Page 1

X1-AC

3.0kw - 5.0kw

User Manual

Solax Power Network Technology(Zhe jiang) Co,. Ltd.

614 .0034 6.02

Copyright Declaration

The copyright of this manual belongs to Solax Power Network Technology(Zhe jiang) Co,. Ltd.

Any corporation or individual should not plagiarize, par titially or fully copy ( including

software,etc.), and no reproduction or distribution of it in any form or by any means. All rights

reser ved. SolaX Power Network Technology (Zhe jiang) Co.,Ltd.. reserves the right of final

interpretation.

Page 2

Contents

Contents

1 Note on this Manual

1.1 Scope of Validity

1.2 Target Group

1.3 Symbols Used

2 Safety

2.1 Important Safety Instructions

2.2 Explanation of Symbols

2.3 CE Directives

3 Introduction

3.1 Basic Features

3.2 Dimension

3.3 Terminals of Inverter

4 Technical Data

4.1 AC output/input

4.2 Internal Charger

4.3 Efficiency, Safety and Protection

4.4 General Data

5. Installation

5.1 Check for Transport Damage

5.2 Packing List

5.3 Mounting

03

03

03

03

04

04

08

09

10

10

13

14

13

13

14

14

15

16

16

16

17

6 Electrical Connection

6.1 Grid Connection

6.2 Battery Connection

6.3 Earth Connection

20

20

22

24

01

Page 3

Notes on thi s ManualContents

6.4 Meter/CT Connection(optional)

6.5 485 Connection

6.6 DRM Connection

6.7 WiFi Connection(optional)

6.9 Inverter Manipulation

7 Firmware Upgrading

8 Setting

8.1 Control Panel

8.2 Menu Structure

8.3 LCD Operation

9 Troubleshooting

9.1 Trouble Shooting

9.2 Routine Maintenance

10 Decommissioning

Dismantling the Inverter10.1

Packaging10.2

Storage and Transportation10.3

25

28

28

29

30

32

34

34

35

36

54

54

58

59

59

59

59

1 Notes on this Manual

1.1 Scope of Validity

This manual is an integral part of X1-AC, It describes the assembly, installation,

commissioning, maintenance and failure of the product. Please read it carefully

before operating.

X1-AC-3.0X1-AC-3.6 X1-AC-5.0X1-AC-4.6

Note: “3.0” means 3.0kW.

Store this manual where it will be accessible at all times.

1.2 Target Group

This manual is for qualified electricians. The tasks described in this manual only

can be performed by qualified electricians.

1.3 Symbols Used

The following types of safety instructions and general information appear in this

document as described below:

Danger!

“Danger” indicates a hazardous situation which, if not avoided, will result in

death or serious injury.

Warning!

“Warning” indicates a hazardous situation which, if not avoided, could result

in death or serious injury.

Caution!

“Caution” indicates a hazardous situation which, if not avoided, could result

in minor or moderate injury.

02

Note!

“Note” provides tips that are valuable for the optimal operation of our

product.

03

Page 4

2 Safety

SafetySafet y

2.1 Important Safety Instructions

Danger!

Danger to life due to high voltages in the inverter!

All work must be carried out by qualified electrician.

The appliance is not to be used by children or persons with

reduced physical sensory or mental capabilities, or lack of

experience and knowledge, unless they have been given

supervision or instruction.

Children should be supervised to ensure that they do not play

with the appliance.

Caution!

Danger of burn injuries due to hot enclosure parts!

During operation, the upper lid of the enclosure and the enclosure

body may become hot.

Only touch the lower enclosure lid during operation.

Caution!

Possible damage to health as a result of the effects of radiation!

Do not stay closer than 20 cm to inverter for any length of time.

Warning!

Authorized service personnel must disconnect AC power from

inverter before attempting any maintenance or cleaning or

working on any circuits connected to inverter.

Prior to the application, please read this section carefully to ensure correct and

safe application. Please keep the user manual properly.

Accesories only together with the inverter shipment are recommanded here.

Otherwise may result in a risk of fire, electric shock, or injury to person.

Make sure that existing wiring is in good condition and that wire is not

undersized.

Do not disassemble any parts of inverter which are not mentioned in installation

guide. It contains no user-serviceable parts. See Warranty for instructions on

obtaining service. Attempting to service the inverter yourself may result in a risk

of electric shock or fire and will void your warranty.

The installation place should be away from humid or corrosive substance.

Authorized service personnel must use insulated tools when installing or

working with this equipment.

Hazardous voltage will present for up to 5 minutes after disconnection from

power supply.

CAUTION-RISK of electric shock from energy stored in capacitor, Never operate

on the inverter couplers, the MAINS cables or when power is Battery cables

applied. After switching off the battery and Mains, always wait for 5minutes to let

the intermediate circuit capacitors discharge before unpluging battery inplug

and MAINS couplers.

When accessing the internal circuit of inverter, it is very important to wait 5

minutes before operating the power circuit or demounting the electrolyte

capacitors inside the device. Do not open the device before hand since the

capacitors require time to sufficiently discharge!

Measure the voltage between terminals + and - with a multi-meter UDCUDC

(impedance at least 1Mohm) to ensure that the device is discharged before

beginning work (35) inside the device.VDC

To protect the AC system,surge suppression devices (SPD type2) should be fitted

at the main incoming point of AC supply (at the custome’s cutout), located

between the inverter and the meter/distribution system; SPD (test impluse D1)

for signal line according to EN 61632-1.

04

WARNING !

Do not operate the inverter when the device is running.

WARNING !

Risk of electric shock!

05

Page 5

SafetySafet y

Anti-Islanding Effect

►

• Islanding effect is a special phenomenon that grid-connected system still

supply power to the nearby grid when the voltage loss is happened in the

power system. It is dangerous for maintenance personnel and the public.

• X1-AC seires inverter provide Active Frequency Drift(AFD) to prevent

islanding effect.

►

PE Connection and Leakage Current

• The inverter incorporates a certified internal Residual Current Device (RCD)

in order to protect against possible electrocution and fire hazard in case of a

malfunction in the cables or inverter. There are two trip thresholds for the RCD

as required for certification (IEC 62109-2:2011). The default value for eletrocution

protection is 30mA, and for slow rising current is 300mA.

• If an external RCD is required by local regulations, check which type of RCD

is required for relevant eletric code. It recommends using a type-A RCD. The

recommended RCD values is 100mA or 300mA unless a lower value is required

by the specific local electric codes. When required by local regulations, the use of

an RCD type B is permitted.

WARNING !

High leakage current!

Earth connection essential before connecting supply.

For United Kingdom

• The installation that connects the equipment to the supply terminals shall

comply with the requirements of BS 7671.

• No protection settings can be altered.

• User shall ensure that equipment is so installed, designed and operated to

maintain at all times compliance with the requirements of ESQCR22(1)(a).

For Australia and New Zealand

• Electrical installation and maintenance shall be conducted by licensed

electrician and shall comply with Australia National Wiring Rules.

►

Battery Safety Instructions

SolaX X1-AC Series inverter should be worked with high voltage battery, for the

specific parameters such as battery type, nominal voltage and nominal

capacity etc., please refer to section 4.2.

As accumulator batteries may contain potential electric shock and short-circuit

current danger, to avoid accidents that might be thus resulted, the following

warnings should be observed during battery replacement:

•

1: Do not wear watches, rings or similar metallic items.

2: Use insulated tools.

3: Put on rubber shoes and gloves.

4: Do not place metallic tools and similar metallic parts on the batteries.

5: Switch off load connected to the batteries before dismantling battery

connection terminals.

6: Only personal with proper expertise can carry out the maintenance of

accumulator batteries.

• Incorrect grounding can cause physical injury, death or equipment malfunction

and increase electromagnetic.

• Make sure that grounding conductor is adequately sized as required by safety

regulations.

• Do not connect the ground terminals of the unit in series in case of a multiple

installation. This product can cause current with a d.c component, Where a residual

current operated protective (RCD) or monitoring (RCM) device is used for protection

in case of direct or indirect contact, only the RCD or RCM of type B is allowed

on the supply side of this product.

06

Note: The instruction applies to lithium battery and please refer to the lead-

acid battery Quick Installation Guide.

07

Page 6

SafetySafety

2.2 Explanation of Symbols

This section gives an explanation of all the symbols shown on the inverter and

on the type label.

Symbols on the Inverter

SymbolExplanation

The inverter is working normally, when the blue light is on.

The battery communication is active, when the yellow light is on.

An error has occurred, when the red light is on.

Symbols on the Type Label

SymbolExplanation

CE mark.

The inverter complies with the requirements of the applicable

CE guildlines.

TUV certified.

RCM remark.

SAA certification.

Beware of hot surface.

The inverter can become hot during operation. Avoid contact

during operation.

Danger of high voltages.

Danger to life due to high voltages in the inverter!

Danger.

Risk of electric shock!

The inverter can not be disposed together with the household waste.

Disposal information can be found in the enclosed documentation.

Do not operate this inverter until it is isolated from battery and. main

Danger to life due to high voltage.

There is residual voltage existing in the inverter after powering off,

which needs 5 min to discharge.

• Wait 5 min before you reoperate the inverter.

