Page 1

I t':

Page 2

GONTENTS

Safety Precautions

-----------

---------

1

fdentification

of

parts ----------

2

lndoor

unit / Operation

and display

-----------

---------

3.4

Remote

control

---------

5.6

Operation instructions/

Modes-----------

_____--____-_

T

Air flow

direction control

--------------

g

"l

FEEL"

mode

g

Timer

operation mode

10

Sleep

operation mode

11

Maintenance

-------

12

Protection

-------------

----.

13

Refrigeration

cycle

---

14

Specifications

-----------

15

f nstallation

instructions

------

16-24

System

start up Procedures

Electrical

Schematics

---------

---.25-27

WARNING

_-________--_____

28

Troubleshooting

--

29.30

Warranty

----31

Page 3

s

o

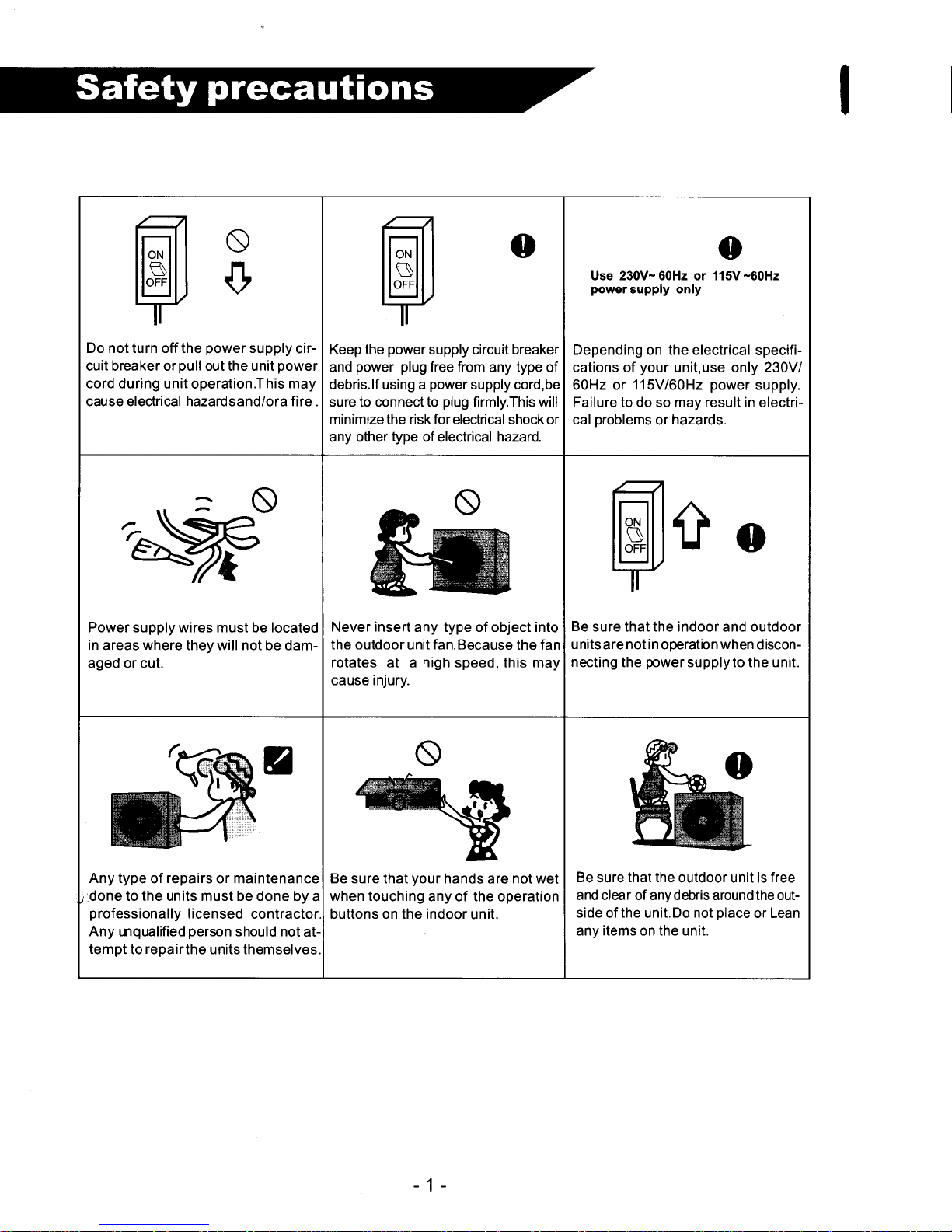

Do not turn off the

power

supply

cir-

cuit breaker orpull out the unit

power

cord during

unit operation.This

may

cause electrical hazardsand/ora fire .

o

Keep the

power

supply circuit breaker

and

power plug

free

from any type of

debris.lf using a

power

supply cord,be

sure to connect

to

plug

firmly.This will

minimize the risk for

electrical shock or

any other

type

of electrical hazard.

o

Use 230V-60H2 or 115V-60H2

power

supply only

Depending on the electrical

specifi-

cations of

your

unit,use only 230V/

60Hz or 115V/60H2

power

supply.

Failure

to do so

may result

in electri-

cal

problems

or

hazards.

Power supply wires must be located

in

areas

where

they will not be dam-

aged or cut.

Never

insert

any type of object into

the outdoor

unit

fan.Because

the fan

rotates at a

high

speed, this may

cause injury.

c

o

Be

sure that the indoor and outdoor

unitsare notin

operatbn

when

discon-

necting

the

power

supplyto the unit.

Any type

of

repairs

or maintenance

done to the units must be done

by a

professionally

I icensed

contractor

Any mqmlified

person

should not

at-

tempt

to

repairthe

units themselves,

Be sure that

your

hands

are

not wet

when touching

any of the operation

buttons on the indoor unit.

Be

sure

that the

outdoor unit is

free

and clear of any debris around the outside

of

the

unit.Do

not

place

or Lean

any items on the unit.

-1-

Page 4

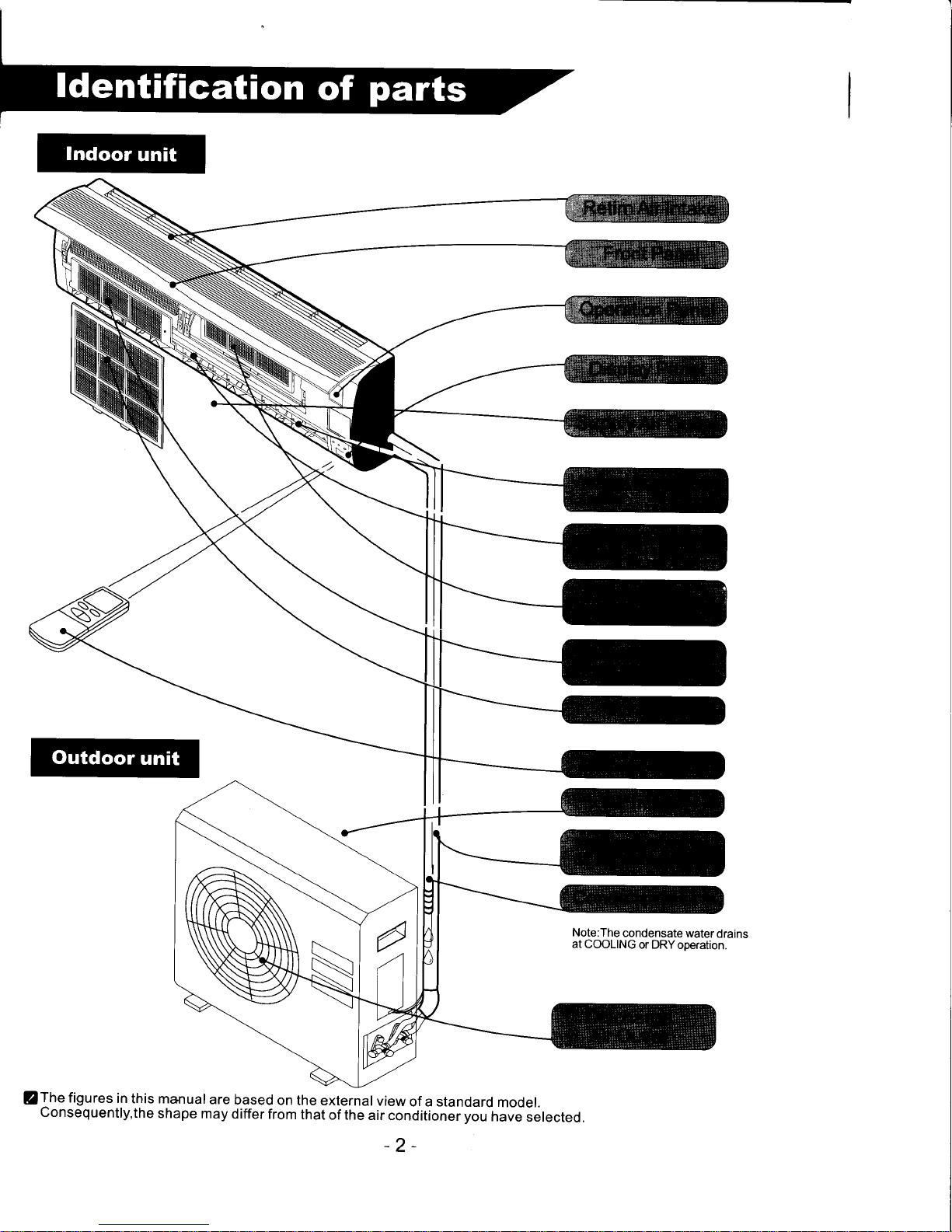

Note:The

condensate

water

drains

at

COOLING

or DRYoperation.

