Soleus Air HCC-C09HP-A,HCC-C12HP-A,HCC-C15HP-A Installation And Operating Instructions Manual

PACKAGED TERMINAL

AIR CONDITIONERHEAT PUMP

Installation and Operating Instructions

Model No.:HCC-C09HP-A

HCC-C12HP-A

HCC-C15HP-A

4004987

V140

CONTENTS

… … …

UNIT FEATURES 2

INSTALLATION INSTRUCTION

WIRING 7

OPERATING INSTRUCTIONS 8

MAINTENANCE AND CLEANING 10

NORMAL OPERA TING SOUNDS AND CONDITION 12

DIAGNOSTIC CODES 12

TROUBLE SHOOTING 13

WARRANTY

… ………………………………………………………

… …………………………………………

… …………………………4

.....................

… ……………………

… …………………………………

………………………………………

………

………

.................................................

14

IMPORTANT NOTES:

IMPORTANT NOTE TO THE SERVICER

Read this manual and familiarize yourself with the specific

items which must be adhered to before attempting to

service this unit. The precautions listed in this Installation

Manual are intended as supplemental to existing

practices. However, if there is a direct conflict between

existing practices and the content of this

precautions listed here take precedence.

manual, the

RECOGNIZE THIS SYMBOL

AS A SAFETY PRECAUTION

Before using this manual, check the serial plate for proper

model identification.

The installation and servicing of this equipment must be

performed by qualified, experienced technicians only.

Due to policy of continual product improvement, the right is

reserved to change specifications and design without

notice.

IMPORT ANT NOTE TO THE OWNER

This manual is to be used by qualified, professionally trained

HVAC technicians only. The

any responsibility for property damage or personal injury for

improper service procedures or services performed by an

unqualified Person.

manufacturer does not assume

WARNING

THE MANUFACTURER WILL NOT BE RESPONSIBLE FOR ANY

INJURY OR PROPERTY, DAMAGE ARISING FROM IMPROPER

SERVICE OR SERVICE PROCEDURES. IF YOU INSTALL OR

PERFORM SERVICE ON THIS UNIT, YOU ASSUME

RESPONSIBILITY FOR ANY PERSONAL INJURY OR PROPERTY

DAMAGE WHICH MAY RESULT, MANY JURISDICTIONS

REQUIRE A LICENSE TO INSTALL OR SERVICE

AIR CONDITIONING EQUIPMENT.

HEATING AND

WARNING

HIGH VOLTAGE

DISCONNECT ALL POWER BEFORE SERVICING OR

INSTALLING THIS UNIT. MULTIPLE POWER SOURCES MAY

BE PRESENT, FAILURE TO DO SO MAY CAUSE PROPERTY

DAMAGE, PERSONAL INJURY OR DEATH.

- 1 -

UNIT FEATURES

This unit has many features which are different than those

found on conventional PTAC units. The servicer must be

familiar with these features in order to properly handle

the unit .