2.3 CE Directives

This chapter follows the requirements of the European low voltage

directives, which contains the safety instructions and conditions of

acceptability for the endues system, which you must follow when installing,

operating and servicing the unit. If ignored, physical injury or death may

follow, or damage may occur to the unit. Read this instructions before you

work on the unit. If you are unable to understand the dangers, warnings,

cautions or instructions, please contact an authorized service dealer before

installing. Operating and servicing the unit.

The Grid connected inverter meets the requirement stipulated in Low Voltage

Directive (LVD) 2014/35/EU and Electromagnetic Compatibility (EMC) Directive

2014/30/EU. The unit is based on:

EN 62109-1:2010 ; EN 62109-2:2011 ; IEC 62109-1(ed.1) ; IEC62109-2(ed.1)

EN 61000-6-3:2007+A:2011 ; EN 61000-6-1:2007 ; EN 61000-6-2:2005

The grid connected inverter leave the factory completely connecting device and

ready for connection to the mains,the unit shall be installed in accordance with

national wiring regulations. Compliance with safety regulations depends upon

installing and configuring system correctly, including using the specified wires.

The system must be installed only by professional assemblers who are familiar

with requirements for safety and EMC. The assembler is responsible for ensuring

that the end system complies with all the relevant laws in the country where it is

to be used.

The individual subassembly of the system shall be interconnected by means of

the wiring methods outlined in national/international such as the national electric

code (NFPA) No.70 or VDE regulation 0107.

08

Observe enclosed documentation.

09

Page 7

IntroductionIntroduction

3. Introduction

3.1 Basic features

X1-AC Seires is a high-quality inverter which can store energe into battery.

The inverter can be used to optimize self consumption, store in the battery for

future use or feedin to public grid. Work mode depends on the battery and user’s

preference.

·Advanced DSP control technology.

·Utilize the latest high-efficiency power component.

·Advanced anti-islanding solutions.

·IP65 protection level.

·Max. efficiency up to 97.0%.

·THD<2%.

·Safety & Reliability: transformerless design with software and hardware

protection.

·Export control.

·Power factor regulation.

·Friendly HMI.

- LED status indications.

- LCD display technical data, Human-machine interaction through press

key.

- Dry contact communication interface.

- Remote control via modbus RTU

- Upgrade through USB interface.

- Pocket Wi-Fi monitoring.

- Control loads’ switch intelligently by RF.

- Energy conservation.

3.2 Dimension

341 .5mm

X1-ACX1-AC

143 .0 mm

430 .0 mm

10

11

Page 8

IntroductionTechnical Data

3.3 Terminals of inverter

Object

A

B

C

D

E

F

G

H

I

Description

Battery connection area

Port for external Pocket WiFi/GPRS/LAN

External meter or CT port

AC connector

DRM port

Groud screw

RS485

Battery communication

USB port for upgrading

ABCD

+

BAT

DRM

-

FEHIGEE

Meter

485

WiFi/LAN/GPRS

A

4. Technical Data

4.1 AC output/input

Model

AC

BMS

Upgrade

AC output

Norminal AC power[VA]

Max. apparent AC power[VA]

Rated grid voltage(range)[V ]

Rated grid frequency[Hz]

Norminal AC current[A]

Max.AC current[A]

Max. overcurrent protection[A]

Displacement power factor

Total harmonic distortion(THDi)

Load control

AC input

Norminal AC power[VA]

Max. apparent AC power[VA]

Rated grid voltage(range)[V ]

Rated grid frequency[Hz]

Norminal AC current[A]

Max.AC current[A]

Max. short current(Isc)[A]

Displacement power factor

X1-AC-3.0

3000

3000

13

13.6

3000

3000

13

13.6

X1-AC-3.6

3680

3680

220/230/240 (180 to 280)

16

16.8 (16 for G98)

0.8 leading...0.8 lagging

3680

3680

220/230/240 (180 to 280)

16

16.8 (16 for G98)

0.8 leading...0.8 lagging

X1-AC-4.6X1-AC-5.0

4600

4600

50/60

20

21

45

< 2%

optional

4600

4600

50/60

20

21

45

4999

4999

230/240 (180 to 280)

21.7

21.7

4999

4999

21.7

21.7

12

WARNING !

Qualified electrician will be required for the installation.

13

Page 9

Technical Data

Technical Data

4.2 Internal Charger

Model

Battery type

Battery voltage range[V ]

Recommended battery voltage[V ]

Rated charge/discharge current[A]

Max. charge/discharge current[A]

Communication interfaces

Reverse connect protection

X1-AC-3.0

4.3 Efficiency, Safety and Protection

Model

Max. efficiency

Max . Batte ry charge e ffici ency

(AC to BAT )(@full l oad)

Max. Battery discharge efficiency

(BAT to AC)(@full load)

Safety & Protection

Over/under voltage protection

DC isolation protection

Grid protection

DC injection monitoring

Residual current detection

Anti-islanding protection

Over load protection

Over heat protection

X1-AC-3.0

97.0%97.0%97.0%97.0%

97.0%97.0%97.0%97.0%

97.5%97.5%97.5%97.5%

X1-AC-3.6X1-AC-4.6X1-AC-5.0

Lithium/Lead-acid battery

70-400

300VDC

25A

35A

CAN

Yes

YES

YES

YES

YES

YES

YES

YES

YES

X1-AC-4.6

X1-AC-5.0

X1-AC-3.6

4.4 General Data

Model

Dimension [W/H/D](mm)

Dimension of packing [W/H/D](mm)

Net weight [kg]

Gross weight [kg]

Installation

Operating temperature range[℃]

Storage temperature [℃]

Storage/Operation relative humidity

Altitude [m]

Ingress Protection

Protective Class

Over Voltage Category

Pollution Degree

Cooling

Inverter Topology

Communication interface

X1-AC-3.0

15.515.516.316.3

18.518.519.319.3

X1-AC-3.6X1-AC-4.6X1-AC-5.0

430*341.5*143

554*446*259

Wall-mounted

-25~+60 (derating at 45)

-25~+60

0~100%, condensing

≤2000

IP65(for outdoor use)

Ⅰ

Ⅲ(MAINS),Ⅱ(DC)

Ⅲ

Natural

Non-isolated

RS485, Meter/CT(optional), Wifi(optional), RF(optional), DRM, CAN, USB

14

15

Page 10

InstallationInstallation

5. Installation

5.1 Check for Physical Damage

Make sure the inverter is intact during transportation. If there is any visible

damage, such as cracks, please contact your dealer immediately.

5.2 Packing List

Open the package and take out the product, please check the accessories first.

The packing list shown as below.

X1-ACX1-AC

X1-AC

I

Object

A

B

C

D

E

F

A

E

J

Description

Inverter

Bracket

Expansion tubes & Expansion screws

AC connector

Battery connectors (1*positive, 1*negative)

Waterproof connector with RJ45 (4*RJ45)

BCD

F

X1-AC 3.0KW-5.0KW

G

KLM

Object

G

H

I

J

K

L

M

N

Description

Ring terminal(for external enclosure grounding)

Set screw( for mounting)

User manual

Warranty card

Quick installation guide

Meter(optional)

Current Sensor(or called CT) (optional)

Wifi/GPRS/LAN module (optional)

5.3 Mounting

Installation Precaution

X1-AC Series inverter is designed for outdoor installation (IP 65).

Make sure the installation site meets the following conditions:

H

N

Not in direct sunlight.

Not in areas where highly flammable materials are stored.

Not in potential explosive areas.

Not in the cool air directly.

Not near the television antenna or antenna cable.

Not higher than altitude of about 2000m above sea level.

Not in environment of precipitation or humidity (>95%).

Under good ventilation condition.

The ambient temperature in the range of -20℃ to +60℃.

The slope of the wall should be within ±5°.

The wall hanging the inverter should meet conditions below:

1.Solid brick/concrete, or strength equivalent mounting surface;

2.Inverter must be supported or strengthened if the wall’s strength isn’t

enough(such as wooden wall, the wall covered by thick layer of decoration)

Please AVOIDE direct sunlight, rain exposure, snow laying up during installation

and operation.

16

17

Page 11

Installation Installation

Space Requirement

Ø

Step 2 Match the inverter with wall bracket

300mm

Table Available Space Size

PositionMin.size

300mm300mm

300mm

Mounting Steps

Ø

Tools required for installation.

Installation tools : crimping pliers for binding post and RJ 45, screwdriver,

manual wrench and 6

Left

Right

Top

Bottom

Front

300mm

300mm

300mm

300mm

300mm

d) Hang the inverter over the bracket, move the inverter close to it,

slightly lay down the inverter, and make sure the 3 mounting bars on the

back are fixed well with the 3 grooves on the bracket.

*Please refer to the Quick Installation Guide for details.

a)b)

Step 1 Hang the inverter over the bracket, move the inverter close to it,

a) Use the wall bracket as a template to mark the position of the 3

holes on the wall.

b) Drill holes with driller, make sure the holes are deep enough (at

least 50mm) for installation, and then tighten the expansion tubes.

c) Install the expansion tubes in the holes, and tighten them. Then

install the wall bracket by using the expansion screws.(Φ10 driller,

torque: 2.5±0.2Nm)

18

c)d)

19

Page 12

Ele ctrical Connec tionEle ctrical Connec tion

6. Electrical Connection

6.1 Grid Connection

X1-AC series inverter are designed for single phase grid. Voltage is 220/230/240V,

frequency is 50/60Hz. Other technical requests should comply with the

requirement of the local public grid.

