Soleus Air HCC-C09HP-A, HCC-C12HP-A, HCC-C15HP-A Installation And Operating Instructions Manual

Page 1

PACKAGED TERMINAL

AIR CONDITIONER with HEAT PUMP

Installation and Operating Instructions

Model No.:HCC-C09HP-A

HCC-C12HP-A

HCC-C15HP-A

V140422

Page 2

CONTENTS

UNIT FEATURES 2

INSTALLATION INSTRUCTION

WIRING 7

MAINTENANCE AND CLEANING 10

NORMAL OPERATING SOUNDS AND CONDITION 12

DIAGNOSTIC CODES 12

TROUBLE SHOOTING 13

… …………………………………………

… …………………………4

… ………………………………………………………

… … …

… … … … …… … … …

………

… …………………………………

………………………………………

OPERATING INSTRUCTIONS 8… … …

-1-

RECOGNIZE THIS SYMBOL

AS A SAFETY PRECAUTION

WARNING

HIGH VOLTAGE

DI SCONNE CT AL L PO WER B E F O R E S E R VICING O R

INSTALL ING TH IS UNI T. MULTIPLE POW ER SOU RCES MAY

BE PRESENT, FAILURE TO DO SO MAY CAUSE PROPERTY

DAMAGE, PE RSONAL INJURY OR DEATH.

IMPORTANT NOTE TO THE SERVICER

Read this manual and familiarize yourself with the specific

items which must be adhered to before attempting to

service this unit. The precautions listed in this Installation

Manual are intended as supplemental to existing

practices. However, if there is a direct conflict between

existing practices and the content of this manual, the

precautions listed here take precedence.

THE MANUFACTURER WILL NOT BE RESPONSIBLE FOR ANY

INJURY OR PROPERTY, DAMAGE ARISING FROM IMPROPER

SERVICE OR SERVICE PROCEDURES. IF YOU INSTALL OR

PERFOR M SE RVICE ON THIS UN IT, Y OU A S S U ME

RESPONSIBILITY FOR ANY PERSONAL INJURY OR PROPERTY

DAM AGE WHICH MAY RESULT, M AN Y JUR IS DICTI ON S

REQUIRE A LICENSE TO INSTALL OR SERVICE HEATING AND

AIR CONDITIONING EQUIPMENT.

WARNING

IMPORTANT NOTES:

Before using this manual, check the serial plate for proper

model identification.

The installation and servicing of this equipment must be

performed by qualified, experienced technicians only.

Due to policy of continual product improvement, the right is

reserved to change specifications and design without

notice.

IMPORTANT NOTE TO THE OWNER

This manual is to be used by qualified, professionally trained

HVAC technicians only. The manufacturer does not assume

any responsibility for property damage or personal injury for

improper service procedures or services performed by an

unqualified Person.

Page 3

• High Pressure Protection The unit will shut off

automatically when the pressure in the system is over

638 psi and within 10 minutes, after the compressor

turns off, the unit will restart when the pressure turns

back below 551 psi. This protection can effectively

avoid the burst and leakage of pipes, lessen the

system failures and prolong the service life.

• Failure Tolerance If the unit is in protection mode

less than 4 times in one hour, the accumulation times

will reset to avoid system failure. Only when the unit

enters protection mode more than 4 times in one

hour, the system will fail to restart automatically and

need manual restart.

•

•

•

-

-

Standard Physical Dimensions-The series PTAC

is with the same dimensions 42" wide x 16" high x 133/4" deep

Replacement of older units is made easy.

Weather-Protected Electrical Components-Vital

electrical components are protected from the weather

by locating them on the indoor side of the weather

barrier.

Highly Featured Microprocessor Controls-

Microprocessor controls are programmed to interface

with the temperature sensors to maximize comfort

conditions for the room occupant and provide

outstanding features.

Thermistors are used to sense small changes in

temperature to give excellent room control and allow

the microprocessor to monitor and react to changing

conditions.

• Automatic Emergency Heat on Heat Pump

Units-Automatically uses electric resistance heat if

the heat pump fails.

selected room temperatur .

• High-Temperature Heat Pump Operation Protection

-Automatically protects the compressor if heat pump is

operated with high indoor coil temperatures. Power to

the outdoor fan turned off if the

indoor coil gets too hot during heat pump operation to

prevent damage to the compressor.

UNIT FEATURES

This unit has many features which are different than those

found on conventional PTAC units. The servicer must be

familiar with these features in order to properly handle

the unit .

• LCDI Cords-Underwriters Laboratories and the

National Electric Code (NEC) now require power

cords that sense current leakage and can open the

electrical circuit to the unit on units rated at 250 volts

or less. In the event that unit does not operate, check

the reset button located on or near the head of the

power cord as part of the normal troubleshooting

procedure.

LCDI pow er Cord

• Automatic 3-minute compressor lockout-After

the compressor cycles off, it will not restart for three

minutes.

• Random restart delay-To help eliminate power

surges after a power outage, the unit is equipped with

a two to four minute random restart delay feature.

Whenever the unit is plugged in with the master

switch turned on and the mode switch set in the cool

or heat mode, a random restart will occur. A random

restart condition can be avoided by setting the mode

switch in the fan only or off position before applying

power to the unit.