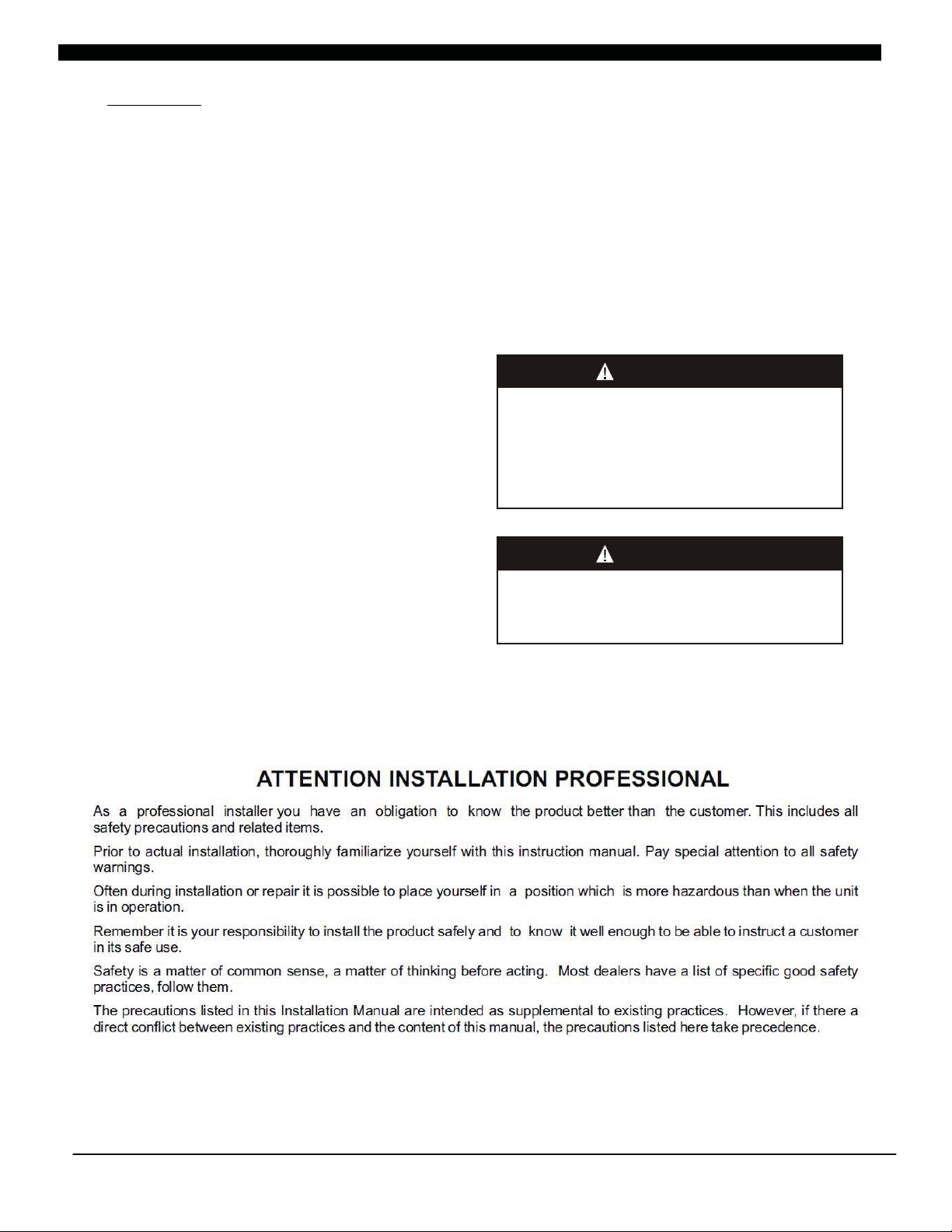

• LCDI Cords-Underwriters Laboratories and the

National Electric Code (NEC) now require power

cords that sense current

electrical circuit to the unit on units rated at 250 volts

or less. In the event that unit does not operate, check

the reset button located on or near the head of the

power cord as part of the normal troubleshooting

procedure.

LCDI power Cord

• Automatic 3-minute compressor lockout-After

the compressor cycles off, it will not restart for three

minutes.

• Random restart delay-To help eliminate power

surges after a power outage, the unit is equipped with

a two to four minute random restart delay feature.

Whenever the unit is plugged in with

switch turned on and the mode switch set in the cool

or heat mode, a random restart will occur. A random

restart condition can be avoided by setting the mode

switch in the fan only or off position before applying

power to the unit.

