品名

材料

料号

单位

页次

设计

审核

核准

技术要 求:

1.封面 封底157g铜 版纸覆亚光 膜彩打,内 部普通纸黑 白印刷正反 打印

2.未注 公差:±1

3.图面 、字体印刷 清晰、无毛 边

4.字体 颜色为PANTO NE Blac k C,无边框, 底色为白色

5.符合R oHS要 求

X1- Mini说明 书

614 .00 .01098

浙江艾罗 电源有 限公司

朱伟 20 16/6/ 28

朱娴红 2 016/6 /28

朱娴红 2 016/6 /28

21 0.0 0 mm

28 5. 0 0 mm

NA

REV. REV.

Description Description

0.0 1.0

1.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

1.0

V0.0首次发行 V0.1应BV认证要求修改文档

V0.1软件修改,升级固件的方式改动

朱伟 2016/1/25 朱伟 2016/6/28

朱伟 2016/7/5

朱伟 2016/3/15

朱伟 2016/3/28

朱伟 2016/4/5

朱伟 2016/4/21

朱伟 2016/4/26

朱伟 2016/5/12

朱伟 2016/5/12

朱伟 2016/6/20

V0.1增加updating和灯显

V0.2 Page7:DRM和RS 485调换位置

V0.3 将1000w改成1100w

V0.4 P21更改updating灯显;

将所有X1-mini改为X1&封皮修改。

V0.5 GFCI fault 改为rcd/rc fault;

usb烧录要求:PV输入电压大于100V。

V0.6 THD改成小于2%.

V0.7 P17 AC连接线线径2mm²改成12AWG

V0.1 机壳增加接地,修改图、安装部分。

品名

料号

单位

X1- Mini说明 书

614 .0009 8.01

页次

浙江艾罗 电源 有限公 司

Sola X Power Co ., Ltd.

Copy Declaration

The co pyrig ht of thi s manua l belon gs to Sol aX

Power C o.,Ltd .. Any cor pora tion or

indi vidua l shoul d not pla giari ze, par titia lly cop y or

X1 Se ries

User Manual

1.1kw~2.0kw

X1-2.0-S-D

X1-2.0-S-N

0.1

V0.5 Page23 升级ARM文件的格式

由".hex"改为".usb"

朱伟 2016/7/22

614 .0009 8.01

X1 Series

User Manual

1.1kw~2.0kw

Copy Declaration

The c opyri ght of th is manu al belo ngs to So laX Powe r Co.,Lt d.. Any c orpor ation o r indiv idual

sho uld not p lagia rize, p artit ially o r fully c opy(i nclud ing sof tware ,etc. ), and no re produ ction o r

dis tribu tion of i t in any fo rm or by any m eans. A ll righ ts rese rved. S olaX Po wer Co., Ltd,. reser ves

the r ight of f inal in terpr etati on.

Contents

1 NOTES ON THIS MANUAL

2 SAF E T Y

3 INT RODUCTI O N

4 TECHN I CAL DATA

5 FUN C T ION

6 INS TALLATION

7 OPE R ATIO N ME T HOD

8 TROUB L ESHOOTIN G

1.1 SCOP E OF VAL IDITY

... ..... ..... ..... .. .. ............. .. .. ............. .. ............. ..... ...

... ..... ..... ..... .. .. ............. .. .. ............. .. ............. ..... ..... ..... ..

... ..... ..... ..... .. .. ............. .. .. ............. .. ............. ..... ..... ..... ..

... ..... ..... ..... .. .. ............. .. .. ............. .. ............. ..... ..... ..... ..... .. .. ............. ..

... ..... ..... ..... .. .. ............. .. .. ............. .. ............. ..... ..... ..... .

... ..... ..... ..... .. .. ............. .. .. ............. .. ............. ..... ...

... ..... ..... ..... .. .. ............. .. .. ............. .. ............. ..... ..... ..

... ..... ..... ..... .. .. ............. .. .. ............. .. ............. ..... ..... ..... ..... .. .. ......

... ..... ..... ..... .. .. ............. .. .. ............. .. ............. ..... ..... ..... .....

... ..... ..... ..... .. .. ............. .. .. ............. .. ............. ..... ..... ..... ..... .. .. .

... ..... ..... ..... .. .. ............. .. .. ............. .. ....

... ..... ..... ..... .. .. ............. .. .. ............. .. ............. ..... ..... ..... ..... .

... ..... ..... ..... .. .. ............. .. .. ............. .. ............. .....

... ..... ..... ..... .. .. ............. .. .. ......

... ..... ..... ..... .. .. ............. .. .. ............. .. ............. ..... .....

... ..... ..... ..... .. .. ............. .. .. ............. .. ............. .

... ..... ..... ..... .. .. ............. .. .. ............. .. ............. ..... ..... ..

... ..... ..... ..... .. .. ............. .. .. ............. .. ........

... ..... ..... ..... .. .. ............. .. .. ............. .. ............. ....

... ..... ..... ..... .. .. ............. .. .. ............. .. ............. ..... ...

... ..... ..... ..... .. .. ............. .. .. ............. .. ............

... ..... ..... ..... .. .. ............. .. .. ............. .. ............. ..... ..... ..... ..... .. .. .....

... ..... ..... ..... .. .. ............. .. .. ............. .. ............. ..... ..... ..... ..... .. .. .

... ..... ..... ..... .. .. .............

... ..... ..... ..... .. .. ............. .. .. ............. .. ............. ..... ..... ..... ...

... ..... ..... ..... .. .. ............. .. .. ....

... ..... ..... ..... .. .. ...........

... ..... ..... ..... .. .. ............. .. .. ............. .. ....

... ..... ..... ..... .. .. ............. .. .. ............. .. ............. ..... ..... ..... .

... ..... ..... ..... .. .. ............. .. .. ............. .. ....

... ..... ..... ..... .. .. ............. .. .. ............. .. .........

... ..... ..... ..... .. .. ............. .. .. ............. .. .....