/The

figures

in

this manual

are

based

on

the external

view

of a standard

model.

Consequently,the

shape

may

differ

from

that

of the

air conditioner you

have

selected.

-2-

Page 5

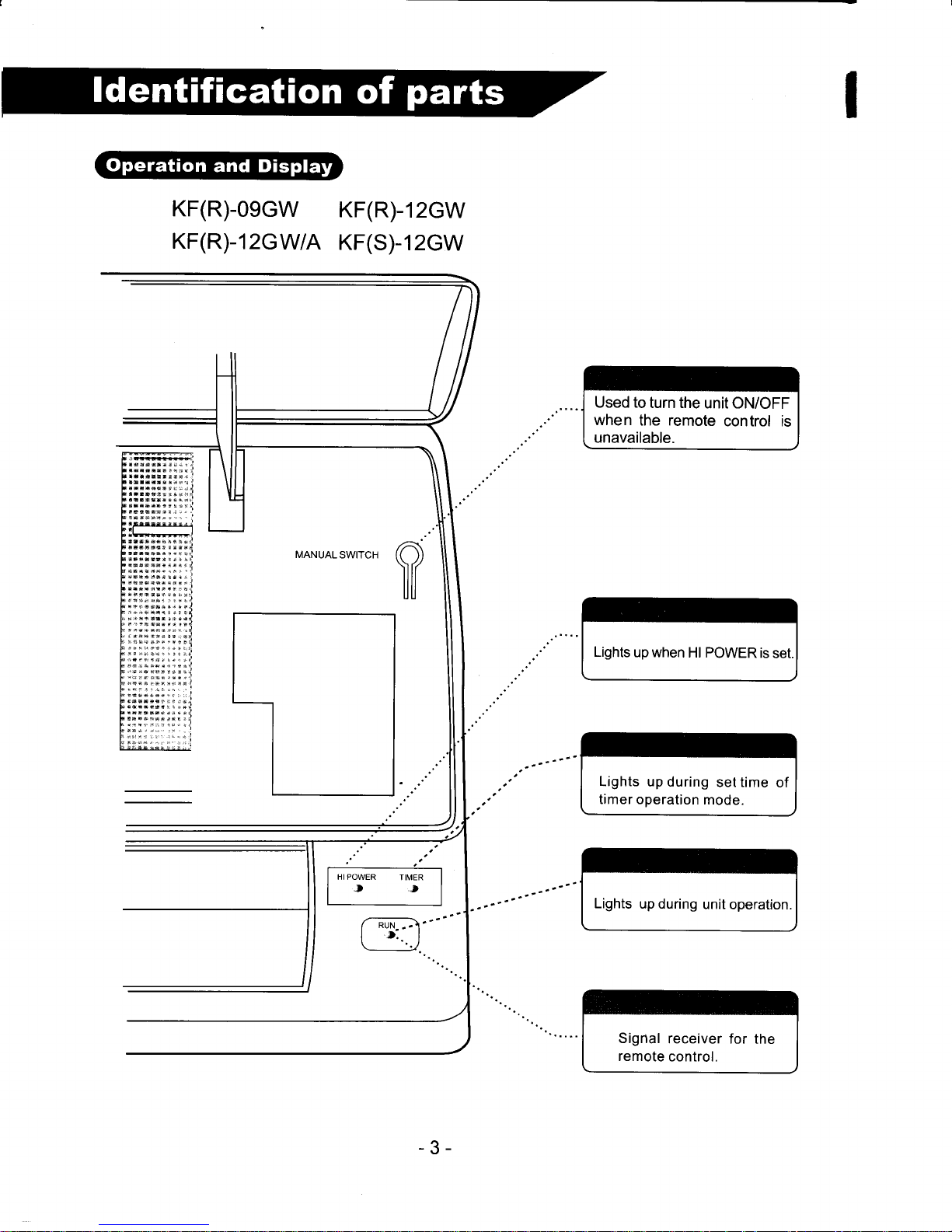

I

KF(R)-0ecw

KF(R)-12cWtA

KF(R)-12GW

KF(S)-12GW

HIPOWER

TIMER

,.t

Used to

turn the

unit ON/OFF

when

the remote

control is

unavailable.

Lights

up when

Hl POWER

is

set.

Lights

up during

set time

of

timer operation

mode.

Lights

up during

unit

operation.

Sigrtal

receiver

for the

remote

control.

-3-

Page 6

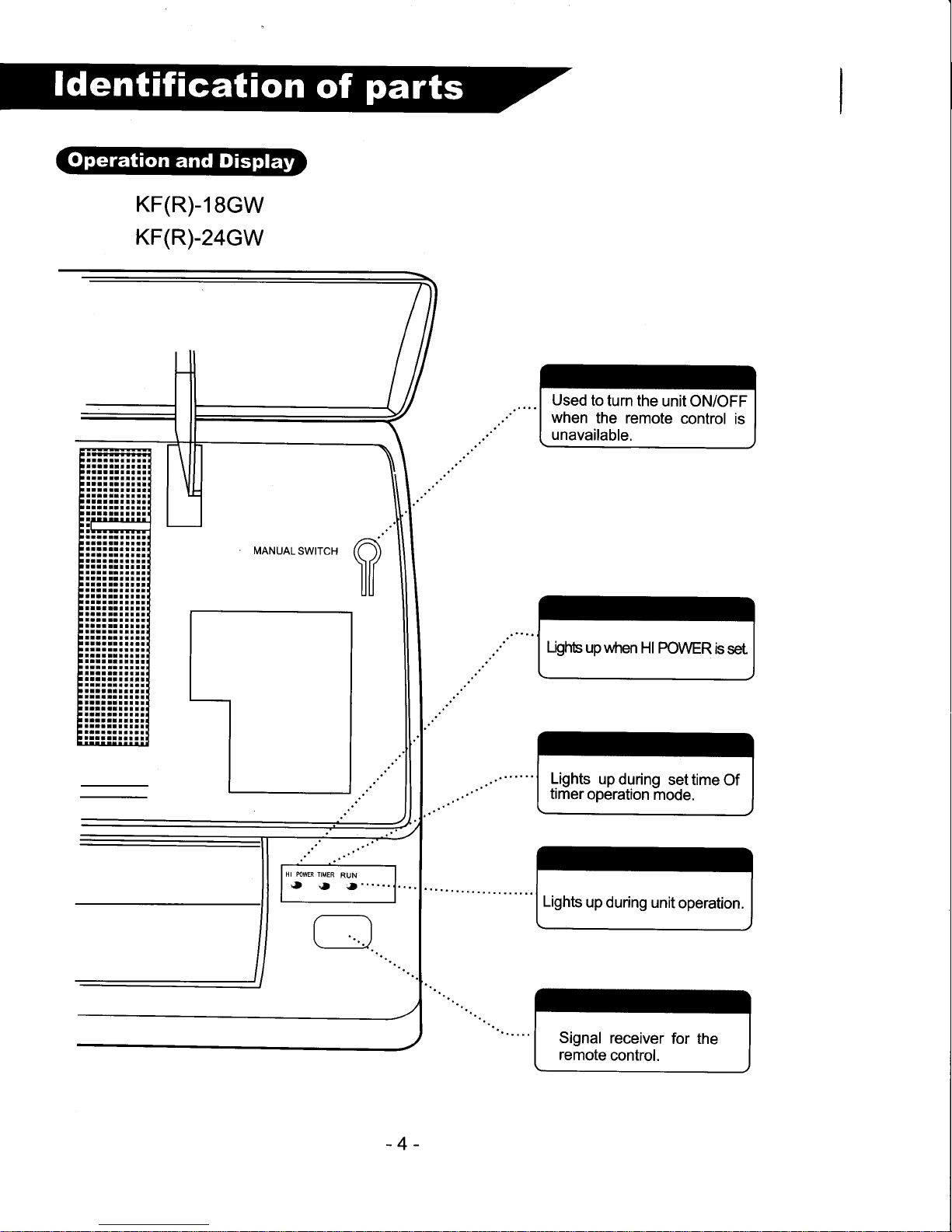

KF(R)-18cW

KF(R)-24cW

Used

to

turn the

unit ON/OFF

when

the remote

control

is

unavailable.

LQhb

up when

Hl POWER

is

set

HI MWER TIMER

RUN

.,

",

;t

"'...

G

Lights

up

during

set time

Of

timer

operation

mode.

Lights

up

during unit

operation.

Signal

receiver

for the

remote

control.

