SOLATHERM THERMOSIPHON SYSTEMS

TECHNICAL, INSTALLATION AND USE

MANUAL

V1.0-03/17

TECHNICAL, INSTALLATION AND USE MANUAL

1

SOLATHERM reserves the right to modify characteristics of the products or their accessories and components without prior notice.

General safety instructions…………………………………………………………………………….…………….page 2

General installation instructions…………………………………………………………………….…………….page 3

…………………………………………………………………………………………………………….…page 5

A. SOLAR COLLECTORS…….…………………..………………………………………………………...page 6

1. General characteristics…………………………………………………..…….…………………..page 6

2. Technical characteristics…………………………………………..………….…………………..page 7

B. STORAGE TANKS…………………………………………………………………………………………page 8

1. Enamelled storage tanks general characteristics….…………..……………………….page 8

2. Enamelled storage tanks technical characteristics.…………..……………………….page 8

3. Primary circuit connecting piping (Between storage tank and collector (s)..page 8

C. MOUNTING STRUCTURES……………………………………………………..…………………….page 9

D. FITTINGS AND CONNECTION ACCESSORIES FOR ALL SYSTEMS…………………….page 10

A. FLAT ROOF MOUNTING STRUCTURE ASSEMBLY FOR SYSTEMS WITH 1

OR 2 COLLECTORS OF 2,00m2 OR 2,37m2 ……………………………………………………page 11

1. General Characteristics…………….……………………….…………..……………………….page 11

2. Common steps for all systems with 1 collector of 2,00m

2

or 2,37m2……….page 11

3. Connection details for STHS 120/2,00m

2

and 120/2,37m2 Systems………...page 12

4. Connection details for STHS 160/2,00m

2

and 160/2,37m2 Systems……......page 13

5. Connection details for STHS 200/2,00m

2

and 200/2,37m2 Systems………...page 13

6. Collector and Tank installation on the Mounting Structure…………….……….page 14

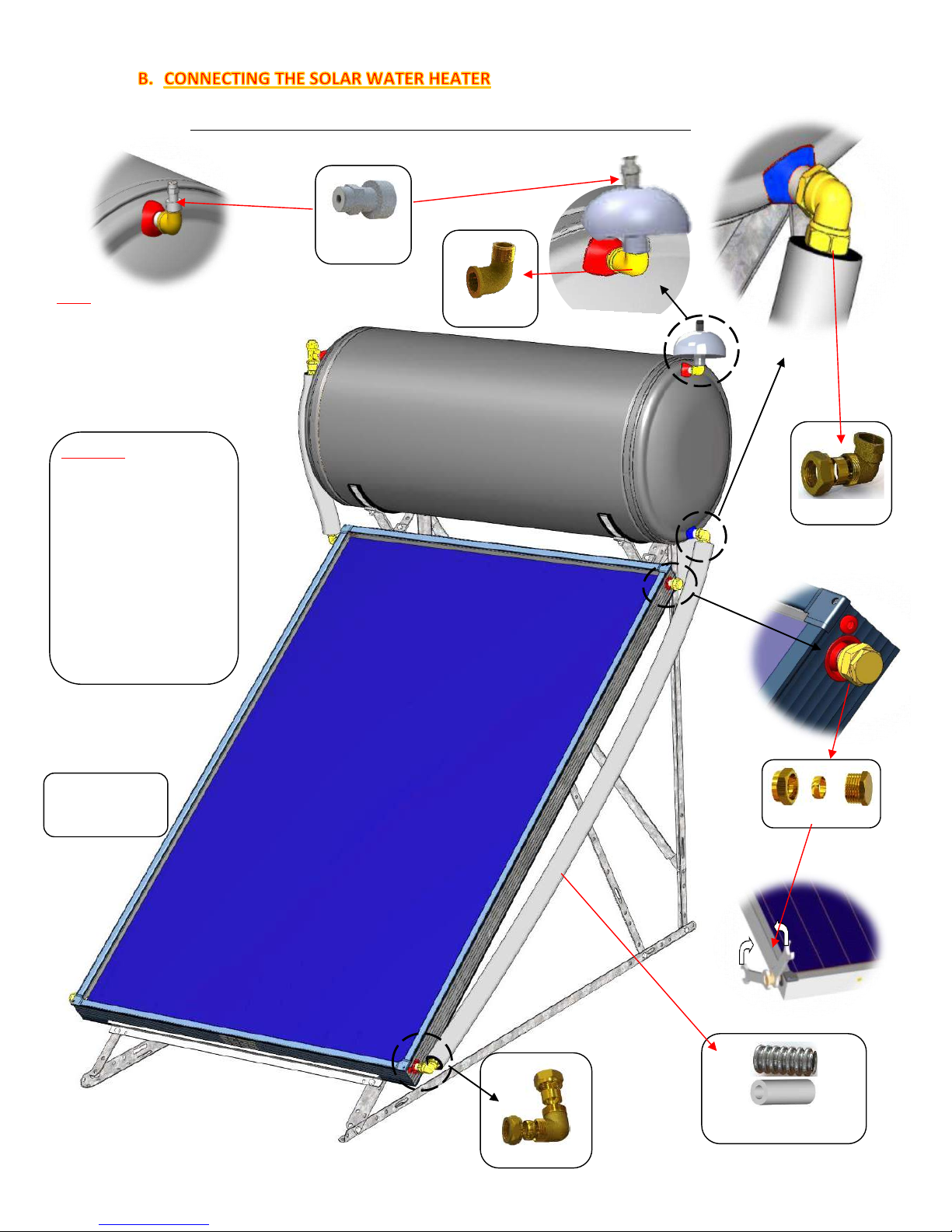

B. CONNECTING THE SOLAR WATER HEATER…………………………………………………page 15

1. Hydraulic connections of the closed circuit (for 1 collector systems)……… page 15

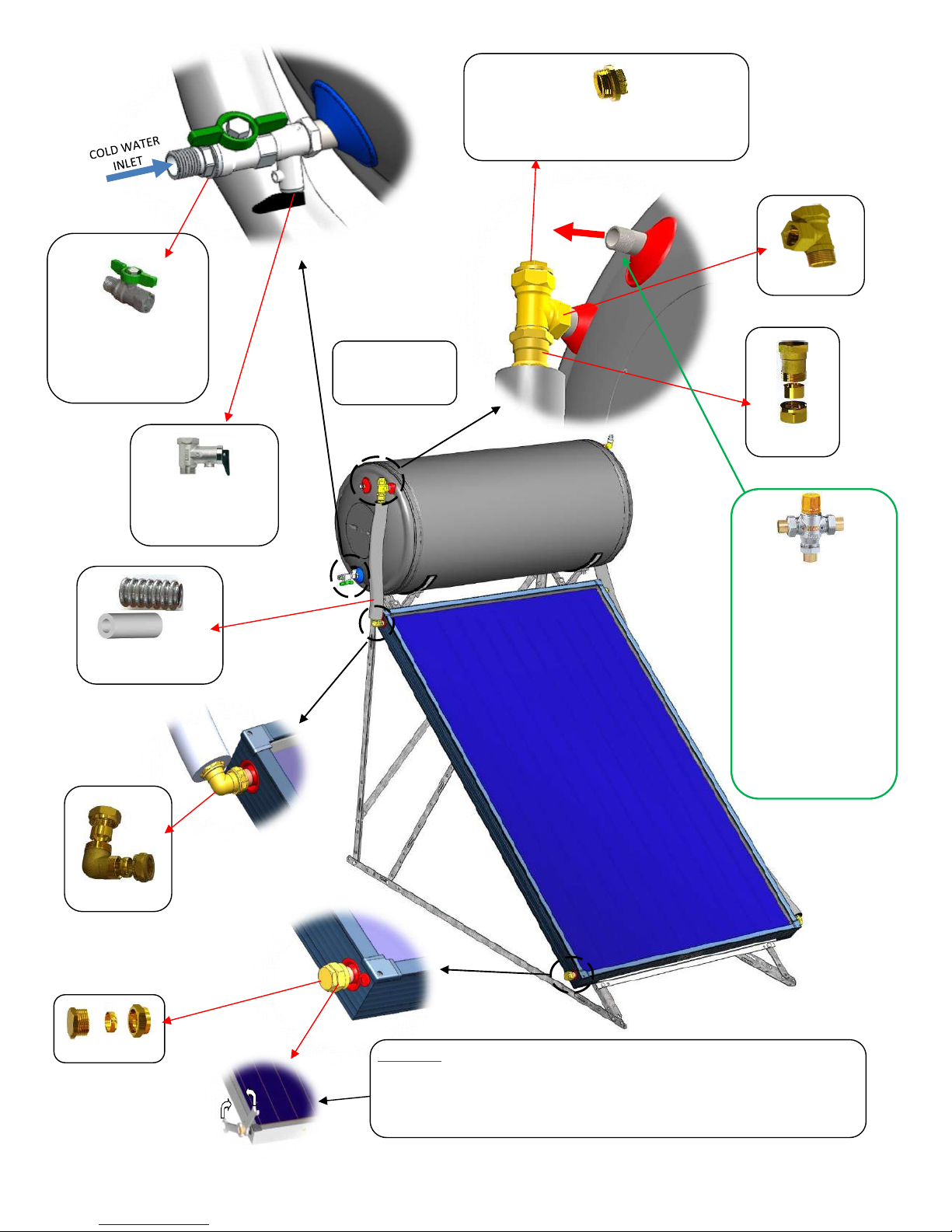

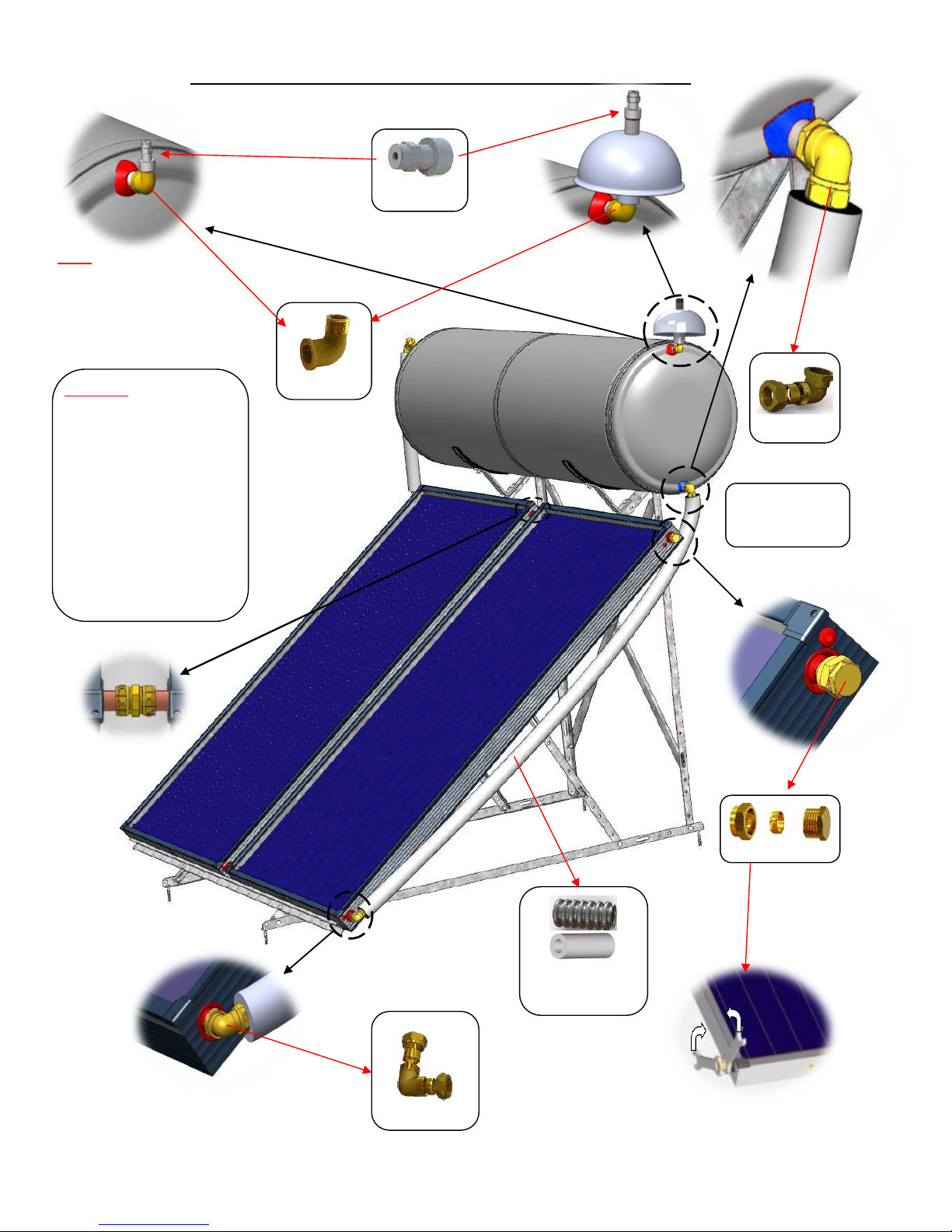

2. Hydraulic connections of the closed circuit (for 2 collector systems)……… page 17

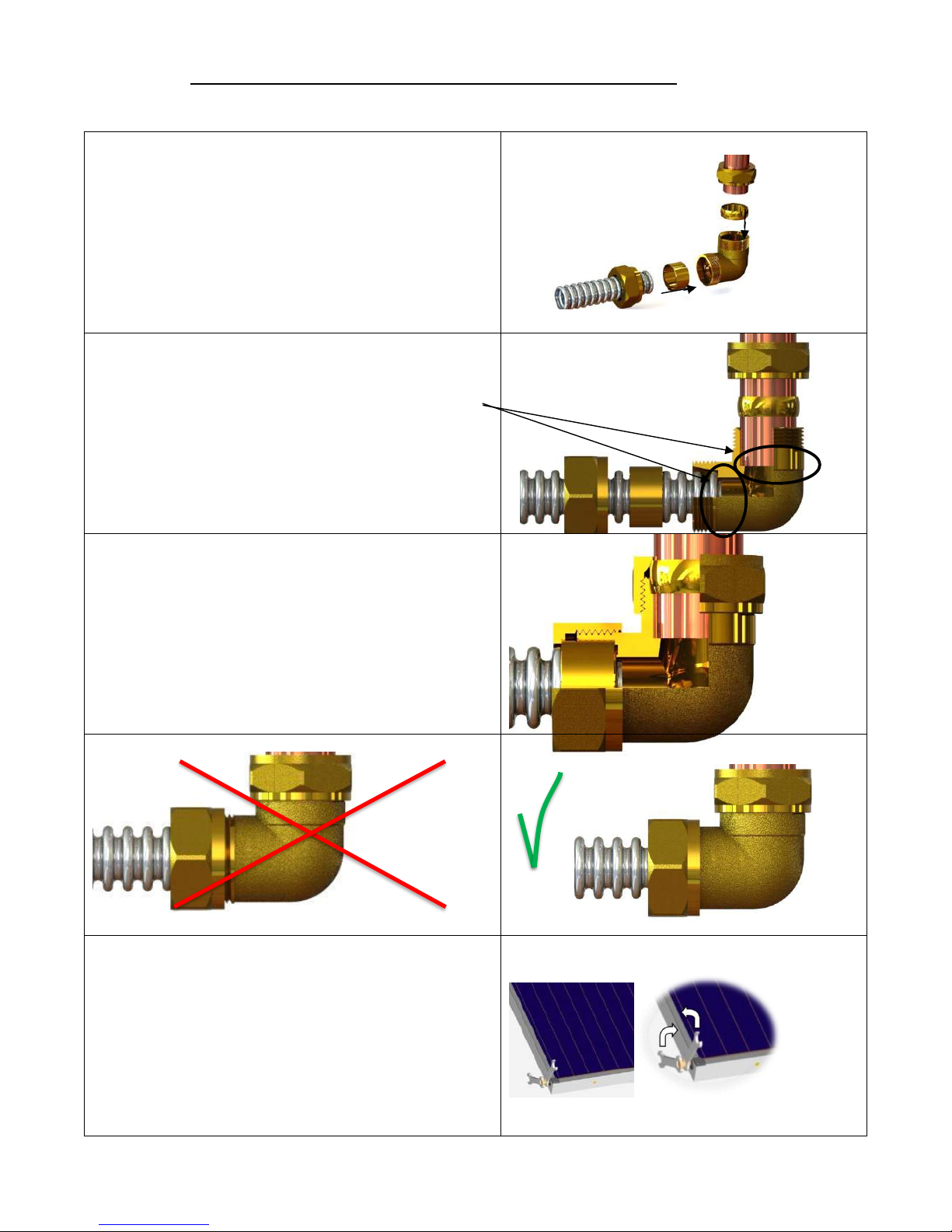

3. Assembly of fittings with the stainless steel corrugated tubes…………………page 19

C. FILLING/DRAINING OF THE SOLAR WATER HEATER…………………………………...page 20

1. Filling the tank………………………………………………………………………………………. page 20

2. Filling the closed circuit……………………………………………………………………….… page 20

D. ELECTRIC BACK-UP

1. General instructions……..………………………………………………………………………..page 21

2. Connection instructions ……………………..………………………………………………….page 22

3. Anti-freeze protection…………………………………………………………………………….page 22

A. MAINTENANCE AND SERVICING OF THE SYSTEM……………………………………..page 22

1. General maintenance...…………………………………………………………………………..page22

2. Replacing the sacrificial anode (magnesium rod) …………………………………..page 22

B. TROUBLESHOOTING…………………………………………………………………………………page 23

……………………………………………………………………………..page 23

……………………………………………………………………...page 24

…………………………………………………………………………………………..page 25

2

SOLATHERM reserves the right to modify characteristics of the products or their accessories and components without prior notice.

