Page 1

Introduction and features

Technical Service Manual

for 13SEER DC INVERTER 24K

SOLEUSAIR

Model

KFHHP-22

Remarks

Page 2

/

3

62/60/58

2

3

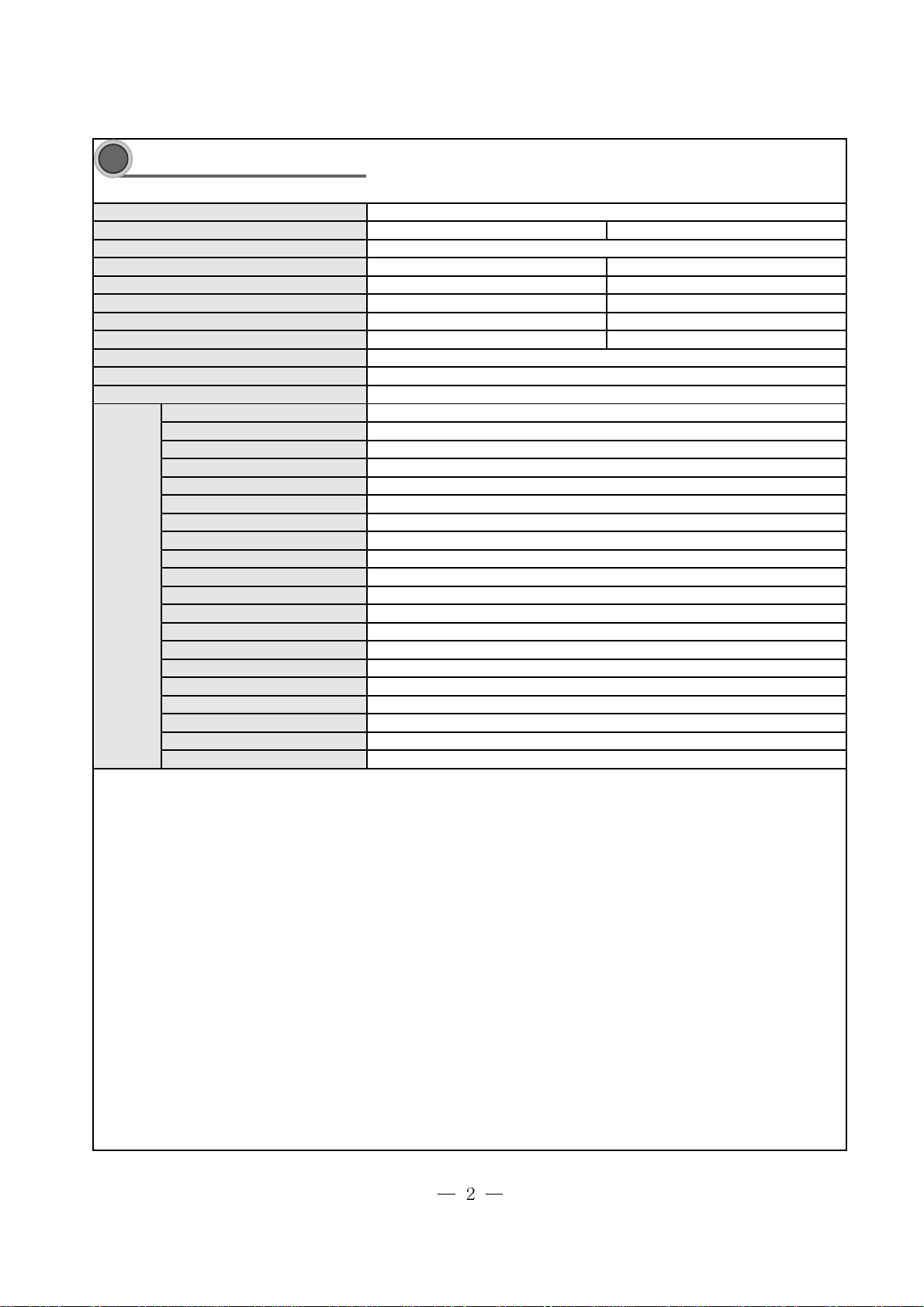

Specifications and technical parameters

2

Model

Function

Rated Voltage

Total Capacit y ( W)

Rated Input ( W)

Rated Cur r ent (A)

Air Flow Volume (m

Dehumidifying Volume (l/h)

Model of Indoor Unit

Fan Motor Speed (r /min)

Output of Fan Mot or ( w)

Input of Heater (w)

Fan Motor Capacitor (uF)

Fan Motor RLA(A)

Fan Type-Piece

Diameter-Length (in)

Evaporator

Indoor

Unit

Pipe Diameter( in)

Row-Fin Gap(in)

Coil lengthxheightxcoil widt h(in)

Swing Mot or Model

Output of Swing Motor ( W)

Fuse (A)

Sound Pr essure Lev el dB ( A)

Sound Power Level dB ( A)

Dimension ( in)

Dimension of P ac k age(in)

Net Weight/Gr oss Weight(lb)

/h) (H/M / L)**

KFHHP-22

COOLING HEA TING

208-230V~

23800/22000B tu 27000/24200B tu

2240 2280

10.18 10.36

1050/950/880

3

KFHHP-22-ID

1400/1300/1200

20

0.4

Cross f low fan – 1

φ4.17 X35.04

Aluminum fin-c opper tube

Φ0.28

2-0.055

35.5X0.083X15

MP24GA

PCB 3.15A Tr ansfor mer 0. 2A

52/50/48

46.38 X12.83X8.94

49.8X16.42X13.11

38.6/53

Page 3

Outdoor

unit

Model of Outdoor Unit

Compressor Model

Compre ssor Type

L.R.A. ( A)

Compre ssor RLA( A)

Compressor Power Input( W)

Overload Prot ec tor

Thr ottling Method

St ar ting Method

Wor k ing Temp Range (ć)

Condenser

Pipe Diameter(in)

Rows-Fin Gap(in )

Coil lengthxheightxcoil widt h(in)

Fan Motor Speed ( r pm)

Output of Fan Motor (W)

Fan Motor RLA(A)

Fan Motor Capacitor (uF)

Air F low Volume of Outdoor Unit

Fan Type-Piec e

FanDiameter (in)

Defr osting Method

Climate Type

Isolation

Moisture Pr otect ion

P er missible E xc essive

Oper ating Pressure for the

Discharge Side(MPa)

P er missible E xc essive

Oper ating Pressure for the

Suction Side(MPa)

Sound Pr essure Lev el dB ( A)

Dimension (W/D/H)( in) 37.4X16.22X33.07

Package Dimension(W/D/H)(in)

Net Weight /Gross Weight (lb)

Refrigerant Charge (oz)

KFHHP-22-OD

C-6RZ146H1A

Rotary

40

8.4

1640

1NT11L-3979

Capillary t hr ottling

Tr ansducer star ting

-10~43

˄

Aluminum fin- c opper tube

26.9X32X1.73

Axial fan –1

Auto defrost

43.3X17.7X35.6

141.1/152.1

R410a/84

ć˅

φ0.3748

2-0.055

780/600

60

0.25

3

/

φ18.11

T1

I

IP24

4

/

59/58

Connection

Pipe

Length(ft)

Outer

Diameter

Max

Distance Length(ft)

Liquid Pipe (mm)

Gas Pi pe (mm)

Height ( ft)

26.25

Φ9.52(3/8”)

Φ16(5/8”)

40

100

The data above is subject to change without notice .Please refer to the nameplate of the unit

