD

SELECT

P

USH

PUSH

PUSH

PUSH

P

USH

PUSH

PUSH

PUSH

+48V

SIG

OVER

LOAD

SELECT

+48V

SIG

OVER

LOAD

SELECT

+48V

SIG

OVER

LOAD

SELECT

+48V

SIG

OVER

LOAD

SELECT

+48V

SIG

OVER

LOAD

SELECT

+48V

SIG

OVER

LOAD

SELECT

+48V

SIG

OVER

LOAD

SELECT

+48V

SIG

OVER

LOAD

SELECT

P

USH

PUSH

PUSH

PUSH

P

USH

PUSH

PUSH

PUSH

C-SB Stagebox

(Front View)

Up to:

48 inputs

48 Split outputs

16 Line outputs

4 GPI I/O

Single or dual Fibre Link

Page 20

MORSE Router

MORSE 3U Stagebox

Page 25

Section 4

System Components

C-SB Stagebox (option)

The C-SB is a Mic/Line input/output stagebox which can be located remotely from the Centuri chassis. It

perates at 48KHz sample frequency and is a 14U high, 462mm deep, rack-mounted unit.

o

At the front of the unit are nine slots for plug-in cards: six slots for mic/line input cards; two slots for line output

cards and one for the CPU card. At the rear is an auto-ranging switch-mode power supply. This will accept input

oltages from 90–250v without adjustment. The PSU units provide two un-switched mains outlets via IEC 6A

v

shuttered sockets. A 2nd power supply unit may be fitted to provide redundancy.

Each micamp input card provides 8 channels, therefore a C-SB rack may be fitted with from 8 to 48 mic inputs.

The line output card also provides 8 channels but also features 4 channels of GPI relay closure. The CPU card is

fitted with a headphone socket to allow local monitoring of sources and also provides four analogue outputs via

a 25-way D-type connector. These outputs are assigned from the console and may be used for additional

analogue feeds, such as talkback or SLS.

Each mic input is provided with a split output. This output functions in the same way as the BMA circuit. (ie.

post pad, limiter and 26dB buffer but pre the variable gain stage). The split outputs are available on 25-way Dtype male connectors.

Remote stageboxes are linked to the Centuri core using duplex LC fibre-optic cable

separate ethernet cable

(2)

for the control functions (gain, pad, filter etc.). The audio fibre links to a stagebox can

(1)

for the audio data and a

be duplicated thus creating audio redundancy for critical or on-air reliability. (Fibre Links for the Centuri rack

should be specified at the time of order).

The standard unit is fanless and so can be located within the live production area; subject to the following note.

A low-noise fan ventilation kit is available as an option.

Note: The stagebox racks are cooled by convection at the front of the rack. The air flow from bottom to top of the front

panel must not be obstructed in any way (cable guides are provided at each side to route cables away from the air

intake). The air temperature at the intake and at the rear PSU heatsinks MUST NOT exceed 30° Centigrade.

Special considerations need to be observed when fitting stageboxes into flight cases – refer to Appendix F.

(1) The fibre optic cable is available in two types: for distances of up to 550m (multimode fibre) and distances of up to 2Km

(singlemode fibre).

(2) The standard maximum limit for ethernet cable is 100m. For distances of over 100m ethernet repeaters may be needed.

Alternatively, the ethernet cable can be converted to fibre. This can then run the same distances as the audio fibre. Please

discuss specific requirements with SSL’s Project Engineering Department.

