Instruction manual

SolarMax MT series

6MT2 / 8MT2 / 10MT2 / 13MT2 / 15MT2 / 13MT3 / 15MT3

SolarMax Produktions GmbH

Zur Schönhalde 10

D-89352 Ellzee

E-Mail: info@solarmax.com

© SolarMax Produktions GmbH 2015

4

Contents

1 About this instruction manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1 Target group. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2 Where to keep this manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.3 Symbols used. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Safety instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Appropriate use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Symbols on the inverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.1 Views of the unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.3 Block circuit diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

4 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

4.1 Transport and storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

4.2 Siting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

4.3 Lightning protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

4.4 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

4.5 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

4.6 Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.6.1 Integrated overvoltage protection . . . . . . . . . . . . . . . . . . . . . . . . . .17

4.6.2 AC connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

4.6.3 DC connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.6.4 Status signalling contact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.6.5 Monitoring external input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.6.6 Communications sockets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.6.7 External protective conductor . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.6.8 External residual-current device (RCD) . . . . . . . . . . . . . . . . . . . . . 24

4.6.9 External output control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5 Commissioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.1 Switching on and off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.1.1 Switching on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.1.2 Switching off. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.2 Initial start-up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.2.1 Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.2.2 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.2.3 Description of country-specic menus . . . . . . . . . . . . . . . . . . . . . 27

5.3 Conguration of the data communication interfaces . . . . . . . . . . . . . . . . . 29

6 Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5

en

6.1 Graphics display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.2 Menu structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.3 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.4 Main menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.5 Measured values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.6 Statistics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.6.1 Daily statistics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.6.2 Monthly statistics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.6.3 Yearly statistics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.6.4 Total . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.6.5 Reset. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.7 Conguration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.8 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6.8.1 Implementing the settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.8.2 Status relay. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.9 Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.10 Auto Test according to DK 5940 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.10.1 Start Auto Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.10. 2 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

7 Operating status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

7.1 Status messages and status LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

7.2 Booting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

7.3 Mains operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7.4 Communications activity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

8 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

8.1 SolarMax Service Center . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

8.2 Diagnosis & measures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

8.2.1 General troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

8.2.2 Warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

8.2.3 Failures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

8.2.4 Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

8.2.5 Blockings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

9 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

10 Disposal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

11 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

11.1 Country-specic settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

11.2 Efciency curve SolarMax 15MT3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

11.3 Temperature-dependent output reduction (power derating) . . . . . . . . . . . . 54

12 Accessories and options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

13 Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

6

1 About this instruction manual

This instruction manual contains a description of the SolarMax MT series string inverters.

It furthermore tells you how to install, commission, and operate the inverters.

Familiarise yourself with the inverter functions and characteristics before you begin the

installation work. Carefully read the safety instructions in this instruction manual in particular, ignoring the safety instructions can result in serious injuries or death.

1.1 Target group

This instruction manual is written for the operator of the PV plant and the responsible

qualied electrician.

1.2 Where to keep this manual

The plant operator must ensure that this instruction manual is available to those responsible for the plant at all times. If this original document is lost, an up-to-date version of

this instruction manual can be downloaded from our website at all times (www.solarmax.

com).

