Gerätedokumentation ■ Instruction manual ■ Documentation d’appareil

■ Documentación del dispositivo ■ Documentazione dell’apparecchio

SolarMax P-Serie

2000P / 3000P / 4000P / 4600P / 5000P

Sputnik Engineering AG

Länggasse 85

CH-2504 Biel/Bienne

Tel: +41 32 545 56 00

Fax: +41 32 346 56 09

E-Mail: info@solarmax.com

© Sputnik Engineering AG 2013

66

Contents

1 Notes on the present instruction manual 68

1.1 Scope. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

1.2 Target groups. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

1.3 Where to keep this manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

1.4 Symbols used. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

2 Safety instructions 69

2.1 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

2.2 Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

2.3 Symbols on the inverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

3 Description 71

3.1 Identication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

3.2 Functionality. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

3.3 Safety installations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

3.4 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

3.5 Views of the unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

3.6 Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

4 Installation 75

4.1 Transporting and storing inverters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

4.2 Checking the delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

4.3 Selecting the installation location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

4.4 Mounting the inverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

5 Electrical connection 79

5.1 Opening the inverter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

5.1.1 Removing the cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

5.1.2 Removing the contact protection. . . . . . . . . . . . . . . . . . . . . . . . . . 80

5.2 Connection area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

5.3 Connecting the inverter to the mains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

5.4 Connecting the inverter to the PV generator . . . . . . . . . . . . . . . . . . . . . . . . 84

5.5 Grid connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

6 Commissioning 88

6.1 Activating the inverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

6.2 Initial start-up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

6.2.1 Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

6.2.2 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

6.2.3 Description of country-specic menus . . . . . . . . . . . . . . . . . . . . . 90

6.3 Auto-test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

en

67

6.4 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

6.4.1 Setting the display language and system time. . . . . . . . . . . . . . . . 93

6.4.2 Setting the network parameters . . . . . . . . . . . . . . . . . . . . . . . . . . 94

6.5 Displaying the conguration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

6.6 Displaying the measured values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

6.7 Registering for MaxView. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

6.8 Update rmware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

7 Operation 103

7.1 Graphics display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

7.2 Menu structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

7.3 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

7.4 Main menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

7.5 Statistics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

7.5 .1 Displaying the daily statistics . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

7.5 .2 Displaying the monthly statistics. . . . . . . . . . . . . . . . . . . . . . . . . 106

7.5 .3 Displaying the annual statistics . . . . . . . . . . . . . . . . . . . . . . . . . . 107

7.5 .4 Displaying the total statistics. . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

7.5.5 Deleting the statistics values. . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

7.6 Displaying information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

7.7 Operating status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

7.7.1 Booting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .110

7.7.2 Mains operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .110

8 Troubleshooting 111

8.1 SolarMax Service Center . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .111

8.2 Diagnosis & measures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .111

8.2.1 General troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .111

8.2.2 Warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .112

8.2.3 Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .112

8.2.4 Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .113

8.2.5 Blockings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .114

9 Maintenance 114

10 Decommissioning 115

10.1 Instructions for inverter replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . .115

10.2 Inverter disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .115

10.3 Disposing of the inverter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .116

11 Technical data 117

12 Accessories and options 123

13 Warranty 124

68

1 Notes on the present instruction

manual

1.1 Scope

This instruction manual is applicable to the Solarmax 2000P, 3000P, 4000P, 4600P and

5000P inverters.

1.2 Target groups

Plant operators

Chapter 2 "Safety instructions"

Chapter 7 "Operation"

Fitters

Chapter 2 "Safety instructions"

The instructions in chapters 4 to 6 and 8 to 10 are only allowed to be performed by

trained skilled electricians (e.g. electricians, electric systems technicians, electrical

mechanics, industrial electronics technicians).

1.3 Where to keep this manual

The plant operator must ensure that this instruction manual is available to the relevant

persons at all times. If this original document is lost, an up-to-date version of this instruction manual can be downloaded from our website at any time (www.solarmax.com).

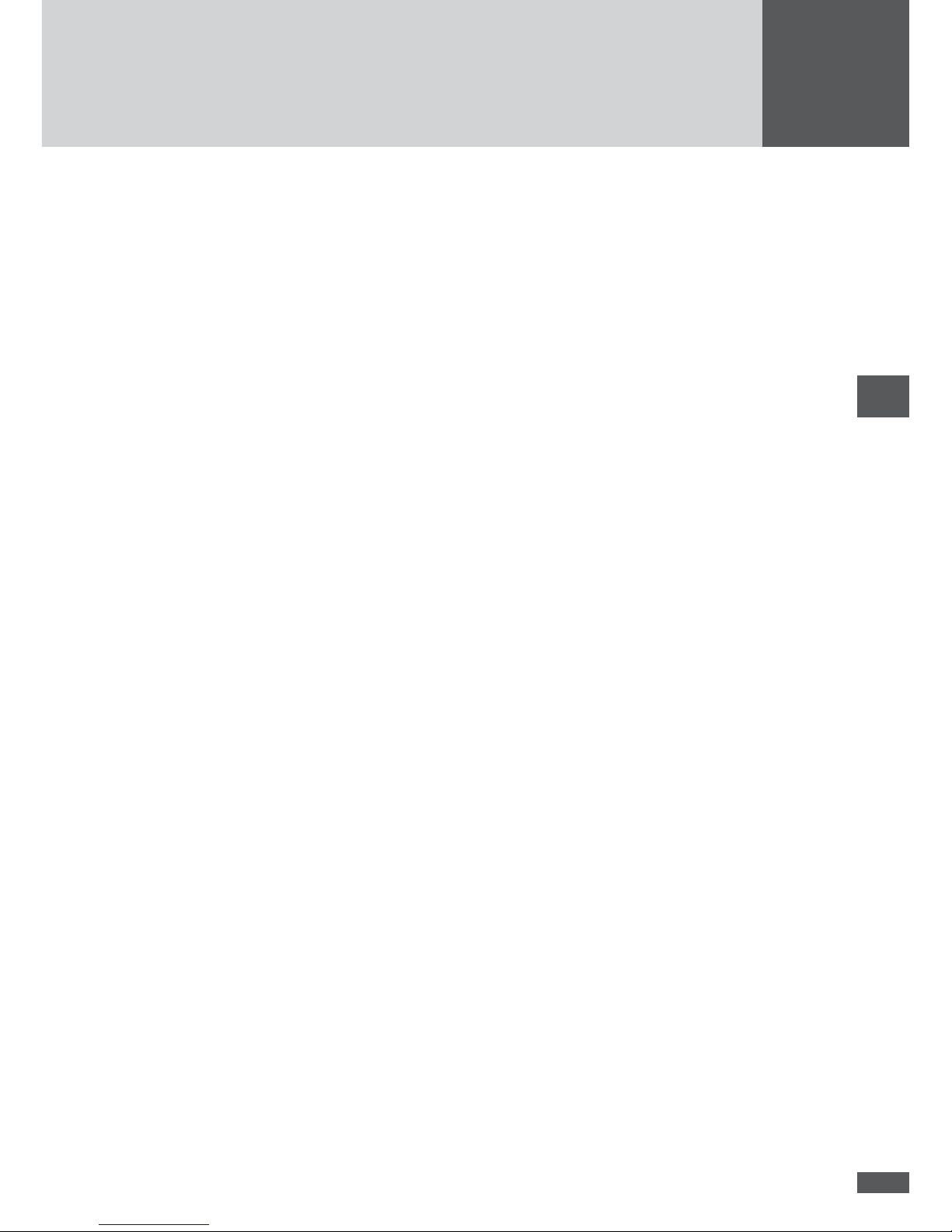

1.4 Symbols used

The following safety instructions and general information are used within this instruction

manual.

DANGER!

Non-observance of these safety instructions may immediately cause serious

injuries or death.

WARNING!

Non-observance of these safety instructions may cause serious injuries.

CAUTION!

Non-observance of these safety instructions may cause minor or medium

injuries.

en

69

ATTENTION!

Non-observance of these safety instructions may cause material damage.

Note

Notes contain additional information or facilitate the inverter operation.

2 Safety instructions

2.1 Intended use

The SolarMax P series inverters are designed exclusively to convert the direct current

generated by PV modules into alternating current which conforms to the parameters of

the public grid. Any other use is contrary to the design purpose.

The inverters of the P series may only be connected to Class II PV generators.

2.2 Safety instructions

DANGER!

Fatal electric shock hazard!

In daylight the PV generator supplies the inverter with a dangerously high DC

voltage.

Make sure that all electrical feed-in lines to the inverter are de-energized

before starting any work on the inverter or the feed-in lines.

DANGER!

Fatal electric shock hazard!

Components within the inverter are charged with a high voltage.

Never open the inverter while it is in operation.

WARNING!

Risk of injury from electric arc!

Removing the DC connector when live can lead to dangerous electric arcs.

Switch off the DC disconnector at the inverter before removing the DC

connectors.

70

2.3 Symbols on the inverter

Symbol Description

Protective conductor connection

The DC disconnector is switched off (the contacts are open).

The DC disconnector is switched on (the contacts are closed).

Risk of death through high voltages! Only qualied electricians may

perform work on the inverter.

Careful - hot surfaces!

5 min

Risk of death due to high voltages! De-energize the inverter. Proceed

to wait for 5 minutes before opening the inverter.

Only qualied electricians may perform work on the inverter.

Read the operating instructions - Please read and follow the instructions supplied with the inverter. Do not remove any symbols on the

inverter. Replace damaged symbols.

CE marking - The inverter complies with the requirements of the

European EMC Directive 2004/108/EC and the Low Voltage Directive

2006/95/EC (see Section 11).

VDE-GS mark - The inverter complies with the relevant requirements

of the German Product Safety Act.

Do not dispose of the inverter and its accessory components in the

household waste.

en

71

3 Description

3.1 Identication

The inverter can be identied on the basis of the information provided on the nameplate

(see Section 3.5).

3.2 Functionality

Inverter operation is completely automatic and depends on the available output of the PV

generator. If there is enough power, the inverter starts mains operation and feeds into

the power grid. If there is not enough power available from the PV generator, the inverter

disconnects from the grid and shuts down.

The graphics display with three function keys allows convenient inverter operation and

reading of all important operating data. The graphics display is only switched on when the

DC input voltage is high enough.

The inverter has congurable functions for grid monitoring, limitation of output and reactive power control.

For the purpose of monitoring the PV power plant remotely, the inverter can be connected

directly to the Internet via Ethernet.

With the optional I/O module, the inverter can be remotely switched off and its output

controlled.

3.3 Safety installations

Overvoltage protection

P series SolarMax inverters feature integrated surge arrestors (varistors) at both input

and output. Each DC input (plus and minus connection) is tted with a surge arrester. The

surge arresters have a common gas discharge tube to ground. On the AC side a surge

arrester is installed between the phase and neutral. A second surge arrester with gas

discharge tube is tted between neutral and ground (for details regarding the tted surge

arresters see section 11).

When designing the PV system, it may be necessary to provide additional external lightning protection. The optional I/O module can be used to monitor external lightning protection modules.

Fault current monitoring

The inverters in the SolarMax P series have an integrated AC/DC-sensitive fault current

sensor. This sensor can distinguish between the operational capacitive stray currents

72

(caused by capacities of the PV modules to ground) and leakage currents (caused by

touching a pole of the PV generator). If the inverter detects an excess in the permissible

leakage or stray currents, it will disconnect from the grid.

Functions for current and power limitation

The inverters of the P series limit the DC feed-in current, the output power and the AC

output current.

Temperature limitation

At ambient temperatures of more than 45 °C the equipment temperature may reach more

than 80 °C. In such cases, the maximum in-feed power is temporarily reduced. When the

equipment temperature rises to over 85 °C, the inverter disconnects from the grid.