Before the installation and use of a SOLATHERM Solar Water Heating System please read and

observe carefully all the instructions concerning the installation, maintenance and use of the

systems, in this manual. The non-observance of these instructions may result in the

cancelation of the warranty.

GENERAL SAFETY INSTRUCTIONS

• All installations and maintenance must be performed by qualified and certified professionals,

following all relevant local norms and regulations (1), industry codes, and according to the

manufacturer’s instructions.

• Always make sure that the installation site, especially on pitched roofs and roof tops, is adapted

to the weight and mechanical restraints of the system, as well as any further weight expected

(snow, rain, etc...). SOLATHERM declines any responsibility that may arise from an improper

or defective installation or from incorrect manipulation of the system or accessories composing

it.

• For a safer installation on roofs, it is recommended that the system be installed in such a way

that the tank be placed over a slat or batten, rather than between them.

• Always make sure there is enough space around the solar system for maintenance purposes, as

well as for the electric cabling and plumbing. It is recommended to agree with the client for the

location of the installation and the routing of pipes and cabling.

• In regions with heavy snow fall or strong winds, it may be necessary to further anchor the system

to the point of installation. In this case it is up to the installer along with the client to determine

the best and safe way to install the system. Additional fixing points or equipment may be

required.

• Avoid installations under direct solar radiation conditions due to the very high performance of

the solar panels and risks of severe burning or thermal shocks to the system. In the case of

installation under these conditions, it is very important to make sure the solar panels are well

covered and shaded from the sun.

• Never fill the closed circuit or connect the electric element with an empty tank. The tank must

always be filled with water during these operations due to a risk of severe damage to the system.

• Before starting the installation or maintenance, the main power supply to the system must

always be turned OFF.

• The use of plastic, PVC or polypropylene piping is not recommended for Solar Water Heaters due

to the very high temperatures developed by the systems. In any case, make sure that all the

piping used in contact or close to the systems outlets can withstand minimum temperatures of

90ºC, or 180ºC if in contact with the primary circuit.

SOLATHERM recommends the use of copper or stainless steel piping for safer and higher

performance.

• Following the first two years from installation, annual maintenance is recommended. Please

refer to the “Maintenance and Servicing of the Solar Water Heating System” section of this

manual.

• A mixing valve is compulsory on the hot water outlet in order to limit risks of burning and a

pressure reducing valve is highly recommended on the cold water inlet.