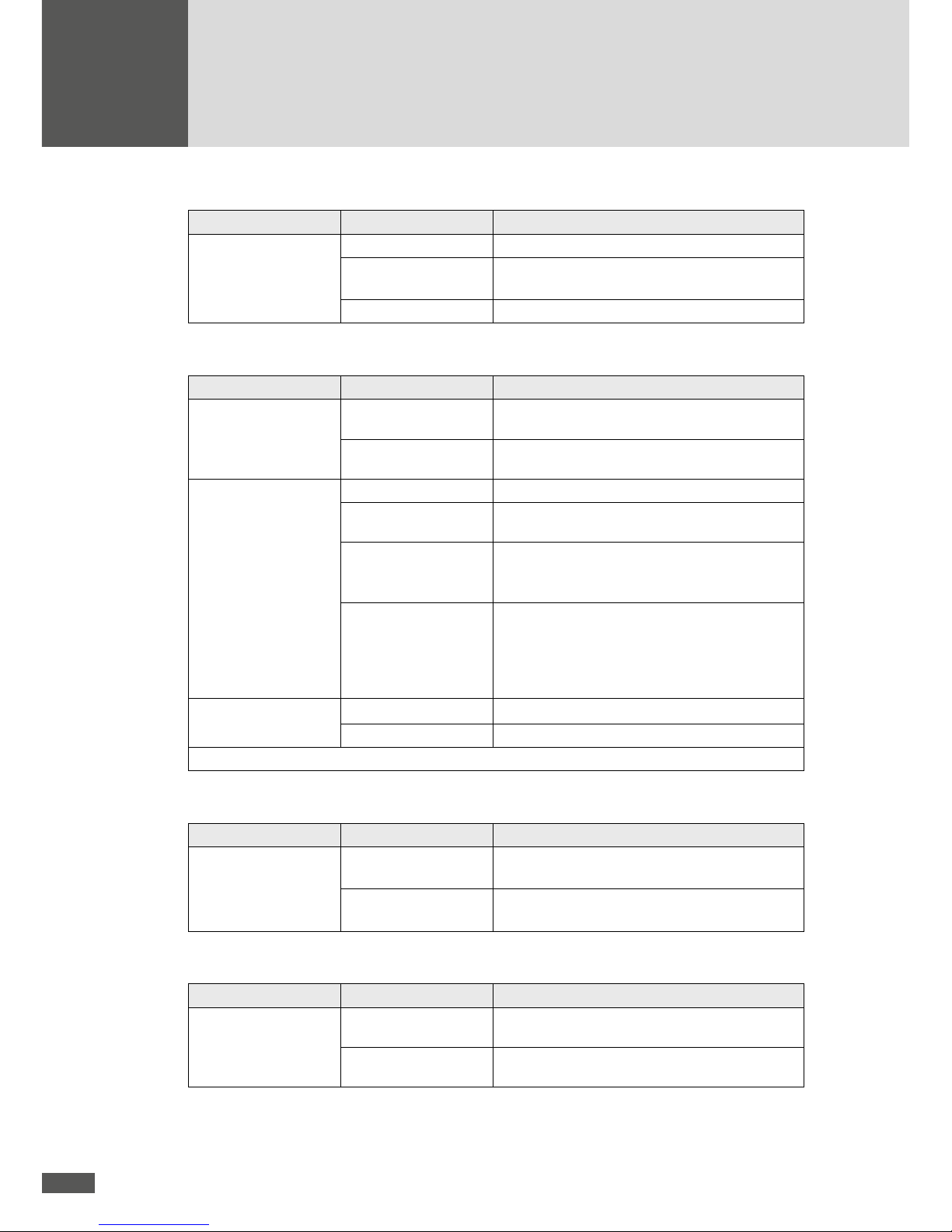

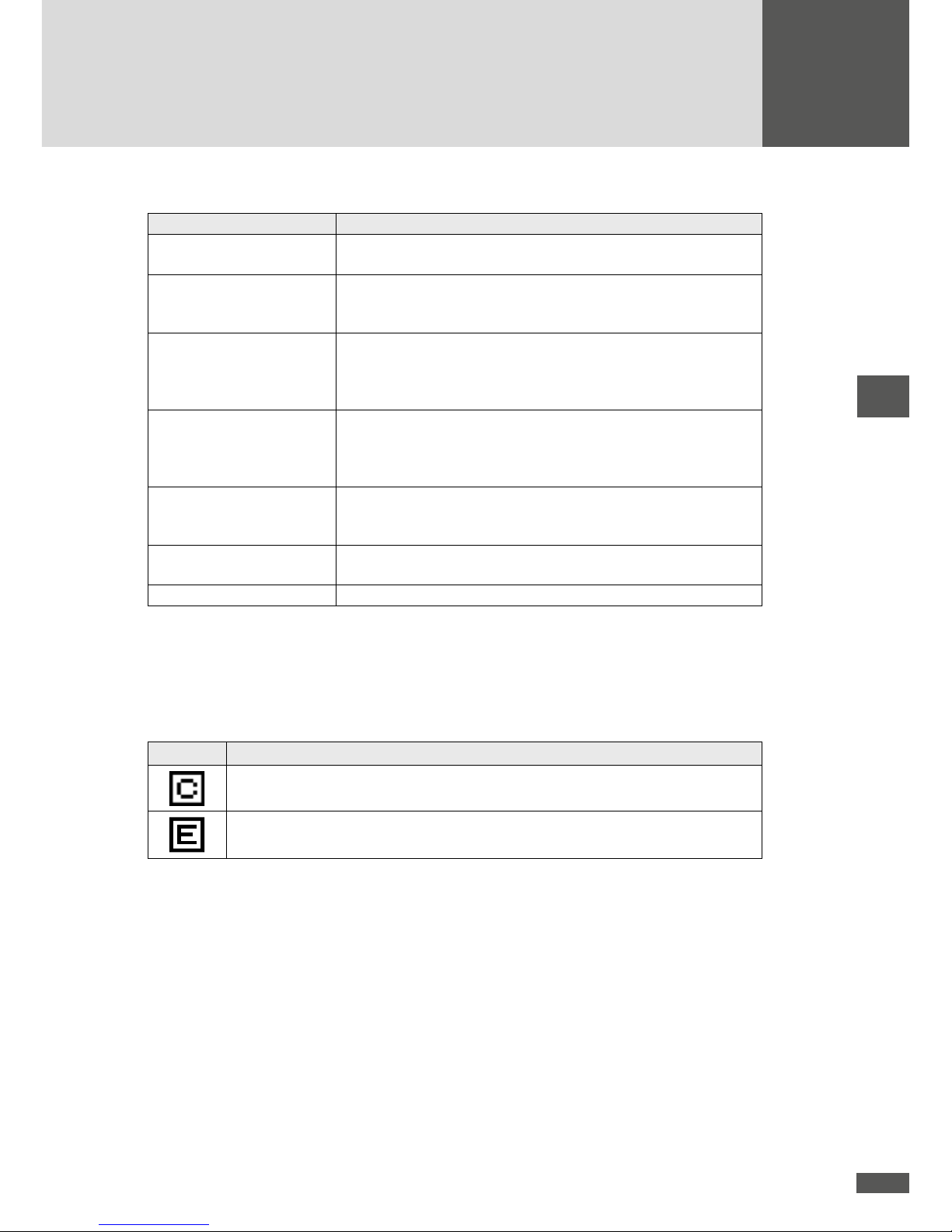

1.3 Symbols used

Symbol Description

DANGER

This symbol indicates that ignoring this instruction may directly lead to serious

injury or death.

CAUTION

This symbol indicates that ignoring this instruction may lead to damage to your

inverter or your PV plant.

NOTE

This symbol indicates information which is especially important for operating the

inverter.

7

en

2 Safety instructions

The MT series solar inverters have been designed and tested according to the latest technological advances and the currently valid product safety standards. However, ignoring

the safety instructions contained in this instruction manual may endanger the user, a third

party, or property. The qualied electrician and the operator of the PV plant can minimise

these risks by following the safety instructions at all times.

DANGER

Only qualied electricians who have already completely read and understood this

instruction manual in advance may install SolarMax inverters.

The photovoltaic generator supplies direct current to the inverter when the PV

modules are exposed to sunlight.

The inverters must remain closed at all times during operation.

The responsible electrician shall be responsible for complying with the applicable

local installation and safety regulations.

Ignoring the installation and safety instructions shall forfeit any and all warranty

and liability claims.

2.1 Appropriate use

The SolarMax MT series string inverters are designed exclusively to convert the direct

current generated by PV modules into grid-compliant alternating current.

The inverters may only be used in combination with PV modules which comply with the

IEC 61730 standard. Any other use, in particular the conversion of direct current from

batteries or other storage elements into alternating current is not permissible.

Any other use is contrary to the purpose for which the inverters were designed. SolarMax

Produktions GmbH accepts no liability for damages resulting from using inverters for purposes other than this. Any modications to the inverter performed by the plant operator

or the tter without any review or approval by SolarMax Produktions GmbH are prohibited.

