Side Channel Blower Silencers

SLCR/SLCRT ½” – 4”

www.solbergmfg.com

Note: Please read the maintenance instructions given by the OEM for the machinery first. The OEM's manual should be

adhered to in order to protect the equipment. Solberg Manufacturing, Inc has made every effort to make sure that these

instructions are accurate but is not responsible for any typos, slight variations or for human errors that may occur.

Ph: 630.773.1363 Fax: 630.773.0727 Email: sales@solbergmfg.com Web: www.solbergmfg.com

Solberg Manufacturing, Inc., 1151 Ardmore Itasca, IL 60143 USA

Page 2

Maintenance Manual

Side Channel Blower Silencers

SLCR/SLCRT ½” – 4”

CONTENTS

Section A

Introduction ....................................................................................... pg. 3

Section B

General Information

1. Identification of Solberg Side Channel Blower Silencers ... pg. 3

2. Side Channel Blower Silencer Specifications .................... pg. 5

Section C

Procedures

1. Installation ......................................................................... pg. 5

2. Securing Silencer to Application Inlet or Outlet ................. pg. 6

3. Equipment Startup ............................................................ pg. 6

Section D

Maintenance Recommendations

1. General .............................................................................. pg. 7

*For Further Information Please Call: 630-773-1363

Solberg Manufacturing, Inc., 1151 Ardmore Itasca, IL 60143 USA

Ph: 630.773.1363 Fax: 630.773.0727 Email: sales@solbergmfg.com Web: www.solbergmfg.com

Page 3

This manual must be read and thoroughly

understood before using and caring for this

air filter. Failure to comply could result in

explosion, product/system contamination

or personal injury.

Section A

INTRODUCTION

The purpose of this manual is instruction on the proper assembly and care of

Solberg side channel blower silencers.

*WARNING*

This manual should be used as a supplement to the user’s understanding of the

proper care needed to maintain a safe and dependable silencer. It is the

responsibility of the user to interpret and explain all instructions to persons who

do not read or understand English BEFORE they are allowed to maintain and

use this silencer.

This manual should be readily available to all operators responsible for operation

and maintenance of the silencers.

We thank you for selecting products from Solberg Manufacturing, Inc. We are

confident that our superior filter and silencer designs will meet your application

requirements.

Section B

GENERAL INFORMATION

1. Identification of Solberg Side Channel Blower Silencers.

All Solberg side channel blower silencers should have an identification

label/nameplate that gives the following information:

(The exception is OEM supplied units. In this case, please enter the OEM part

numbers below.)

Fill in the actual nameplate data from your new Solberg product(s):

Ph: 630.773.1363 Fax: 630.773.0727 Email: sales@solbergmfg.com Web: www.solbergmfg.com