Table 4 Cable and Micro-breaker recommended

Model

Model

Copper Cable

Micro-breaker

X1-AC-3.0

X1-AC-3.0

4-5mm²

20A20A32A32A

X1-AC-3.6X1-AC-4.6X1-AC-5.0

X1-AC-3.6

4-5mm²5-6mm²5-6mm²

Micro-breaker should be installed between inverter and grid, any load should

not be connected with inverter directly.

Connection Steps

a) Check the grid voltage and compare with the permissive voltage range (refer

to technical data).

b) Disconnect the circuit-breaker from all the phases and secure against re-

connection.

c) Trip the wires:

- Trip all the wires to 52.5mm and the PE wire to 55mm.

- Use the crimping plier to trip 6mm of insulation from the end of wire.

X1-AC-4.6X1-AC-5.0

d) Separate the AC plug into three parts as below.

- Hold the middle part of the female insert, rotate the back shell to

loose it, and datach it from female inset.

- Remove the cable nut (with rubber insert) from the back shell.

e) Slide the cable nut and then back shell onto the cable.

f) Insert the tripped end of each three wires into the appropriate hole in

the female insert, and then tighten each screw (to tighten each wire in

place). ( PH1 cross screwdriver, torque:0.8±0.1Nm)

g) Screw down the threaded sleeve the pressure screw.

h) Screw down the pressure screw.(torque:3.0±0.3Nm)

20

I) Connect the AC plug to the inverter.

6mm

21

Page 13

Ele ctrical Connec tionEle ctrical Connec tion

6.2 Battery Connection

Charging & discharging system of X1-AC series inverter is designed for

high-voltage lithium batterry or lead-acid battery.

Before choosing battery, please note the maximum voltage of battery can not

exceed 360V, and the battery communication should be compatible with X1-AC

inverter.

Battery breakerØ

Before connecting to battey, please install a nonpolarized DC breaker to make sure

inverter can be securely disconnected during maintanance.

Model

Model

Model

Voltage

Current[A]

Battery connection diagramØ

X1-AC-3.6X1-AC-4.6X1-AC-5.0

X1-AC-3.0

X1-AC-3.0

X1-Hybrid-3.0-NX1-Hybrid-3.7-NX1-Hybrid-4.6-NX1-Hybrid-5.0-N

X1-AC-3.6

Nominal voltage of DC breaker should be larger than maximum

voltage of battery.

+

BAT

-

Meter

DRM

485

WiFi/LAN/GPRS

X1-AC-4.6X1-AC-5.0

50A

AC

BMS

Upgrade

Note!

The battery communication can only work when the battery BMS is

compatible with the inverter.

Power Connection Steps:

Ø

Step1. Choose the 10 AWG wire and strip the cable to 15mm.

Step2. Insert the stripped cable up to the stop ( negative cable for DC plug(-) and

positive cable for DC socket(+) are live). Hold the housing on the screw

connection.

Step3. Press down spring until it clicks audibly into place.(it must be possible to

see the fine wire strands in the chamber)

Step4. Tighten the screw connection(tighten torque:2.0±0.2Nm)

Step5. Plug the conntector into the corresponding BAT connector on inverter.

Step2.

screw connection

DC plug housing(-)

Step3.Step 4.

spring

screw connection

DC socket housing(+)

Nonpolarized

Power connection

DC breaker

-

+

CAN

high-voltage lithium battery.

Communication connection

Note: When working with Pylontech batteries, It is recommended the number of battery module

(H48050-15S) is 2-6 and the number of battery manager system (SC0500A-100S) is 1.

BMS PIN DefinitionØ

Communication interface bewteen inverter and battery is CAN with a RJ45

connector.

1

8

BMS

1

NTC

34678

2

GND GND

BMS_CANH

5

BMS_CANL

GND

22

chamber

wire strands

Step5.

+

BAT

DRM

-

WiFi/LAN/GPRS

BMS_485BBMS_485A

Not e: The pos itive l ine and n egati ve line ar e not all owed to a ccess anti-Li ne.

AC

Meter

485

BMS

Upgrade

23

Page 14

Ele ctrical Connec tionEle ctrical Connec tion

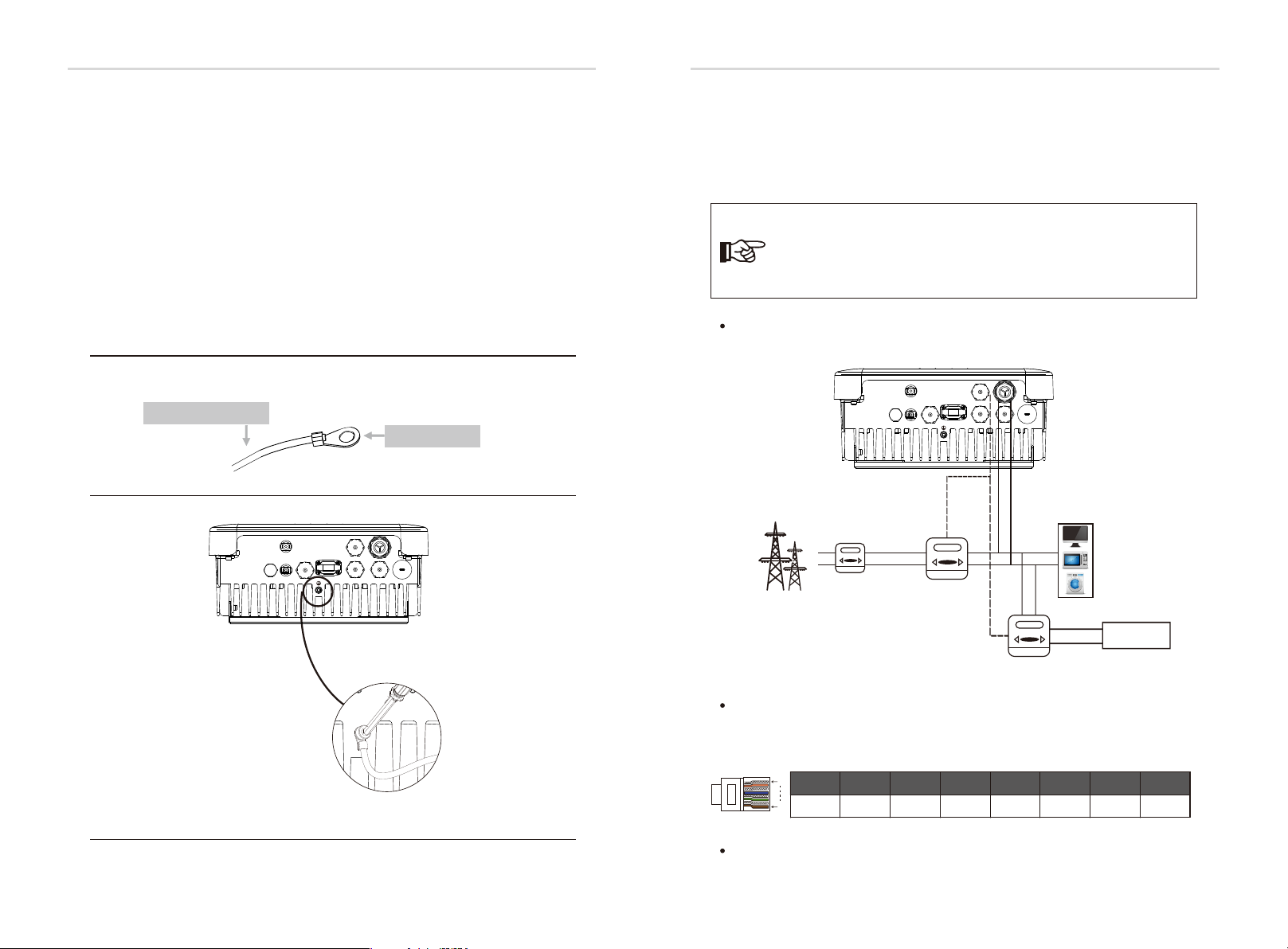

6.3 Earth Connection (mandatory)

Users must addtionally earth the inverter to the enclosure of a second earthing or

equipotential bonding. This prevents electric shock if the original protective

conductor fails.

Earth Connection Steps:

Ø

Step1. Strip the earthing cable insulation and insert the stripped cable into the

ring terminal, then clamp it .

Step2. Place the ring terminal into the earthing rod and screw the earthing screw

tightly.( Φ4 hexagon wrench, torque:1.5±0.2Nm)

Step1

Cable size: 10AWG.

ring terminal

Step2

+

BAT

-

Meter

DRM

485

WiFi/LAN/GPRS

AC

BMS

Upgrade

6.4 Meter/CT Connection

Meter connectionØ

Meterisusedformonitoringthepowerusageforentirehouse,atthemeantime,

inverterwillalsoneedthedatafromMetertoachievetheExportControlFunction.