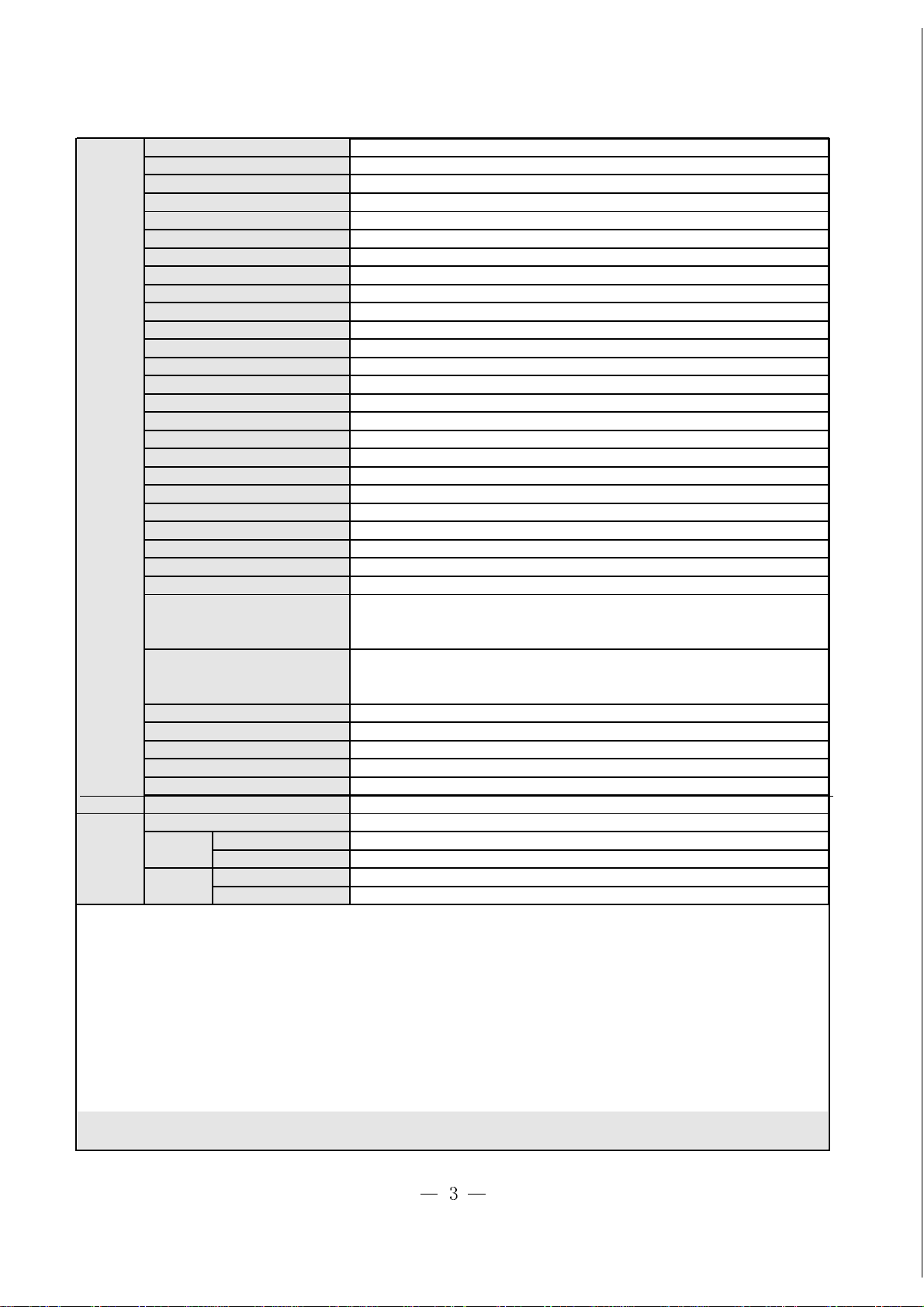

Page 4

Components name

front panel

filter

air guider

dispaly board

front case

cover of electrical box

remote control

display

heating

cooling

run

receiver

connecting pipe and calbe

air outlet grill

drain hose

manual switch

manual switch

Outdoor unit

Indoor unit

Page 5

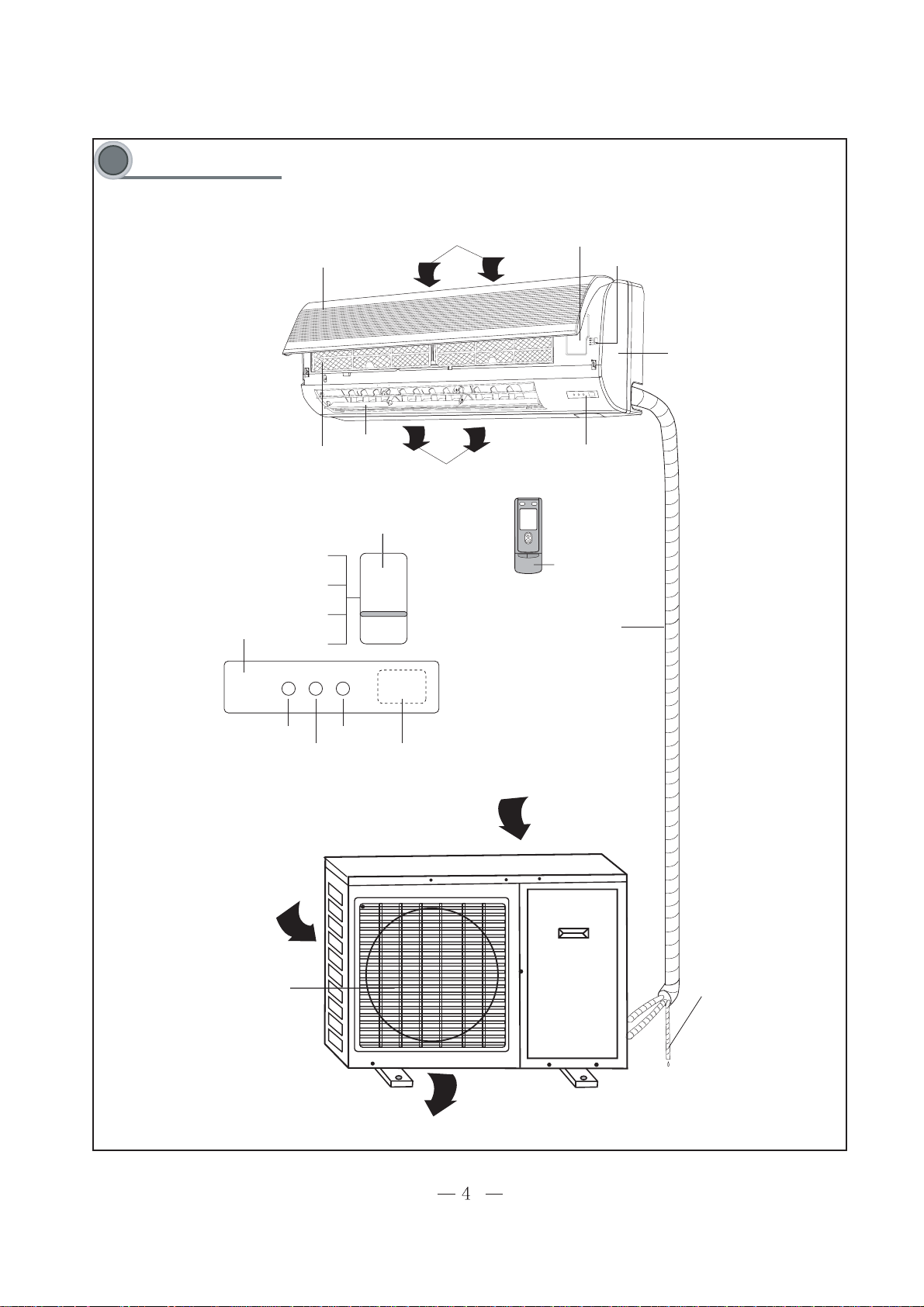

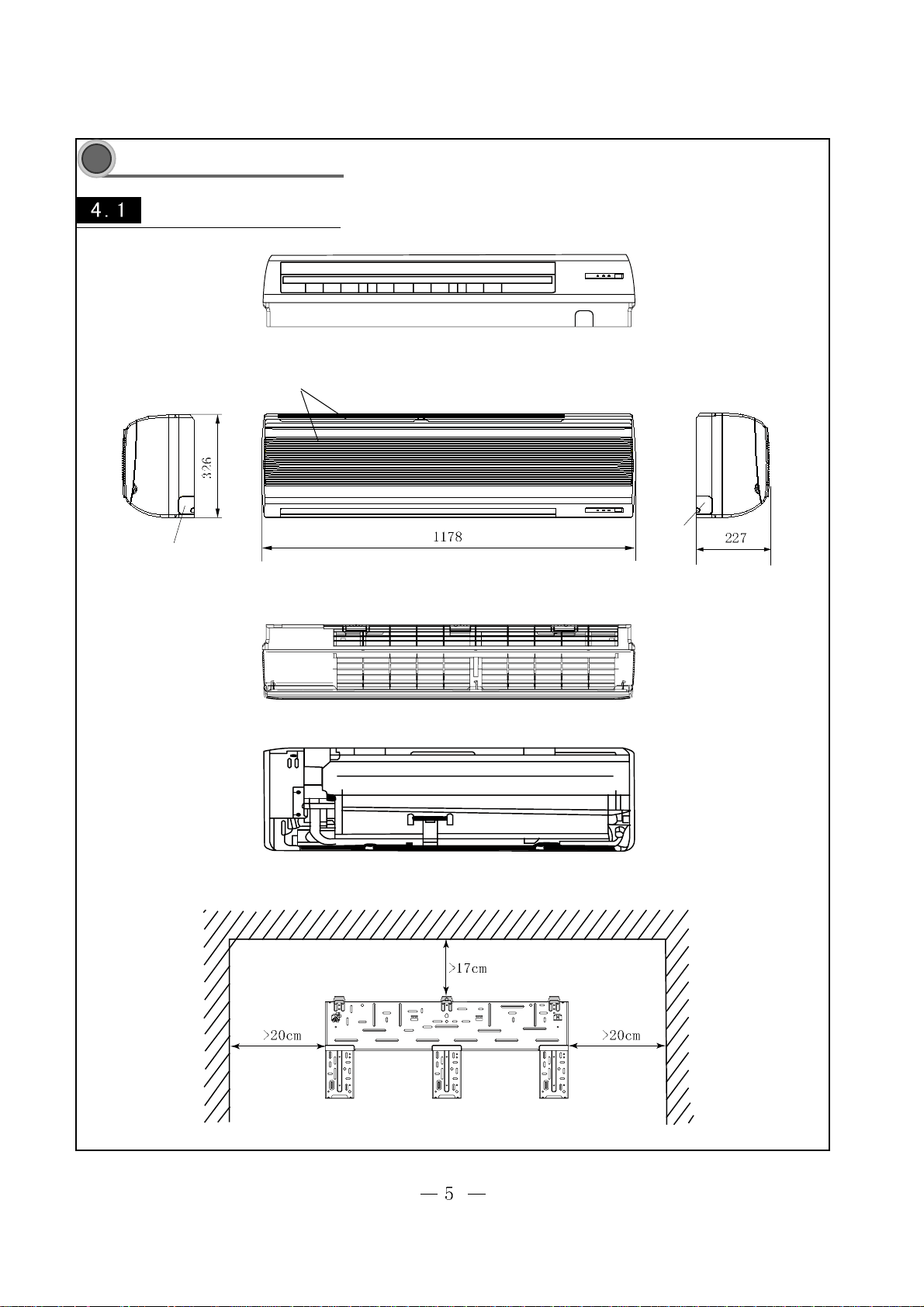

Overall and installation dimension

4

Overall and installation dimension of indoor unit

air inlet grill

left tube-exit sign

top view

KFHHP-22-ID

right tube-exit sign

left

rear view

Unit:mm

Ceiling

right

Page 6

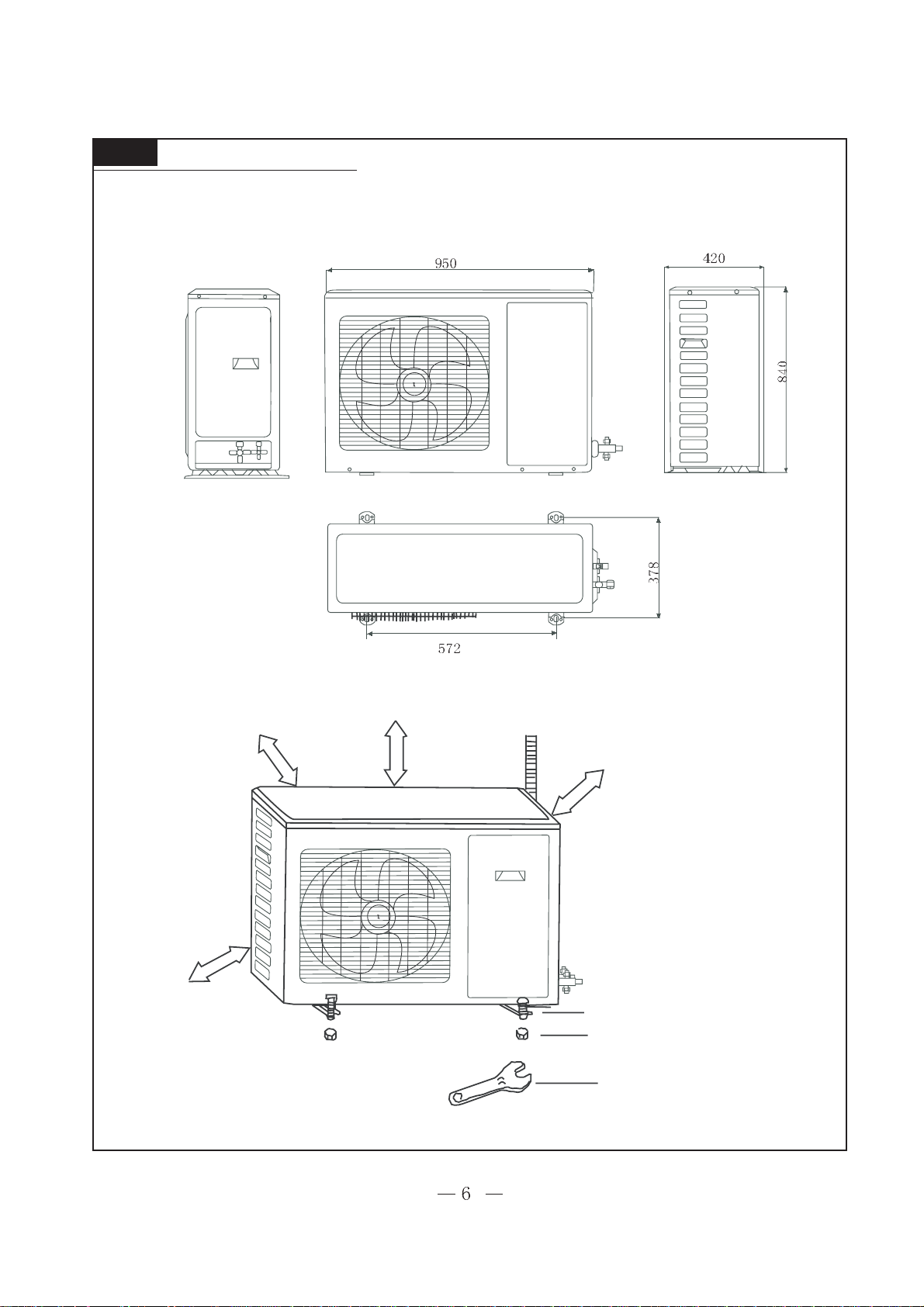

Overall and installation dimension of outdoor unit KFHHP-22-OD

over

over

over

bolt

nut

wrench

unit :mm

Ggggg

Page 7

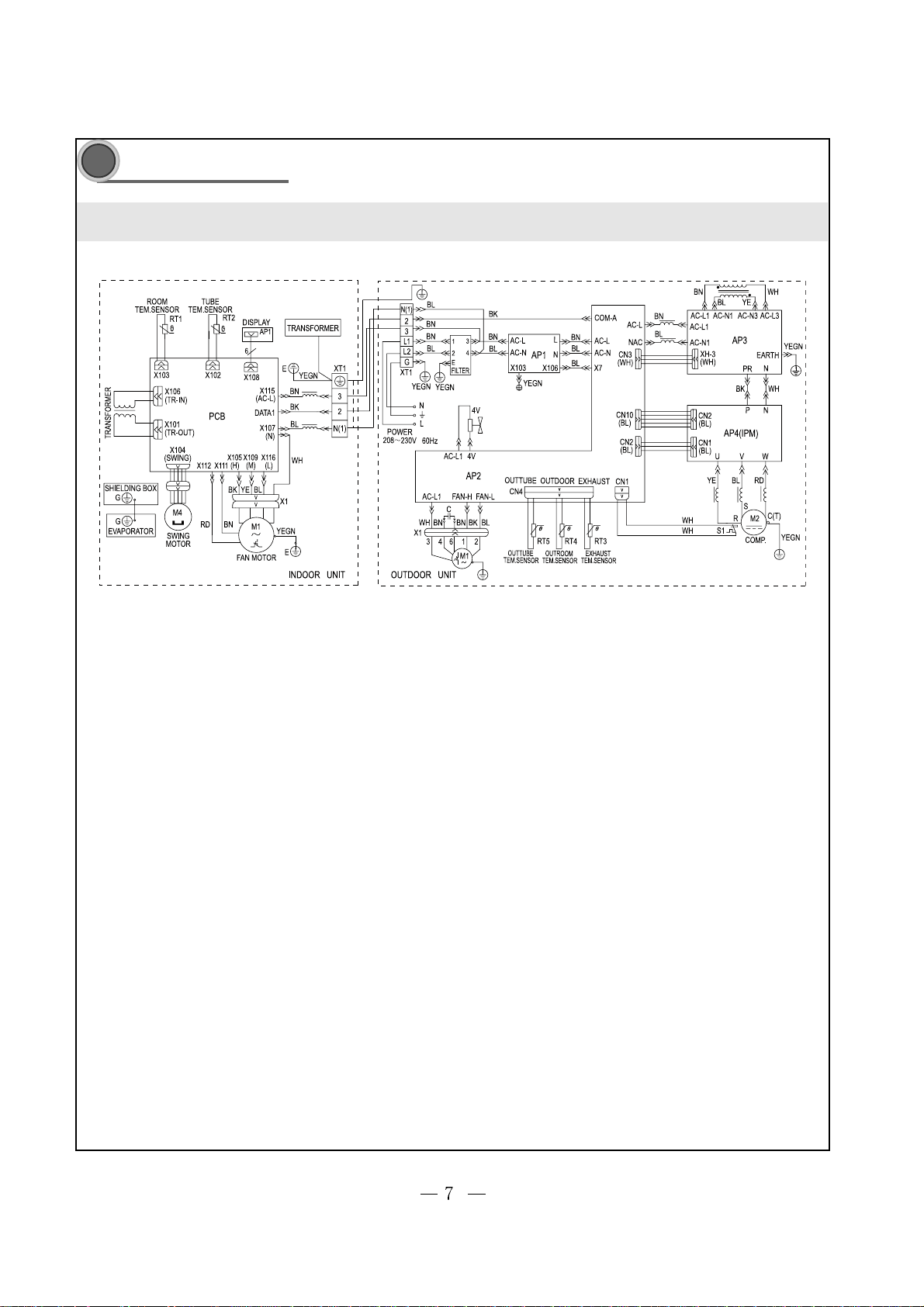

Electrical diagram

55

5

55

KFHHP-22

The diagram above is subject to change without notice.Please refer to the diagram label on the unit

Page 8

Function manual and operating method of controller

6.1 Function manual

6.1.1 Temperature parameters

ƹ

Room set temperatures(Tset)

ƹ Room ambient temperatures(Tin-amb)

6.1.2 Fundamental function