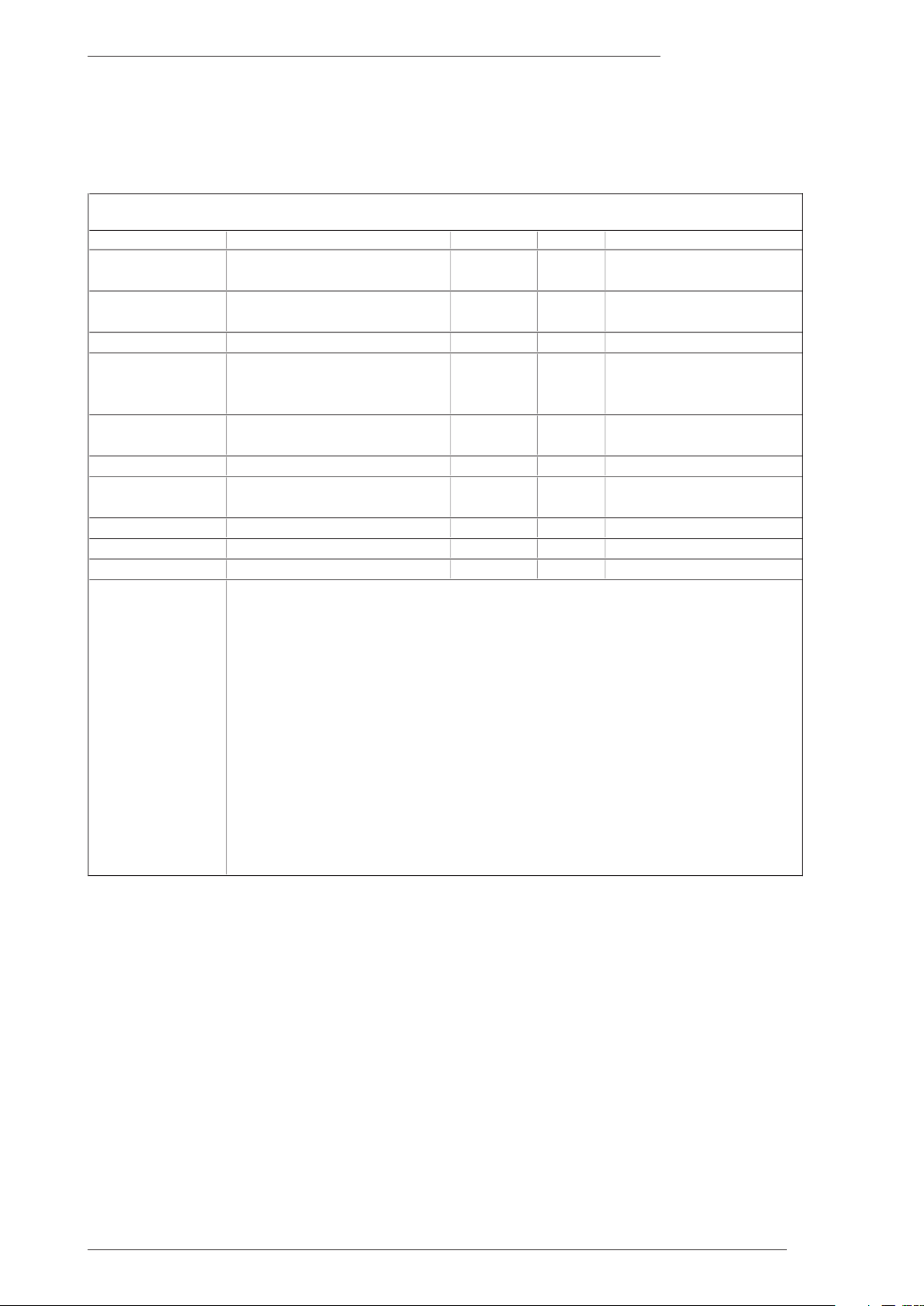

MORSE System (option)

The MORSE (MOdular Resource Sharing Engine) system provides a cost-effective, scalable solution for the

sharing of local or remote audio I/O and managing control data. The system is designed for on-air reliability and

features optional redundancy on all data links and fault tolerant proprietary software.

The system comprises a central router to which remote stageboxes and consoles are connected via optical MADI

links. Up to 24 individual links are available.

The router is a 3U 19” rack unit. Stageboxes are connected to the router and I/O can then be allocated to any

C100 console connected to the router.

Stageboxes can be 3U or 6U 19” rack units and each can be fitted with up to 56 channels of I/O. Plug-in modules

are available for mic, line, AES, MADI and SDI (due 2007). A 2nd redundant power supply can be fitted to the

6U version. Stageboxes are connected to the router using one or two duplex optical MADI links.

The MORSE system is more fully described in a separate document. Part number 82S69MOR10A.

Page 21

Page 26

C100 Installation Guide

Solid State Logic

NetBridge

S

ERIAL 1 - 8

T

ERMINALSERIAL 9

230

SSLT

CP/IP

Model

Serial No.

Solid State Logic

Oxford • England

FUSE risk of fire, use same type

and rating

(IEC 127)

250V

250V

Ratings: AC ~ 50/60Hz

Volts

Amps

626755X4

90-125 1.2-0.9

195-255 0.6-0.5

10A(T)

5A(T)

D

ATEINITIALS

TESTED

230

230

115

NetBridge (Front View)

NetBridge (Rear View)

NetBridge - PSU Voltage Selection

Voltage select switch shown

in the 230V position

Page 22

Voltage select switch shown

in the 115V position

Page 27

Section 4

System Components

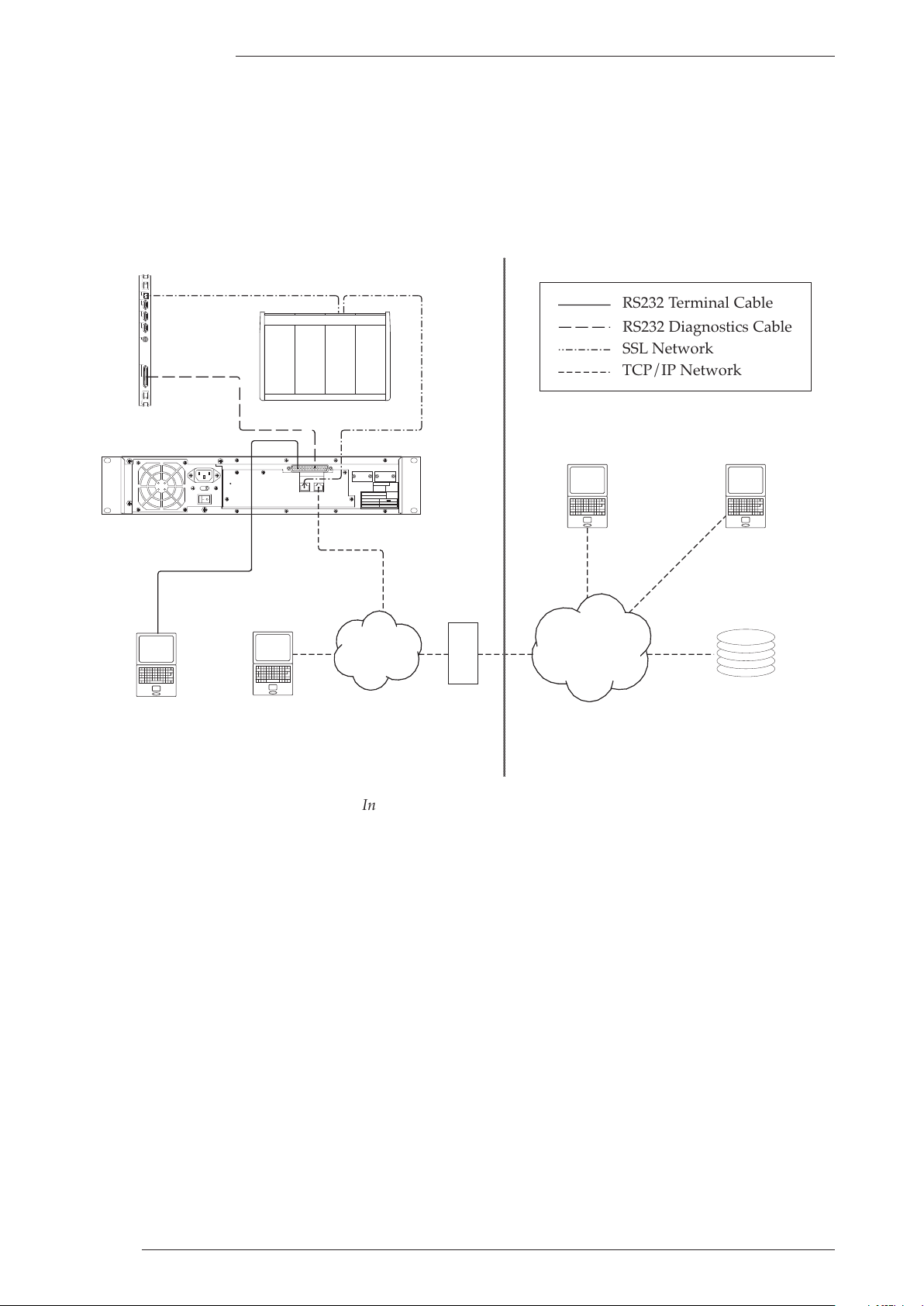

NetBridge (option)

NetBridge is a 2U rack mounting unit.