-4-

Page 7

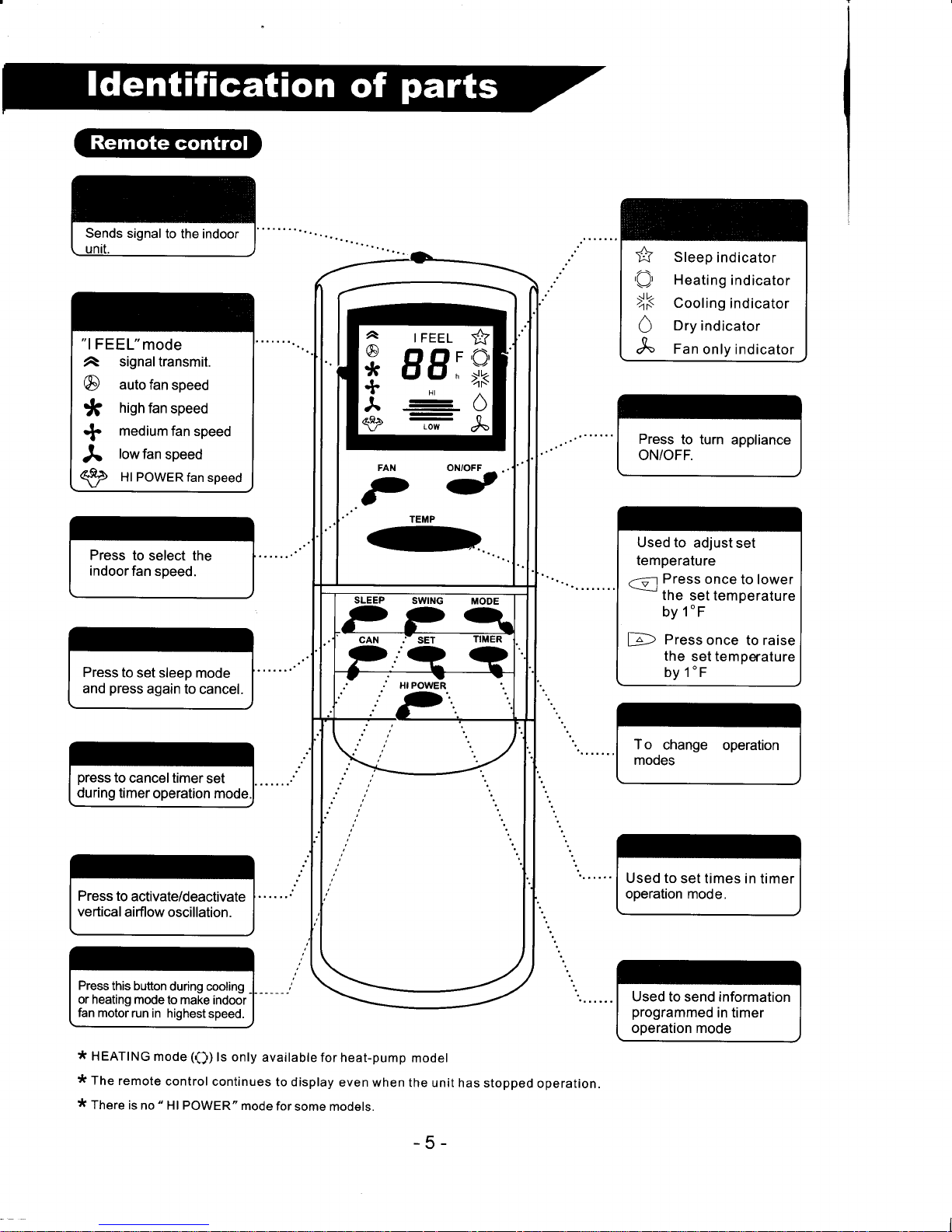

"lFEEL"mode

signal transmit.

@

auto

fan speed

*

high

fan

speed

+

medium

fan speed

A

lowfan

speed

€2

Hl PowERfan

speed

Press

to select the

indoorfan

speed.

Press

to set sleep

mode

and

press

again to

cancel.

press

to

cancel timer

set

during

timer

operation mode

Press to

activate/deactivate

vertical

airflow oscillation.

Press

this button

during cooling

or heating mode

to make

indoor

fan motor

run in highest

speed.

:t

HEATING

mode

(Q)

ls only

available

for heat-pump

model

:k

The

remote

control

continues

to display

even when

the unit

has stopped

operation.

:k

There

is no " Hl POWER"

mode for

some models.

Press

to turn

appliance

ON/OFF.

Used to

adjust

set

temperature

.-=-r

Press

once

to lower

rne

sel temperature

by

1"F

D

Press

once

to raise

the

set temperature

by 1"F

To

change

operation

mooes

Used to

set times in

timer

operation mode.

Used to send information

programmed

in timer

operation mode

\+

,C),

-.f.'

a\

Sleep

indicator

Heating

indicator

Cooling

indicator

Dry

indicator

Fan

only indicator

I FEEL

EIEIT

LfLln

+

A

@

*

+

J.

s2

+?

,f)'

>K

0

"\

SLEEP

SWING MODE

P?q

cAN ."

sET

TIMER

tDj,Q a

.7

j

", ro*l'n

t

rtP

-5-

Page 8

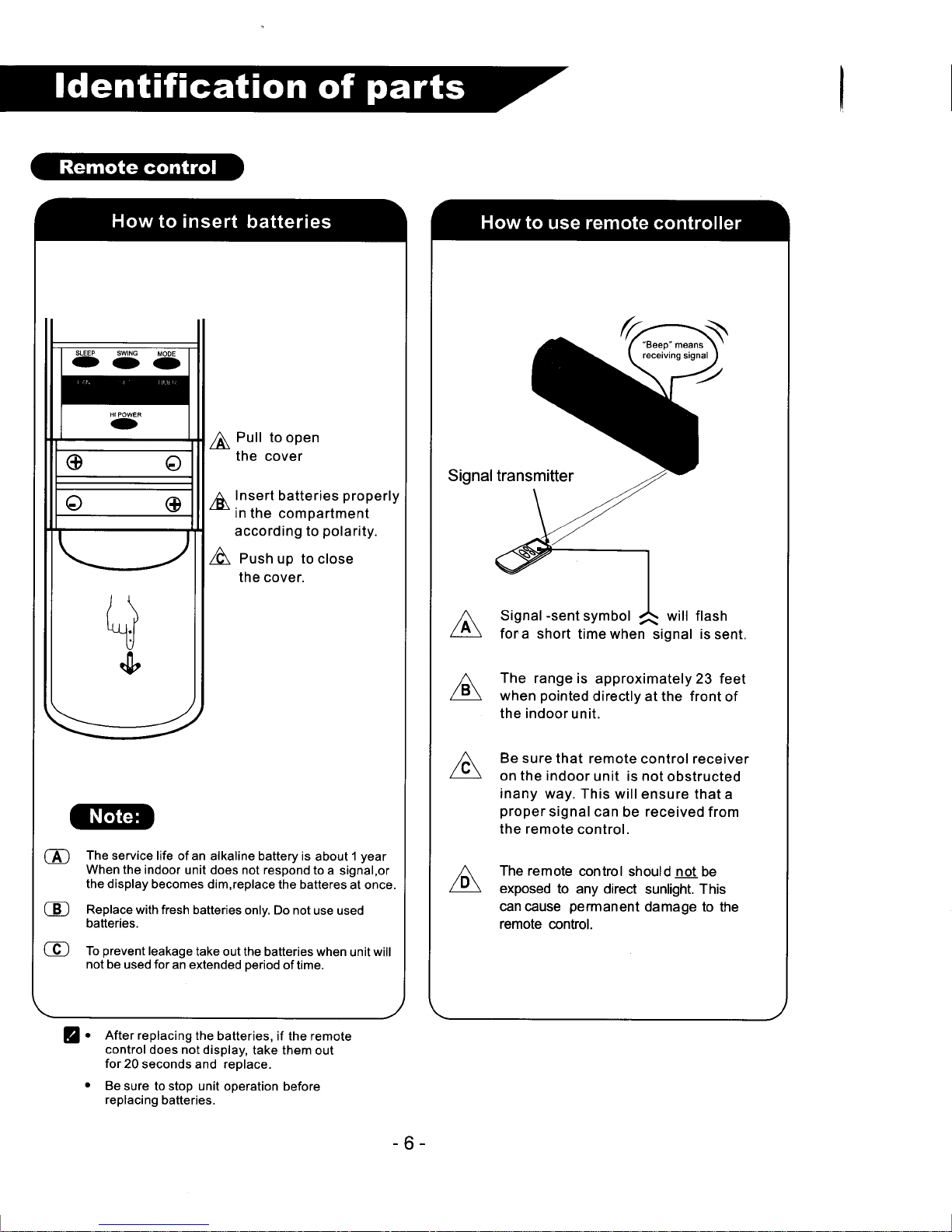

fi

Pull

to open

the

cover

6

Insert

batteries

properly

*

in

the compartment

according to

polarity.

/& Pusn up to

close

the cover.

The

service life of an

alkaline battery is

about

1

year

When the indoor

unit does not respond

to

a signal,or

the display

becomes dim,replace

the batteres

at once.

Replace

with fresh

batteries only. Do not

use used

batteries.

To

prevent

leakage

take

out the batteries when

unit

will

not be

used

for

an extended

period

of time.

fora short

timewhen

signal

The

range is

approximately 23 feet

when

pointed

directly at the front

of

the indoor

unit.

Be sure

that remote

control receiver

on

the indoor

unit

is not

obstructed

inany

way. This

will ensure that

a

proper

signal can

be

received

from

the remote

control.

The remote

control

should not be

exposed

to any direct

sunlight. This

can cause

permanent

damage to

the

remote

control.

Z.

After replacing

the

batteries, if the remote

control

does notdisplay,

take them

out

for20

seconds

and

replace.

o

Be

sure to stop

unit ooeration before

replacing

batteries.