3

SOLATHERM reserves the right to modify characteristics of the products or their accessories and components without prior notice.

d

GENERAL INSTALLATION INSTRUCTIONS

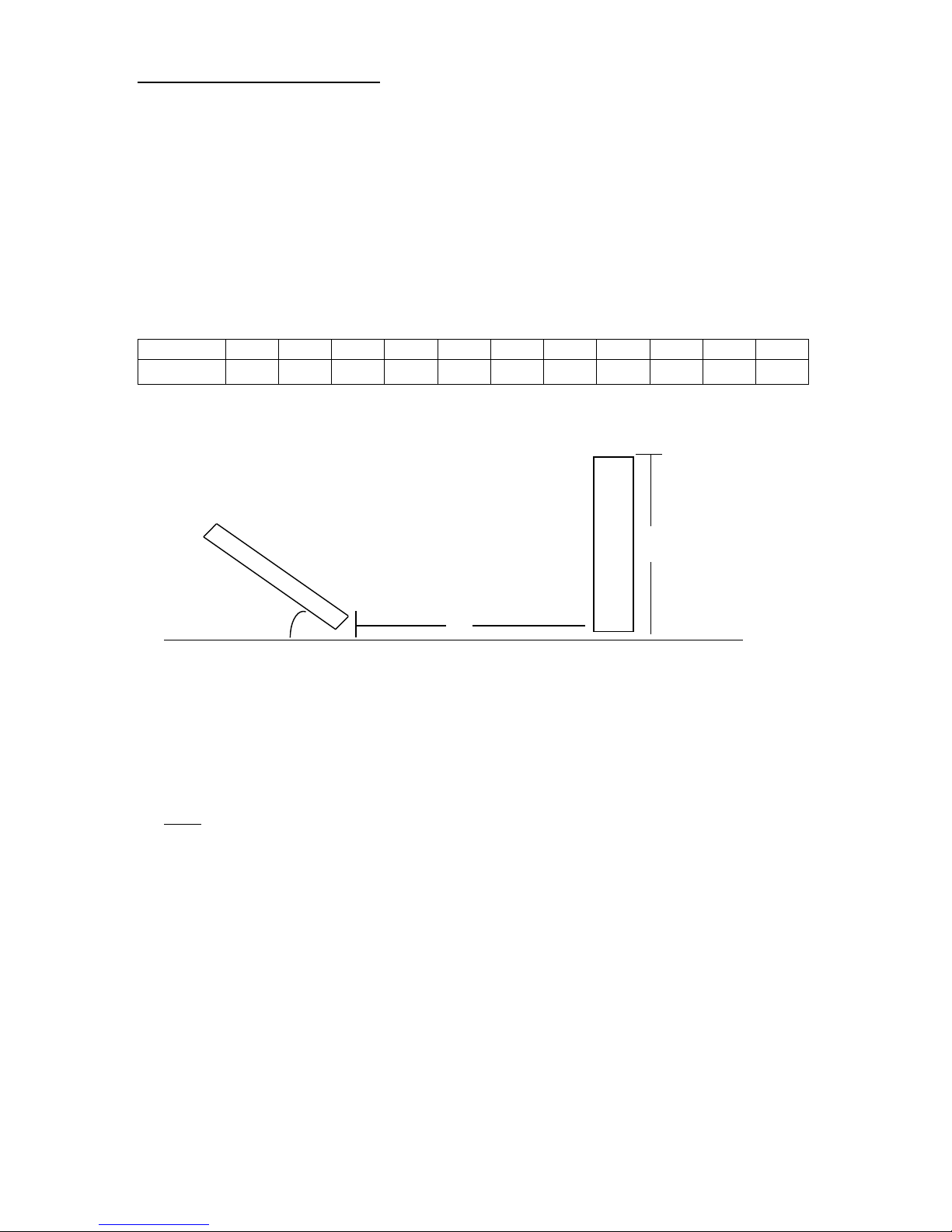

• Always make sure that the location chosen for the installation of the solar water heater is not

shaded by any obstacles (walls or other structures, trees and vegetation, other buildings, etc…)

at any moment. It is recommended to ensure at least 4 hours of direct sunlight around mid-day

during the winter solstice. In case of obstacles please observe minimum distance of the

collector(s) from the obstacle, as per the following calculation:

d=h x κ

where: κ=1/ tg(61°-φ) and φ= latitude of installation point.

The table below represents the (κ) coefficients for some latitudes:

LATITUDE 36° 37° 38° 39° 40° 41° 42° 43° 44° 45° 46°

κ (m) 2,144 2,246 2,355 2,475 2,605 2,747 2,904 3,077 3,270 3,487 3,732

In order to calculate the minimum distance (d) of the system from the obstacle one must multiply the

height (h) of the obstacle by the appropriate (κ) coefficient.

For latitudes, other than the ones reported in the table above, the formula must be used in order to

calculate the (κ) coefficient.

• The collectors must face towards the South when installed North of the equator and towards

the North when installed South of the equator. A deviation of up to 30º East or West is tolerated

with a minimum effect on the performance of the system.

Note: a deviation towards the East will result in a greater output of the system until mid-day, while

a deviation towards the West will result in a greater performance of the system in the afternoon.

• The optimal inclination depends on latitude of the installation point. In order to avoid fastidious

calculations, it is recommended as follows:

o If the system is used mainly during summer months: β=φ - (10 to 15)

o the system is used mainly during winter months: β=φ + (10 to 15)

o the system is used all year round: β=φ

Where β is the collector inclination and φ the latitude of the installation point.

• If the Solar System is installed in a location with a pitch lower than 13º or greater than 45º, additional

or different equipment may be necessary.

• Always make sure that all the piping of the primary and secondary circuits, going to and coming from

the Solar Water Heater, are very well insulated, even in hot climate regions and treated for UV

radiation.

h

4

SOLATHERM reserves the right to modify characteristics of the products or their accessories and components without prior notice.

• Always use counter force (opposite force) when installing the tightening fittings (especially olive

fittings) to avoid internal cracking and breaking of copper welds between tubes. Breaking of the

welds due to non-observance of this point is excluded from warranty and will result in cancelation

of the warranty.

• For closed circuit systems, always prepare and mix thoroughly the thermal fluid mixture in a bucket

before filling the system. Never fill the system with thermal fluid and water separately.

• Avoid leaving the Solar System for long periods without using hot water (holidays, prolonged

absences, etc...) due to risks of overheating, or make sure the solar panels are covered during this

period.

WARNING:

IF THE HOT WATER SYSTEM IS NOT USED FOR TWO WEEKS OR MORE, A QUANTITY OF HIGHLY

FLAMMABLE HYDROGEN GAS MAY BE ACCUMULATED IN THE WATER HEATER. TO DISSIPATE THIS GAS

SAFELY, IT IS RECOMMENDED THAT A HOT TAP BE TURNED ON FOR SEVERAL MINUTES UNTIL DISCHARGE

OF GAS CEASES. USE A SINK, BASIN, OR BATH OUTLET, BUT NOT A DISHWASHER, CLOTHES WASHER OR

OTHER APPLIANCE. DURING THE PROCEDURE THERE MUST BE NO SMOKING, OPEN FLAME OR ANY

ELECTRICAL APPLIANCE OPERATING NEARBY. IF HYDROGEN IS DISCHARGED THROUGH THE TAP, IT WILL

PROBABLY MAKE AN UNUSUAL SOUND AS WITH AIR ESCAPING.

• The safety of the system and validity of the warranty are conditioned by the use of genuine

SOLATHERM spare parts and accessories. Please only use genuine SOLATHERM spare parts and

accessories from your nearest SOLATHERM dealer or contact the manufacturer.

SOLATHERM declines any responsibility that may arise from the non-observance of the installation,

maintenance and use instructions herein, non-observance of relevant local norms, regulations and

industry codes, improper or defective installation, or incorrect manipulation of the system or the

accessories composing it.

SOLATHERM STHS SERIES SOLAR WATER HEATER RANGE

Model

Nominal Tank

Volume (lt)

Solar Collector

Model

Absorber

Type

Collector Surface

Weight Empty

(kg)

STHS 80/150

80 EFM 150 1 x 1,50 m2 88

STHS 120/182

120 EFM 182 1 x 1,82 m2 106

STHS 120/182H

120 EFM182H 1 x 1,82 m2 105

STHS 160/182

160 EFM182 1 x 1,82 m2 122

STHS 160/200

160 EFM 200 1 x 2,00 m2 125

STHS 160/200H

160 EFM 200H 1 x 2,00 m2 125

STHS 200/200

200 EFM 200 1 x 2,00 m2 137

STHS 200/200H

200 EFM 200H 1 x 2,00 m2 134

STHS 200/237

200 EFM 237 1 x 2,37 m2 146

STHS 200/237H

200 EFM 237H 1 x 2,37 m2 143

STHS 200/272

200 EFM 272 1 x 2,72 m2 152

STHS 300/364

300 2 x EFM 182 2 x 1,82 m2 201

STHS 300/400

300 2 x EFM 200 2 x 2,00 m

2

206

STHS 300/474

300 2 x EFM 237 2 x 2,37 m2 212

STHS 500/546

500 3 x EFM 182 3 x 1,82 m2 302

STHS 500/600

500 3 x EFM 200 3 x 2,00 m

2

310

STHS 500/711

500 3 x EFM 237 3 x 2,37 m2 333

5

SOLATHERM reserves the right to modify characteristics of the products or their accessories and components without prior notice.

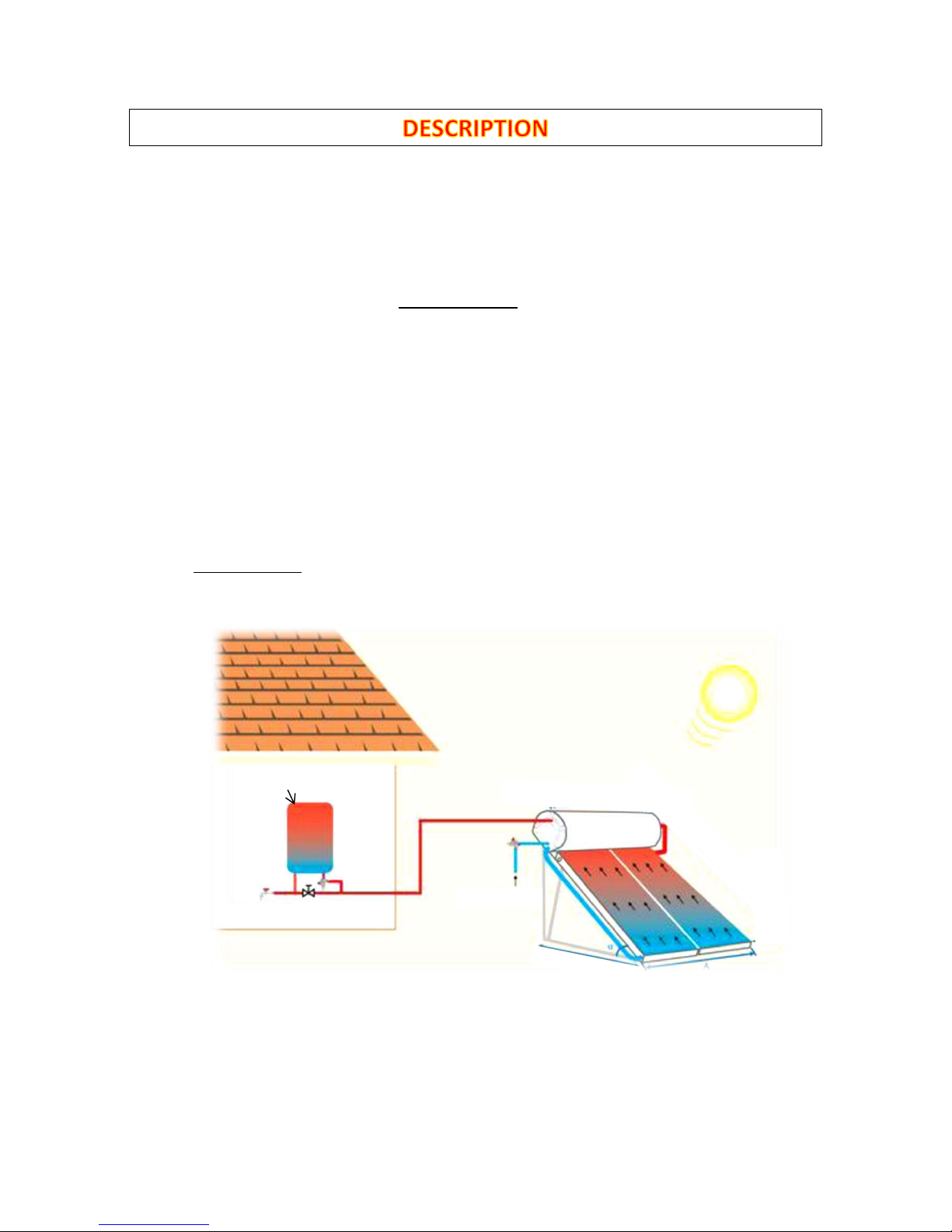

A solar water heater (SWH) is a system that can provide hot water, using the direct and indirect

solar irradiation. It consists from a storage tank where the sanitary water is stored (secondary

loop) and the solar panel(s) (solar collectors) which, along with the annular heat exchanger of

the storage tank (jacket) and the connection pipes connecting them, constitute the primary

circuit.

