S

S

o

ollsstt

a

arrtt--

1

1

P

P

MMiinniiaattuurree SSiinnggllee PPhhaassee SSoofftt SSttaarrtteerr

11--1188AA,, 223300VV

I

Innssttrruuccttiioonn

M

Maannuuaall

Ver. 13.01.2008

2 • Solcon Industries Ltd.

________________________________________________________________________________________________________

Solstart 1-P Manual

Index

1.

Safety & Warnings .................................................................................................................................. 3

1.1 Safety......................................................................................................................................................... 3

1.2 Attention .................................................................................................................................................... 3

1.3 Warnings.................................................................................................................................................... 3

2. General ..................................................................................................................................................... 4

2.1 Introduction................................................................................................................................................ 4

2.2 Soft-Start Characteristics...........................................................................................................................4

2.3 Rating and Frames size.............................................................................................................................. 4

2.4 Starter Selection......................................................................................................................................... 4

2.4.1 Motor current & Starting Conditions.............................................................................................4

2.4.2 Mains Voltage (line to line)...........................................................................................................4

2.4.3 By- Pass .........................................................................................................................................5

2.4.4 Starting Voltage adjustment...........................................................................................................5

2.4.5 Additional current limiting.............................................................................................................5

2.5 Signal reading with and without “SOLSTART-1P”.................................................................................. 5

2.6 Wiring Notes.............................................................................................................................................. 6

2.6.1 Short Circuit Protection .................................................................................................................6

3. Installation................................................................................................................................................ 6

3.1 Prior to Installation .................................................................................................................................... 6

3.2 Mounting.................................................................................................................................................... 6

3.3 Temperature range & heat dissipation.......................................................................................................6

4. Recommended Wiring Diagrams...........................................................................................................7

4.1 Typical connection..................................................................................................................................... 7

4.2 Connection with Starting booster............................................................................................................... 7

4.3 Wiring Connections...................................................................................................................................8

5. Back plate dimensions............................................................................................................................. 8

6. Setting and StartUp Procedure .............................................................................................................. 9

7. Technical Specifications........................................................................................................................ 10

Safety & Warnings• 3

1. SAFETY & WARNINGS

1.1 Safety

1

Read this manual carefully before operating the equipment and follow its

instructions.

2

Installation, operation and maintenance should be in strict accordance with this

manual, national codes and good practice.

3

Installation or operation not performed in strict accordance with these

instructions will void manufacturer’s warranty.

4

Disconnect all power inputs before servicing the soft-starter and/or the motor.

5

After installation, check and verify that no parts (bolts, washers, etc) have fallen

into the starter.

1.2 Attention

1

This product was designed for compliance with IEC 947-4-2 for class A

equipment.

2

Use of the product in domestic environments may cause radio interference, in

which case, the user may be required to employ additional mitigation methods.

3

Utilization category is AC-53a or AC53b, Form 1.

4

For further information, see Technical Specification.

1.3 Warnings

1

Internal components and P.C.Bs are at mains potential when the SOLSTART-1P

is connected to mains. This voltage is extremely dangerous and will cause death

or severe injury if contacted.

2

When SOLSTART-1P is connected to mains, even if control voltage is

disconnected and motor is stopped, full voltage may appear on starter’s output

and motor’s terminals. Therefore, for isolation purposes it is required to connect

an isolating device (C/B, switch, etc) upstream to the SOLSTART-1P.

3

The starter must be grounded to ensure correct operation, safety and to prevent

damage.

4

Check that Power Factor capacitors are not connected to the output side of the

soft starter.

5

Do not interchange line and load connections

The company reserves the right to make any improvements or modifications to its products without prior notice and does not

guaranty any data in its preliminary publishments .

________________________________________________________________________________________________________

3

4 • General

2. GENERAL

2.1 Introduction

The SOLSTART-1P is a Miniature Analogue soft starter which incorporates a thyristor to start a single phase squirrel cage

induction motor. By supplying a slowly increasing voltage, it provides soft start and smooth step-less acceleration, while drawing

the minimum current necessary to start the motor.

After the acceleration is completed a bypass is energized, supplying the motor its full voltage.

2.2 Soft-Start Characteristics

M%

Torque

I%U%

CurrentVoltage

100

100

400

10

50

100

2.3 Rating and Frames size

Max Motor

FLA

[A]

Starter type

FLC

[A]

Frame

Size

Dimensions

WxHxD

[mm]

Weight

[Kg]

18 Solstart-1P P1 130x50x40 0.2

2.4 Starter Selection

The starter should be selected in accordance with the following criteria:

2.4.1 Motor current & Starting Conditions

Select the starter according to motor's Full Load Ampere (FLA) - as indicated on its nameplate (even if the motor will

not be fully loaded).

The SOLSTART-1P is designed to operate under the following maximum conditions:

Ambient

Temperature

[

0

C]

Starting Current

[A]

Acceleration

Time

[sec]

40 400% x In 1.2

Max. Starts per Hour: twenty (20) starts per hour at maximum ratings.

