SolarMax TS-SV

330TS-SV / 360TS-SV

Bedienungsanleitung ■ Operating manual ■ Notice d’emploi

Documentación del dispositivo

■ Istruzioni per l’uso

49

Contents

1 About this operating manual 51

1.1 Scope 51

1.2 Target group 51

1.3 Where to keep this manual 51

1.4 Symbols used in this manual 51

2 Safety instructions 52

3 Description 53

3.2 Operating elements 53

3.2.1 Inverter 54

3.2.2 Master Control Unit (MCU) 55

4 Operation 56

4.1 How the main switch works 56

4.2 How the DC and AC power switches work 56

4.3 Switching on the inverter 57

4.4 Switching off the inverter 58

4.5 Operating the graphics display 59

4.5.1 Menu button symbols 59

4.5.2 Menu structure 60

5 Data communication 72

5.1 Configuration of the data communications interfaces 73

6 Options 74

6.1 MaxControl 74

6.1.1 Scope of services 74

6.1.2 Duration 74

6.2 Accessory components 74

7 Operating status 75

7.1 Status messages and status LED 75

7.2 Booting 76

7.3 Mains operation 76

7.4 Communications activity 76

50

en

8 Troubleshooting 77

8.1 SolarMax Service Center 78

8.2 Diagnosis & corrective steps 78

8.2.1 General troubleshooting 78

8.2.2 Warnings 78

8.2.3 Malfunctions 80

8.2.4 Error 81

8.2.5 Blockages 81

9 Maintenance 82

9.1 Inspections by the plant operator 82

9.2 Maintenance by a qualified electrician 82

9.3 Testing grid monitoring 83

10 Disposal 86

51

1 About this operating manual

1.1 Scope

This operating manual describes the operation, troubleshooting, and maintenance processes for the inverters SM330TS-SV, SM360TS-SV (TS-SV inverter) and their control

unit TS-SV Master Control Unit (MCU).

1.2 Target group

This operating manual is written for the operator of the PV system and the quali ed

electrician.

1.3 Where to keep this manual

The system operator must ensure that this operating manual is available to those responsible for the system at all times. If this original document is lost, an up-to-date version of

the operating manual can be downloaded from our website (www.solarmax.com).

1.4 Symbols used in this manual

From time to time you will see the following symbols when reading this operating manual:

DANGER

This symbol indicates that ignoring this instruction can lead directly to serious

injury or death.

CAUTION

This symbol indicates that ignoring this instruction can lead to damage to your

inverter or your PV power plant.

NOTE

This symbol indicates information which is especially important for operating

the inverter.

52

en

2 Safety instructions

DANGER

■ In daylight the PV generator supplies the inverter with a dangerously high DC

voltage.

■ SolarMax inverters and accessories may only be installed or opened by quali ed

electricians who have completely read and understood this instruction manual in

advance.

■ Only quali ed electricians who have already completely read and understood this

instruction manual in advance may install and open SolarMax inverters.

■ Ignoring the installation and safety instructions shall cancel any and all warranty

and liability claims.

■ Touching live parts is life-threatening.

■ The inverters and accessories must not be opened at any time during operation.

■ Before the inverter or the MCU is opened, the DC and AC feed lines must be dis-

connected according to the instructions and secured against being reconnected

accidentally.

■ After disconnecting the inverter wait at least 5 minutes before opening the device

to permit internal capacitors to discharge.

53

3 Description

All SolarMax inverters work completely automatically. The DC and AC power switches

(Q4-Q6 and Q1-Q3) as well as the main switch (Q7) are always on during normal operation. The inverter starts when there is enough input power and continues to operate until

the available input power from the PV generator drops below the necessary minimum.

The inverter is operated using the external master control unit (MCU). The MCU controls

the connected inverters and is also the communications and user interface.

3.2 Operating elements

The following section describes the operating elements of the TS-SV inverter and the

master control unit (MCU).

54

en

3.2.1 Inverter

Legend:

1

AC power switch Q1

4

DC power switch Q4

2

AC power switch Q2

5

DC power switch Q5

3

AC power switch Q3

6

DC power switch Q6

1 42 53 6

55

3.2.2 Master Control Unit (MCU)

Legend:

1

Main switch Q7

4

Status LED

2

Graphics display

5

Lock

3

Push-buttons

1

5

2

3

4

56

en

4 Operation

The inverter is operated using the external MCU. The MCU allows all the connected inverters to be operated simultaneously, only the DC and AC power switches must be operated

directly on the respective inverter.

For all other functions described below the MCU is the shared interface for all the connected inverters.

4.1 How the main switch works

When you switch off the main switch Q7, turning it to the OFF position, the inverter opens

the contacts of the AC protections K1, K2 and K3. This disconnects the inverter from the

mains.

DANGER

If you switch the main switch Q7 to the OFF position, the inverter’s components are

still live! This includes the 3 power units and the lters on the input end!

4.2 How the DC and AC power switches work

The DC power switches Q4, Q5 and Q6 are used to connect or disconnect the direct

current of the PV plant to the inverter. The AC power switches Q1, Q2 and Q3 connect or

disconnect the inverter to or from the mains. The DC as well as the AC power switches

are equipped with thermomagnetic overcurrent fuses.

DANGER

Even when the DC and AC power switches are switched off, the connections for the DC

and AC feed lines in the inverter are still live!

57

4.3 Switching on the inverter

Procedure

Action Reaction

1. Switch off main switch Q7

(to “OFF” position)

2. Switch on DC power switch Q4, Q5 & Q6

(to “ON” position)

The graphics display is activated after a

maximum of 20 seconds (if there is enough

sunlight).

3. Switch on AC power switch Q1, Q2 & Q3

(to “ON” position)

4. Switch on main switch Q7

(to “ON” position)

After several seconds the Overview menu is

displayed. The message “Startup....” appears

in the “Status” line. The status LED blinks

green.

When the connected inverters have been

started up and are feeding power into the

mains, indicates the device status “Mains

operation”. The status LED glows green.

NOTE

■ When the inverters are commissioned the “Initial Setup” menu appears rst,

during subsequent start-ups the “Overview” menu; see the installation manual.

■ If several inverters are connected to one MCU steps 2 and 3 must be performed

for each inverter before the main switch Q7 switches on the whole system (step 3).

58

en

4.4 Switching off the inverter

DANGER

■ Even when the inverter is switched off, the connections for the DC and AC feed

lines in the inverter remain live!

■ Before the inverter or the MCU is opened, the DC and AC feed lines must be dis-

connected according to the instructions and secured against being reconnected

accidentally.

■ After disconnecting the inverter wait at least 5 minutes before opening the device

to permit internal capacitors to discharge.

Procedure

Action Reaction

1. Switch off main switch Q7

(to “OFF” position)

Message on the graphics display is: “Main

switch off”. The device disconnects from the

mains.

2. Switch off AC power switch Q1, Q2 & Q3

(to “OFF” position)

3. Switch off DC power switch Q4, Q5 & Q6

(to “OFF” position)

After a short time the graphics display of the

MCU is shut down.

NOTE

Steps 2 and 3 must be repeated for each inverter connected to the MCU.

59

4.5 Operating the graphics display

The graphics display on the front of the MCU shows the system dimensions, status information and the malfunction messages of the connected inverters. The display allows you

to learn the current device status, access the integrated data logger and enter various

system settings. Navigate the various menus using the three push-buttons under the

display.

Since the MCU is supplied with power both from the DC end and the AC end, it is also

possible to use the MCU functions at night or when the DC end is shut down. However,

the inverters connected to the MCU only deliver data and measured values if the inverters

are in operation (when there is enough power from the DC end).

To the left of the graphics display there is a status LED indicating the device status, see

7.1 “Status messages and status LED”.

4.5.1 Menu button symbols

With the help of the symbols shown here you can navigate the various menus and functions visible in the display. The current button function changes from one menu to the

next, corresponding to the symbol appearing directly over the button:

Symbol Function

Scroll up, increase number or next element

Scroll down, or previous element

Back to higher level menu

Select next number

Display selected submenu or con rm changes

Launch edit mode for selection

Abort

60

en

4.5.2 Menu structure

61

4.5.2.1 Main menu

The main menu is the starting point for all the submenus and displays, see 4.5.2 “Menu

structure”. Use the arrow keys

and to select a menu. Click to con rm your

selection.

4.5.2.2 Overview

If none of the three buttons is pushed for 120 seconds, the display returns automatically

to the Overview menu which shows the three most important values as well as the current

operating status of the system (all the inverters connected to the MCU).

Operating parameters Description

17.02.2010 (example) Current date

11:44:35 (example) System time

Pac Momentary effective output

Today Total energy fed into the mains on the current date and as of the

momentary time.

Total Total energy fed into the mains since the inverter’s

commissioning.

Status For status messages and warnings of the system, see 7 “Operat-

ing status” and 8.2.2 “Warnings”.

4.5.2.3 Measured values

62

en

The “Measured values” menu allows the display of currently measured values in relation

to the system or the power unit selected.

NOTE

■ The number of power units listed in the “Measured values” menu depends on the

number of inverters connected to the MCU.

■ Three power units are displayed per inverter.

■ The numbering of the power units follows the addresses allocated to the power

units at the time of the installation (see Installation Manual).

Use the button to highlight a category. Select a category by pressing the button.

In each case only four measured values are displayed at the same time.

Use the arrow buttons and to navigate the measured values. Press the left button

to return to the Main menu.