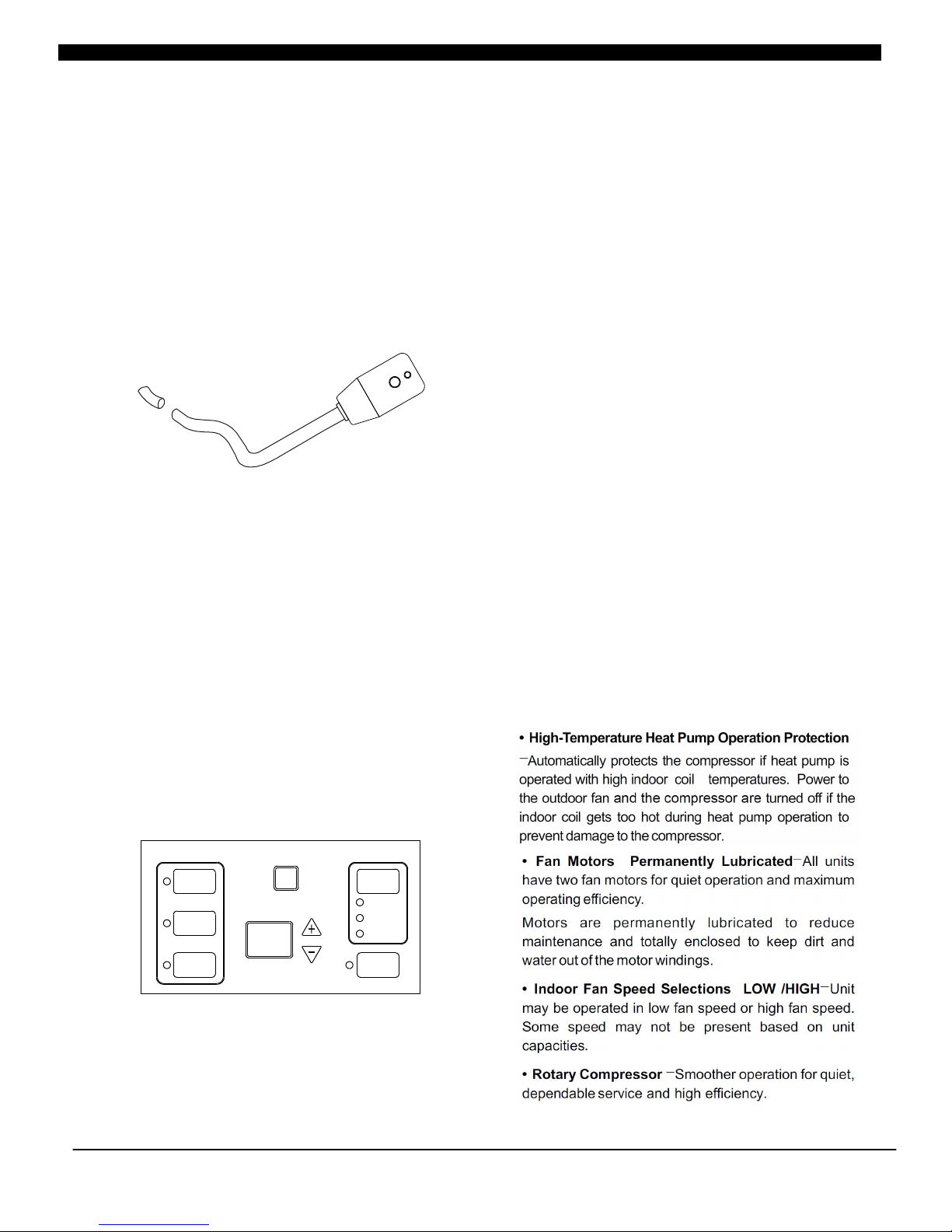

• Indication LEDs-The control panel has LEDs that

correspond to fan operation and to indicate unit

status. The LEDs next to the selections ON/OFF,

FAN, COOL, and HEAT indicate which operational

-2 -

HEAT

COO L

FAN

ON/ OFF

AUT O

LOW

HIG H

SPEE D

FAN

Page 4

• Fan Motors Permanently Lubricated-All units

have two fan motors for quiet operation and maximum

operating efficiency.

Motors are permanently lubricated to reduce

maintenance and totally enclosed to keep dirt and

water out of the motor windings.

• Indoor Fan Speed Selections LOW /HIGH-Unit

may be operated in low fan speed or high fan speed.

Some speed may not be present based on unit

capacities.

• Rotary Compressor -Smoother operation for quiet,

dependable service and high efficiency.

• Indoor Coil Frost Control-Prevents indoor coil from

freezing. Frost can form on the indoor coil when the unit

is operated in cooling when the outdoor temperature is

low. The unit automatically shuts the compressor off

until the indoor coil temperature warms to the point

where frosting will no longer occur. Then restart the

compressor.