-6-

Page 9

Each

time the

MODE

button

is

pressed,the

operation

mode

is

changed

in the

following

sequence:

HEATTNG

+cOOL|NG

+

DRy+

FANONLY->

|IFEEL/

"lFEEL"mode

is

desenbed

on

page

10

When

operating

at fan

only

mode,the

compressor

will

not operate.

*

On"FAN

ONLY" mode,only

"Hl","MED"and

"LO"

are available.

* While

on"DRY"

mode

airflow is

set

by air conditioner

automatically

"FAN"

button is ineffective

in this

case

Range

of available

set temperatures

Heatinq,

Coolinq

64'F-90

"F

DRY

room

temperature+4

-F

Press

"ON/OFF"

button,

When

the

appliance

receives

/

a signal,

a

"beep"

will

be heard.

The

RUN

indicatorwill

t

then

ughrup.

L

Open the

front

panel

to

press

the

manual

switch

to turn

on/off

the

unit when

your

remote

control

is

damaged

or

batteries

have

died.

4)

Open

the front

panetof

\)

tne indoor

unit

and

press

the

switch.

The

appliance

operates

at

"l

FEEL"mode.

The

RUN

indicator

lights

up.

@

tr"",

again

to turn

off.

The

RUN indicator

light

turns

off

and

unit shuts

down.

*

:|(

I

rn"

name

and

position

of the manual

switch may

vary from

different

modets,

but

their function

are the

same.

When

the

compressor

shuts

off or if

changing

modes

during

operation

of

the unit,

the unit may

not respond

at once

It

may be necessary

to wait

up to

3 minutes

due to

built-in

compressor

protector.

There

is a 2-5

minutes

delay

on the indoor

fan

in the

heating

mode

operation.Time

of delay

depends

on how

long

it

takes for

the indoor

coil to come

up to

a desirable

tenperarure.

@

*

+

A

B8:

Hl

.zr

/\

Each

time

the

"FAN"

button is

pressed,

the

fan

speed is

changed

in

sequence:

€

Press

once to lower

temperature

by 1

"F

D

Press

once to raise

temperature

by 1'F

-7

-

Page 10

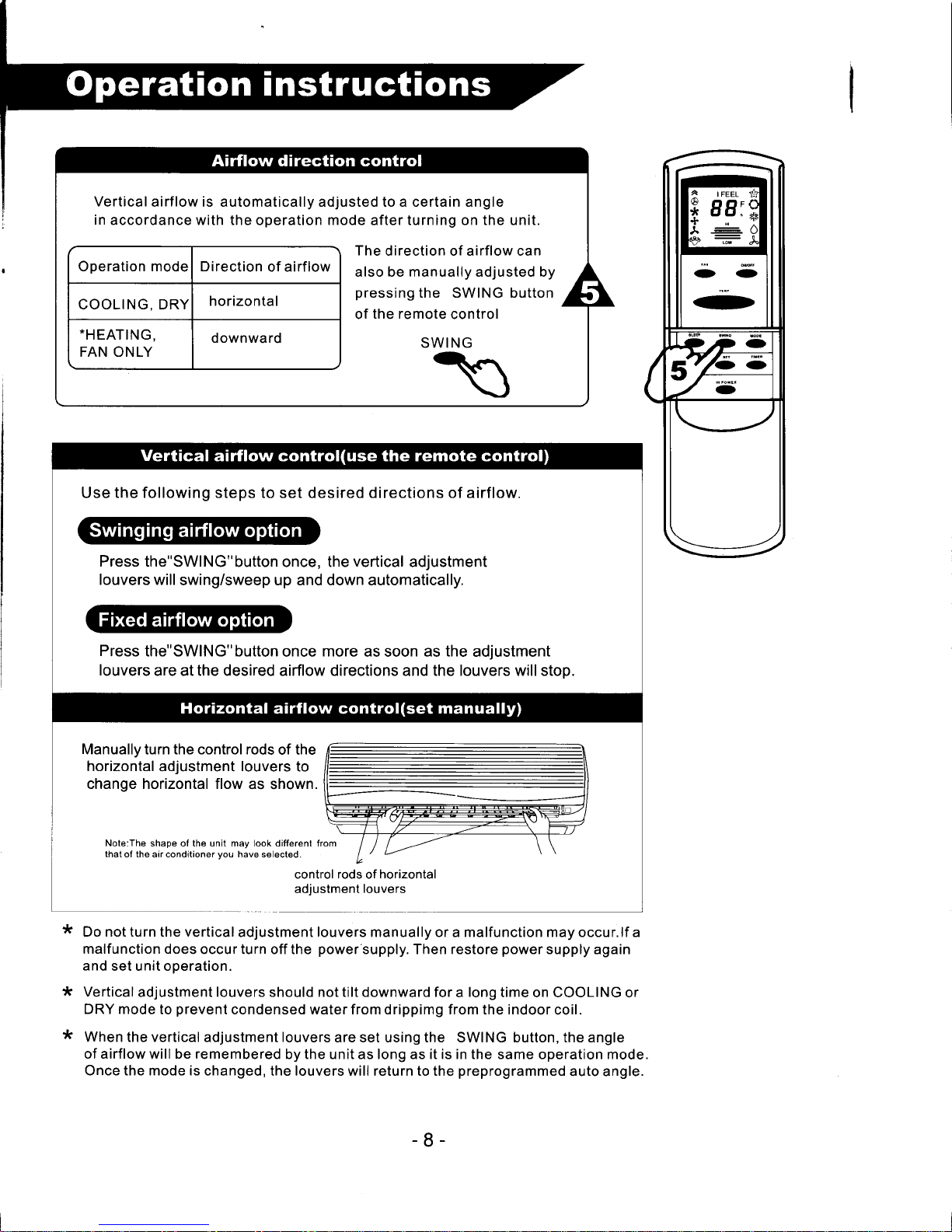

Verticalairflow

is automatically adjusted to a certain angle

in

accordance with the operation mode after turning on the unit.

Operation mode Direction

of airflow

COOLING. DRY

horizontal

-HEATING,

FAN ONLY

downward

The

direction of airflow can

also be manually adjusted by

pressing

the SWING button

of

the remote

control

Use the following steps to set desired directions of airflow.

Press the"SWlNG"button

once, the

vertical

adjustment

louvers will

swing/sweep up and down automatically.

Press

the"SWlNG"button

once

more

as soon as

the

adjustment

louvers

are at the desired airflow directions and the louvers will stop.

*

*

*

Manually turn the control rods

of the

horizontal

adjustment

louvers

to

change horizontal flow

as shown.

Note:The

shape of the unit may look different 1

that of the airconditioner

you

have selected.

control

rods

of

horizontal

adiustment

louvers

Do not turn the vertical

adjustment louvers manually or a malfunction may occur.lf a

malfunction does

occur turn off the

power

supply. Then restore

power

supply again

and

set unit operation.

Vertical

adjustment louvers should not tilt downward for a long

time on COOLING or

DRY mode

to

prevent

condensed water from drippimg from

the

indoor

coil.

When

the vertical adjustment louvers

are set using the SWING button, the angle

of airflow will be remembered

by the unit as long as it is in the same operation mode.

Once the mode is

changed, the louvers will return to the

preprogrammed

auto angle.

-8-

Page 11

Press

the

"ON/OFF"button

then

choose

the"

l

FEEL"mode

by

pressing

"MODE'

button.

The

optimum

temperature

and

airflow

volume

will

be automatically

controlled

by

the

set

indoor

temperature.

Indoor

temperature

Operation

mode

Set temperature

below

70"F

{.HEATING

73"F

7o"F-77"F

DRY

Room

temperature

a

initial

operation

77"F-82"F

COOLING

77"F

over82'F

79"F

*Not

available

for

cooling

only

models.

Slightlywarmer

Adecrease

by

4"F

can

be

set

Slightly

cooler

A rise

by €r

can

be

set

Press

twice

to lower

the

Hl

set

temp

by

2"F

EF

/\

Press

four

times

to lower

the

+

r-e-\

set

temp

bv 4'F

LOW

Press

twice

to

raise

the

Hl

set

temp

by

2"F

LOrt-

Press

four

times

to

raise

16s

Hl

set

temp

by 4"F

ffi

Uncomfortable

because

of

unsuitable

air

flow

volume.

Indoor

fan

speed

alternates

between

Hi,

Med

and

Low

each

time

this

button

is

pressed.

Uncomfortable

because

of

unsuitable

flow

direction.

SWING

(D

Press

it

once,

the verticaladjustment

louver

swings

to

change

vertical

airflow

direction.

Press

it

again,

swings

stops.

For

horizontal

airflow

direction, please

refer

to the

previous

page

for

details.

9-

Page 12

With

the

"TlMER"

funcition,

you

con

set the

unit to automatically

Start

or Stop from

30 minutes

to 24 h-ours

after

simple

programing.

For

example,

to save

energy

you

may want

to leave

the

unit off while

at work

and set the

timer

to start the

unit

one hour

before returning

home

so

a

comfortable

room

temperature

can be

achieved,

or

you

may

want

to set the

timer to

stop the

unit

late

at night.

@

As

time

passes,

the LCD

displays

the

remaining

time.

@

The

previous

set time

is stored

and

the next

set time

begins

with the

previously

set

one.

@

On-timer

and off-timer

cannot

be set at

the same

time.

