THIS POWER VENT KIT IS ONLY FOR USE WITH THE FOLLOWING MODELS:

SINGLE SIDE MODELS: BI-48-SSL, BI-48-SSR, BI-60-SSL, BI-60-SSR, BI-72-SSL, BI-72-SSR

DIRECT VENT

PART # PV-800HZ AND PV-850V

Report #0361GF006S

Ce manual est disponsible en Francais sur demande.

PV-800HZ SHOWN

POWER VENT KIT

SEE-THRU MODELS: BI-48-ST, BI-60-ST, BI-72-ST

TABLE OF CONTENTS

Power Vent Kit Contents 2

Power Vent Clearances 3

Venting Configurations 5

Horizontal (side wall) Venting 6

Vertical (through roof) Venting 8

Control Installation Instructions 11

Electrical Instructions 15

Replacement Parts List 16

Warranty Information 17

WE STRONGLY SUGGEST THAT YOU READ THIS MANUAL THOROUGHLY BEFORE BEGININNG THE

INSTALLATION OF THE SÓLAS POWER VENT KIT. THIS SPECIFIC PRODUCT HAS ITS OWN UNIQUE SETUP AND INSTALLATION REQUIREMENTS THAT MUST BE FOLLOWED EXACTLY. PLAN YOUR

INSTALLATION IN ADVANCE BY CAREFULLY RE-VIEWING ALL THE INFORMATION CONTAINED IN THIS

MANUAL.

