Page 1

10000 / 12000 BTU

Room Air Conditioner

OPERATING AND INSTALLATION MANUAL

Models: KC-30H / KC-35H

with Heat Pump

Thank you for selecting Soleus Air. To ensure proper

operation, please read this manual and keep it for

future reference.

Page 2

TABLE OF CONTENTS

INTRODUCTION……………………………..…………………………………….…................................1

SAFETY INFORMATION………………………………………………....…………........…..……......….1

NORMAL CARE AND MAINTENANCE……………………………………………….…..………….…3

INSTALLATION REQUIREMENTS………………………………………………..……….……….....…5

ELECTRICAL REQUIREMENTS…………………………………...………..………..…..................……6

INSTALLATION INSTRUCTIONS………………………………………………..……….……….…..…8

THROUGH-THE-WALL CABINET INSTRUCTIONS..……………………………………….……......10

COMPLETE INSTALLATION INSTRUCTIONS..…………………………………………………........12

GENERAL OPERATING INSTRUCTIONS…………………………………………………….......……13

OPERATING CONTROLS……………………………………………………………………..…………14

BEFORE CALLING SERVICE………………………………………………….…………..……………15

WHEN SERVICE IS REQUIRED………………………………………………………...........…………15

ANY QUESTIONS?…………………………………………………………………….……....…………15

THROUGH-THE-WALL INSTALLATION INSTRUCTIONS..…………………………………............16

SPECIFICATION………………………………………………..…………………………………............19

WARRANTY…………………………………………………………………………………....…………20

Thank you for selecting Soleus Air. To ensure proper operation, please read this

manual and keep it for future reference.

This mark indicates a direction/procedure that must be followed!

Page 3

Introduction

Room air conditioners cool, dehumidify, and filter air inside

your home. Heat pump and electric heat models offer both

heating and cooling. Opening sections of manual provide

general information for all room air conditioner models.

Operating Controls section describes operation of controls

for each model. After reading the opening sections, turn to

Operating Controls section and find the panel layout that

matches the model of your unit.

Read entire manual thoroughly before beginning installation

and operation of your new room air conditioner. Be sure you

have all necessary tools and materials on hand for the job.

Study illustrations to familiarize yourself with important details

of the installation process. Review manual for operating

instructions.

NOTE

1. Mechanical experience is required to install air conditioner.

2. Installation can take from 1 to 3 hours, depending on installer’s knowledge and skill.

3. If you encounter problems during installation, call our Technical Support and Warranty Service at

1-888-8-SOLEUS. If your problem cannot be resolved by phone, contact an authorized Soleus Air

brand servicer. Contact and service will be at your expense.

Safety Information

Be sure electrical service is adequate for chosen model of air conditioner. Complete electrical rating for

unit is found on serial plate located behind front grille. Electrical outlet must be close enough to unit for

power cord to reach without strain. Air conditioner should be the only appliance on individual circuit.

For personal safety and to avoid possible damage to appliance or home, observe all safety instructions

highlighted by symbol shown below.

RECOGNIZE THIS SYMBOL AS A SAFETY PRECAUTION.

After installing unit, reread instructions to ensure each step is complete and that all parts are fastened in

place. For best results and to minimize installation time, perform all procedures in the order shown.

1

Page 4

WARNING

To prevent heat related illness or death, do

not use this device for unattended cooling

of persons or animals unable to react to

product failure. Failure of unattended air

conditioner may result in extreme heat in

area intended for cooling, causing heatrelated illness or death of persons or

animals.

WARNING

HIGH TEMPERATURE STRESS HAZARD

This room air conditioner is not meant to

provide unattended cooling or life support

for persons or animals that are unable to

react to failure of the product.

The failure of an unattended air conditioner

may result in extreme heat in the conditioned space causing overheating or

death of persons or animals.

Precautions must be taken to ward off or

guard against such an occurrence.

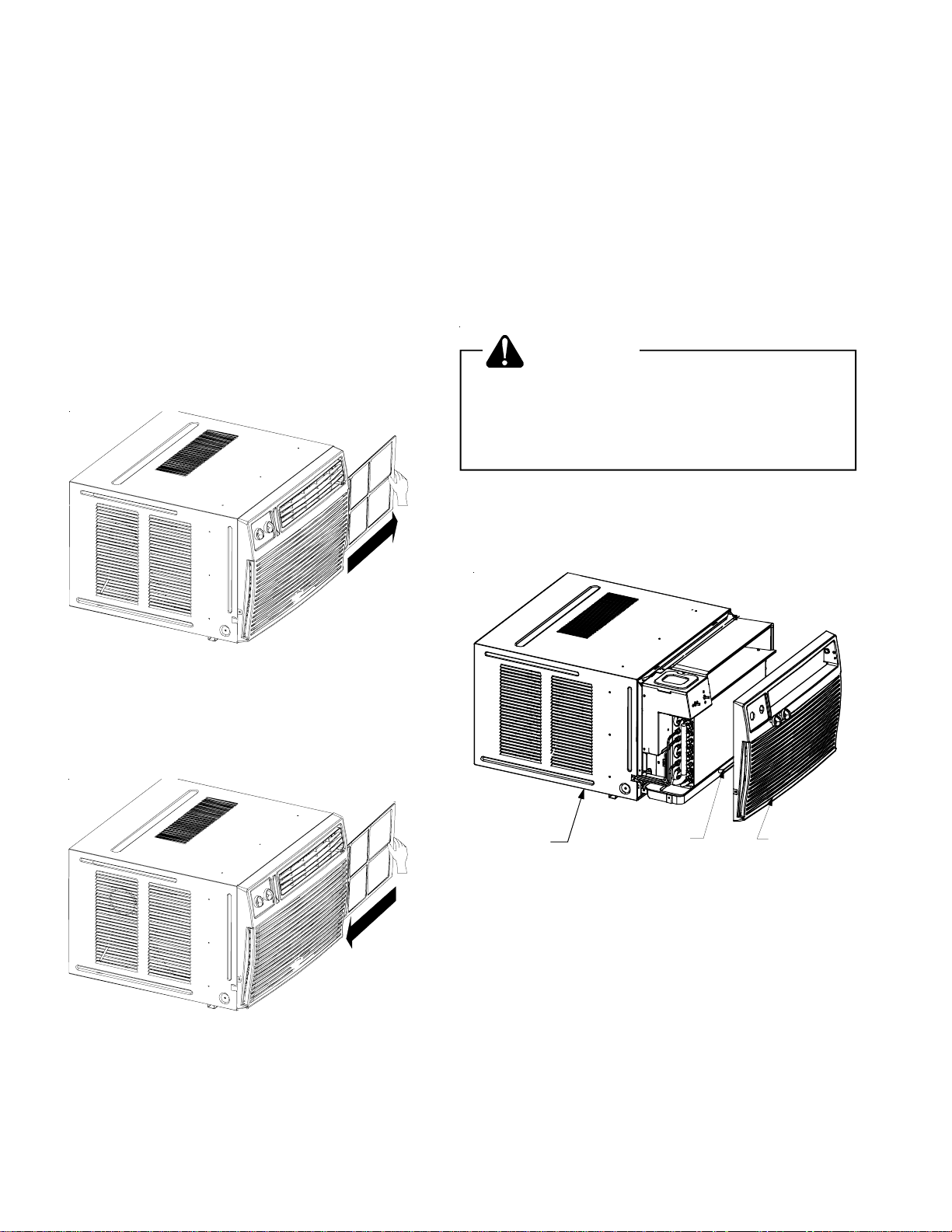

Unpacking

Unpack and visually inspect the unit. Report any damage to

the delivering carrier immediately. Remove and discard all

packing material.