Note!

It is necessary to connect meter to inverter otherwise inverter will

shutdown with a “Meter fault” alert.

The meter communication only works when meter is compatible

with the inverter.

Meter connection diagram

Electrical

grid

Home Electric meter,

+

BAT

-

Single phase

DRM

meter

Meter1

WiFi/LAN/GPRS

Meter

485

AC

BMS

Upgrade

Load

L

N

other generator

24

Meter2

Meter PIN Definition

Communication interface bewteen inverter and meter is BMS port with a RJ45

connector.

1

12345678

XXX

8

X

X

GND

485A485B

Meter Connection Steps:

Please refer to Page 27.

25

Page 15

Ele ctrical Connec tionEle ctrical Connec tion

Meter

CT Connection Steps:

Ø

The current sensor measures the current on the phase wire that runs between the

inverter and the grid. This enables the inverter to determine the Power

requirements of the connected consumer. The current sensor is connected to the

CT port on the inverter.

NOTE!

• Do not place the sensor on the N Wire or the earth wire.

• Do not place the sensor on the N and L wire simultaneously.

• Do not place the sensor on the L wire going to the consumer.

• Do not place the sensor with the arrow pointing to the

generation meter.

• Do not place the sensor on the non-insulated wires.

• Do not use the wire over 25m.

NOTE!

• The sensor can be upgraded to meter.

• With a one phase meter provided by SolaX can monitoring

the 24hr usage of electric.

• With a three phase meter provided by SolaX can implement

three phase compensation.

CT connection diagram

Electrical

grid

+

BAT

-

Meter

DRM

485

WiFi/LAN/GPRS

AC

BMS

Upgrade

Load

L

CT PIN Definition

When connectingthe RJ45 connector with the wire of the CT, please follow the

below sequence :

1

12345678

CT+XX

8

CT-

X

X

XX

CT Connection Steps:

1. Insert the CT terminal on the current sensor into the Meter port on the

inverter.

+

BAT

DRM

-

WiFi/LAN/GPRS

AC

Meter

485

BMS

Upgrade

→

Public grid

AC port

L line

2. Place the current sensor around the phase wire L which the inverter is

connected.

3. Place the current sensor around the phase wire L to measure the current

going to or coming from the grid.

4. Make sure the current sensor is installed in the right direction: The arrow

on the current sensor must point to the public grid.

Home Electric meter,

Pub lic

Gri d

N

L line

CT

26

Meter

27

Page 16

Ele ctrical Connec tionEle ctrical Connec tion

WiFi/LAN/GPRS

485

DRM

Meter

6.5 485 Connection

485 is provided the function of remote control that allows external control device

to make the inverters remote cluster control through 485 port on thr inverter.

485 PIN Definition:

Ø

1

12345678

COM0

8

485 Connection Steps:

Ø

Shut DownGND

485A

485BXXX

Please refer to the bellow(Page 28).

6.6 DRM Connection

DRM is provided to support several demand response modes by emitting control

signals as below through DRM port on the inverter.

Note: Only PIN6(DRM0) is available now, and other PIN functions are being developed.

DRM PIN Definition:

Ø

1

12345678

DRM1/5

8

Communication Connection Steps Of Meter, RS485 and DRM:

Ø

DRM2/6DRM3/7

DRM4/8

+3.3VDRM0GNDGND

6.7 WiFi Connection(optional)

Inverter provides a WiFi port which can collect data from inverter and

transmit it to monitoring-website via a Pocket WiFi.

(Purchase the product from supplier if needed)

Diagram

Ø

X1-ACX1-AC

Router

WiFi Connection Steps:

Ø

Step1. Plug Pocket Wifi/GPRS/LAN into “WiFi/LAN/GPRS” port at the bottom of

the inverter.

Step2. Build the connection between the inverter and router.

Step3. Create a user account on the SolaX web.( Please check the Pocket WiFi user

manual for more details)(torque:0.6±0.1Nm)

Could

Please kindly noted the PIN definition and port position will be slightly different.

1. Prepare RJ45 connector and a communication cable.

2. Trip the insulation from the communication cable.

3. Let the communication cable pass though the waterproof connector with

RJ45, then insert it into the RJ45 connector following the PIN definition rule.

Han d tight en,to rgue:1 .5±0. 1NmHan d tight en,to rgue:1 .2±0. 1Nm

4. Crimp the RJ45 connector with the crimping plier.

5. Insert the cable into the corresponding port of the inverter, and tighten the

waterproof connector.

28

29

Page 17

Ele ctrical Connec tionEle ctrical Connec tion

6.8 Inverter Manipulation

Start inverter after checking all below steps:

Ø

Ensure the inverter fixed well on the wall.

Make sure all the AC wirings are completed.

Make sure the meter is connected well.

Make sure the battery is connected well.

Turn on the AC and battery switch.

Press the “Enter” key for five seconds to exit Off Mode.(The mode is factory

defaulted as Off Mode)

Inverter

-

+

SolaX meter

Main switch

5

Check the inverter:

Ø

Step1. Check the status of indicators and LCD screen. The left indicator should

be blue and the indicator screen should display the main interface.

Note!

If the left indicator is not blue please check below the two points:

- All the connections are correct.

- All the external breakers are switched on.

Step2. There is a setting guide on the LCD screen if it is the first time to start up,

please follow it. For specific setting, please refer to section 8 (Setting).

Step3. Set WiFi according to wifi user manual.

Step4. Operate “Self Test”. (applies to Italy only)

Self-test in accordance with CEI 0-21(applies to Italy only)

Ø

The self-test is only required for inverters, which are commissioned in Italy. The

Italian standard requires that all inverters feeding into the utility grid are equipped

with a self-test function in accordance with CEI 0-21. During the self-test, the

inverter will consecutively check the protection reaction times and values for

overvoltage, undervoltage, overfrequency and underfrequency.

PE

RCD

E-BAR

Note: External connections should be made according to the local regulations.

30

Battery

Selftest function is available at any time, and the test report will show on the LCD

display for end-user.

Shut down the inverter :

Ø

All you have to do is turn off the AC switch and battery switch.

31

Page 18

Firmware Up grading

Firmware Up grading

7. Firmware Upgrading

User can upgrade inverter’s firmware via a U-disk.

Preparation

Ø

Please ensure the inverter is steadily powered on.

Inverter must keep the battery on through whole procedure of upgrading.

Please prepare a PC and a U-disk.

Warning!

Ø

Step1. Please contact our service support to get the update les, and extract it

into your U-disk as follow:

“update\ARM\618.00211.00_X1AC_Manager_Vx.xx_xx-xx.usb”;

“update\DSP\618.00209.00_X1AC_Master_Vx.xx_xx-xx.hex”;

Note: Vx.xx is version number, xx-xx is the le completion date.

Step2. Press the “Enter” key for 5 seconds to enter Off Mode. Then unscrew the

waterproof lid and insert U-disk into the “upgrade” port at the bottom of the inverter.

Make sure the inverter charged normally (the battery capacity is stable),

otherwise it may result in serious failing during upgrading.

Upgrading Steps:

Warning!

Make sure the directory is in accordance with above form strictly!

Do not modify the program file name, or it may cause the inverter

not work anymore!

Step2

Step3

U-disk

Update

>ARM

DSP

Warning!

If the upgrading is broken off during operation, please ensure the inverter

is steadily powered on and reinsert the U-disk.

Update(ARM)

Upd ating----- ----2 5%

Step3. The LCD will be shown as the picture bellow. Then press up and down to

select the one that you want and press “OK” to confirm to upgrade.

Step4. After the upgrade is finished, the LCD will display “succeed”(only for DSP

upgrades), please remember to pull off the U-disk, screw the waterproof lid and press

the “Esc” to return to the Main interface. Then press the “Enter” key to exit Off Mode.

32

33

Page 19

SettingSetting

8. Setting

8.1 Control Panel

C

B

Object

A

B

C

D

E

F

G

H

Name

LCD

Screen

Indicator

LED

Function

Button

A

D

X1-ACX1-AC

EFGH

Description

Display the information of the inverter.

Light in blue: The inverter is in normal status.

Flash in blue: The inverter is in waiting status.

Light in yellow: The battery communication is normal.

Flash in yellow: The battery is in idle mode.

Light in red: The inverter is in fault status.

ESC button: Return from current interface or function.

Up button: Move cursor to upside or increase value.

Down button: Move cursor to downside or decrease value.

OK button: Confirm the selection.