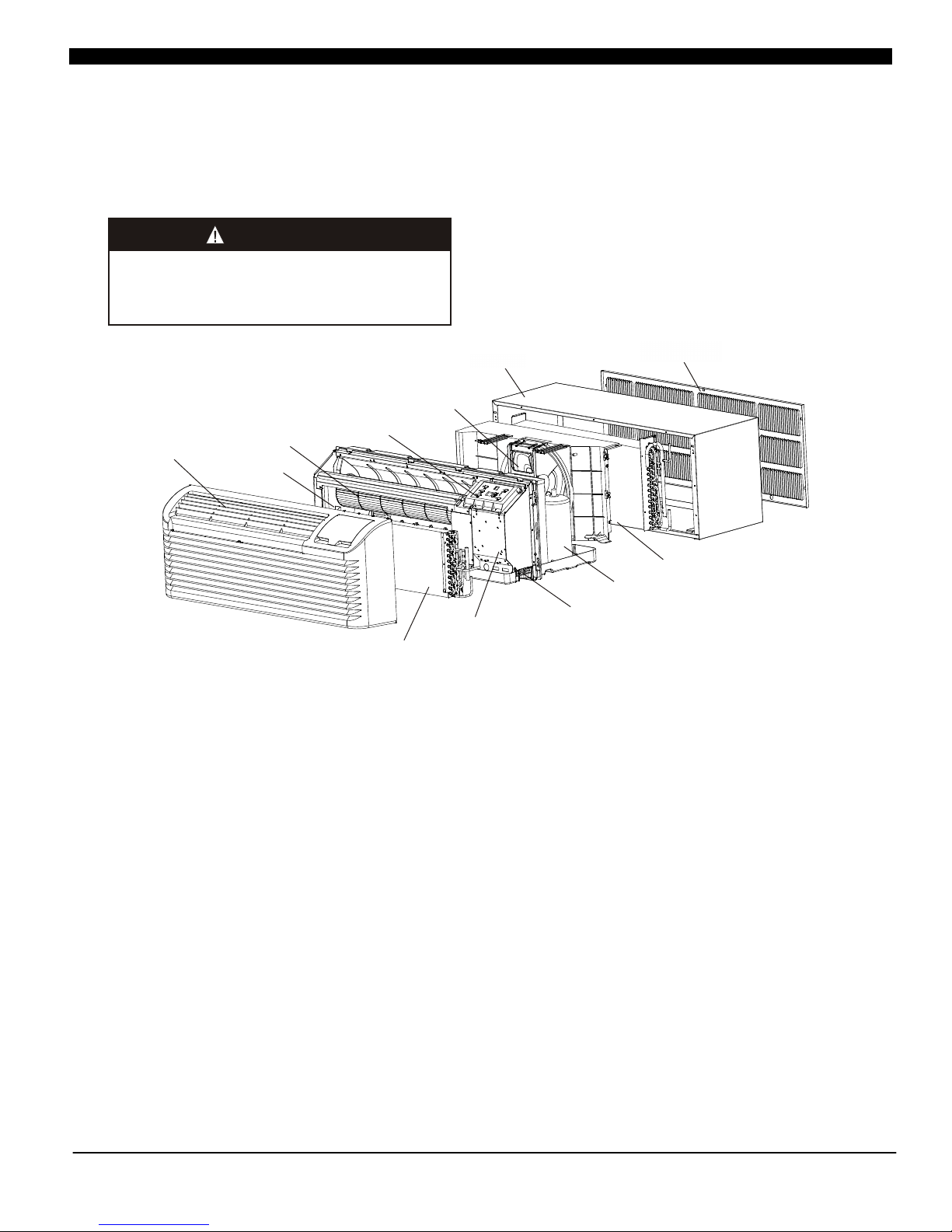

UNIT ACCESSORIES

This unit is designed for through-the-wall installation in

new or existing buildings. To complete the installation

of this PTAC, an insulated wall sleeve and an outdoor

grille (either the stamped aluminum grille, or the

architectural grille ) are required.

The chassis and the cabinet front are shipped in one

carton. Optional accessories to complete a particular

installation are the following:

OPTIONAL ACCESSORIES

Power switch Kit

Wall Sleeve Kit

Key Lock Kit

Drain Kit

Filter Kit

Hard Wire Kit

Wire Harness Kit

Architectural Grille Kit

Stamped Louver Kit

LCDI Power Cord

Wireless IR Antenna

Wireless IR Thermostat

Electric And Non Electric Sub Base Kit

IR REMOTE CONTROLLER

NOTE: Cons ult sale s lit erature for the approp ria te

volta ge and ampe rage sele ctions, i f applica ble.

-3 -

WARNING

HIGH VOLTAGE

DIS CONNECT AL L P O W E R BE FORE S E RVICIN G O R

INSTALL ING THIS UNIT. MULTIPLE POWER S OURCES MAY

BE PRESENT, FAILURE TO DO SO MAY CAUSE PROPERTY

DAMAGE, PE RSONAL INJURY OR DEATH.

Page 5

-4 -

WARNING

HIGH VOLTAGE

DI S C O N NECT AL L P O WER BEF ORE SE R V I CIN G O R

INSTALL ING THIS UNIT. MULTIPLE POWER SOURCES MAY

BE PRESENT, FAILURE TO D O SO MAY CAUSE PROPER TY

DAMAGE, PE RSONAL INJURY OR DEATH.

INSTALLATION INSTRUCTIONS

To ensur e th at t he unit o per ates saf ely and eff icientl y, it mus t be ins tall ed, operate d and mainta ined acc ording

to these instal lation and operat ing ins tructio ns and all local cod es and ord inan ces or, in the ir abse nce, wi th the

lates t edition of the Nationa l Electric Code. The proper ins tallati on of this unit is descri bed in the following

secti ons. Foll owing the s teps in the o rder pres ented sho uld ensur e proper in stallat ion.

WALL SLEEVE ASSEMBLY (OPT IONAL ACC ESSORY)

Two kind s of wall sle eve are opt ional for c ustomer s, one is rea ssemble w all sleev e and the oth er one is

weldi ng integr ated wall s leeve.

Remov able Wa ll Sleeve

The rem ovable wa ll sleeve c an be remov ed and occu pies l ess s pace a nd is c onve nie nt to tr ans port . Fol low th e

below s teps to ins tall :

a) Unpa ck all part s and acces sories, r eferrin g to Fig 1.

b) Assem ble the wal l sleeve by f irst “cli p locking ” the side pi eces to the b ottom pie ce.

c) Assem ble the top p iece to the a ssemble d side and to p piece.

Weld ed integr ated wall s leeve

Weld ed integr ated wall s leeve is fe atured by a rtistic a ppea ran ce and s tab le str uct ure re fer ring t o Fig 2 .

Custo mers can pu rchase to gether wi th unit.