8

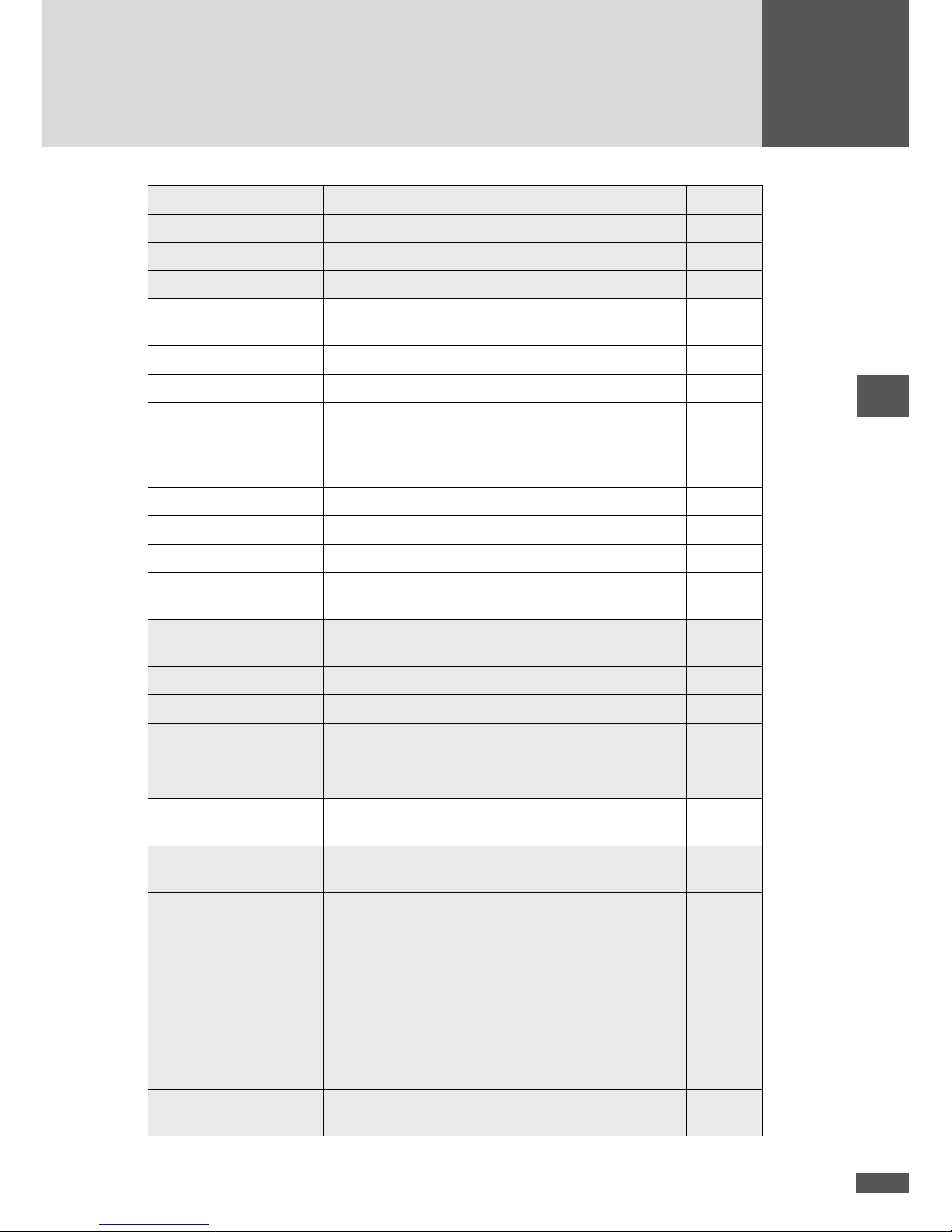

2.2 Symbols on the inverter

Symbol Description

Protective conductor connection

DC disconnector Q1 position OFF - In this position the DC disconnector Q1 is off (open)

DC disconnector Q1 position ON - In this position the DC disconnector Q1 is on (closed)

Risk of death through high voltages! Only qualied electricians may

perform work on the inverter.

Careful - hot surfaces!

5 min

Risk of death due to high voltages! De-energize the inverter. Proceed to wait for 5 minutes before opening the inverter.

Only qualied electricians may perform work on the inverter.

Read the operating instructions - Please read and follow the instructions supplied with the inverter. Do not remove any symbols on the

inverter. Replace damaged symbols.

CE marking - The inverter complies with the requirements of the

European EMC Directive 2004/108/EC and the Low Voltage Directive 2006/95/EC.