6.1.2.1 Cooling mode

ƽtemperature setting range is 16-30¨C

ƽunder this mode, fan motor of indoor unit operates at setting speed.

ƽwhen compressor stops because of malfunction protection, fan motor of indoor unit still operates at setting speed.

6.1.2.2 Dehumidifying mode

ƽTemperature setting range is 16-30`C

ƽIndoor fan motor runs at low setting speed.

ƽwhen compressor stops because of malfunction protection, indoor motor still operates at low speed.

6.1.2.3 Fan mode

ƽTemperature setting range is 16-30`C

ƽIndoor fan can operates at selected speed of HIGH,MED,LOW and AUTO.

6.1.2.4 Heating mode

ƽTemperature setting range is 16-30`C

ƽsending out remaining heat: after indoor fan runs at setting speed for 60s

ƽanti cold air: indoor fan will start in 2 minutes at latest

ƽwhen compressor stops at setting temp., indoor fan motor operates in discharging remaining heat

ƽwhen compressor stops because of malfunction protection, indoor fan runs in discharging remaining heat.

ƽon receiving signal of defrosting, indoor fan motor stops; when defrosting ends, fan motor runs under anti cold air status.

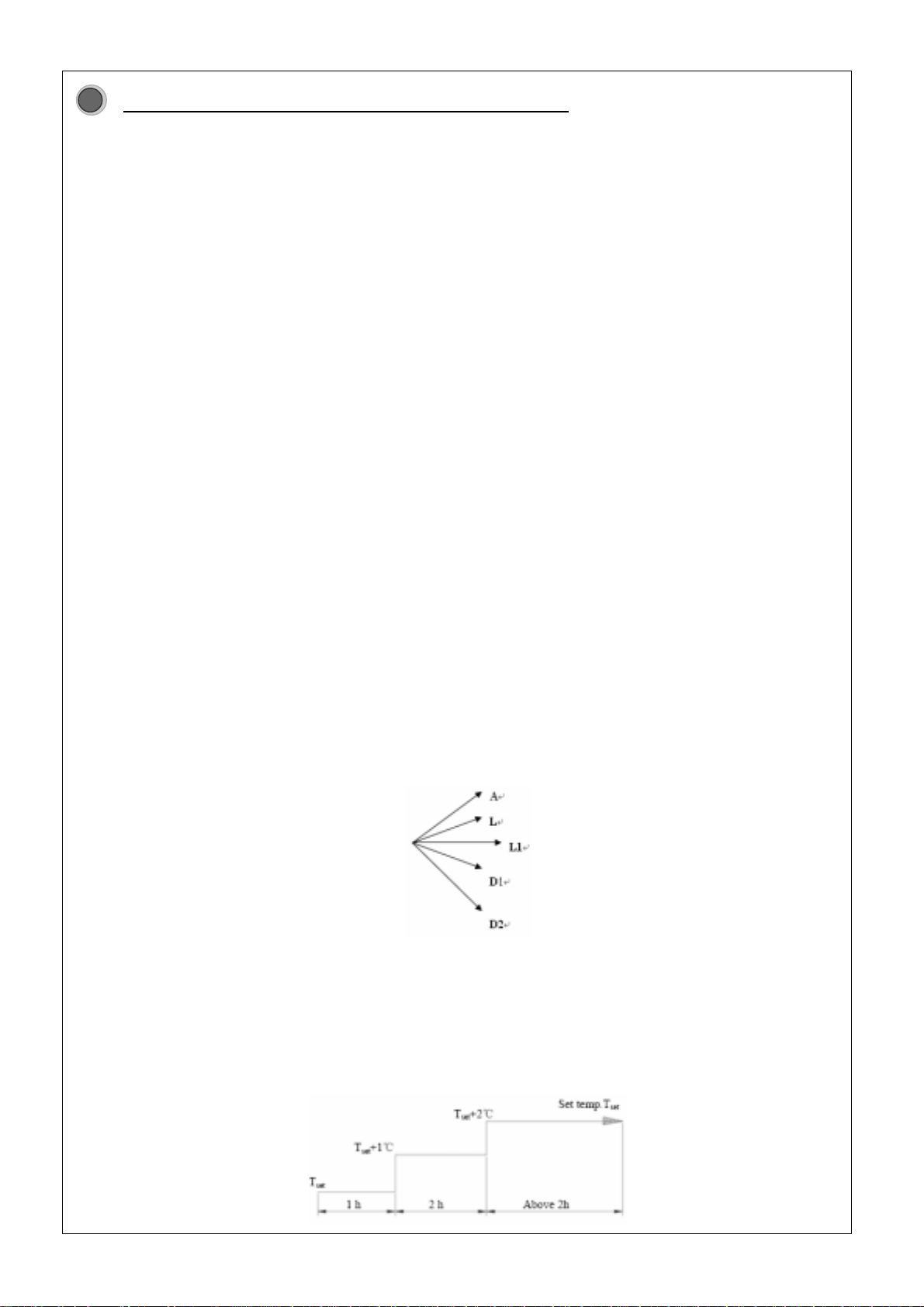

6.1.2.5 Auto mode

In this mode, indoor fan will run in Cooling, heating, air discharging mode according to the change of ambient temperature. And the protection

function is the same as under Cooling, Heating mode.

6.1.3 Other control

6.1.3.1 auto control of speed of indoor fan

indoor fan runs automatically at HIGH,MED,LOW speed according to the change of ambient temperature. The interval of speed switching is 3

minutes and 30 seconds at least. When in dehumidifying mode, fan runs at setting low speed.

6.1.3.2

when the power is on, the air guide louver will turns to A position counter-clockwise and closes the air outlet went.; after the unit starts in heating

mode, it turns to the max air outlet position D2; after unit starts in cooling mode, it will turns to D1 position and then back to L1 position; when in swinging

state, it will swing between L1 and D1 in cooling; between L and D2 in heating. After the unit is off, it will turns back to A position to close the air outlet

vent.

6.1.3.3 Timer control

The auto-start timer function can be set when the unit is off. When it reaches the time, the controller will function in the originally set mode. The

interval is 0.5 hour and the range of timer is 0.5-24 hours.