Fig 1

K

C

O

L

I

P

L

C

M

O

T

T

O

B

E

V

E

E

L

S

E

C

I

E

P

Front and discharge grille

Electric heater

Indoor Fan

Display Module

Outdoor Fan

Wall sleeve

Indoor coil

Control box

Power cord coverplate(not show)

Rotary compressor

Outdoor coil

Outdoor grille

Fig 2

4

2

"

1

6

"

"

3

1

3

4

Page 6

In order for condensate water to drain properly inside the

unit, the sleeve must be installed properly:

Level from right to left.

A slight downward pitch from the indoor side to the

out-door side as shown below .

•

•

(Fig 6)

• Fasten the wall sleeve(Fig 7).

-5 -

SLEEVE INSTALLATION

Preparation of the wall

The sleeve should be installed during construction and

lintels should be used to support the block above the wall

sleeve. The sleeve can not support the load of bricks/

blocks.

For existing construction, wall opening must be created,

the proper dimensions are necessary to avoid use of fillers

or additional framing .The sleeve is modular in height and

width(refer to Fig 5& Chart 2).

Height:

Fits 2 courses concrete block

Fits 6 courses standard brick

Fits 5 courses jumbo brick

Width:

Fit approximately 3 stud spaces.

Wall sleeve location

When making the wall opening, please observe the

following requirement:

A) The air inlet and outlet should be unblocked and the air

can be delivered to every corner of the room

B) Install the unit in places that are away from heat source

or sources of flammable gases.

C) Do not install the unit in places that are subject to strong

dust

D) Do not install the unit in places where the operational

noise and exhausted air might trouble your neighbour.

E) There should be sufficient space margins around the

unit to facilitate maintenance and repairs(refer to Fig 3

and 4)

NO.1

NO.2

minium finished opening

dimensions

sleeve dimensions

Heig ht

widt h

dept h

heig ht

widt h

16-1/4"

16-1/4"

16"

13-3/4"

(16"/18"/24")

42-1/2"

42-1/4"

42"

NOTE: NO.1 means using field supplied sleeve angles

NO.2 means not using field supplied sleeve angles

Fig 4

Fig 3

1

2

WOOD

SCREW

MOLLY

OR TOGGLE

BOLT

EXPANSION

ANCHOR

BOLT

MAIN STUD

JACK STUDS

HEADER-4"×4"OR

2-2"×4"ON EDGE

16-1/4"MIN

ADJUSTABLE FRAMING TO SECURE

THIS DIMENSION

42-1/4"MIN

SUB-FLOOR

FINISHED FLOOR

CRIPPLE

JACK STUD

Note:Do not remove the stiffener

support from inside the wall case

until the chassis is to be installed.

Fig 5

Inside

Outside

Level

Wall

Sleeve

Outside

Wall

1/4 Bubble

Tilt to

Outside

Proper Sleeve Tilt

Fig 6

Fig 7

Dimensions Recommended installation clearance

D1

D2

Projection of case into room-1/2"minimum up to1-3/4"maximum

without use of electrical sub-base.

Note: 2-3/8" minmum when sub-base is used.

Height above finished floor or top of carpet-1/2"minimum,

2" recommended without sub-base-3" minimum with sub-base.

Chart 1

Chart 2

Page 7

Cabinet Front Removal View 2

Cabinet Front Removal View 1

4. Secure the chassis to the wall sleeve using three screws

on each side of the chassis to ensure a proper seal

between the chassis and the wall sleeve. The screws are

supplied in a plastic bag.

IMPORTANT NOTES:

1. The unit is equipped with a rubber grommet mounted

compressor. These grommets are factory set and require

no adjustment.

2. Check the indoor and outdoor grilles for obstructions to

air flow. The unit must be located where curtains, furniture,

trees, or other objects do not block the air flow to and from

the unit. If air is obstructed and/or deflected back into the

unit, the air conditioner compressor may cycle on and off

rapidly. This could damage the compressor or possibly

void the warranty.

-6 -

OUTDOOR GRILLE

An outside grille must be installed to direct air flow for

proper unit operation and also protect the outdoor coil. The

grille must be installed before installing the chassis.

When replacing an old chassis with an existing grille or

using a specialized grille in a new installation, please

check with after-sales engineer of supplier to determine if

the new chassis should be used with the nonstandard

specialized grille. An improper outdoor grille can decrease

cooling or heating capacity, increase energy usage and

shorten compressor life and possibly void the warranty.

(OPTIONAL ACCESSORY)

FRONT REMOVAL

1. Grasp the cabinet front.

2. Pull the bottom of the cabinet front away from the

chassis until the retaining clips disengage.

3. Lift the cabinet front off the chassis. Reverse this

procedure to reinstall the cabinet front

Chassis Installation View 1

Page 8

VOLTAGE MEASUREMENTS

Once the unit is properly wired, measure the unit supply

voltage. Voltage must fall within the voltage utilization

range given in .Chart 3

WIRING

Cord connection to a wall socket is not permitted for 265V

units. All 265V units must be hard wired using the hard

wire kit or make use of the plug in receptacle in the

standard subbase.

230~208V units are equipped with LCDI power cords and

can open the electrical circuit to the unit. In the event the

unit does not operate, check the reset button located on or

near the head of the power cord as part of the normal

trouble shooting procedure.

WARNING

HIGH VOLTAGE

DISCONNECT ALL POWER BEFORE SERVICING OR INSTALLING

THIS UNIT. MULTIPLE POWER SOURCES BE PRESENT, FAILURE

TO DO SO MAY CAUSE PROPERTY DAMAGE, PERSONAL INJURY

OR DEATH.

DO NOT SERVICE THIS UNIT WITHOUT FIRST SHUTTING OFF THE

POWER TO THE UNIT FROM THE CIRCUIT BREAKER AND/OR

REMOVING THE UNIT CORD SET PLUG FROM THE WALL OUTLET.