WARNING

Do NOT operate unit with shipping foam

blocks in place. Always remove prior to

running unit.

On some models the air conditioner front and/or mounting kit

hardware may be packed separately.

Record the model, serial and manufacturing numbers of your

unit in the space provided below. This information is found on

a nameplate visible after the front of the air conditioner has

been removed. The rated voltage, amperage and capacity for

your specific model can also be found on this nameplate.

Read the warranty packaged with the unit. Keep the warranty

and a copy of your sales receipt for future reference. You may

also want to record in the space provided the date purchased

and the selling dealer.

OWNER'S PRODUCT IDENTIFICATION

MODEL NUMBER

SERIAL NUMBER

MANUFACTURING NUMBER

Owner's Name

Address

City State Zip

/ /

Date of Purchase

Authorized Dealer

Address

City State Zip

( )

Phone Number

WARNING

To avoid death, personal injury or property

damage due to electrical shock:

Observe all local codes and ordinances.

•

Disconnect electrical power to unit before servicing.

•

•

Ground appliance properly.

Check with a qualified electrician if you are not

•

sure this appliance is properly grounded.

DO NOT ground to gas line.

•

DO NOT ground to cold water pipe if pipe is

•

interrupted by plastic, non-metallic gaskets, or

other insulating (non-conducting) materials.

•

DO NOT modify plug on power cord. If plug

does not fit electrical outlet, have proper outlet

installed by qualified electrician.

DO NOT have a fuse in the neutral or ground

•

circuit. A fuse in the neutral or ground circuit

could result in an electrical shock.

DO NOT use an extension cord with this appliance.

•

DO NOT use an adapter plug with this appliance.

•

DO NOT pinch power cord.

•

DO NOT REMOVE warning tag from power cord.

•

Electrical Requirements

Grounding Instructions

This appliance is equipped with a three-prong grounding plug

for protection against possible shock hazards. If a two-prong

2

Page 5

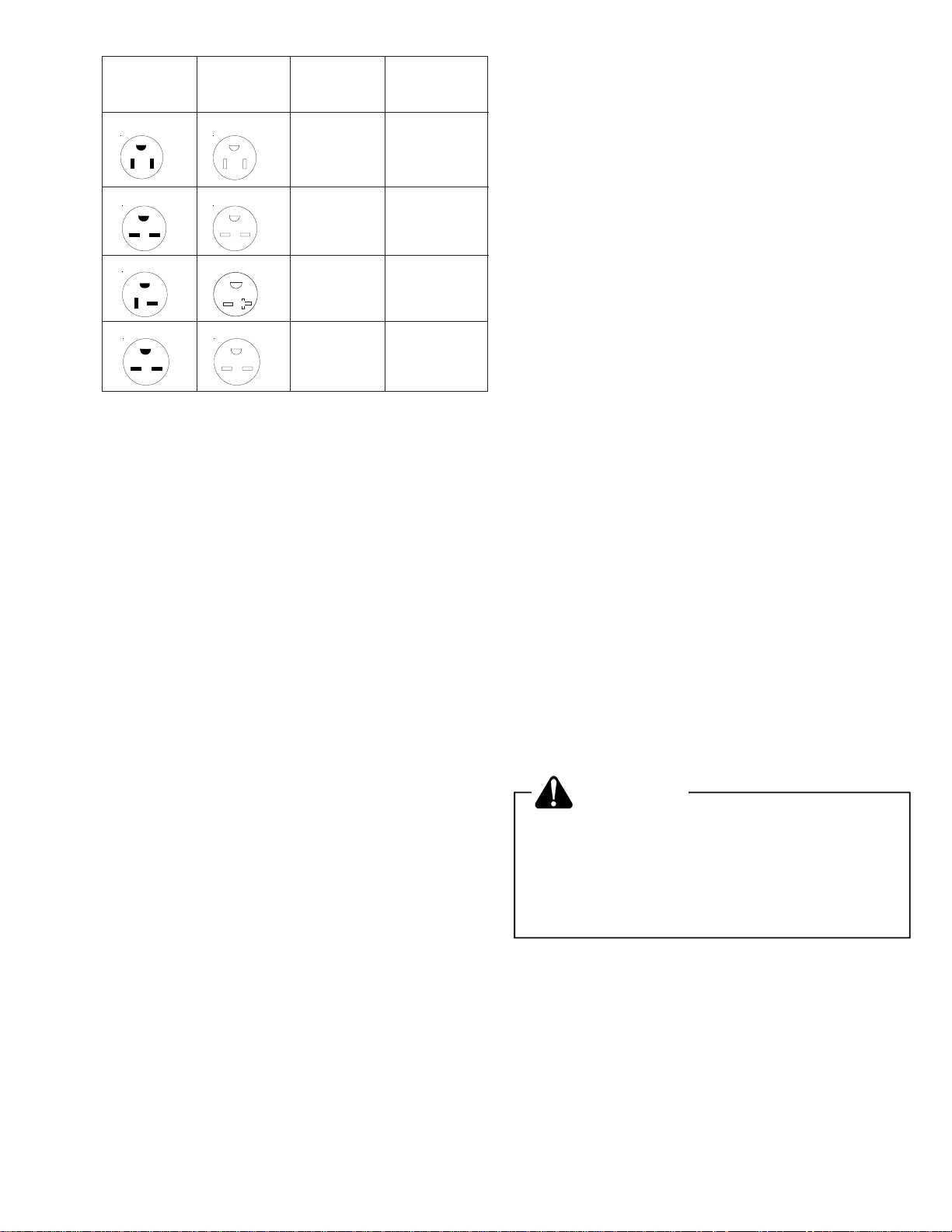

Unit Plug Receptacle Circuit Rating, Voltage

Type Required Breaker, Time Rating On

Delay Fuse Nameplate

NEMA No. 5-15P NEMA No. 5-15R 125V-15AMP 115V

NEMA No. 6-15P NEMA No. 6-15R 250V-15AMP 230/208V rated

at 12 amperes or

less

NEMA No. 6-20P NEMA No. 6-20R 250V-20AMP 230/208V rated

over 12 amperes,

but not more than

16 amperes

NEMA No. 6-30P NEMA No. 6-30R 250V-30AMP 208V rated over

16 amperes, but

not more than

24 amperes

wall receptacle is encountered, the customer is required to

contact a qualified electrician and have the two-prong wall

receptacle replaced with a properly grounded three-prong

wall receptacle in accordance with the National Electrical

Code.