63

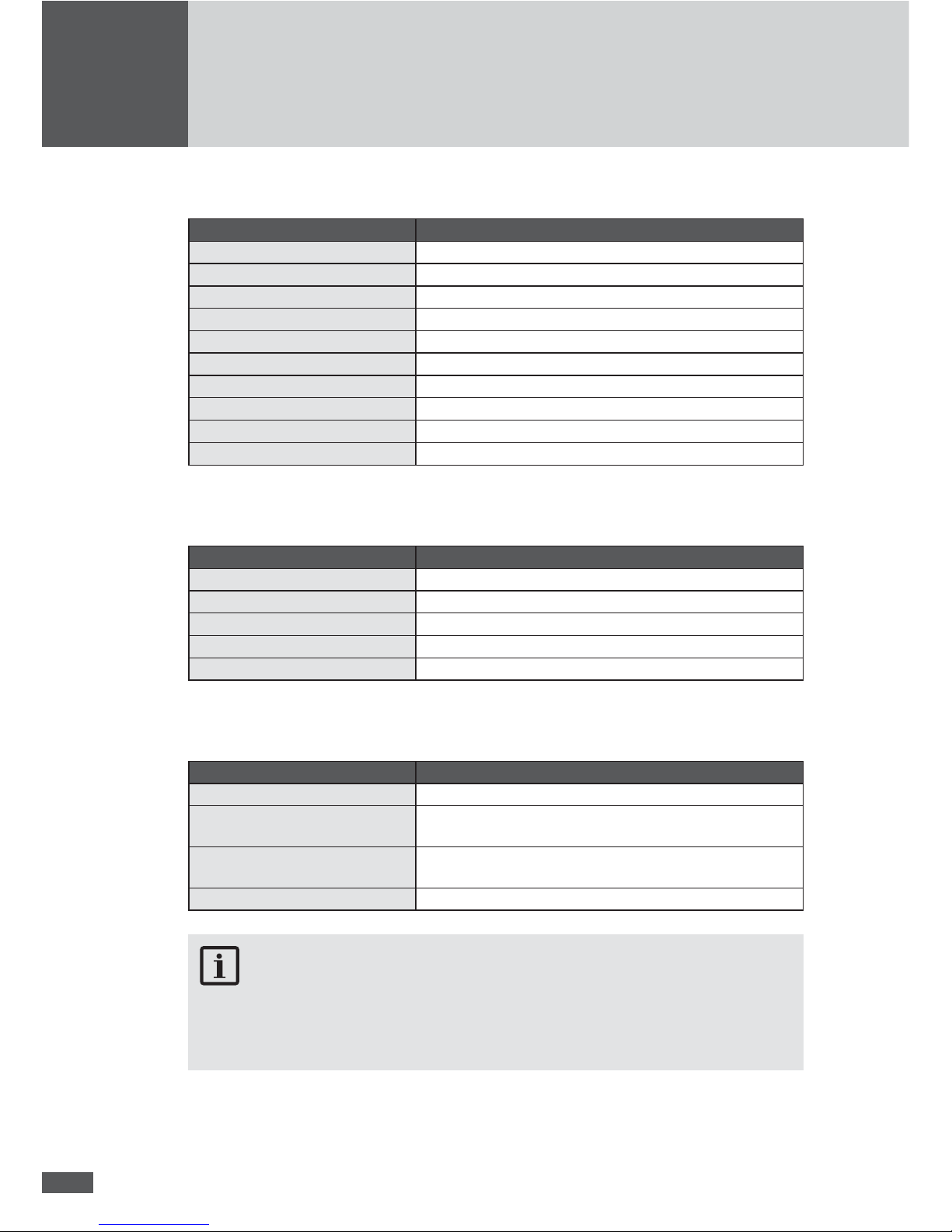

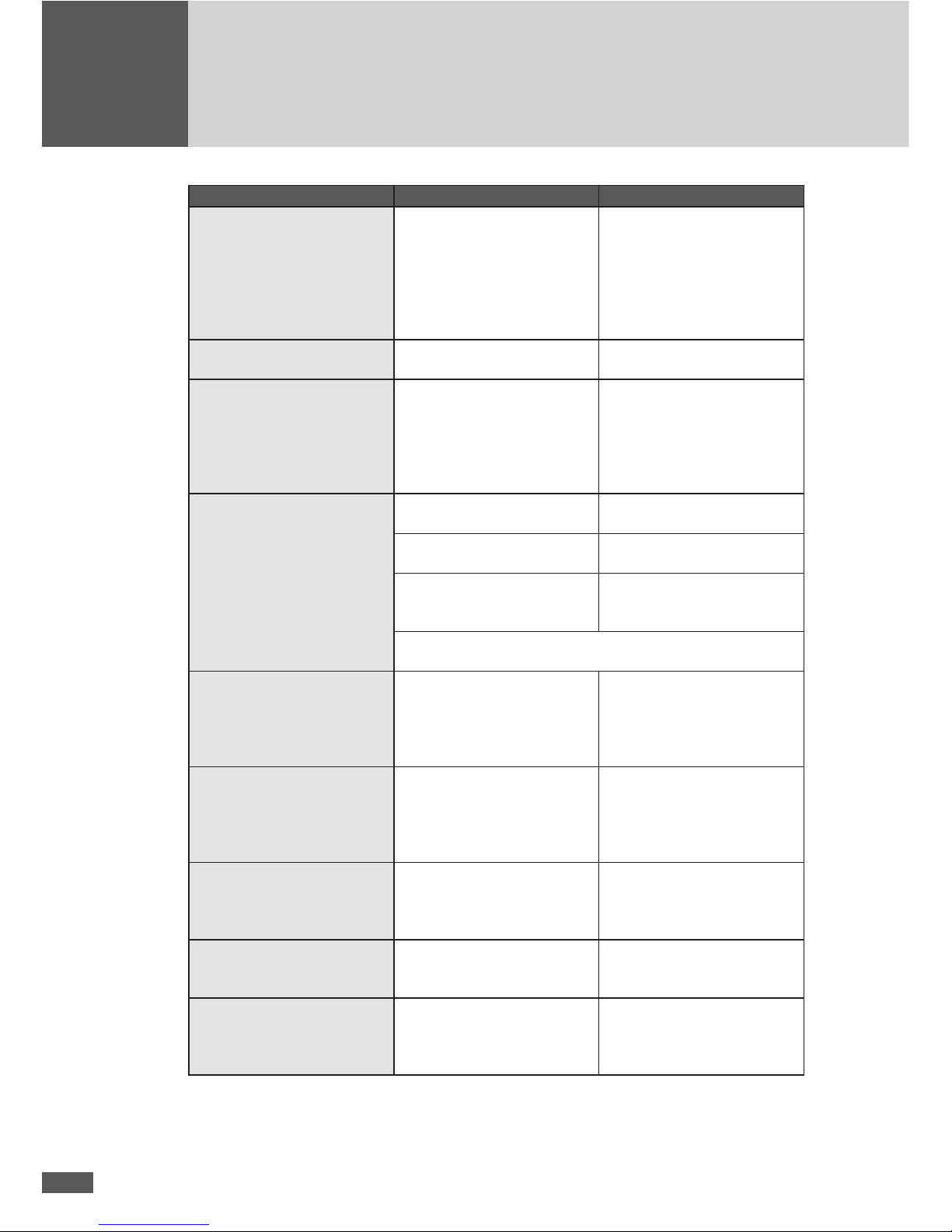

The following measured values can be accessed for the system:

Measured value Description

Vdc DC Input voltage (only in single MPPT operation)

Idc DC Input current (only in single MPPT operation)

Vac (L1L2, L2L3, L3L1) Mains voltage (Phase to Phase)

Iac (L1, L2, L3) AC Input current (per Phase)

Pac Active output power

Q Reactive power (+: overexcited / −: underexcited)

S Apparent output power

Cosφ

Power factor (OEX: overexcited / UEX: underexcited)

Frequency Mains frequency

Temperature Highest currently measured temperature in the power unit

The following measured values are available for the relevant power unit:

Measured value/Status Description

Vdc DC Input voltage

Pdc Input power at the power unit

Temperature Highest currently measured temperature in the power unit

Fan Operating condition of fans

Status Operating status of the power unit (On/Off/Error)

Measured values only to be displayed with MaxTalk (menu: device/measured values):

Measured value Description

Prel Relative output (Prel = (Pac/Pinst tot) × 100%)

Vsym Voltage of the PV generator in comparison with the earthing

potential(DC+ and DC- against earth)

Vsym AC Effective value of the AC voltage share of the DC symmetry

voltage

Ief Earth fault current

NOTE

Remember that the MCU measured values must not be used for billing purposes or

calculating ef ciency. Only the measured values of a calibrated electricity meter are

the basis for billing purposes.

64

en

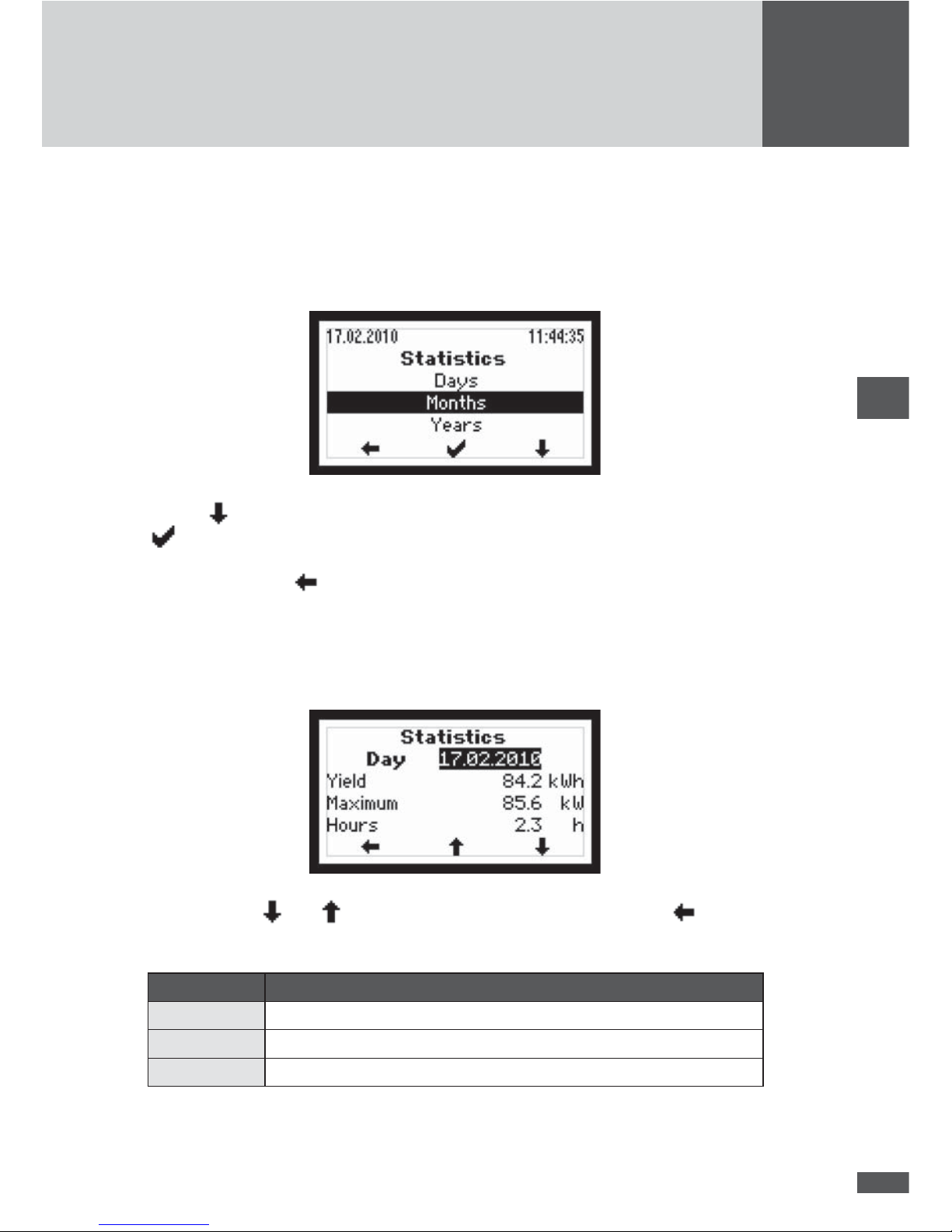

4.5.2.4 Statistics

In the Statistics menu you can access the MCU’s internal data logger. The accessible

statistics are for the most recent 31 days, 12 months or 10 years. The displayed statistical

values each refer to the system as a whole.

Use the button to highlight a statistic category. Select a category by pressing the

button.

Press the left button

to return to the Main menu.

Daily statistics

This menu provides access to the data from the most recent 31 days.