CD

The room

may

not reach

your

desired

temperature

within

the

preset

time

because

of

varying

room

size and/or

outdoortemperatures.

With

the

unit off,

press

the

fir.r.

,F(

With

the

unit operating,

press

button until

desired

countdown

f'

t,

lf

the Timer

button

until

desired

hours

ard

displaved.

\_,,

countdown hours ard

disotaved

I

Set the

operating

mode,

temperature

and indoor

fan

speed first,

then

press

the

"TlMER"

button

until

"9.5h"

appears.

Z

Press

the TIMER

button,

"h"

flashes

on the LCD,

then

you

can

set the

timer.

Each

time

the button

is

pressed,

the

set time increases

byhalf

an hour

withinl0

hours

and

increases

by

one hour

beyond 1

0 hours.

The range

can be set

is 0.5 hour

to 24 hours.

Point

the

remote

control

at the

signal

receiver

of the indoor

unit,

press

the

"SET"

button

when

the letter

"h"

flashes.

A

"beeo'

will be heard:

@

Timer indicator

on the indoor

unit lights

up

@

Letter

"h"

stops flashing.

to cancelthe

set timer:

press

the

"CAN"

button,

a

"beep"

will

be

heard

and the

timer indicator

light

on the

indoor

unit will

turn

off.

-

10

Page 13

'

SLEEP

mode

can

be

set in

I FEEL,

DRy,

cooLlNG

or

HEATING

operation

modes.

'

This

function

allows a

more

comfortable

environment

for

times

of sleeping.

'

The

fan

speed

is

automatically

set at

ultra-low

speed,

which

is lower

than

low

soeed

.

The

fan

does

NOT

shut

off

during

sleep

mode.

'

Before

going

to

sleep,

press

the"slEEp"button.

The

sreep

mode

wiil

then

oe

activated.

'

when

operating

under

the

cooling

or Dry

modes,

set the

temperature

increases

by

2'F

degree

over a

2 hour

period.

lt will

then

remain

at that

temperature

until

the

unit

is

manually

turned

off

of

operation

mode

is

changed.

See

chart

below

for

more

detail.

'

when

operating

under

the

Heating

mode,

the

set

temperature

decreases

a total

of

5.5"F

degrees

over

a 3 hour

period.

lt will

then

remain

at that

temperature

until

the unit

is

manually

lurned

off

or

operation

mode is

changed.

see

chart

below

for

more

detail.

'

lt

is recommended

to

use

sLEEp

mode

together

with

oFF TIMER

to

achieve

a

more

economical

and energy-saving

operation.

SET

TEMP.

(.HEATING

mode is

not

available

for

cooling

only

models)

SET

TEMP.

t

hour

-;

t hour -l -

t

hour

-11

-

Page 14

Q

cut

off

the

powersuppty

@@

Grasp

position

"a"

and

pull

outward

to

remove

the

front

panel.

Wipe

panelwith

a

soft,

dry

cloth

Use

lukewarm

water

to

clean

if

the

unit

is

very

dirty.

Never

use

chemicals

such

as

gasoline

or

polishing

liquids

to

clean

the

unit.

Never

use

water

direcfly

onto

the

Reinstall

and

shut

the front

panel.

Reinstall

and

shut the

front

panel

by

pressing

position

"b"

downward.

The

filter

must

be

cleaned

as follows

when

the

air

conditioner

has

run

for

approximately

1 00

hours.

Stop

the

appliance

and

remove

the

air

filter.

1.Open

the

front

panel.

2.Press

the

handle

of the

filter

from

the

front.

3.

Slide

out the

filter.

O

Clean

and

reinstail

the

air

fitter.

lf

the filter

is

extremely

dirty wash

the

filter

with

a solution

of

deteroent

in lukewarm

water.

After

cleaning

allow

filter

to dry

thoroughly

out

of direct

sunlight.

For

an

air

conditioner

equipped

with

an

electrostatic

and

a

charcoal

precipitator

(optional

parts)

:

*

Do

not

clean

the

electrostatic

filter

with

water.

lt

should

be

cleaned

using

a soft,

dry

cloth.

*

The

charcoal

filter

can

be washed

using

lukewarm

water

and

a neutral

detergent.

*

lt is recommended

that

electrostatic

and

charcoal

filter

be replaced

after

8 months

of

operation,

-12-

Page 15

The following

may cause the

internal safety

device

to trip:

lf the air conditioner

runs in

"COOLING"

or

"DRY"

mode with door

or window opened

for a

long time when

relative humidity is above

80%,

dew may drip

down from the air

outlet.

*HEATING

Outdoor air

temperature

is over

75:F

Outdoor air

temperature

is

below

32'F

Room temperature

is

over

81'F

}OOLING

Outdoor air

temperature

is over

'l09'F

Room temperature

is below

70"F

DRY

Room temperature

is below 64r

o

lnstall

the indoor unit on

a wall

that will be

able to

hold its own weight,

this will ensure

that

it operates

more

quietly.

(See

page

1 7 for further

instructions about

indoor

unit

installstion.)

o

lnstall the outdoor unit

on a

location where

air

discharge and

operation

noise will not

be bothersome

to surrounding

residents.

(See

page

17 for

further

instructions

about indoor

unit installstion.)

o

Do

not

place

any obstacles

in front of

the air

discharge of

the outdoor unit.

This will cause

damage

to the compressor

and

motor and

will cause these components

to be

noisier.

(See

page

16 for further

instructions on

unit

clearances.)

The

fault

protector

device

might shut down

unit

for the following

reasons:

Stopping

the unit and

immediately restarting

it or

changing

modes

without waiting 3

minutes

for

time delay.

Plugging the

unit into the

power

source and

immediately starting

without 20 seconds

time

delay.

lf all operations

have stopped due

to the fault

protector, press"ON/OFF"button

to reset the

unit.

Set timer again

if it has been cancelled.

After using the unit

for an extended

period

of time,

the unit should be

inspected

for the

following

items:

o

Overheating of

the

power

supply

cord or

plug.

o

Abnormal operating sound

or unit

vibrations,

o

Water leaking

from the unit excessively,

o

Indoor unit cabinet becoming

electrified.

p

lf any of theses symptoms

occurs,

call a

qualified

service technician

immediately.

It is recommended

that a detailed

inspection be made

by a

qualifed

technician afbr 3

years

of

operation,

even

if the above symptoms

do not occur.

At the beginning

of

HEATING

operation,

This is to allow

the indoor coil to

raise in

there is a 2-5

minute delay on the

indoor fan

temperature

for

proper

operation.

In HEATING

operation the appliance

will

defrost

the outdoor

coil automatically

to raise

efficiency.

This

procedure

usually

lasts 2-10

minutes. During defrost

mode,the

indoor fan

stops operation.

After defrost

is complete,

it returns to the

HEATING mode automatically.

It may be difficult

to raise the

indoor temperature

when outdoor

temperature are

very low

(30'F)

this is due to

nature of heat

pumps

and their loss

in efficiency as outdoor

temperatu

res decrease.

-13-

Page 16

HEAT

PUMP

Outdoor unit

Indoor

unit

+

defrost

1l

tl

ll

heatlinc

1

coolinq

Flows of refrigerant

liquid

side

accumulator

_>

------------)

-14-

Page 17

PERFORMANCE

RATINGS

MODEL KFR.O9G/W

KFS.12G/W

KFR.12GlWKFR.18G/W

KFR.24GlWKFR.12GW(D)KFR.l8GW(D)

Capacity

Cooling

[BTU/h]

9000

12000

12400

1

8500

23100

12400 1 8500

Capacity Heating

[BTU/h]

9100

12000

1

2800

1

8800

tJzoo

1 2800+1 706 1 8800+2388

SEER

10.4

10.5

10.5

10.2

10.4

10.5

10.2

Moisture Removal[Pts/h] 2.3

2.9 2.9

3.1 5.2

2.9 3.1

Air Flow

300/370/450340t450t520

340t450t520

690/810/900

890/1100/1200

340t450t520690/810/900

Sound Rating Indoor dB

<40

<42

<42

<44

<45

<42 <44

Sound

Ratinq Outdoor dB

<5U

<52

<52

<58

<59

<52 <58

)oeratino Ranoe - Coolino [F

60 to

109 60 to 109 60 to

109 60 to 109

60 to 109

60 to 109 60 to 109

)oeratino Ranqe - Heatinq

[F

28 to 75 28 to

75 28 to 75

281o75

28 to 75 1l

to

75

2fto75

ELECTRICAL

DATA

Power Source

1 1

5-60-1

1 1

5-60-1

230/208-60-1

230/208-60-1

230/208-60-1230/208-60-1230/208-60-1

Min. Ampacity

[A]

14

15

10

15 15

10

15

Cooling

WattsAmps

810 / 7.5

1440t11.7

1230

/ 5.3

1870

/ 8.1 2323t10.1

1230/5.3

1870/8.1

Heating WattsAmps

900 / 8.0

1420t10.8

1300 / 5.7

1890 / 8.2

2375t10.3

1300w5.7A

+500W2.1A

1490/a_24

+7OOW3A

E-Aeating wattsAmps 500w2.1A

700w3A

Max

TD Fuse/Breaker

[A]

22

28

15

22

27

zz

28

REFRIGERANT LINES

Connections

Flare Flare

Flare

Flare

Flare Flare Flare

Liouid Line OD

[inl

1t4 1t4 1t4

114 3/8

1t4 114

Suction Line OD

[in]

3/8 112 1t2

uL 5/8

1t2 1t2

Max line Lenqth

lft]

49

49 49

49 49

49 49

Max Height Difference

[ft]

16 16

16

to

to

to 16

DIMENSIONS &

WEIGHTS

INDOORSECTION

KFR.O9G KFS.12G KFR.12G KFR.18G KFR.24G KFR.12G/D KFR.18G/D

WxHxDtinl

31.3x11x7.731.3x11x7.731.3x11x7.7

39x13x8

42.5x13.25x9

31.3x11x7 .739x13x8

Shiooino Weioht tlbsl

21

tt

22 23 31

LL

29

OUTDOORSECTION

KFR.O9W KFS-12W KFR.12W KFR.18W KFR.24W

KFR.12WD KFR.18WD

WxHxD[in]

25.5x19.5x12

32x21.5x1275

32x215x1215

M.5x24x1434.5x34x15

32x21.5x1215

M.5x24x14

Shipping

Weight

Ibs]

co

/J IJ

115 143

73 115

Refriqerant Charqe

ilbsl

2.1

2.4

2.8 4.5

3.3 2.8

Specifications are subject

to

change

without

prior

notice. Visit our website - www.soleusair.com

Copyright

2003

Soleus

International Inc.