Heating of the water in based on a natural principle of hot being lighter and less dense than

cold, therefor by stratification, is always at the highest point while cold always sinks below. This

is why these types of solar systems are referred to as Natural Circulation or Thermosiphon

Systems.

In a Solar Water Heater, the thermal fluid (in the primary circuit) is heated by the sun in the

solar panels, getting lighter, so tends to rise up the solar panels, through the connecting pipes

and inside the heat exchanger, where it transfers the heat (calories) to the sanitary water stored

in the storage tank. While it exchanges heat with the sanitary water, the thermal fluids

temperature is lowered, slowly returning back to normal and regaining weight, thus returns by

gravity back to the solar panels to start the heating cycle all over again.

Principle Diagram

6

SOLATHERM reserves the right to modify characteristics of the products or their accessories and components without prior notice.

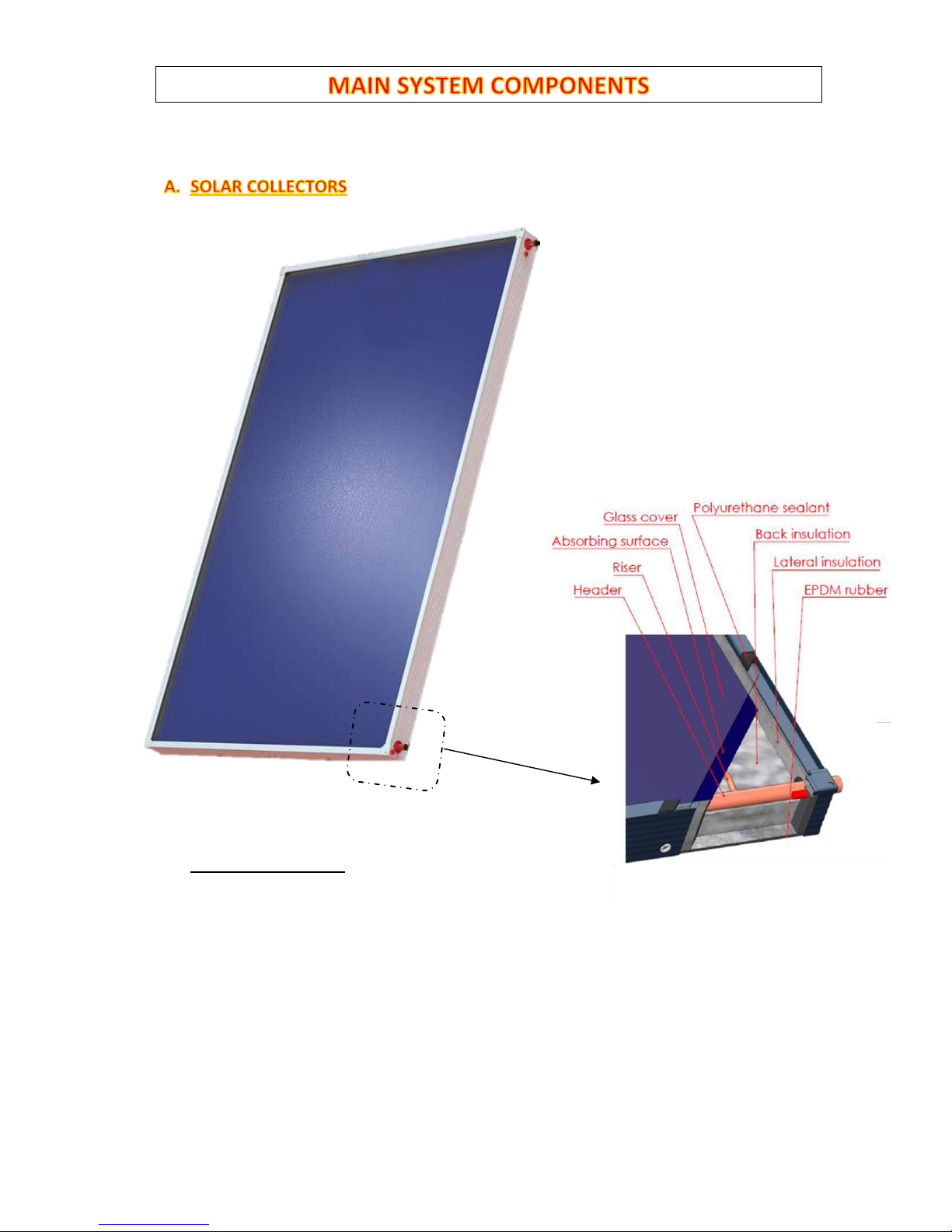

1. General Characteristics

• Low Iron, Mistlite, Tempered Solar Glass (Security)

• Laser Welded Al/Cu Titanium Selective Absorber 5mm

• Rear Insulation: Rock Wool 40mm

• Copper Headers and Risers

• Aluzinc Rear Cover of the Collector

• Side Insulation: Rock Wool 20mm

• Aluminium Alloy Collector Frame with “Sea Side” Class Treatment

• Maximum Negative Pressure Load 3000Pa

7

SOLATHERM reserves the right to modify characteristics of the products or their accessories and components without prior notice.

2. Technical Characteristics

• Frame: Special aluminium alloy Casing with Electrostatic Treatment

• Absorber Type: Laser Welded Single Sheet Selective Aluminium on Copper Harp (Grid)

• Absorber Surface: Highly Selective Blue Titanium Treatment (α≥ 0,95 +/-0,02, ε≤ 0,05 +/-0,02).

• Headers: Copper tubes Ø 22 mm

• Risers: Copper tubes Ø 8 mm

• Transparent Cover: Low Iron, Securit, Prismatic Solar Glass – Transmissibility: t≥0,91 –

Thickness: 3.2mm or 4mm,

• Back Side Collector Cover: in aluzinc, thickness 0,4 mm with EPDM rubber joint to avoid all

possibility of humidity infiltration.

• Rear insulation: in 40mm thick rock wool - density 50kg/m

3

(0,035W/m k)

• Side insulation: in 20mm thick glass wool - density 70kg/m

3

(0,034W/m k)

• Water tightness: black silicone and EPDM rubber

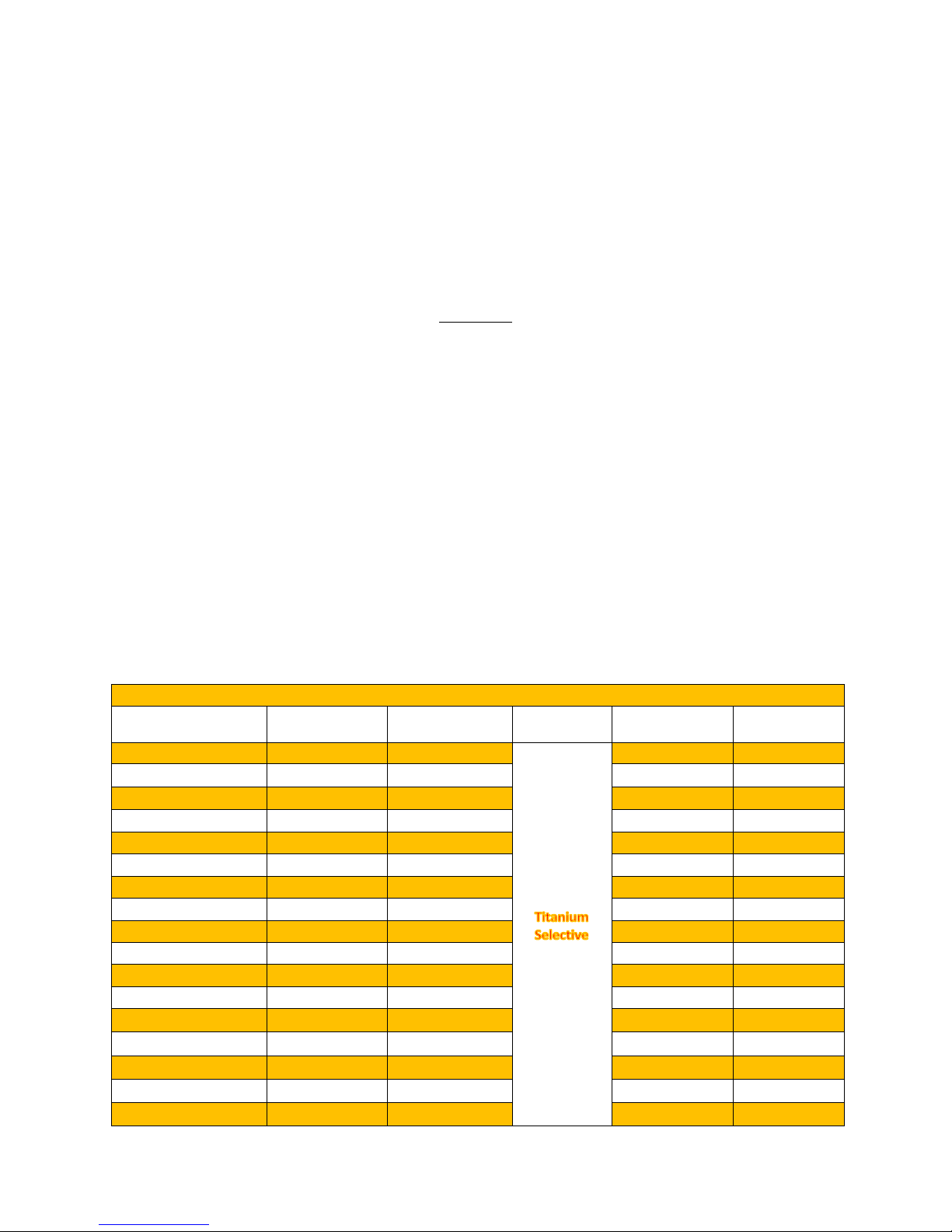

EFM SELECTIVE COLLECTORS TECHNICAL DATA

Model Dimensions

Absorber

Treatment

Number

of Risers

Total

Area (m²)

Aperture

Area (m²)