Room air conditioners are designed to operate according to

requirements on the nameplate and as shown in Table 1.

Fuse or circuit breaker ratings must be according to the fuse

instruction label and as shown in Table 1. Do not plug models

marked “Use on Single Outlet Circuit Only” into a circuit with

another appliance or light fixture.

Receptacle Wiring

Receptacle wiring must be of adequate size for unit. Refer

to unit identification plate for exact power requirements.

Minimum size of wiring, based on power requirements, is:

Units up to 20 amps: 12 gauge

20–30 amp units: 10 gauge

LCDI or AFCI Power Cords

Underwriters Laboratories (UL) and the National Electric

Code (NEC) now require power cords that sense current

leakage and can open the electrical circuit to the unit. In the

event, the unit does not operate, check the reset button

located on or near the head of the power cord as part of the

normal troubleshooting procedure.

Use copper wire only. Consumer’s responsibility is to provide

proper and adequate receptacle wiring that conforms to all

applicable codes. All wiring should be installed by qualified

electrician.

Installation

Complete step-by-step installation instructions are furnished

with your unit. These instructions will be found on a separate

page included with this manual or in the mounting kit

assembly. Follow these instructions carefully. Keep these

instructions with this manual for future reference. Your unit

will be one of the following three designs:

• Unit with a window mounting kit

These models are designed for mounting though an

opening in a wall. These units can be adapted to

window installation by using the optional window mounting kit supplied with your unit.

• Unit without a window mounting kit

No window mounting kit is supplied with the unit.

These models are designed for mounting through an

opening in a wall. These units can be adapted to

window installation by purchasing an optional window

mounting kit. Consult your dealer to choose the kit that

is appropriate for your model and installation.

Room Heat Pumps

Heat pumps work by moving heat instead of creating it. In the

summer, the cool indoor coil absorbs heat from your room

and moves it outdoors, providing cooling. In the winter, heat

pumps reverse this operation. By lowering the temperature

of the outdoor coil below the outdoor temperature, the heat

pump absorbs the heat from outdoors and moves it inside

your house. This heat transferring process is very efficient.

For example, at 45°F outdoor temperature, a heat pump can

provide 2 ½ watts of heat for every watt of electricity it

consumes.

As outdoor temperatures drop, the heating capacity and

efficiency of the heat pump declines. At temperatures below

45°F, it is likely that ice will form on the outdoor coil. Heat

pump units are designed to operate as a heat pump above

approximately 40°F. Below 40°F, these units switch automatically from reverse cycle heat pump to auxiliary electric

heating. No defrost is required. There is no minimum

operating temperature.

Normal Care and Maintenance

CAUTION

Installing an air conditioner through a wall

requires extensive carpentry and/or masonry experience. Thru-wall installations performed by inexperienced or unqualified

individuals can result in costly damage to

home.

Annual Inspection

It is suggested that your unit be inspected by your dealer or

servicer once a year. It is advisable to have the outer case

removed and the unit thoroughly cleaned.

3

Page 6

Note: The life of your unit may be greatly reduced if you live

in a salt air or other corrosive type environment. Under these

conditions, the unit should be removed from its case and

completely cleaned at least once a year. At that time any

scratches or blisters on the painted surfaces should be

sanded and repainted. Placing an algaecide tablet in the

outdoor side of the unit’s basepan is suggested in humid

areas where algae formation is common.

Front Grille and Filter Removal

The front contains an air filter that can be removed on left or

right side of front. To clean the filter use one of the following

methods for filter removal:

METHOD ONE

Grasp filter handle and slide filter out of unit.

Air Filter Cleaning

A dirty air filter reduces operating efficiency of unit. Filter

should be inspected at least once every week during operation. Clean filter with vacuum cleaner or wash in warm water

and mild detergent. Filter should be thoroughly dried before

replacing in unit. Do not operate unit without filter in place.

Fan Motor Care

The fan motor is permanently lubricated for long life. There is

no need to oil the motor.

Slide-out Chassis Removal from Outer Case

4. If the unit has a screw holding the basepan clip to the

chassis, remove the screw.

CAUTION

To reduce the risk of personal injury be

sure to have sufficient help when moving

your unit. A room air conditioner can

weigh between 70 and 240 pounds.

5. Using basepan handle, pull chassis straight out, slowly

and evenly, until approximately 9-12 inches extends

from outer case. Use both hands to grasp basepan and

pull remaining chassis from outer case.

1. Remove two side Phillips screws attaching case to

chassis basepan.

2. Remove two control knobs.

3. Remove two side Phillips screws attaching front panel

to case.

Reinstall air filter by reversing removal procedure.

Front Grille and Cabinet Cleaning

Grille and cabinet may be cleaned with warm water and mild

soap or detergent. Cleaning and polishing compounds are not

recommended, as they may damage plastic surfaces.

CHASSIS

NOTE: Basepan clip is shipped in plastic bag with mounting

screw and condensate drain cup. Install clip after reinserting

chassis into outer case to prevent accidental chassis removal.

BASEPAN

CLIP

PLASTIC

FRONT

4

Page 7

WARNING:

To reduce the risk of fire, electrical shock or injury when using your air conditioner, follow these basic precautions:

Plug into a grounded 3 prong outlet.

IMPORTANT SAFETY INSTRUCTIONS

Do not use an extension cord.

Do not remove ground prong.

Do not use an adapter.