15

Page 18

fN

\!

Distance

from

ceiling

should

be

2 in

Distance

from

the

wall

should

be 2 in

fl

U

air intake

distance

from

the wall

should

be 10

in

Z

.

The

above

diagram

illustrates

atypical

unit.

\

The

unit

you

purchased

may

vary

in

appearance.

o

The

unit

must

be

installed

in

accordance

with

state

ard

local

codes.

-16-

Page 19

---

Indoor unit installation location:

.

Locate indoor

unit so that there is no obstructions near the

supply air or return air

outlets.

o

The wall that

the

indoor

unit hangs on must

be

free from internal

obstructions to

facilitate a clear hole for the refrigeration

lines and condensate line to

go

through.

o

Proper clearances must

be maintained to ceilings and walls

per

instructions

on

page

16.

o

Easy access must

be maintained for removal of the air filter.

r

Indoor unit and remote

control must be at least 3 feet from televisions, radios,

etc.

r

Indoor

unit and

remote

control must be kept

out of direct sunlight and/or fluorescent

lighting.

o

The

wall that the indoor unit hangs

on

must

strong enough to bear the weight of the

unit to ensure

quieter

operation.

Outdoor unit

Outdoor unit installation location:

o

Outdoor unit location must be well ventilated. Avoid installing

where any type of flammable

gas

could

leak.

tr-J--

o

Proper

clearances must be maintained

per

instructions

on

page

16.

ll =E I

r

The maximum length for refrigeration

lines is 49 ft. For refrigeraton lines

exceeding 23ft. an

ll d: I

additional. 75

pounds

must

be added

per

3.5 feet.

(al]

ll ?E I

o

The

Maximum height between indoor

and outdoor units

in

25ft. lf the

outdoor unit

is located

l/ | I ll H fr |

abovetheindoorunitmorethan4ft.,asuctionlineoiltrapmustbeinstalled.

ll I I Il

€g

I

r

The

outdoor unit

must not

be located in environments that have high

contents of acidic

K-

j

n\ ll J

substances, vulcanized

gasses,

or high salt contents in the air.

Indoor

r;itffitd;i;it

o

The

outdoor unit must not be located near locations where

dirt. mud. or debris

can be caked

Suction

line

oil trap

onto

the outdoor coil or unit.

o

The foundation

that the outdoor unit

sits on

must

be solid and sound so as to decrease noise

vibration.

.

No obstructions should be

olaced around the outdoor unit.

Installation Diagram

lndoor unit

9n

]N

vE

oo

co

6(l)

.92

o)

1. Installing

the mounting

plate

o

Hold mounting

plate

on the wall where unit will be located.

Using a level or

plumb

line, ensure that the

plate

is

level. Once the

plate

is level, mark holes

that

will

be

used to hold olate on the wall.

o

Remove

plate

and

drill

marked

hole at a depth of 1.75 inches.

.

Insert the screw

plugs

into the holes

and affix the mounting

plate

using the tapping

screws.

o

Once

mounting

plate

is securely fastened to the wall, then locate

an area on the wall for the

access

hole for

the

refrigeration

line/condensate line/wiring

bundle,

E

2. Access hole for refrigeration

lines/condensate drain line/wiring

bundle.

E

r

These directions must

be

followed

at least for the condensate

drain

line.

There must

be

rear

access for the condensate

drain

line

to drain

properly

from the unit.

r

Decide

on a location for the access hole

according to the location of the unit.

r

Drill a 2.5 inch hloe, making

sure that there is a tilt downward of

a 114

inch. This will ensure that

proper

drainage is maintained for the

condensate drain line.

(lf you

are not using rear access for the refrigeration

lines and wiring, the hole

does

not

need to be as large.)

o

lt is recommended that a wall

sleeve of some sort

(i.e.

PVC

pipe)

be used to keep the hole neat and tidy.

Note: The shape

of

y@r

mnting

plate

may

be difieront from

the one above. but installationretfbd is similar

Pipe

length is

49 ft Max.

3o

fN

"'E

oo

co

6(l)

-92

a)

Dropping line

17

Page 20

Saw the cut-out access off

along the side of the casing

3. Indoor unit

refrigeration line installation

o

The refrigeration

lines

and

wiring

can be

routed

to the outdoor unit

in a number of ways

(left

or right from the back of the

unit), by using the cut-out access

pieces

on the casing of

the

unit.

r

Bend the refrigeration

lines

carefully to the

required

position

in

order

to

be aligned

with the

drilled

hole.

When installing the refngeration lines

at

the directions 1

,2

or 4,

saw the corresponding cut-out

piece

off the indoor unit casing.

e

Afterconnecting refrigeraton lines

(see

directions below), install the condensate drain line

(see page

21+24for detailed

instructions on connecting condensate drain line). Then connect all wiring

(see

pages

25-27

for

detailed

instructions

on

wiring).After all connections are

made,

bundle the

refrigeration lines, wiring,

and

condensate drain line together using a

thermal insulation and vinyl/duct tape

Refrigeration lines insulation:

o

lt is important that

both

the liquid

and suction

refrigeration lines are individuallv insulated to ensure

that they do no sweat and also to maintain

proper

unit

capacities. This is necessary since the refrigeration is

metered from

the outdoor unit and

will

produce

condensation on both

refrigeration

lines if not

proper

insulated.

power

Refrigeration lines/Condensate drain line/wiring bundle thermal insulation:

o

Place

the condensate drain

line

under the refrigeration

lines.

r

lnsulation material should be a

polythene

foam that is approximately a 114

inch wall thickness.

r

Condensate drain

line

should have a downward slooe at all times to ensure

proper

drainage. Do not allow the drain line to

be

twisted, horizontal or the

defrost cable(for heat-pump)

end of the

line

be

immersed in water. lf

an extension is added to the drain

line, make

sure that it is also

properly

insulated.

Connection of

refrigeration

lines:

o

Do not

use contaminated or damaged copper tubing

for refrigeration lines.

lf any of the tubing,

evaporator or condenser coils have been exposed to the air for more that 15 seconds, it is

@@-

important

that

they

are

vacuumed

and

purged

with

field-supplied refrigerant.

Do

not removeimportant

that

they

are

vacuumed

and

purged

with

field-supplied refrigerant.

Do

not remove

...+fq-

plastic

or

rubber

plugs

and brass

nuts

from the valves,

fittings,

tubing, or coils until they are

-itA

t-

ready to

be connected.

\$\ \

Jse

proper

tubing cutters to cut the refrigeration lines, advancing the blade of the tubing cutters

slowly. Extra force or improper cutting will

cause

tubing

distortion

and

also extra burrinq.

\

oncerefrigerationtubesarecut,remoVeburrsfromcutedgeswitharemover.Thiswi||avoid_b.

unevenness on

the flare faces, which

could cause a

gas

lelk. Hold the ends of the

pipes

+A

downward to

prevent

metal from

going

into the tubes.

-r

l(

lnsert the flare nuts, mounted

on the connection ends of both the indoor and outdoor units onto

./_€l

l

the ends of the copper tubing.

/o

/

,A

The length of the

pipe protruding

from the face

of

the flare

die

is determined

by

the

particular

flaring tool that will be

plastic

or

rubber

plugs

and brass

nuts

from the valves,

fittings,

tubing, or coils until they are

readv

to be connected

.

Use

proper

tubing cutters to cut the refrigeration lines, advancing the blade of the tubing cutters

slowly. Extra force or improper cutting will

cause

tubing

distortion

and

also extra burring

o

Once

refrigeration

tubes are cut,

remove

burrs from cut edqes with a remover. This will avoid

used.

r

Fix

the

pipe

firmly

on the flare die. Match the centers of both the flare die and the flaring

punch,

and then tighten the

flaring

punch

fully.

Once flaring is

complete, connection of the tubing is

ready. Align

the center of the tubing and tighten the flare nuts

using a torque wrench.

wrapped with

vinyl

or duct type

Thermal insulation

thermal insulation

-18-

Page 21

Properly

connect the

electrichl wiring

between

the indoor

and outdoor

unit

as shown below

Heat

pump

THIS

APPLIANCE

MUST BE

GROUNDED.