The auto-stop timer can be set when the unit is on. When it reaches the time, unit will be off automatically. The interval is 0.5 hours and range of

timer is 0.5-24 hours.

6.1.3.4 Sleep control

When units in cool or dry mode, after sleep mode has been set properly, the preset Tset will be increased by 1ć after sleep program has run for 1

hour. And Tset will be increased by another 1ć after 2 hours.Tset has been increased by 2ć totally in two hours. Then the unit will run at this set

temperature and at the set speed.

66

66

6

-8-

Page 9

When unit is in HEAT mode, after sleep mode has been set properly, the preset Tset will be increased by 1ć after the sleep program has run for 1

hour, and Tset will be decreased by another 1ć after 2 hours.Tset has been increased by 2ć totally in two hours Then the unit will run at this

temperature and at the set speed.

In Auto OR fan mode, the setting temp. will not change.

6.1.3.5 Toggle switch

1, If memory function is on, when unit is power-on and start operation and toggle switch is in STOP position, the unit will operates with STOP position; or

else unit starts under power-off memory. There is memory function with AUTO,RUN,STOP position. TEST position is without memory function.

2, If there is no memory function, unit will operate under previous switch position.

ƾ When toggle switch is on AUTO, unit operates in AUTO mode, and air swing on; if there is signal of remote control, then unit operates according to

signal.

ƾ When toggle switch is on TEST, indoor fan runs in high speed, and air swing on; indoor unit sends out signal of Cool mode on 16ć and 30ć

ambient temperature to outdoor unit. If malfunction of indoor or outdoor temp. sensor is detected, buzzer will give out beep to alarm. If there is signal of

remote control, unit operates as per remote control and indoor unit sends remote control signal to outdoor unit.

6.1.3.6 Communication failure

Communication failures happen if there is no correct signal received for 3 minutes

6.1.3.7 Buzzer control

When unit is power on or receiving remote control signal or the toggle switch is pressed, the buzzer will give out a beep.

6.1.3.8 Power-off memory function

1) contents of memory: mode(AUTO, COOL, DEHUMIDIFYING, HEATING, etc), setting fan speed, setting temperature, Timing etc.

2) if unit was on when power off, 3 minutes is delayed for indoor unit to send signal of starting to outdoor unit.

3) When power is on again, unit will operate in previous mode before power-off.

4) If there was no timer function in the last remote control dictation, then unit will memorize the last remote control dictation and operate according to

the previous mode

5) If there was timer function in the last remote control dictation and system was power-off before the time set, unit will memorize the last timer function

and it will time from the begin of restarting.

6) If there was timer function in the last remote control dictation and system was power-off at the time set, unit will operate in the mode before

power-off but timer won’t be on.

6.1.3.9 Failure detect of indoor temp. sensor

When unit is defrosting, temp sensor malfunction is not under detection. In other status temp sensor malfunction of indoor ambient and tube are

under malfunction. If the temperature is not between the minimum and maximum for continuous 30s, signal of error will be sent out.

When indoor temp sensor failures, it will send signal of closing down unit to outdoor unit.

6.1.3.10 Method for testing (min, med, nominal, max cooling or heating)

Temp. set in remote control 16 17 18 19

In Cool mode, press Sleep button 4

times in succession within 3

seconds

Temp. set in remote control 27 28 29 30

In Heat mode, press Sleep button 4

times in succession within 3

seconds

Press any button to exit.

Cooling mode: temperature signal sent to outdoor unit is compulsively set 16ć when cooling capacity is min, med, nominal or max.

Heating mode: temperature signal sent to outdoor unit is compulsively set 30ć when heating capacity is min, med, nominal or max.

Notice: when test is started, relevant indicating lamp blinks quickly. If there is malfunction, it will be displayed directly

Min. cooling Med. Cooling Nominal cooling Max. cooling

Min. heating Med. heating Nominal heating Max. heating

-9-

Page 10

Controller function of outdoor unit

6.1.1 Parameters of temperature

Exhausting gas temperature of outdoor unit(Tex)

Ambient temperature of outdoor unit(Tam)

6.1.2 Fundermental function of system

In wichever mode, once compressor start-up, it can only be close down 6 minutes later at

least(not including malfunction protection/mode switch which requires compressor to stop);Once

compressor closes down, it can only restart 3 minutes later at least(including mode switch, stop by

remote control etc.);compressor starts up after outdoor motor runs for 5 seconds

6.1.2.1 Cool mode

6.1.2.1.1

Working conditions and process of cooling

ƽwhen compressor in closing down state and (Tin-am-Tset)ı0.5ć,if unit start in cooling mode,

then cooling mode operates; outdoor fan motor and compressor start to run. The frequency of

compressor can be adjusted automatically according to need of cooling power by micro-computer.

ƽ during cooling process, when 0 ćİ(Tset-Tin-am) İ 2 ć ,the compressor operates in low

frequency.

ƽduring cooling process, when 0 need of cooling power and (Tset-Tin-am)˚2ć, then compressor

stops running. And outdoor fan motor stops in 60s.

NJIn this mode, there is no power supply for reversing valve. Range of temperature setting is 16-30

ć.

6.1.2.1.2 Frost-proof protection

In cool and dehumidifying mode, when frost-proof protection is detected, the compressor will run in

lower frequency or stops. And outdoor fan motor stops in 60s. When frost-proof protection ends,

Compressor resumes running.

6.1.2.1.3 Controlling principles of outdoor fan motor

If Tout-amı26ć, the fan motor runs in high speed.

If Tout-amİ24ć, the fan motor runs in low speed.

If 24ć˘Tout-amb˘26ć, the fan motor runs in original speed.

After fan motor runs in compulsive high speed for 3 minutes in starting-up, then the speed will be

controlled by the set principles

6.1.2.2 Dehumidifying mode

ƽWorking conditions and process of dehumidifying: the same with the ones in cooling mode

ƽstatus of 4-way valve: closed

ƽrange of temperature setting: 16-30 ć

ƽprotection function: the same with the ones in cooling mode.

6.1.2.3 Fan mode

ƽcompressor, outdoor fan motor and 4-way valve are closed and stopped.

ƽrange of temperature setting: 16-30 ć

6.1.2.4 Heating mode

6.1.2.4.1 Working conditions and process of heating

ƽwhen compressor in closing down state and (Tin-amb-3) ćİ(Tset-0.5) ć, if unit start in heating

mode, then heating mode operates. Outdoor fan motor ,compressor and 4-way valve start to run.

The frequency of compressor can be adjusted automatically according to need of heating power by

micro-computer.

-10-

Page 11

ƽ during heating process, when Tset ćİ(Tin-amb-3) ćİ(Tset +2)ć,the compressor operates

in low frequency.

during heating process, when (Tin-amb-3) ć˚(Tset +2)ć, then compressor stops running. And

outdoor fan motor stops in 60s.

Notice: It will take 2 minutes to power-off in 4-way valve when the unit closes down in heating mode

or switch from heating mode to other modes.

NJIn this mode, there is power supply for reversing valve. Range of temperature setting is 16-30ć.

6.1.2.4.2 Controlling principles of outdoor fan motor

If

Tout-ambİ19ć, the fan motor runs in high speed.

If Tout-ambı21ć, the fan motor runs in low speed.

If 19ć˘Tout-amb˘21ć, the fan motor runs in original speed.

After fan motor runs in compulsive high speed for 3 minutes in starting-up, then the speed will be

controlled by the set principles

6.1.2.4.3 Defrosting process

When defrosting conditions is detected, if compressor run in high frequency, then frequency will

be demultiplied first. Later compressor stops running and indoor fan motor stops. Outdoor fan motor

stops in 50s later. 4-way valve will be power-off in 45s. The defrosting functions operates when

compressor restart in 55s and frequency reaches 90hz. When the defrosting is over, the frequency

will drop until it reaches 60hz. 50s later 4-way valve and outdoor fan motor will be power-on.Then

frequency of compressor will rise to the required. But indoor fan motor have to start 2 minutes later

at least.

If compressor closes down for malfunction in heating mode, indoor motor will only exhausting

remaining heat.

6.1.3 Universal protection function of cool, heating, dehumidifying and auto

mode

6.1.3.1 Overloading protection function

When over-high temperature of tube (Ttube) is detected, frequency of compressor will be

demultiplied or limited. When Ttube is beyond maximum, compressor stops until Ttube restrores to

normal value.