3.4 Dimensions

104.5

480 189

[mm]

256.5

361

en

73

3.5 Views of the unit

4 1

5

7

23

6

No. Description

1 Cover

2 Graphics display

3 Type plate

4 DC disconnector

5 Cooling ns

6 Connection area

7 Mounting rail

74

3.6 Block diagram

−

−

+

+

I

0

U

U

U

Status signalling contact

Ethernet

DC measurement

AC measurement

Fan

RS485

External shutdown

Monitoring

lightning protection

Inverter control

Booster control

Inverter

LCL lter

Booster 2

Booster 1

SolarMax P series

DC

DC

AC

K2K1

DC

DC

DC

External power control

Control unit

Communication module

Graphics display

* Tracker 2 only SolarMax 4000P / 4600P / 5000P ** optional

DC disconnector

DC input

Tracker 1

DC input

Tracker 2 *

I/O module **

AC output

EMC lter

EMC lter

EMC lter

en

75

4 Installation

4.1 Transporting and storing inverters

Make sure that the ambient conditions during transportation and storage are within the

specied limits (for details see section 11).

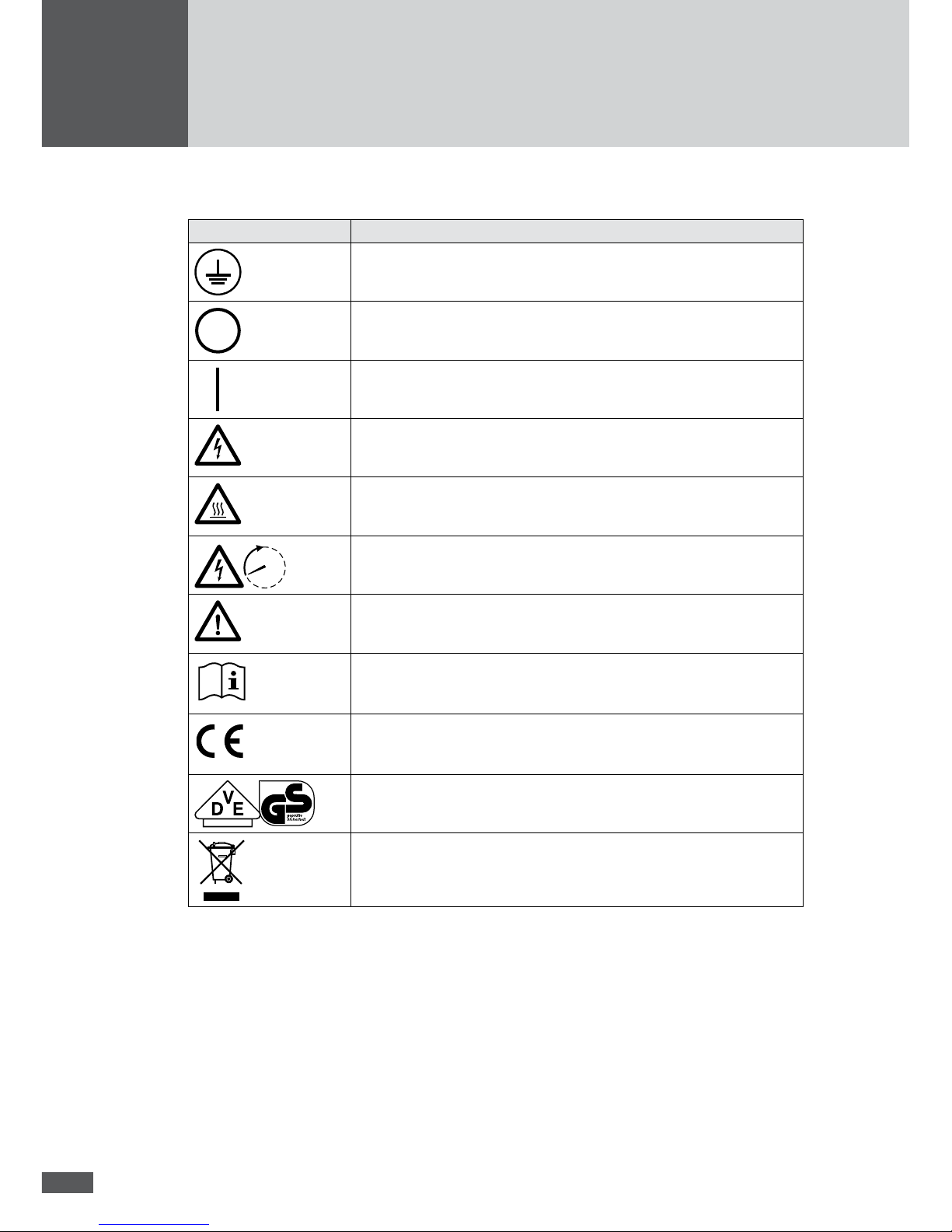

4.2 Checking the delivery

Check the contents of the delivered package for completeness and possible damage. In

the case of an inadequate delivery please contact your dealer or the SolarMax Service

Center.

3

1

2

6

7

8

9 11 12 13 1410

54

Gerätedokumentation

SolarMax P-Serie

2000P / 3000P / 4000P / 4600P / 5000P

No. Quantity Description

1 1 Inverter

2 1 Instruction manual

76

No. Quantity Description

3 1 Mounting rail

4 2 Plastic dowels 8 x 40 (for xing in brickwork)

5 2 Washers M6 x 18 INOX (for the installation of the inverter)

6 2 External hexagon wood screws 6 x 50 INOX (for the installation of the

inverter)

7 2 Phillips head sheet metal screws 4.8 x 13 (for locking the inverter on the

mounting rail)

8 3 Locking pins (for plugging unused holes in multiple cable connectors)

9 4 Locking clips (for DC plugs)

10 1 Toothed lock washer M5

(for connection of 2nd protective

conductor)

11 1 Cable lug M5 x 10mm

2

12 1 Washer M5

13 1 Spring lock washer M5

14 1 Phillips head screw M5 x 12

4.3 Selecting the installation location

DANGER!

Fatal fire or explosion hazard!

The inverter is an electrical device with heat generation and the possibility of

sparking.

Install the inverter in an environment that is free of ammable gases and

uids.

Never install the inverter near combustible materials. The installation

base must be non-combustible.

Follow the local re safety regulations.

The ambient conditions are specied in the specications, see Section 11.

Location and installation conditions

Select a dry location protected from water and snow.

Install the inverter in an easily accessible location, so that maintenance work can be

carried out easily.

Do not expose the inverter to direct sunlight.

Never install one inverter above another (this would reduce the cooling effect; see

Section „Temperature dependent output reduction“; page 122).

en

77

Maintain the following installation distances:

50

50

[cm]

°C

20

20

Install the inverter in a vertical position.

Do not install the inverter in a horizontal or inclined position.

OK !

The optimal cooling of the inverter is only guaranteed when the cooling ns (see sec-

tion 3.5) are absolutely free of dust and dirt.

When installing the inverter on a mast, a mounting plate with at least the same

dimensions as the back of the inverter is needed.

The ambient air around the inverter must be free from dust, salt and ammonium

vapors.

The location must meet the requirements regarding electromagnetic immunity and

interference emission.

78

4.4 Mounting the inverter

The inverter is xed to the wall by a mounting rail. The mounting rail and the necessary

xing accessories are included in the delivery package.

Procedure

1. Use the mounting rail as a template for drilling the holes.

2. Use a spirit level to position the mounting rail horizontally.

3. Mark two drilling holes.

446

376

26

[mm]

26

6.5

6.5

– For the other measurements see section 3.4.

4. Drill two holes ø8 x 50 mm.

5. Fix the mounting rail.

– Assembly sequence: plastic dowels 8 x 40, mounting rail, M6 washers, hexagon

head wood screws 6 x 50.

6. Attach the inverter to the mounting rail (A).

7. Fix the inverter on both sides with the Phillips head sheet metal screws 4.8 x 13 (B)

and (C):

(A)

(B)

(C)

en

79

5 Electrical connection

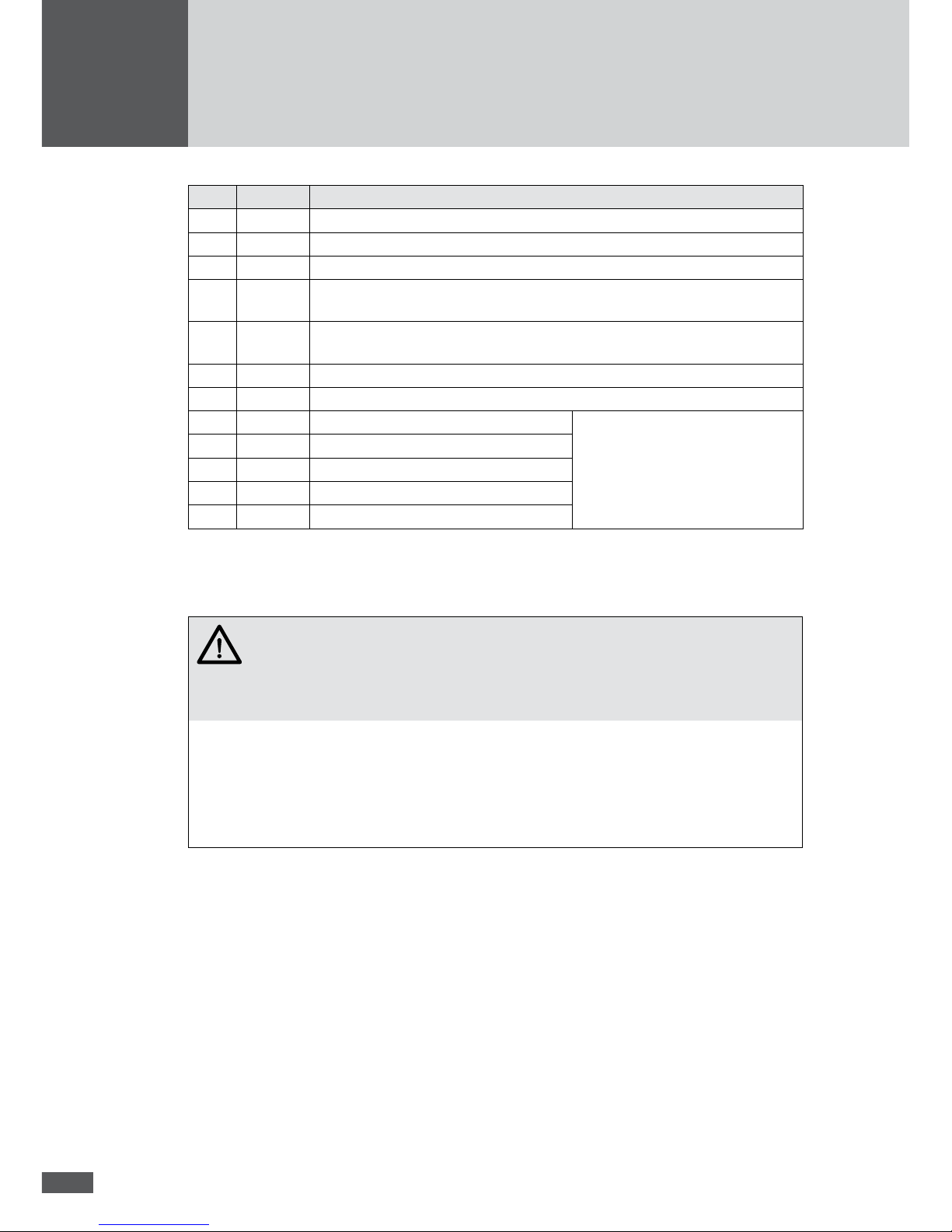

5.1 Opening the inverter

For the purpose of connecting the AC and communication lines, the inverter has to be

opened.

5.1.1 Removing the cover

Once the cover is removed, the low voltage and communication terminals are accessible.

Procedure

1. Disconnect the AC power supply to the inverter.

2. Disconnect all control cables connected to the inverter (status relays, external grid

monitoring and shut-down).

3. Switch off the DC disconnector at the inverter.

DANGER!