WARNING

THI S A IR CO NDITI ONER IS NOT MEANT TO PROVI DE

UNATTEN DED COOLING O R LIFE SUPPORT FOR PERS ONS

OR ANIMALS WHO ARE UNAB LE REA CT TO THE FAILURE OF

THIS PRODUCT.

THE FAILUR E OF AN UNATTENDED AI R CO NDITIONER MAY

RESULT IN EXTREME HEAT I N THE CONDITIO NED SPACE

CAUSING OV ERHEATING OR DEATH OF PERSONS OR

ANIMALS.

Oper at in g Vol ta ge

Rati ng

230/ 2 08

265

Unit Voltag e

Mini mu m

197

238

Volt age Uti li za tion Ra ng e

Maxi mu m

253

292

Chart 3 -Operating Voltage

-7 -

RED-24VAC

Purple-LS control

Green-High fan speed

Blue-Reversing valve

Yellow-Compressor

White-Heater

Orange-Low fan speed

Black-Common ground

R LS GH B Y W GL C

R LS GH B Y W GL C

WALL MOUNTED THERMOSTAT INTERFACE

Thermostat

WARNING

TO AVOI D THE RIS K OF P RO PERTY DAMAG E, P ER SONAL

INJU RY OR , USE ON LY COP PE R CONDU CTOR S.FIRE

WARNING

TO AVO ID PR OP ERTY DA MA GE, P ER SONAL I NJ URY OR

DEATH DU E T O E LE CTRIC AL SH OC K, D O N OT USE A N

EXTE NS IO N CORD WI TH T HI S UN IT.

WARNING

TO AVO ID THE R IS K OF PR OPERT Y DA MAGE, PERS ONAL

INJU RY OR FIRE DO N OT I NS TAL L WITH PO WER CORD

STRE TC HE D OR UND ER A STR AIN AS TH IS M AY CREATE

LOOS E PL UG /R ECE PTACL E CO NN ECTIO N.

WARNING

TO AVOID THE RISK OF PERSONAL INJURY, WIRING TO THE

UNIT MUST BE PROPERLY POLARIZED AND GROUNDED.

Fig 9 wall mounted thermostat wiring

Fig 8 Receptacles/Sub-bases

NOTE: See the “ " before

use the thermostat.

Remote Thermostat Change instructions

Tandem

230/208V 15Amp

265V 15Amp

Perpendicular

230/208V 20 Amp

265V 20 Amp

Large tandem

230/208V 30Amp

265V 30Amp

Page 9

OPERATING INSTRUCTIONS ( A CCESS ORY OPTIO NAL )

HEAT

COOL

FAN

ON/ OF F

AUTO

LOW

HIGH

SPE ED

FAN

Oper at io n mode butt on s

Pres s th es e butto ns t o

sele ct t he u nit ope ra te o n

heat m od e, c ool mod e or f an

mode .

Oper at io n mode indi ca to r

lamp s

when t he u ni t opera te s on

heat o r co ol o r fan mod e th e

indi ca to r lamps w il l be

acti ve d.

Digi ta l di splay er

On nor ma l op erati on i t in dicat es r oo m tempe ra tu re;

When p re ss ing + or - bu tt on , it indi ca te s setti ng t em pe rat ur e ;

On tim e op er ation , it i nd icate s ti me r time;

On fai lu re o perat io n, i t indic at es f ailur e co de .

Fan Speed button

Press this button to select

the fan speed on high, low or

auto.

Fan speed indicator lamp.

Operation status indicator

lamp.

Rece iv er o f IR remo te c on troll er s ig nal

ON/OFF button

Press this button to turn the

unit ON or OFF.

WARM button

Pressing this button to set room

temperature warmer.

COOL button

Pressing this button to set room

temperature cooler.

Fig 10 Use of unit mounted control panel

-8 -

Fig 11 Use of hand held remote controller

Page 10

The vent control allows outside air to be drawn into the

conditioned area. This outside air can provide ventilation

when the blower is operating, but it will increase the

heating or cooling load and operating costs.

To obtain access to the vent control

1. Remove the cabinet front (see Front Removal).

2. Remove the shipping screw (if installed) from the vent

door.

3. Remove the label (if present) from over the vent control

lever on the left side of the chassis. Remove the vent door

shipping screw.

4. Rotate the vent control lever to either open or close

the damper.

Remo ve sh ipp ing

scre w if pr ese nt

Fig 13 Sh ipp ing Screw L ocation

TIMER PROCEDURE ( Remote controller)

When cells are inserted, the present time is automatically

set to AM 0:00.EX.:set to AM10:30.

Open the back cover, push the CLK button .The time

indicator is flickering and can set the present time.

Press the HOUR button.(set to AM 10:00)

Press the MIN button.(set to 30)

Press the CLK button again, and then close the back

cover.

COOL/FAN/HEAT MODE OPERATION

PROCEDURE

Control panel:

Press the ON/OFF button.

Press the HEAT COOL FAN button, select the operation

mode: heat cool fan.

Press + or - button, to set your desired temperature. The

setting temperature range is 60-90°F(16-32°C).

Press the FAN SPEED button, to set your desired air

flow rate: high/ low auto.

° °

auto

/ /

/ /

/

Remote controller:

Press the ON/OFF button with the remote controller

pointing toward the packaged terminal air conditioner.

Press the MODE button, select the operation mode:

cool/fan/heat.

Press + or - button, to set your desired temperature. The

setting temperature range is 61-88 F(16-31 C).

Press the FAN SPEED button, to set your desired air

flow rate:hig/ low/ .

VENTILATION CONTROL

The ventilation control lever is located at left side of unit,

behind front panel.

NOTE: The vent door shipping tape must be removed before

using vent control lever. See Fig 12 and Fig13.