SAVE THESE INSTRUCTIONS

INSTALLATION REQUIREMENTS

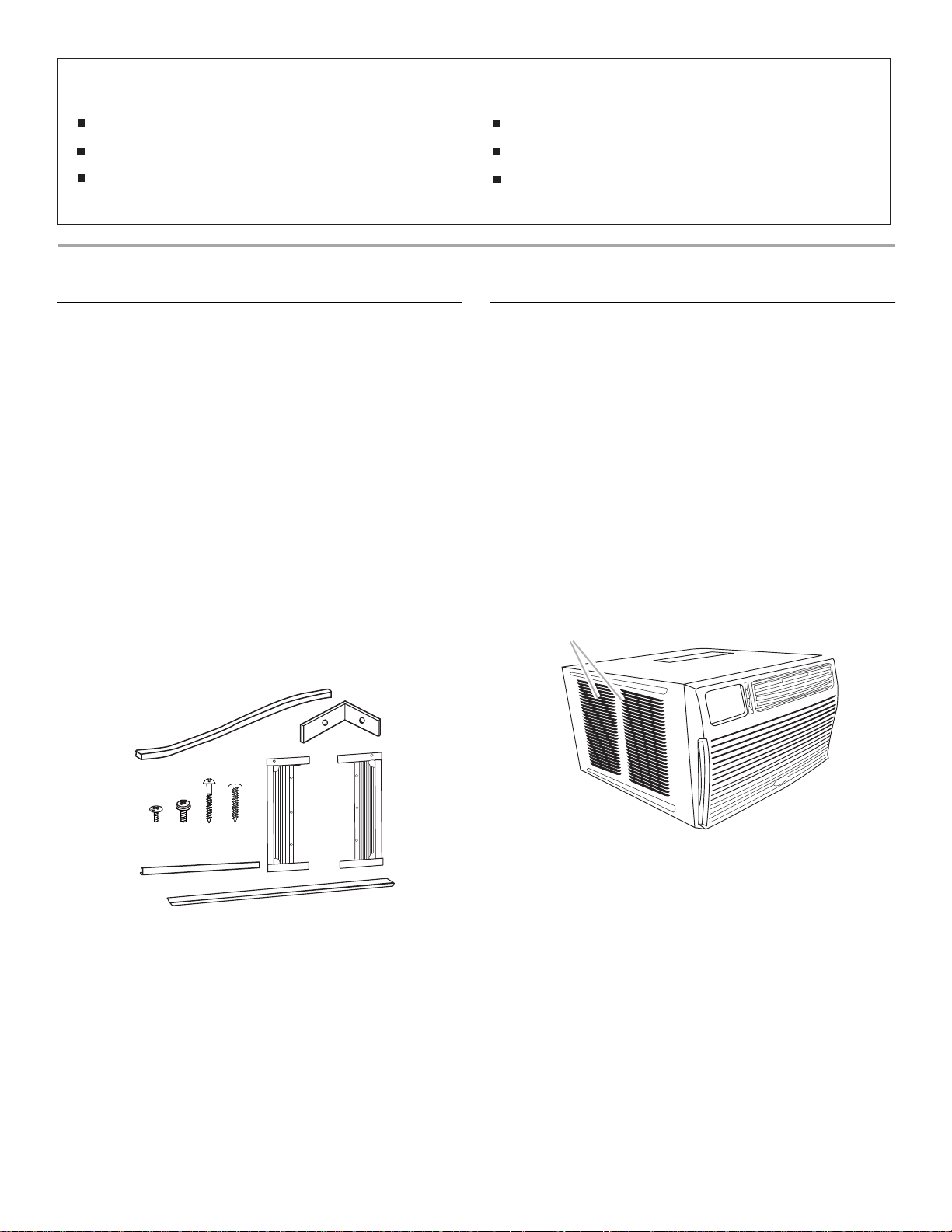

Tools and Parts

Gather the r e qu ired tools and parts before st ar t in g insta llation.

Read and follow the instruction s provided with any tools listed

here.

Tools Needed

■ Flat-blade and Phillips

screwdrivers

■ Level

Through-the-wall installation:

In addition to the tools listed above, the following tools are

needed for though-the-wall install ation.

■ Saw

■ Wood preservative

■ Caulk

Parts supplied (on some models)

Check that all parts are included in parts package.

■ Tape measure

■ Drill and ³⁄₁₆" or smaller bit

■ 1" (2.5 cm) or thicker

lumber

■ 7 - #10 x 1" wood screws

Unplug air conditioner before servicing.

Use two or more people to move and install air conditioner.

Location Requirements

IMPORTANT: Observe all governing codes and ordinances.

Check the location where air conditioner will be installed. Proper

installation is your responsibility. Make sure you have everything

necessary for correct installation.

The location should provide:

■ Grounded electrical outlet within 4 ft (122 cm) of where the

power cord exits the air conditioner.

NOTE: Do not use an extension cord.

■ Free movement of air in room to be cooled.

■ A large enough opening for the air conditioner.

■ Adequate wall support for weight of air conditioner. Air

conditioner weighs between 94 and 103 lbs (43 to 47 kg).

NOTE: Cabinet louvers must not be obstructed. Air must be able

to pass freely through the cabinet louvers.

A

B

A

H

D

C

F

E

G

I

A. Foam window sash seal

B. Window lock brackets (2)

¹⁄₄

C. #10 x

D. #10 x

" pan-head Phillips

screws (6)

³⁄₈

" pan-head

Phillips screws (3)

E. #10 x

³⁄₄

" round-head screws (6)

F. #10 x 1/2" pan-head Phillips

screws (3)

G. Top channel

H. Side curtains (2)

I. Foam seal

NOTE: Installation parts are supplied for double-hung windows

up to 40" (101.6 cm) wide. A special Wide Window Kit is available

from your dealer or service center. See “Accessories.”

A.Cabinet louvers

5

Page 8

Window installation

C

Window opening measurements:

■ 27" min. to 39" max. (68.6 cm to 99 cm) opening width.

■ 16¹⁄₄" min. (41.3 cm) opening height.

A

B

A.27" m in. (68.6 cm)

¹⁄₄

" min. (41.3 cm)

B.16

Through-the-wall installation

The wall opening measurements should be:

■ Height: 16" (40.6 cm) plus twice the thickness of wood used

to build frame.

■ Width: 22⁵⁄₈" (57.5 cm) plus twice the thickness of wood used

to build frame.

A

B

Electrical Requirements

WARNING

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

Ground wire must be connected to ground screw located in lower

right corner of air conditioner when air conditioner is in cabinet.

The electrical ratings for your air condit ioner are listed on the

model and serial number label. The model and serial number

label is located behind the front panel on the flange below the

control panel area.

Specific electrical requirements are listed in the chart below.

Follow the requirements for the type of plug on the power supply

cord.

Power supply

cord Wiring requirements

■ 115-volt (103.5 min. - 126.5 max.)

■ 0-12 amps

■ 15-amp time-delay fuse or circuit breaker

■ Use on single outlet circuit only.

A.16" (40.6 cm)

⁵⁄₈

" (57.5 cm)

B.22

C

C.Wood thickness

¹⁄₄"

(0.6 cm)

¹⁄₂"

(1.3 cm)

■ 230-volt (207 min. - 253 max.)

■ 0-12 amps

■ 15-amp time-delay fuse or circuit breaker

■ Use on single outlet circuit only.

■ 230-volt (207 min. - 253 max.)

■ 0-16 amps

■ 20-amp time-delay fuse or circuit breaker

■ Use on single outlet circuit only.

■ 230-volt (207 min. - 253 max.)

■ 0-24 amps

■ 30-amp time-delay fuse or circuit breaker

■ Use on single outlet circuit only.

6

Page 9

Recommended grounding method

This air conditioner must be grounded. This air conditioner is

equipped with a power supply cord having a grounded 3 prong

plug. To minimize possible shock hazard, the cord must be

plugged into a mating, grounded 3 prong outlet, grounded in

accordance with all local codes and ordinances. If a mating outlet

is not available, it is the customer's responsibility to have a

properly grounded 3 prong outlet installed by a qualified electrical

installer.

It is the customer's responsibility:

■ To contact a qualified electrical installer.