Fatal electric shock hazard!

Components within the inverter are charged with a high voltage. After the

inverter has been disconnected, high residual voltages remain in the inverter

for approx. 5 minutes.

Wait 5 minutes until the voltages inside the inverter have reduced before

removing the cover and carrying out connection work.

4. Loosen the two M5 screws at the bottom of the cover.

5. Remove the cover by gripping it at the bottom and pulling it away.

5 min

80

5.1.2 Removing the contact protection

When the contact protection has been removed, the internal connections - with dangerous voltage charges - are accessible.

Procedure

1. Press slightly on the two side snap closures and take the contact protection out of the

holder.

2. Use a voltage tester to check that all connections at the inverter and, if applicable, at

the I/O module, are de-energized.

en

81

5.2 Connection area

The connection area with the cover removed and without contact protection.

10

9 8

7

6

5

4

3

2

1

No. Description

1 DC connections

2 Left-hand cable pass-through (multiple cable gland for the communication cables)

3 Right-hand cable pass-through (AC connection)

4 Locking screw (the locking screw is replaced by the cable gland when the I/O module

is installed)

5 Connection option for 2nd protective conductor

6 Slot for the optional I/O module

7 AC connection

8 RS485 socket

9 Ethernet socket

10 DC bridges for single tracking (tted ex works)

82

5.3 Connecting the inverter to the mains

DANGER!

Fatal electric shock hazard!

Make sure the AC line is not live during connection work.

Connection conditions

Comply with the connecting conditions set by the grid operator in charge.

Connectable cable diameter: min. 9.5 mm / max. 12.5 mm

Permissible conductor cross-sections:

– exible conductors (with or without ferrule) or rigid conductors: max. 16 mm

2

– exible conductors with ferrules (with plastic sleeves): max. 10 mm

2

The AC feed cable must be fused.

Minimum conductor cross sections and suggested mains fuses:

SM2000P SM3000P SM4000P SM4600P SM5000P

Minimum conductor cross-section 1.5 mm

2

1.5 mm22.5 mm24 mm

2

4 mm

2

Mains fuses (characteristic C) 10A 16A 20A 25A 25A

Make sure the ambient temperatures for the mains fuses specied by the producer

are not exceeded.

WARNING!

Risk of death by fire!

Provide separate fuses for each inverter.

Do not attach any loads between inverter and fuse.

If you use an external leakage current circuit breaker (RCD switch), you must comply

with the following connection conditions:

– Use an A type RCD (residual current device) switch with a rated fault current of at

least 100 mA.

– In PV power plants with high leakage capacities, an RCD switch with a rated fault

current of at least 300 mA. must be used.

en

83

Procedure

1. Open the inverter as described in section 5.1.

2. Route the AC conductor through the right-hand cable gland to the AC connection

terminals.

3. Remove an 18 mm length of conductor isolation (A).

4. Connect the wires in the following sequence:

– the protective conductor to the "PE" terminal

– the neutral conductor to the "N" terminal

– the live conductor (phase L) to the "L" terminal

– press and close the levers (B) and (C) completely. If a lever is not completely closed,

the conductor connection is not secured.

(C)

(D)

(B)(A)

[mm]

NPEL

18

Abbildungen Klemme: Phoenix Contact

5. Check the cable connections for rm seating.

6. Tighten the cable gland (wrench size: 34 mm).

7. Check the cable strain relief.

8. Connect the second protective conductor (D).

– Assembly sequence: toothed lock washer M5, lug, washer M5, spring washer M5,

Phillips head screw M5 x 12

9. Close the inverter:

– insert the contact protection until it engages;

– then tighten the cover.

84

5.4 Connecting the inverter to the PV generator

The inverters of the P series can be operated in single tracking or dual tracking mode,

depending on the conguration of the PV plant. In the dual tracking mode a separate MPP

tracker is available for each DC input (2 trackers). The ex works conguration of the P

series inverters is for single tracking (1 tracker).

Connection conditions

Connection of maximum 2 conductors (1 conductor in the case of SM2000P /

SM3000P)

DANGER!

Risk of death by fire!

High return currents can cause a re risk for the PV generator.

When Y plugs are used in order to connect more than 2 conductors (more

than 1 conductor in the case of SM2000P and SM3000P), each DC conductor must be protected individually against dangerous return currents.

Maximum DC input current: 10 A per DC input / 20 A when operating in single tracker

mode (only SM4000P SM4600P and SM5000P)

Maximum DC input voltage: 600 V

Select the conductor cross-section to suit the system conguration.

Exclusively use Wieland PST40i1C connectors (the mating connectors are not

included in the package supplied)

Do not t a ground connection to either the negative terminal or the positive terminal

of the PV generator.

Procedure

1. Make sure the DC disconnector and the external AC disconnector are off.

2. Connect the pre-tted DC conductors (A).

3. Use the locking clips (included in the delivery package) to secure the connectors

against manual opening (B).

en

85

DC− DC+DC+ DC−

(A) (B)

Configure the inverter for dual tracking operation

If necessary, congure the inverter for dual tracking operation (only SM4000P, SM4600P

and SM5000P).

4. Remove the cover as described in section 5.1.1.

5. Remove both DC bridges (see Section 5.2 / No.10) using a size 2 screwdriver.

6. Close the inverter by tting and tightening the cover.

Close off any unused DC connection points.

Any unused DC connection points must be closed off to ensure that the installation complies with the IP65 protection rating requirements. Please use the following closing parts

made by Wieland (www.wieland-electric.com):

for plug components: order number 05.566.6380.0

for socket components: order number 05.566.6480.0

86

Increasing overvoltage protection

If you want to increase the overvoltage protection on the DC side using additional external

surge arresters, the following connection conditions must be met:

Use a surge arrester with a response voltage of > 600 V.

Connect the external surge arresters as follows:

> 600 V> 600

V>

600 V> 600 V

Install the connector cables close together to avoid overvoltages in the case of a

lightning strike.

Avoid ground loops in the wiring.

Wire the earth connections in a star conguration with the neutral point close to the

inverter.

en

87

5.5 Grid connections

The inverter is tted with two RJ45 sockets as standard to provide an interface to an

Ethernet or RS485 network.

Note

You will nd more details about data communications in the technical information “MaxComm network”. This document can be downloaded from our website at: www. solarmax.com; Downloads/Data communication/MaxComm.

Connection conditions

Use shielded RJ45 cable

Connectable cable diameter: min. 5.5 mm / max. 7.0 mm

Procedure

1. Remove the cover of the inverter as described in section 5.1.1.

2. Thread the network cables through the multiple cable gland (see Section 5.2) to the

network terminals.

Note

The RJ45 connectors can be pulled through the multiple cable gland.

3. Depending on the type of network, connect the cable either to the "Ethernet" or

"RS485" connection.

4. Close off any unused holes in the multiple cable gland using the locking pins (see No.

8 in Section 4.2).

5. Tighten the multiple cable gland (wrench size: 34 mm).

6. After that, check the cable strain relief.

7. Close the inverter by installing and tightening the cover.

88

6 Commissioning

6.1 Activating the inverter

Procedure

1. Check that the cover is installed.

– If the cover is not tted, close the inverter as follows:

– insert the contact protection until you hear the two snap closures engage

– then t the cover and tighten.

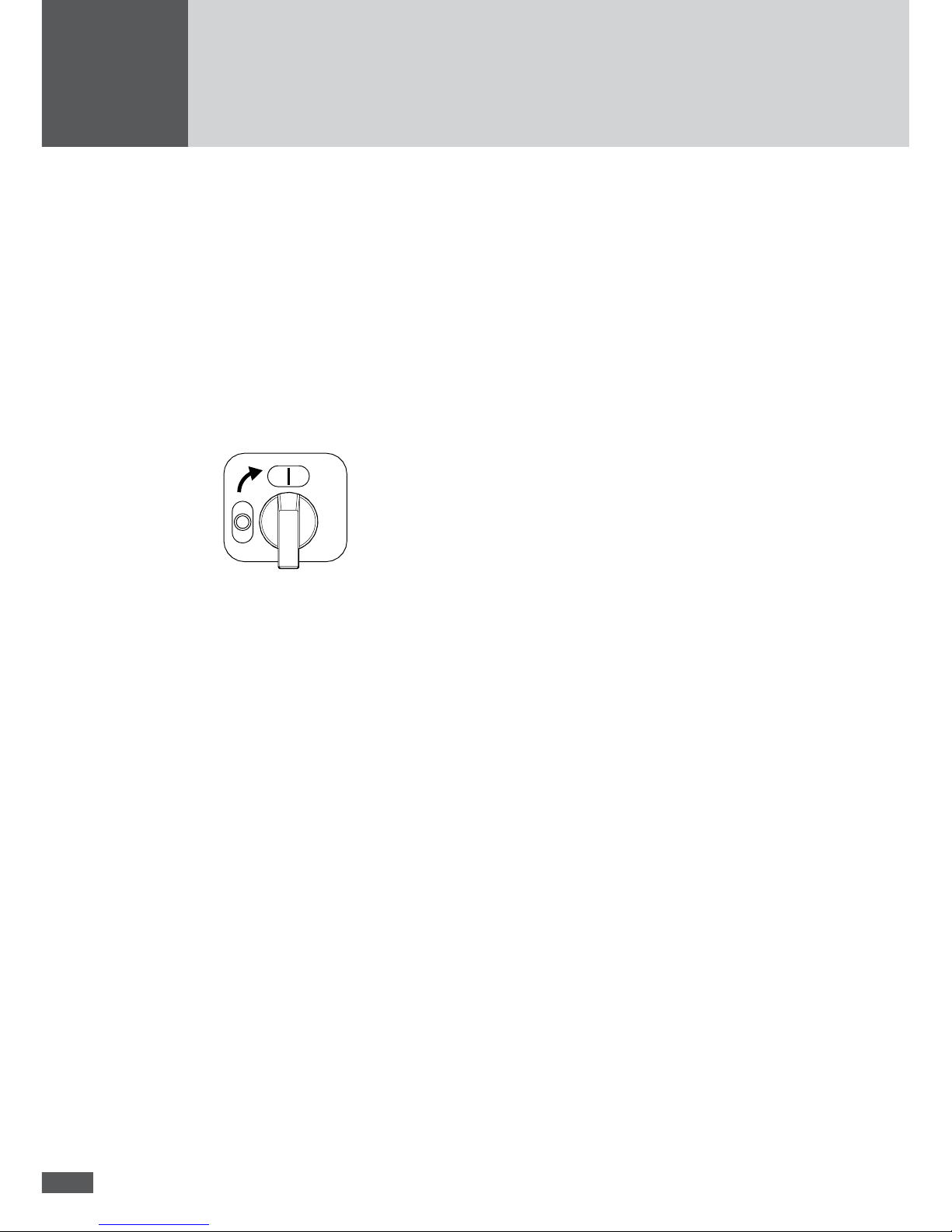

2. Switch on the DC disconnector at the inverter.

– The graphics display shows the "Overview". The status message "Start up..."

appears.

3. Switch on the AC power supply to the inverter.

– Wait for the "Mains operation" status message to be displayed. This indicates that

the inverter is in mains operation.

– During initial start-up of the inverter, instead of the “Overview” menu, an “Initial

setup” menu appears (see Section 6.2).

6.2 Initial start-up

This section describes the initial start-up of the inverter and the graphics display settings required for this purpose. Once initial start-up has been successfully completed, the

inverter will start feeding into the public network.

6.2.1 Requirements

The inverter has been installed and is fully connected.

The contact protection and cover of the inverter are tted.

There is sufcient solar irradiation (sufciently high DC input voltage).

When operating the inverter in dual tracking mode (2 trackers) the DC bridges have to

be removed (see Section „Congure the inverter for dual tracking operation“; page

85).

en

89

Note

Entering an incorrect country setting may lead to problems regarding

inverter operation and to the withdrawal of the operating license by the

respective grid operator.