Volume

(lt)

Weight empty

(kg)

EFM 150

1480x1010x86

Titanium

Selective

9 1,50 1,38 1,21 26,20

EFM 150H

1010x1480x86

Titanium

Selective

14 1,50 1,38 1,56 28,20

EFM 182

1480x1230x86

Titanium

Selective

11 1,82 1,72 1,46 31,50

EFM 182H

1230x1480x86

Titanium

Selective

14 1,82 1,72 1,68 32,00

EFM 200

1980x1010x86

Titanium

Selective

9 2,00 1,86 1,40 34,00

EFM 200H

1010x1980x86

Titanium

Selective

18 2,00 1,86 2,05 34,80

EFM 237

1930x1230x86

Titanium

Selective

11 2,37 2,23 1,70 41,50

EFM 237H

1230x1930x86

Titanium

Selective

18 2,37 2,23 2,20 42,50

EFM 272

2160x1260x86

Titanium

Selective

11 2,72 2,57 1,82 47,50

EFM 272H

2160x1260x86

Titanium

Selective

19 2,72 2,57 2,30 48,50

TITANIUM SELECTIVE COLLECTORS DATA

• Instant Efficiency* 0: 0,830

• First degree heat loss* α1: 3,93W/m²K

• Second degree heat loss*: α2: 0,015W/m²K

2

• Stagnation temperature (at 1000 W/m² at 30°C): 231,09°C

• Effective Thermal Capacity: 10.85 kJ/(m

2

K)

Flow Rate: 0.021kg/(s m2)

Irradiance G=1000W/m2 – Ambient temperature Ta= 30°C

*Compared to collector aperture area as per EN12975 – Solar Keymark Certification

8

SOLATHERM reserves the right to modify characteristics of the products or their accessories and components without prior notice.

1. Enamelled Storage Tank (Boiler) General Characteristics

2. Enamelled Storage Tank (Boiler) Technical Characteristics

3. Primary Circuit Connecting Piping (Between Storage Tank and Collectors)

• Material: 316 L Stainless Steel

• Insulation: ISOPIPE UV - thickness: 13mm

TECHNICAL DATA OF EGBM ENAMELED STORAGE TANKS

GLASS LINED EGBM 80 EGBM 120 EGBM 160 EGBM 200 EGBM 300 EGBM 500

Capacity (lt) 76 117 156 197 296 468

Max. operating pressure (bar) 10 10 10 10 10 10

Pressure Test (bar) 15 15 15 15 15 15

Max. working Temp. (°C) 99 99 99 99 99 99

Tank Dimensions ΦxL (mm) 530x960 580x915 580x1116 580x1356 580x1970 700x2120

Jacket capacity (lt) 5,0 8,6 12,9 18,3 25,8 30

Jacket Heat exchanger surface (m2) 0,53 0,62 0,91 1,28 1,79 2,1

Weight empty (kg) 43 54,9 66,8 81,8 114,5 160

1. Storage tank: low carbon steel, thickness: 2,5mm

2. Internal Protection Treatment: double glass enamel

internal coating, backed at 860ºC, as per German

standards DIN 4753/3

3. Heat Exchanger: Jacket type made of low carbon

steel, thickness 1,5mm.

4. Thermal Insulation: high density (>50kg/m³),

ecological (CFC free), incombustible expansive CFC

free polyurethane foam, thickness 50mm

4. External casing: made of hot dipped galvanized

steel with electrostatic powder coating treatment

5. Accessibility: Large Side flange (man hole) for inspection and maintenance. Position of anode and electrical back-up element

6. Anodic protection: 2 large magnesium rods (anodes) for protection against corrosion and electrolysis

7. Safety / Overheating Protection: 2 BAR safety Valve (or Expansion Vessel) Connection Outlet made of Stainless Steel: BSP ½’’ M

8. Jacket Heat Exchanger Outlet: made of Stainless steel BSP: ¾’’ M

9. Jacket Heat Exchanger Inlet: made of Stainless steel: BSP ¾’’ M (Also acts as filling point for the closed circuit of the system. Must be

plugged after filling)

10. Domestic Hot Water Outlet: made of Stainless Steel: BSP ¾’’ M

11. Cold Water Inlet: made of Stainless Steel: BSP ¾’’ M

12. Electrical back-up Heating Element: power rate according to local norms and regulations of the country of destination

13. Safety Thermostat with Bipolar Protection and Auxiliary Fuse: All Electrical components carry CE marking as per EN 60335-1 and

EN660335-2-21 standards.

14. Cable Gland and Cable Tube: Water Resistant Passage for the Electric Element Connection Cable

5

7

8

4

3

10

9

2

1

6

12

13

11

14

9

SOLATHERM reserves the right to modify characteristics of the products or their accessories and components without prior notice.

Note: All Systems are accompanied by the Installation instructions for the Mounting Structure

included in the kit.

SOLATHERM Thermosiphon Solar Systems are available with a variety of different mounting structures

in order to fit and adapt to all possible situations, inclinations and environment.

They are adapted for installations on:

• Ground

• Flat roof

• Roof with Clay or Concrete Tiles

• Roof with Asphalt Shingles

• Roof with Slates

• Roof with Wood Shingles and Shake

• Roof with Synthetic Roofing Products

• Sheet Metal roofing

Available Mounting Structure Materials:

• Hot dipped galvanized steel

• Powder coated galvanized steel

• Aluminium

Available inclinations include:

• 45° inclination for flat roof

• 38° inclination for flat roof

• 25° inclination for flat roof

• 15° inclination for flat roof

• Any pitched roof inclination between 45° and 13°

• For pitched roofs with an inclination above 45° or lower than 13° are upon request

Inclination 45°: H= 1770mm to 2030mm depending on the system

Inclination 38°: H= 1570mm to 2015mm depending on the system

Inclination 15°: H= 600mm to 860mm depending on the system

Inclination 25°: H= 1400mm to 1550mm depending on the system

Inclination identical to pitched roof

between 15° and 45°

10

SOLATHERM reserves the right to modify characteristics of the products or their accessories and components without prior notice.

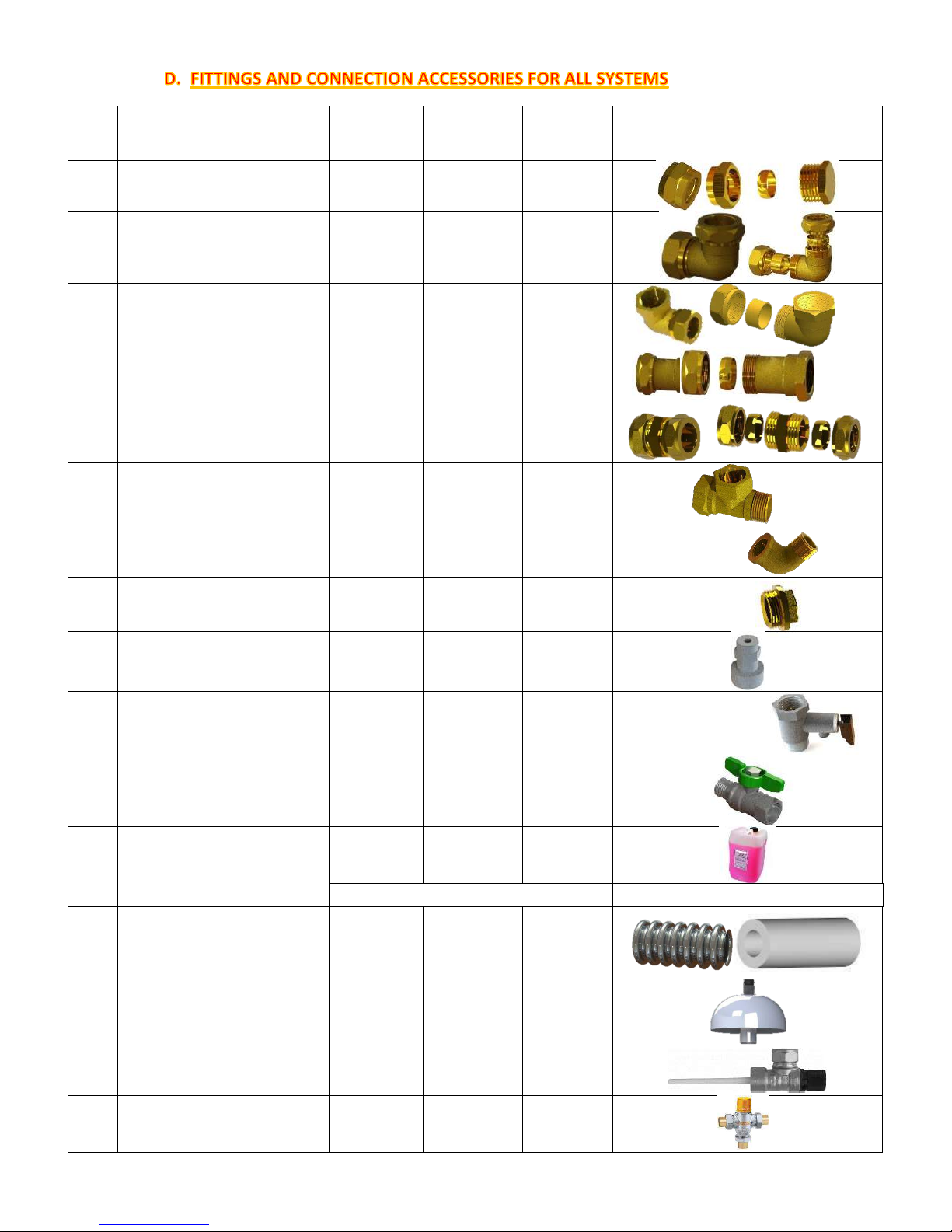

Piece

No.

DESCRIPTION

Qty FOR 1

COLLECTOR

SYSTEMS

Qty FOR 2

COLLECTOR

SYSTEMS

Qty FOR 3

COLLECTOR

SYSTEMS

SAMPLE DRAWING

1

PLUG FOR COPPER TUBE Ø22

MECHANICAL TIGHTENING

2 2 2

2

ELBOW FITTING FOR COPPER

TUBE Ø22 MECHANICAL

TIGHTENING X INOX TUBE

2 2 2

3

ELBOW FITTING FOR

3/4’’FEMALE x DN16 SS TUBE

1 2 1

4

STRAIGHT FITTING FOR

3/4’’FEMALE X INOX TUBE

1 --- 1

5

STRAIGHT FITTING FOR Φ22mm

COPPER TUBE

--- 2 4

6

TEE FITTING 3/4" MALE x 3/4”

FEMALE x 3/4" FEMALE

1 1 1

7

ELBOW FITTING MALE 1/2" x

1/2" FEMALE

1 1 1

8 MALE PLUG 3/4" 1 1 1

9

SAFETY VALVE 2 BAR FOR CLOSE

LOOP CIRCUIT

1 1 1

10

SAFETY NON RETURN VALVE 9

BAR FOR INLET OF CITY COLD

WATER

1 1 1

11

BALL VALVE 1/2’’ MALE X 1/2’’

FEMALE

1 1

1

12 ANTIFREEZE LIQUID

2lt 3lt 6lt

(depending on local climatic conditions)

13

STAINLESS STEEL TUBES

INSULATED WITH UV PROTECTED

INSULATION (Short for HOT +

Long

for COLD)

2 2 2

14

EXPANSION VESSEL 1Lt FOR

CLOSE CIRCUIT

1 (Optional) 1 (Optional) 1 (Optional)

15

TEMPERATURE-PRESSURE

VALVE (95°C-10 BAR)

1 (Optional) 1 (Optional) 1 (Optional)

16 THERMOSTATIC MIXING VALVE 1 (Optional) 1 (Optional) 1 (Optional)

11

SOLATHERM reserves the right to modify characteristics of the products or their accessories and components without prior notice.