■ To assure that the electrical installation is adequate and in

conformance with National Electrical Code, ANSI/NFPA 70 latest edition, and all local codes and ordinances.

Copies of the standards list e d may be obtained from:

National Fire Protection Association

One Batterymarch Park

Quincy, MA 02269

Power Supply Cord

NOTE: Your unit’s device may differ from the ones shown.

B

TEST

TEST

B

A.Reset button

B.Test button

A

RESET

RESET

A

WARNING

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

To test your power supply cord :

1. Plug power supply cord into a grounded 3prong outlet.

2. Press RESET.

3. Press TEST (listen for click; Reset button will trip and pop

out).

4. Press and release RESET (listen for cl ick; Reset button will

latch and remain in). The power supply cord

operation.

NOTES:

■ The Reset button must be pushed in for proper operation.

■ The power suppl y cor d must b e repl aced if it fails to trip wh en

the test button is pressed or fails to reset.

■ Do not use the power supply cord as an off/on switch. The

power supply cord is designed as a protective device.

■ A damaged power supply cord must be replaced with a new

power supply cord obtained from the product manufacturer

and must not be repaired.

■ The power supply cord contains no user serviceable parts.

Opening the tamper-resistant case voids all warranty and

performance claims.

is ready for

This room air conditioner is equipped with a power supply cord

required by UL. This power supply cord contains state-of-the- art

electronics that sense leakage current. If the cord is crushed, the

electronics detect leakage current and power will be

disconnected in a fraction of a second.

7

Page 10

INSTALLATION INSTRUCTIONS

A

Unpacking

WARNING

Excessive Weight Hazard

Excessive Weight Hazard

Use two or more people to move and install

Use two or more people to move and install

air conditioner.

air conditioner.

Failure to do so can result in back or other injury.

Failure to do so can result in back or other injury.

Remove packaging materials

■ Remove and dispose of/recycle all packaging materials.

Remove tape and glue residue from surfaces before turning

on the air conditioner. Rub a small amount of liquid dish soap

over the adhesive with your fingers. Wipe with warm water

and dry.

■ Do not use sharp instruments, rubbing alcohol, flammable

fluids, or abrasive cleaners to remove tape or glue. These

products can damage the surface of your air conditioner.

■ Handle air conditioner gently.

1. Remove air conditioner from carton and place it on

cardboard.

2. Remove shipping screws from both sides of cabinet.

3. Remove front panel by removed 2 phillips screws on both

bottom left right sides of front.

3A: Remove both knobs from control panel.

4. Remove ground screw and ground wire from front of air

conditioner base. Save ground screw.

A

B

A. Green ground wire

B. Ground screw

5. Pull on handle to slide air conditioner out of cabinet. Place air

conditioner on cardboard.

6. Remove any paking foam from inside of unit.

A

A.Shipping screw

NOTES:

■ Handle air conditioner gently.

■ Be sure your air conditioner cabinet does not fall out of the

opening during installation or removal.

■ The location where the power cord exits the air conditioner

should be no more than 4 ft (122 cm) from a grounded

3prong outlet.

■ Do not block the louvers on the front panel.

■ Do not block the louvers on the outside of the air conditioner.

Window Installation (on some models)

Attach Top Channel

NOTE: Attach top channel and side curtains to air conditioner

cabinet before placing cabinet i n window.

1. Locate supplied bag of screws.

2. Place top channel on top of air conditioner cabinet, lining up

the 3 holes in top channel with the 3 holes on top of air

conditioner cabinet.

A. Handle

NOTE: Do not lift, push, pull or remove any expanded

polystyrene (foam) from inside the air conditioner. It is not

packing material.

3. Using 3 - #10 x ³⁄₈" pan-head Phillips screws, attach top

channel to air conditioner cabinet.

B

A.Top channel

B.#10 x

³⁄₈

" pan-head Phillips screws (3)

B

A

B

8

Page 11

Attach Side Curtains

A

C

Attach foam adhesive seal

1. Locate provided bag of screws.

2. Insert top and then bottom of right-hand curtain housing in

top and bottom curtain guides on air conditioner cabinet.

Back View

A

A.Curta in housing

B.Curtain guides

B

Bottom View

A

B

A.Curtain housing

B.Curtain guides

3. Extend right-hand curtain outward so you may insert the

first screw through the middle hole of the curtain. Using

#10 x ¹⁄₄"

hole in air conditioner cabinet.

NOTE: This screw is required to correctly attach curtain (top

to bottom) to the air conditioner cabinet.

pan-head Phillips screw, screw curtain to middle

Attach foam adhesive seal along the bottom of the curtain

bottom channel.

A

B

A.Curtain housing

B.Foam adhesi ve seal

Install Cabinet into Window

■ Handle air conditioner gently.

■ Be sure your air conditioner cabinet does not fall out of the

opening during installation or removal.

■ The location where the power cord exits the air conditioner

should be no more than 4 ft (122 cm) from a grounded 3

prong outlet.

■ Do not block the louvers on the front panel.

■ Do not block the louvers on the outside of the air condit ioner.

1. Center empty cabinet in window. Check that lower rail of air

conditioner cabinet is behind and against back side of

windowsill. Maintain a firm hold on the air conditioner

cabinet. Lower window sash to hold cabinet in place.

Top channel must be on inside room of window sash.

Windower sash

Top channell

4. While the right-hand curtain is still extended, insert

#10 x ¹⁄₄" pan-head Phillips screws into the top and bottom

slots of curtain. Screw curtain to the top and bottom holes

in air conditioner cabinet.

NOTE: Some curtains may have 2 slots at each end. You will

be able to see a mounting hole through the correct slot.

5. Slide curtain housing into guides as far as it will go.

6. Repeat above steps for left-hand curtain.

2. Measure the distance between the right-hand side of the

cabinet and the inside of the window channel.

3. Repeat for the left side. Adjust the cabinet until the distance

on each side is the same.

B

A. Window sash

B. Empty cabinet

C. Window channel

9

Page 12

4. Use a ³⁄₁₆" drill bit to drill 3 starter holes 1/2" deep through the

B

D

3 holes in the cabinet and into the windowsill.

5. Attach cabinet to windowsill with 3 - #10 x 1/2" pan-head

Phillips screws.

2. Insert one of the #10 x ³⁄₄" round-head screws through

hole and into lower window sash. Insert one of the

#10 x ³⁄₄" round-head screws through threaded hole in top

of curtain and one in bottom of curtain.

A

B

A

A. #10 x 1/2" pan-head Phillips screws

B.Windowsill

6. Check that air conditioner cabinet is tilted 1/2 bubble on

carpenters level to the outside so that water will run to

A

the outside.

Attach Side Curtains to Window Frame

1. Pull left-hand curtain out until it fits into window channel. Use

a ³⁄₃₂" drill bit to drill a starter hole through the hole in the

curtain housing and into the lower window sash.