If there are 6 continuous times of over-high Ttube protection, compressor will stop and can not

restart by itself. It can only be restart by pressing “ON/OFF” button. In operation if operating time of

compressor is over 7 minutes, the number of times will be zero cleared.

6.1.3.2 Time-delay protection of compressor

Compressor will restart in 3 minutes after it closes down.

6.1.3.3 High exhausting gas temp. protection of compressor

When over-high temperature of gas exhausted (Tex) is detected, frequency of compressor will

be demultiplied or limited. When Tex is beyond maximum, compressor stops until Ttube restrores to

normal value.

If there are 6 continuous times of over-high Tex protection, compressor will stop and can not

restart by itself. It can only be restart by pressing “ON/OFF” button. In operation if operating time of

compressor is over 7 minutes, the number of times will be zero cleared.

6.1.3.4 Current protection function

(1) overcurrent protection

If current of whole unit is beyond max. limit, unit will close down as if indoor temperature reaches

the set temperature. Unit will restore automatically after compressor has been stop for 3 minutes.

-11-

Page 12

If there are 6 continuous times of protection, compressor will stop and can not restart by itself

and send signal of error to indoor unit. It can only be restart by pressing “ON/OFF” button. In

operation if operating time of compressor is over 7 minutes, the number of times will be zero

cleared.

(2) frequency demultiplying, limitation of current control

If current of whole unit is high, frequency of compressor will be demultiplied or limited. If normal

current value is detected, whole unit restore to operate normally.

6.1.3.5 Communication failure

When there is no right signal from indoor unit for continuous 3 minutes or no right signal from

driving slug within 60s, communication failure happens. Outdoor unit will closes down.

6.1.3.6 Module protection

Compressor will detect signal of module protection right away after it starts. Compressor closes

down in module protection status as if room temperature reaches the set value. And relevant error is

displayed. Compressor restores to run after stopping for 3 minutes.

If there are 6 continuous times of protection, compressor will stop and can not restart by itself. It

can only be restart by pressing “ON/OFF” button. In operation if operating time of compressor is

over 7 minutes, the number of times will be zero

6.1.3.7 overheating protection of module

When IPM temperature is too high, frequency of compressor will be demultiplied or limited. Wen

IPM temperature is beyond maximum, compressor closes down. The whole unit can only restart

when IPM temperature returns to norm and compressor has been stopping for 3 minutes.

If 3 times of IPM temperature protection happens in 1 hour, compressor will stop and can not

restart by itself. It can only be restart by pressing “ON/OFF” button.

6.1.3.8 overloading protection of compressor

When overloading switch of compressor operates, it will closes down as if room temperature

reaches set value. Whole unit can only restart when compressor has been stopping for 3 minutes

and overload switch resets.

6.1.3.9 PFC protection

When air conditioner starts in cooling, heating or dehumidifying mode, compressor starts and

frequency rises to 30hz. PFC protection is on after it runs for 30s.

Compressor closes down in whatever condition, PFC and compressor closes down at the same

time.

PFC protection signal will be detected once after PFC starts; when PFC protection is on, PFC and

compressor closes down at the same time.

PFC restores automatically 3 minutes later after failure happens

6.1.3.10 Testing of malfunction of temp. sensor and IPM overheating

(1) In stand-by status outdoor tube temperature sensor, ambient temperature sensor and sensing

device error of overheating IPM are not under detection.

(2) error of temp. sensor of exhausting gas and error of IPM overheating will be under detection after

the whole unit is on and compressor operates for continuous 3 minutes.

(3) within 10 minutes after compressor starts or within 10 minutes after defrosting or oil returning in

heating mode, error of outdoor tube temp. sensor are not under detection.

(4) when error of IPM overheating or failure of temp. sensor is detected, whole unit will closes down

immediately.

-12-

Page 13

6.1.3.11 The status of indicator in outdoor unit

Notice: When the unit is power-on again, the times of all the protection above (including: overloading protection, high

exhausting gas temp. protection of compressor, overcurrent protection, module protection etc.) will be reset.

D11 Meaning D12 Meaning D13 Meaning

blink 1 time compressor starts to run blink 1 time cooling overload

protection stop

blink 1 time quick cooling/heating

blink 2 tim es exhaust protection st op blink 2 tim es heating overload

protection stop

blink 2 times defrosting

blink 3 times closing down for NEC

driving module protection

blink 3 times communication failure

with indoor unit

blink 3 times oil returning

blink 4 times closing down for

overcurrent protecti on

blink 4 times communication failure with

NEC module

blink 4 times nominal

cooling/heating

blink 5 times closing down for

overloading protection

blink 5 times communication failure with

computer

blink 5 tim es max. cooling/heating

blink 6 tim es cooling antifreezing stop blink 6 times failulre of outdoor ambient

temp.sensor

blink 6 times medial cooling/heating

bli nk 7 times sensor m alfunc ti on st op blink 7 times failure of outdoor

tube-temp.sensor

blink 7 tim es min.cooling/heating

blink 8 times closing down for

communication

failure(including indoor

unit and NE C driving

module)

blink 8 times failure of outdoor

gas-discharge

temp.sensor

blink 8 tim es unit off

blink 12 times closing down for IPM

overheating protection

blink 9 times communication failure

sent from indoor

blink 9 tim es low pressure and can’t

resume

blink 10

times

wrong parameters sent to

NEC driver, unit closes

down

blink 11

times

IPM temp. sensor failure

D14 meaning D15 meaning D16 meaning

blink 1 tim e frequency demultiplying

for high t emp.of gas

discharged

blink 1 tim e frequency limiting for high

temp.of gas discharged

on Be receiving or sendi ng

computer data

blink 2 tim es frequency demultiplying

for overcur rent protection

blink 2 times frequency limiting of

overcurrent protecti on

off receiving or sending

computer data finished

blink 3 tim es frequency demultiplying

for cooling overload

blink 3 times frequency limiting for

cooling overloading

blink 4 tim es frequency demultiplying

for heating overload

blink 4 times frequency limiting for

heating overloading

blink 5 tim es frequency demultiplying

for frost-proof

blink 5 tim es frequency of current 9.4 A

lasting for 2 minutes

-13-

Page 14

D14 Mean ing D15 Meaning

blink 6 times Unit closing down for

min.frequency

blink 6 tim es frequency of current 12 A lasting for 2 minutes

blink 7 times Unit closing down for

PFC protection

blink 7 tim es frequency limiting or demultiplying for rate of

frequency variation out of control

blink 8 times Unit closing down for

compressor overloading

blink 8 tim es frequency limiting or demultiplying of compressor

current

blink 9 tim es frequency limiting or demultiplying for over temp.of

IPM module

D17 Mean ing D18 Meaning

blink 1 tim e too low DC input voltage On receiving or sending indoor d ata

blink 2 tim es too high DC voltage

when no short-circuit in

computer monitor port

off receiving or sending indoor data finished

blink 3 tim es AC current protection blink normal communication between main borad and

driving board

blink 4 times IPM abnormality

short-circuit in

computer monitor port

not

blink

abnormal c ommunication between m ain board and

driving board

blink 5 times reserved built-in PFC

protection

blink 6 times start-up failure

bli nk 7 times phase-losi ng or ou t of

control

blink 8 times first PFC protection ;then

module protection

-14-

Page 15

Disassembly procedures

77

7

77

Disassembly procedures for indoor unit

Procedures and pictures

Disassembly front panel

(Refer to figure 7-1)

Disassemble filter

Push filter inside and pull it upward.Take the filter away

(Refer to 7-2)

Disassemble guide louver

filter

front panel

electrical box top cover

hook

screw

Bend the guide louver with strength and let out the hook

(Refer to figure 7-3)

-15-

hook

guide louver

Page 16

Disassemble electrical box

Disassemble electrical box cover

Disassemble front case

Unclench 3 screw covers;then unscrew 6 screws and lift

it backward.

(Refer to figure 7-4)

screws

screws

hook

electrical box cover

display board

Unscrew the srew fixing the display board and take the

board off.Hold the cover and press it to loosen the hook.

lift it upward and remove the box cover

(Refer to figure 7-5)

grounding nut

tube sensor

ambient sensor

disassemble the grounding nut on evaporator;take away tube sensor

unplug the connecting terminal for indoor fan motor and stepping motor

Unscrew the screw fixing electrical box.Take out it.