1. General Characteristics

2. Common Steps for all systems with 1 collector of 2,00m

2

or 2,37m2

Νo. Description Qty

1 “L” shaped brackets 2420mm 2

2 “L” shaped brackets 2085mm 2

3 “L” shaped brackets 1320mm 2

4 “L” shaped brackets 955mm 2

5 Cross brackets 1430mm 2

6 “L” shaped brackets 1000mm 2

7 Tank support brackets 2

8 Rubber cover of tank support brackets 2

9 Hexagonal Bolt M8x20 29

10 Hexagonal Bolt M8x30 4

11 Hexagonal Nut M8 27

12 Washers Φ8.5 4

13 Anchor bolt M8X60 6

14 Plastic Anchor M8X60 6

STHS120/200 STHS120/237 STHS160/200 STHS160/237 STHS200/200 STHS200/237

C 660mm 660mm 850mm 850mm 940mm 940mm

W 1130mm 1385mm 1250mm 1385mm 1490mm 1490mm

W

C

1

2

3

4

5

6

7

8

1

3

4

2

Step 1: Assemble the Side Brackets using

M8x20 Bolts and Nuts

5

3

Step 2: Form the Rear

Cross using the 2

brackets No.5 and

Connect the 2 side

brackets between them

using M8x20 Bolts and

nuts.

The exact connection

point between them

depends on the model

(120lt, 160lt or 200lt)

please refer to the

appropriate model

connection details in

the following pages.

Lower collector support bracket No. 6

6

Step 3: Connect the Lower and

Upper Collector Support Brackets

No.6 with the Side Brackets using

M8x20 Bolts and nuts but do not

tighten.

The exact connection point between

them depends on the model (120lt,

160lt or 200lt) please refer to the

appropriate model connection

details in the following pages.

Upper collector support bracket No. 6

6

12

SOLATHERM reserves the right to modify characteristics of the products or their accessories and components without prior notice.

M8x30

2nd hole on

Nr.3

3. Connection details for STHS 120/2,00m

2

and 120/2,37m2 Systems

7

M8x30

8

Step 4: Connect the Tank Support

Brackets No.7 to the Side Brackets

No.1 using the M8x20 and M8x30

nuts and bolts as indicated above.

1

Step 5: After both Tank

Support Brackets No.7 are

installed fit the Rubber

Covers No.8 to avoid

scratching and damaging

the tank.

8

13

SOLATHERM reserves the right to modify characteristics of the products or their accessories and components without prior notice.

4. Connection details for STHS 160/2,00m

2

and 160/2,37m2 Systems

5. Connection details for STHS 200/2,00m

2

and 200/2,37m2 Systems

4

th

hole on

Nr.3

M8x30

M8x30

Oval hole

on Nr.3

8

8

14

SOLATHERM reserves the right to modify characteristics of the products or their accessories and components without prior notice.

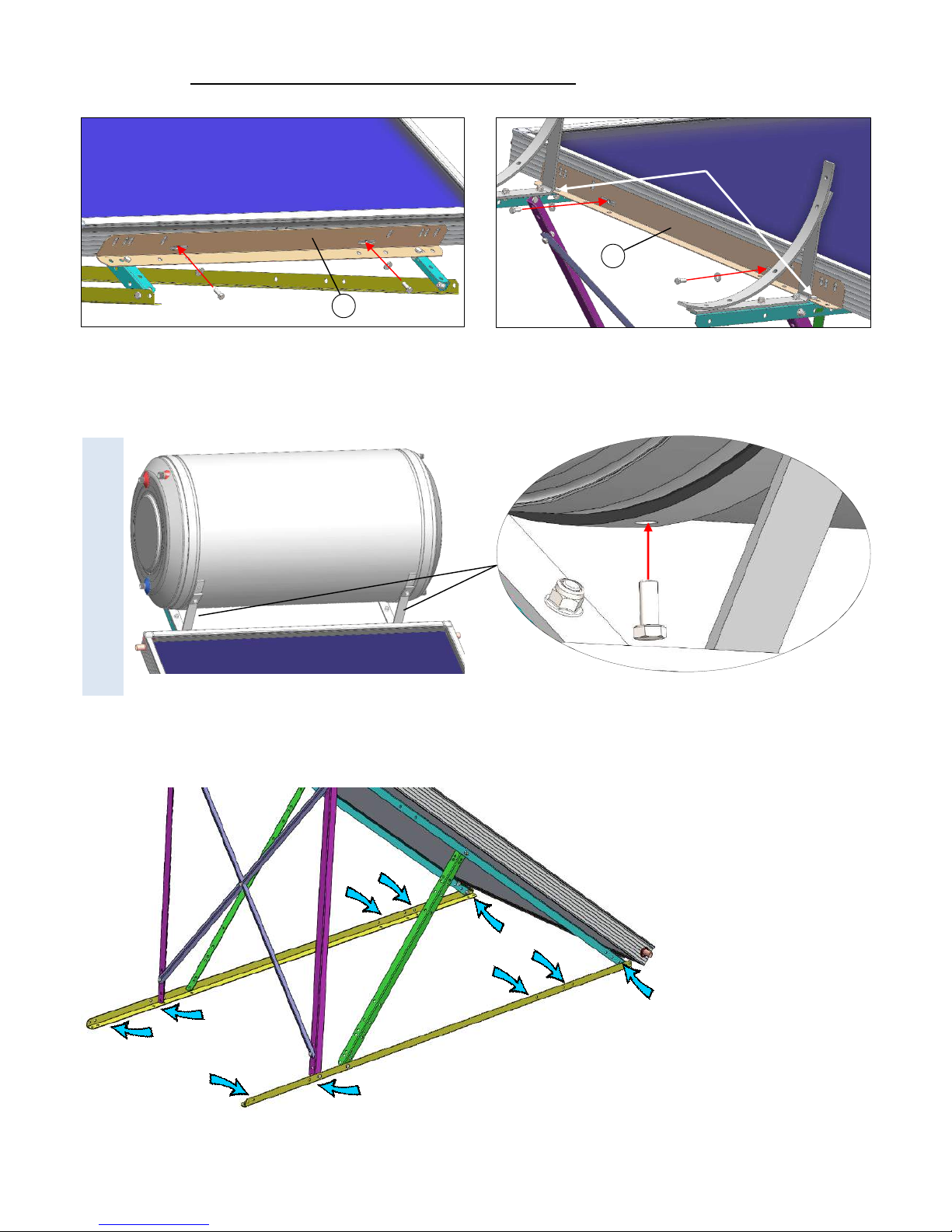

6. Collector and Tank installation on the Mounting Structure

6

Tighten No.6 with No.1

after collector is fixed

6

Install the Collector and Secure it with the Lower and Upper Collector Support Brackets No.6 as indicated

in the drawing

above using M8x20 bolts and washers, and tighten upper Collector Support Bracket Nr.6 with Support brackets Nr.1.

Install the Tank making sure the cold-water inlet is on the left side when looking at the system from the

front.

Connect the Tank to the Mounting structure through the Tank Support Brackets as indicated on the picture above

using M8x20 bolts through the middle strip’s hole into the tanks rivets.

Attention:

This side on the left

Choose the most convenient

holes provided on the

horizontal

brackets No.2

(preferably on

the edges and

center) and secure the system

to the ground using the

six

plastic anchors and anch

or

screws M8x60 provided.

15

SOLATHERM reserves the right to modify characteristics of the products or their accessories and components without prior notice.

1. HYDRAULIC CONNECTIONS OF THE CLOSE CIRCUIT (1 COLLECTOR SYSTEMS)

ATTENTION: when placing the

brass fittings with mechanical

tightening on the Ø22 copper

tubes of the collector do it

carefully in order not to rotate

the copper tuber. If the copper

tube is rotated, it can cause

damage to the absorber and

break the wildings between

the vertical tubes (risers) with

the Ø22 tubes (headers), which

will not be covered by the

warranty. Opposite force is

necessary to avoid damage!

SAFETY VALVE

No.9

FITTING No. 2

RIGHT FRONTAL

VIEW OF THE

SOLAR SYSTEM

LONG STAINLESS STEEL

TUBE & INSULATION No.

FITTING No.1

FITTING No.7

FITTING No. 3

Note: If the (optional) Expansion

Vessel (No.14) is not includes in the Kit

then then the Safety Valve Nr.8 must

be placed directly on the Fitting No.6

16

SOLATHERM reserves the right to modify characteristics of the products or their accessories and components without prior notice.

FITTING No.1

SAFETY/NON-RETURN

VALVE No.10 is placed

on the cold-water inlet

LEFT FRONTAL

VIEW OF THE

SOLAR SYSTEM

The THERMOSTATIC

MIXING VALVE No. 16

(OPTIONAL) is placed after

the HOT WATER OUTELT as

per instructions included

in the mixing valve, in

order to limit the hot

water temperature

delivered to the Tap and

avoid burning. It is

recommended that the hot

water delivered at the Tap

is limited to 50°C.

SHORT

STAINLESS STEEL TUBE

& INSULATION No. 13.

BALL VALVE ½’’MALE X ½’’

FEMALE No.11 is installed

right after the Safety/Non-

Return Valve No 10.

FITTING Nr. 6

FITTING No.8: Plug it only after closed loop is

filled with the thermal fluid/water mixture (see

“filling the closed circuit” section D2)

FITTING No. 4

HOT WATER

OUTLET

ATTENTION: when placing the brass fittings with mechanical tightening on the Ø22 copper

tubes of the collector do it carefully in order not to rotate the copper tuber. If the copper

tube is rotated, it can cause damage to the absorber and break the wildings between the

vertical tubes (risers) with the Ø22 tubes (headers), which will not be covered by the

warranty. Opposite force is necessary to avoid damage!

FITTING No. 2

17

SOLATHERM reserves the right to modify characteristics of the products or their accessories and components without prior notice.