The NetBridge provides two main features. Firstly (as the name suggests) it is a bridge between the proprietary Solid

State Logic network, and the standard TCP/IP protocol, allowing remote diagnostic connection over the Internet. Up

to 7 diagnostic ports may be served by a single NetBridge unit, with secure log-in facilities enabling trained staff

r SSL engineers to access diagnostic functions remotely from any location worldwide.

o

Note: Do not combine the SSL Network and the facility’s TCP/IP network; they are different protocols.

Secondly it can be used to transfer data files between the C100 console to which it is dedicated and the ‘SSL-Network’

central file server (CFS). This allows C100 session templates (used for offline configuration) and project archives to be

moved across the Internet without requiring access to the console’s CPU.

Using the secure login access provided by NetBridge, users may upload a console template to a secure website,

edit the configuration offline and then reload their profile prior to the production saving valuable setup time.

Parameters available for offline configuration include fader strip allocations, channel names and type, bus

routing assignments, processing order, output options and fader grouping setup.

NetBridge requires access to the facility’s internet service. To do this, an Ethernet connection will be required.

The NetBridge will also need permission to access the SSL Network secure server; this may require the

configuration of any firewall software that may be in use. (See page 39 for further information.)

NetBridge does not have dual power supplies as it is not critical to console operation.

Note: NetBridge is not fitted with an auto-ranging power supply and the input setting must be confirmed before

applying power. The voltage select switch is located on the rear of the PSU unit, see opposite for switch location.

To change the setting:

1. Switch off and remove the IEC lead.

2. Using a small flat-bladed screwdriver, slide the select switch so that the appropriate voltage is indicated.

Page 23

Page 28

C100 Installation Guide

E

THER

1

E

THER

2

E

THER

3

E

THER

4

T

/SCRMIC GNCTRL

1

C

TRL 2CTRL 3BT/PADKBD

USB

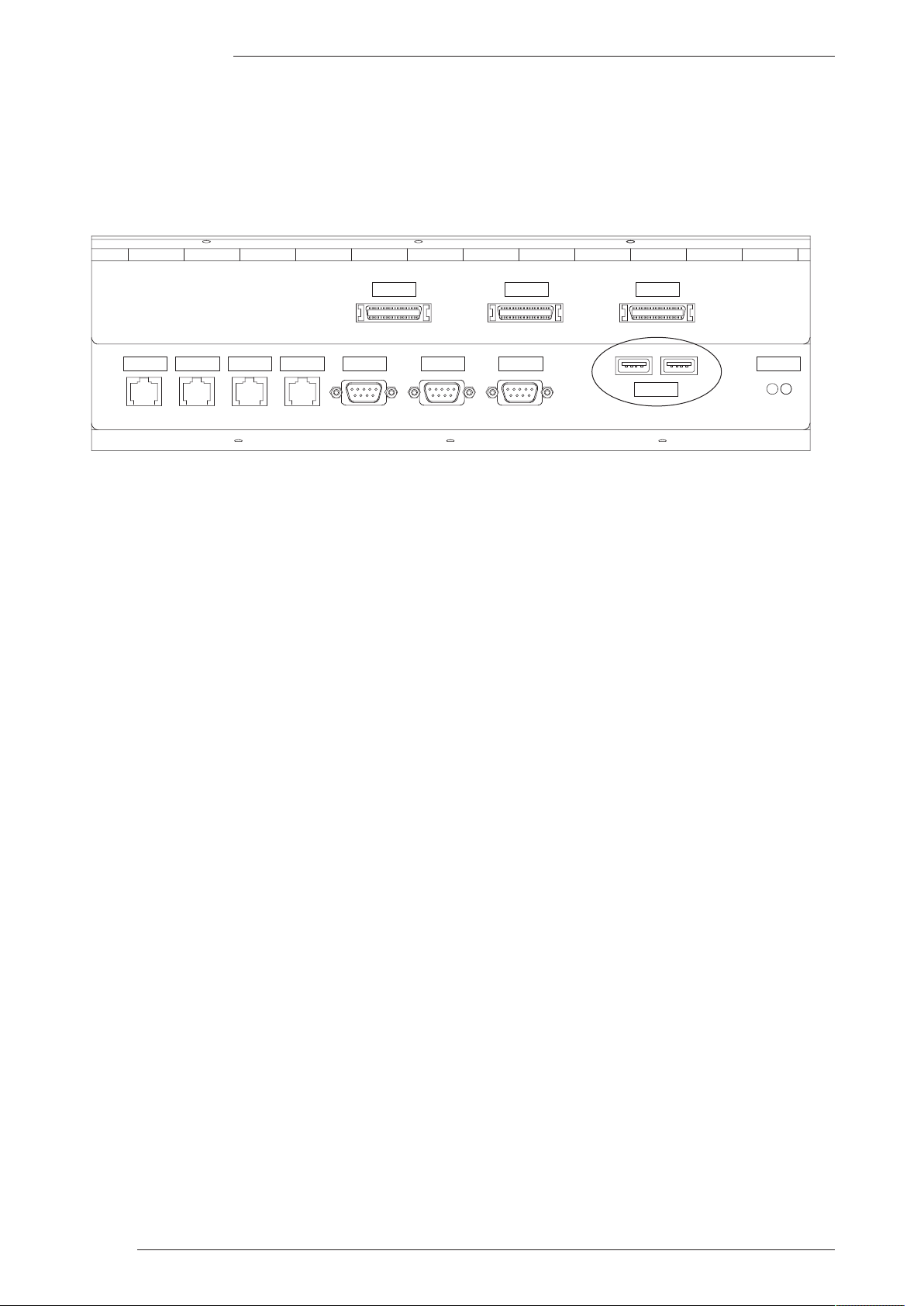

Location Of Bellypanel USB Connectors

Page 24

Page 29

Section 4

System Components

External Keyboard / Trackball (options)

There is an inbuilt software keyboard included in the C100 system. This is accessed via the Centre Section touch

creen.

s

Alternatively an external USB computer keyboard and or USB mouse/trackball may be connected to the audio

connector panel using the connectors provided. The diagram opposite shows the location of these connectors.