Use the buttons and to select a daily statistic. Press the left button to return

to the Statistics menu.

Parameter Description (refers to the day displayed)

Yield Total amount energy fed into the mains

Maximum Peak value of the output fed into the mains

Hours Total operating hours (in device status “mains operation”)

65

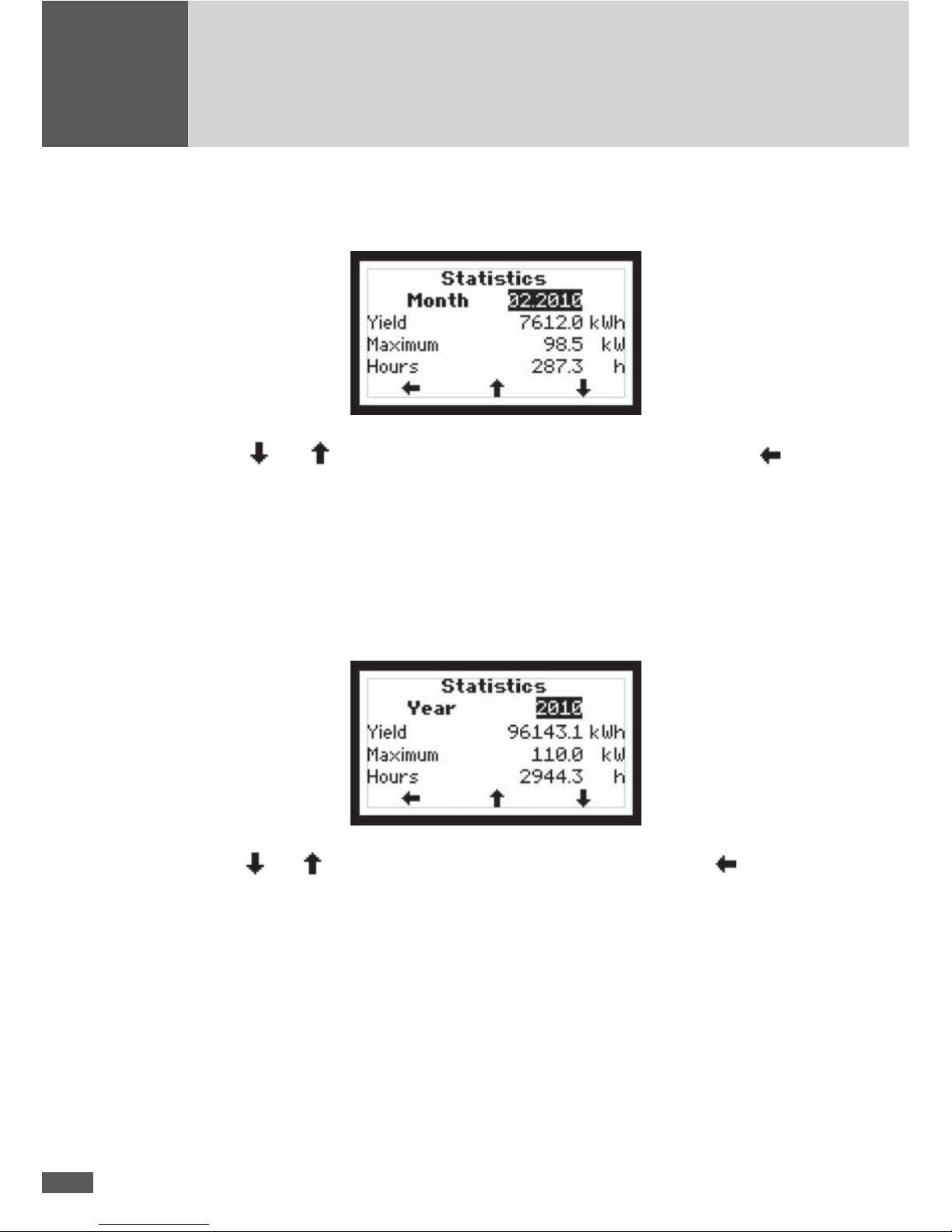

Monthly statistics

This menu provides access to the data from the most recent 12 months.

Use the and buttons to select a monthly statistic. Press the left button to

return to the Statistics menu.

The displayed values correspond to those in the daily statistics; but the values refer to

the month displayed.

Yearly statistics

This menu provides access to the data from the most recent 10 years.

Use the and buttons to select a yearly statistic. Press the left button to return

to the Statistics menu.

The displayed values correspond to those in the daily statistics; but the values refer to

the year displayed.

66

en

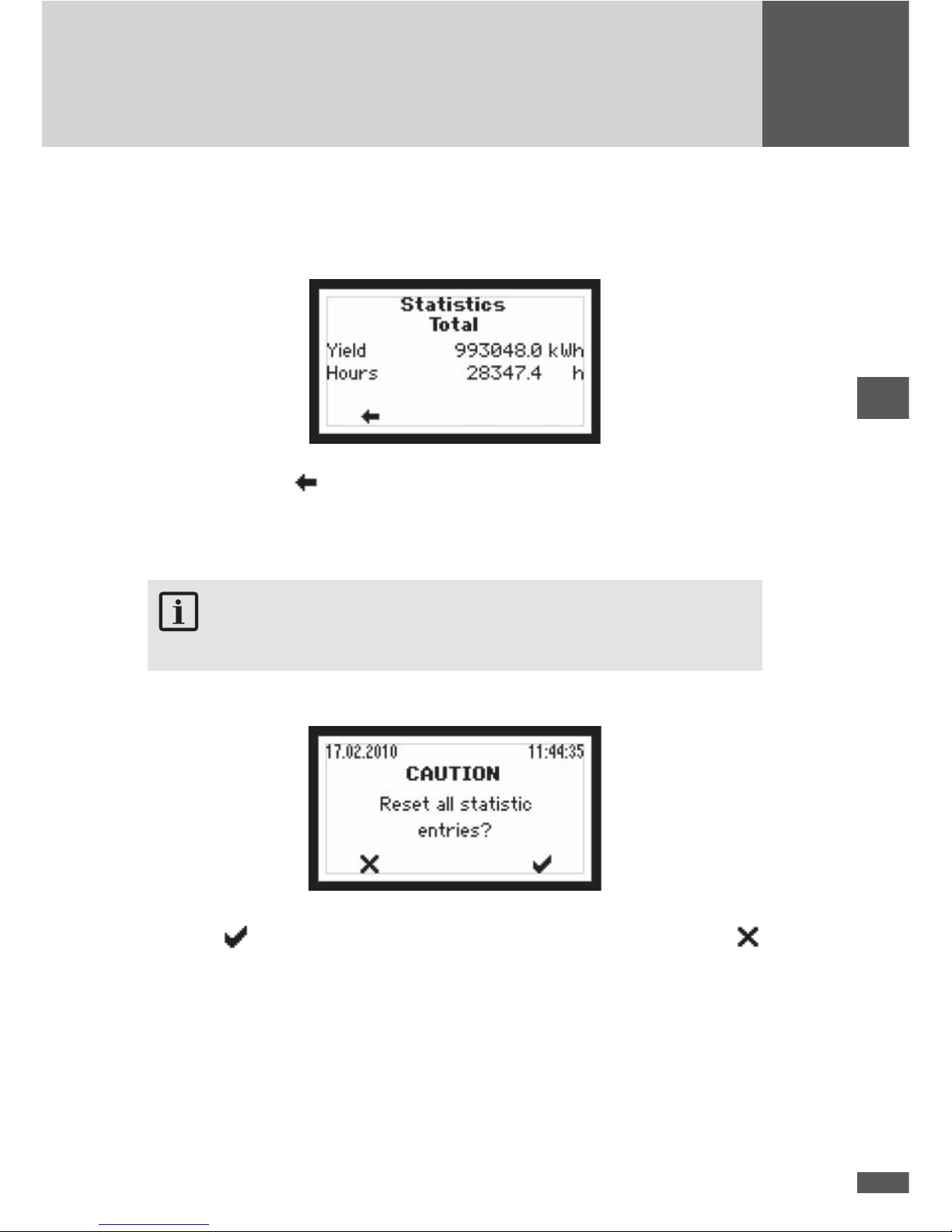

Total

This menu lists the total yield and the total number of operating hours of the inverter or

the system since it was commissioned.

Press the left button to return to the Statistics menu.

Reset

In this menu you can delete all the entries in the Statistics menu.

NOTE

Once deleted these data are irretrievably lost!

Press the button to con rm the deletion of all the statistics entries. Use the

button to enter the Statistics menu without deleting the statistics entries.

67

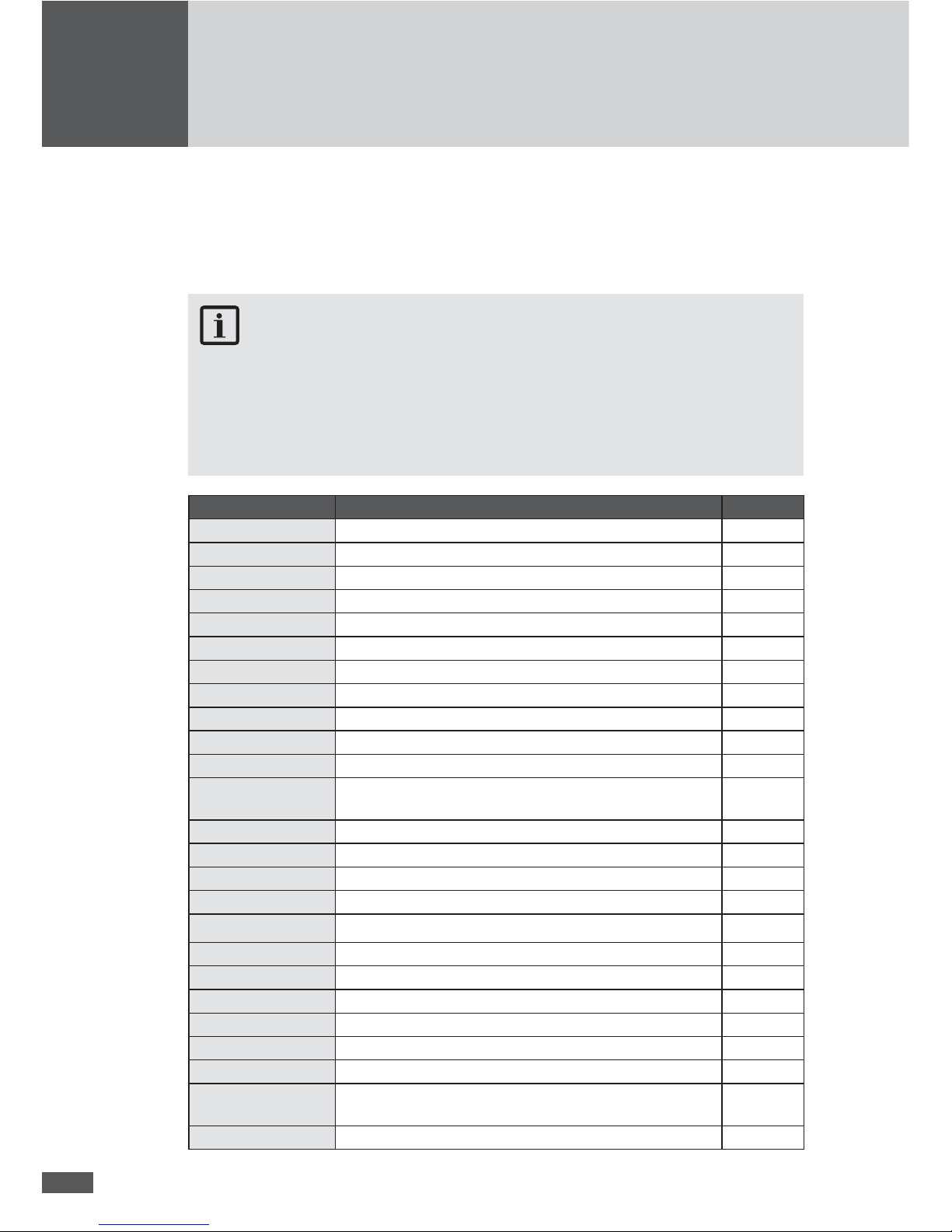

4.5.2.5 Con guration

The “Con guration” menu contains the inverter’s available operating parameters and advanced functions. The settings displayed for the limit values and the functions depend on

the country selected during initial start-up.