IMPORTANT:

The figures

shown

below are for information

purposes

only.

Make

sure that local

andior national

codes and regulations

are complied

with when

making

connections.

4 .

lnterconnecting

wires

(1)

Remove

the indoor

terminal

cover:

Open the front

panel

and remove

the indoor

terminal board

cover.

Jt

D-sstrygp__-O

5. Conduit

fittings

Outdoor

unit

ConduitA--Jor

P@er

Inter Cffmcting tundudm

(2)

Supply wiring,control

wiring

and defrost

cable connection.

defrost wire

Heat

pump

connector

Defrost

cable

Indoor

unit

terminal block

Power

supply

Conduit

Connector

Turning the

Conduit Connector

clockwise

can loosen it from

conduit.

Cabinet

Control wiring

-

19

-

Page 22

a

a

la

6. Installation

of conduit

bracket

rhe

shape

of conduit bracket is

shown

Put the

conductors through

the

Conduit

and Connector. Tighten

the

Conduit Connector

to the

conduit.

Put the

conductors through

the Connector

and the

Condult Bracket. Tighten

the

Connector

Nut to the

Connector.

Turn the locknut

counterclockwise

to tighten

the locknut.

Mounting

the Indoor

unit tothe Mounting

Plate:

o

Hook

the indoor

unit onto the

upper

portion

of the mounting

plate

by

connecting the hooks

at the

rear top

of the indoor

unit with the upper

edge of the mounting

plate.

r

To

ensure that

the hooks are

properly

seated

on the mounting

plate,

check if the unit

can slide

by moving

it to the left

and right. lf the

unit moves, it

is not

properly

seated.

o

A unit

support

plate

in the mounting

plate

can be used if

the unit is

on a slanted wall

and can

also be used

to ease the connection

of the refrigeration

lines.

o

After connecting

the refrigeration

lines, remove

suppopt

plate

and

afiix the bottom

of the mounting

plate

to the wall with

screws.

Support

plate

Connection

of condensate

drain

extension

line:

Place

glue

on the

end of the

drain

line

extension

end.

Fully insert

the end of the

drain line to

the extension line.

Make

sure it is

properly

inserted

to no less than

3/8 of an inch

so that water

does not leak

from the hose.

Glue

<

3i8 inch

Locknut

(Turn

the locknut

counterclockwise

to

Conduit

Connector Connector

Nut

-20-

Page 23

FIGURE

currNG coPPERrueea*@

#@

FIGURE

FIGURE

TUBE

A(mm)

lnch

mm

lmoerial Rioid

1t4" 6.35

1a

0.7

3i8"

9.52

t-o

1.0

1t2"

12.70 1.9 1.3

5/8" 15.88

2.2

1.7

3t4"

19.05

2.5 2.0

1. lnstall

the outdoor unit

o

Outdoor unit

must be mounted on

a solid,

level foundation.

lf

possible,

affix unit using bolts

to the

foundation.

o

lf installing on a

wall

or

structure, be sure

that construction

of the wall or structure

can support the

weight of the unit

and

that

consideration

is

given

to the integrity of

the construction. Since

the unit can

vibrate during operation,movement

of

sound of

the unit should be

considered

when installing the unit.

o

Since

the unit discharges

air during operation,

plants

or other

obstruction should

be free and clear

of the unit

to

ensure

proper

operation.

.

Owners

should be

advised to avoid

lawn mowers or other

machinery discharge

toward the unit,

as debris can damage

the finned coil surfaces and reduce effciency

of the unit.

2. Outdoor

unit

refrigeration line connection

o

Remove

the valve caps at

the outdoor unit

where refrigeration

tubing will be connected.

o

Connect

the refrigeration tubing

using flaring techniques

described earlier

in the

indoor unit installation.

Be sure to use

required torque.

f

Atteniton

o

A baffle

is needed when

installation is in locations

near the sea or areas

with strong

winds.

.

Be sure that unit

airflow is not obstructed

in any

way

or

that reciculation

of discharge air

does not occur.

FLARE JOINT

FLARED

TUBE

\+t

rurorEItr

\\

INDOOR

PIPING

|

/'^

"u'

G4 nth

// ))tr/

V..

q7

\roReuewReuc*

PIPE SIZE(mm/in) TORQUE(Nm)

6.35(1/4)

18

9.53(3/8)

42

12.7(12\

55

1 5.88(5/8)

65

1e.05(3/4) 78

END

DIPPED

INTO

WATER

FIGURE I

nll rlll

*ft,,^-JIl

ll"o^'^ofl

@@

CORRECT WRONG

@

WRONG

-21 -

Page 24

3. Wiring

connection

Remove the

electrical cover of outdoor unit

(1

screw).

Connect

wires

as shown below in the illustrations.

Heat Pump

Connect to Power Supply

Power

supply inter connecting

conductors

(in

conduit

A)

(to

the indoor

unit)

Control inter connecting

conductors

(in

conduit

B)

(to

the indoor

unit)

The

conduit should not

be

loosened

after being fixed, otherwise, it may

cause abnormal noise when

the

unit is running.

Number 14 wire

should be used for KFR-18GW.

Number 12wire

should be

used

for KFR-24GW.

KFR-18GW/(D)

Number 14 wire

should be used for KFR-09GW. KFS-12GW.

KFR-12GW/(D)

Number 16

wire should be used for KFR-12GW.

Outdoor unit terminal

block

-22-

Page 25

System

Start

Up

and Charge

Adjustment

Procedures

Additional

Charge

Needed

for

Refrigeration

lines over

15 feet

Liquid

Line O.D.(lnches)

Additional

R-22

(ozlft)

1t4

.22

3/8

.58

Properly

check

refrigeration

tubes

and connections

for any

leaks

prior

to system

start up

procedures.

NOTE:

A is the low-pressure

valve

B is the

high-pressure

valve

C and

D are the

joints

of

connecting

pipes

of

indoor unit.

The outdoor

unit

is

supplied

with a R-22

charge sufficient

for 15 feet of

refrigeration

tubing.

The outdoor

unit's

liouid and suction

valves

are closed

to contain

the charge

within

the

unit.

The recommended

procedures

for charge

adjustments

are

as follows:

\

Vacuum

pump

il'6-l-

,ffi)

1. After connecting

the

refrigeration

tubing to

the indoor

and outdoor

units. connect

a

Low-pressure

vacuum

pump

to the refrigeration

valve service

ports.

2. Evacuate

through

the liquid

and suction

valve service

ports

to 500

microns or

less for a

minimum

of

30 minutes' Close

the valves

to the

pump

and

monitor

the vacuum

for

15 minutes.

The vacuum

should not

rise above

800 microns.

3.

lf a vacuum

of 500

microns cannot

be obtained,

or

if it rises above

800

microns over

the 15

minute

period,

discontinue

evacuation,

pressurize

the system

with

nitrogen and

look

for leaks. Repair

any

leaks that are

found and

repeat step

2.

4.

Close

the

valves to

the vacuum

pump,

tufn the

pump

off, and

disconnect

it from

the refrigerant

valve

service

ports.

Open

the liquid

and suction

service

valves

fully, releasing

the

R-22 into the system.

Connect

the service

gauges

to

the refrigerant

Valve service

ports.

5. Set

the

indoor remote

control

to cool

mode and ensure

proper

operation.

Allow unit

to run

for a

period

of 10

minutes to

allow system

pressures

to stabilize.

-

Make sure

that

proper pressures

are observed.

'

Check

proper

temperatures

in space,

to ensure

temperatures

match

those on

remote control.

-

Check condensate

drain

hose

for

proper

drainage.

'

Check

for any abnormal

vibration

noises

and correct

as

needed.

-

Check

for any signs

of refrigerant

leakage.

6. Set

the indoor

remote control

to

heat mode

and ensure

proper

operation.

Allow unit to

run for a

period

of

10 minutes

to allow system

pressures

to stabilize.

Allow same

checkouts

as cool

mode'

-tSonHg'

Lorod'

Filling

hose

+

Hi rod

Filling hose

Checking

points

of outdoor unit

I I

Connecting

PiPe

nut

|r'

-%) Limit brocx

/7\#^ / ...

l9]-JJ.(@-,

rvarvecao

l\A

Valve body

I

t{/

Valve rod

Manifold

valve

-23-

Page 26

HOW

TO

INSTALL

DRAIN

ACCESSORIES

There

will

be sone water

dripping

from

the

condenser

when

the heat

pump

is

working

during

the heating

mode.

Two

drain

caps,

a drain

elbow with

rubber

collar

and a

plastic

hose

(5/8"

x

6") are

supplied for

user if

choice.

INSTALLATION

STEPS

(1

)

Observe the

drainage

flow

of the

three drain

holes

on the

base while

pouring

water into

the

condensing

unit

evenly

around

the condenser. (Figure

1)

(2)

Connect

the drain

elbow

and the

plastic

hose.

(Figure

2)

(3)

Insert

the

drain

elbow

connected

with the

drain hose

into

the hole

which

has

the largest

drainage

flow

and

rohte

it

to the wall

side

of the

building in

order to make

the

drainage

flow

against

the wall.

The

other two holes

of the base

should

be

plugged

by

using the

two

drain caps.(Figure)

NOTE:

lf

the drain

hole inserted

with

the

drain elbow

is not

at the

desired location,

adjust the

level

of the

condensing

uint

slightly,

and then reinstall

the accessories

according

to the

above steps.