Front View

Top View

A.#10 x

B. Hole for #10 x

³⁄₄

" round-head screw

³⁄₄

" round-head screw

3. Repeat for right-hand curtain.

Complete Window Installation

1. Insert foam seal behind the top of the lower window sash and

against the glass of the upper window.

2. Place window-lock bracket on top of lower window and

against upper window sash.

3. Use a ³⁄₃₂" drill bit to dril l a st arter hole through the hole in the

bracket and into the window sash .

4. Attach window-lock bracket to window sash with

#10 x ³⁄₄" round-head screw to secure window in place.

B

A

C

B

A

C

A.Left-hand curtain

B.Windo w channel

C.#10 x

³⁄₄

" round-head screw

Through-the-Wall Cabinet Installation

NOTES:

■ Handle air conditioner gently.

■ Be sure your air conditioner cabinet does not fall out of the

opening during installation or removal.

■ The location where the power cord exits the air conditioner

should be no more than 4 ft (122 cm) from a grounded

3prong outlet.

D

A. Window lock bracket(2)

B.Foam seal

■ Do not block the louvers on the front panel.

■ Do not block the louvers on the outside of the air condit ioner.

■ It is the customer's responsibility and obligation to have this

C.Upper window glass

D. #10 x 1/2" pan-head Phillips screws (3)

product installed by a qualified technician familiar with

through-the-wall room air conditioner installations.

10

Page 13

Option 1—Wood , metal or pl asti c molding

D

D

C

B

A

When you are using wood, metal or plastic molding, the wood

frame should line up with inside wall as shown.

B

C

A

■ Use 1" (2.5 cm) or thicker lumber for wood frame.

A

B

A.Outside width

B.Outside height

C.Depth

A.Molding

B.Inside wall

C.Wood frame

D.Louvers

Option 2—Plastered wall with no molding

If the plastered wall is to be flush with the cabinet and no molding

is used, the wood frame must be set ¹⁄₂" (13 mm) into the inside

wall.

B

C

A

A.Plastered wall

B.Inside wall

C.Wood frame

D.Louvers

Install Wood Frame

1. Construct wood frame. See “Location Requirements” for

dimensions.

2. Measure outside width and height of frame to determine wall

opening dimensions.

3. Cut opening through the wall. Remove and save insulation.

NOTES:

■ Dimension for depth depends on wall thickness and type

of molding.

■ Do not block louvers in air conditioner cabinet.

4. Apply wood preservative to the outside exposed surface.

5. Insert the frame in the wall opening. Square and level frame.

6. Attach frame securely to the wall.

Install Cabinet into Wood Fra me

1. Insert cabinet into the framed wall opening.

The top of the cabinet should extend ¹⁄₂" (13 mm) into the

room. If ther e is trim, the cabinet should extend ¹⁄₂" (13 mm)

past the trim.

A

¹⁄₂

" (13 mm) extending into room

A.

B.Trim

2. Use a level to check that cabinet is level side to side.

A.Level

3. Check that air conditioner cabinet is tilted to the outside so

that water will run to the outside. 1/2 bubble on carpenters

level.

4. Reuse the insulation to seal opening between cabinet and

5. Use existing holes and 6 - #10 x 1" wood screws (not

6. Caulk all outside wall openings around cabinet.

frame.

provided) to attach cabinet to frame.

NOTE: Do not overtighten screws or cabinet will distort and

provide a poor air seal between cabinet and air conditioner.

11

Page 14

Complete Installation

A

NOTE: Handle air conditioner gently.

1. Make sure the free end of the ground wire is outside of the

cabinet.

WARNING

Position ground wire pointing straight up. Put excess ground

wire between coil and air conditioner cabinet.

Excessive Weight Hazard

Use two or more people to move and install

air conditioner.

Failure to do so can result in back or other injury.

2. Insert air conditioner into cabinet.

REMEMBER: Make sure the free end of the ground wire is

outside of the cabinet.

A

+

+

+

B

A.Green ground wire

B.Ground screw

4. Install shipping screws on both sides of cabinet.

5. Insert front tabs of front panel into top of cabinet and swing

front into place.

6. Attach bottom front of panel with front panel screws. Replace

control knobs (on some models).

NOTE: For through-the-wall installations, if needed, install

molding around room side of cabinet.

A.Make sure the free end of the ground wire

is outside of the cabinet.

WARNING

Electrical Shock Hazard

Connect green ground wire to ground screw.

Failure to do so can result in death or electrical shock.

3. Connect green ground wire to cabinet base with ground

screw.

WARNING

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

7. Plug into a grounded 3 prong outlet.

8. Pres s RESET on the power supply cord plug.

12

Page 15

General Operating Instructions

While operation of all units is similar, controls vary slightly

from model to model. Operating Controls section shows

control panel of unit purchased and gives detailed information

about operation of controls.

Airflow Around Unit

Select the highest fan speed and set temperature control to

its coldest position. When the desired temperature is

reached, slowly move the temperature control toward a

warmer setting until the compressor shuts off. The thermostat will then cycle the compressor on and off to maintain this

selected temperature. Adjust the fan speed for desired air

circulation.

BAFFLES

To install, remove the unit chassis from the outer case. Insert

the condensate drain cup through the recessed ½” hole on

the back center of the outer case. Once inserted, place a ½”

diameter hose or tube on the drain cup bottom spout. The

hose allows you to route where you want the excess water to

go. Reinsert the unit chassis into the outer case. The unit

basepan overflow hole will be positioned directly above the

drain cup and will catch any water that might run out.

Outer Case

Condensate

Drain Cup

1/2" Diam eter

Hose

OUTDOOR

LOUVERS

INDOOR

GRILLE

Changing Airflow Direction Baffles

Airflow on unit may be diverted left or right from center by

baffles. Upward and downward air discharge is provided by

tilting louvers. Adjust baffles and tilt louvers for desired

airflow pattern.

Airflow Around Unit

Check the indoor grille and outdoor louvers for obstructions

to airflow. Do not block the airflow to and from the unit. If air

is obstructed and/or deflected back into the unit, the air

conditioner’s compressor may cycle on and off rapidly. This

could damage your unit.

Drain Cup Installation and Use

Your air conditioner uses a system where the water removed

from the indoor air (condensate) is channeled to the outdoor

side of the unit. The outdoor fan blade has a “slinger” ring

attached to it that dips into the water and slings the water

onto the outdoor coil surface. This is the sound of water you

hear during normal operation. The water quickly evaporates

on this warm surface and improves the efficiency of your air

conditioner. In normal conditions the unit can evaporate the

water as fast as it is removed from the indoor air.

However, in very humid conditions excess amounts of water

may drip off the unit chassis. If this proves to be a problem,

install the condensate drain cup included with the unit to

route excess water where it would not be a problem (see

illustration).

Switchover Thermostat Control

Emergency heat switch overrides heat pump (compressor)

and starts auxiliary electrical heater. When switch is ON,

heat pump is locked out.