C-Tick - compliance with the Australian EMC regulations

Do not dispose of the inverter and its accessory components in the

household waste.

9

en

3 Description

The SolarMax MT series string inverters convert the direct current (DC) of a photovoltaic

generator into grid-compliant alternating current (AC). In this, the current is inverted by

a two-phase, transformerless circuit type. The connection and synchronous feed of the

inverted current into the public power grid are permanently three-phase.

The inverter is operated completely automatically and depends on the power supplied by

the photovoltaic modules. If there is enough power, the inverter starts mains operation

and feeds the existing output into the power grid. If there is not enough power available

from the PV generator, the inverter disconnects from the grid and shuts down.

The two (SolarMax 6MT2 / 8MT2 / 10M T2 / 13MT2 / 15MT 2) and/or three (SolarMa x

13MT3 / 15MT3) independent MPP trackers adapt to a changed energy supply from the PV

generator with the help of two digital signal processors within seconds. The completely

digital current form regulation ensures an outstanding quality of the fed-in current and,

as a result, extremely negligible grid feedback.

During mains operation the integrated grid monitoring permanently checks various

parameters of the AC grid; in this, the set limit values depend on the installation site

selected. An integrated AC/DC sensitive leakage current sensor monitors the stray and

leakage currents at the generator end during operation. If values exceed or fall short of the

set limit values, the inverter disconnects from the grid within a pre-set time. Reconnection

is attempted after a dened period of time.

A graphics display with three buttons permits comfortable operation of the inverter and

reading out all important operating data. The integrated data logger allows for recording

the most important operating parameters of the most recent 31 days, 12 months, and

10 years.

The built-in temperature sensor monitors the temperature inside the casing; the heat is

dissipated to the outside by the cooling ns on the back of the inverter. The heat exchange

with the ambient air is actively supported by two controlled fans producing a horizontal

air ow. If the temperature inside the casing becomes excessive, the inverter gradually

reduces its output power.

10

3.1 Views of the unit

Front view

1

1

Graphics display with status LED and three buttons

Side view left

432 5

2

Fan cover (air intake)

3

Name plate

4

DC disconnector Q1

5

Connection option for external protective conductor

Side view right

6

6

Fan cover (air outlet)

11

en

3.2 Dimensions

545

77

200

[mm]