NOTE

MaxTalk 2 Pro, the extension to the standard MaxTalk 2 software, allows author-ised

skilled workers to individually adjust the operating parameters. The required “TS series/TS-SV parameter con guration using MaxTalk 2 Pro” instruction manual can be

found on our website www.solarmax.com (Downloads area). You can request MaxTalk

2 Pro from the SolarMax service centre. The contact details can be found overleaf.

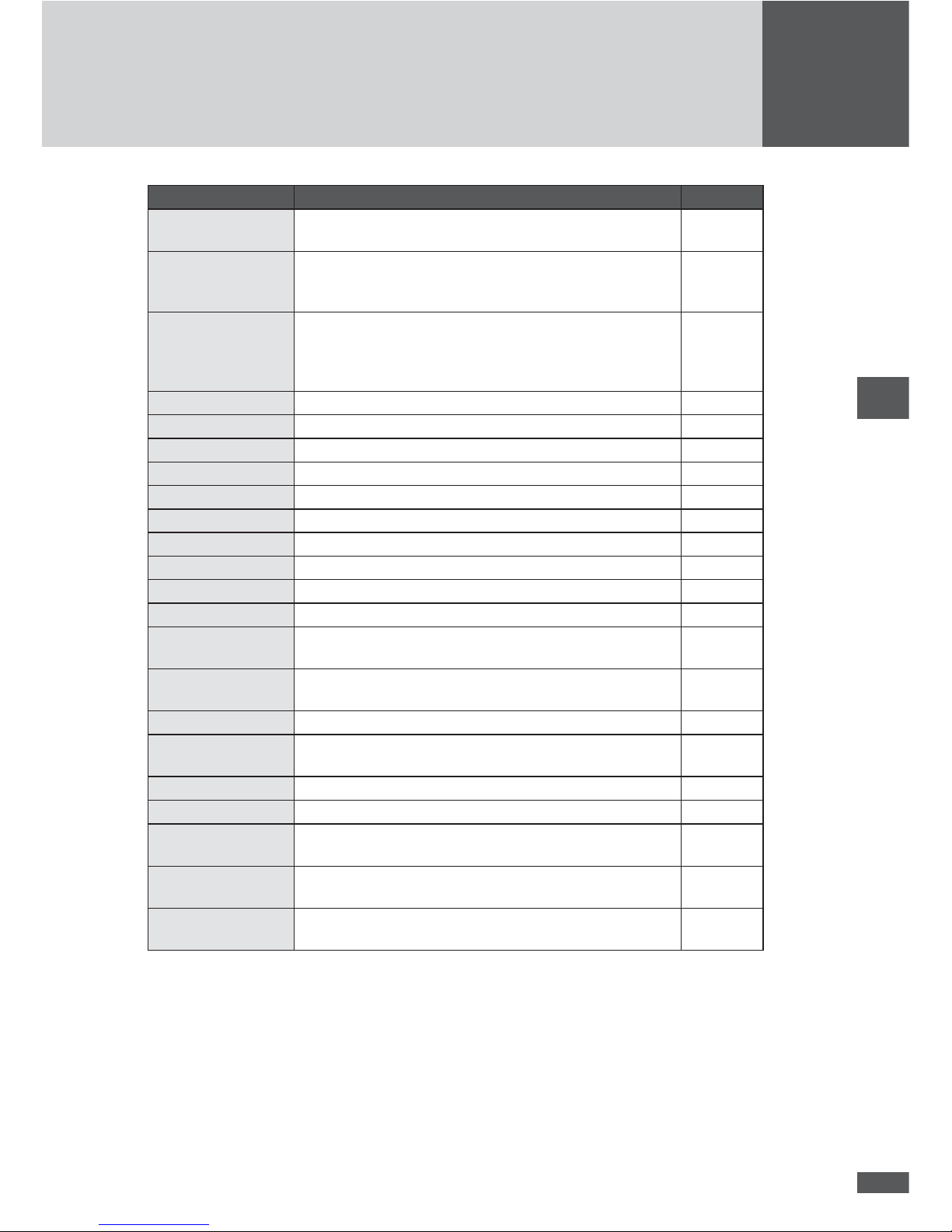

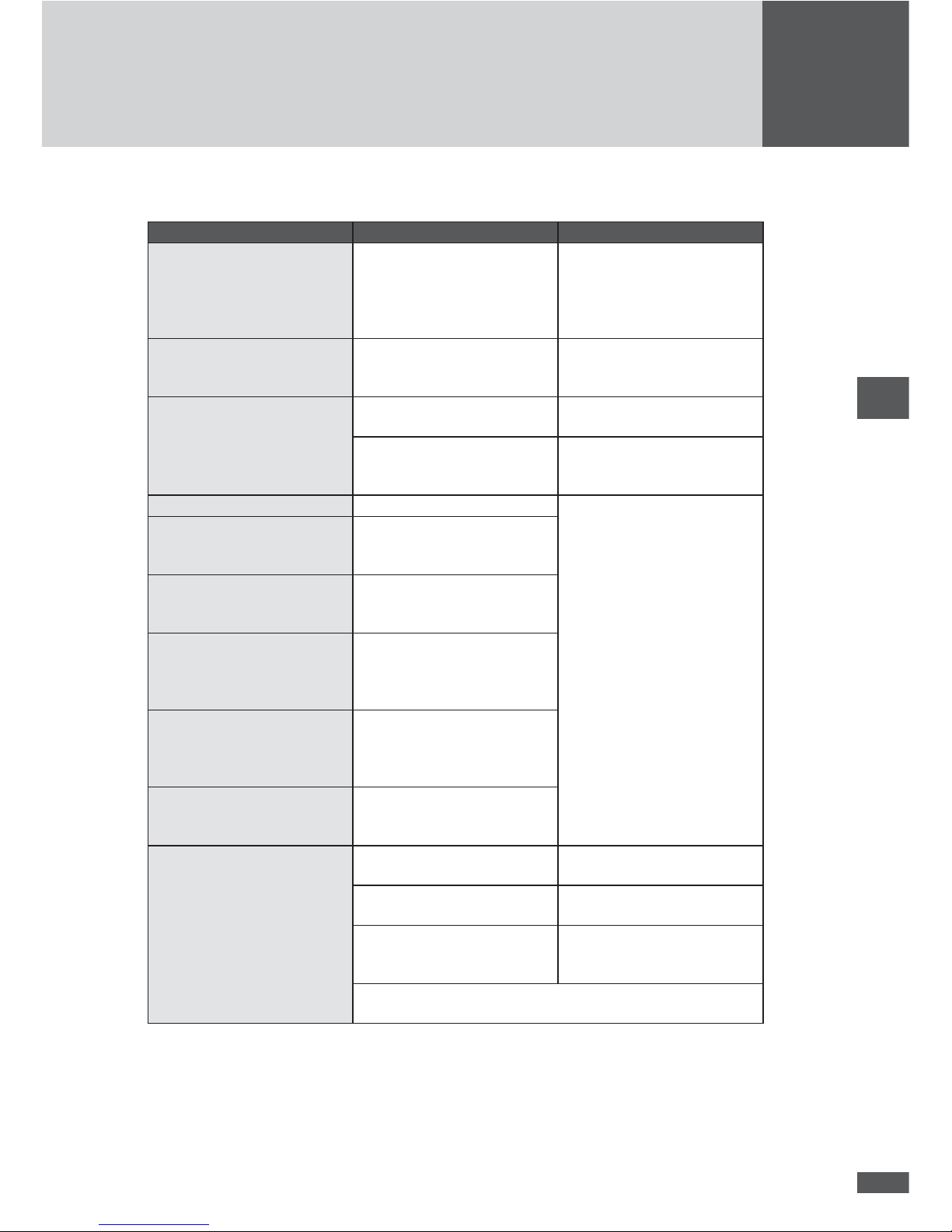

Parameter Description Unit

Country Country settings selected during initial start-up f nominal Mains nominal frequency Hz