When set at close, only the air inside the room is circulated

and filtered;

When set at open, some outdoor air will be drawn into room,

this will reduce heating or cooling efficiency.

-9 -

: unit control panel has control of unit.

: wall thermostat has control of unit.

67

R3

R1 R2

R4

R5

R6

R7

R8

Heating Temperature Limits(°F)

9086 86

74

92 90

72

90

72

63

65

72

69 68 60

Cooling Temperature Limits(°F)

Page 11

M O N T H LY M A I N T E N A N C E A N D

CLEANING

Intake Air Filters

To properly maintain the operational performance of

your PTAC unit, it is extremely important that the inlet

air filters be cleaned once per month or more often if

operated in dusty or dirty locations or conditions. The

inta k e ai r fi l te r s ar e const r u c te d of dur a b l e

polypropylene. The "air intake" air filters can be easily

inserted into the cabinet front, using the filter guides.

Before cleaning the intake filter, turn the unit off by

setting the mode switch to the OFF position. Filter

should be cleaned as required.

The following procedure is used to remove the intake

filler:

1. Grasp each filter by its molded handle, located on the

front edge of the front, below the discharge grill.

-10-

Locat ion of 7 Scre ws

Discharge Air Flow Grille Removal

4. Rotate the grille 180° clockwise

5. Reinstall the screws securing the discharge air grille to

the cabinet front. Reinstall the cabinet front on the unit.

WARNING

HIGH VOLTAGE

DI SCONN ECT ALL P O WER B E F O R E SE R V I C I N G OR

INSTALLING THIS UNIT. MULTIPLE POWER SOURCES BE

PRESENT, FAILURE TO DO SO MAY CAUSE PROPERTY

DAMAGE, PERSONAL INJURY OR DEATH.

Vent door lever positions

MAINTENANCE AND CLEANING

WARNING

HIGH VOLTAGE

DI SCONNE CT ALL P O WER B E F O R E SE R V I C I N G OR

INSTALLING THIS UNIT. MULTIPLE POWER SOURCES BE

PRESENT, FAILURE TO DO SO MAY CAUSE PROPERTY

DAMAGE, PERSONAL INJURY OR DEATH.

Discharge Air Flow

3. Remove the seven (7) screws which secure the

discharge air grille to the cabinet front.

AIR DISCHARGE GRILLE

The d ischarg e gril le can be a dju sted to expel a ir at

eithe r a 15°or 55°angl e。

Discharge Grille Orientation Options

15°

Disc har ge

Air

55°

Disc har ge

Air

Use the following procedure to change the angle of the

discharge air flow:

1. Remove the front cabinet (see Front Removal).

2. Position the front so that the backside is accessible.

Page 12

Vent Screen

Before cleaning the vent screen, disconnect power to the

unit by unplugging the power cord at the wall outlet or

subbase, or disconnect power at the fuse box or circuit

breaker. If unit is operated with vent door closed, the vent

screen does not need

to be cleaned.

1. Remove the cabinet front as described in Front

Removal.

2. Remove the six screws securing the chassis to the wall

sleeve.

3. Slide the chassis out of the wall sleeve far enough so

that the vent screen is accessible.

4. Clean the vent screen, slide the chassis back into the

wall sleeve, secure it in place with six screws and reinstall

the front cabinet.

Cabinet Front

The cabinet front and discharge air grille can be cleaned

with a water dampened cloth. Under no circumstances

should hydrocarbon-based cleaners (e.g. acetone,

benzene, naphtha gasoline, etc.) or ammonia based

cleaners be used to clean the front or air grilles. Use care

when cleaning the control area.

Y E A R LY M A I N T E N A N C E A N D

CLEANING

NOTE: Use a mild biodegradable detergent when

cleaning the unit. Special care must be taken to protect the

unit's control board and other electrical components from

getting any water on them while cleaning. The use of harsh

or caustic cleaning agents or materials such as bleach or

coil cleaners that are not designed for PTAC products will

cause damage or deterioration of the aluminum fin or coil

material and is not recommended. Care must be taken not

to bend the aluminum fin stock.

Base pan and Condenser coil

Before cleaning the base pan and condenser coil, turn

OFF unit mode switch and disconnect power to the unit.

To disconnect power, either unplug the power cord at the

wall outlet or subbase, or disconnect power at the fuse box

or circuit breaker

1. Create a water tight seal by tightly covering the entire

control panel area and fan motor with plastic. Creating this

seal prevents water from entering the control area or the

fan motor and damaging the unit.

2. Spray condenser coil and base pan down with water.

Next spray a mild biodegradable detergent onto the

condenser coil and base pan. Let set for five (5) minutes.

3. Rinse condenser coil and base pan with water again.

NOTE: Ensure water pressure is no higher than that of an

ordinary garden hose and the water temperature no higher

than 120°F.

-11-

Routine scheduled Maintenance

To achieve continuing top performance and high efficiency,

establish a “once a year" cleaning/inspection schedule for

the unit. Take the unit out of the sleeve and thoroughly

clean and rinse. Be sure to include in the yearly cleaning

the evaporator coil, and condenser coil, basepan, and

drain passages.

Scheduled maintenance can be accomplished by either

qualified local maintenance staff or by an authorized

servicer. They must follow the instructions described in this

manual.

Adverse Operating Conditions Maintenance

Units operating in dusty or corrosive locations; i.e.

dusty construction site or sea coast, must be cleaned

more often. A minimum of four (4) times a year will

maintain proper operational conditions and protect unit

components.

Wall sleeve

Clean the wall sleeve while cleaning the unit. The

caulking around the sleeve should be checked to make

sure that any potential air and water openings around

the sleeve are properly sealed. The wall sleeve's level

should also be rechecked. Proper leveling for most

installations are a 1/4 bubble tilt to the outside and

level from right to left. Contact your sales person for

detailed maintenance or cleaning instructions.