1.2 TARG ET GRO UP

1.3 SY MBO LS US ED

2.1 AP PROPR IATE U SAG E

2.2 IM POR TAN T SAF ETY INS TRU CTI ONS

2.3 PE CONN ECT ION A ND LE AKAGE CU RRENT

2.4 EX PLANAT ION OF S YMBOL S

3.1 BA SIC F EATU RES

3.2 T ERM INA LS OF PV IN VER TER

3.3 DI MENSI ON AN D WE IGH T

4.1 DC I NPU T

4.2 AC O UTPUT

4.3 EF FICIE NCY, SAF E T Y A ND PR OTECTI ON

4.4 GE NERAL DATA

6.1 PACK AGI NG

6.2 IN STALLATIO N PRE CAUTI ON

6.3 PR EPARAT ION

6.4 IN STALLATIO N STE PS

6.5 CONN ECTI ONS OF THE X 1 SYS TEM

6.6 RU N TH E I NVE RTE R

7.1 IN DICATOR PAN EL

7.2 IN DICATOR INF ORM ATI ON

8.1 TOU BOL ESHOOTI NG

8.2 RO UTINE MA INT ENA NCE

01

01

01

01

02

02

04

06

06

08

08

09

10

11

11

11

12

12

13

14

14

14

15

15

17

25

26

26

27

30

30

32

Note!

Note provides tips that are valuable for the optimal operation

of your product.

X1- 1.1-S -N

X1- 1.1-S -D

X1- 1.5-S -N

X1- 1.5-S -D

X1- 2.0-S -N

X1- 2.0-S -D

Ple as e store thi s ma nu al where it w il l be a ccessible a t all tim es.

Note: “1.1” means 1.1kW. ”S” means “single” or one MPPT string. “D” means

with “DC Switch”, ”N” means without “DC Switch”.

9 DECOMM I SSION I NG

... ..... ..... ..... .. .. ............. .. .. ............. .. ............. ....

... ..... ..... ..... .. .. ............. .. .. ............. .. ............. ..... ...

... ..... ..... ..... .. .. ............. .. .. ..........

... ..... ..... ..... .. .. ............. .. .. ............. .. ............. ..... ..... ..... ..... .. .. .....

9.1 DE COMMI SSI ONI NG

9.2 STOR AGE A ND TRAN SPORTATION

9.3 DI SPOSA L

34

33

33

33

inverters.

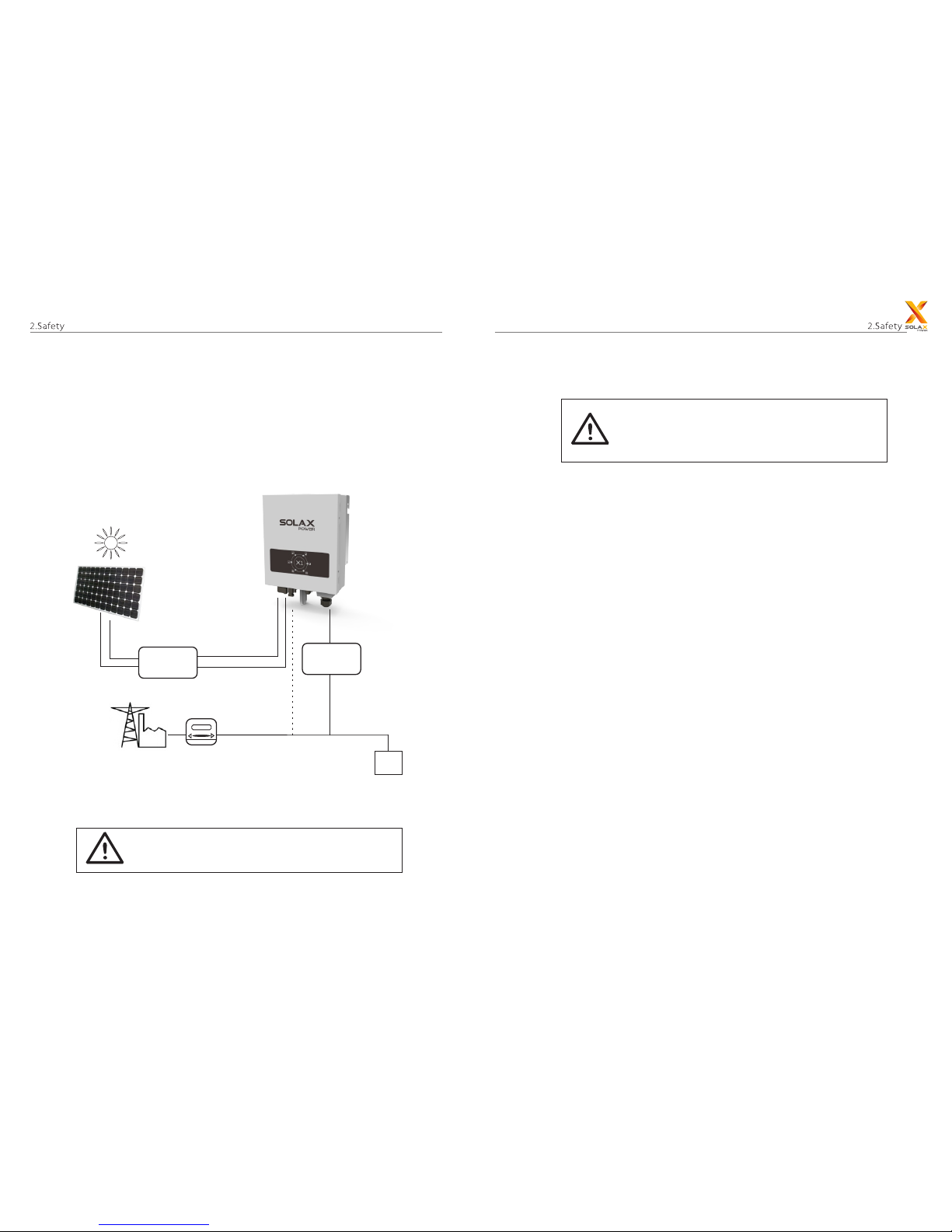

2 Safety

2.1 Appropriate Usage

The X1Series are PV inverters which can convert the DC current of the P V

generator into AC current and feed it into the public grid.

Surge protection devices (SPDs) for PV installation

Over-voltage protection with surge arresters should be provided

when the PV power system is installed.

The gr id connec ted i nverter is not fitted with SPDs in both PV

input side and MAINS side.