Script Tray (option)

The script tray is a movable transparent panel which fits over a channel bay. It has rollers fitted to allow it to

move along the length of the desk.

The script tray does not require modifications to the console and can be added to existing consoles.

Loudspeaker Shelf (option)

A flat secure shelf is available for the positioning of loudspeakers, monitors etc. Each shelf is 400mm wide by

253mm deep. A supporting rail is fixed to the console back panel for each speaker shelf. Additional support rails

can be fitted so that shelves may be moved to different positions along the console.

TFT External Input (option)

This option allows any of the channel bay TFT screens to be switched to show an external XGA (1024x768) video

signal. The switchover is effected either by a GPI closure triggered from a free button or by a dedicated switch

mounted on a custom panel (not included).

Page 25

Page 30

C100 Installation Guide

P

OWER IN

P

OWER IN

BACKUP

IOI

O

CONSOLE

POWER

INDICATORS

REMOTE

POWER

INDICATORS

PSU 1

PSU 1

SERIAL 1 - 8

TERMINAL

SERIAL 9

230

SSL

TCP/IP

Model

Serial No.

Solid State Logic

Oxford • England

FUSE risk of fire, use same type

and rating

(IEC 127)

250V

250V

Ratings: AC ~ 50/60Hz

Volts

Amps

626755X4

90-125 1.2-0.9

195-255 0.6-0.5

10A(T)

5A(T)

DATE

INITIALS

TESTED

Console Mains Inlet Panel

Earth Bolt

Earth Bolt

Centuri Mains Inlet Panel

NetBridge Rear Panel

Page 26

Page 31

Section 5

Section 5 – Installation Wiring

This section provides the details for connecting the system components together.

Power Supply Connections

This section refers to the following supplied cables (:

Description SSL Part No. qty Notes

Installation Wiring

Con IEC Free Socket 6A 2m

Cable Power Digital 2m

Lead Chassis Earth 16m

a) Connect both the console’s Harting mains leads to independent mains supplies. For live transmissions

work it is recommended that one of the power sources will be from an un-interruptable source. The

console is fitted with auto-ranging power supplies which will accept mains voltages which range from 90

to 255V without adjustment.

THE TWO POWER SOURCES MUST NOT BE FROM DIFFERENT PHASES OF A 3-PHASE SUPPLY.

THE MAINS SAFETY EARTH MUST BE CONNECTED

b) Connect both the Centuri’s IEC leads to independent mains supplies. The Centuri crate is also fitted with

auto-ranging power supplies which will accept mains voltages which range from 90 to 255V without

adjustment.

c) If specified, do not connect a source of power to the NetBridge until the voltage select switch position has

been confirmed. The NetBridge operates at either 115V or 230V ranges and its power supply must be set

to the appropriate range for the local supply.

Refer to the diagram on page 22 for the location of the voltage select switch.

32VGL362

32VALXVX

66C93115

2 Centuri

2 Main & Redundant Console power

1 Console to Centuri

d) Earth Wiring – A chassis to chassis earth cable needs to be installed between the console and the processor.

This keeps the two earths at the same potential thus preventing currents flowing along the signal cables.

Run the green chassis earth cable from the Console’s earth bolt to the similar earth bolt located on the

Centuri chassis.

Page 27

Page 32

C100 Installation Guide

960XA

MACHINE

CONTROL

TIME

CODE

CONTROL

S

URFACE 1

CONTROL

SURFACE 2

CONTROL

S

URFACE 3

906XA

SYNC

VIDEO 3

VIDEO 2

VIDEO 1

E

THERNET

S

ERIAL

CTRL 1 CTRL 1CTRL 1

ETHER 4 ETHER 3 ETHER 2 ETHER 1 T/SCR BT/PAD KBD

USB

MIC GN

VIDEO

IN DIAG

MSD ME

INP

RJ45 Ethernet

lead

ontrol Surface Wiring - Block Diagram

C

CPU Card

XGA video

lead

ontrol Card

C

TTY-C TTY-G TTY-B

RS422 serial

cables x 3

Front Panel

cables x 2

Page 28

Connector Panel

Audio

Console

Connector Panel

Page 33

Section 5

Centuri to Console Surface Connections

his section refers to the following supplied items:

T

Description SSL Part No. qty Note

Installation Wiring

ead 9WD plug to 9WD plug 16m

L

Lead RJ45 Shielded 15m

Lead Video HD15W D-Type 16m

Loom 36-way H/D Digital 16m

Cable assembly 62 way plg to 8 x 9WD plg 1m

Adapter 9 way D con F to F

a) Front Panel Cables – Locate the two MDR–MDR front panel cables and connect them between the Centuri

Control card and the console interface panel as shown opposite. Although there are three connectors at

both the Centuri and the console end, only connectors 1 and 2 are used.

These cables are symmetrical, having the same connectors at each end.

Note: The front panel cables are only supplied in 16m, 48m or 80m lengths. This is due to a timing requirement for

the high speed serial data. Do not attempt to shorten these cables. The connectors on these cables are not removable.

b) Network Cable – The Centuri processor uses an RJ45 Ethernet network to communicate with the C100

console, Stageboxes and NetBridge. The console has a built-in 4-way Ethernet repeater.