Solberg Manufacturing, Inc., 1151 Ardmore Itasca, IL 60143 USA

Assembly Model #

Page 4

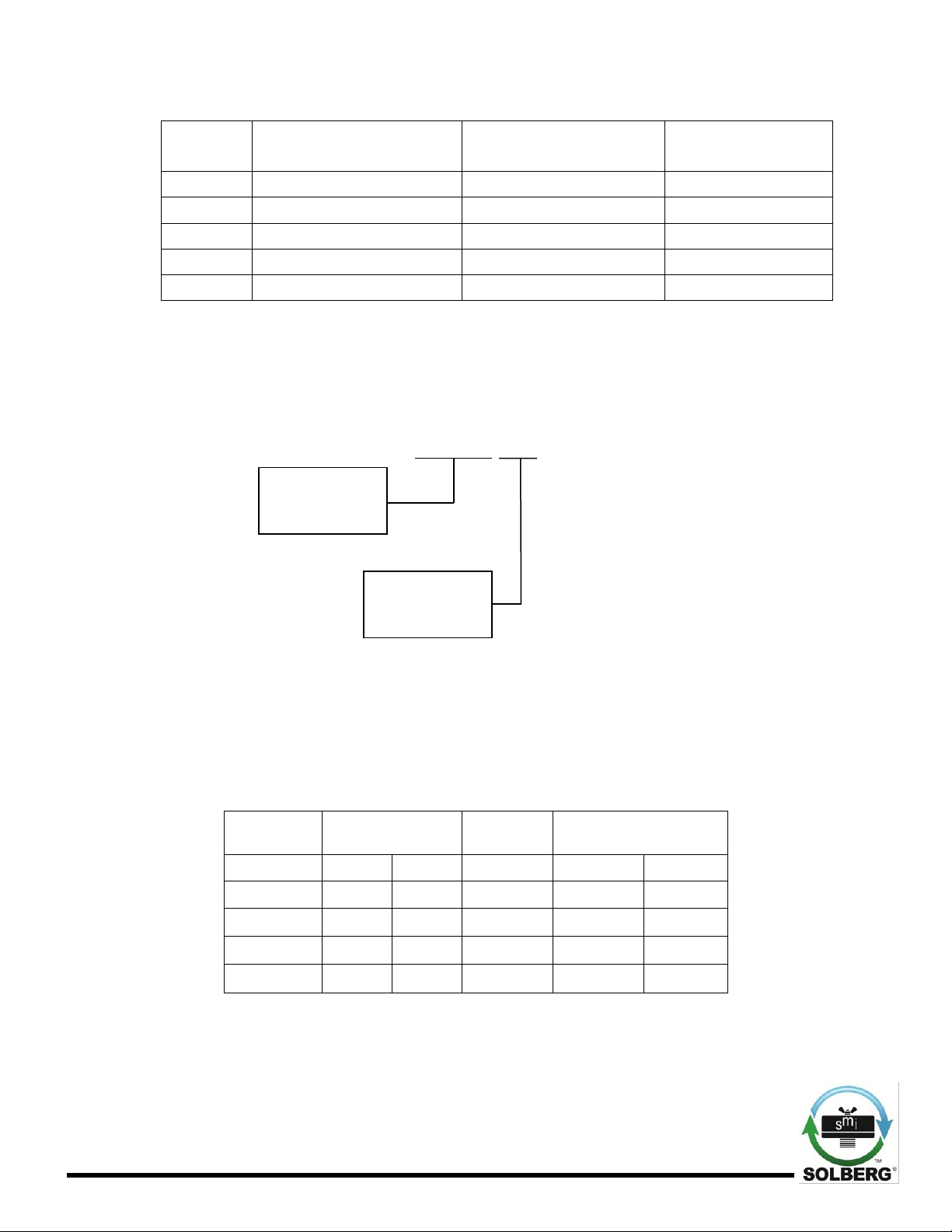

No.

Filter Model

Number

Replacement

Element

Initial Delta P

Readings

1

2

3 4 5

Pipe Size

(inches)

Max Airflow

Pipe Size

(inches)

Max Airflow

1/2"

10 CFM

17m3/h

2"

135 CFM

230m3/h

3/4"

20 CFM

34m3/h

2 ½"

195 CFM

332m3/h

1"

35 CFM

60m3/h

3"

300 CFM

510m3/h

1 ¼"

60 CFM

102m3/h

4"

520 CFM

884m3/h

1 ½"

80 CFM

136m3/h

Connection

size and type

Silencer type:

SLCR

SLCRT

Table 1

The model number designates the silencer type and connection size. For

example, the following part number identifies the product as being a ‘SLCR’

design side channel blower silencer with a 1” FPT connection size:

SLCR100

Note: The inlet connection greatly influences the overall pressure drop of the

filter system. To minimize the restriction contributed by a side channel blower

silencer, a velocity of 6,000 ft/min (10200m3/h) or less is suggested through the

outlet pipe. The table below lists the suggested flows based on pipe size:

Table 3 *Note: This information is for general use only. A qualified engineer must properly design each system.

Solberg Manufacturing, Inc., 1151 Ardmore Itasca, IL 60143 USA

Ph: 630.773.1363 Fax: 630.773.0727 Email: sales@solbergmfg.com Web: www.solbergmfg.com