WARNIN G!

For X1-1.1-S-N, X1-1.5-S-N, X1-2.0-S-N, external dc breaker must

be connected on the PV side.

CAUTION!

Induced surges are the most likely cause of lightning damage in majority or installations,

especially in rural areas where electricity is usually provided by long overhead lines.

Surge may be included on both the PV array conduction and the AC cables

leading to the building.

Specialists in lightning protection should be consulted during the end use application.

Using appropriate external lightning protection, the effect of a direct lightning

strike into a building can be mitigated in a controlled way, and the l ightn ing

current can be discharged into the ground.

Installation of S PDs to protect the inverte r against mechanical damage and

excessive stress include a surge arrester in case of a b uilding with ex terna l

lightning protection system (LPS) when separation distance is kept.

To protect the DC system, surge suppression device (SPD type2) should be fitted

at the inverter end of the D C cabling and at the array located between the

inverter and the PV generator, if the voltage protection level (VP) of the surge

arresters is greater than 1100V, an additional SPD type 3 required for surge protection

for electrical devices.

To protect the AC system, surge s uppression devices (SPD type2) should be

fitted at the main incoming p oint of A C supply (at t he co nsume r’s cutout ),

located between the inverter and the meter /dist ribution system; S PD ( test

impulse D1) for signal line according to EN 61632-1.

All DC cables should be installed to provide as short a run as possible, and positive

and negative cables of the string or main DC supply should be bundled

together. Avoid ing the creation of loops in t he system. This requirement for

short runs and bundling includes any associated earth bundling conductors.

Spark gap devices are not suitable to be used in DC circuits once conducting,

they won’t stop conducting until the voltage across their terminals is typically

more than 30 volts.

Lightning will cause a damage either from a direct strike or from surges due to a

nearby strike.

►

DC di stri butio n box

AC di stri butio n box

Ele ctric al

gri d

Ele ctric m eter,

bid irect ional

Loa d

PV a rray

Surg e arres tor

Fuse

DC br eaker

Surg e arres tor

Fuse

AC br eaker

2

3

2.2 Import an t Sa fety I ns tr uc ti on s

Dan ger!

Danger to life due to high voltages in the inverter!

All work must be carried out by qualified electrician.

The appliance is not to be used by children or persons with

reduced physical sensory or mental capabilities, or lack of

experience and knowledge, unless they have been given

supervision or instruction.

Children should be supervised to ensure that they do not play

with the appliance.

Cau tion!

Danger of burn injuries due to hot enclosure parts!

During operation, the upper lid of the enclosure and the

enclosure body may become hot.

Only touch the lower enclosure lid during operation.

Cau tion!

Possible damage to health as a result of the effects of radiation!

Do not stay closer than 20 cm to inverter for any length of time.

Not e!

Grounding the PV generator.

Comply with the local requirements for grounding the PV

modules and the PV generator. SolaX recommends connecting

the generator frame and other electrically conductive surfaces

in a manner which ensures continuous conduction and ground

these in order to have optimal protection of system and persons.

Warni ng!

Ensu re input DC voltage ≤Ma x. DC voltage .O ver vol tage

may cause permanen t damage to inve rte r or other losses,

whic h will not be i ncluded i n warrant y!

Warnin g!

Authorized service personnel must disconnect both AC and

DC power from X1-boost before attempting any maintenance

or cleaning or working on any circuits connected to the X1boost.

Prior to the application, please read this section carefully to ensure correct

and safe application. Please keep the user manual properly.

Use only attachments recommended or sold by SolaX. Otherwise may

result in a risk of fire, electric shock, or injury to person.

Make sure that existing wiring is in good condition and that wire is not

undersized.

Do not disassemble any parts of inverter which are not mentioned in

installation guide. It contains no user-serviceable parts. See Warranty for

instructions on obtaining service. Attempting to ser vice the X1-boost Series

inverter yourself may result in a risk of electric shock or fire and will void

your warranty.

Keep away from flammable, explosive materials to avoid fire disaster.

The installation place should be away from humid or corrosive substance.

Authorized service personnel must use insulated tools when installing or

working with this equipment.

PV modules shall have an IEC 61730 class A rating.

Never touch either the positive or negative pole of PV connecting device.

Strictly prohibit touching both of them at the same time.

The unit contains capacitors that remain charged to a potentially lethal voltage

after the MAINS and P V supply has been disconnected.

Hazardous voltage will present for up to 5 minutes after disconnection from

power supply.

CAUTION-RISK of electric shock from energy stored in capacitor,. Never operate

on the solar inverter couplers, The MAINS cables, PV cables or the P V generator

when power is applied. After switching off the PV and Mains, always wait for

5minutes to let the intermediate circuit capacitors discharge before you unplug

DC and MAINS couplers.

When accessing the internal circuit of solar inverter, it is very important to wait

45minutes before operating the power circuit or demounting the electrolyte

capacitors inside the device. Do not open the device before hand since the

capacitors time to sufficiently discharge! require

Measure the voltage between terminals UDC+ and UDC- with a multi-meter

(impedance at least 1Mohm) to ensure that the device is discharged before

beginning work (35VDC) inside the device.

Do not operate the inverter when the device is running.

Warning!

Risk of electric shock!

Warning!

4

5

2.3 PE Connection and Leakage Current

Island detection method

• The end-use application shall monitor the protective conductor by residual

current operated protective device (RCD) with rated fault current Ifn≤240mA

which automatically disconnects the device in case of a fault.

• DC differential currents are created (caused by insulation resistance and through

capacities of the PV generator). In order to prevent unwanted triggering during

operation, the rated residual current of the RCD has to be min 240mA.

The device is intended to connect to a PV generator with a capacitance limit of

approx 700nf.

High leakage current!

Earth connection essential before connecting supply.

WARNIN G!

• Incorrect grounding can cause physical injury, death or equipment malfunction

and increase electromagnetic.

• Make sure that grounding conductor is adequately sized as required by safety

regulations.

• Do not connect the ground terminals of the unit in series in case of a multiple

installation. This product can cause current with a d.c component, Where a residual

current operated protective (RCD) or monitoring (RCM) device is used for protection

in case of direct or indirect contact, only an RCD or R CM of type B is allowed

on the supply side of this product.