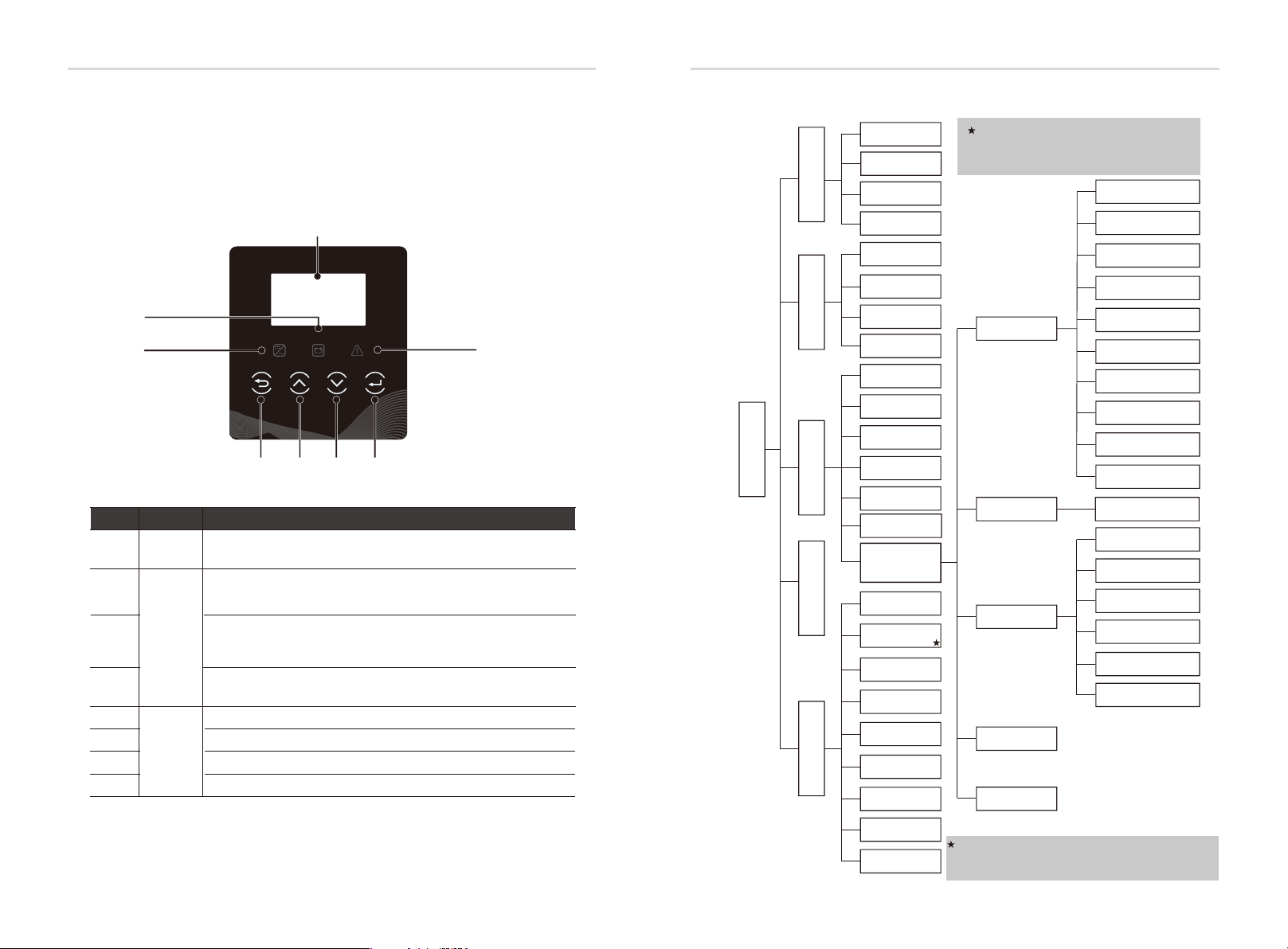

8.2 Menu Structure

Status

History

Menu

Setting

System Switch

About

Grid

Charger

Load

Charger-setting

Inverter Yield

Load Consume

Meter Yield

Error Logs

Date Time

Language

Work Mode

RF Control

RS485/Modbus

Self Test

Advanced

need password

Inverter SN

Register SN

Inverter Type

Inverter DSP1

Inverter DSP2

Manager ARM

Internal Code

All advance setting can only be set

by the technician or the installer with

the installer password.

Safety

Power Factor

Grid

Export Control

On-grid

Battery

Reset

Meter Setting

New Password

Remote Control

Grid Service

P(U) Function

DRM Function

W(Gra)

Power Limit

Charger

Reset Errorlog

Reset Meter Energy

Reset Load Consume

Config Guide

Reset Inverter Energy

Factory Reset

34

SystemRunTime

BAT_Version

Register SN: it indicates the serial number of the

external monitoring devices,such as pocket WiFi,

pocket LAN and pocket GPRS.

35

Page 20

SettingSetting

Status

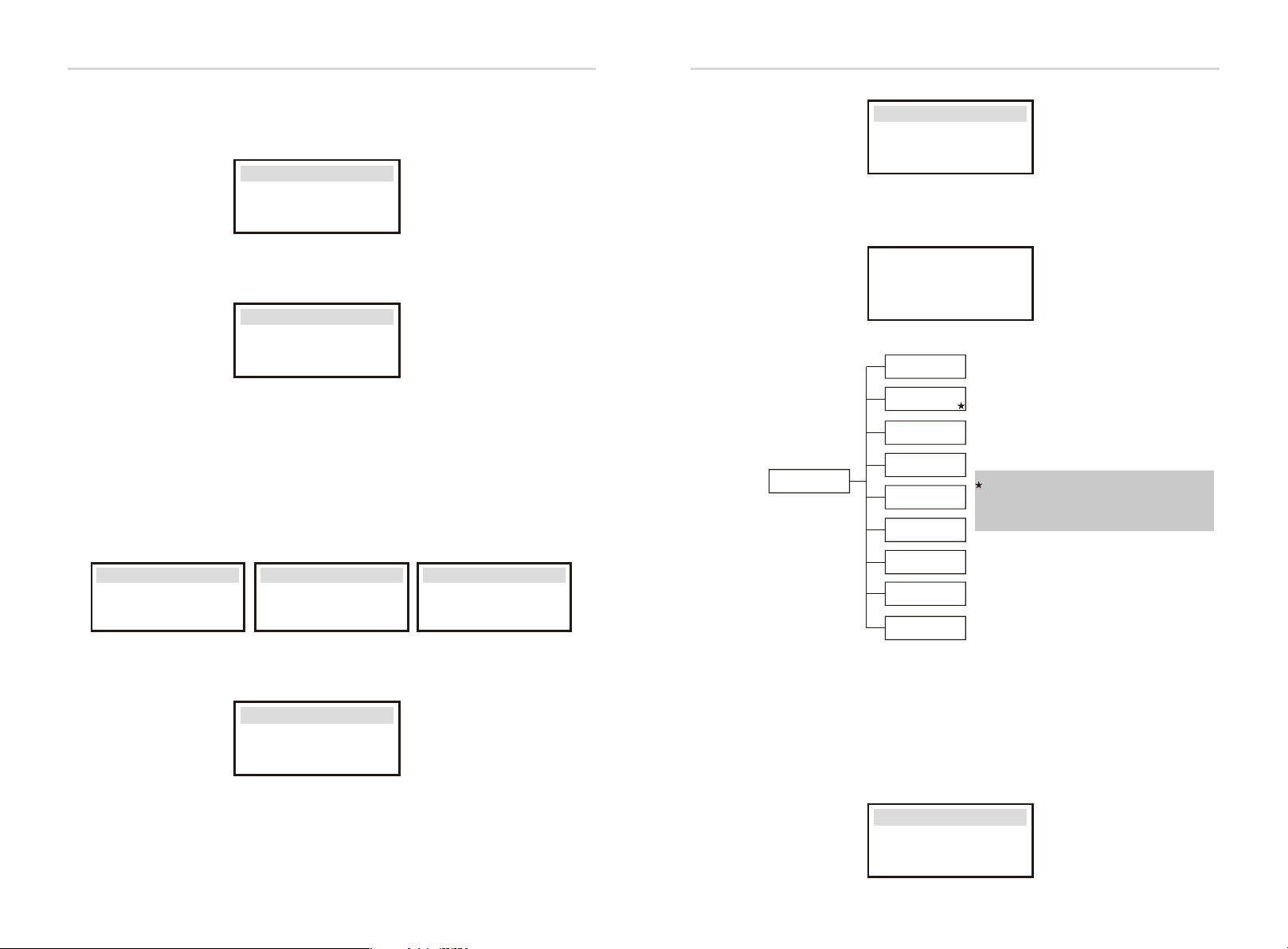

8.3 LCD Operation

Ø

LCD Digital Display

The main interface is the default interface, the inverter will automatically jump to

this interface when the system started up successfully or not operated for a

period of time.

The information of the interface is as below. “Power” means the instant output

power; “Today” means the power generated within the day. “Battery” means the

left capacity of lithium battery energy(%) shown as the table, while the unit of

lead-acid battery is voltage(V).

Power 0W

Today 0.0KWh

Battery

Normal

%

Menu interface

The menu interface is a transfer interface for user to get into another interface

to change the setting or getting the information.

-User can get into this interface by pressing “OK” button when LCD displays the

main interface.

-User can select interface by moving the cursor with function button,and press

“OK” to confirm.

Menu

Status

History

Settings

Grid

Charger

Status

Load

Charger-settings

● Status

The status function contains three items of the inverter(grid, charger and Load).

Press up and down to select and press “OK” to confirm the selection, press “ESC”

to return to Menu.

Status

Grid

Charger

Load

a) Grid

This status shows the current grid condition such as voltage, current, output

power , the local consumed power and the frequency.