Page 5

Media

Micron Rating

Standard Polyester

99+% @ 5 micron

Media

Micron Rating

“MX” & “MXD” Series – Nomex Cloth

99+% @ 5 micron

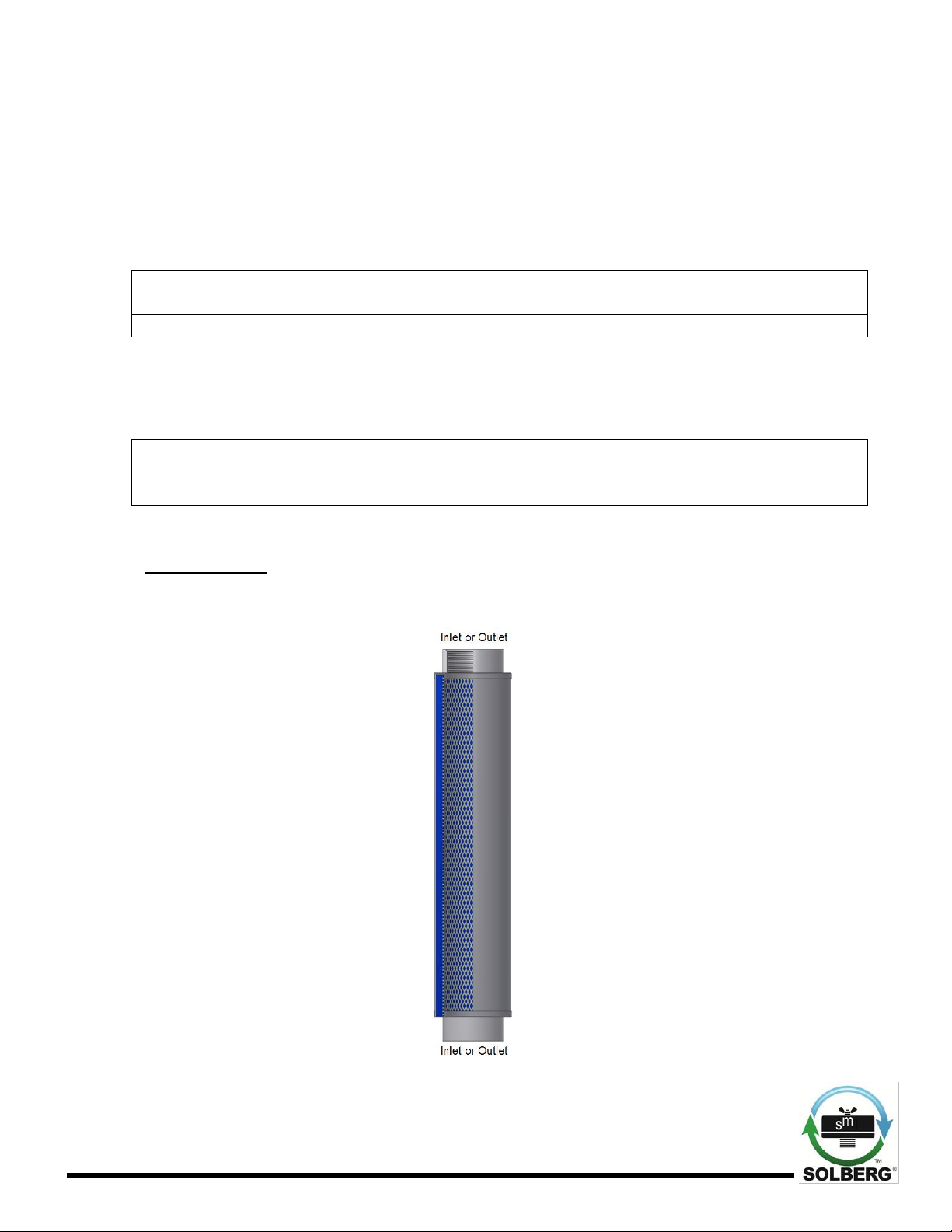

Figure C.1: Housing Terms

2. Side Channel Blower Silencer Specifications.

The Solberg side channel blower silencer is made with polyester as a standard,

but Nomex material is available for high temperature applications.

Temperature Range: -15° to 220°F / -26° to 105°C

Filter Change-Out Differential: 10” to 15” / 250-380mm H2O Over Initial Delta P

Table 4

Temperature Range: -15° to 385°F / -26° to 196°C

Filter Change-Out Differential: 10” to 15”/ 250-380mm H2O Over Initial Delta P

Table 5

Section C

PROCEDURES

1. Installation.

Ph: 630.773.1363 Fax: 630.773.0727 Email: sales@solbergmfg.com Web: www.solbergmfg.com

Solberg Manufacturing, Inc., 1151 Ardmore Itasca, IL 60143 USA

Page 6

If at any time the operator is unable to

verify the integrity of the silencer, the

factory or a regional representative should

be contacted prior to start-up.