• Use emergency switch only when heat pump fails to

provide adequate heat. Cause of heat pump malfunction should be determined by authorized servicer. Cost

of operating unit will increase when emergency heat

switch is engaged.

Only for Qualified Service Personnel

To access and engage emergency switch:

• Unplug unit.

1. Remove front grille, air filter, and plastic front, as described

in Installation Instructions.

2. Remove basepan clip.

3. Slide chassis out of case about two inches.

4. Locate access hole for emergency switch above label on

right front of control box.

5. Remove control panel for access.

6. Remove outdoor thermostat from control box and locate

"flat head" adjustment screw on back of thermostat.

7. To start emergency heat, insert flathead screwdriver into

slot and turn counterclockwise until switch-stop is reached.

8. Return chassis to case.

9. Re-install lthermostat and mount control panel door.

10.Replace basepan clip, plastic front, air filter, and front

grille.

13

Page 16

Operating Controls

COMFORT ZONETM AND HEAT PUMP MODELS

Fan Control

OFF – Completely shuts off the unit. To prevent blowing

fuses, wait two minutes after turning the unit off before

turning it on again.

LOW COOL – Filters and circulates room air with the fan

running continuously on low speed. Also cools and dehumidifies while the compressor is running. Select this setting

for quiet cooling operation.

HIGH COOL – Filters and circulates room air with the fan

running continuously on high speed. Also cools and dehumidifies while the compressor is running. Select this setting

for maximum air circulation and cooling effect.

LOW HEAT – Filters and circulates room air with the fan

running continuously on low speed. Also heats while the

compressor or electric heat is running. Select this setting for

quiet heating operation.

HIGH HEAT – Filters and circulates room air with the fan

running continuously on high speed. Also heats while the

compressor or electric heater is running. Select this setting

for maximum air circulation and heating effect.

FAN ONLY– Select this setting for circulating or exhausting

room air without cooling.

Temperature Control

Slide this control to the left for a warmer room temperature,

to the right for a cooler room temperature.

Vent Control (On Some Models)

Choose one of the following two settings by sliding the vent

control under the appropriate marking:

EXHAUST – Exhausts room air to the outdoors. Also

circulates and filters room air. This position can be used to

exhaust stale or smoky air. To conserve energy, it is advised

that the Fan Control be in the Fan Only setting when using

this feature.

CLOSED – Exhaust damper is closed. Unit circulates and

filters room air. This position should be used for normal

cooling operation.

14

Page 17

Before Calling Service

To reduce the risk of electric shock, personal injury, or death, turn the fan control to the

off position and remove the unit plug from the wall outlet before doing any inspection

or maintenance work.

The following is a list of problems that are sometimes encountered when using a room air con ditioner. Possible cause and

suggested remedies are given for each problem.

If the problem cannot be fixed using the suggested remedies, see WHEN SERVICE IS REQUIRED section.

PROBLEM POSSIBLE CAUSE SUGGESTED REMEDY

UNIT WILL NOT RUN

LITTLE OR NO COOLING

LITTLE OR NO HEATING

(fan and compressor run)

LITTLE OR NO COOLING

LITTLE OR NO HEATING

(only fan runs)

NOISY UNIT

MOUNTING SUPPORT NOT

INSTALLED

FROST ON INDOOR COIL

FROST ON OUTDOOR COIL

(heat pump models only)

ODORS IN COOLING

ODORS IN HEATING

When Service Is Required

Your room air conditioner dealer can give you the name of your nearest Authorized Service Center. Help them give you

prompt service by providing:

• An accurate description of problem.

• Complete model, serial, and manufacturing (P) numbers from serial plate.

• Proof of purchase (sales receipt) upon request.

Repair by unauthorized servicer that results in subsequent failure of unit voids warranty. Warranty details are contained

in warranty certificate enclosed with unit.

Keep accurate records of service calls, including what was done, servicer’s name, and date of servi ce.

Any Questions?

Most questions can be answered by your local Soleus Air brand dealer. If you have other matters that cannot be resolved

locally, or you need additional information regarding other heating and cooling products offered by us - please call:

No power to unit

Fresh air/exhaust damper open

Obstructed indoor or outdoor airflow

Dirty air filters

Unit undersized for application

Temperature Control not set properly

Loose front on mounting assembly

Weak building construc tion

Water hitting fan blade

Unit oversized for application:

compressor cycles on and off frequently

Storm window frame installed in window Some models require removal of storm window frame before

Dirty air filter

Normal for low outdoor temperatures

Normal for outdoor temperatures at or

below 45°F

Mold, mildew, or algae formation on wet

Surfaces

Normal for first time electric heater is

used each season

CONSUMER INFORMATION LINE

1-888-8-SOLEUS

Push reset button on power cord.

Set Fan Control to position other than OFF.

Make sure plug is firmly seated in outlet.

Check for blown fuses, tripped circuit breakers.

Set vent to CLOSED.

Remove obstruction from indoor grille or out do or louv ers.

Dirty air filter. Clean or replace, as needed.

Check with dealer to determine proper capacity unit for application.

For cooling, turn Temperature Control to cooler setting.

For heating, turn Temperature Control to warmer setting.

Tighten any loose parts.

Provide additional support for unit.

Normal in high humidity. Stop noise by removing drain plug or adding

condensate drain cup.

Check with dealer to determine proper capacity unit for application.

installation.

Clean air filter by vacuuming or washing with water and mild soap.

Turning Temperature Control to warmer setting reduces occurrence and

duration of frost.

Call for service only if unit does not heat room and you have

checked all problems and remedies listed under LITTLE OR NO

HEATING.

To reduce algae growth, use algaecide tablet in base pan; remove

drain plug; add condensate drain cup and hose. Thoroughly clean unit.

Caused by dust accumulation during unused months.

Odor dissipates quickly with heater use.

(Technical Support and Warranty Service)

15

Page 18

Thru-wall Installation Instructions

23 3/5"

®

brand Room Air Conditioner

for GREE

Introduction

This instruction sheet provides guidelines for installing a

compact air conditioner through an outside wall.

CAUTION

Installing an air conditioner through a wall

requires extensive carpentry and/or masonry experience. Thru-wall installations performed by inexperienced or unqualified

individuals can result in costly damage to

home.

Air Conditioner Dimensions

The following figures show the outside dimensions of air

conditioner with chassis installed, and dimensions of outer

case with chassis removed.

22 3/5''

15 3/8''

5 4/5''

21 1/3''

Outer Case Dimensions

(chassis removed)

22 3/5"

24 3/8"

Air Conditioner Dimensions

(with chassis installed)

General Instructions

All GREE® brand Compact Room Air Conditioners feature

a slide-out chassis. Chassis and front cover must be removed from outer case for installation.

CAUTION

In order to reinstall the chassis and reattach the air conditioner front cover, the

installed outercase must be square and

level from side to side. Use wood shims

between sides of case and finished opening - especially where case is secured to

opening - to prevent warping or distorting.