Connect the ethernet lead between the Centuri CPU card and any of the four ‘Ether’ sockets beneath the

console.

6C66815

6

66C67316

66DN(16)V1

66CN00(16)

66DNCSA8

32PM09XV

3

2

1 (20)=20m, (25)=25m, (48)=48m

2 (48)m and (80)m options only

1

8 converts above to female connectors

Touchscreen,

If Netbridge is specified then a second RJ45 Ethernet lead will be supplied with the system. This lead is

connected between the console and the ‘SSL Network’ connector on the NetBridge rear panel.

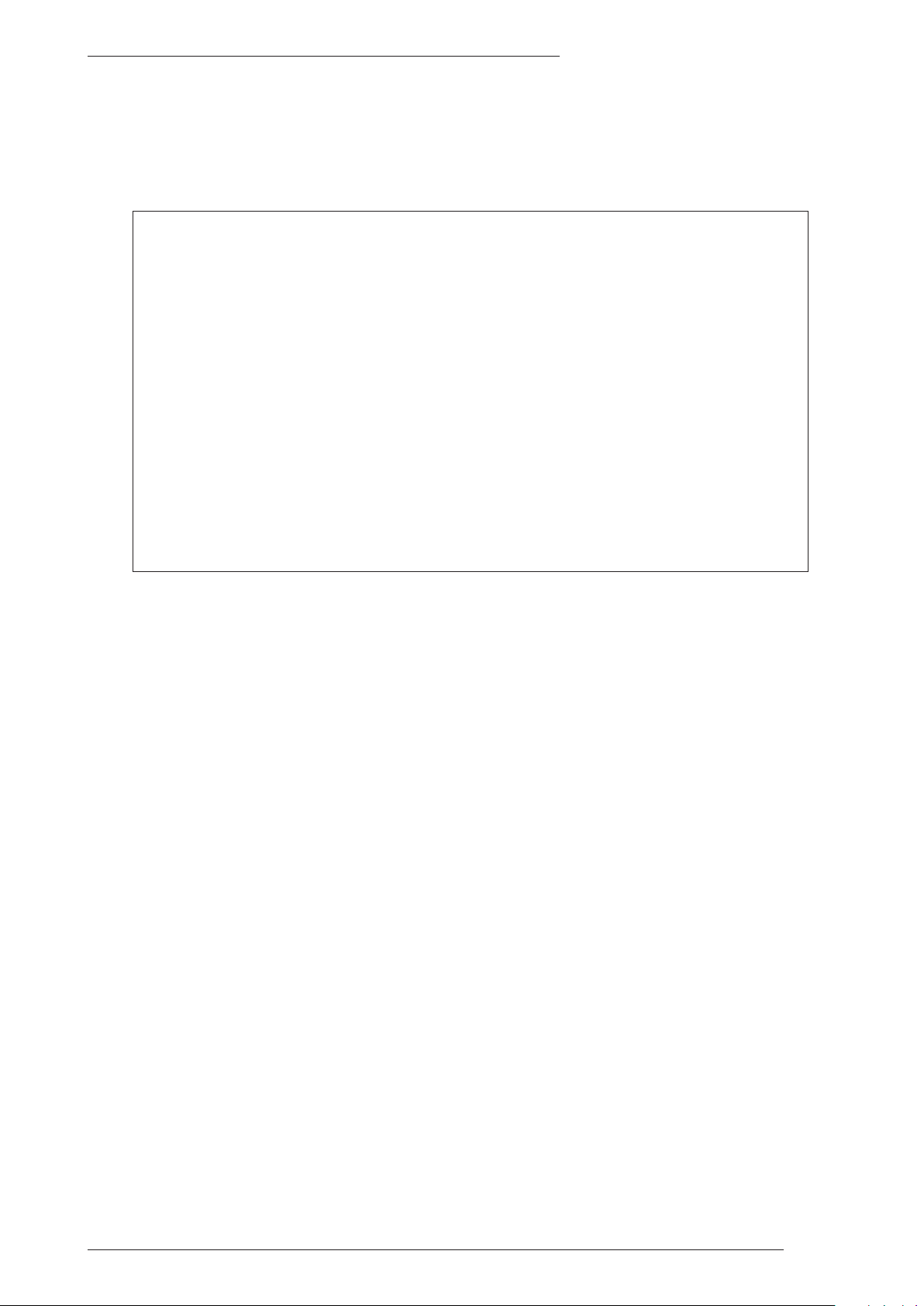

c) Serial Cables – Three RS422 serial cables are supplied for the installation. These connect the CPU card in

the Centuri to the touch screen, the bitpad (keyboard trackball) and the keyboard (if fitted).

The processor card is fitted with a 62-pin connector for the eight serial ports. An adapter lead which

breaks-out the 62-pin connector to eight off 9-way D-type male connectors is provided. Connect the three

serial leads as shown in the diagram opposite ensuring that the correct ‘TTY’ connector is used in each

case. Note that 9-way D socket–socket adapters will be necessary at the Centuri end.

d) Video Cable – There are three video outputs available on the CPU card. Video 1 and Video 3 are static

background displays. Video 2 is used for the Centre section touch-screen display.

Note that the picture output from video 2 is rotated 90° so the Centre Section touchscreen can be used in

‘portrait’ orientation. If for any reason you wish to duplicate the video 2 output, then any monitor used

will have to be turned onto its side to display correctly.

Connect the video cable as shown in the diagram opposite. The cable is male-male so does not have to be

run in a particular direction.

Note: SSL does not recommend that the supplied video cable be extended. Doing so may reduce the video quality as

the cable is matched to function over long runs; these cables are of a high quality individually screened type. Longer

cables are available from SSL.