(Refer to figure 7-6)

-16-

Page 17

Disassemble water tray

Unloose the clasp fixing water tray;lift and disassemble it

(Refer to figure 7-7)

Disassemble evaporator assy

Unscrew 2 screws on the clamp and remove the clamp

unscew the 2 screws fixing evaporator on left and right side.

Take out the evaporator by you hand and push it backward to let out

the side clasps from the groove.Take out the evaporator carefully

,-,protect the connecting pipe

(Refer to figure 7-8,7-9,7-10)

water tray

hook

screws

clasp

screws

clamp

-17-

Page 18

Disassemble cross flow fan

Disassemble motor

take out the bearing on the left and remove the cross flow fan

fan bearing

cross flow fan

screws

screws

motor

press plate

Unscrew the screws fixing press plate and take out press plate

Unscrew the one M4 screws and remove the motor

(Refer to 7-11)

(Refer to 7-12)

-18-

Page 19

Disassembly procedures for outdoor unit

Operating procedures /pictures

Disassemble front side plate

unsrew the 4 srews around the front side plate and take off it

(Refer to figure 7-13)

Disassemble top cover

Unsrew the srews around the top voer plate;lift the

top cover and remove it

(Refer to figure 7-14)

front side plate

srews

top cover

srews

Disassemble rear grill

Unscrew the 4-self tapping screws on rear side plate

and take off the grill.

-19-

srews

rear grill

Page 20

Disassemble right side plate

Disassemble electrical box

Disassemble housing case

unsrew the screws around the housing case and take off it

housing case

screws

screws

cover of electrical box

screws

screws

right side plate

unscrew the 7 srews in right side plate,condensor side plate and

valve support;lift right side plate and remove it.

(Refer to 7-19)

Screw out the 2 screws fixing the electrical box;

lift it and remove it.

(Refer to figure 7-17,7-18)

-20-

Page 21

Operating procedures /pictures

Disassemble axial-flow fan

Loosen the nut with spanner and remove it.

axial-flow fan

Disassemble motor and motor support

Unscrew four tapping screws fixing the motor,and

remove the motor.Unscrew the two tapping screws fixing

the motor support,lift and remove it.

(Refer to figure 7-21)

motor support

nut

motor

screws

cable

screws

Disassemble 4-way valve

Unscrew the nut holding 4-way coil and remove the coil;

Use wet cotton cloth to wrap 4-way valve;unsodler 4 points

connecting 4-way valve and remove it.

Be quick during the process;try to make the cotton

wet all the time.Don't allow the flame to burn the

lead-out calbe of compressor

Refer to figure 7-22)

4-way valve

soldering points

-21-

Page 22

Disassemble compressor

Unsolder the soldering points between the pipes and compressor;unscrew

the three nuts with washers at the foot of compressor;take out the compressor

compressor

(Refer to figure 7-25)

Figure

compressor nuts

Disassemble valves

Unsrew the two screws fixing the big valve;unsoldering the soldering

points between the big valve and air-return duct;remove big valve

(When unsoldering,use wet cloth to wrap the big valve completely

to prevent it from being harmed by high temperature.

Unscrew the 2 screws fixing small valve;unsolder the joint points

between small valve and fork type pipe;remove small valve

(Refer to figure 7-24)

small valve

screws

big valve

Disassemblle capillary

Unsolder the joint points between capillary and other pipelines;them it

can be removed

(Refer to figure 7-23)

capillary

Operating procedures/pictures

-22-

Page 23

Exploded view and components&part list

8

indoor unit

KFHHP-22-ID

-23-

Page 24

Components and part list of indoor unit

Part Code

QtyNo Description

KFHHP-22-ID

1 Wall- Mounting Fr ame 01252398 1

2 Rear Case 22202040 1

3 Water T r ay 20182043 1

4 Rear G r ill 01473007 1

5 Upper Air Deflect or 10512062 1

6 Lower G uide Louver 10512063 1

7 Scr ew Cap 242520053 3

8 Air Louver 10512030 15

9 Swing Lever 10582040 3

10 Drain Pipe 05232411 1

11 Cross Flow F an 10352420 1

O-Gasket of Cross Fan

12

Bearing

13 Ev apor ator Assy 010041291 1

14 Ev apor ator Lef t Support 24212041 1

15 Front Case Sub-Assy 20002572 1

16 Filter S ub- Assy 11122051 2

17 Remote Control 30510029 1

18 Front P anel 20002375 1

19 Receiv er B oar d 30046093 1

Ambient Temperat ur e

20

Sensor˄15K

21 Wire Clamp 71010103 1

22 Terminal Board 42011233 1

23 Toggle Swit c h 10582007 1

24 Electr ic B ox Cover 201022521 1

25 Electr ic B ox Cover 201022512 1

26 Main P CB M9WA25A 30039161 1

27 Fuse T3.15AL 250V 46010014 1

28 Transformer 41X26. 5F 43110025 1

29 Electr ic B ox 201022501 1

30 Tube Sensor˄20K

31 Sensor Insert 42020063 1

Lower Shield Cover for

32

Electric B ox

33 Fixed Clip 02112009 1

34 Motor F ixed Clip 26112069 1

35 Fan Motor FN30C 150121071 1

Retaining P late of

36

Evaporator

37 Sheet Met al P iec e 02123005 1

38 Stepping Mot or MP24GA 15212102 1

Upper Shield Cover for

39

Electric B ox

40 Pipe Clamp 26112071 1

˅

˅

76512203 1

390000451 1

390000591 1

01592048 1

24212042 1

01592033 1

-24-

Page 25

Exploded view of outdoor unit

KFHHP-22-OD

-25-

Page 26

Components and part list of outdoor unit

Part Code

KFHHP-22-OD

1 Fr ont Gr ill 01473001 1

2 Housing 01433011 1

3 Small Handle 26235401 1

4 Clapboard Assy 01233039 1

5 Axial Flow Fan 10335253 1

6 Fan Motor F W60H 15013704 1

7 Motor S uppor t Sub-Assy 01703087 1

8 Condenser A ssy 01103813 1

9 Temp Sensor Support 24213005 1

10 Top Cover 01255262 1

11 Rear Grill 01475252 1

12 Reactor 43120011 1

13 Electr ic B ox Assy 01403591 1

14 Module S uppor t 24213008 1

15 PCB JG P 011 30111018 1

16 Electr ic B ox Cover S ub- Assy 01403629 1

17 Main P CB 2 W9W2 30039165 1

18 PCB Support˄up

19 PCB Support˄down

20 PCB Support 24213009 1

21 Main P CB 1 W9W2 30039164 1

22 Filter ing B oar d W9W2 30039163 1

23 Temperature S ensor 3900028001 1

24 Sensor Insert 42020063 1

25 Sensor Insert 42020066 1

26 Capacitor 33010027 1

27 Terminal Board 42010255 1

28 Filter 43130008 1

29 Wire Clamp 71010102 1

30 Isolation Washer 70410523 1

31 Wire Clamp 71010003 1

32 Cable-Cross Loop 76514004 5

33 Radiator 49013011 1

34 Capillary S ub- Assy 03103391 1

35 Cut-of f Valve 07130209 1

36 4-way Valve 43000411 1

37 4-way Valve Fittings 4300040022 1

38 Gas Valve Sub-Assy 07103030 1

39 Rear Side Plat e S ub- Assy 01302005 1

40 Compress or 00103501 1

41 Underpan A ssy 01203560 1

42 Front S ide P late 01302007 1

43 Choke Plug 06813401 1

˅

˅

26153031 8

24213010 8

QtyNo Description

-26-

Page 27

Troubleshooting

d

N

hei

r

y

p

9

Analysis in this section is used for D.C. Variable Frequency Series. Before analysis, you can diagnose

according to the code displayed on indoor unit or indicator display on outdoor unit. (Refer to Malfunction

display section).

Air

conditi

oner

cannot

start up

Breaker trippe

or fuse burnt out

Air conditioner

does not response

after powered on.

(The buzzer does

not sound after the

plug is connected

and the unit does

not response after

the remote

controller is used

to turn it on)

Remote

controller does

not receive signal

(When powered

on, the buzzer

will send out a

sound, unless it is

broken)

When the breaker is set ON, it will

trip at once

When the unit is turned on, the

breaker will trip in a few minutes

o power supply

The power plug is not or poorly

connected

Controller fuse is burnt out

Loose or poor contact of transformer

connection, or transformer malfunction

The controller is broken

Batteries of remote controller are low

Malfunction of remote controller

Loose or poor connection of receiving

head

Receiving head is broken

Measure t

for grounding to confirm whether

there is electrical leakage or short

circuit in the unit

Insulation malfunction of line or componen

in the air conditioner. Insulation breakdow

occurs after radiation, which causes shor

circuit or electricity leakage. Measure

insulating resistance or use one-by-on

elimination method;

Malfunction of fuse. Replace it.