Vac nominal Mains nominal voltage V

Vac min 1 Minimum admissible mains voltage ( rst limit) V

t Vac min 1 Release time for minimum admissible mains voltage ms

Vac max 1 Maximum admissible mains voltage ( rst limit) V

t Vac max 1 Release time for maximum admissible mains voltage ms

Vac min 2 Minimum admissible mains voltage (second limit) V

t Vac min 2 Release time for minimum admissible mains voltage ms

Vac max 2 Maximum admissible mains voltage (second limit) V

t Vac max 2 Release time for maximum admissible mains voltage ms

Vac 10 min max Maximum admissible average value of the mains voltage

over the last 10 minutes

V

f min 1 Minimum admissible mains frequency ( rst limit) Hz

t f min 1 Release time for minimum admissible mains frequency ms

f max 1 Maximum admissible mains frequency ( rst limit) Hz

t f max 1 Release time for maximum admissible mains frequency ms

f min 2 Minimum admissible mains frequency (second limit) Hz

t f min 2 Release time for minimum admissible mains frequency ms

f max 2 Maximum admissible mains frequency (second limit) Hz

t f max 2 Release time for maximum admissible mains frequency ms

Iac max Maximum admissible mains current (per shift) A

Pac max Maximum effective power to be fed W

S max Maximum apparent power to be fed. VA

Island Detection Immediate grid disconnection when island operation

detected

-

OV Detection Immediate grid disconnection with transients to Vac -

68

en

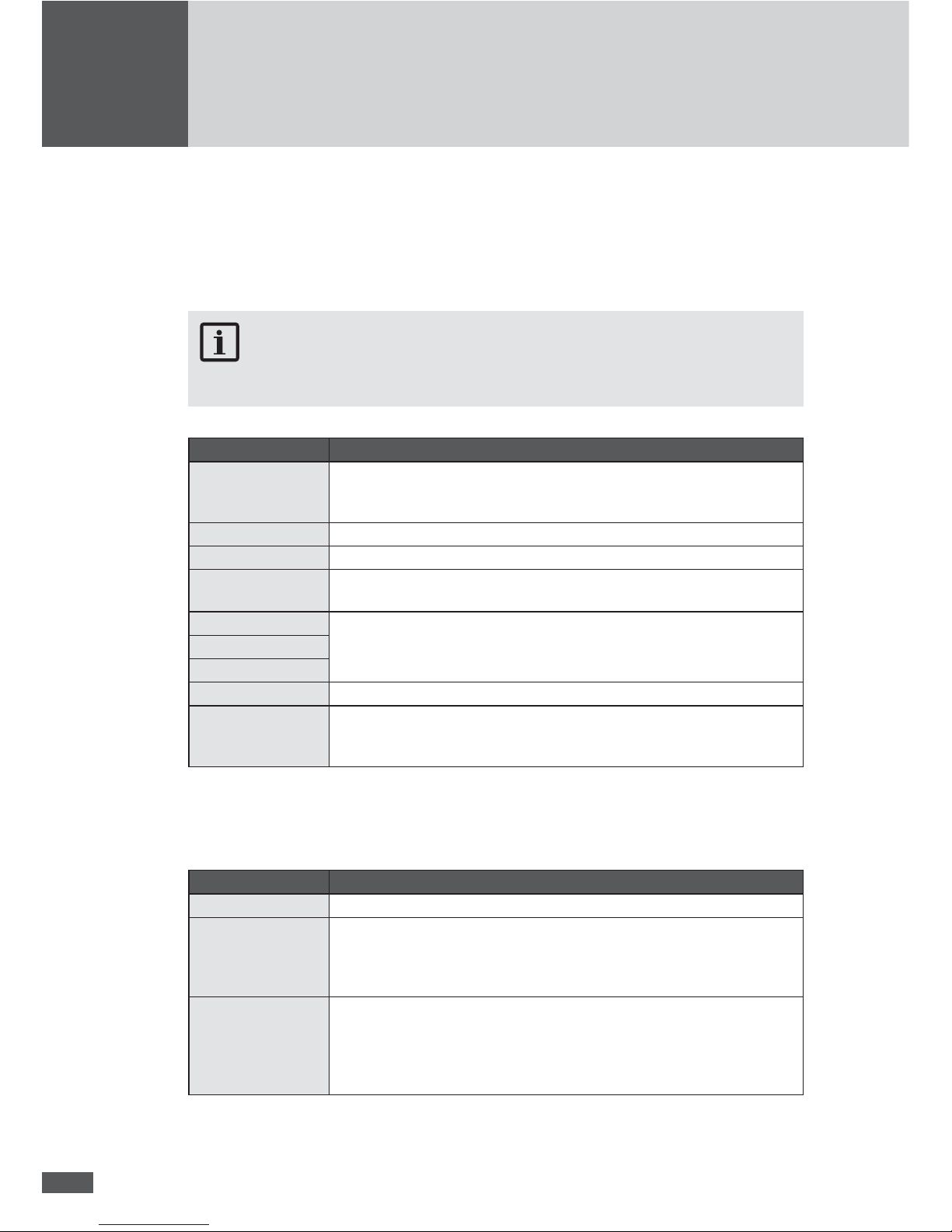

Parameter Description Unit

Restart delay Delay time before mains reconnection upon previous

failure-related mains disconnection.

s

Pac Progression Maximum increase of the effective power during mains

reconnection upon previous failure-related mains

disconnection.

%/Minute

Soft Start Maximum increase of the effective power at mains con-

nection. This gradient, if activated, is always effective,

as opposed to Pac Progression (even during restart in the

morning).

W/s

Mains check Additional monitoring before connecting to the mains -

- Vac MC max Maximum admissible mains voltage at mains check V

- Vac MC min Minimum admissible mains voltage at mains check V

- f MC max Maximum admissible mains frequency at mains check Hz

- f MC min Minimum admissible mains frequency at mains check Hz

- t MC monitoring Duration of mains check s

P(f)-Mode Frequency-dependent power reduction (1/2/3/Off)

- Reduction Reduction of effective power Pac in P(f) mode %/Hz

- f start Starting frequency of the P (f) mode Hz

- f stop Stop frequency of the P(f) mode Hz

- MC f max Maximum admissible mains frequency at mains check in

P(f) mode

Hz

- MC f min Minimum admissible mains frequency at mains check in

P(f) mode

Hz

- MC time Duration of mains check in P(f) mode W/s

- Re-increase Maximum increase to the maximum effective power Pac

max in P(f) mode.

%/Minute

Q-Mode

Reactive power mode (Off/cosφ/cosφ(Pac)/Q/Q(Vac))

-

FRT Fault ride through function for dynamic grid support -

- K factor Reactive current static factor for voltage support with reactive current during mains drops

-

RC mode Remote control by solar plant controller

(Off/On/Guarded)

-

- Timeout Maximum admissible time without control commands at

remote control by solar plant controller.

s

69

4.5.2.6 Settings

This menu can be used to set different communication parameters and monitoring functions.

All settings can also be implemented with MaxTalk (menu: Devices/Settings).

NOTE

The term “system” comprises all TS-SV inverters connected to the MCU.

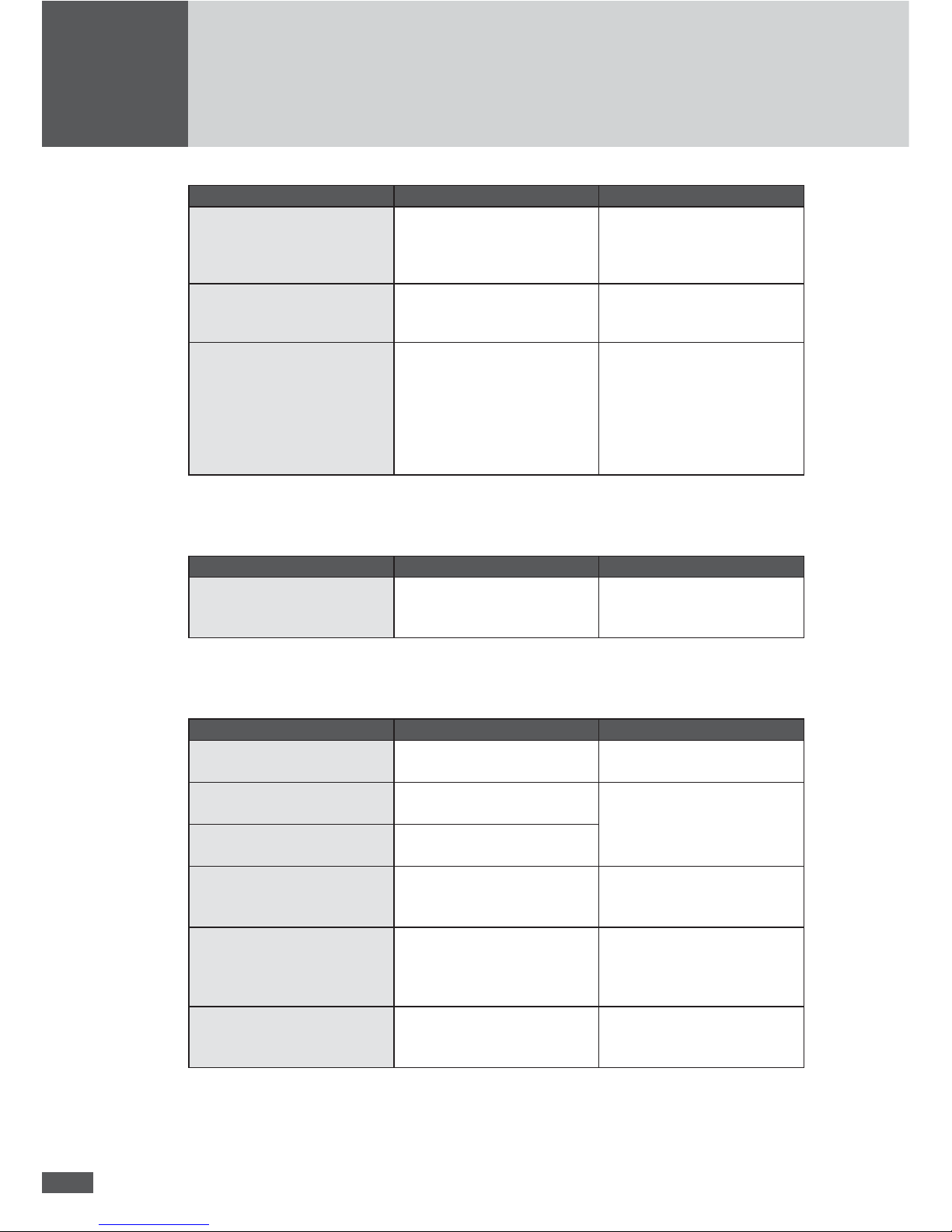

Parameter Description

Language Selection of the display language (German, English, French, Italian, or

Spanish). The display language can be selected independently of the

selected speci c country settings.

Time Setting the internal clock (RTC)

Date Setting the displayed date

Device address De nition of a device address between 1 and 249. For details see 5.1

“Con guration of the data communication interfaces”.

IP

Con guration of the Ethernet interface. For details see 5.1 “Con guration

of the data communication interfaces”.

Netmask

TCP Port

Status relay delay Setting the switching delay of the status signalling contact (status relay)

Pinst tot Rated output power of the PV generator (entry only possible in MaxTalk).

“Pinst tot” is used to calculate PreI (see 4.5.2.3 “Measured values”) and

the target yield (display in the MaxWeb portal).