Page 29

Page 34

C100 Installation Guide

SYNC

IOI

O

C

ONSOLE

POWER

I

NDICATORS

R

EMOTE

POWER

IND

ICATORS

PSU 1

PSU 1

E

XT T/B

MIC IN

T

ALKBACK

OUTPUT

X1

X2D5D4

D3

REMOTE

P

OWER IN

PHASE

S

COPE

METER

I

NPUTS

D2

D1

MSD

D

IAG

VIDEO

I

N

SU Status Wiring Diagram

P

CPU Card

Sync Input connector

Console

Audio

Connector Panel

Page 30

Page 35

Section 5

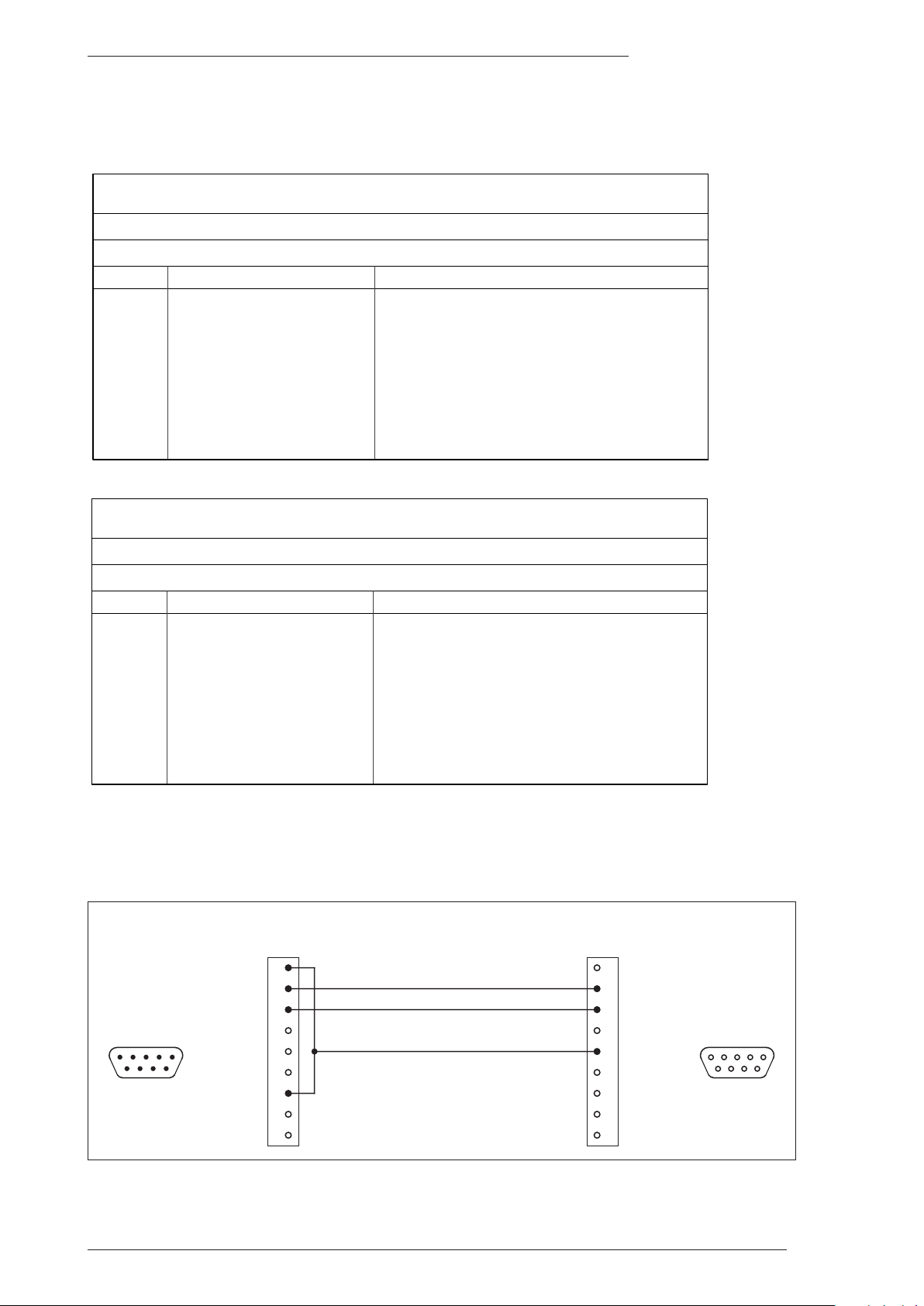

PSU Status

This section refers to the following supplied items:

Description SSL Part No. qty Note

Installation Wiring

Cable 25-way D Plug to Socket 16m screened

a) The PSU Status cable carries the status indication of the two Centuri crate PSU units.

Install the the 25 pin male to female lead and connect as shown opposite; the male end of the cable

connects to the Centuri and the female to the console.

Note that the 9-way connector ‘Remote Power Indicators’ is not used. This connector was allocated for power

indication from remote I/O units which are no longer available.

66C67781

1

Sync Source

This section refers to the following supplied items:

Description SSL Part No. qty Note

Terminator plug 75R

BNC 75R TEE Adaptor

a) Connect the source of video sync to the SYNC IN connector on the processor crate using the T-adaptor

and 75Ω Terminator supplied to provide termination.

32TKB7TC

32TKU7CC

1

1

Page 31

Page 36

C100 Installation Guide

+5V

1-6

7-12

SPLIT OUTPUTS

MIC IN

1 - 12

A1

A1

ANALOGUE IN

1 - 24

ANALOGUE OUT

1 - 24

M

Split Output Connectors

25-pin D-type female

icamp Input Card

nalogue I/O Card

A

Analogue Input Connector

DL96 female

Page 32

Microphone input Connector

Varicon 56-way female

Analogue Output Connector

DL96 female

Page 37

Section 5

Installation Wiring

I/O – MicAmp Card (SSL ref. 908)

Each MicAmp Input Card contains 12 Microphone circuits. The inputs are accessed via a Varicon (aka. EDAC or

lco) 56-way female connector.

E

The split outputs are accessed via two 25-pin D-type female connectors.

efer to Appendix C for the connector pinouts.

R

SSL is able to supply mating connectors if requested, (at additional cost).

If more than one micamp card is fitted then the card furthest to the right will have the lowest input number and

the channel numbers will increment by 12 as each card is added. Any cards added subsequently, should be

placed to the left of any existing cards otherwise the channel numbering will be altered.