Pout measures the output of the inverter;

Pgrid measures power export to or import from grid.

Positive value means the energy feeds into grid, negative value means the

energy used from the grid.

36

Status

History

Menu

Setting

System Switch

Grid

U 000.0V

I 00.0A

Pout 00.0W

About

37

Page 21

SettingSetting

b) Charger

This status shows the charger situation of the system, including the battery

voltage, charge or discharge current and power, battery capacity, battery

temperature( “+” means in charging; “-” means in discharging) and system

voltage.

Charger

U 100.0V

I +1.0A

P +100W

c) Load

If the inverter is plugged with a smart plug, this status shows the real time

load power, include load1 power, load1 switch, load2 power and load2

switch.

L1 Power

Load

0.0W

c) Charger-Settings

The user can watch the parameters (min capacity, max charge current and

max discharge current) of the lead-acid battery, if the user choose the lead-

acid battery.

History

Ø

History

● History

Inverter Yield

Load Consume

Meter Yield

Error Logs

The history function contains four items of the information: Inverter yield, load

consume, meter yield and error logs.

Press up and down to select, and press “OK” to confirm the selection, press “ESC”

to return to Menu.

History

Inverter Yield

Load Consume

Meter Yield

a) Inverter Yield

This Inverter Yield contains four items: OutputGridToday, OutputGridTotal,

InputGridToday and InputGridTotal.

38

ChargerSettings

>Min Capacity

20%

ChargerSettings

Imax_charge

35A

Chargersettings

Imax_discharge

35A

Inverter Yield

>OutputGridToday

0.8KWh

39

Page 22

SettingSetting

b) Load consume

The Load consume contains the energy consumed by specific loads by today

and total.

Load consume

>Load 1 consume

Load 2 consume

c) Meter Yield

The Meter Yield contains four items: FeedInToday, FeedInTotal, ConsumeToday

and ConsumeTotal.

d) Error Logs

The Error logs record the lastest six error messages happened.

Meter Yield

>FeedInToday:

0.0KWh

Error logs

>

No error

Ø

Setting

Setting

(a)

Date Time

(b)

Language

c)(

Work Mode

(d)

Relay Control

(e)

RS485/Modbus

(f )

Self Test

(g)

Advanced

need password

(g- 1)

On-grid

(g- 2)

Battery

(g- 3)

Reset

(g- 4)

Meter Setting

Safety

Power Factor

Grid

Export Control

Remote Control

Grid Service

P(U) Function

DRM Function

W(Gra)

Power Limit

Charger

Reset Errorlog

Reset Meter Energy

Reset Load Consume

Config Guide

Reset Inveter Energy

Factory Reset

(g- 1-1)

(g- 1-2)

(g- 1-3)

(g- 1-4)

(g- 1-5)

(g- 1-6)

(g- 1-7)

(g- 1-8)

(g- 1-9)

(g- 1-10)

(g- 2-1)

(g- 3-1)

(g- 3-2)

(g- 3-3)

(g- 3-4)

(g- 3-5)

(g- 3-6)

40

(g- 5)

New Password

● Setting

This function is used for setting the time, connection, battery, grid and

others below of the inverter.

Enduser can set Date Time, Language, Woke Mode, Relay Control and

RS485CommAddr directly.

But for advanced setting, it requires installer password to operate most of

the professional settings.

Settings

Date Time

Language

Work Mode

41

Page 23

SettingSetting

a) Date Time

This interface is for user to set the system date and time.

Date time

2018 ->06 <-06

10:19

b) Language

This inverter provides the languages for customer to select.

Language

English

Deutsch

c) Work Mode

There are 4 work modes for choice.

Users can set the modes such as Self Use, Feedin Priority, Back up Mode and Force

Time Use.

Work Mode

> Mode Select

Self Use

ParameterComment

Because there is no PV supplied, battery will discharge for local

Self Use

(default)

loads firstly, and grid will supply power when the battery

capacity is not enough.

Battery will stop discharing to keep higher capacity when the

grid is on. Only when the gird is off is not enough, battery will

Back Up Mode

start to discharge to keep the emergency load working

normally.

This work mode applies to the area where suffering from

blackout regularly.

The priority of inverter output power is:

Feed in Priority

feeding to the grid supplying the load charging the

battery.

This work mode applies to the area with high feed-in tariff.

In this work mode the charging and discharging time can be set

Force Time Use

flexibly, and it also allows to choose whether charge from the

grid or not.

For “Force Time Use” mode, there are 4 parameters that needs to be set.

Work Mode

>Mode Select

Force time use

Work Mode

> Charge

Start time 1

08:00

42

Parameter

Charger start time1

Charger end time1

Charger start time2

Charger end time2

Commen t

The start time of the rst charger period.

The end time of the rst charger period.

The start time of the second charger period.

The end time of the second charger period.

43

Page 24

SettingSetting

d) RF Control

RF Control is an optional function which can control designated load

intelligently by consuming the surplus energy when feed in power reaches

certain value.

This function can only be achieved with solax product “Smart Plug”.

For specific operation, please refer to “ Smart Plug user manual”.

RF Control

>RF1 Setting

>RF2 Setting

e) RS485/MODBUS

User can set the the braud rate (9600, 14400, 19200, 38400, 56000, 57600 and

115200)and modbus communication address (1~255).

RS485/Modbus

>Braud Rate:

115200

RS485/Modbus

>RS485 Addr:

1

f)Self Test (applies to CEI 0-21 only)

user can test operating status of inverter by choosing ”Start Test” . It will turn back

to the Home page automatically and shows ”SelfTesting...”. 60 seconds later, it will

display “success” , which means selftest completed successfully. Then it will turn

back to the“Test Report” page as below automatically and shows specic parameters.

Test Report

Start Test

Test Report

01234560123456

OvpValue 0.0V

OvpTime 0ms

g) Advanced

All the advance setting can be set here, such as battery, grid, meter and so on.

“Advanced” is divided five parts: On-grid, Battery, Parallel Setting, Reset, Meter

Setting and New Password. And every part has lower level parts.

Please contact with your installer or factory for the installer password to enter.

Advanced

On-grid

Battery

Reset

44

(g- 1)

On-grid

Safety

Power Factor

Grid

Export Control

Remote Control

Grid Service

P(U) Function

DRM Function

W(Gra)

Power Limit

(g- 1-1)

(g- 1-2)

(g- 1-3)

(g- 1-4)

(g- 1-5)

(g- 1-6)

(g- 1-7)

(g- 1-8)

(g- 1-9)

(g- 1-10)

g-1-1) Safety

User can set safety standard according to different countries and grid tied

stanndards.There are 8 standards to select. (May change without notice)

Item

1

2

3

4

5

6

7

8

Standard

VDE 0126

ARN 4015

AS 4777

G83/2

G59/3

EN 50438_NL

CEI 0-21

IEC61727_In

Country

German

German

Australia

UK

UK

Netherland

Italy

India

g-1-2) Power Factor ( For specific country if required by the local grid.)

There are 6 modes for selecting: Off , Lagging, Leading, Curve, Q(u)

and Fixed Q Power.

ModeComment

Off

LaggingPF value

LeadingPF value

Curve

Q( u )

Fixed Q PowerQ Power

-

Upper limit

Lower limit

Power Upper

Power Lower

PFLockInPoint ( CEI 0-21 only)

PFLockOutPoint ( CEI 0-21 only)

QuVupRate ( EN50438_NL only)

QuVlowRate ( EN50438_NL only)

45

Page 25

SettingSetting

Reactive power control, Reactive standard curve cos φ = f(P)

For VDE ARN 4105, curve cos φ = f(P) should refer to curve A. default value of setting is as

shown in curve A.

For E 8001, curve cos φ = f(P) should refer to curve B. default value of setting is as shown in

curve B.

For CEI 0-21, default value of PFLockInPoint is 1.05, when Vac > 1.05Vn, and Pac> 0.2 Pn,

curve cos φ = f(P) should refer to curve C. Default value of PFLockOutPoint is 1, when Vac < 1

Vn, cos φ = f(P) will exit curve C.

Upper limit

0.9

Power Upper

0.7

curve A

0.50.21.0

curve C

f (P)

0.9

cosφ

0.95

0.95

inductive

Power Lower

capactive

Lower limit

inductive

capactive

0.3

Reactive power control, Reactive standard curve Q= f(V)

Q

Qmax

V1iV2i

-Qmax

f (P)

0.9

0.9

V2sV1s

Upper limit

inductive

0.2

0.3

Power Lower

capactive

Lower limit

V2s=1.10Vn

V1s=1.08Vn=QuVlowRate

V2i=0.90Vn

V2i=0.92Vn=QuVlowRate

V

curve B

Power Upper

0.8

0.7

f (P)

g-1-3) Grid

The enduser do not need to set the grid parameters. All default value has set on

factory according to safety rules.

If need to reset, any changes should according to the requirement of local grid.

ParameterComment

Normally

Vac upper

Voltage high protect

Vac lowerVoltage low protect

Vac upper slowVoltage high slow protect

Vac lower slowVoltage low slow protect

Fac upperFrequency high protect

Fac lower

Frequency low protect

Fac upper slowFrequency high slow protect

Fac lower slowFrequency low slow protect

Vac 10m avg10 min voltage high protect

Apply to Italy(CEI0-21) only.