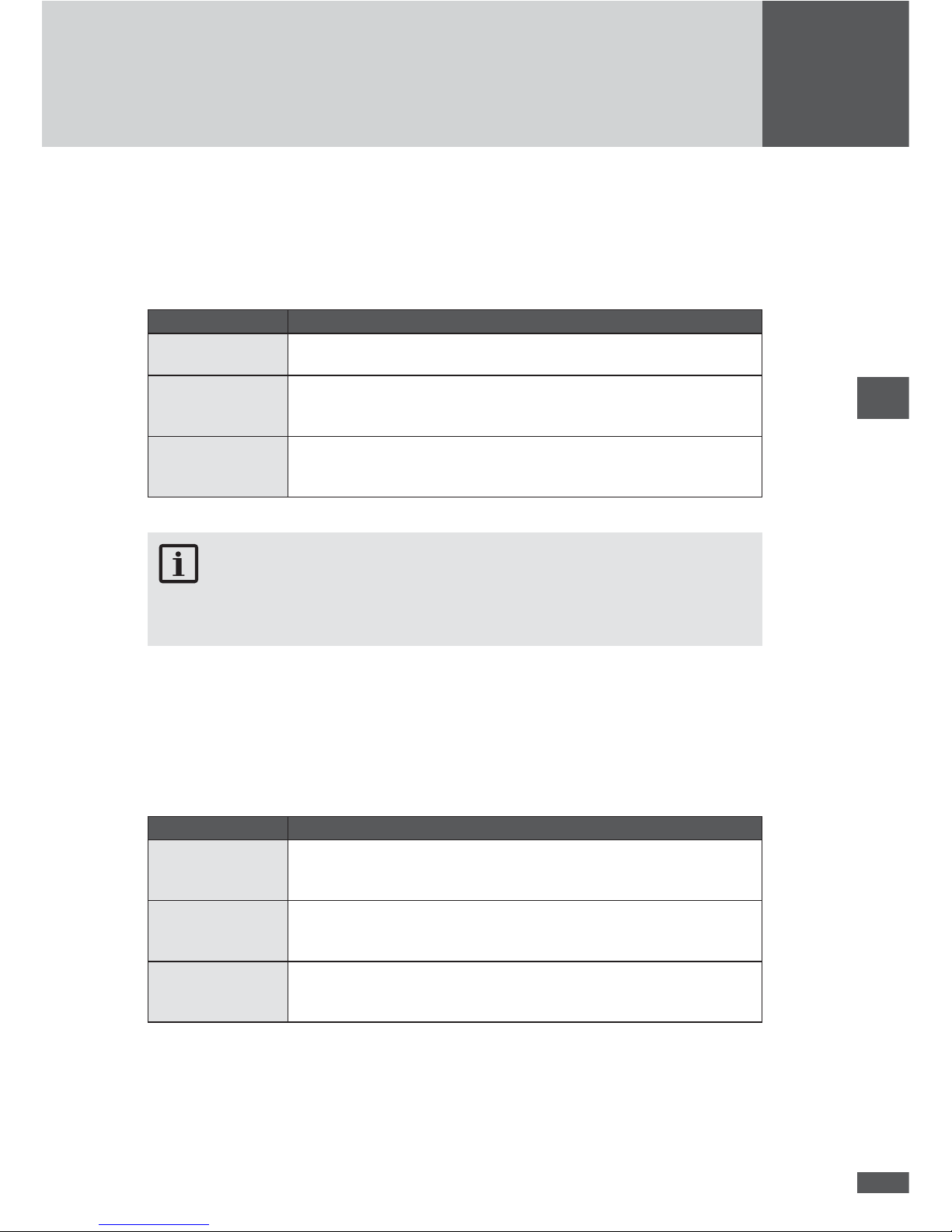

Status relay

The functions of the status relay or the status signalling contact can be adjusted. There

are three different functional settings.

Setting Description

Off The status signalling contact is always open.

Grid When the system starts grid operation, the status signalling contact of

the MCU will close immediately and remains closed as long as the system

feeds in. When the system no longer feeds into the grid, the status signal-

ling contact will open upon expiration of the adjustable delay time.

Error If a warning, malfunction or device error occurs with the system, the

status signalling contact of the MCU will close after the adjustable delay

time has expired (the events are listed in 8.2 “Diagnosis & corrective

steps”). The status signalling contact will immediately open if the error is

no longer present.

The monitoring electronics are supplied by the PV generator, in other words during the

night and when the DC side is switched off, the status signalling contact is open.

70

en

Fuse failure PAS

The equipotential bonding kit (PAS) is an accessory component and serves for earthing

the PV generator. The behaviour of the system during fuse failure on the equipotential

bonding kit can be controlled. For this, the function “Fuse failure PAS” offers three different settings:

Setting Description

Off Monitoring the fuse in the equipotential bonding kit is switched off. Select

this setting for test purposes only.

Warning The warning message “Fuse failure PAS” is displayed. The system will

continue to feed into the mains. The status signalling contact of the MCU

will be closed (factory setting).

Error The malfunction message “Fuse failure PAS” is displayed. The system will

disconnect from the mains immediately. The status signalling contact of

the MCU will be closed.

NOTE

Read the hazard warnings and instructions in the device documentation on the equipotential bonding kit before replacing the fuse.

Vsym Monitor (MaxTalk: Usym DC Monitor)

The DC insulation monitoring (Vsym Monitor) checks the symmetry of the voltage of the

PV generator regarding the earthing potential before mains activation. If the voltages

(DC+ and DC- against earth) are not symmetrical or if there is a short-circuit against

earth, this will be detected by the MCU. Three settings are possible:

Setting Description

Off The DC insulation monitoring is switched off.

Switching off DC insulation monitoring is only required when using the

equipotential bonding kit.

Warning The warning message “Insulation failure DC” is displayed. The system will

continue to feed into the mains. The status signalling contact of the MCU

will be closed (factory setting).

Error The malfunction message “Insulation failure DC” is displayed. The system

will disconnect from the mains immediately. The status signalling contact

of the MCU will be closed.

Vsym AC Monitor

The monitoring of the AC share on the DC side (Vsym AC Monitor) detects too high parasitic oscillations and capacitive leakage currents on the PV generator. Furthermore, insulation failures between the transformer and the system can be detected. Three settings

are possible:

71

Setting Description

Off The AC insulation monitoring is switched off. Select this setting for test

purposes only.

Warning The warning message “Insulation failure DC” (MaxTalk: “DC insulation

failure (AC)”) is displayed. The system will continue to feed into the mains.

The status signalling contact of the MCU will be closed (factory setting).

Error The malfunction message “Insulation failure DC” (MaxTalk: “DC insulation

failure (AC)”) is displayed. The system will disconnect from the mains im-

mediately. The status signalling contact of the MCU will be closed.

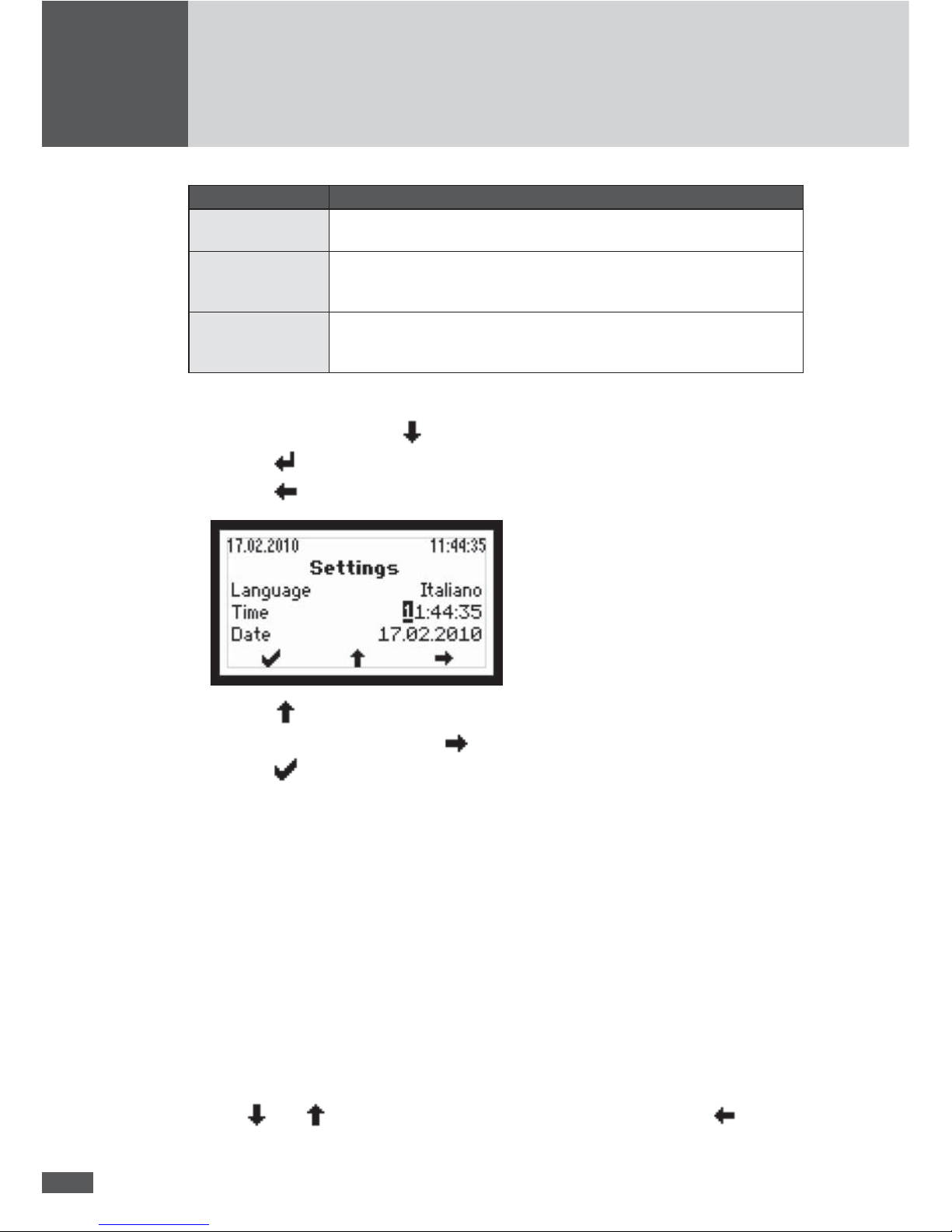

Implementing the settings

1. Select parameter using the

button; e.g. time.

2. Push the

button to switch into the editing mode.

3. Push the

button to get to the desired position of the parameter:

4. Push the button to increase the gure.

5. Select the next position using the

button or

6. Push the

button to con rm the value and exit the editing mode.

4.5.2.7 Information

This menu contains the following information:

■ Device type

■ Series number

■ Firmware version

■ Status message and two-digit number code (if a device error occurs)

■ Warning (alternating display if several warnings are active at the same time)

■ Date of commissioning

■ Accumulated operating hours

■ Date and Time

Use the

and keys to move through the menu. Press the left button to return

to the Main menu.

72

en

5 Data communication

For PV power plants equipped with SolarMax inverters Sputnik Engineering provides the

MaxComm communications platform. This provides many ways of recording data and

monitoring your PV power plant. Below is an overview of the current products.

NOTE

You can nd detailed information on our website at www.solarmax.com.

MaxTalk 2.0: For occasional communication and the configuration of the inverters

If you only need to access your system data or modify your system’s settings occasionally, the MaxTalk PC software is ideal for you. MaxTalk can be downloaded at no charge

from our website.

MaxWeb xp: The gateway to Internet-supported communication

MaxWeb xp is a data logger, monitoring unit and web server in one. For all those who want

to have their PV power plant monitored and checked reliably and professionally MaxWeb

xp is the ideal solution.You can access your PV power plant from any internet-connected

PC to check current measured values and yields or to modify your system settings. The

data logger records operating parameters, yield values and events and communicates

them automatically to the SolarMax web portal.

If there is a malfunction, MaxWeb xp sends out alarm messages by e-mail or SMS.

MaxWeb Portal: For accessible power plant data at any time

The MaxWeb Portal is the ideal complement to the MaxWeb xp data logger. When you use

MaxWeb Portal you can access the data of your PV power plant from anywhere on the

Internet. The MaxWeb Portal provides a wide variety of graphic and chart display options

for the evaluation of your PV power plant’s operating parameters.

73

5.1 Con guration of the data communications interfaces

In order to use the RS485 and Ethernet communications interfaces, you must enter the

following settings in the “Settings“ display menu:

Device address

If you connect several systems and/or MCUs to become one network, you will need a

separate address for each system.

NOTE

■ You can assign addresses between 1 and 249. Please make a point to remember

to assign a unique address to each system in the network!