Fron t re mo val is no t

nece ss ar y to

remo ve t he f ilter

Filter is removed by grasping

the filter's top and gently

pulling up

2. Pull the filter straight up and remove.

3. Clean filter with vacuum or with running water.

Reverse this procedure to reinstall the filter.

CAUTION!

DO NOT USE COMMERCIAL GRA DE CO IL CLEANERS. SOME

OF THESE CLEANERS MAY CONTAIN ETHYLENE DIAMINE

TETRACET IC ACID (EDTA) WHI CH CAN SHORTEN TH E LIFE

OF THE CONDENSER COI L.

Page 13

4. Tilt the non-compressor side of the unit up no higher

than 45 degrees and allow water to drain out the other side

of the unit.

5. Remove excess water left in the base pan by wiping the

base pan with a dry cloth.

6. Remove the water-tight seal from the motor and

control panel area.

7. Reinstall unit back into wall sleeve.

8. Allow unit to dry for 24 hours before reapplying power.

When power is reapplied test unit for proper operation.

9. Place a non-acidic algaecide in the base pan to inhibit

bacteria growth. Ensure the algaecide is compatible with

wet coil operation and is not corrosive to the coil.

Clearance Check

Clearances around the unit should also be checked to

make sure that the intake air and discharge air paths have

not become blocked or restricted. A minimum of eight

inches clearance is needed from unit to furniture, beds, or

other objects for proper operation. Restricted discharge or

intake air will reduce the unit's operational performance. In

severe airflow restrictions damage can occur to unit

components such as the compressor, electric heater or fan

motor.

NORMAL OPERATING SOUNDS

AND CONDITIONS

Water trickling sounds

Water is picked up and distributed over the coil. This

improves the efficiency and helps with water removal.

Water dripping

Water will collect in the base pan during high humidity

days. This can cause overflow and drip from the outside of

the unit.

Air sounds

The fan cycle switch sets the operational mode of the fan.

In the ON position the fan will run continuously whenever

power is applied in this mode. In the AUTO position, the

fan will cycle on and off with the compressor or electric

heater.

Starting delay

You may notice a few minutes delay in the starting if you

try to restart the unit too soon after turning it off or if you

adjust the thermostat right after the compressor has

shut off. This is due to a built– in delay to protect the

compressor.

Buzzer Response

The buzzer will chime “Di”(0.1 sec) as response when

receiving the effective order from key pad control and

remote control.

DIAGNOSTIC CODES

Th e Diagn ostic Mainte nance provid es deta iled

information on PTAC control operation and operational

status including present modes, failures , airflow restriction

warnings , operating temperatures, and past failures.

To enter Diagnostic Status Report mode, press and hold

the down arrows and, while hold press the FAN SPEED

key for a period of five (5) seconds.

The meaning of figure on display pad is as below:

X.X----(0~4: time of protection)

└ ━ is protection mode(1: anti-frost; 2: overheat; 3: high

pressure; 4:anti-freezing)

-12-

Fail ur e co de

E2

E3

E5

E8

E9

Cont en t of d efect

Indo or c oi l te mpe ra tu re s ensor f ai lu re

Indo or t em pe rat ur e se ns or fa il ur e

Outd oo r co il t emp er at ur e senso r fa il ure

Over he at ing pro te ct ion/defr os ti ng

High p re ss ure pro te ct ion

CAUTION!

HIGH P RE SS URE AN D HI GH TEMP ER ATU RE CLEA NI NG I S

NOT RE CO MM ENDED .

DOIN G SO COULD DAM AG E THE ALUMINU M FIN STOC K

AND EL EC TR ICAL COMPON EN T.

Page 14

TROUBLESHOOTING

POSSIB LE CAUS ES

UNIT D OES N OT START

● Unit m ay ha ve be come un plu gge d

● Fuse m ay ha ve bl own

● Circ uit b rea ker may h ave b een t rippe d

● Unit m ay be o ff o r in wa ll ther mos tat m ode.

Ch e c k s e c ti on o n d ip s wi tch se tt in g s t o ve r if y

dips wit che s are set p rop erl y.

● Uni t m ay be in a pr ote ction or d iag nos tic fa ilure

mode . See s ect ion on di agn ost ic code s.

●

●

●

●

●

●

●

●

●

●

●

DISP LAY H AS ST RANGE NUM BER S/CHA RAC TER S

ON IT

UNIT M AKI NG NOIS ES

UNIT N OT CO OLING / H EATING R OOM

Unit a ir di sch arge se cti on is b locke d

Temper atu re se tting i s not h igh o r low eno ugh

Note : S etpoi nt limit s may not all ow the u nit t o h eat o r

cool the ro om t o the t emp eratu re d esi red. C hec k

sect ion o n dip switc h set tin gs.

Unit a ir fi lte rs are di rty.

Room i s exc ess ively h ot or c old w hen uni t is st arted

Vent do or le ft op en

Unit may be in a pr ote cti on or d iagnosti c fa ilure mod e.

Chec k sec tio n on Inte lli gen t Se lf -- - che cking C ont rol .

Comp res sor is in ti me del ay. Th ere is a pro tecti ve tim e

dela y (appr ox . 3 mi nutes ) on sta rti ng t he c omp ressor

afte r a powe r o utage (or re start ing afte r i t h as bee n

turn ed off ), to preve nt tripp ing of the compre sso r

over loa d.

WATER DRIPPING OUTSIDE

WATER DRIP PIN G INS IDE

Wal l sle eve is no t ins tal led lev el

ICE OR F ROS T FORMS O N IND OOR C OIL

Low ou tdo or te mpera tur e

Dirt y fil ter s

COMP RES SOR P ROTEC TIO N

Powe r may h ave c ycl ed, s o com press or is in a re sta rt

prot ect ion .