2.4 Explanation of Symbols

This section gives an explanation of all the symbols shown on the inverter and

on the type label.

Symbols on the Type Label

Symbol Explanation

CE mark.

The inverter complies with the requirements of the applicable

CE guildlines.

TUV certified.

RCM remark.

SAA certification.

Beware of hot sur face.

The inverter can become hot during operation. Avoid contact

during operation.

Danger of high voltages.

Danger to life due to high voltages in the inverter!

Danger.

Risk of electric shock!

Observe enclosed documentation.

The inverter can not be disposed together with the household waste.

Disposal information can be found in the enclosed documentation.

Do not operate this inverter until it is isolated from battery,mains

and on-site PV generation suppliers.

Danger to life due to high voltage.

There is residual voltage in the inverter which needs 5 min to

discharge.

• Wait 5 min before you open the upper lid or the DC lid.

No protection settings can be altered.

For Australia and New Zealand:

Electrical installation and maintenance shall be conducted by licensed

electrician and shall comply with Australia National Wiring Rules.

The island detection method for X1 series inverter is Active Frequency Drift

(AFD).

6

7

For United Kindom:

RS 485 communication interface.

PC remote control.

Update system by USB.

Plug and Play Pocket WiFi.

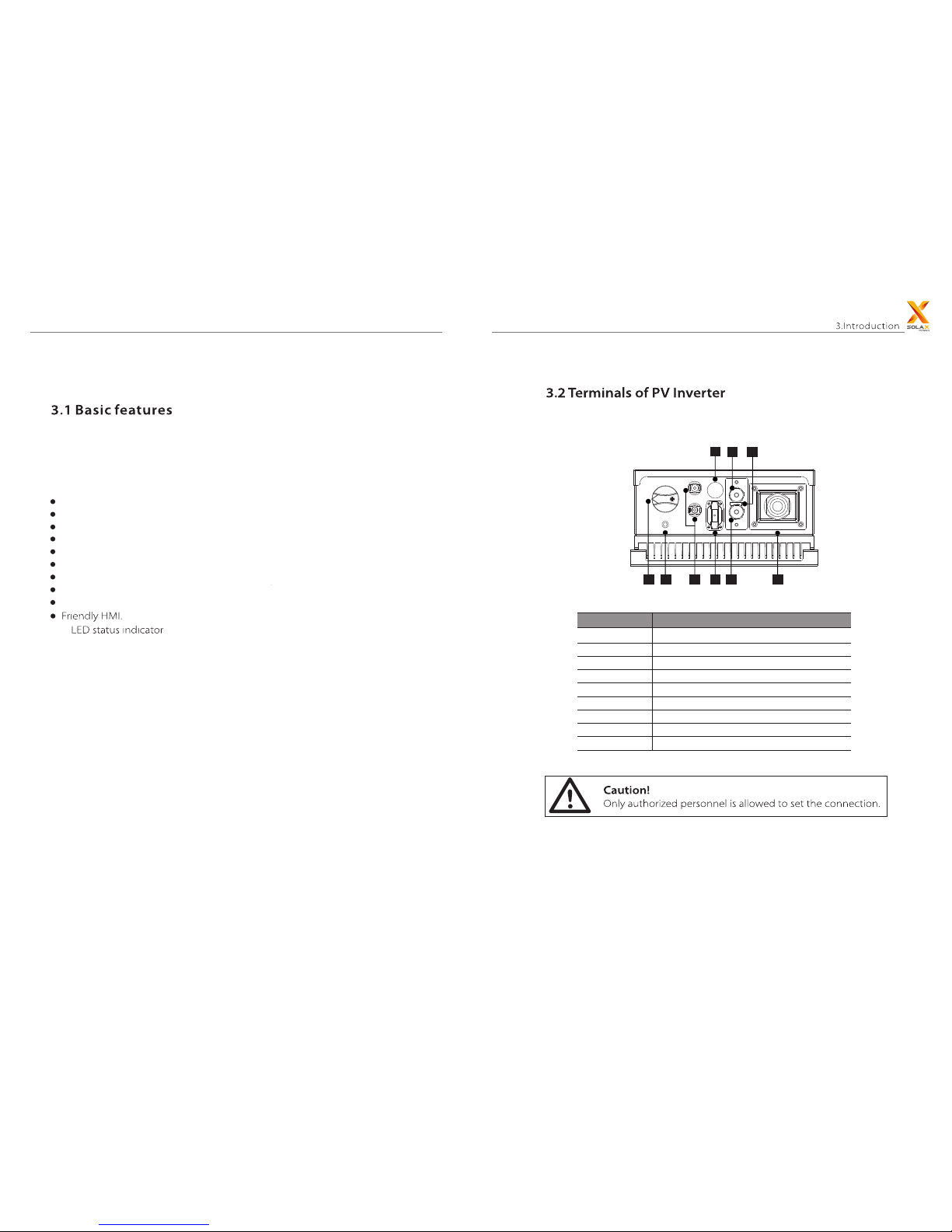

3. Introduction

A I B

D

CHE

F G

Object

A DC Switch (opt)

DC Connector

WiFi (opt)

E.F.Alarm (opt)

DRM

RS 485

USB for Update

AC Connector

Ground connection

B

C

D

E

F

G

H

I

Description

Congratulations on your purchase of a X1 Series inverter from SolaxPower

company.

The X1 Series inverter is one of the finest inverter on the market nowadays,

incorporating state-of-the-art technology, cost-effective, high reliability.

Optimal MPPT technology.

Advanced anti-islanding solutions.

Excellent protections.

IP 65 protection level.

Efficiency up to 97%.

THD < 3%.

Current (inrush) < 60A.

Maximum output fault current < A.50

Safe & Reliable: transformer-less design with software and hardware protection.