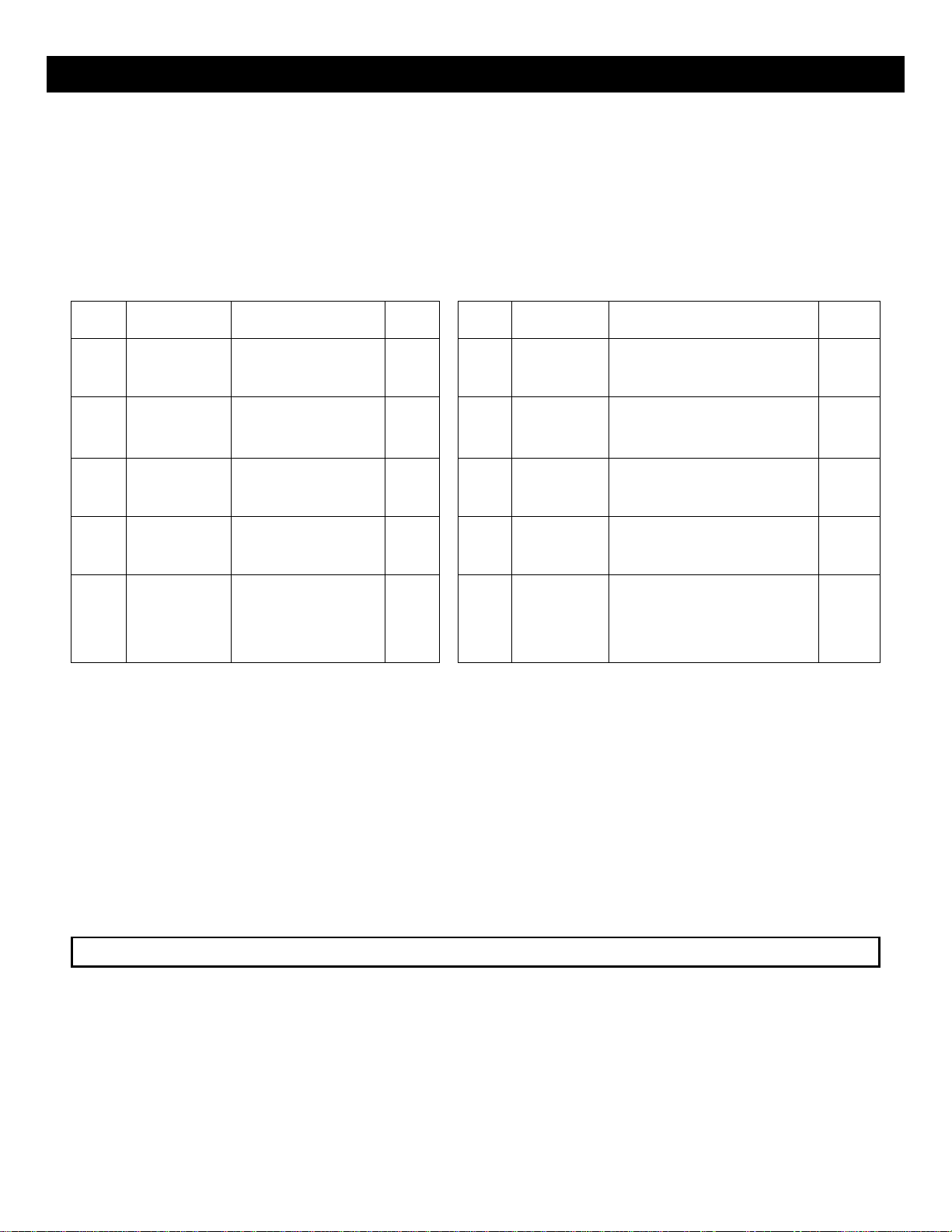

POWER VENT KIT CONTENTS

This kit can only be used in conjunction with the SÓLAS Contemporary Fire products listed below. This

installation must conform with local codes, or, in the absence of local codes, with the National Fuel Gas

Code, ANSIZ2223.1/NFPA 54, or the Natural Gas and Propane Installation Code, CSA B149.1.

THIS POWER VENT KIT IS ONLY FOR USE WITH THE FOLLOWING SÓLAS MODELS:

SEE-THRU MODELS: BI-48-ST, BI-60-ST, BI-72-ST

SINGLE SIDE MODELS: BI-48-SSL, BI-48-SSR, BI-60-SSL, BI-60-SSR, BI-72-SSL, BI-72-SSR

CONTENTS OF POWER VENT KIT

ITEM PART# DESCRIPTION QTY.

1 HRD-800HZ

2 HRD-801

3 HRD-802 HARDWARE KIT 1 8 HRD-850V

4 HRD-803

5 HRD-804

HORIZONTAL

POWER VENT KIT

VENT ADAPTER W/

PRESSURE TAP

POWER VENT RELAY

HARNESS

POWER VENT

CONTROL W/

PRESSURE SWITCH

1 6 HRD-805 ADJUSTABLE RESTRICTOR 1

1 7 HRD-806 PRESSURE SWITCH TUBING 1

1 9 HRD-851V

1 10 HRD-852V

ITEM PART# DESCRIPTION QTY.

OPTIONAL VERTICAL

TERMINATION CAP

OPTIONAL VERTICAL

TERMINATION BOX

OPTIONAL VERTICAL

TERMINATION HARDWARE

KIT

1

1

1

This kit uses either M&G Duravent direct vent pipe, Secure Vent direct vent pipe, or Selkirk Directtemp vent pipe with a 4” inner pipe and a 6” outer pipe.

Vertical installations must use the optional HRD-850V vertical termination cap. HRD-850V includes

HRD-851V vertical termination box, and HRD-852V vertical termination hardware kit. The vertical

termination box can only be installed on flat surfaces; sloped surfaces require construction of a chase

which provides the minimum interior square opening of 11”x11” (279mm x 279mm) for the venting and

wiring to pass through. Flat roofs may require a chase depending on local codes and roof construction.

(If in doubt check with local inspector)

ALWAYS MAINTAIN 1.5” (38mm) CLEARANCE TO COMBUSTIBLES AROUND VENT PIPE.

The Power Vent termination must be located in accordance with the clearances outlined in the venting

section of this manual on page 3.

For replacement parts, refer to page 9. Replacement parts can be ordered through your authorized

SÓLAS dealer.