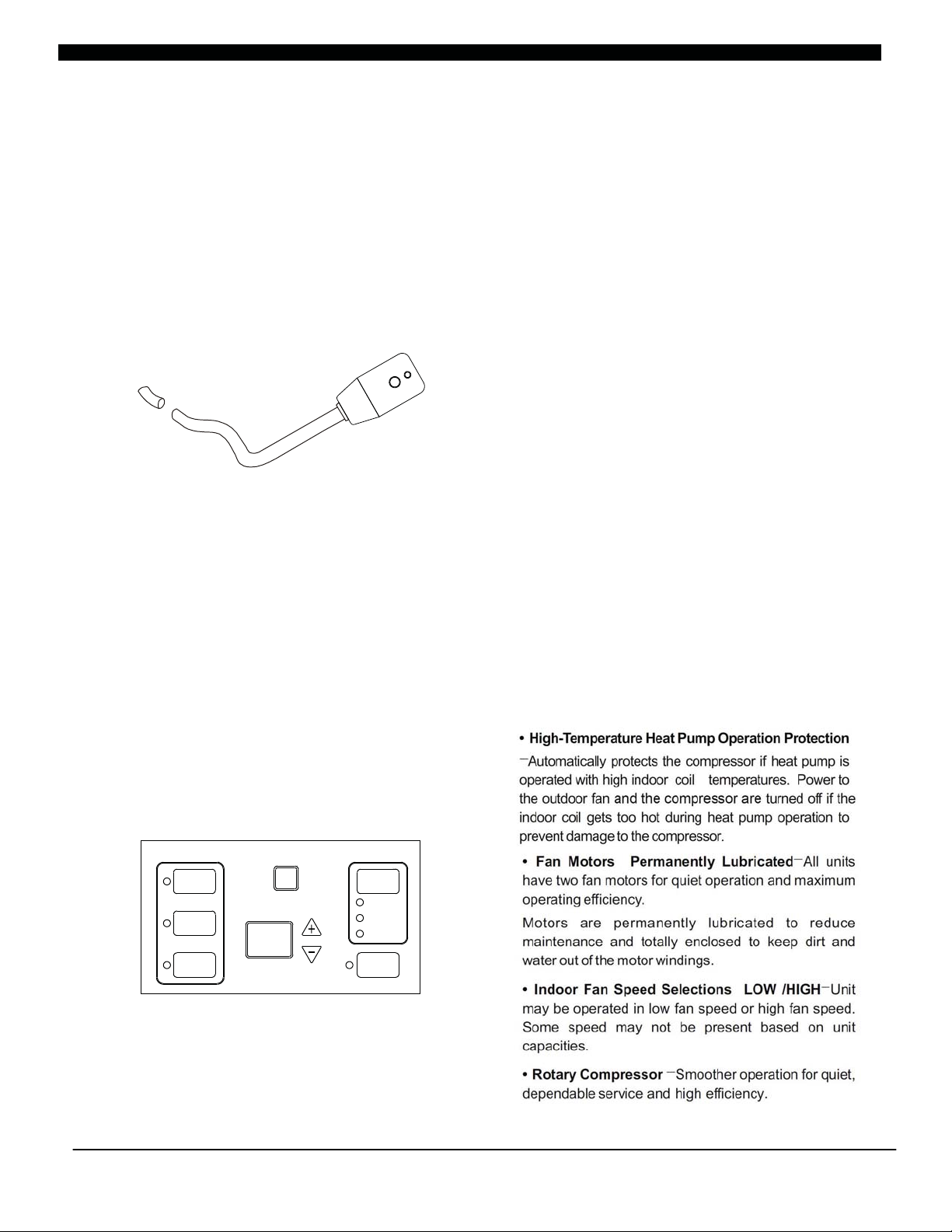

• Indication LEDs-The

correspond to fan operation and to indicate unit

status. The LEDs next to the selections ON/OFF,

FAN, COOL, and HEAT indicate which operational

leakage and can open the

the master

has LEDs that

-

• High Pressure Protection The unit will shut off

automatically when the pressure in the system is over

638 psi and within 10 minutes, after the compressor

turns off, the unit will restart when the pressure turns

back below 551 psi. This protection can effectively

avoid the burst and leakage of pipes, lessen the

system failures and prolong the service life.

-

• Failure Tolerance If the unit is in protection mode

less than 4 times in one hour, the accumulation times

will reset to avoid system failure. Only when the unit

enters protection mode more than 4 times in one

hour, the system will fail to restart automatically and

need manual restart.

Standard Physical Dimensions-The series PTAC

•

is with the same dimensions 42" wide x 16" high x 133/4" deep

Replacement of older units is made easy.

Weather-Protected Electrical Components-Vital

•

electrical components are protected from the weather

by locating them on the indoor

side of the weather

barrier.

Highly Featured Microprocessor Controls-

•

Microprocessor controls are programmed to interface

with the temperature sensors to maximize comfort

conditions for the room occupant and provide

outstanding features.