Contact your grid operator or the SolarMax Service Center if you have any

doubt regarding the settings you must select.

You can restart initial start-up by pressing in the "Conrmation"

menu at any time.

6.2.2 Procedure

1. Switch on the inverter as described in section 6.1. The "Initial setup" menu will be

displayed:

2. Select the display language from the "Language" menu.

3. If necessary, update the time and the date.

– The inverter saves the date entered as the initial start-up date.

– The "DC input cong." menu will be displayed (only with the SM4000P, SM4600P

and SM5000P):

4. Select the required setting:

Setting Description

1 Tracker The inverter has been congured for single tracking mode operation.

The DC bridges have been tted in the inverter (default conguration ex

works).

90

Setting Description

2 Tracker The inverter has been congured for dual tracking mode operation. The

DC bridges have been removed from the inverter.

5. Conrm that the DC bridges have been tted (for "1 Tracker" setting) or that the DC

bridges have been removed (for "2 Tracker" setting).

Note

If you select the "2 Tracker" setting while the DC bridges are still in place

in the inverter, you must abort the start-up at this point.

Open the inverter as described in Section 5.1 in order to remove the DC

bridges as per Section 5.4.

You can then carry out the initial start-up.

– The "Country" menu will be displayed:

6. Select the correct country setting.

– Press

to conrm your entry.

– Depending on the country setting selected, additional menus may be displayed

(see Section 6.2.3).

– The "Conrmation" menu is then displayed.

7. Check the data in the "Conrmation" menu.

8. To complete initial start-up, press

.

– The main menu will then be displayed (see section 7.4).

– Should commissioning be taking place in Italy, the auto-test must be carried out

after the initial start-up (see Section 6.3).

6.2.3 Description of country-specic menus

Depending on the country setting, additional menus will be displayed during initial startup. This section describes these menus.

en

91

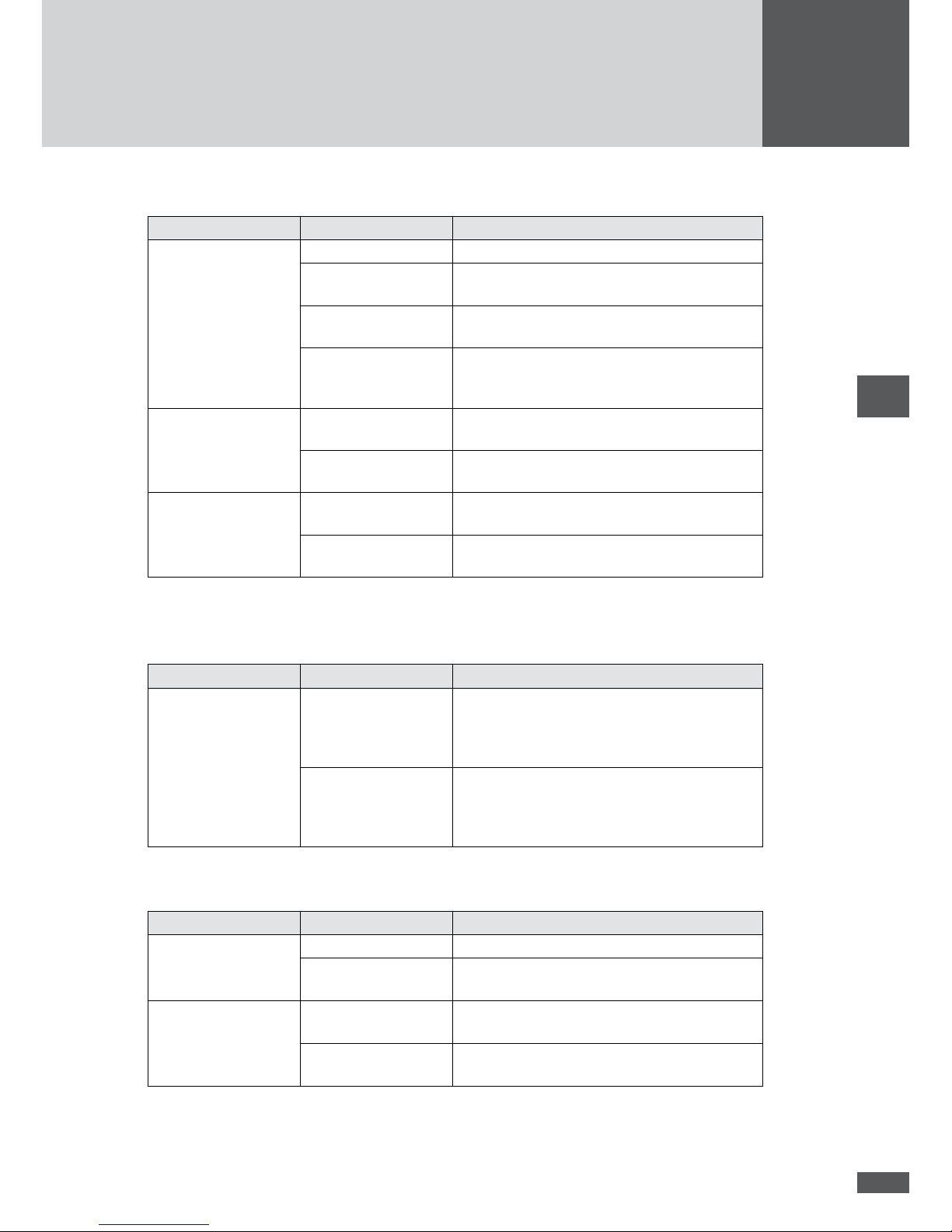

Country setting "Germany"

Menu Setting Description

System power ≤ 3.68 kVA The maximum plant system rating is 3.68 kVA.

> 3.68 – 13.8kVA The plant system rating is higher than 3.68 kVA

and/or does not exceed 13.8 kVA.

> 13.8 kVA – 30 kVA The plant system rating is higher than 13.8 kVA

and/or does not exceed 30 kVA.

> 30 kVA The plant system rating is higher than 30 kVA.

An external grid monitoring and remote shutdown will be used.

I/O module

1)

Inactive The function for the external shutdown is

deactivated (EISD-ENA status: Disabled).

On The function for the external shutdown is

activated (EISD-ENA status: Enabled).

CosPhi(Pac) - QMCPP Inactive

The "cosφ(Pac)" function is deactivated (no

reactive power feed-in, cosφ=1).

On

The "cosφ(Pac)" function for the feed-in / input

of reactive power is activated.

1)

the menu is only displayed when the optional I/O module has been tted.

Country setting "Great Britain"

Menu Setting Description

System power ≤ 16 A per phase The output current is max. 16 A (inverter

settings in accordance with standard G83/2;

available only for SM2000P, SM3000P and

SM4000P.)

> 16 A per phase The output current is greater than 16 A (inverter

settings in accordance with standard G59/2;

available only for SM4000P, SM4600P and

SM5000P).

Country setting "Italy"

Menu Setting Description

System power ≤ 3 kW The maximum plant system rating is 3 kW.

> 3 kW – 6 kW The plant system rating is higher than 3 kW

and/or does not exceed 6 kW.

I/O module

1)

Inactive Remote control of the inverter via SPI logic is

deactivated (SPIL-ENA status: Disabled).

On Remote control of the inverter via SPI logic is

activated (SPIL-ENA status: Enabled).

1)

the menu is only displayed when the optional I/O module has been tted.

92

Country setting “Greece”

Menu Setting Description

Location Mainland The PV power plant is to be installed on the

Greek mainland.

Islands The PV power plant is to be installed on an

island in Greece.

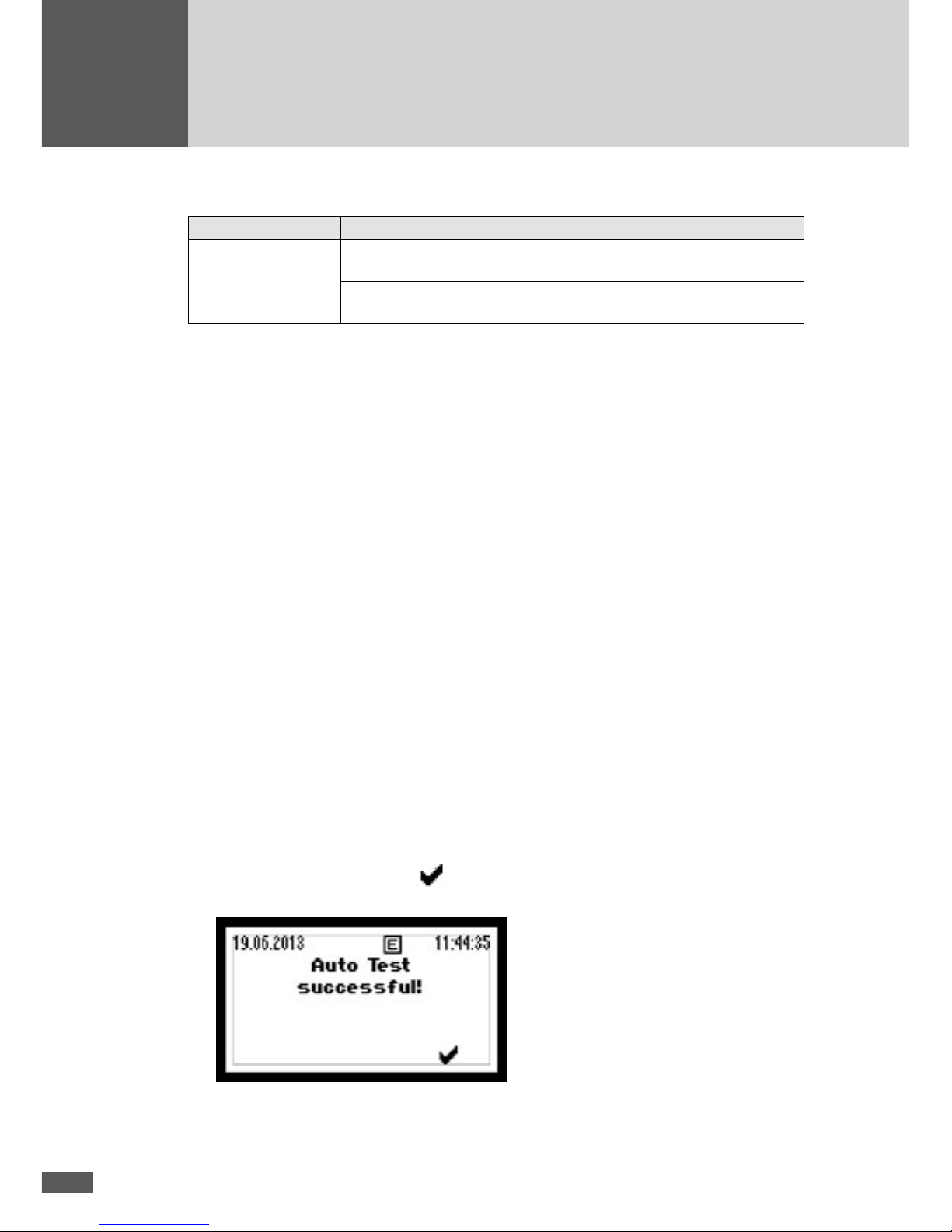

6.3 Auto-test

The auto-test (only available in the "Italy" country setting) checks the grid monitoring

of the inverter. The auto-test consists of 7 test steps in which the triggering behavior is

checked in the case that the voltage and frequency limits are exceeded.

In the auto-test, the respective limit value is successively changed until it reaches the

triggering threshold (i.e. the current reading). If the grid monitoring function is working,

the inverter triggers the grid monitoring. For each step of the test, the graphics display

shows the current reading, the trigger value, the trip time and the set limit. During the test

of the frequency limits, the activation status of the limit value is also displayed.

The auto-test is performed automatically. Following completion of the auto-test, the

inverter returns to normal operation. If an error occurs or irradiation is insufcient during

the auto-test, the auto-test is aborted. In this case the message "Auto-test aborted" is

shown on the display. The auto-test takes approximately 5 minutes.