■ Start the address numbering with the lowest numbers possible (if possible with

001).

When connecting to a LAN network, the following settings are required in addition to the

device address:

IP

If you want to access your system from a local area network (LAN), enter here an unassigned IP address from your LAN.

Netmask

Please enter here the pertinent sub-netmask for your IP address.

TCP port

Enter your TCP port selection for communications with the system. Remember that the

TCP port must be greater than 1023 since this range is reserved for prede ned applications (referred to as “well known services”).

NOTE

You will nd more details about data communications in the technical information

“MaxComm network”. This document can be downloaded from our website at: www.

solarmax.com; downloads/data communication/MaxComm.

74

en

6 Options

6.1 MaxControl

6.1.1 Scope of services

MaxControl is a service package for your solar system with SolarMax central inverters.

It is based on the MaxComm communications system and includes:

■ Automatic yield control including monthly analysis

■ Forwarding of malfunction reports to the client via email and/or SMS

■ Troubleshooting and on-site service by Sputnik Engineering

■ Warranted availability of 97 % annually

■ Yield shortfall payments if availability < 97 %

■ Free inverter repair

6.1.2 Duration

■ Two years and three months from the date of shipment.

■ When the period is up the warranty can be renewed for one more year.

Remember that a MaxControl service package can only be agreed at the time the

SolarMax central inverter is purchased and afterwards it is no longer possible.

The agreement is automatically renewed if you do not cancel it in writing at least one

month before the end of the calendar year. The agreement can be renewed no more than

eighteen times. The total term of the package is thus 25 years and three months.

NOTE

You can obtain further details about MaxControl directly from Sputnik Engineering.

6.2 Accessory components

Here is a list of other available accessory components.

MaxConnect plus

Generator connection box with integrated string monitor

MaxMeteo

Unit which records irradiation data and cell temperature of PV modules

75

MaxCount

Unit which records meter gures with S0-interface

MaxDisplay

Interface for large display to visualise PV power plant data

Potential equalization set

The potential equalization set enables the earthing of the PV generator

7 Operating status

NOTE

The term “system” comprises all TS-SV inverters connected to the MCU.

7.1 Status messages and status LED

The status message on the graphical display of the MCU describes the current operating

status of the system. Each system status message belongs to one of the ve possible operating statuses. The status LED always displays one of these operating statuses through

a variety of colours. In addition to the status messages, the system can also display warnings. Warnings result from device errors or external malfunctions which, however, do not

affect the mains operation of the system. Losses of yield are possible, however. Warnings

have no relation to the operating status and are displayed on the graphical display alternately with the current status message.

The status messages of the “Malfunction”, “Error”, and “Blocked” operating statuses, as

well as the warnings, usually require certain measures to be taken, see 8 “Troubleshooting”.

LED status Operating status Description

Off - The system is switched off > mains disconnection

Flashing

green – – –

Booting The system is booting > mains disconnection

Green

Mains operation Power supply (normal operation)

Flashing

orange – – –

- Warning > no mains disconnection; yield losses

possible

Orange

Malfunction External malfunction > mains disconnection

Red

Error Internal device error > mains disconnection

Flashing red – – – Locked The system is locked > mains disconnection

76

en

7.2 Booting

Status message Description

Irradiance too low The solar irradiation or rather the available output is too low for mains

operation.

Startup… The system checks the internal hardware and software components

before connecting to the mains.

Restart delay The system disconnected from the mains and is delaying re-connection

to the mains.

Idle The system does not start since at least one power unit is unavailable

for the MCU.

7.3 Mains operation

Status message Description

Mains operation The system has been connected and is feeding power to the mains.

Maximum power The system limits the fed output to the maximum permissible output.

Limiting the output can occur when the PV generator has been overdimensioned or in the event of high irradiation.

Idc limitation The system limits the DC input current to the maximum permissible

value. This can occur if the PV generator was designed so that the

current in the MPP is higher than the maximum permissible DC current

of the system.

Iac limitation The system limits the input mains current to the maximum permissible

value. This can occur in response to major uctuations in irradiation,

low mains voltage, or due to an over-dimensioned PV generator.

Restart limitation The system increases the effective power upon completion of an

external limitation with a de ned progression (Pac Progression and/or

Soft Start).

Frequency limitation The system limits the fed-in effective power due to an active frequen-

cy-dependent power reduction - P(f) mode.

External limitation The fed-in effective output of the system is limited via a remote access.

Remote controlled The system is controlled remotely by solar plant controller or by radio

ripple control receiver.

7.4 Communications activity

The communications activity of the MCU is displayed via two different symbols on the

graphical display.

Symbol Description

This symbol is displayed when the MCU sends or receives data (via RS485 or

Ethernet).

This symbol is displayed when there is an Ethernet connection (corresponds to the

"Link" display on network cards).

77

8 Troubleshooting

Sputnik Engineering delivers only SolarMax inverters which have stood up to our extensive testing regime. Moreover, each inverter is subjected to several hours of endurance

testing under full-load conditions.

This section describes in several tables all the possible error messages, their possible

causes and suggestions on how to remedy them.

If despite this your PV power plant suffers a malfunction or an error we recommend these

procedures:

DANGER

Work on the PV power plant and on the opened inverter must be performed solely by

quali ed electricians. Switch off the inverter and make sure that the DC and AC feed

lines are dead before you start work on the opened device.

1. Make sure that the system and PV generator have been correctly installed.

2. Check the cable connections and follow the instructions contained in the Installation

Manual.

3. Determine the cause of the malfunction by consulting the message on the graphic

display unit. Section 8.2, “Diagnosis & corrective steps” explains possible ways of

correcting malfunctions.

4. If you cannot correct the malfunction using the recommended procedures, or you are

not sure what sort of fault is involved, please contact our SolarMax Service Centre.

78

en

8.1 SolarMax Service Center

If you have technical questions or dif culties our Service Centre would be happy to help

you. If you have questions about central inverter malfunctions we need from you the following details:

■ Device type

■ Serial Number S/N

■ Installation location

■ Information about the malfunction you are experiencing (status message, etc.)

Availability

The contact details of the SolarMax Service Center can be found overleaf.

Sputnik Engineering AG

Länggasse 85

CH-2504 Biel/Bienne

8.2 Diagnosis & corrective steps

The following tables describe how to troubleshoot malfunctions. If the steps suggested

do not correct the malfunction please contact the SolarMax Service Centre immediately.

8.2.1 General troubleshooting

Problem Cause Steps

The display remains blank MCU or display is defective. Notify the SolarMax Service

Centre.

8.2.2 Warnings

Warning Cause Measure

Power unit malfunction At least one power unit has

a malfunction. The system

will continue to feed into the

mains.

Contact the SolarMax service

centre.

Failure temp. sensor A temperature sensor in

the system has ceased

functioning.

Failure fan The displayed fan is defective.

79

Warning Cause Measure

Burst error The system disconnected from

the mains ve times or more

on the same day. The warning

is displayed for the remainder

of the day. The error counter

will be reset when the system

is restarted in the morning.

Check the status logger of

your system in MaxWeb xp (if

available) or check the mains

parameters. If this problem

occurs frequently, contact the

SolarMax service centre.

Flash error A ash error has occurred. Contact the SolarMax service

centre.

Ief too high The earth fault current in the

potential equalisation set

(PAS) is too high (can only be

displayed if the PAS is used).

There is an insulation fault in

the PV generator.

Correct the insulation fault in

the PV generator.

Insulation fault DC There is a short-circuit in the

PV generator to earth.

Correct the short-circuit.

Poor wiring of the PV

generator.

Repair the wiring.

High creeping currents in

the PV generator caused by

dampness.

Seal the generator connection

box better and improve the

insulation materials.

Note: Check the setting of the functions Vsym Monitor or Vsym

AC Monitor.

Power unit blocked At least one power unit is

blocked temporarily.

Switch off the main switch Q7

and then switch it back on in

order to remedy the blocking

(or wait for the next restart of

the system).

RTC error The RTC (real-time clock) in

the MCU has a malfunction, the

date and time were re-set.

Set the time and date correctly

(see 4.5.2.6 “Settings”.

If this problem occurs frequently, contact the SolarMax

service centre.

Fuse failure PAS Fuse failure in the potential

equalisation set (PAS) (can

only be displayed when using

the PAS).

Contact the SolarMax service

centre. Note: Check the setting of the fuse failure PAS

function.

Temperature limitation The feed-in power has been

temporarily reduced to limit the

temperature of the system.

Clean the fan grids and

improve ventilation in the

operations room.

Warning MaxConnect The alarm contact X501 of the

MCU was closed.

Check the generator connection box (MaxConnect)

connected to the alarm contact

X501.

80

en

8.2.3 Malfunctions

Status message Cause Measure

Vdc too high The DC input voltage of an

individual power unit or the

system is too high.

Switch off all DC circuitbreakers immediately and then

disconnect the PV generator

from the system. Check the PV

generator’s dimensioning.

Vdc too low The DC input voltage has

dropped to too low a value.

Wait for the next restart of the

inverter and check whether it

starts mains operation.

No mains

No mains BP

The AC circuit-breakers are

switched off.

Switch on the AC circuit-breakers Q2, Q4, and Q6.

There is no mains voltage

or the AC feed line has been

disconnected.

Check the AC feed line.

Mains error The grid was shut down.

If this occurs repeatedly,

contact the responsible grid

operator.

Frequency too high

Frequency too high BP

The mains frequency is outside

of the f max 1 or f max 2 limit

values.

Frequency too low

Frequency too low BP

The mains frequency is outside

of the f min 1 or f min 2 limit

values.

Vac too high

Vac too high BP

The mains voltage at the

speci ed phase is outside of

Vac max 1 or Vac max 2 limit

values.

Vac too low

Vac too low BP

The mains voltage at the

speci ed phase is outside of

Vac min 1 or Vac min 2 limit

values.

Vac 10min too high

Vac 10min too high BP

The maximum 10-minute average value of the mains voltage

(Vac 10 min max.) is too high.

Insulation fault DC There is a short-circuit in the

PV generator to earth.

Correct the short-circuit.

Poor wiring of the PV

generator.

Repair the wiring.

High creeping currents in

the PV generator caused by

dampness.

Seal the generator connection

box better and improve the

insulation materials.

Note: Check the setting of the functions Vsym Monitor or Vsym

AC Monitor.

81

Status message Cause Measure

Fuse failure PAS Fuse failure in the potential

equalisation set (PAS) (can

only be displayed when using

the PAS).

Contact the SolarMax service

centre. Note: Check the setting of the fuse failure PAS

function.

Incorr. rotation dir. The rotational direction of the

connected mains phases is

wrong.

Connect the mains phases

properly.

Error ext. control The communication to the

remote control is interrupted.

The time limit between two

control commands was

exceeded.

Once the remote control reestablished communication,

the system will automatically

continue mains operation. If

this occurs repeatedly,

please check the network

connections.

8.2.4 Error

Status message Cause Measure

Device error (+ error code) An internal fault has occurred

in the system.

Check the two-digit error code

displayed and contact the

SolarMax service centre.

8.2.5 Blockages

Status message Cause Measure

Main switch off Main switch Q7 is in “OFF”

position.