Thermistors are used to sense small changes in

temperature to give excellent room control and allow

the microprocessor to monitor and react to changing

conditions.

• Automatic Emergency Heat on Heat Pump

-Automatically uses electric resistance heat if

Units

the heat pump

selected room temperatur .

• High-Temperature Heat Pump Operation Protection

-Automatically protects the compressor if heat pump is

operated with high indoor

the outdoor fan turned off if the

indoor coil gets too hot during heat pump operation to

prevent damage to the compressor.

coil temperatures. Power to

HEAT

COOL

FAN

Figure 1

FAN

SPEED

HIGH

LOW

AUTO

ON/OFF

-2-

• Fan Motors Permanently Lubricated-All units

have two fan motors for quiet operation and maximum

operating efficiency.

Motors are permanently lubricated to reduce

maintenance and totally enclosed to keep dirt and

water out of the motor windings.

• Indoor Fan Speed Selections LOW /HIGH

may be operated in low fan speed or high fan speed.

Some speed may not be present based on unit

capacities.

• Rotary Compressor

dependable service and high efficiency.

• Indoor Coil Frost Control

freezing. Frost can form on the indoor coil when the unit

is operated in cooling when the

low. The unit automatically shuts the compressor off

until the indoor coil temperature warms to the point

where frosting will no longer occur. Then

compressor.

-Smoother operation for quiet,

-Prevents indoor coil from

outdoor temperature is

-Unit

restart the

WARNING

HIGH VOLTAGE

DISCONNECT ALL POWER BEFORE SERVICING OR

INSTALLING THIS UNIT. MULTIPLE POWER SOURCES MAY

BE PRESENT, FAILURE TO DO SO MAY CAUSE PROPERTY

DAMAGE, PERSONAL INJURY OR DEATH.