Requirements

Sufcient solar irradiation

The inverter has been connected to the mains and switched on for at least 10

minutes.

Procedure

1. In the main menu, select the "Auto Test" menu.

2. To start the auto-test, press

.

3. Wait for the display of the successful completion of the auto-test:

4. Ensure that the inverter resumes normal operation (in this case the status message

"Mains operation" will be shown on the graphics display).

en

93

6.4 Settings

Different communication parameters and monitoring functions can be set in the "Settings" menu of the graphics display. All settings except the IP mode can also be made

using the MaxTalk service software.

In the "Main menu" select the "Settings" menu. The settings can then be made as follows:

back to the main menu / select parameter (e.g. "Time")

Edit parameter

Conrm parameter / increase number / highlight next number

6.4.1 Setting the display language and system time

After initial start-up, set the display language and check the system time of the inverter.

In the "Settings" menu, select the following parameters and enter the desired values:

Parameter Description

Language Selection of the display language: German, English, French, Italian or

Spanish. The display language selection does not depend on the selected

country.

Time System time of the inverter

Date The date displayed by the inverter

94

6.4.2 Setting the network parameters

Device address

In order to communicate via RS485 or Ethernet interface the inverter needs a unique

device address on the network.

1. In the "Settings" menu, select the "Device address" parameter.

2. Set the parameter to the required value:

Parameter Description

Device address Address range: 1…249

Configuring the Ethernet interface

In addition to the device address, the following settings must be made to communicate

via Ethernet:

1. In the "Main menu" select the "Network" menu.

2. Select the necessary setting in the "IP-Mode" menu:

Setting Description

DHCP-Client The inverter is a DHCP client and is connected to a network with DHCP

server (factory setting).

Static The inverter is connected to a network with static IP addresses and has

to be congured in accordance with step 3.

3. If appropriate, congure the following parameters. These settings are only required in

“Static” IP mode (see step 2):

Parameter Description

IP IP addres s (192.16 8.1.123)

Gateway (192.16 8.1.1)

TCP Port (1234)

DNS1 Domain Name Server 1 (192.168.1.1)

DNS2 Domain Name Server 2 (192.168.1.1)

Netmask Subnet mask (255.255.255.0)

(in brackets: factory settings)

4. Check whether the indicator for the Ethernet connection appears on the graphics

display (see Section 7.1).

en

95

6.5 Displaying the conguration

All available operating parameters, standard-specic functions and their parameterization can be retrieved in the "Conguration" menu. Conguration of the standard-specic

function depends on the country setting selected.

Note

MaxTalk 2 Pro allows authorized qualied technicians to adjust the operating

parameters individually (see section 12).

In the main menu, select the "Conguration" menu.

back to main menu / select parameter or menu / conrm selection

The following parameters and menus are available:

Menu / parameter Description

Country Country setting selected at the time of initial start-up.

DC input cong. Conguration selected at initial start-up: 1 tracker (single

tracking) or 2 trackers (dual tracking, only available with

SM4000P, SM4600P and SM5000P).

System power Plant rating selected at initial start-up (only available with "Ger-

many", "Italy" and "Great Britain" country settings).

I/O module Status display of I/O module

Location Part of country selected at initial start-up (only available with

"Greece" country setting).

SSF Menu of standard-specic functions and parameters

To display the menus of the standard-specic functions, select "SSF". The following

menus are available:

Menu Description

External input Display of external control functions (external shutdown and

external output control). To use these functions, the optional I/O

module is required.

Inverter start-up Those functions are displayed which are active before the

inverter is connected to the network (start conditions).

Grid operation Those functions are displayed which are active during the

inverter's grid operation (grid monitoring).

96

Menu Description

Limitation Those functions are displayed which limit the inverter‘s output

values, such as active and reactive powers and AC output current (output limitation).

Reactive power Those functions are displayed that have an impact on the reac-

tive power taken up or given off by the inverter (reactive power

control).

Reference parameters Display of nominal values and reference parameters.

External input

Function / arameter Description Unit / status

EISD Monitoring the "external shutdown" input at the I/O

module.

-

EISD-ENA EISD function status Disabled/enabled

EISD-SL "External shutdown" input logic High active /

low active

EPC Output control by radio ripple control receiver or

similar external control unit.

-

EPC-ENA EPC function status Disabled/enabled

SPIL Remote control using SPI logic (only available with

"Italy" country setting)

-

SPIL-ENA SPIL function status Disabled/enabled

SPIL-SESL Signal logic of input "Segnale Esterno" (Input "K6"

on I/O module)

High active /

low active

SPIL-CL Logic state of "Comando Locale" 0/1

SPILFM1 SPI frequency monitoring mode 1 SPILFM1-ENA SPILFM1 function status Disabled/enabled

SPILFM1-THRMIN Minimum permissible mains frequency, mode 1 Hz

SPILFM1-DLYMIN Tripping time s

SPILFM1-THRMAX Maximum permissible mains frequency, mode 1 Hz

SPILFM1-DLYMAX Tripping time s

SPILFM2 SPI frequency monitoring mode 2 SPILFM2-ENA SPILFM2 function status Disabled/enabled

SPILFM2-THRMIN Minimum permissible mains frequency, mode 2 Hz

SPILFM2-DLYMIN Tripping time s

SPILFM2-THRMAX Maximum permissible mains frequency, mode 2 Hz

SPILFM2-DLYMAX Tripping time s

SPILFM3 SPI frequency monitoring mode 3 SPILFM3-ENA SPILFM3 function status Disabled/enabled

SPILFM3-THRMIN Minimum permissible mains frequency, mode 3 Hz

SPILFM3-DLYMIN Tripping time s

SPILFM3-THRMAX Maximum permissible mains frequency, mode 3 Hz

en

97

Function / arameter Description Unit / status

SPILFM3-DLYMAX Tripping time s

Inverter start-up

Function / parameter Description Unit / status

PVGIT Checking the insulation resistance of the PV

generator to ground

-

PVGIT-ENA PVGIT function status Disabled/enabled

PVGIT-THR Minimum permissible insulation resistance Ω

RCMUT Checking the integrated fault current monitoring RCMUT-ENA RCMUT function status Disabled/enabled

IST Checking the grid relay

IST-ENA IST function status Disabled/enabled

GPT Checking the grid parameters GPT-ENA GPT function status Disabled/enabled

GPTVMIN-THR Minimum permissible mains voltage V

GPT V MA X-THR Maximum permissible mains voltage V

GPTFMIN-THR Minimum permissible mains frequency Hz

GPTFMAX-THR Maximum permissible mains frequency Hz

GPT-MOT Checking duration s

Grid operation

Function / parameter Description Unit / status

GVMMIN1 Checking the minimum permissible mains voltage

(limit 1)

-

GVMMIN1-ENA GVMMIN1 function status Disabled/enabled

GVMMIN1-THR Limit value V

GVMMIN1-DLY Tripping time s

GVMMAX1 Checking the maximum permissible mains voltage

(limit 1)

-

GVMMAX1-ENA GVMMAX1 function status Disabled/enabled

GVMMA X1-THR Limit value V

GV M M A X1-DLY Tripping time s

GVMMIN2 Checking the minimum permissible mains voltage

(limit 2)

-

GVMMIN2-ENA GVMMIN2 function status Disabled/enabled

GVMMIN2-THR Limit value V

GVMMIN2-DLY Tripping time s

GVMMAX2 Checking the maximum permissible mains voltage

(limit 2)

-

98

Function / parameter Description Unit / status

GVMMAX2-ENA GVMMA X2 function status Disabled/enabled

GVMMA X2-THR Limit value V

GV MMA X2-DLY Tripping time s

GVM10AMA X Checking the maximum permissible average value

for mains voltage over the last 10 minutes

V

GVM10AMAX-ENA GVM10AMAX function status Disabled/enabled

GVM10AMA X-THR Limit value V

GV M10AMAX-DLY Tripping time s

GFMMIN1 Checking the minimum permissible mains fre-

quency (limit 1)

-

GFMMIN1-ENA GFMMIN1 function status Disabled/enabled

GFMMIN1-THR Limit value Hz

GFMMIN1-DLY Tripping time s

GFMMAX1 Checking the maximum permissible mains fre-

quency (limit 1)

-

GFMMAX1-ENA GFMMAX1 function status Disabled/enabled

GFMMA X1-TH R Limit value Hz

GF MM A X1-DLY Tripping time s

GFMMIN2 Checking the minimum permissible mains fre-

quency (limit 2)

-

GFMMIN2-ENA GFMMIN2 function status Disabled/enabled

GFMMIN2-THR Limit value Hz

GFMMIN2-DLY Tripping time s

GFMMAX2 Checking the maximum permissible mains fre-

quency (limit 2)

-

GFMMAX2-ENA GFMMAX2 function status Disabled/enabled

GFMMA X2-THR Limit value Hz

GFMMA X2-DLY Tripping time s

AIS Detection of island operation AIS-ENA AiS function status Disabled/enabled

AIS-DLY Tripping time s

RSCD Detection of recurring short circuits on the AC side RSCD-ENA RSCD function status Disabled/enabled

RBCM Monitoring the continuous leakage current RBCM-ENA RBCM function status Disabled/enabled

RBCM-THR Maximum permissible leakage current A

RSCM Monitoring the leakage current step value RSCM-ENA RSCM function status Disabled/enabled

AOT Auto-test (only available with the "Italy" country

setting)

-

AOT-EN A AOT function status Disabled/enabled

en

99

Function / parameter Description Unit / status

DCCIM Monitoring the DC component in the AC current -

DCCIM-ENA DCCIM function status Disabled/enabled

DCCIM-THR Maximum permissible DC component in AC current A

DCCIM-DLY Tripping time s

Limitation

Function / parameter Description Unit / status

ACPPL Maximum increase of the active power during grid

connection

-

ACPPL-ENA ACPPL function status Disabled/enabled

ACPPL-MGDT Increase % of Pac nom/

min

ACPPL-INI ACPPL at every boot Disabled/enabled

ACPPL-RCN ACPPL at boot after grid disconnection through

coupler breaker

Disabled/enabled

ACPL Limit of active output power AC PL- L MT Limit value W

APPL Limit of the apparent power APPL-LMT Limit value VA

OCL Limit of the output current OC L-L M T Limit value A

PFLM2 P(f) mode 2 PFLM2-STRTFQ Start frequency Hz

PFLM2-RDN Reduction of active power

% of P

M

/Hz

PFLM2-RNC Increase to rated output power % of Pac nom/

min

PFLM3 P(f) mode 3 PFLM3-STRTFQ Start frequency Hz

PFLM3-STOPFQ Stop frequency Hz

PFLM3-RDN Reduction of active power

% of P

M

/Hz

PFLM3-RNC Increase to rated output power % of Pac nom/

min

PFLM3-UFQTHR Maximum permissible mains frequency Hz

PFLM3-LFQTHR Minimum permissible mains frequency Hz

PFLM3-UVTHR Maximum permissible mains voltage V

PFLM3-LVTHR Minimum permissible mains voltage V

PFLM3-MOT Checking duration s

100

Reactive power

Function / parameter Description Unit / status

QMO-AM Reactive power control 0=OFF

QMCQ Reactive power mode constant "Q" -

QMCQ-QSV Reactive power value % of Pac nom

[OEX/UEX]

QMCQ-VLE Status of the voltage-dependent reactive power

control hysteresis for QMCQ

Disabled/enabled

QMCQ-VLIH Upper limit value of the mains voltage V

QMCQ-VLOL Lower limit value of the mains voltage V

QMCQ-PLE Status of the active power-dependent reactive

power control hysteresis for QMCQ

Disabled/enabled

QMCQ-PLI Upper limit value of the active power W

QMCQ-PLO Lower limit value of the active power W

QMCPP

Reactive power mode "cosφ(Pac)"

QMCPP-PSP1…PSP10 Characteristic values 1 to 10 of Pac active power % of Pac nom

QMCPP-CPSP1…

CP SP10

Characteristic values 1 to 10 of power factor cosφ

- [UEX/OEX]

QMCPP-VLE Status of mains voltage-dependent reactive power

control hysteresis for QMCPP

Disabled/enabled

QMCPP-VLIH Upper limit value of the mains voltage V

QMCPP-VLOL Lower limit value of the mains voltage V

QMCCP

Reactive power mode "cosφ"

QMCCP-CPSV

cosφ value

- [UEX/OEX]

QMCCP-VLE Status of mains voltage-dependent reactive power

control hysteresis for QMCCP

Disabled/enabled

QMCCP-VLIH Upper limit value of the mains voltage V

QMCCP-VLOL Lower limit value of the mains voltage V

QMCCP-PLE Status of active power-dependent reactive power

control hysteresis for QMCCP

-

QMCCP-PLI Upper limit value of the active power W

QMCCP-PLO Lower limit value of the active power W

Reference parameters

Function / parameter Description Unit

NAP Rated output power (Pac nom) -

NAP-VAL Value W

NOC Rated output current NOC-VAL Value A

GCD Switching delay of the coupler breaker GCD-CDLY Tripping time s

en

101

6.6 Displaying the measured values

The current measured inverter values can be accessed in the “Measured values” menu.