For other starting conditions – consult factory

2.4.2 Mains Voltage (line to line)

220 – 240V (+10% - -15%)

Each starter is suitable for one of the above levels & for 50/60 Hz.

________________________________________________________________________________________________________

General. • 5

2.4.3 By- Pass

30A, 8310VA, 277VAC. (Maximum ratings)

The SOLSTART-1P incorporates a change-over internal by-pass. While starting, the by-pass allows current flow

through the thyristor. At the end of the starting process the by-pass closes and carries the current to the Motor.

The by-Pass is responsible for 2 functions at the end of acceleration:

1. The NO contact closes, shortens soft starter’s thyristor and bypasses it.

2. The NC contact opens and disconnecting the Starting booster (If exist – Consult factory for

utilizing a starter booster)

2.4.4 Starting Voltage adjustment

The SOLSTART-1P incorporates a potentiometer (P15) allows the user to adjust the starting voltage of the motor thus

controlling motor’s current and starting time.

2.4.5 Additional current limiting

In case of high starting current it is possible to add a starting buster to decrease the starting current.

Consult factory for additional information.

2.5 Signal reading with and without “SOLSTART-1P”

________________________________________________________________________________________________________

3

DOL starting without softstarter and current limiter

Soft-Starting with the

“SOLSTART-

1P”

soft-starter and the current limiter

Shown below are signal readings with and without the

“SOLSTART-1P”

CAUTION!

Power factor correction capacitors, if any, must not be installed on starter's Load side.

When required, Install capacitors on the Line side.

WARNING!

When Mains voltage is connected to the starter, full voltage will appear on the starter’s

load terminals. Therefore, for isolation purposes it is required to connect an isolating

device (C/B, switch, etc) upstream to the SOLSTART-1P (on the Line Side).

6 • Installation

2.6 Wiring Notes

2.6.1 Short Circuit Protection

The SOLSTART-1P should be protected against a short circuit by Thyristor Protection fuses.

The recommended fuses are: FWP-25B by Bussmann or equivalent.

3. INSTALLATION

WARNING!

Do not interchange line and load connections

3.1 Prior to Installation

Check that Motor’s Full Load Ampere (FLA) is lower than or equal to the starters Full Load Current (FLC).

3.2 Mounting

The starter must be mounted with all four mounting holes.

It is recommended to mount the starter directly on the rear metal plate of the equipment for better heat dissipation.

Do not mount the starter near heat sources.

Protect the starter from dust and corrosive atmospheres

Surrounding air temperature in the cabinet should not exceed 40ºC

3.3 Temperature range & heat dissipation

The starter is rated to operate over a temperature range of 0ºC (32ºF) to + 40ºC(104ºF).

Relative non-condensed humidity inside the enclosure should not exceed 93%.

ATTENTION!

Operating at surrounding air temp. (Inside the cabinet) higher than 40ºC may cause

damage to the starter.

Starter’s heat dissipation while motor is running and the internal bypass is closed is typically less than 0.1 x In (in

watts)

Example

: For an 18A motor, heat dissipation is less than 2 watts while running.

_______________________________________________________________________________________________________

9

Recommended Wiring Diagrams. • 7

4. RECOMMENDED WIRING DIAGRAMS

4.1 Typical connection

Solstart-1P

By-Pass Relay

AC single phase motor

(HVAC, Air Compressor,

Conveyor etc)

L

M

Rotation

Capacitor

N

M

C

NONC

COM

Gnd

LN

Gnd

L

N

MCap

Notes:

(1) Motor protection is not shown on this drawing

(2) Contact factory for different kind of motor than shown on this drawing.

4.2 Connection with Starting booster

Note:

(1) Consult factory to utilize this application

Solstart-1 P

By-Pass Relay

AC single phase motor

(HVA C , A ir C o mpres so r,

Conveyor etc)