2. HYDRAULIC CONNECTIONS OF THE CLOSE CIRCUIT (2 COLLECTOR SYSTEMS)

FITTING No.1

ATTENTION: when placing the

brass fittings with mechanical

tightening on the Ø22 copper

tubes of the collector do it

carefully in order not to rotate

the copper tuber. If the copper

tube is rotated, it can cause

damage to the absorber and

break the wildings between the

vertical tubes (risers) with the

Ø22 tubes (headers), which will

not be covered by the warranty.

Opposite force is necessary to

avoid damage!

FITTING No. 2

RIGHT SIDE

FRONTAL VIEW

OF THE SOLAR

INOX TUBE &

INSULATION No. 13

FITTING No. 3

SAFETY VALVE

No.9

FITTING No.7

Note: If the (optional)

Expansion Vessel (No.14) is

not includes in the Kit then

then the Safety Valve Nr.8

must be placed directly on

the Fitting No.7

18

SOLATHERM reserves the right to modify characteristics of the products or their accessories and components without prior notice.

FITTING No.1

SAFETY NON-RETURN

VALVE No.9

LEFT FRONTAL

VIEW OF THE

SOLAR SYSTEM

BALL VALVE ½’’MALE X ½’’

FEMALE No.10 (IF

INCLUDED IN THE KIT) IS

INSTALLED RIGHT AFTER

THE SAFETY NON-RETURN

The THERMOSTATIC MIXING

VALVE No. 16 (OPTIONAL) is

placed after the HOT WATER

OUTELT as per instructions

included in the mixing valve,

in order to limit the hot water

temperature delivered to the

Tap and avoid burning. It is

recommended that the hot

water delivered at the Tap is

limited to 50°C.

FITTING No. 4

COPPER TUBE &

INSULATION

No.13

FITTING No. 2

FITTING No. 6

COLD INLET

FITTING No. 3

FITTING No. 8 Attach it after close loop

is filled with heat transfer medium

(see “close loop filling” in this manual)

ATTENTION: when placing the brass fittings

with mechanical tightening on the Ø22

copper tubes of the collector do it carefully

in order not to rotate the copper tuber. If

the copper tube is rotated, it can

cause

damage to the absorber and break the

wildings between the vertical tubes (risers)

with the Ø22 tubes (headers), which will not

be covered by the warranty. Opposite force

is necessary to avoid damage!

19

SOLATHERM reserves the right to modify characteristics of the products or their accessories and components without prior notice.

3. ASSEMBLY OF FITTINGS WITH THE STAINLESS STEEL CORRUGATED TUBES

STEP 1: INSERT THE Φ22 COPPER NUT AND THEN THE RING

FOR COPPER FITTING ON THE COPPER TUBE AND THE DN16

INOX NUT AND THEN THE RING FOR INOX DN16 ON THE

STAINLESS STEEL FLEXIBLE TUBE.

STEP 2: INSERT STAINLESS STEEL FLEXIBLE TUBE IN THE MAIN

CORP OF THE ELBOW FITTING, UNTIL THE TUBE CAN’T GO

FURTHER IN. REPEAT THE SAME THING FOR COPPER TUBE.

STEP 3: TIGHTEN BOTH NUTS.

CAUTION: TAKE EXTRA CARE ON THE FLEXIBLE TUBE NUT.

THE THREADS ON THE FITTING’S BODY MUST BE FULLY

COVERED BY THE NUT (SEE BELOW).

ATTENTION: When tightening the fittings on collectors the

copper tubes always do it carefully in order not to rotate the

copper tube Ø22 of the collector. If the copper tube is rotated,

the welds between the copper risers and Ø22 copper headers

can be broken, resulting in a permanent damage to the

collector. It is imperative to always use opposite force

(counter force) to avoid damage!

20

SOLATHERM reserves the right to modify characteristics of the products or their accessories and components without prior notice.

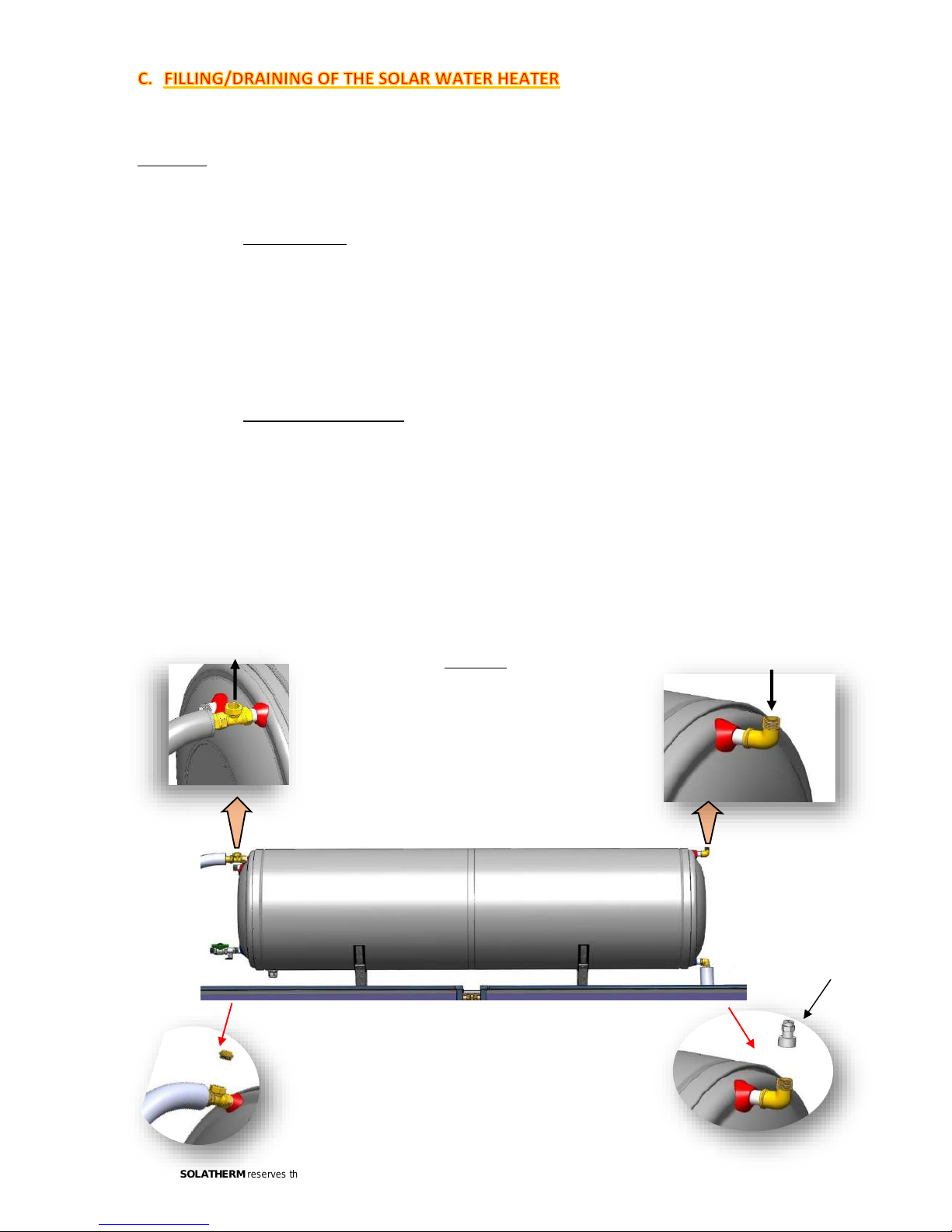

For the filling and draining of the system, please follow carefully the following steps:

Attention: Always fill the tank with water before filling the closed circuit with the thermal fluid

mixture. Similarly, when draining the system, always drain the closed circuit before emptying the tank

of water.

1. Filling the tank:

Fill the tank with water by opening a hot water tap somewhere in the house and the BALL VALVE (No.10) on

the cold-water inlet of the tank.

Once the tank is full, close the tap inside the house and proceed to the filling of the closed circuit with

the thermal fluid/water mixture. Closed circuit is filled

Note: If water hardness is above 250ppm or if the water is not very clean, it is recommended to install a

water filter. Above 400ppm, a water softener is advised.

2. Filling the closed circuit:

Use a bucket in order to mix the thermal fluid with purified water before filling the solar system. Always

put the thermal fluid in the bucket before the water and mix thoroughly.

Place the bucket with the mixture above the tank and fill the system through the outlet where the safety

valve (No.9) or expansion vessel (No.14) will be fitted, on the top right side of the tank.

The system will be full when the mixture starts coming out the outlet on the other side of the tank where

fitting No.8 is placed. At this point plug and tighten fitting No.8. Shake the system so that any eventual

air bubbles that are trapped can exit through the filling valve and complete with more thermal fluid

mixture until fluid is spilled. Install the safety valve (2 bar) and plug on the outlets.

Closed circuit filling

inlet

Loop is filled when water

flows from the outlet

Procedure

1. Mix thermal fluid with water in a bucket and start the

filling process. The use of a funnel is recommended

for ease of filling.

2. When all thermal fluid is inserted, continue filling

with water. It may take some time, do not rush or air

can be trapped in the system and the process will

take much longer.

3. When the closed circuit is filled, plug the fill-in fitting

with the ¾” male plug (image on the left) and install

the safety valve or expansion vessel with safety valve

if included (image on the right)

Safety Valve or

Expansion Vessel

connection

21

SOLATHERM reserves the right to modify characteristics of the products or their accessories and components without prior notice.

The percentage of thermal fluid to be used in the mixture depends on the table below (Percentage of

thermal fluid/water depending on the minimum ambient temperatures). The solar system must be

protected from frost; thus, it is important to know the minimum temperatures in the region.

For draining of the system use the same steps backwards.

Attention: Avoid filling/draining the system when under solar radiation, due to severe risks of burning

and thermal shocks that may be caused to the system, due to high collector temperatures. Thermal

shocks may damage the absorber of the collectors and non-observance of this warning may result in

cancelation of the product warranty. If filling/draining of the system under solar radiation cannot be

avoided, then it is imperative that the collectors be covered and shaded from the sun.

1. General

The solar water heater is equipped with an electric element and a built-in thermostat (factory

programmed at 60ºC), under the protective cap on the left-hand side of the tank, on the metallic flange

(apparatus plate). On the same flange one of the 2 magnesium rods (anode) is also installed [picture 1].

Note:

a) Electrical connections should be carried out by a qualified electrician and in accordance with local

norms and regulations for each particular application.

b) The mains switch must be switched off throughout the electrical connection procedure and servicing

of the solar systems.

c) Even in the case that the electrical element is not connected, always connect the ground cable either

directly to the ground or on the mounting structure of the system.

d) The heating element must be switched OFF when storage tank is empty. It can cause damage to the

tank and also severe burning. In such a case the warranty of the heating element will be invalid.

e) A safety relay for protection against electrical shock should be fitted.

f) Do not adjust the thermostat temperature above the 60 °C.

Attention: In these cases, the manufacturer’s warranty will not be valid.