Switch on the main switch Q7.

Shutdown 1 The shutdown 1 (shutdown

contact 1) is activated.

Eliminate the shutdown /

blocking.

Shutdown 2 The shutdown 2 (shutdown

contact 2) is activated.

External blocking There is a 0% command from

MaxRemote (based on the grid

operator).

None. Wait until the grid operator suspends the blocking

of the system via MaxRemote.

Program firmware The system rmware is cur-

rently being updated.

None. The system automatically re-assumes mains operation once the rmware update

is complete.

Recurring short circuit The MCU detected several (>2)

short-circuits during a certain

period of time on the AC side.

Contact your grid operator in

order to eliminate the cause of

the short-circuits.

82

en

9 Maintenance

All SolarMax inverters work completely automatically. However, to ensure perfect operation over the course of several years, in addition to regular controls of the operating

and yield data via the inverter display or remote monitor we also recommend having the

simple maintenance work described below performed at regular intervals. The maintenance intervals must be set keeping the ambient conditions in mind (especially exposure

to dust).

DANGER

Work on the opened inverter or MCU must be performed solely by quali ed electricians. The inverter must be shut down before it is opened. Then the DC and AC feed

lines must be disconnected according to the instructions and secured against any

accidental reconnection.

9.1 Inspections by the plant operator

The following checks can be performed by the plant operator. If you discover problems

while performing these checks, contact the electrician in charge of maintenance or our

SolarMax Service Centre.

■ A functional check of the inverter via the graphics display on the MCU

■ On-site check of visible traces of wear and tear (damage, rain, snow, rodents, etc.)

■ Cleaning and check of plant room

9.2 Maintenance by a quali ed electrician

1. Switch off the inverter and make sure that the DC and AC feed lines are dead.

2. Then wait 5 minutes to give the internal capacitors time to completely discharge.

3. Open the inverter by removing the front cover plate.

4. Tighten the screws on the DC and AC terminals.

5. Carefully clean the fan and the fan screen.

6. Check if there are any foreign bodies (rodents, etc.) in the inverter and remove them.

7. Re-close the inverter.

83

CAUTION

Have you left any tools in the device?

8. Switch on the DC and AC feed lines and the inverter.

9. If the PV power plant has the MaxControl option, a communications test is advisable.

For this purpose contact our SolarMax Service Centre.

9.3 Testing grid monitoring

With the help of the test contacts the grid monitoring of the system can be tested. The test

can be carried out for both single MPPT operation and multi-MPPT operation.

The test contacts permit a separation of the measuring lines between the respective

power unit and the three phase voltages U L1, U L2, and U L3. This allows for connecting

an AC generator for grid simulation. A DC voltmeter can be connected to the test contacts

in order to check the control voltage of the AC contactors K1, K2, or K3. The power units

within the system must be tested separately. The test contacts are located on the top right

in the inverter, see the Installation Manual.

Prerequisites / aids

■ Suf cient solar irradiation during the test

■ 3-phase AC generator

■ DC voltmeter

Procedure

The following instructions describe the test for the inverter’s LT1 power unit. When testing

power unit LT2 or power unit LT3, please observe the corresponding information in the

square brackets.

DANGER

The functional test of the inverter’s grid monitoring is performed using high volt-ages

while the inverter is open. Coming into contact with exposed power lines or noninsulated electrical contacts may result in serious injury or death!

1. Switch off the system as described in 4.4 “Switching off the inverter”.

2. Open the inverter to be tested and remove the covers.

3. Loosen the slide switches of the test contacts U L1, U L2, U L3, and K1EN from termi-

84

en

nal block “LT1” secured by means of slotted-head screws. [power unit LT2: terminal

block “LT2”], [power unit LT3: terminal block “LT3”].

4. Slide all 4 slide switches downwards and secure the slide switches by tightening the

slotted screws.

5. Connect the three-phase AC generator to the test contacts U°L1, U°L2, and U°L3 on

terminal block “LT1” [power unit LT2: terminal block “LT2”], [power unit LT3: terminal

block “LT3”]. Only use the lower 4mm sockets on the test contacts.

Remember to connect the rotational eld of the generator phases to rotate clockwise.

6. Connect the DC voltmeter to measure the control voltage of the AC contactor at the

upper and lower test contact K1EN.

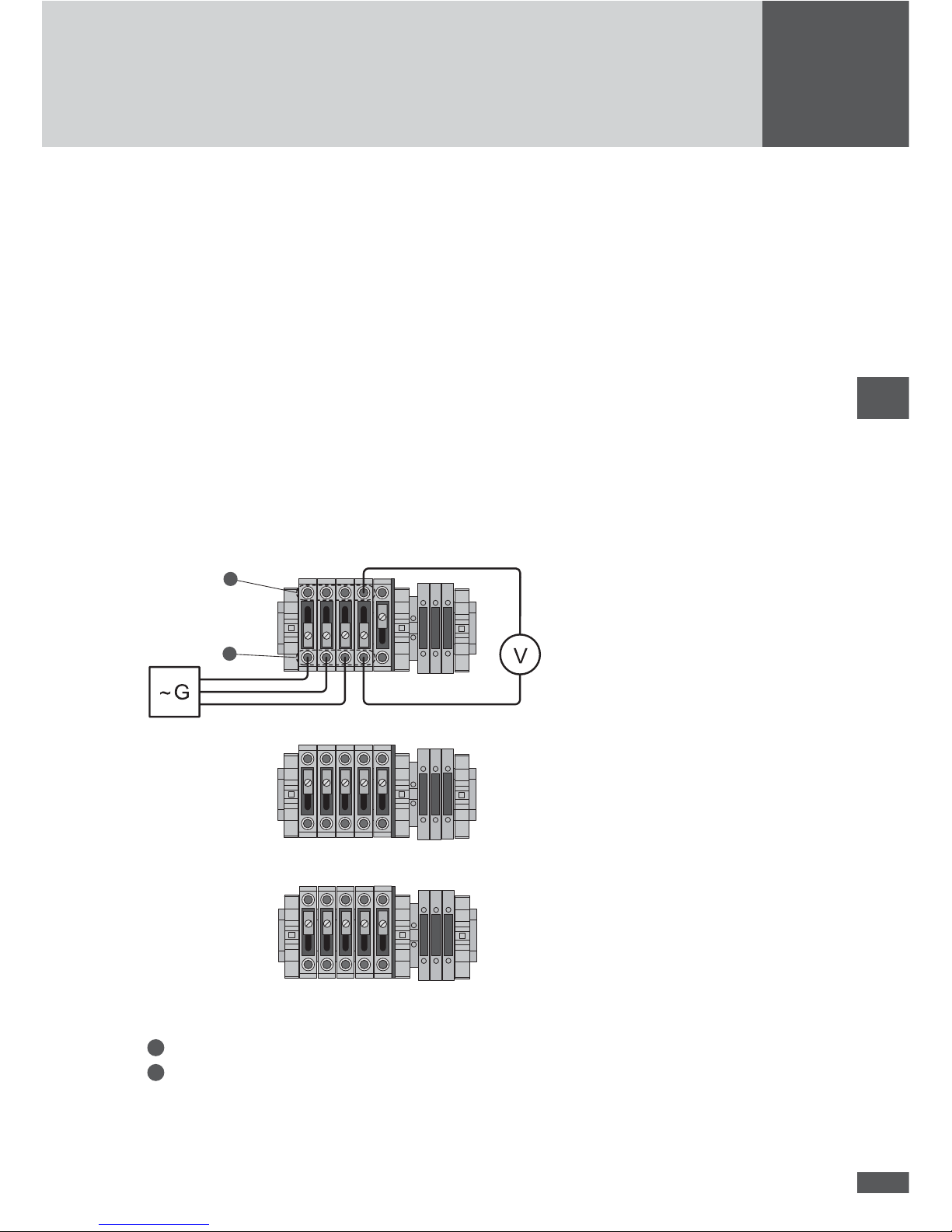

7. Check the wiring of the testing assembly against the following diagram:

Wiring diagram when testing power unit LT1

U L1

U L2

U L3

K1EN

LT 1

K1

U L1

U L2

U L3

K1EN

K1

U L1

U L2

U L3

K1EN

K1

2

1

LT 2

LT 3

Legend:

1

4mm sockets to control unit of the power unit

2

4mm sockets to the AC connections

G: AC generator

V: DC voltmeter

85

8. Switch on the DC circuit-breaker Q4 [power unit LT2: Q5], [power unit LT3: Q6]. The

other DC circuit-breakers and all AC circuit-breakers in the system remain switched

off.

9. Switch on the AC generator. The external conductor voltages must correspond to the

nominal mains voltage and frequency (3 x 280 U

ac / 50Hz).

10. Switch on the main switch Q7 (on the MCU). The inverter starts and, after roughly 30

seconds, switches to (simulated) mains operation.

11. Con rm that the control voltage of the AC contactor is 24 V

DC.

12. Now increase the voltage or frequency of any phase up to just under the set limit (see

11.5 “Individual country settings”.

CAUTION

Damage to the device possible! Never set the test voltage higher than 364 V (130 % of

the nominal voltage). This may damage the inverter’s measurement circuits. Sputnik

Engineering assumes no liability for damages which result from incorrectly conducted

tests.

13. Slowly increase the phase voltage or the frequency beyond the limit. Check whether

the inverter’s grid monitoring reacts appropriately: the measured control voltage of

the AC contactor must drop to 0V.

The test for power unit LT1 is completed when the control voltage of the AC contactor

drops.

14. Switch off the main switch Q7 (on the MCU).

15. Switch off the AC generator.

16. Switch off the DC circuit-breaker Q4 [power unit LT2: Q5], [power unit LT3: Q6] (all

the DC circuit-breakers are switched off).

17. Remove the AC generator and the DC voltmeter from the inverter.

18. Slide the 4 slide switches of the test contacts back into the upper position and screw

them down rmly.

19. If required, repeat the test for power units LT2 and LT3: in each case start with step

3 of these instructions. Pay attention to the information in the square brackets.

20. Remove all tools from the inverter.

21. Attach the covers and close the inverter.

22. If required, repeat the test for the remaining power units of the system.

23. Switch on the system as described in 4.3 “Switching on the inverter”.

The system is back in normal mains operation.

86

en

10 Disposal

Please dispose of the inverter at the end of its service life in compliance with the disposal

regulations currently valid where it is installed. You can also return the inverter at your

own cost for professional disposal to Sputnik Engineering (address as stated in the section on “Troubleshooting”).

2013/04

SolarMax Service Center

Deutschland +49 180 276 5 276

Schweiz / Svizzera / Suisse +41 32 346 56 06

France +33 4 72 79 17 97

Italia +39 0362 312 279

España +34 902 160 626

Benelux +32 2 535 77 32

Česká Republika

+420 222 191 456

United Kingdom +44 208 973 2556

Ελλάδα +30 210 727 91 61

България +39 0362 312 279

Australia +61 2 8667 3161

Other countries +41 32 346 56 06

Fax +41 32 346 56 26

E-Mail hotline@solarmax.com

www.solarmax.com/service

Loading...

Loading...