8

9

3. Instruction

Model

Net Weight

Gross Weight

7KG

9KG

7KG

9KG

7KG

9KG

Rated Output Power

Max.Output Power

Nominal Voltage

Max.Output Current

Maximum Output

fault current

On-grid Connection

Voltage Range

Frequency Range

Nominal Frequency

Power Factor

THD

24 8mm

35 0mm

124mm

X1-1.1-S-D

X1-1.1-S-N

X1-1.1-S-D

X1-1.1-S-N

X1-1.5-S-D

X1-1.5-S-N

X1-1.5-S-D

X1-1.5-S-N

X1-2.0-S-D

X1-2.0-S-N

X1-2.0-S-D

X1-2.0-S-N

1250W 1650W 2200W

400V

360V

70~380V 70~380V 70~380V

10A 10A 10A

12A 12A 12A

1

1

400V 400V

Model

Model

Max.PV Input Power

Max.PV Voltage

Max.PV Current

ISC PV

Nominal Voltage

MPPT Voltage Range

MPPT Tracking No.

No. of PV Input

1100VA

1100VA

1500VA

1500VA

2000VA

2000VA

Single-Phase

180-280V

220/230/240V

5.5A 7.5A 9.5A

7A 9A

11A

50/60Hz

44-55/55-65 Hz

0.8leading~0.8lagging

<2%

X1-1.1-S-D

X1-1.1-S-N

X1-1.5-S-D

X1-1.5-S-N

X1-2.0-S-D

X1-2.0-S-N

10

11

checking if PV array has enough power to

The corresponding state of the inverter shows as right. “ “

The corresponding state of the inverter shows as right. “ “

Under this mode, X1 series inverters convert PV array’s DC into AC and feed back

into grid.

The corresponding state of the inverter shows as right. “ “

If any fault/error occurs, the inverter will stop delivering power until the fault/error

is cleared. Some fault/error will auto recover, and some may need manual restart.

If inverter passed load-dump test and no error/fault occurs, start checking to

deliver power.

feedback into grid.

Operation Mode

[Waiting Mode]

[Checking Mode]

[Fault Mode]

It is normal that the inverter decreases the power output in

the condition of thermal protection, but if this phenomenon

occurs frequently, you need to check the heatsink, or

consider putting the inverter in the place where have better

air ow. If output power decreases caused by electrical,

please ask for professional supports.

Euro - Efficiency

95.5%

97.1%

99.9% 99.9%99.9%

96.5%96%

97.1%97.1%

YES

YES

YES

YES

YES

Max.Efficiency

Over Voltage Protection

Over Current Protection

DC isolation Impedance

Monitoring

MPPT Efficiency

Safety & Protection

Ground Fault Current

Monitoring

DC injection Monitoring

Protective Class

Net Dimension(W/H/D)

Wall-mounted

-20℃~ +60℃(derating at 45℃)

248*350*124mm

7kg

-20℃~ +60℃

0%~95%,no condensation

<2000m

IP 65 (for outdoor use)

Transformerless

0W

<10W

Natural Cooling

<30dB

RS485/WiFi(optional)/USB/DRM

5years(10 years optional)

Ⅱ / Ⅲ

Net Weight

Storage Temperature

Storage/Operation

Relative Humidity

Altitude

Installation

Operating Temperature

Range

Protection Level

Isolation Type

Night-time Consumption

Operating Loss

Cooling

Noise Level

Communication Interface

Standard Warranty

Pollution degree

Over voltage range(PV/AC)