2

POWER VENT CLEARANCES

Figure #1

A. clearances above grade, veranda, porch, deck, or balcony [*12 inches (30 cm) minimum]

B. clearance to window or door that may be opened [* 12 inches (30 cm) minimum]

C. clearance to permanently closed window [minimum 12 inches (30 cm) recommended to prevent condensation on

window]

D. vertical clearance to ventilated soffit located above the terminal within a horizontal distance of 2 feet (60 cm) from the

edge of the terminal [12 inches (30 cm) minimum]

E. clearance to unventilated soffit [12 inches (30 cm) minimum]

F. clearance to outside corner [6 inches (15 cm) minimum]

G. clearance to inside corner [6 inches (15 cm) minimum]

H. * not to be installed above a meter/regulator assembly within 3 feet (90 cm) horizontally from the center-line of the

regulator

I. clearance to service regulator vent outlet [* 6 feet (1.8 m) minimum]

J. clearance to non-mechanical air supply inlet to building or the combustion air inlet to any other appliance [* 12

inches (30 cm) minimum]

K. clearance to a mechanical air supply inlet [* 6 feet (1.8 m) minimum]

L. ^ clearance above paved side-walk or a paved driveway located on public property [* 7 feet (2.1 m) minimum]

M. clearance under veranda, porch, deck, or balcony [12 inches (30 cm) minimum**]

^ a vent shall not terminate directly above a side-walk or paved driveway which is located between two single family

dwellings and serves both dwellings*

** only permitted if veranda, porch, deck, or balcony is fully open on a minimum of 2 sides beneath the floor*

* as specified in CGA B149 Installation Codes, Note: local Codes or Regulation may require different clearances

* for U.S.A. Installations follow the current National Fuel Gas Code, NSI Z223.1

3

4

VENTING CONFIGURATIONS

Maximum venting – 110ft

plus (6) 90 degree elbows.

Maximum vent length is 110 ft.

plus six 90-degree elbows or

combination of other elbows

equaling 90-degrees, with a

maximum 66ft vertical rise.

Minimum horizontal vent length

is 3 ft. plus one 90-degree elbow.

The vent can be installed with

any combination of rise and run

between the figures including up

to 3 ft. below the unit.

Figure #2

WARNING:

A minimum clearance to combustibles of 1.5” (38mm) is required around the vent pipe at all times.

Failure to maintain this clearance may result in property damage, injury, or death.

NOTE:

IT IS PERMISSABLE TO VENT HORIZONTALLY, DIRECTLY OFF OF THE UNIT, NO VERTICAL RISE IS

REQUIRED WHEN EQUIPPED WITH A POWER VENT AS SHOWN IN FIGURE #3.