Check power supply circuit

Check and plug well plug, make

Change control fuse

Secure the wire connection: measure

the output voltage of the transformer

and replace it if the value is wrong

Replace the controlle

Change batter

First press the "AUTO" button of the

manual switch. If there is no response,

check according to the above method;

if it is normal after the button is

ressed, check if the installation

location and wire connection of the

receiving head are correct. If correct,

replace the receiving head, or the

remote controller.

nsulating resistance

-27-

Page 28

When unit is

cooling or

heating, both

compressor and

outdoor fan don'

t

run

When unit is

cooling or

heating, the

compressor runs

b

ut outdoor fan

doesn't run

When cooling or

heating, outdoor

fan runs, but

compressor

doesn't run.

When cooling or

heating, outdoor

fan runs, but

compressor

doesn't run.

Fan doesn't run

when FAN mode

is set

Abnormal power supply of outdoor unit

Damage of outdoor main control board

Breakage of outdoor power module

Improper setting of temperature

Breakage of outdoor fan motor

Wrong wire connection

Breakage of outdoor main control board

Breakage of outdoor fan capacitor

Malfunction of compressor

Poor contact of connection between the

main control board and module

Abnormal input of power module

Abnormal output of power module

Compressor temperature is too high

Wrong wiring

Damage of outdoor main control board

Check the circuit according to circuit diagram

Replace the main control board

Replace the power module

Adjust the set temperature

Replace the fan motor

Wire according to the circuit diagram

Replace the main control board

Replace the fan capacitor

Replace the compressor

Re-fasten the connection

Check if input is 320V. If not, replace the

rectifie

r

Replace the power module

Cool the compressor for 30 min before running

Wire according to the circuit diagram

Replace the outdoor main control board

Burn-out or broken wire of indoor fan

moto

r

Wrong wirin

g

Circuit break or damage of fan motor

Repair or change the fan motor

Wire according to the circuit diagram

Replace the indoor main control board

-28

Page 29

Improper setting of temperature

d

f

D

f

Repl

Adjust the set temperature

Poor cooling

(heating) effect

Whether cooling (heating) loa

Leakage or shortage of refrigerant

Leakage occurs between high and

low pressure inside compressor

Malfunction of

refrigerant flow

Malfunction of four-way valve

Partial blockage of capillary

Blockage of cooling system

Poor thermal insulation of connecting

Heat exchanger of outdoor unit

Check the estimated load of cooling (heating)

Vacuumize after leakage detection

and leakage repair. Charge refrigerant

according to specification.

Replace the compressor

Replace the four-way valve

Replace the capillary

Use the method of observing condensation

on the evaporator and pressure value o

high pressure manometer to see whether

the system is blocked and carry out

corresponding handling on the system

Ensure that both thick pipe and thin pipe are insulated

well. The exposed part of the connector and copper pipe

Clean the dust accumulated on the

Air filters are blocked

Air circulation

Fan speed is set too slow

is insufficient

Fan speed turns low

Improper installation location

Outdoor temperature is too high

Indoor sealability is inadequate; too many

people go in and out frequently; there is

heating unit in the room.

Clean the filter

Set the fan speed to high or medium

amage o

capacitor

damaged

Damage of

motor

Outdoor unit should be installed in a

place with well ventilation

Flashing or awning can be installed appropriately. If the

max. cooling capacity cannot be satisfied, replacement of

the air conditioner is recommended.

ace the

capacitor

Replace the motor

Maintain a certain degree of indoor sealability. Try not to

use appliance with high amount of heat.

29

Page 30

water leakage

drain hose is blocked or broken replace the drain hose

wrap and tight it again

adjust the location of fan

abnormal things in indoor unit

remove it

compresoor shakes overly

pipes in outdoor unit collides set the pipes apart

adjust the washer and tight the bolt

metal plates collides

tighten the connecting bolt

indoor fan collides with other parts

outdoor fan collides with case

adjust the fan location

abnormal sound inside compressor

replace compressor

abnormal electromagnetic sound in

short circuit inside electromagnetic valve;repalace it

4-way valve in HEAT mode

stick shake-reduction plaster between the metal plates

CAUTION:

1,When repairing,before the voltage between module PN is measured below 50V,do not touch any terminal

to avoid electrical shock

2,When replacing power module and rectifier,make sure to spread the indicating paste evenly

abnormal shake

or sound

-30-

connector of refrigerant pipe isn't wrapped well

Page 31

Malfunction display section

9.2

Analysis or handling of some malfunction display:

1, Compressor discharge protection:

Possible reasons: shortage of refrigerant; block of air filter; poor ventilation or air flow short pass

in condenser; system has noncondensing gas(ge. Water, air);blockage of capillary (including

filter); leakage inside 4-way valve causes incorrect operations; malfunction of compressor;

malfunction of protection delay; malfunction of gas discharge sensor; too high outdoor temperature.

Handling process: refer to the malfunction analysis in the above section

2, low voltage overcurrent protection:

Possible reasons: sudden drop of power supply or overloading

3, Communication malfunction:

Handling method: check if communication signal cable is connected reliably

4, temp sensor open or short circuit:

Handling method: check whether sensor is normal, connected with the corresponding position on

the controller and if damage of lead wire is found

5, compressor overload protection:

Possible reasons: insufficient or too much refrigerant; blockage of capillary and increase of

suction temp.; improper running of compressor, burning in or stuck of bearing, damage of discharge

valve; malfunction of protector.

Handling method: adjust refrigerant amount; replace the capillary; replace the compressor; use

universal meter to check if the contactor of compressor is fine when it is not overheat, if not replace

the contactor.

6, system malfunction:

i.e overload protection. When tube temperaturec (Checking the temperature of outdoor heat

exchanger when cooling and checking temperature of indoor heat exchanger when heating) is too

high, protection will be activated.

Possible reasons: outdoor temperature is too high when cooling; insuffient outdoor air circulation;

refrigerant flow malfunction.

7, IPM module protection:

Handing method: if module malfunctions and can not be restored for long time, please

disconnect power supply. And connect again after about 10 minutes later. If repeating this method

for several times and malfunction still exist, please replace the module.

8, PFC protection:

Possible reasons: outdoor temperature is too high; over-high temperature of PFC module; power

of whole unit is too high and current is too high; low vollage in PFC; bad contact between the cables

in PFC control board.

Handing method: If PFC protection happens, please check connecting cables of PFC board first.

If the whole unit can not operate normally and PFC protection happens all the time, please replace

PFC.

9, refrigerant charging:

Similar with the procedures of the over 5kw wall split models.

Notice: refrigerant charging can only be started after whole unit has been operating stably for about

10 minutes.

-31-

Page 32

7. Module protection :

Handling method:

Check if the voltage between power module P and N is too low and

if the current is too high. In normal condition, voltage between P and

N should be about 320V.

Normal

Abnormal

Check power supply circuit of outdoor unit (if PTC resistance

rectifying bridge, reactor, capacitance etc. is ok).

Temperature of power module is too high,

which causes overheating protection

Protection is still displayed

Confirm the setting status of outdoor unit (cooling)

Normal

Confirm if outdoor fan motor is running; unplug the

three connecting wires between U, V, W of compressor

and power module. Turn on the unit to see if outdoor

fan runs normally (about 1 minute)

Outdoor fan stops

Measure the voltage of outdoor

fan connector

No voltage

Normal voltage

Replace the fan

Replace the mainboard

motorof outdoor unit

Check if radiating paste is spread

evenly or radiating sticker is stuck

well; if screws of power module

is tightened

Reinstall power module and

re-spread radiating paste or

stick radiating sticker on the

radiator of power module.

Poor radiation, heat exchanger

is dirty

Remove obstructions

and clean

Outdoor fan runs

Confirm if there is voltage output and balance of

voltage between any two phases of U, V and W.

Yes

No

Whether module type

Replace the power module

is correct

Normal

Abnormal

Normal

Abnormal

Measure the three-phase

Replace the module

with correct type resistance of compressor

Replace the

Whether cylinder of

compressor is stuck

compressor

If the unit runs normally after connected

with the new compressor for trial run, the

cylinder of original compressor is stuck

32

Loading...

Loading...