Note: all elements comply with EN 60335-1 and EN 60335-2-21 safety regulations

Percentage of thermal fluid/water depending on the minimum ambient temperatures

Thermal fluid [%]

10 16 20 26 30 36 40 45 50

Freezing Point

-4 -6 -8 -12 -15 -20 -24 -30 -36

22

SOLATHERM reserves the right to modify characteristics of the products or their accessories and components without prior notice.

2. Connection instructions

a) Remove the protective cap which covers the electrical components.

b) Connect with 3x4mm² section cable (for heating element). The cable should pass through the plastic

spiral tube located at the Protective Cap and through the cable gland located on the cap.

c) Connect the black wire to the L (Phase) connector, the blue wire to the N (Neutral) connector and

the yellow-green cable to the M4 screw (Ground) marked with ground symbol.

d) Adjust thermostat to the desired temperature (not more than 60°C).

e) Put back in place the electrical connections cover.

f) Connect the other side of the cable to the power.

3. Anti-freeze protection

In areas subject to freezing, adjust the thermostat to position 1, in order to allow the heating element

to turn ON and protect the tank from frost. Always connect the back-up element directly to electricity

with an independent cable and provide a switch.

1. General maintenance

In order to ensure the constant well-functioning of the system, SOLATHERM solar water heater must be

reviewed and maintained periodically (see warranty sheet) and the warranty sheet accompanying must

be completed accordingly by the installer.

All installations and maintenance must be performed by qualified and certified professionals, following

all relevant local norms and regulations (1), industry codes, and according to the manufacturer’s

instructions.

Revisions consists by the optical and physical inspection of the tightness of all connections (hydraulic

and electrical), verification that all safety valves, pressure reducing valves and mixing valves are working

properly (safety valves on primary and secondary circuit), and cleaning of the glass cover.

2. Replacing the sacrificial anodes (magnesium rods)

For optimal protection of the system against electrolysis, all SOLATHERM tanks include 2 magnesium

rods (sacrificial anodes) on each side of the tank, which must be checked and replaced if necessary at

least every 26 months depending on the quality of the water. The size of the anode varies depending

on local norms and requirements. For replacing the anode, proceed as follows:

• Shut down the main power supply

• Remove the safety valves (2,5 bar) or expansion vessel.

• Empty the tank.

• Remove the protective cover of the flange.

• Pull out the thermostat with caution.

• Remove the flange (apparatus plate) and unscrew the anode. Screw-on a new anode and following

the same procedure backwards prepare and set the system back to work.

Sacrificial Anode (Magnesium Rod)

23

SOLATHERM reserves the right to modify characteristics of the products or their accessories and components without prior notice.

In case the Solar Water Heater does not produce enough hot water, please verify the following:

1. That all hydraulic connections of the system are water tight and there are no leaks.

2. That there are no leaks on the taps or on the piping of the building

3. That the collectors are not dirty, or covered with leaves or dust, or shaded. Clean them.

4. If the level of the thermal fluid in the system is not too low. Set to level filling with thermal fluid

mixture through the fluid inlet where the safety valve or expansion vessel is placed.

5. That the stainless-steel tubes connecting the collector(s) to the tank are not bent twisted nor

have any angles. The must be always rising, with no elbows, from collector(s) to tank.

6. That there is no air trapped in the closed circuit of the system. A single bubble can stop

circulation and heat transfer.

7. That the system is level, not leaning towards one side.

8. That the supply of cold and hot water is not connected.

9. That the temperature set on the mixing valve is not too low (below 50ºC depending on local

regulations)

10. If the electric back-up is working. In case it is not working please check the following:

• That the main power supply is ON

• That the thermostat is not set too low

• That the back-up element is not on security mode. The security button must be pushed-in

• That the thermostat and back-up element are not damaged

• That the back-up element wiring is properly connected and to the relevant terminals

If problems persist, then please consider:

a) That the weather conditions allow the proper heating of the system

b) The hot water consumption does not exceed the solar system’s capacity, or the consumers’

expectations of are not above this capacity.

c) The consumer has understood the use of the electrical back-up

Note: all verifications and interventions must be carried out by qualified and certified personnel.

All installations and decommissioning must be performed by qualified and certified

professionals, following all relevant local norms and regulations (1), industry codes, and

according to the manufacturer’s instructions.

Always respect the following order:

• Disconnect all electrical connections (if any)

• Disconnect and empty the pipes and the closed circuit

• Empty the water from the tank

• Dismount the tank first and the collectors after

• Disassemble the brackets.

24

SOLATHERM reserves the right to modify characteristics of the products or their accessories and components without prior notice.

* Solar-Only: only solar energy without back-up heating element or any other source of energy

CALCULATIONS ARE EXECUTED ACCORDING TO THE ANNEX D OF SOLAR KEYMARK -

“SPECIFIC SCHEME RULES”

TESTING LABORATORY NCSR DEMOKRITOS – REPORT CODE: 6082-F1

Thermosiphon System: STHS 120/182

Performance Indicators for Solar-Only* Systems on Annual Base for a Demand Value of 110 lt/day

Location (Latitude) Qd (MJ) QL (MJ) f

sol

(%)

Stockholm (59.2°N) 6150 2870 46.8

Würzburg (49.5°N) 5897 2952 50.1

Davos (46.5°N) 6654 4226 63.6

Athens (38.0°N) 4573 3658 80.0

Thermosiphon System: STHS 160/200

Performance Indicators for Solar-Only* Systems on Annual Base for a Demand Value of 140 lt/day

Location (Latitude) Qd (MJ) QL (MJ) f

sol

(%)

Stockholm (59.2°N) 7821 3311 42.3

Würzburg (49.5°N) 7506 3500 46.8

Davos (46.5°N) 8483 4920 58.2

Athens (38.0°N) 5834 4447 76.4

Thermosiphon System: STHS 200/200

Performance Indicators for Solar-Only* Systems on Annual Base for a Demand Value of 200 lt/day

Location (Latitude) Qd (MJ) QL (MJ) f

sol

(%)

Stockholm (59.2°N) 11164 3813 34.2

Würzburg (49.5°N) 10691 4131 38.6

Davos (46.5°N) 12110 5645 46.6

Athens (38.0°N) 8326 5550 66.7

Thermosiphon System: STHS 200/237

Performance Indicators for Solar-Only* Systems on Annual Base for a Demand Value of 200 lt/day

Location (Latitude) Qd (MJ) QL (MJ) f

sol

(%)

Stockholm (59.2°N) 11164 4320 38.7

Würzburg (49.5°N) 10691 4636 43.4

Davos (46.5°N) 12110 6433 53.2

Athens (38.0°N) 8326 6023 72.4

Thermosiphon System: STHS 300/364

Performance Indicators for Solar-Only* Systems on Annual Base for a Demand Value of 300 lt/day

Location (Latitude) Qd (MJ) QL (MJ) f

sol

(%)

Stockholm (59.2°N) 16746 6623 39.6

Würzburg (49.5°N) 16052 7190 44.7

Davos (46.5°N) 18165 9997 55.1

Athens (38.0°N) 12488 9209 73.8

Thermosiphon System: STHS 300/400

Performance Indicators for Solar-Only* Systems on Annual Base for a Demand Value of 300 lt/day

Location (Latitude) Qd (MJ) QL (MJ) f

sol

(%)

Stockholm (59.2°N) 16746 6938 41.5

Würzburg (49.5°N) 16052 7474 46.6

Davos (46.5°N) 18165 10533 58.0

Athens (38.0°N) 12488 9492 76.0

25

SOLATHERM reserves the right to modify characteristics of the products or their accessories and components without prior notice.

1. The present warranty covers the repair or substitution of the defective parts or part of

the system from authorised personnel. The replacement of th

e complete system can

only happen if the repair is not possible. In any case of failure or malfunction of the

system, the buyer must immediately inform the company as well as the distributor.

2. The present warranty covers only the free supply of spare parts

and in any case does

not cover any expenses for shipping costs. Dispatch costs as well as any authorized

personnel expenses or expenses for replacement of the defective parts are on clients

charge.

3. In case of malfunction, the dispatch of the defective pa

rts/products to the company

headquarters or place of repair of the defective product is on clients charge. Otherwise,

all costs for on-spot repair from authorised personnel at the clients location is at client’s

expense. The company reserves the right of decision on the type and how the repair

will be made according to its judgment. Every repair crew visit, even for just auditing

and checking the system is charged with the expenses and fees of the technician.

4. Any warranty claim can only be valid if this original warranty card is presented

accompanied with the original purchase receipt edited by the distributor. Furthermore,

for the warranty to be valid the buyer must complete and sign both parts of the warranty

(clients copy and distributors copy) and send the relative parts to the parties intended

within 10 days from the date of installation.

5. All spare parts or parts repaired or replaced have the same benefit of warranty period

as the remaining period of the general warranty of the system.

6. The electric parts of the system (electric element, thermostat, etc…) carry only two (2)

years warranty from the date of purchase.

7. The manufacturer assumes no responsibility and the present warranty

is invalid in the following cases:

A. When the product has not been checked, repaired, altered or installed by non

-authorized

personnel by the manufacturer or the distributor

– or his partners

B. If the ordinary services of the system have not been perform

ed by authorised by the company

personnel and as per Maintenance Schedule in the product Installation Manual.

The 1st service must

be conducted within 1 year (12

months) after the date of purchase of the product at the clients care

and expense. Proof of se

rvice is the signature and stamp of the authorised personnel at the bottom

of the present warranty card in combination with the original invoice of the service from the service

technician.

C. When any damage or malfunction is done to people or thing or the

product itself due to accident,

mishandling, improper or inappropriate use (intentional or unintentional), negligence, maltreatment

or bad installation of the product, lack of servicing of the product, wrong technical intervention on

the product or its parts, or to wrong connexions – cabling of the electrical resistance or other

electrical parts, other the instructions provides by the manufacturer.

D. If damage or malfunction of the system is due to bad weather conditions and natural disasters

(such as: natural disaster, frost, storms, floods, hail, earthquakes, fires, arson, etc…)

E. Damage or breakage of the collector glass

F. In case of normal wear and deterioration (due to time, etc…) of the external parts of the product

which do not affect the proper use of the system.

8. Manufacturer retains the right of control of the validity of the warranty at each stage of product repair

and to charge the owner for the costs of the repairs (value of the parts included) in this case the

conditions described in detail in the present warranty card are not met.

9. The present warranty does not affect the owner's and consumer’s rights, as these are foreseen by

Greek law

DATE STAMP AND SIGNITURE OF MAINTENANCE

PERSON

1

st

2

nd

3

rd

4

th

5

th

6th

7

th

8

th

26

SOLATHERM reserves the right to modify characteristics of the products or their accessories and components without prior notice.

STHS SERIES THERMOSIPHON SYSTEMS TECHNICAL, INSTALLATION AND USE MANUAL - Version V1-1.17 - All rights reserved. Text and Illustrations correspond to specifications at the time of printing, subject to change without prior notice.

Loading...

Loading...