Figure #3

5

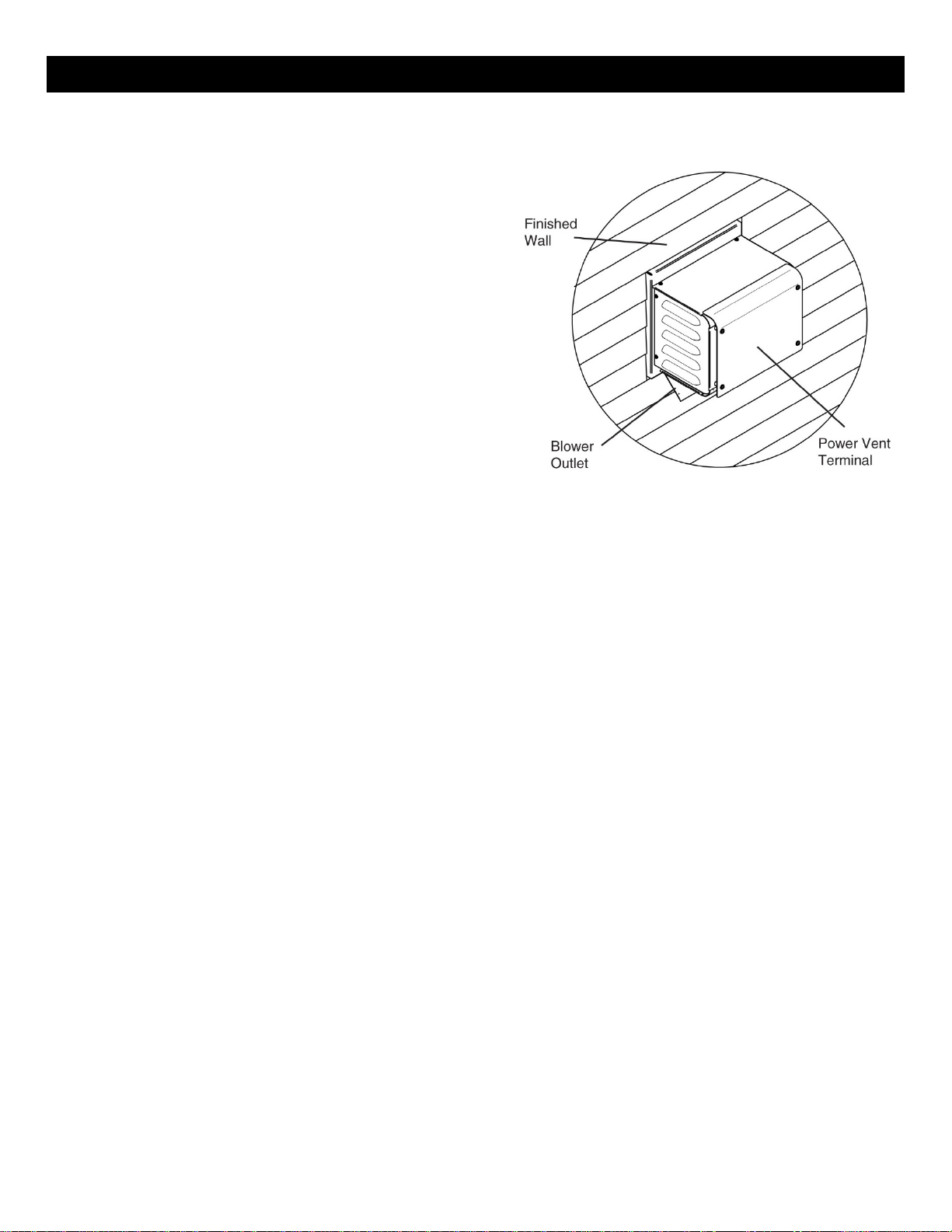

HORIZONTAL (SIDE WALL) VENTING

This kit uses either Simpson Duravent GS direct vent pipe, Secure Vent direct vent pipe or Selkirk

Direct-temp vent pipe with a 4" inner pipe and a 6" outer pipe.

1. Locate the power vent termination following

the clearance to combustible table, venting

configuration diagram (Fig. #2 & 3), and

terminal location diagram (Fig. #1).

2. Cut and frame an 11" x 11" opening. The center

of the square hole should line up with the

center

3. Install the M&G Duravent (or equivalent) Wall

thimble, part number 46DVA-WT (not supplied

with kit) in the opening to retain any insulation

in the wall and maintain proper clearances. If

the wall being penetrated is constructed of

noncombustible material only (i.e., Masonry

block or concrete) the wall thimble is not

required and a hole with zero clearance is

acceptable. (6 5/8” hole)

Figure #4

4. Attach the terminal to the outside wall. Ensure that the terminal is the right way up and that only

the outer flanges that are used to secure the terminal to the building are covered by the exterior

wall or siding. (Fig.#4) Note: No other part of the terminal can be recessed into the exterior

wall or siding.

5. Attach the vent adaptor directly to the appliance after the initial 45⁰ elbow before any

horizontal or vertical pipe is added. Tape all exterior seams on the venting system with foil HVAC

tape. Note: The inner pipe does not need to be sealed. (Fig. #5)

6. Connect the high temperature silicone tube to the vacuum pressure tap on the adaptor, secure

with the hose clamp provided and route the tube through the utility access panel back to Power

vent control location. (Fig. #5) Tube may touch unit and be trimmed if required. Connect the

pressure switch tubing to the light grey port on the power vent control. Note: Ensure that there

are no blockages in this tube, as this will cause the control to malfunction. Do not allow tube to

rest on firebox after it is routed.

7. Run the required Simpson Duravent GS / Secure Vent / Selkirk Direct-temp pipe from the adaptor

to the terminal assembly. Assemble as per the vent pipe manufacturer’s instructions.

6

Loading...

Loading...