In the main menu, select the "Measured values" menu.

back to the main menu / scrolling measured values

Measured value Description Unit

Vdc 1, Vdc 2

Input voltage at DC terminal 1 and DC terminal 2 (when operating in single tracker mode, the DC terminal 2 = 0)

V

Idc1, Idc2

Input current to the DC terminal 1 and DC terminal 2 (when

operating in single tracker mode, the Idc2 terminal = 0)

A

Vac

Mains voltage V

Iac

Output current A

Pac

Output power W

Q

Reactive power (+: overexcited / −: underexcited) var

cosφ

Power factor (OEX: overexcited / UEX: underexcited) -

Frequency

Mains frequency Hz

Temperatur e

Equipment temperature °C

Note

The measured inverter values are not suitable for billing purposes or calculating the efciency. The measuring error may amount to up to ±5% depending

on the measured value. Only the measured values of a calibrated electricity

meter can be relied upon for billing purposes.

MaxTalk measured values

The following additional values can be viewed with the MaxTalk 2 service software:

Measured value Description Unit

Vac 10 min 10 minute average value of the mains voltage V

Iac mean Mean value of output current A

Ierr Ground leakage current mA

Ierr DC Leakage current mA

102

6.7 Registering for MaxView

Register for the free web-based MaxView application. With MaxView it is possible to view

and graphically display the yield data of your PV power plant from anywhere.

Note

Frequently asked questions about MaxView and the replies to these can be

found on our website at https://maxview.solarmax.com/faq.xhtml.

Procedure

1. Connect the inverter to the Internet via the Ethernet interface (see Sections 5.5 and

6.4.2).

2. Enter your registration data in a web browser under https://maxview.solarmax.com.

3. Learn about the various functions of MaxView.

6.8 Update rmware

The inverter rmware can be updated with the help of the MaxTalk 2 service software.

For further information, please refer to the MaxTalk 2 operating manual, which you can

download from our website (www.solarmax.com; Downloads/Software/MaxTalk 2).

en

103

7 Operation

7.1 Graphics display

The graphics display shows the system values, status information, and the inverter’s fault

messages. The graphics display can be used for obtaining information on the current

operating status, accessing the integrated data logger and entering various settings on

the inverter.

1

3

4

2

5

No. Description

1 Graphics display with backlighting

2 Status LED: operating status display (see section 7.7)

3 Function keys (membrane keypad)

4 Display with Ethernet connection (link display)

5 Display when data transfer takes place (communication).

The function keys can be used for navigating within the menu structure:

Symbol Description

Select menu or parameter

Edit parameter

Highlight number (parameter editing)

Increase highlighted number / select menu or parameter

Confirm

Cancel

104

7.2 Menu structure

Main menu

Overview

Statistics

Conguration

Auto-test**

Information

Measured values

* only if I/O module is installed

** only for country setting “Italy”

Time

Language

Date

Device adress

Days

Months

Years

Total

Reset

Network

IP

IP-Mode

Netmask

Gateway

TCP Port

DNS1

DNS2

Status relay*

Status relay delay*

SPD Monitor*

SSF

Settings

Grid operation

External input

Inverter start-up

Limitation

Reactive power

Reference parameter

en

105

7.3 Overview

The overview shows the most important operating data of the inverter. The graphics

display automatically switches to the "Overview" if no function button is pressed for 120

seconds.

In the main menu, select the "Overview" menu.

Display Description

Date and system time Pac Current output power [W]

Today Daily yield [kWh]

Tot al Total yield since commissioning [kWh]

Status

Current operating status (see section

7.7 )

7.4 Main menu

From the "Main menu", you can open all menus.

In order to switch from "Overview" to the "Main menu", press any function key.

: select menu / conrm your selection

106

7.5 Statistics

The "Statistics" menu can be used for accessing the inverter's data logger. The data

logger saves the statistics values of the past 25 years. The daily, monthly, yearly and total

statistics can be displayed. All statistics values can be deleted.

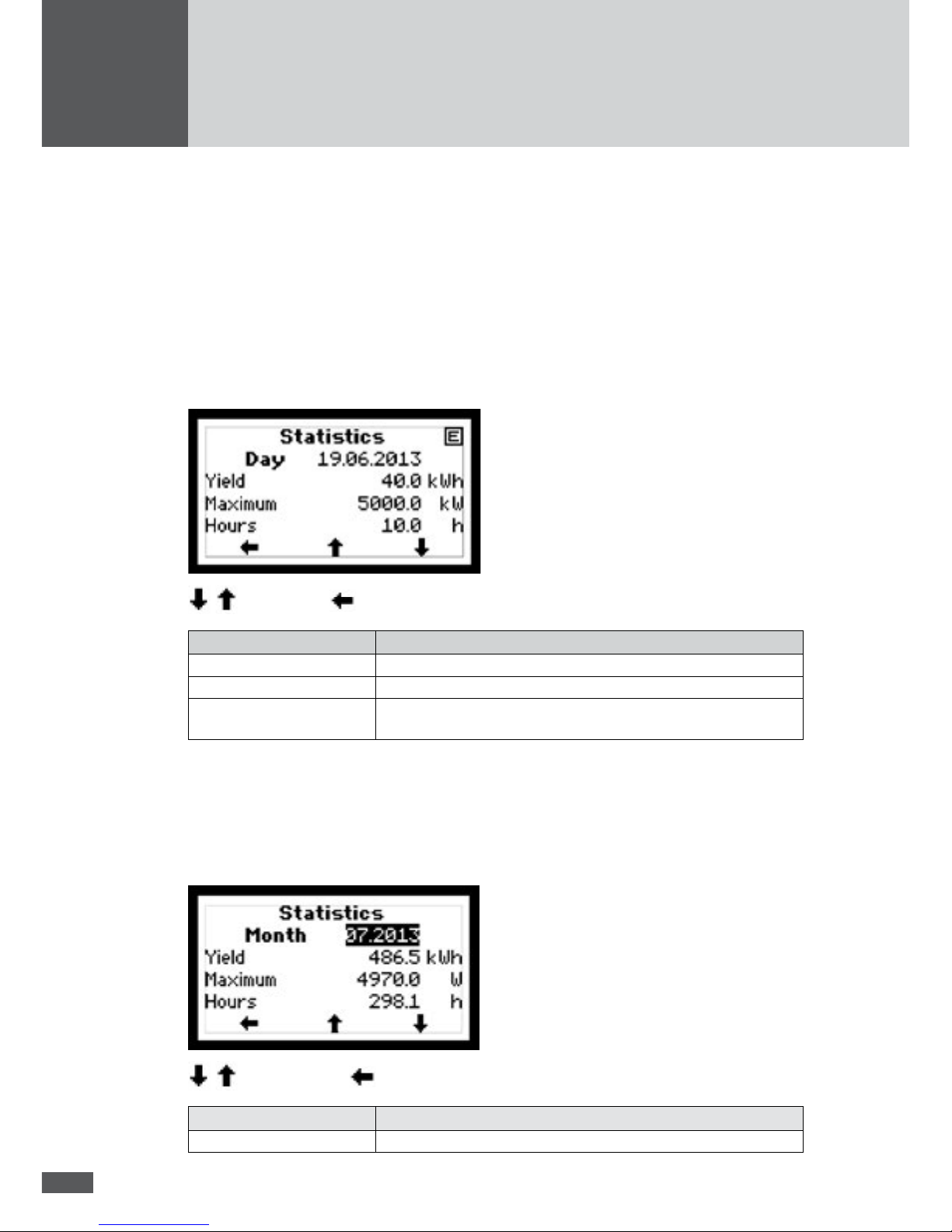

7.5 .1 Displaying the daily statistics

The daily statistics displays the statistics values for the last 31 days.

In the "Statistics" menu, select the "Day" sub-menu.

Select day / back to the Statistics menu

Statistics value Description

Yield Daily yield [kWh]

Maximum Fed-in maximum power [W]

Hours

Number of operating hours in the "Mains operation" operating

status

7.5 .2 Displaying the monthly statistics

The monthly statistics displays the statistics values for the last 12 months.

In the "Statistics" menu, select the "Month" sub-menu.

Select month / back to the Statistics menu

Statistics value Description

Yield Monthly yield [kWh]

en

107

Statistics value Description

Maximum Fed-in maximum power [W]

Hours Number of operating hours in the "Mains operation" operating

status

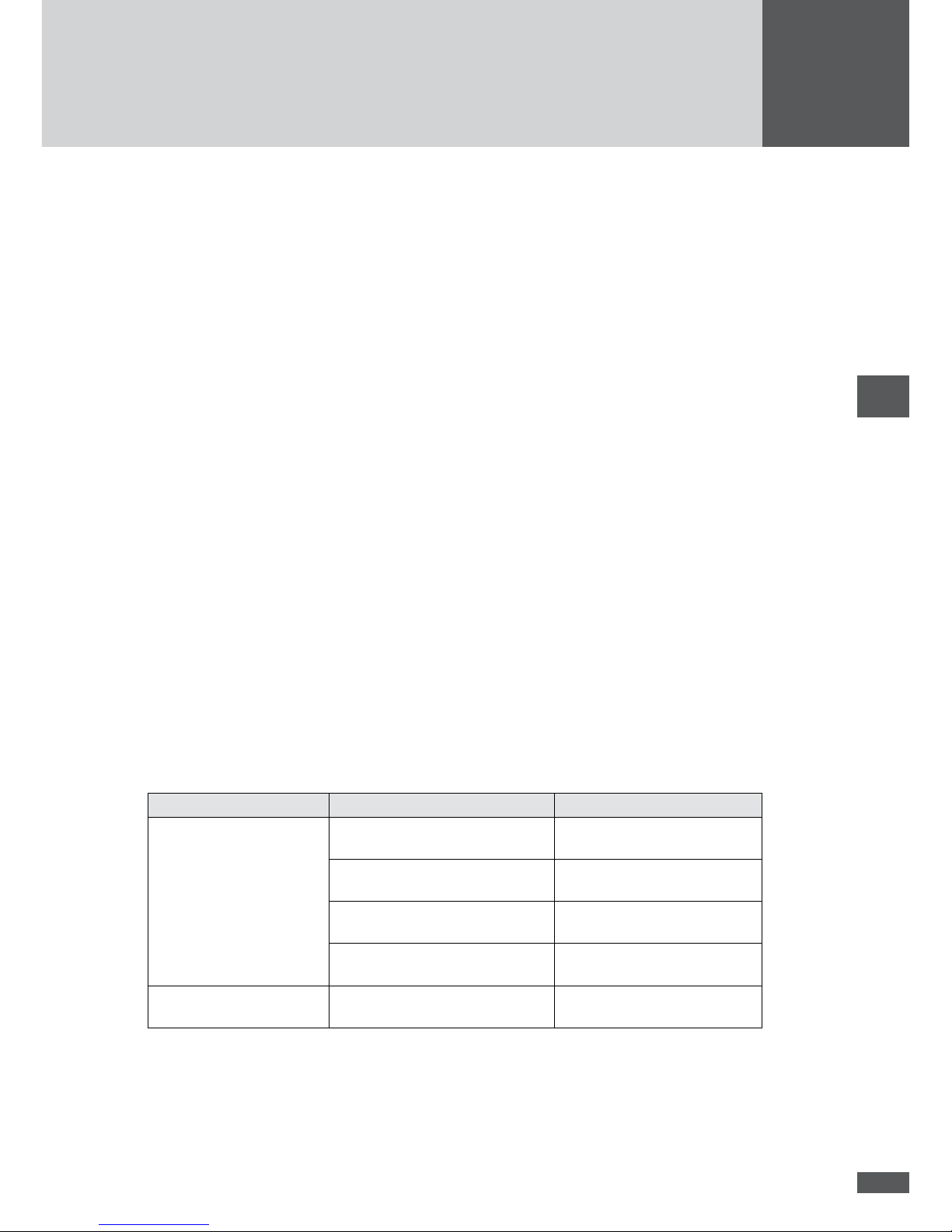

7.5 .3 Displaying the annual statistics

The annual statistics displays the statistics values for the last 25 years.