I/O – Analogue input/output Card (SSL ref. 904)

The Analogue Card provides 24 circuits of electronically balanced input and output. These circuits are accessed

via Canon DL 96 way female connectors; mating connectors are available to order

Refer to Appendix C for the connector pinouts.

As is the case for the MicAmp, cards added subsequently should be placed to the left of existing cards.

The default line-up level for analogue I/O is 0dBFS = +18dBu. This level may be globally altered and can range

from +9dBu to +24dBu. The value can be adjusted from a setup screen to match the standard operating level for

the facility.

Note. When assigning analogue card output channels as insert sends, the routing system will automatically assign

the same input channel number as the corresponding return. It is therefore necessary to physically wire outboard

equipment so that circuit allocation follows this arrangement.

Page 33

Page 38

C100 Installation Guide

9 - 16

1 - 8

2

5 - 3217 - 24

AES/EBU IN

9 - 16

1 - 8

25 - 32

17 - 24

AES/EBU OUT

IN

OUT

WORD

SYNCINOUT

AES

SYNC

T

x

RxTxRx

LOCK

A

LOCK

B

MADI

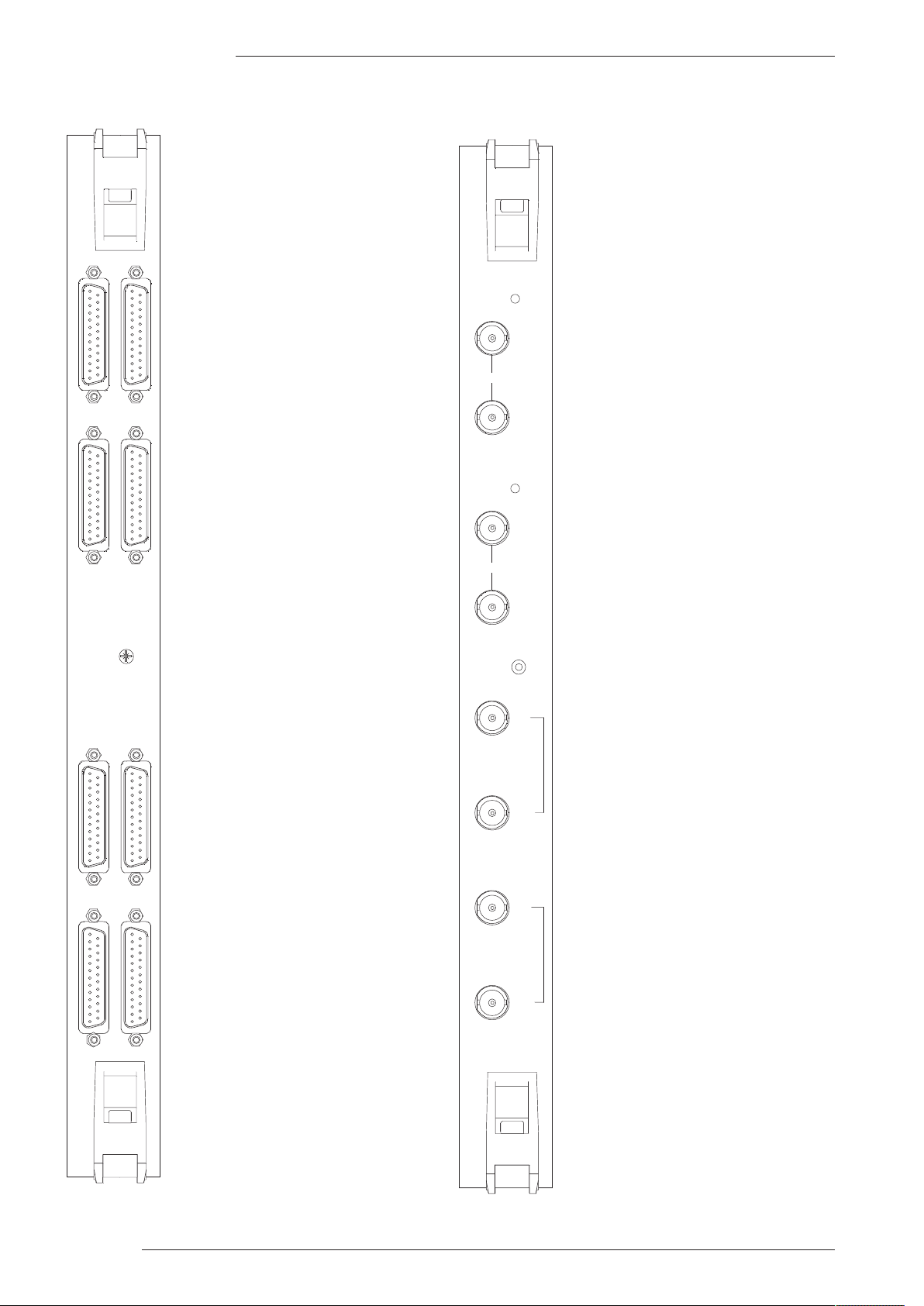

Digital I/O Card

(D25 version)

AES/EBU Input Connectors

25-pin D-type female

MADI I/O Card

(Copper version)

MADI Link A

BNC 75Ω

MADI Link B

BNC 75Ω

AES/EBU Output Connectors

25-pin D-type female

MADI Word Sync

BNC 75Ω

AES Sync

BNC 75Ω

Page 34

Page 39

Section 5

Installation Wiring

I/O – Digital Input/Output Card 110Ω (SSL ref. 902XF)

The Digital Input Card provides 32 balanced AES/EBU signal pairs of both input and output. All circuits are

accessed via 25-pin D-type female connectors.

efer to Appendix C for the connector pinout for this card.

R

Mating connector kits can be ordered for the card.

As in the case of the Analogue I/O, cards added subsequently should be placed to the left of existing cards.

Note. When assigning digital card output channels as insert sends, the routing system will automatically assign the

same input channel number as the corresponding return. It is therefore necessary to physically wire outboard

equipment so that circuit allocation follows this arrangement.