1

Look

2

Drain

cap

Install

Draln

e!!ry---L

-=

'Plastic

hose

o

x

6u)

0

-24-

Page 27

ELK'IRICAL SCHN,,IATIC

DIAGRAM OF TIIE INMOR

(NN

KFR{9/12G

KFS.12G

E

lwl

tot

-l';

-{;I

{,;t

-Ll

--tE

{O

ELECTRICAL SCHEMATIC DIAGMM OTTHE

INDOOR UNIT

Fl

FI

td

FI

-ill

-tt

+t

-T;1

--t!

----.,4

v

OUTDOOR

UNIT

t-l

rrt

H

i

3Ll

J,l

{,;t

{;t

-E

A

OIJTDOOR

UNIT

-25-

Page 28

ELECTRICAL

SCHET4{TIC DTAGMM OF TI{E IIIDOOR

TNIT

KFR.12G/D

ELECIRICAL SCHI\{ATIC

DT{GMM OF THE INDOOR

UNIT

E

F]

[+n

-lLl

{t

T-'l

--,Ll

-fit

{i-]

--.-.-ai\

oIJ.]W)RUNIT

*uo

\J/*

(9'u'.**

s ,__,-\

0\tRicm mmECI

rT

Dattt

a\\cYEL^r

ELECTRICAL

SCHEMATIC DIAGRAM

OF

THE

CO{DENSINC

L]NIT

POTER SUPPLY

CORD

1

l0 120V-60H2

lr

KFR.OgW

KFS-12W

-26-

Page 29

ELECTRICAL

SCHEMATIC

DIACRAM

0F TI{E C0.IDENSING IJNIT

PO{ER

SUPPLY

208-230V'60H2

-l

I

---l-

KFR-12W

KFR-12w/D

REVERS ING VAI\T

CAPACITOR

ELECTRICAL

SCHEMATIC DIAGRAM OF THE CONDENSING

UNIT

REVERS INC

VALVE

CAPACITOR

KFR.ISW

KFR-18w/D

ELECTRICAL

SCHEMATIC DIAGRAI\,{ OF THE CONDENSING INIT

-27 -

Page 30

A

wnRNrNG

Q

use coppER wtRES

oNLy FoR

powER

supply.

Q

wnnuNG:RrsK

oF ELECTRTc

sHocK,

cAN cAUSE

TNJURv

oR DEATH.

DISCONNECT

ALL ELECTRIC

POWER

SUPPLIES

BEFORE

SERVICING.

Q

ountruc

coNNEcroN

oF

THE

REFRTcERATToN

TUBES,

rF

EXcESSTvE

TORQUE

IS

IMPOSED

ON FLARE NUTS,

SERVICE VALVE

ON

DISCHARGE

LINE MAY

BE DAMAGED.

WHEN

TIGHTENING

FLARE

NUTS

OR NARROW

PIPE,

TORQUE

SHOULD BE ADJUSTED

BETWEEN

13.7-18.6N.M

(140-190GF.CM).

O

oo

Nor

pur

tNDooR

uNtr tN LocATtoNS

wHERE

tr MAy

cET

wET.

Q

rlecrRtcAl

INSTALLATToN

MUST BE

rN ACcoRDANCE

wtrH LocAL

AND

STATE ELECTRICAL

CODES.

Q

rHe tNSTALLATIoN

oF

THESE

uNrrs REQUTRES

euALtFtED

pERSoNNEL.

Q

crmFrED

(AppRovED)

powER

supply

coNDUcroRS

MUST

BE

usED.

O

nru

INDEPENDENT

BRANcH

cIRCUIT BREAKER

MUST

BE

USED.

Q

unxnltuM

TNTER

coNNEclNG wtRE

LENGTH

sHouLD

Nor

EXcEED

11.3M

(37FT.)

Q

ne

rntcERATtNG

ptpE

LENGTH

MUST BE

LtMtrED

BETWEEN

4-10M

(13FT-33FT.)rF

THE

LENGTH EXCEEDS

7.62M(25FT.),

THE

COOLTNG

(oR

HEATTNG)

CApACtTy

MAy

BECOME tMpAtRED.

Q

otrrrRENcE

tN HETcHT

BETWEEN

rNDooR

AND

ourDooR

uNlr

sHouLD

NOT

EXCEED

7M(26FT.).

-28-

Page 31

lf after checking

the

following conditions

the unit

still does

not operate,

call a

qualified

service

technican.

o

Fault trip or

fuse is blown.

o

Fault device

trips to

protect

the appliance.

o

Batteries

in the remote control

are

dead.

o

Plug is

not

properly plugged

into outlet.

o

ls the air

filter dirty?

o

Are the intakes and outlets

of

the indoor

or outdoor

units blocked?

o

ls

the

temperature

set

properly?

-

,t4#

kl 1l)

lf strong

interference

(from

excessive

static

electricity discharge,

power

supply

voltage

abnormality)

is

present,

operation

may be

abnormal.

lf this occurs

,

disconnect

from the

power

supply

and connect

back

2-3

seconds

la

Changing

modes during

operation,

must wait for

3 minute delay.

Does

notoperate

-

(ffi')l

immediatery

Gffi

Odors may come

from another

source

such as

furniture, cigarettes,

etc.

These odors

may remain on

the indoor

coil,

or filter

which may

require cleaning.

o

Caused

by

the flow of

refrigerant

in the

air conditioner.

o

Sound

from defrost

mode in

heating mode.

(Note:For

some

model with a compressor

indicator

(red),

it lights up

during

defrosting.)

o

The sound

may

be

generated

by the expansion

or contraction

of

the front

plastic panel

due

to

change

of

temperature.

a)-

lw

tt t

ro-

6)

Mist appears

when the

room air becomes

very cold because

of cool air

discharged

from

indoor unit during

"COOL|NG"

or

"DRY"

operation

mode.

-29

-

Page 32

RUN

light

blinks

Defect

What

to

check

l time

Abnormality

of room

temperature

sensor.

o

Open

circuit

or

short

circuit

of room

temperature

sensor.

o

Incorrect

connection

of

the

sensor.

2

times

Abnormality

of

defrost

sensor.

o

Open

circuit

or short

circuit

of defrost

sensor.

o

Incorrect

connection

of the

sensor.

3 times

Abnormality

of

indoor

fan

motor.

a

o

Indoor

fan

motor

is

defective.

Bad

connection

to motor.

4 times

Abnormality

of

outdoor

unit.

o

Compressor

is

defective.

o

Refrigerant

is low.

r

Capacitor

is

defective.

Continuous

blink

No

defect-unit

in

defrost

mode.

-30-

Page 33

LIMITED

WARRANry

Soleus

International Inc.

warrantsthe accompanying

Hitachi RAS09,

Hitachi RAS12, and Soleus

Air KFR and KFS series

ductless mini split air conditioner

/ heat

pump

to

be

free of defects

in

material andworkmanshipforthe

applications

specified in its operation

instruction

for

the

period

of labor and

parts

specified

below.

LABOR

PARTS

30

DAYS

(COMPRESSOR)

5

YEARS FOR

COMPRESSOR

1 YEAR FOR

OTHER

COMPONENTS

This

warranty shall not apply to broken

or

marred

cabinets,

accessories,

knobs, filters or

routine

maintenance.

This warranty does

not

apply

to uncrating, setup,

installation, removal of

the

product

for repair or reinstallation of

the

product

after

repair..

This

wananty

does

not apply to

repairs or replacements

necessitated by any cause

beyond the

control

of Soleus

International including,

but not

limited

to, any

malfunction, defect or

failure

caused by or

resulting from unauthorized

service or

parts,

improper maintenance,

operation

contrary

to

furnished

instructions, shipping

or transit accidents,

modification or

repair by the user,

abuse,

misuse, neglect, accident,

incorrect

power

line voltage, fire, flood or otherActs of

God, or

normalwere and tear.

Warranty service

must

be

performed

by a

qualified

HVAC contractor. Soleus

maintains a

centralized

service

network to

provide parts

and

assist in resolving service

problems

if

dfficulties

are encountered. Soleus

agrees to

provide

service

information, sell repair

parts

and

reimburse

the dealer / servicer

for

parts

and servi@s

in accordance

with Soleus International's

Policies and

Procedures.

SOLEUS

INTERNATIONAL MAINTAINS

THAT ALL

WARRANTIES, INCLUDING

IMPLIED

WARRANTY OR

MERCHANTABILITY

ARE LIMITED

TO THE TERMS AND CONDITIONS

SPECIFIED

ABOVE. SOLEUS

INTERNATIONAL

DISCLAIMS ANY LIBILITY

FOR

CONSEQUENTIAL

OR

INCIDENTAL

DAMAGES AND IN

NO EVENT

SHALL

SOLEUS

INTERNATIONAL INC.'S

LIABILITY EXCEED

THE RETAIL VALUE OF

THE AIR

CONDITIONER.

FOR

CUSTOMER

SERVICES.

WARRANTY CLAIM

AND PARTS PURCHASING, CONTACT:

Soleus lnternational

Inc.

Tel:

1-888-8

Soleus

Monday Through

Friday, 9:00 AM to 5:00

PM, PST

Email: Contact@soleusair.com

Website:

www.soleusair.com

-31 -

Loading...

Loading...