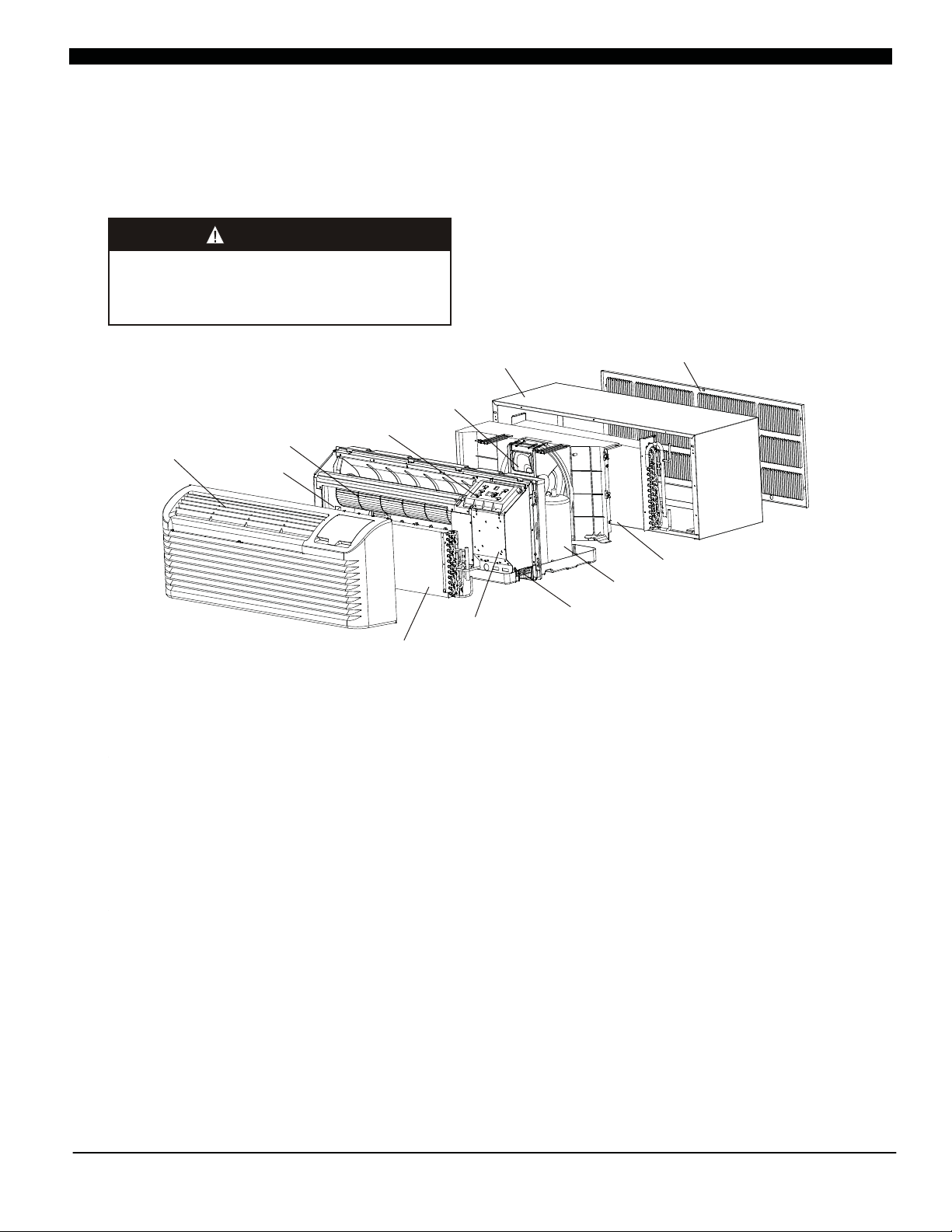

UNIT ACCESSORIES

This unit is designed for through-the-wall installation in

new or existing buildings. To complete the installation

of this PTAC, an insulated wall sleeve and an outdoor

grille (either the stamped aluminum grille, or the

architectural grille ) are required.

The chassis

are shipped in one carton.

,cabinet front and wall mount thermostat wiring

(not included in this package).

OPTIONAL ACCESSORIES

Power switch Kit

Wall Sleeve Kit

Key Lock Kit

Drain Kit

Filter Kit

Hard Wire Kit

Wire Harness Kit

Architectural Grille Kit

Stamped Louver Kit

LCDI Power Cord

Wireless IR Antenna

Wireless IR Thermostat

Electric And

IR REMOTE CONTROLLER

NOTE: Consult sales literature for the appropriate

voltage and amperage selections, if applicable.

Non Electric Sub Base Kit

-3-

INSTALLATION INSTRUCTIONS

(

)

(

)

To ensure that the unit operates safely and efficiently, it must be installed, operated and maintained according

to these installation and operating instructions and all local codes and ordinances or, in their absence, with the

latest edition of the National Electric Code. The proper installation of this unit is described in

the following

sections. Following the steps in the order presented should ensure proper installation.

WARNING

HIGH VOLTAGE

DISCONNECT ALL POWER BEFORE SERVICING OR

INSTALLING THIS UNIT. MULTIPLE POWER SOURCES MAY

BE PRESENT, FAILURE TO DO SO MAY CAUSE PROPERTY

DAMAGE, PERSONAL INJURY OR DEATH.

Outdoor Fan

Wall Sleeve

not included in the package

Wall sleeve

Outdoor Grille

not included in the package

Outdoor grille

Display Module

Outdoor coil

Rotary compressor

Power cord coverplate(not show)

Control box

Indoor coil

Front and discharge grille

Indoor Fan

Electric heater

Figure 2

WALL SLEEVE ASSEMBLY (OPTIONAL ACCESSORY)

Two kinds of wall sleeve are optional for customers, one is reassemble

welding integrated wall sleeve.

Removable Wall Sleeve

The removable wall sleeve can be removed and occupies less space and is convenient to transport. Follow the

below steps to install :

a) Unpack all parts and accessories, referring to Fig 1.

b) Assemble the wall

sleeve by first “clip locking” the side pieces to the bottom piece.

c) Assemble the top piece to the assembled side and top piece.

Welded integrated wall sleeve

Welded integrated wall sleeve is featured by artistic appearance and stable structure referring to Fig 2.

Customers can purchase together with unit.

wall sleeve and the other one is

4

2

"

K

C

O

L

P

I

L

C

S

P

Fig

EV

E

E

L

E

C

E

I

M

O

T

T

O

B

1

Fig 2

1

6

"

3

"

4

3

1

-4-

Loading...

Loading...