I/O – Digital Input/Output Card 75Ω (SSL ref. 902XJ)

This version of the Digital I/O card is externally identical to the the 110Ω version (apart from its designation

number). The Impedance of each input and output circuit however, is now 75Ω for correct matching to

installations using co-axial cabling.

A separate BNC interface panel is available as a cost option. This is 2U high and is fitted with 64 chassis mounted

BNC plugs – 32 input and 32 output. 1metre D25–D25 interconnecting looms are provided.

As in the case of the Analogue I/O, cards added subsequently should be placed to the left of existing cards.

Note. When assigning digital card output channels as insert sends, the routing system will automatically assign the

same input channel number as the corresponding return. It is therefore necessary to physically wire outboard

equipment so that circuit allocation follows this arrangement.

I/O – MADI Card (SSL ref. 902XG copper version / 902XH/K fibre versions)

The MADI I/O card can operate in two ways: either as a 56 channel varispeed I/O (multitrack interface) or as a

64 channel 48kHz link (station router). In either case a source of sync is required. The sync source can be AES,

Word sync or self clocked from the MADI bitstream.

The Card is fitted with dual MADI connections – MADI A and MADI B. The outputs are duplicates of the MADI

signal so that a safety backup can be made without having to use external distribution. On the input side, MADI

A has priority but MADI B will take-over if the A signal is lost.

The fibre version of the card – see page 18 – has duplex SC optical connectors for both MADI A and B. The Fibre

type can be either singlemode or multimode (this must be specified at time of order).

Page 35

Page 40

C100 Installation Guide

IN

O

UT

1 - 12

13 - 24

25 - 36

37 - 48

49 - 60

1 - 12

13 - 24

25 - 36

37 - 48

49 - 60

GPI

GPI I/O Card

GPI input Connectors

25-way D-type Male

GPI output Connectors

25-way D-type Female

Page 36

Page 41

Section 5

GPI in

Installation Wiring

I/O – GPI I/O (SSL ref. 907XA)

The GPI I/O Card contains 60 circuits of opto-isolated input and 60 circuits of relay-closure output. Inputs are

accessed by 25-pin D-type male connectors and outputs by 25-pin D-type female connectors; mating connector

kits are available to order.

Both the input and the output circuits are fully isolated from the processor electronics. On output connectors,

there is a protected source of +15V available an, a 0V reference is available on input connectors.

The input and output signals can be either latching or momentary; this is individually assigned in software using

the touch screen. When set to momentary, the input signal duration needs to be greater than 50mS.

Note: When used for track arming and tally, the tally must return to the same number input as the output signal.(ie.

the tally for GPI out 1 will be on GPI in 1).

The switch closure is by DIL relay. Contact rating is 100Vdc, 125Vac, 100mA max. Do not use the output contacts

to directly switch capacitive or reactive loads; always use an external relay with a suitable contact rating.

Contact A

GPI Output circuit

Contact B

The signal input requires AC or DC voltage between 4V and 30V. The current drawn is approximately 10mA.

Input A

GPI Input circuit

Input B

Page 37

Page 42

C-SB

LC

Fibre i/f 1a

Network

LC

Fibre i/f 1a

Network

Ethernet hub/switch

Centuri

Processor

C-SB

LC

Fibre i/f 1a

Network

LC

Fibre i/f 1a

Network

Ethernet hub/switch

Centuri

Processor

audio link

control link

Media converter

Media converter

audio link (main)

control link

LC

Fibre i/f 1b

LC

Fibre i/f 1b

audio link (backup)

duplex fibre link

RJ45 ethernet

C100 Installation Guide

PORT 2

PORT 1

123

4

1

2

3

4

NETWORK

FIBRE

LINK

CH1

CH2

CH3

CH4

1

2

ibre Link Connectors and Panels

F

Centuri Link Card

With four redundant links

With redundant Fibre Link

C-SB CPU Card

C-SB Cabling Diagrams

Single Fibre-Link

with RJ45 control

link (100m max)

Dual Fibre-Link

with fibre control

link (>100m)

Page 38

Page 43

Section 5

Installation Wiring

Stageboxes & Fibre Links

The C-SB Stagebox utilises fibre-optic connection between itself and the Centuri Processor. This has the

dvantages of noise immunity, reduced weight and bulk of wiring and the elimination of earth loops. A separate

a

control signal (for gain, pad, filter etc.) is carried over the SSL ethernet network. This control signal can be

converted into fibre optic for runs longer than 100m.

he standard connectors for the fibre links are duplex LC at both the Centuri and the Stagebox ends. A 2m lead

T

is provided as standard with each stagebox.

When Stageboxes are specified, it is recommended that a 10/100 ethernet hub/switch is installed so as to provide

isolation for the remote network connection(s). A 1U rack mounting 16-port switch is available as a cost option.

Longer fibre cables and/or ruggedised OB cable using adaptor panels/patch panels are options. SSL is able to

provide a range of fibre solutions although the facility may prefer to provide its own fibre installation. Details of

fibre installation options should be discussed with SSL’s Project Engineering Department at the time of order.

For location of Stageboxes at distances of greater than 100m from the Centuri rack the ethernet control cable will

have to be buffered – using an ethernet repeater/switch – or converted to fibre.

The maximum length for a multimode Fibre Link is 550m, and for singlemode is 2km.

The Centuri Routing card can be fitted with up to eight Fibrelinks. These are arranged in four groups of two

labelled as ‘Port 1’ to Port 4’.

Note: Each Port on the Routing/Link card actually provides up to four separate connections (two pairs).

Connections numbered 1 and 3 are for the primary Fibre Link and numbers 2 and 4 are reserved for the optional

redundant links.

Remote stageboxes may be connected to the Centuri core in any order.

Page 39

Page 44

C100 Installation Guide

S

ERIAL 1 - 8

TERMINAL

S

ERIAL 9

2

3

0

SSL

TCP/IP

Model

Serial No.

Solid State Logic

Oxford • England

FUSE risk of fire, use same type

and rating

(IEC 127)

250V

250V