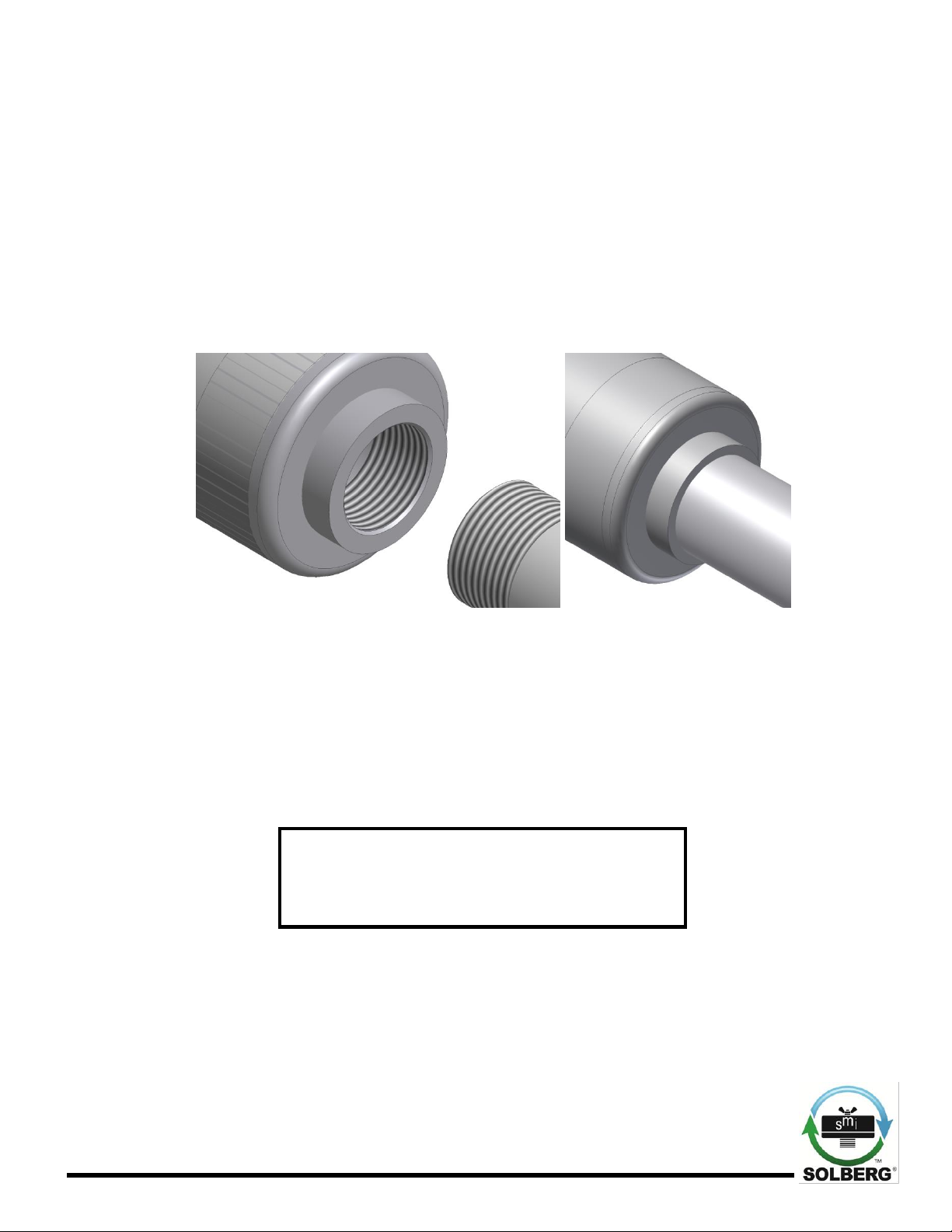

Figure C.2.1: Silencer and inlet/outlet connection.

Figure C.2.2: Silencer in secured

position.

A. Maximum operating temperature for most Solberg side channel blower

silencers is 275°F / 135°C. Temperatures in excess of this could cause

damage. High temperature products are available.

B. Ensure that pipe connections are adequately sealed so the potential for

leaks is reduced to a minimum.

2. Securing Silencer to Application Inlet or Outlet.

Place silencer on inlet or outlet connection and rotate to tighten. Note: Do NOT

over tighten!

3. Equipment Startup.

A. Be sure to read the instructions on installation as listed above before

starting equipment.

*WARNING*

B. Please check the listed steps prior to startup.

1. Check silencer to make sure it is securely tightened onto

inlet/outlet connection. See figure C.2.2

Ph: 630.773.1363 Fax: 630.773.0727 Email: sales@solbergmfg.com Web: www.solbergmfg.com

Solberg Manufacturing, Inc., 1151 Ardmore Itasca, IL 60143 USA

Page 7

Failure to seat the element properly may

result in contaminant by-pass resulting in

damage to equipment.

If the air flow is reversed through a Solberg

filter unit, be sure to check the element and

housing internals for damage. Failure to do

so may result in damage to equipment.

*WARNING*

*WARNING*

Section D

MAINTENANCE RECOMMENDATIONS

1. Operate only when a proper seal exists.

Ph: 630.773.1363 Fax: 630.773.0727 Email: sales@solbergmfg.com Web: www.solbergmfg.com

Solberg Manufacturing, Inc., 1151 Ardmore Itasca, IL 60143 USA

Loading...

Loading...