Tuvp_FastOvervoltage protect fast time

Tovp_FastUndervoltage protect fast time

Tufp_FastOverfrequency protect fast time

Tofp_FastUnderfrequency protect fast time

Tuvp_Slow

Tovp_Slow

Tufp_Slow

Tofp_Slow

FreDrpDlyTime

Overvoltage protect slow time

Undervoltage protect slow time

Overfrequency protect slow time

Underfrequency protect slow time

Frequency droop delay time

Apply to EN50438_NL only.

FreqSetPoint

FreqDropRate

Frequency set point

Frequency droop rate

g-1-4) Export control

This function allows the inverter able to control energy.There are user value and

factory value. The factory value is default which can not be changed by user. The

user value setting by installer must be less than the factory value.

Choose”Disable” means the function will be shut off.

Export Control

User value:

4000W

46

47

Page 26

SettingSetting

g-1-5) Remote Control

Remote control function allows external control device to make the inverter

remote cluster control through 485 port on the inverter. And it can control

the inverter’s active power output and reactive power output.

The default value is “enable”. Choose “disable” means the funciton is turn off.

If you have the requirement, please feel free to let us know.

Remote Control

>Func Select

>Enable<

connecting...

g-1-6) Grid Service(applies to CEI 0-21)

Grid Service can be selected from “Enable” or “Disable” . The default is “Enable”.

According to the requirements for the safety of battery storage inverter is different.

some may be opposite to the rights of the user. User can select “Disable” to turn off

these features if user receives legal permission.

Grid Service

Func Select

>Enable<

g-1-8) DRM Function(applies to NZS4777.2)

DRM function is Demand Response Mode which is required by standard

NZS4777.2 and applies to NZS4777.2 only.

The default value is “enable”. Choose “disable” means the function is turned off.

DRM Function

Function:

Enable

g-1-9) W(Gra) (applies to NZS4777.2)

W(Gra) is Gradient of power rate limit which is required by standard NZS4777.2

and applies to NZS4777.2 only. This funciton is defined as a precentage of rated

power per minute.

The default value is “enable”. Choose “disable” means the function is turned off.

W(Gra) Setting

W(Gra):

16.67%

g-1-7) P(U) Function(For specific country if required by the local grid)

P(U) function is volt-watt response mode which is requried by some specific

country standard such as AS4777.2.

“Enable” is the default value and means this function is turned on.

Choose “Disable” means the function will be shut off.

P(U) Funciton

Function

>Enable<

48

g-1-10) Power Limit

The user can set the power limit of the inverter(0.0~1.0)

Power Limit

>Proportion

1.0

49

Page 27

SettingSetting

(g- 2)(g- 2-1)

Battery

Charger

g-2-1) Charger

Here the user can see the type of the battery and can (lithium or lead-acid)

set the parameters of min capacity, charge max current and discharge max

current. For the detailed parameters , please refer to below table.

For Lithium battery

Ø

Charger

>Min Capacity

20%

For Lead-acid-battery

Ø

Charger

Cha rge Absorp

Voltage

Charger

Cha rge Max

Current

0.0 V

0.0 A

Charger

Charge Max Current

Charger

Cha rge Float

Voltage

Charger

Dis charge Max

Current

30A

0.0 V

0.0 A

Charger

Discharge Max Current

Charger

Dis charge cut

Voltage

30A

0.0 V

Reset Errorlog

Reset Meter Energy

(g- 3)

Reset

Reset Load Consume

Config Guide

Reset Inverter Energy

Factory Reset

g-3-1) Reset Errorlog

User can reset all inverter errorlog record here.

Reset Errorlog

Reset

>No<

g-3-2) Reset Meter Energy

User can reset the meter energy record here.

Rst Meter Energy

Reset Meter1

>No<

(g- 3-1)

(g- 3-2)

(g- 3-3)

(g- 3-4)

(g- 3-5)

(g- 3-6)

(1) When the battery voltage reachs the value( discharge cut voltage for lead-acid battery,

min capacity for lithium battery) in on-grid mode(no PV power), battery will stop

discharging and the system will go into IDLE mode.

(2) The way to exit from “BAT power low”.

-Press ESC button can exit from “BAT power low” manually.

50

g-3-3) Reset Load Consume

User can reset the specific load’s energy if the inverter is installed with a

smart plug.

Rst Load Consume

Reset Load 1

>No<

g-3-4) Config guide

This interface will trigger the initial setting guide reset again.

Config guide

>Star t

51

Page 28

Setting

Setting

g-3-5) Reset Inverter Energy

User can reset the inverter energy records here.

Rst Inv Energy

Reset

>No<

g-3-6) Factory Reset

User can reset the factory settings to the original state.

Factory Reset

Factory Reset

>No<

g-4) Meter Setting

X1-AC inverter needs to work with Energy meter to achieve the functions.

User also can turn off meter function so that X1-AC inverter can work as

normal grid-tied inverter without meter connected.

In hybrid system, if there is other power device in the system to be monitored,

It can install two meters to monitor both solax inverter and other power device.

These two meters need to be set different to address. Address 001 and address

002 are default and will be written to meters in factory.

So user do not need to change the address except specific situation.

MeterSetting

>MeterFunction>Meter1Addr>Meter2Addr

Disable

MeterSetting

MeterSetting

1

2

System Switch

>Switch

>ON<

Long press “Enter” key can also switch on ”System Switch” “ON” or “OFF”.

Do you want to

Switch on ?

ON>

Inverter SN

Register SN

Inverter Type

Inverter DSP1

About

Inverter DSP2

Manager ARM

Internal Code

SystemRunTime

BAT-Version

Register SN: it indicates the serial number

of the external monitoring devices,such

as pocket WiFi,pocket LAN and pocket GPRS.

g-5) New Password

User can set the new password here.

New Password

>

0 0 0 0

System Switch

Ø

●”System Switch” can be chosen from “ON” or “OFF”.

“ON” means that the inverter is in working condition and which is default status.

“OFF” means that the inverter stop delivering all power, but the LCD remains on.

52

About

Ø

●This interface shows information of the inverter including inverter serial

number, register serial number, inverter type, inverter DSP1,inverter DSP2,

manager ARM, internal code, system run time and bat_version (The master

and the slave versions of the our supplied battery).