Ⅱ

12

13

X1-1.1-S-D

X1-1.1-S-N

X1-1.5-S-D

X1-1.5-S-N

X1-2.0-S-D

X1-2.0-S-N

Model

X1-2.0-S-D

X1-2.0-S-N

X1-1.1-S-D

X1-1.1-S-N

X1-1.5-S-D

X1-1.5-S-N

Model

4. Technical data

Left

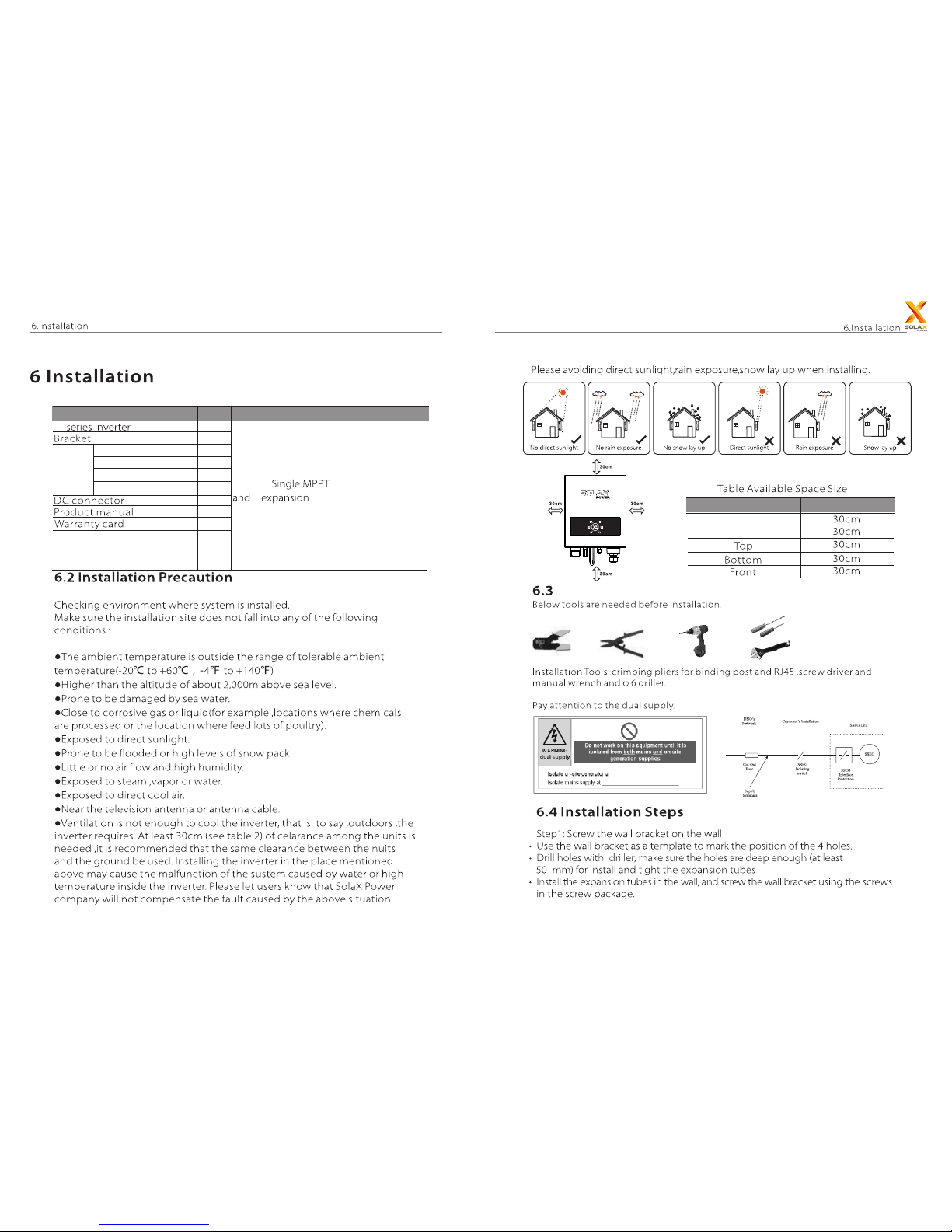

Right

2 expansion screws

1.1~2kw

AC terminal

Pocket WiFi (optional)

Description QTY Remark

X1

Position Min.size

3

1

1

1

1

2

1

2

2

1

1

1

Preparation

Expansion tube

Expansion screw

Cross recessed screw

Ring terminal

Screw

package

2

tubes;

6.1 Packaging

14

15

Quick installation

connected

inverter only after eliminating these problems.

1.1 k w - 2.0 kw

6.5 .1 The Mai n Steps to Con nect The I nverter

X1 se ries inve rter h ave one- st ri ng P V conn ec tor.

Max.DC Voltage

400V 400V 400V

Connections of the Inverter

PV String

16

17

X1-1.1-S-D

X1-1.1-S-N

X1-1.5-S-D

X1-1.5-S-N

X1-2.0-S-D

X1-2.0-S-N

Model

Cable

Micro-Breaker

12AWG

10A

16A 16A

12AWG 12AWG

I

X1 se ries inve rter a re d esign ed for si ngle phase gr id . Voltage rang e is

X1 series

recommended

AC Output Connection

18

19

X1-1.5-S-D

X1-1.5-S-N

X1-2.0-S-D

X1-2.0-S-N

X1-1.1-S-D

X1-1.1-S-N

Model

(refer to technical data)

stripped

L

N

P

E

WiFi Connection (optional)

Ground Connection

You can read the real time data in the internet either from PC or smartphone

with WiFi monitoring.

Screw the ground screw with allen wrench shown as follow.

Connection Step:

1. Open the WiFi lid on the back of the inverter.

2. Plug the Pocket WiFi (from Solax) into the port named “WiFi” on inverter,

and tighten the four screws as below.

L N PE

20

21

This product has a series communication interfaces : RS 485, USB, DRM.

Operating information like output voltage, current, frequency, fault information,

etc., can be delivered to PC or other monitoring equipment via these interfaces.

When user wants the information of the power station and manage the entire

power system. We offer RS 485 communication.

RS 485 is generally for inverter’s communication. System monitor should be

configured to realize one PC communicates with inverter at same time. Through

PC could get real time PV plants operating data.

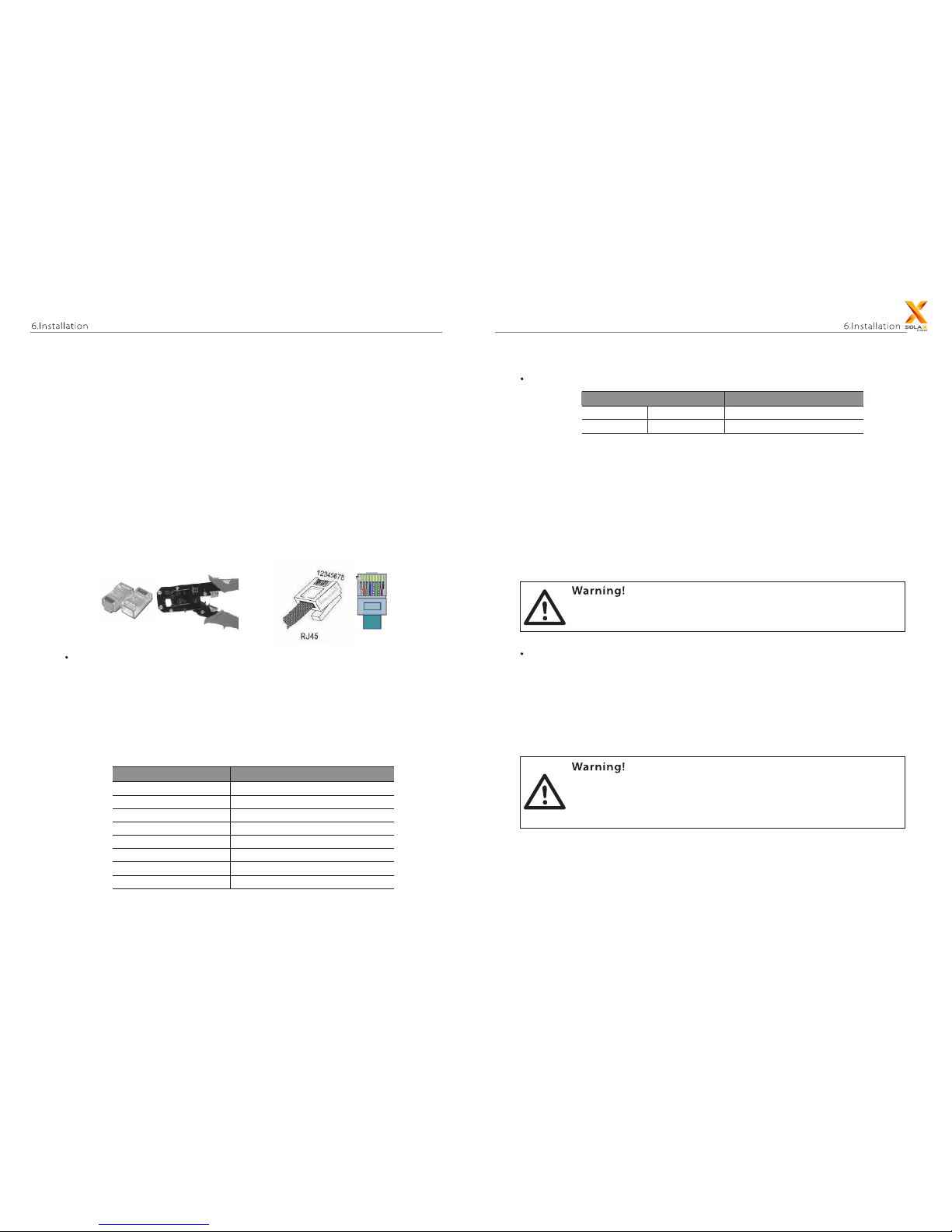

The correspond relationship of the pins of RJ 45 and network cable color shows

as below.