SOLUTI ONS

Chec k tha t plu g is plug ged s ecu rely in w all r ece ptacl e.

Note :Pl ug h as a test/ res et b utton on i t. M ake sure t hat the

plug h as no t tri pped.

Repl ace t he fu se.

Rese t cir cui t break er.

Tur n uni t on (bot tom r igh t butto n on ke ypad).

Note : If the u nit t urns on, t he LE D wil l be gr een . If th e u nit i s

off, the LED will be red. If there is no LED on, the re i s a

prob lem w ith p ower or d ama ge to t he cont rol .

Th e u n it may be i n a d iagn ost i c c ondi tio n. C hec k

--- ch eck ing Co ntr ol sec tion t o d ete rmi ne

if uni t has h ad a fa ilure .

The unit may b e set f o r ° C ( ins tead of ° F) , s ee th e key pad

conf igu rat ion sec tio n

Clic ki ng , gurg li ng and wh oo shing no is es a re n ormal du ri ng

oper at io n of unit .

Make sure that cur ta in s, blind s o r f ur ni ture are not rest ricti ng or

bloc ki ng u nit air fl ow.

Rese t to a l ow er or hig he r te mpera tu re s ettin g.

Remo ve a nd c lean fi lt er s.

Allo w su ff ic ie nt amou nt o f ti me for un it t o he at or coo l th e ro om.

Star t he at ing o r co ol ing e ar ly befo re outd oo r tem pe ra ture, c oo ki ng

heat o r ga th ering s of p eo ple mak e ro om u ncomf or ta ble.

Clos e ve nt d oor.

Chec k di ps witch s et ti ngs for d es ir ed comf or t.

Wai t ap pr oxi ma te ly 3 m inu te s fo r co mpres so r to s tart

If a drai n kit has not bee n install ed, conde nsa tio n runoff

duri ng ver y hot an d hum id wea ther is norma l. See Note 2. If

a d rai n kit h as b een insta lle d and is con necte d to a drain

syst em, che ck g ask ets and fitti ngs aro und drain for lea ks

and pl ugs .

Wal l sle eve m ust be insta lle d lev el for prope r dra ina ge of

cond ens ati on. C hec k tha t ins tal lat ion i s lev el and m ake any

nece ssa ry ad justm ent s.

When outdoor tem p e r a t u r e i s a p p r o x i m a t e l y 5 5 ° F

(12. 8°C ) or b elo w, f ros t may form o n the indoo r coi l when

unit i s in C ool ing mod e. S wit ch u nit t o FAN o peration u ntil

ice or f ros t mel ts.

Remo ve an d cle an filt ers .

Rand om Comp resso r re sta rt—Wh ene ver the unit is

plug ged in, o r p owe r h as bee n r estar ted , a rando m

comp res sor rest art will occur. Aft er a pow er outag e, the

comp res sor w ill res tar t aft er appr oxi mately 3 min ute s.

Comp res sor P rotec tio n — To preven t sho rt cy cling of the

comp res sor, t her e i s a r and om st art up de lay of 3 m inu tes

and a mi nim um co mpres sor r un ti me of 3 min ute s

●

●

●

●

●

diag nos tic co des

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

-13-

Page 15

Soleus Home Comfort warrants the accompanying Soleus Air PTAC to be free of defects in material and

workmanship for the applications specified in its operation instruction for the period of labor and parts

specified below.

This

warranty shall not apply to broken or marred cabinets, accessories, knobs, filters or routine maintenance.

This warranty does not apply to uncrating, setup, installation, removal of the product for repair or reinstallation of

of the product after repair.

This warranty does not apply to repairs or replacemen

Soleus Home Comfort including, but not limited to, any malfunction, defect or failure caused by or resulting from

unauthorized service or parts, improper maintenance, operation contrary to furnished instructions, shipping or

transit accidents, modification or repair by the user, abuse, misuse, neglect, accident, incorrect power line voltage,

fire, flood or other Acts of God, or normal wear and tear.

Warranty service must be performed by a qualified HVAC cont

service network to provide parts and assist in resolving service problems if difficulties are encountered.

Soleus Home Comfort agrees to provide service information, sell repair parts and reimburse the dealer /servicer for

parts and services in accordance with Soleus Home Comfort’s Policies and Procedures.

SOLEUS HOME COMFORT

MERCHANTABILITY ARE LIMITED TO THE TERMS AND CONDITIONS SPECIFIED ABOVE. SOLEUS HOME

COMFORT DISCLAIMS ANY LIBILITY FOR CONSEQUENTIAL OR INCIDENTAL DAMAGES AND IN NO

EVENT SHALL SOLEUS HOME COMFORT'S LIABILITY EXCEED THE RETAIL VALUE OF THE AIR

CONDITIONER.

This warranty covers only new products purchased from our

salvaged, refurbished products or internet sales.

FOR CUST

Soleus Home Comfort. 17911 East Ajax Circle, City of Industry, CA 91748. USA

Tel: 1-888-876-5387

Monday through Friday, 9:00 AM to 5:30 PM, PST

OMER

SERVICES, WARRANTY

5 YEARS FOR COMPRESSOR

1 YEAR FOR OTHER COMPONENTS

MAINT

AINS THAT ALL WARRANTIES, INCLUDING IMPLIED WARRANTY OR

WARRANTY

ts necessitated by any cause beyond the control of

ractor. Soleus Home Comfort maintains a centralized

authorized dealers or retailers. It does not cover used,

CLAIM AND PARTS PURCHASING, CONTACT:

Page 16

Loading...

Loading...