About

Inver ter SN

Register SN

Inverter Typle

53

Page 29

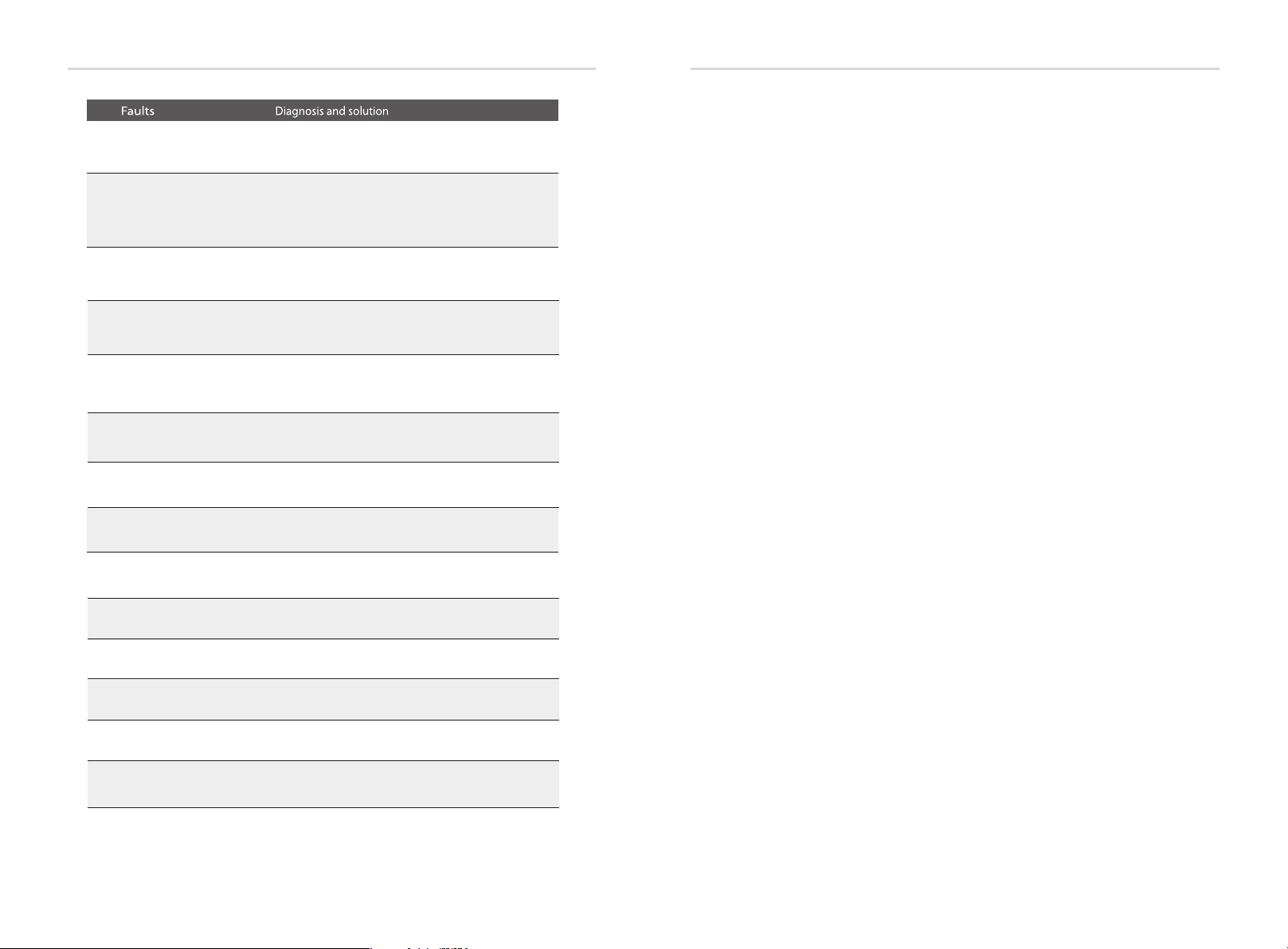

Troublesh ootin g

9. Troubleshooting

9.1 Trouble shooting

This section contains information and procedures for solving possible problems

with X1-AC inverters, and provides you with troubleshooting tips to identify and

solve most problems that could occur with the X1-AC inverters.

This section will help you narrow down the source of any problems you may

encounter. Please read the following troubleshooting steps.

Check warnings or fault messages on System Control Panel or Fault codes on the

inverter information panel. If a message is displayed, record it before doing

anything further.

Attempt the solution indicated in below table.

AC10M Volt Fault

DCI OCP Fault

SW OCP Fault

RC OCP Fault

Isolation Fault

The grid voltage is out of range for the last 10 Minutes.

• The system will back to normal if the grid is back.

• Or seek for help from us.

DCI over current protection Fault.

• Wait for a while to check if back to normal.

• Or seek for help from us.

Over current fault detected by software.

• Wait for a while to check if back to normal.

• Turn off the battery and grid , reconnect them.

• Or seek for help from us.

DCI over current protection Fault.

• Please check if the insulation of electric wires are damaged.

• Wait for a while to check if back to normal.

• Or seek for help from us.

Isolation Fault

• Please check if the insulation of electric wires are damaged.

• Wait for a while to check if back to normal.

• Or seek for help from us.

Troublesh ootin g

54

TZ Protect Fault

Grid Lost Fault

Grid Volt Fault

Grid Freq Fault

Meter Fault

Bus Volt Fault

Bat Volt Fault

Over current Fault.

• Wait for a while to check if go back to normal status.

• Disconnect battery and reconnect it.

• Or seek help from us, if can not go back to normal state.

Grid is Lost.

• Please wait for a while and system will reconnect if the utility is back to normal.

• Please check whether the cable connection at AC side is normal or not.

• Or seek help from us.

Grid Voltage Out of Range

• Please wait for a while and system will reconnect if the utility is back to normal.

• Please check whether the grid voltage is in the normal range.

• Or seek help from us.

Grid Frequency Out of Range

• System will reconnect if the utility is back to normal.

• Or seek help from us.

Meter Fault.

• Please check if the meter is abnormal working.

• Or seek for help from us if can not go back to normal.

Bus Voltage Out of Normal Range

• Disconnect battery, reconnect it.

• Or seek help from us, if can not go back to normal state.

Battery Voltage Fault

• Check if the battery input voltage.is within the normal range

• Or seek help from us.

Temp Over Fault

BatConDir Fault

Sample Fault

BMS Lost

Inter Com Fault

Fan Fault

AC H CT Fault

Temperature over the limitation

• Check if the envirement temperature is over limitation.

• Or seek help from us.

Battery Reverse Connection Fault

• Check if the positive pole and negtive pole of battery are connected

in a contrary way

• Or seek help from us.

The detection circuit Fault

• Disconnect battery, reconnect it.

• Or seek help from us.

BMS Communication Lost

• Check if the BMS cable is loose or broken.

• Or seek help from us, if can not go back to normal state.

Internal Communication Fault

• Turn off the battery and grid , reconnect them.

• Or seek help from us, if can not go back to normal state.

Fan Fault

• Turn off the battery and grid , reconnect them.

• Or seek help from us, if can not go back to normal state.

AC Current Sensor Fault

• Turn off the battery and grid , reconnect them.

• Or seek help from us, if can not go back to normal state.

55

Page 30

Troublesh ootin gTroublesh ootin g

● If your inverter's information panel is not displaying a Fault light, check the

following list to make sure that the present state of the installation allows

proper operation of the unit.

— Is the inverter located in a clean, dry, adequately ventilated place?

Inv EEPR OM Fault

Inverter EEPROM Fault

• Turn off the battery and grid , reconnect them.

• Or seek help from us, if can not go back to normal state.

— Are the cables adequately sized and short enough?

— Are the input and output connections and wiring in good condition?

— Are the configurations settings correct for your particular installation?

— Are the display panel and the communications cable properly

connected and undamaged?

Contact SolaX Customer Service for further assistance. Please be prepared to

describe details of your system installation and provide model and serial number

of the unit.

RCD Fault

Grid Relay Fault

OtherDevideFault

Residual Current Device Fault

• Check the impedance of AC output.

• Disconnect battery, reconnect it.

• Or seek help from us, if can not go back to normal state.

Grid Relay Fault

• Disconnect grid and battery, reconnect them.

• Or seek help from us, if can not go back to normal state.

Other Devide Fault

• Disconnect grid and battery, reconnect them.

• Or seek help from us, if can not go back to normal state.

Mgr EEPROM Fault

BMS_External_Err

BMS_TemHigh

BMS_TemLow

BMS_CellImblance

BMS_Internal_Err

BMS_OverVoltage

BMS_LowerVoltage

BMS_ChargeOCP

BMS_DischargeOCP

Manager E EPROM Fault.

• Turn off the battery and grid , reconnect them.

• Or seek for help from us if can not back to normal.

Battery Fault-extarnal fault

• Please contact battery suppiler.

Battery Fault-over-temperature fault

• Please contact battery suppiler.

Battery Fault-under-temperature fault

• Please contact battery suppiler.

Battery Fault-cell imbalance fault

• Please contact battery suppiler.

Battery Fault-intarnal fault

• Please contact battery suppiler.

Battery Fault-overvoltage fault

• Please contact battery suppiler.

Battery Fault-undervoltage fault

• Please contact battery suppiler.

Battery Fault-charge overcurrent fault

• Please contact battery suppiler.

Battery Fault-discharge overcurrent fault

• Please contact battery suppiler.

56

57

Page 31

Decommis sioni ng Troublesh ootin g

9.2 Routine maintenance

Inverters do not need any mainteinance or correction in most condition,but if

the inverter often loses power due to overheating,this can be the following

reason:

● The cooling fins on the rear of house are coverd by dirts.

Clean the cooling fins with a soft dry cloth or brush if necessary.

Only trained and authorized professional personnel who are familiar with the

requirements of safety was allowed to perform servicing and maintenance

work.

Safety checks

Ø

Safety checks should be performed at least every 12 mouths, please contact

manufacturer to arrange qualified person who has adequate training,kownledge,

and practical experience to perform these tests.(Please kindly noted this action is

not covered by warranty).The data should be recorded in an equipment log.If the

device is not functioning properly or fails any of test,the device has to be

repaired.For safety check details ,refer to this manual,section 2 Safety instruction

and EC Directives.

Maintain Periodically

Ø

Only qualified person may perform the following works.

During the process of using the inverter,the manage person shall examine and

maintain the machine regularly.The concrete operations are follow.

1: Check that if the cooling fins on the rear of house are covered by dirts, and the

machine should be cleaned and absorbed dust when necessary.This work shall

be check time to time.

2: Check that if the indicators of the inverter are in normal state,check if the keys

of the inverter are in normal state,check if the display of the inverter is normal.This

check should be performed at least every 6 months.

3: Check that if the input and output wires are damaged or aged.This check

should be performed at least every 6 months.

4: You should keep the inverter panels clean and their security checked at least

every 6 months.

10. Decommissioning

10.1 Remove the Inverter

Disconnect the inverter from DC Input and AC output.

Wait for 5 minutes for de-energizing.

Disconnect communication and optional connection wirings.

Remove the inverter from the bracket.

Remove the bracket if necessary.

10.2 Packaging

Please pack the inverter with the original packaging.

If the original package is no longer available, you can also use an equivalent

carton that meets the following requirements.

Suitable for loads more than 30 kg.

With handle.

Can be fully closed.

10.3 Storage and Transportation

Store the inverter in a dry environment where ambient temperature keep

always between -20 °C - +60 °C. Take care of the inverter during the storage

and transportation,keep less than 4 cartons in one stack.

When the inverter or other related components need to be disposed. Have

it carried out according to local waste handling regulations. Please be sure

to deliver wasted inverters and packing materials to certain site, where can

assist relevant department to dispose and recycle.

58

59

Page 32

Loading...

Loading...