In the "Statistics" menu, select the "Year" sub-menu.

: select year / back to the Statistics menu

Statistics value Description

Yield Annual yield [kWh]

Maximum Fed-in maximum power [W]

Hours

Number of operating hours in the "Mains operation" operating

status

7.5 .4 Displaying the total statistics

The total statistics shows the statistics values since commissioning.

In the "Statistics" menu, select the "Total" sub-menu.

back to the Statistics menu

108

Statistics value Description

Yield Total yield [kWh]

Hours Total operating hours in the operating status "Mains operation"

7.5.5 Deleting the statistics values

The statistics values of the data logger can be deleted.

In the "Statistics" menu, select the "Reset" sub-menu.

Note

The deletion process cannot be undone!

Cancel / Conrm deletion

7.6 Displaying information

This menu displays information about the inverter. The menu can be used to identify the

inverter.

In the main menu, select the "Information" menu.

back to the main menu / scroll display

Display Description

Device type Inverter type

Serial No. Inverter serial number

Firmware Firmware version installed in the inverter

en

109

Display Description

Status Current operating status

Warning Current warning message

Commissioning Date of initial start-up

Operating hours Total operating hours in mains operation

Mac address Mac address of the inverter

7.7 Operating status

The status message displayed on the graphics display describes the current operating

status of the inverter. Each status message relates to one of ve possible operating statuses. The status LED has different colors with which to indicate one of these operating

statuses.

In addition to the status messages, the inverter also displays warnings. Warnings result

from device errors or external malfunctions. The inverter continues to feed power into

the mains, but it is possible that yield is reduced. Warnings are independent of the operating status and are displayed on the graphics display alternately with the current status

message.

Status LED Operating status Description

Off

- Inverter is switched off

Flashes green

Booting Inverter is starting up

Green

Mains operation Mains feed-in (normal operation)

Flashes orange

-

Warning → no grid disconnection

Orange

Fault

External fault → grid disconnection

Red

Error

Device error → grid disconnection

Flashes red

Blocked

Inverter is blocked → grid disconnection

The "Fault", "Error", and "Blocked" operating status messages, as well as the warnings,

usually require certain measures to be carried out by the qualied electrician in charge

(see section 8).

110

7.7.1 Booting

Status LED: ashes green

Status message Description

Irradiation too low The solar irradiation or rather the available output is too low for

mains operation.

Startup… The inverter checks the internal hardware and software compo-

nents before connecting to the mains.

Restart delay The inverter delays connection to the grid (after a disconnection

from the grid or when starting up).

7.7.2 Mains operation

The status LED lights up green.

Status message Description

Maximum power The inverter limits the in-feed power to the maximum permissible

value. This may occur if the PV generator is oversized.

Mains operation The inverter is in feed mode.

Idc limitation The inverter limits the PV generator current to the maximum

permissible value. This may occur if the PV generator is designed

such that the current at Maximum Power Point (MPP) exceeds the

maximum permissible input current of the inverter.

Iac limitation The inverter limits the output current to the maximum admissible value

(where the PV generator is oversized).

Restart limitation Following an external output limitation the inverter increases the

active power with a dened progression (Pac progression and/or

Soft Start).

Frequency limitation The inverter temporarily limits the active power owing to an active

frequency-dependent power reduction.

External limitation The inverter's fed-in active power is limited by external output

control.

Temperature limitation The output power is temporarily reduced in order to limit the

inverter‘s temperature.

en

111

8 Troubleshooting

8.1 SolarMax Service Center

If you have technical questions or difculties, our Service Center will be happy to help you.

To do that we need the following information:

Device type

Serial number (S/N)

Installation location

Information about the failure you are experiencing (status message, etc.)

Contacting the SolarMax Service Center

The contact details of the SolarMax Service Center can be found on the back of this

instruction manual.

Sputnik Engineering AG

Länggasse 85

CH-2504 Biel/Bienne

8.2 Diagnosis & measures

The following tables describe possible actions for remedying faults. If the actions suggested do not correct the fault, please contact the SolarMax Service Center.

8.2.1 General troubleshooting

Problem Cause Actions

The graphics display

remains blank

The DC disconnector is switched

off.

Switch on the DC disconnector.

The irradiation is too low. Wait until irradiation is high

enough.

The strings are interrupted. Check the PV generator and

eliminate the interruption.

It is possible that the inverter is

defective.

Contact the SolarMax Service

Center.

The graphics display only

ashes briey.

The irradiation is too low. Wait until irradiation is high

enough.

112

8.2.2 Warnings

The status LED ashes orange.

Warning Cause Actions

Temperature limitation The output power is temporarily

reduced in order to limit the

inverter‘s temperature.

Ensure that

the recommended maximum

ambient temperature is not

exceeded; that the cooling ns

are free from dust and dirt.

Fan failure A fan is defective or soiled. Contact the SolarMax Service

Center.

RTC error Date and time in the RTC (real-

time clock) were reset due to a

malfunction.

Set the date and time (see

section 6.4.1). If this problem

occurs frequently, contact the

SolarMax Service Center.

Firmware mismatch The rmware versions of the

inverter controllers do not match.

Contact the SolarMax Service

Center.

Flash error An error has occurred in the ash

memory.

Contact the SolarMax Service

Center.

SPD failure An active signal is present at

the "SPD Monitor" input of the

I/O module (monitoring lightning

protection).

Check the external lightning

protection module (or the

device connected to the "SPD

Monitor" input).

8.2.3 Faults

The status LED lights up orange.

Note

MaxTalk can be used to read out the last error messages.

Status message Cause Actions

Vdc too high The DC input voltage of the

inverter is too high.

Switch off the DC disconnector. Check the PV generator’s conguration.

Ierr too high The ground leakage current has

exceeded the permissible RBCM-

THR limit value.

Check the PV generator.

Ierr step too high The leakage current has exceeded

the admissible RSCM step value.

No mains There is no mains voltage. Check the AC conductor

(fuses).

en

113

Status message Cause Actions

Frequency too high The mains frequency is outside

the GFMMAX1-THR, GFMMAX2THR or GPTFMAX-THR limit

values.

If this problem recurs, contact

the grid operator in charge.

Frequency too low The mains frequency is outside

the GFMMIN1-THR, GFMMIN2THR or GPTFMIN-THR limit values.

Mains error The inverter detects island mode. If this problem recurs, contact

the grid operator in charge.

Vac too high The mains voltage is outside the

GVMMA X1-THR, GV M M AX 2-TH R

or GPTVMAX-THR limit values.

If this problem recurs, contact

the grid operator in charge.

Vac too low The mains voltage is outside the

GVMMIN1-THR, GVMMIN2-THR or

GPTVMIN-THR limit values.

Vac 10 min too high The maximum 10-minute average

value of the mains voltage

GVM10AMAX-THR is too high.

Insulation fault DC The insulation resistance of the PV

generator to ground is too low.

Check the PV generator.

Phase and neutral conductor are

interchanged.

Connect the AC supply

conductors as described in

section 5.3.

Error ext. input 1 The external grid monitoring (NA

protection / Teledistacco) has

disconnected the inverter from the

grid. An active signal is present at

the "NA" input (external shutdown)

of the I/O module.

If this problem recurs, contact

the grid operator in charge.

8.2.4 Error

The status LED lights up red.

Status message Cause Actions

Device error (+ error code) The inverter is defective. Note the displayed two-digit

error code and contact the

SolarMax Service Center.

114

8.2.5 Blockings

The status LED will ash red.

Status message Cause Action

Programar rmware The inverter's rmware is being

updated.

None. The inverter automatically resumes mains operation

once the rmware update is

complete.

9 Maintenance

The following maintenance work should be carried out when required:

Regularly check the operating status of the inverter on the graphics display, see sec-

ti on 7.7.

Clean the graphics display with a damp cloth. Do not use harsh or abrasive cleansing

agents.

Check the inverter for external damage. If any damage is found, inform the respective

qualied electrician.

en

115

10 Decommissioning

10.1 Instructions for inverter replacement

When replacing the inverter, note the following:

Before replacing the inverter, write down the total yield. The procedure for viewing

the total yield is described in Section 7.5.4.

If an I/O module was used in the existing inverter, this can be re-used in the replace-

ment inverter.

10.2 Inverter disassembly

DANGER!

Fatal electric shock hazard!

Components within the inverter are charged with a high voltage. After the

inverter has been disconnected, high residual voltages remain in the inverter

for approx. 5 minutes.

Before starting inverter disassembly, the inverter must be fully discon-

nected in accordance with the procedure described in this chapter.

WARNING!

Risk of injury from electric arc!

Dangerous electric arcs could occur when removing live DC conductors.

Switch off the inverter DC disconnector before removing the DC

conductors.

ATTENTION!

Electrostatic discharge can damage the inverter

Do not touch any electronic components inside the inverter.

116

Procedure

1. Switch off the external AC disconnector.

– The "No grid" status message is shown on the inverter.

2. Switch off the DC disconnector at the inverter.

3. Use a size 2 screwdriver to remove the locking clips on the DC plugs.

4. Pull out the DC conductors to fully separate the inverter from the PV generator.

5. Loosen the two M5 screws on the cover.

6. Open the inverter as described in Section 5.1.

7. Use a suitable charge indicator to check that all terminals are free from voltage.

– When all terminals are de-energized, you can remove the AC supply conductor, the

second protective conductor and all communication lines from the inverter.

CAUTION!

Risk of burns due to hot casing components!

Wait until the back of the casing has cooled down.

8. Close the inverter:

– insert the contact protection until it engages;

– then tighten the cover.

9. Remove the 2 Phillips head sheet metal screws (4.8 x 13) on the side which secure

the inverter on the mounting rail.

10. Disengage the inverter from the mounting rail.

11. Remove the I/O module if there is one.

10.3 Disposing of the inverter

Dispose of the inverter as indicated by the local waste disposal regulations. You can also

return the inverter, at your own cost, to Sputnik Engineering AG for professional disposal.