Choose high-quality network cable, trip the insulation from the wire ends. For the

end use for the inverter, follow T568B order with press pliers to push into the 8wire RJ 45 crystal head. For the other end, follow the 2-wire RJ 45 crystal head to

connect with the RS 485 converter connector.

User can update the system through a USB flash drive.

RS 485 converter connection

Communication

Connection steps

6.5 .2 Communica tion In terface

RS 485 Communication

USB for Updating

RJ 45 Line NO.

Cable Color

T568B connection order

1

4

2

5

3

4

5

6

7

8

Cable Color

RS 485 Converter

Whight orange

A

B

Orange

White green

Blue

Blue

White blue

White blue

Green

White brown

Brown

3. Connect the WiFi with the router. ( Please refer to “WiFi Setting Guide”.)

4. Set the station account on the Solax web. (Please refer to “WiFi Setting Guide”.)

Connection steps

b) Make sure the DC switch is off and disconnect the AC with grid. Insert USB flash

drive into the “USB” port on the bottom of X1. Then turn on DC switch or connect

the PV connector, green light “a” and red light “b” flash alternately for 10 times.

Indicator light “c”, “d”, “e”, “f” are unlit.

a) Prepare a USB flash drive. Download the latest installation package named

“update.rar” from Solax website: www.solaxpower.com. And then extract it into

following directory:

“update\ARM\618.000 _X1MINI_ARM_Vx.xx_xxxxxxxx.usb”;72.00

“update\DSP\618.000 _X1MINI_DSP_Vx.xx_xxxxxxxx.hex”.70.00

Make sure the input voltage is more than 100V (in good illumination

condition). Or it may result in failing during updating.

Make sure the d irect or y is in accorda nc e wi th above form s tr ic tly!

Do not mo di fy t he progra m fi le name and the c apita l lette r ca n no t

be ch anged t o lo wer case! Or it m ay c ause the inve rter d oe sn’ t

wor k anymo re !

22

23

DRM: demand response mode.

DRM is provided to give a remote control with the optional accessory. The

remote control function provides a contact signal to operate the inverter. The

pin definition and the circuit connection show as below.

1. Choose at least 1mm² wire. Trip the insulation from the wire ends.

2. Insert the tripped wire into the hole of the terminal block.

3. Screw down the screws on the terminal block.

DRM

E.F.Alarm (optional)

Communication

Connection steps

1

8

Pin

Definition

1 2 3 4 5 6 7 8

DRM1 DRM2 DRM3 DRM4 3.3V DRM0 GND G ND

3. About 10 seconds later, the system will be updated automatically. During this

period, green light “a” is always been on and red light “b” is unlit. Indicator light “c”,

”d”, “e”, “f” show the progress of system updating. Refer to figure , it represents Ⅱ

the updating is half-finished.

4. Once system updating has been finished completely, light “a” “c” “d” “e” “f ” are all

being on, as shown in figure . Ⅲ

b

c

f

d

e

a

(Ⅰ ) (Ⅱ )

(Ⅲ )

24

25

E.F.Alarm means Earth Fault Alarm. It is the additional detection for functionally

earthed PV arrays, as required by AS 4777.2 and AS/NZS 5033.

a) Measure the resistance to earth of each conductor of the PV array.

b) If the earth resistance is above the resistance limit(R limit) threshold 30KΩ , the

iso

system shall reconnect the functional earth and shall be allowed to start.

c) If the earth resistance is equal to or less than the resistance limit(R limit) threshold

iso

30KΩ , the inverter shall shut down and initiate an earth fault alarm in accordance with

the requirements of IEC 62109-2.

Dir ec t fu nc ti onal ear th ing of syst em i s no t recomme nd ed.

Function al e ar thing via a r es is itor is a saf er option .

Not e !

Dur ing updatin g, d on’ t switch of f th e DC switch or c ut o ff t he

external dc b re ak er !

If the updati ng p rocess is pau se d for more th an 3 m inutes,

ple ase rei ns er t the US B flash drive.

Not e !

The updating process for ARM needs about 5 seconds and DSP needs about 3

minutes.

Checking: Inverter will check output environment automatically when DC

output voltage of PV panels. Under this mode, the green light “a” is ickering,

shown as gure . Ⅲ

Normal: begins to operate normally with green light on. Inverters will Inverter

work in MPPT mode when P V voltage is in the MPPT voltage range, inverter

will stop feedback power to grid when PV power is not enough.

Under this mode, the green light “a” is always on, light “b, c, d, e” represent the

output power. As shown in gure , the output power is 0%~25%.Ⅳ

If indicator light “b” turns red (Fault status), please refer to page

26-27.

60Vgreater

100V

Under this mode, the green light “a” is ickering,

shown as gure .Ⅱ

ed.

V

(Ⅰ ) (Ⅱ )

(Ⅲ ) (Ⅳ)

b

c

f

d

e

a

indicator lamps that identify the inverter output

power range and type of fault.

I

operating

Fault(red) Normal(green)

26

27

Waiting/Checking

Updating

Indicator light “a“ is always being on. And

indicator light “c” ,“d” , “e” ,“f” represent the

output power refer to Table-part 2. As

shown left, it represents the output power

is 25% ~ 50%.

Indicator light “b“ is always being on. And

indicator light “c” ,“d” , “e” ,“f” represent the

type of error refer to Table -part 2.

Under this mode, indicator light “a” is

ickering. Other lights are unlit.

Please refer to page 21.

First, read all indicator lamps, if the state of lamps “a” to “f” is ” bright, unlit, bright,

bright, unlit, unlit”, the corresponding gures is ” ” . Refer to Table-Part2,

it can be concluded that the operating state

of inverter is normal.