Check installed case for distortion using

carpenter's square.

A finished opening 23-inches wide x 16-inches high is

recommended. The lower left inside corner of opening must

be within 5 feet of an appropriate electrical outlet (see Use

and Care manual for electrical requirements.)

When wall thickness exceeds 5 1/2-inches, opening must

be modified to allow air to enter side louvers on case (see

special instructions on back ). Do not install air conditioner

in walls thicker than 10 1/2-inches.

.

16

Page 19

15 9/16"

22 13/16"

Electrical outlet must

be located within 5-feet

of this point.

Dimensions of Finished Opening

Masonry Construction

See CAUTION under General Instructions. In masonry

walls, cut or build a finished opening 15 9/16-inches high by

22 13/16-inches wide. When case is properly positioned in

opening, secure it in place with mortar or concrete nails

driven through holes in sides of outer case (shim case and

predrill holes before securing with nails).

Placement of Outer Case in Opening

Place outer case in opening, flush against one side of

opening. Use carpenter’s level and ensure case is level

from side to side and has a 3/8-inch slope from front to back

(back of case must be 3/8-inch lower than front to ensure

proper condensate drainage). If needed, use shims to level

case (from side to side) and to obtain proper back slope.

Front of case must project ¾-inch (minimum) beyond inside wall in order to attach air conditioner front frame. If

framing indoor side of opening with wood molding (or other

decorative material), extend outer case ¾-inch beyond

molding.

When case is properly positioned in opening, use wood

shims to fill any gaps between case and finished opening,

especially in area where case will be secured to opening.

Take care not to warp or distort case when installing

shims. For condensate drainage, install drainage cup in

drain hole on baseplate of case.

Outercase must project

a minimum ¾"

beyond inside wall

or molding to attach front frame

Lintel and

flashing

(if required)

Brick Veneer or Frame Wall Construction.

See CAUTION under General Instructions. Cut or build

rough opening large enough to allow a framed, finished

opening 15 9/16-inches high and 22 13/16-inches wide.

When case is properly positioned in opening, secure it to

framing material with nails or screws driven through holes in

sides of outer case (shim case and predrill holes before securing).

9

15

Framing

lumber

22 13/16"

/16"

nstall case

3

/8"

Caulk all

sides

5 1/2"

Front of outer case

to side air louvers

Optional

molding

(not provided)

Installed Case

(brick veneer or frame wall construction

shown)

Framed/Finished Opening

(brick veneer or frame wall construction)

17

Page 20

Installation in Wall Thicker Than 5 ½inches

The side louvers in outer case provide ventilation to air conditioner compressor and fan motor and must not be

blocked. When installing unit in a wall over 5 1/2-inches

thick, provisions must be made in wall opening to ensure

free air flow to the side louvers. This can be accomplished

by chamfering the vertical portions of the outside opening

as shown.

Ventilation louvers on top of case must not be obstructed.

Do not attempt to install unit in walls thicker than

10 1/2-inches.

Front of

outercase

1

5

/2"

4"

22

30

10 1/2"

3

5

/

"

3

5

"

/

¾" minimum

projection

4"

Chamfering Walls Thicker Than 5

Side air

louvers

(both sides)

1

/2-inches

18

Page 21

Specifications

Cooling Capacity (BTU/HR) 9500/9700 11400/11600

Heating Capacity (BTU/HR) 8300/8500 10100/10500

Electric Heat (BTU/HR) 8500/10700 8500/10700

Rated Voltage 208/230V~ 208/230V~

Rated Frequency 60Hz 60Hz

Design Pressure Lowside 150 P.S.I. 150 P.S.I.

Design Pressure Highside 330 P.S.I. 380 P.S.I.

Cooling AMPS 4.8/4.6 5.9/5.5

Cooling Watts 970/990 1210/1235

Model KC-30H KC-35H

Cooling EER 9.8 9.4

Heating AMPS 4.5/4.2 5.8/5.1

Heating Watts 850/870 1100/1140

Heating EER 9.8 9.2

Electric Heat AMPS 15.6/16 15.6/16

Electric Heat Watts 3500 3500

Air Flow Volume (CFM) 310 310

Dehumidifying Volume (Pint/Day) 71 71

Refrigerant Charge (Ounce) R22 / 26.81 OZ R22 / 34.57 OZ

Dimension (W/D/H)(inch) 22.6” X 23.62” X 15.31” 22.6” X 23.62” X 15.31”

Dimension of Package (W/D/H)(inch) 25.79” X 27.40” X 16.54” 25.79” X 27.40” X 16.54”

Net Weight /Gross Weight (lbs) 97/114.6 97/114.6

19

Page 22

Warranty

Soleus International Inc. warrants the accompanying Soleus Air 10000 / 12000BTU Heat Pump Room Air

Conditioner (KC-30H / KC-35H) to be free of defects in material and workmanship for the applications specified

in its operation instruction for the period of parts specified below.

5 YEARS FOR COMPRESSOR

1 YEAR FOR OTHER COMPONENTS

This warranty shall not apply to broken or marred cabinets, accessories, knobs, filters or routine maintenance.

This warranty does not apply to uncrating, setup, installation, removal of the product for repair or reinstallation of

the product after repair.

This warranty does not apply to repairs or replacements necessitated by any cause beyond the control of Soleus

International including, but not limited to, any malfunction, defect or failure caused by or resulting from

unauthorized service or parts, improper maintenance, operation contrary to furnished instructions, shipping or

transit accidents, modification or repair by the user, abuse, misuse, neglect, accident, incorrect power line voltage,

fire, flood or other Acts of God, or normal wear and tear.

Warranty service must be performed by a qualified HVAC contractor. Soleus maintains a centralized service

network to provide parts and assist in resolving service problems if difficulties are encountered. Soleus agrees to

provide service information, sell repair parts and reimburse the dealer /serviceman for parts in accordance with

Soleus International’s Policies and Procedures.

SOLEUS INTERNATIONAL MAINTAINS THAT ALL WARRANTIES, INCLUDING IMPLIED

WARRANTY OR MERCHANTABILITY ARE LIMITED TO THE TERMS AND CONDITIONS

SPECIFIED ABOVE. SOLEUS INTERNATIONAL DISCLAIMS ANY LIBILITY FOR

CONSEQUENTIAL OR INCIDENTAL DAMAGES AND IN NO EVENT SHAL L SOLEUS

INTERNATIONAL INC.’S LIABILITY EXCEED THE RETAIL VALUE OF THE AIR CONDITIONER.

This warranty covers only new products purchased from our authorized dealers or retailers. It does not cover

internet sales, used, salvaged, or refurbished products.

FOR TECHNICAL SUPPORT AND WARRANTY SERVICE

Soleus International Inc.

Tel: 1-888-8 SOLEUS

Monday through Friday, 9:00 AM to 5:00 PM, PST

Email: Contact@soleusair.com

Website: www.soleusair.com

20

Loading...

Loading...