The contact details of the SolarMax Service Center can be found on the back of this

instruction manual.

en

117

11 Technical data

SM2000P SM3000P SM4000P SM4600P SM5000P

Input

values

MPP voltage

range

1)

210…480 V 310…480 V 190…480 V 240…480 V 260…480 V

Minimum DC

voltage

120 V 120 V 120 V 120 V 120 V

Maximum DC

voltage

600 V 600 V 600 V 600 V 600 V

Maximum DC

current

10 A 10 A 10 + 10 A 10 + 10 A 10 + 10 A

Number of MPP

trackers

1 1 2 2 2

Number of string

connections

1 1 2 2 2

Connection type Wieland PST40i1 (identical to MC4)

Overvoltage

category

II

Output

values

Rated output power 2,000 W 3,000 W 4,000 W 4,600 W 5,000 W

Maximum apparent

output power

2,000 VA 3,000 VA 4,000 VA 4,600 Va 5,000 VA

Maximum AC

current

9 A 13.5 A 17. 5 A 22A 22A

Nominal mains

voltage / range

230 / 184 … 276 V

Mains nominal

frequency / range

50 / 45…55 Hz

Power factor cosφ

Adjustable from 0.8 overexcited to 0.8 underexcited

Distortion factor at

rated output power

< 1.5 %

Connection type Terminal 2.5 - 10 mm

2

Grid connection Single phase (L / N / PE)

Overvoltage

category

III

Efciency Max. efciency 97. 5 % 9 7. 5 % 98 % 98 % 98 %

Europ. Efciency 97 % 97 % 97.5 % 9 7. 5 % 9 7. 5 %

Power

input

Own consumption

night

0 W

Environment

Protection rating IP 65

Ambient temperature range (for rated

power output)

−20 to +60 °C (−20 to +45 °C)

Max. operating level

above sea level

2000 m

Relative humidity

0 … 100 % (condensation)

Fire protection class V0

118

SM2000P SM3000P SM4000P SM4600P SM5000P

Environment

Environmental

category

In the open

Suitable for wet

rooms

Yes

Degree of soiling 3

Conguration

Display Graphics display with backlighting and status LED

Inverter topology HERIC

®

, transformerless

DC disconnector Integrated

Data logger Energy yields, peak output and operating duration of the last 31 days, 12

months, 10 years / output curves of the last 7 days

Fault current

monitoring

Internal, AC/DC sensitive

Casing / cover Aluminum / plastic ASA+PC

Overvoltage conductor, DC and AC

Requirement class D (VDE 0675-6) and/or type 3 (EN 61643-11)

Standards &

guidelines

CE-compliant

Yes

2)

EMC EN 61000-3-2 / EN 61000-3-3 / EN 61000-3-11 / EN 61000-3-12 / EN

61000-6-2 / EN 61000-6-3

Grid connection

VDE 0126-1-1 / VDE-AR-N 4105

3)

/ CEI 0-21 4) / RD 661 / RD 1699 /

G83/2 / G59/2 / PPC Guide / C10/11 / EN 50438

5)

Device safety IEC/ EN 62109-1/ -2

Interfaces Data

communication

RS 485 / Ethernet

Status signaling

contact

Optional

Connection to radio

ripple control signal

receiver

Optional

Connection to

external lightning

protection

Optional

Connection to

external grid

monitoring

Optional

Weight &

dimensions

Weight 17 kg 17 kg 19 kg 19 kg 19 kg

Dimensions (W x

H x D)

476 x 360 x 180 mm

Warranty Standard 5 years / extension to 10, 15, 20 or 25 years possible

1) for rated output power

2) the complete conformity declaration can be found on our website at www.solarmax.com.

3) not for SM5000P

4) for installations ≤ 6 kW

5) Portugal and Czech Republic

en

119

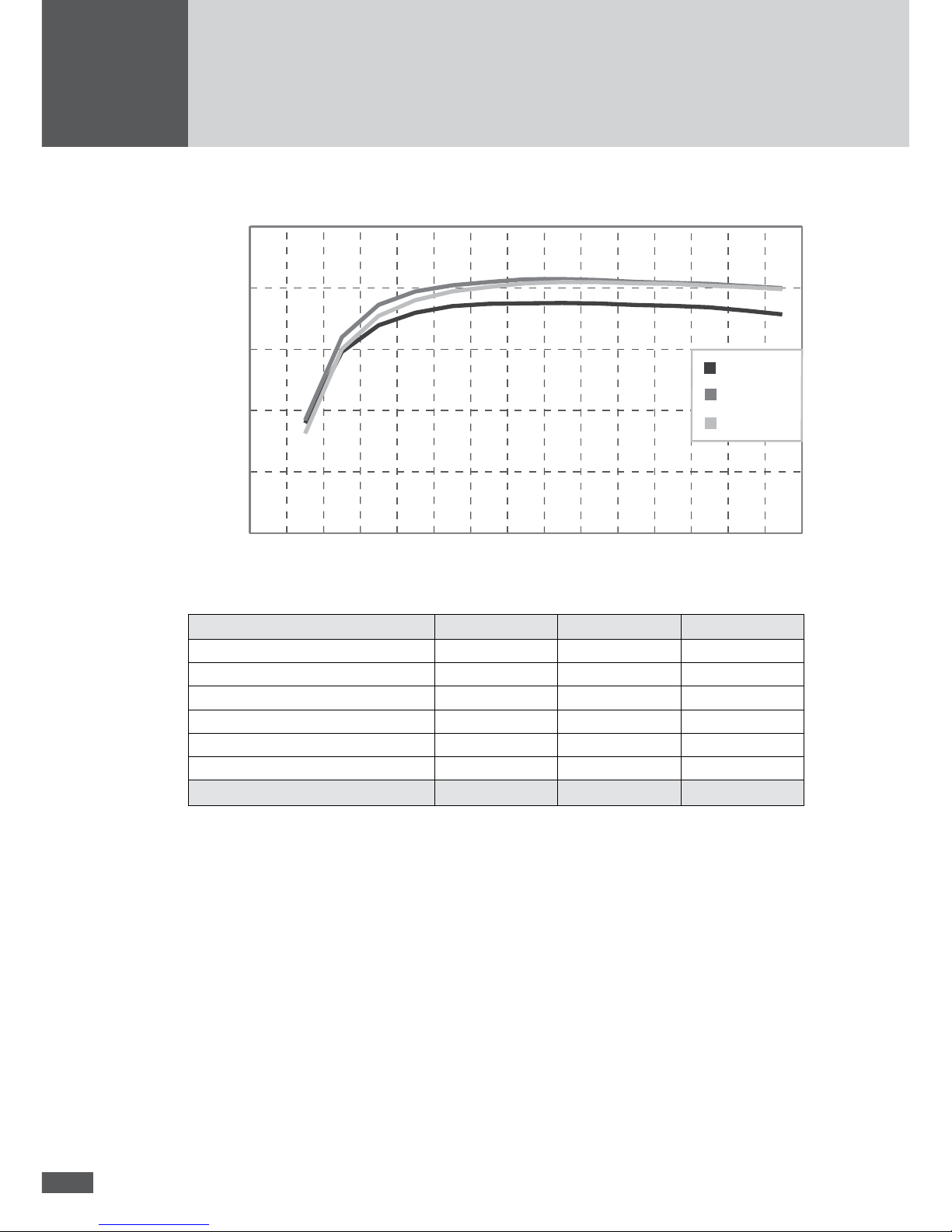

Efficiency curve SM5000P

100.0

97.5

95.0

92.5

90.0

87.5

0 5 102 15 20 25 30 40 50 7060 80 75 90 100

η 260 V

DC

η 400 V

DC

η 480 V

DC

Standardised output Pac/Pac max [%]

Efciency η [%]

Pac/Pac max [%] η 260 V

DC

[%] η 400 V

DC

[%] η 480 V

DC

[%]

5 92.21 92.32 91.79

10 95.38 96.04 95.57

20 96.66 97. 5 2 97.2 2

30 96.89 97. 83 97.6 3

50 96.92 97. 88 97.78

100 96.30 97.4 3 97.4 0

Europ. Efciency η

EU

[%]

96.52 97.4 6 97. 30

120

Efficiency curve SM4600P

100.0

97.5

95.0

92.5

90.0

87.5

0 5 102 15 20 25 30 40 50 7060 80 75 90 100

η 260 V

DC

η 400 V

DC

η 480 V

DC

Standardised output Pac/Pac max [%]

Efciency η [%]

Pac/Pac max [%] η 260 V

DC

[%] η 400 V

DC

[%] η 480 V

DC

[%]

5 92.01 92.12 91.58

10 94.92 95.52 95.03

20 96.51 97. 3 8 97.0 3

30 96.88 97. 7 7 97.57

50 96.91 97. 89 97.77

100 96.45 97. 52 9 7.4 8

Europ. Efciency η

EU

[%]

96.50 97.42 97.2 5

en

121

Efficiency curve SM4000P

100.0

97.5

95.0

92.5

90.0

87.5

0 5 102 15 20 25 30 40 50 7060 80 75 90 100

η 260 V

DC

η 400 V

DC

η 480 V

DC

Standardised output Pac/Pac max [%]

Efciency η [%]

Pac/Pac max [%] η 260 V

DC

[%] η 400 V

DC

[%] η 480 V

DC

[%]

5 92.01 92.12 91.58

10 94.92 95.52 95.03

20 96.51 97. 3 8 97.0 3

30 96.88 97. 7 7 97.57

50 96.91 97. 89 97.77

100 96.45 97. 52 9 7.4 8

Europ. Efciency η

EU

[%]

96.50 97.42 97.2 5

122

Temperature dependent output reduction

The inverter can feed 100 % of its rated output for an unlimited time up to an ambient

temperature of 45 °C. When operating in ambient temperatures in excess of 45 °C it is

possible that the yield is reduced. For this reason excessive ambient temperature should

be avoided. In the specied ambient temperature range the power output of the SM2000P

will be consistent.

110

100

90

80

70

60

−20 −10 0 10 20 30 40 45 50 60

SM5000P

SM4600P

SM4000P

SM3000P

SM2000P

Output Pac/Pac nom [%]

Ambient temperature [°C]

Country-specific settings

The factory's default settings for different countries can be viewed in the technical information "SSF - Standard specic functions and parameters - Factory settings". This document can be downloaded from our website at: www.solarmax.com; Downloads/String

inverters/P series/Manuals.

en

123

12 Accessories and options

Accessory/option Description

I/O module Communication module with the following congurable interfaces:

status signaling contact for remote monitoring of the inverter, interfaces for remote control (external shutdown, external output control)

and for lightning monitoring

MaxView Free web-based application with various functions for remote call-up,

graphic visualization and export of yield data.

Ma xTalk Free communication and service software for local monitoring of the

PV plant.

MaxTalk Pro Professional version of MaxTalk for the conguration of inverters. The

required "SolarMax P series parameter conguration using MaxTalk

2 Pro" operating manual can be downloaded from our website; www.

solarmax.com ("Downloads" area).

MaxMonitoring Using the free MaxMonitoring software, you can display the per-

formance data of your photovoltaic system at any time from home.

MaxMonitoring is available for PC, MacOS and Linux and also as an

app for Android and iOS.

MaxDesign Free software for determining the size of PV plants.

You can nd further information on our website at www.solarmax.com.

124

13 Warranty

Sputnik Engineering AG (hereafter SPUTNIK) guarantees full function and lack of defects of its

technical devices for a warranty period as specified below for each type of device. Such warranty

period can be extended by means of a warranty extension, subject to the conditions named below.

This manufacturer’s warranty exists next to the seller’s warranty (if any) as prescribed by law. As

far as identical with regards to the content, the rights under this manufacturer’s warranty supersede

any rights under the seller’s warranty. Please contact the seller with regard to any claims based on

the seller’s warranty.

1. Warranty Period (Basic)

Central inverters and accessories: 24 months from the date of purchase, but at maximum 30

months after dispatch of the device by SPUTNIK.

String inverters: 60 months from the date of purchase, but at maximum 72 months after dis-

patch of the device by SPUTNIK.

If in individual cases SPUTNIK has agreed in writing to a different warranty period, such arrangement supersedes the above provisions.

2. Scope of Manufacturer’s Warranty

In case of defect or malfunction of a device within the manufacturer’s warranty period, and

upon fulfillment of the conditions for warranty claims named hereafter, the device will be repaired