L

M

Rota tio n

Capacitor

N

M

C

NONC

COM

Gnd

LN

Gnd

L

N

MCap

Starting

Booster

________________________________________________________________________________________________________

9

8 • Back plate dimensions

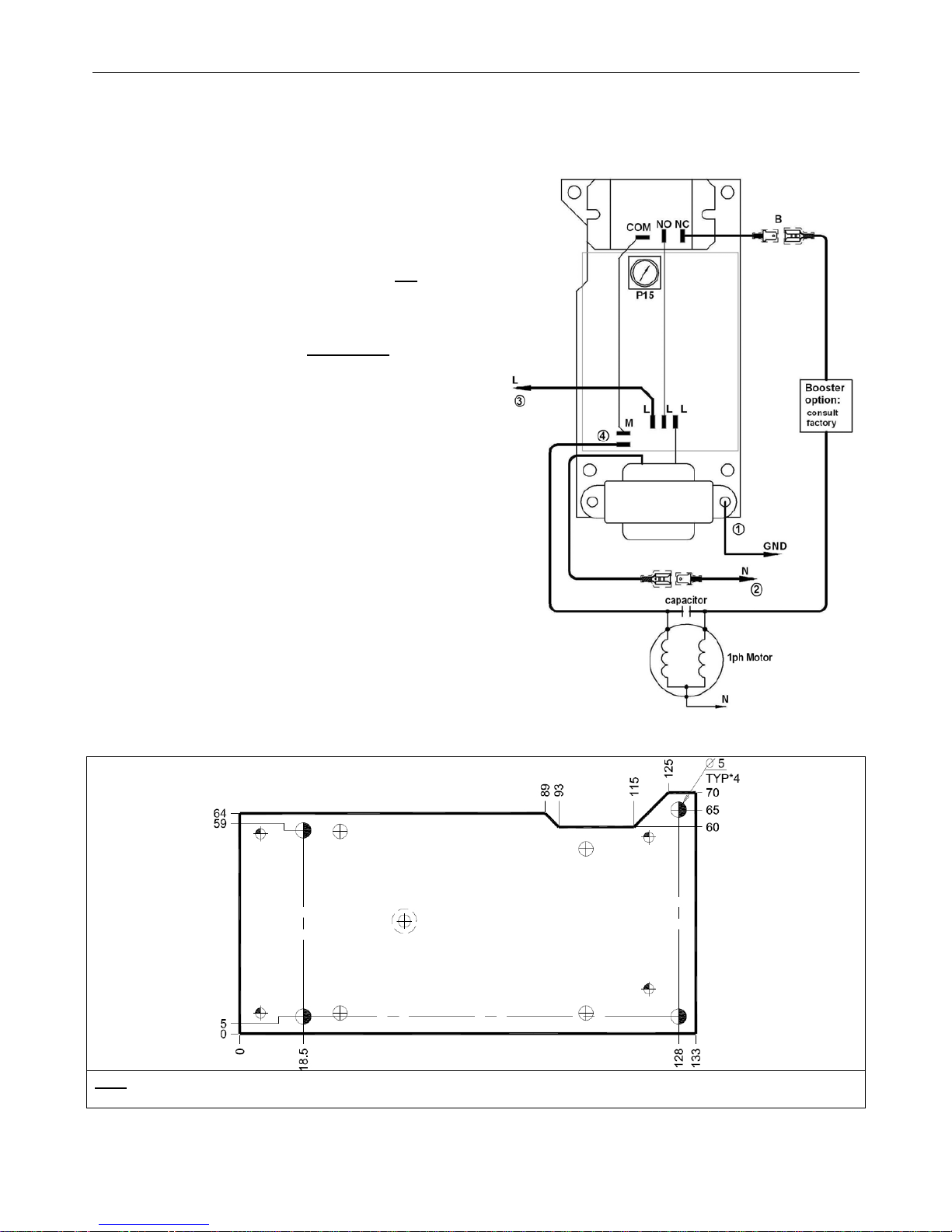

4.3 Wiring Connections

1 Connect grounding wire to the SOLSTART-1P.

2 Connect Neutral wire to the SOLSTART-1P as shown in

the drawing.

3 Connect phase to the PCB as shown in the drawing to

point “L” indicated on the PCB.

4 Make sure motor is connected to neutral. (not

via the

SOLSTART-1P)

5 Connect wire to the motor from point “M” indicated on

the PCB.

6 Leave wire B not connected and isolated

.

(Wire B is used for “Starting Booster” – Consult

factory.)

5. BACK PLATE DIMENSIONS

Note:

Add 20mm to width dimension (133+20mm) for transformer protrusion

_______________________________________________________________________________________________________

9

Setting and StartUp Procedure. • 9

6. SETTING AND STARTUP PROCEDURE

Start the motor and measure the

starting current by a recorder or

by

an oscilloscope

Starting current is

acceptable?

By-pass changes its

position after motor

ends starting?

Rotate potentiometer (P15) c.c.w

by 20º

Consult factory

Startup procedure ends.

Rotate potentiometer (P15) to its

maximum c. w

Note

:

By-Pass should change its position about one second after start process is completed and current should reduce to the

motor’s normal current.

________________________________________________________________________________________________________

9

10 • Technical Specifications

_______________________________________________________________________________________________________

9

7. TECHNICAL SPECIFICATIONS

Environment

Supply voltage One phase, line to line,

220 – 240 Vac +10% -15%

Frequency 50 / 60 Hz

Load Single Phase, Two-Wire, Squirrel

Cage Induction Motor

Degree of protection IP 00

Altitude Up to 1000 m above sea level Consult factory for derating

Adjustments

Ramp Up Time (soft start) 0.1 -1.2 sec.

Temperatures

Operating 0°C to 40°C

Storage -10°C to 70°C

Relative humidity 93 % - non condensed

Loading...

Loading...