Then, read the power/fault indicator state, if the state of lamps “a” to “f ” is ‘’unlit,

bright, bright, unlit, unlit, unlit, unlit”, the corresponding gures is “ ”

It could be nd that the type of error is “PV Over Voltage Fault”

refer to Table-Part 3.

Description

b

c

f

d

e

a

Indicator Light

a, b

c, d, e, f

Indicate normal / error

Indicate output power or the type of error

Explanation

28

29

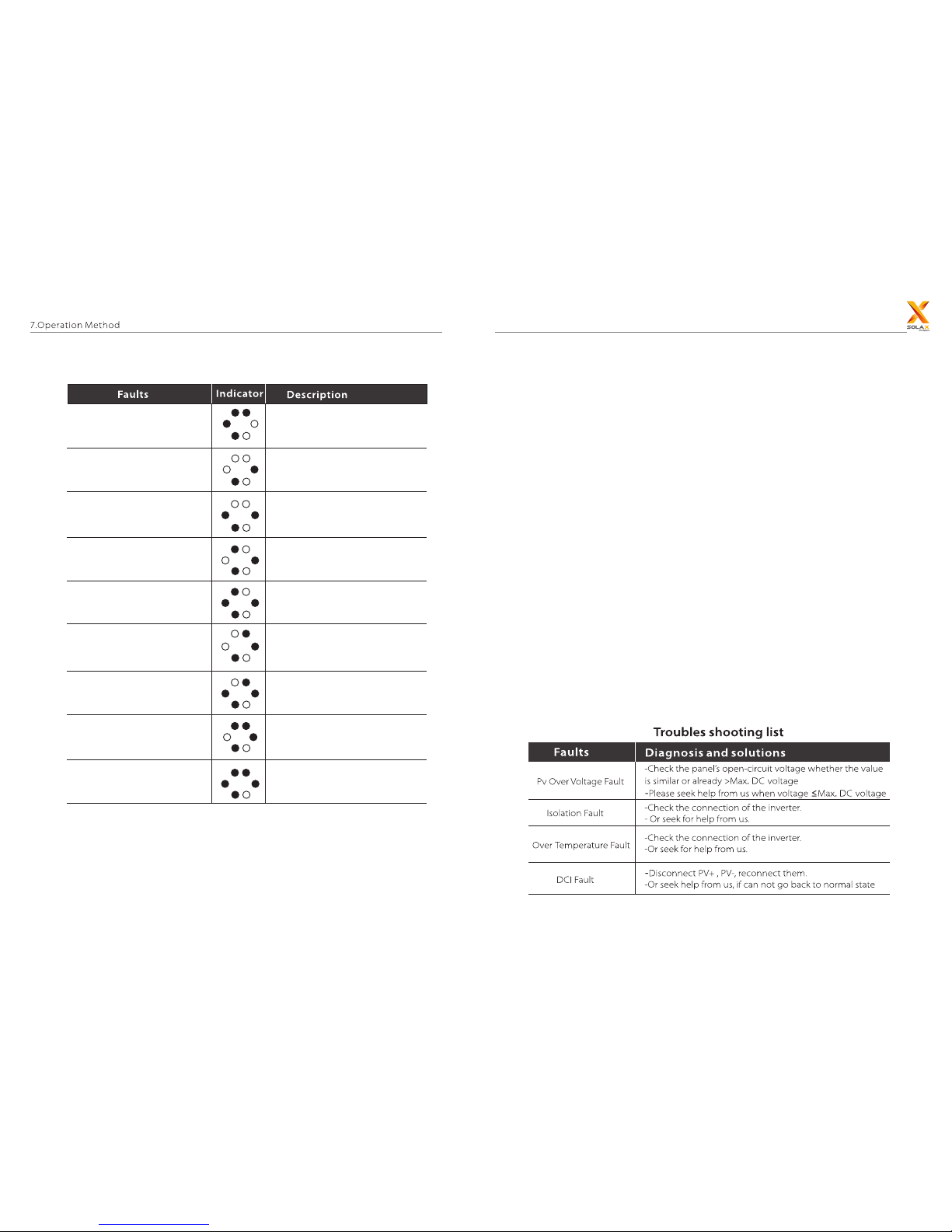

PV Volt Fault

PV Over Voltage Fault

Isolation FaultIsolation Fault

Temp Over FaultOver Temperature Fault

DCI Device Fault

DCI OCP Fault

DCI Fault

RCD Fault

Grid Lost Fault

Mains Lost

RCD /RC Fault

Sample Fault

Consistant Fault

Relay FaultRelay Fault

Inv Eeprom Error

Eeprom Fault

Mgr Eeprom Fault

Include SPI,SCI Faults

Comms Lost

Bus Volt Fault

Bus High

Tz Protect Fault

Tz Fault

SW OCP Fault

Other Device Fault

Other Device Fault

PLL Lost Fault

Grid Volt FaultGrid Volt Fault

Grid Freq FaultGrid Freq Fault

30

31

8. Troubleshooting

8.1 Troubleshooting

This section contains information and procedures for solving possible problems

with the X1 series inverter, and provides some troubleshooting tips to identify

and solve most problems that could occur with X1 series inverter.

This section will help you narrow down the source of any problems you may

encounter. Please read the following troubleshooting steps.

Check the indicator light state. Record it before anything further solutions.

Attempt the solution indicated in troubles shooting list.

If the indicator lamp unlit, check the following list to make sure that the present

state of the installation allows proper operation.

- Is the inverter located in a clean, dry, adequately ventilated place?

- Have the DC input breakers been opened?

- Are the cables adequately sized and short enough?

- Are the communication cable properly connected and undamaged?

Please contact SolaX Power company customer service for further assistance.

Please be prepared to describe details of your system installation and provide

the model and serial number of the unit.

8. Troubleshooting

8. Troubleshooting

Tz Fault

RCD /RC Fault

32

33

9. Decommissioning

2.

3.

8.2 Routine Manitenance

9. Decommissioning

9.1 Decommissioning

9.2 Storage and Transportation

9.3 Disposal

8. Troubleshooting

~

34

Loading...

Loading...