745

12

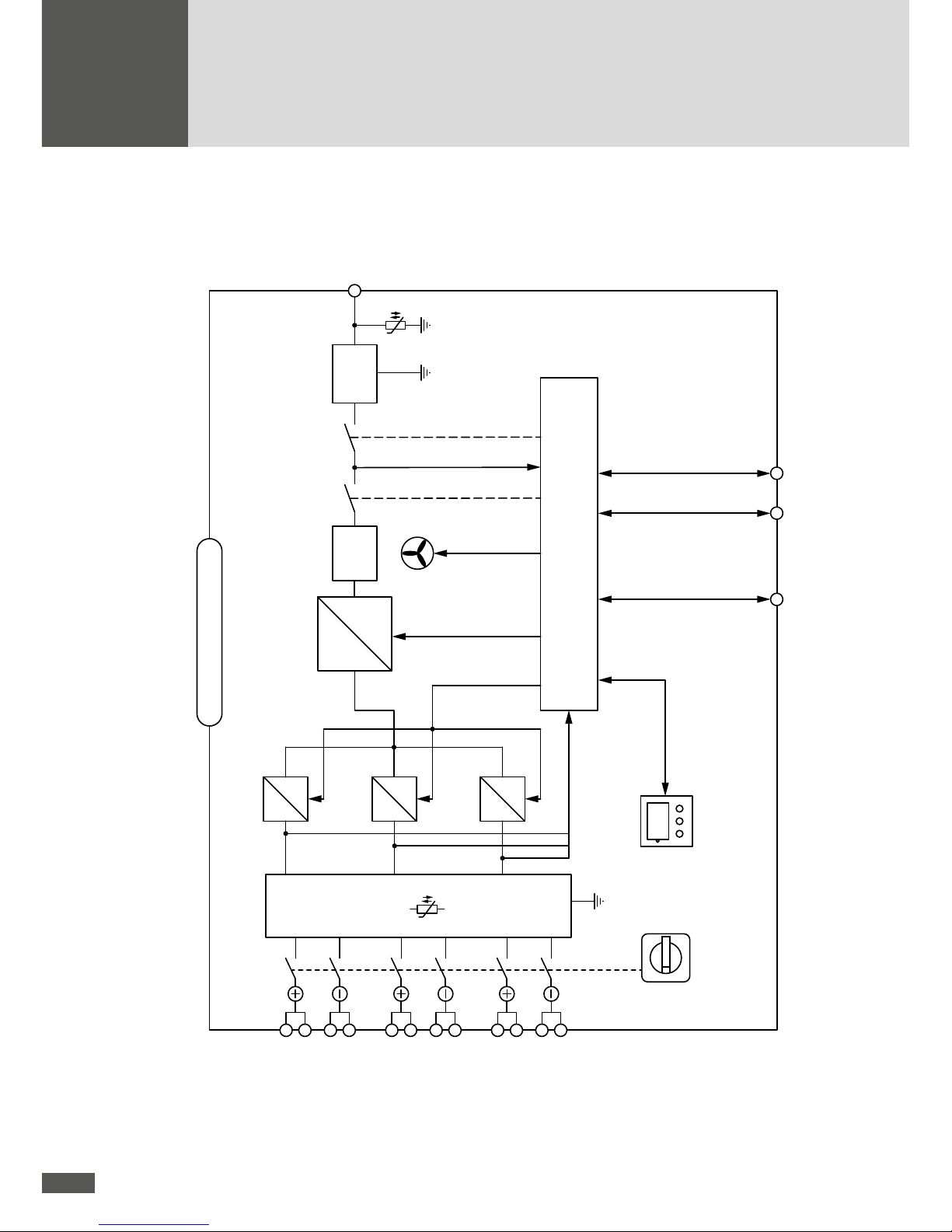

3.3 Block circuit diagram

I

0

U

U

Status signalling contact

Ethernet / RS485

DC measurement

AC measurement

Fan

RS485

Monitoring external input

Inverter control

Booster control

Inverter

LC lter

Booster 2

Booster 1

SolarMax MT seriesDCDC

AC

K2K1

DC

DC

DC

Booster 3

DC

DC

Control unit

Graphics display

* Tracker 3 only SolarMax 13MT3 / 15MT3

DC disconnector Q1

DC input

Tracker 1

DC input

Tracker 2

DC input

Tracker 3 *

AC output

EMC lter

EMC lter

13

en

4 Installation

4.1 Transport and storage

During transport, attention must be paid to the following aspects:

During transport and any interim storage period, you must ensure that the local

ambient conditions (temperature and humidity) are always within the limit values

specied in the technical data. Any longer term, unattended, and unprotected interim

storage of the inverter in the open must be avoided.

Since this is a two-section package, you must absolutely ensure that the top and the

bottom of the package are glued together when the inverter is returned or

forwarded.

4.2 Siting

Choosing a suitable location for the inverter is decisive for its operating safety as well as

its expected service life and efciency.

When you select an installation site for the inverter please follow these instructions:

DANGER

The inverter and all feed lines must be installed out of reach of children or pets

(especially rodents).

Install the inverter in an environment that is free of ammable gases and uids.

Never install the inverter near combustible materials. The installation base must

be non-combustible.

The installation substrate must have sufcient structural strength.

CAUTION

The casing of the SolarMax MT series inverter complies with protection class

IP65. Thus, it can be installed outdoors, but the stated IP protection is only

ensured if the included AC connector, an appropriate DC connector (MultiContact

series 4) and the recommended RJ45 communications connectors are used.

When installing outdoors do not expose the inverter to direct sunlight.

14

CAUTION

The inverter must be installed in a location protected from rain and snow.

When installing several inverters next to each other, you must observe a distance

of 0.5 metres between the inverters. This distance prevents the mutual thermal

inuence due to the hot exhaust air of the ventilation systems.

The ventilation inlet and the ventilation outlet must never be covered. Free air

circulation is absolutely necessary to permit the inverter to function properly.

The installation location must meet the requirements related to electromagnetic

emissions (EN 61000-6-4).

NOTE

For easy installation of the DC and AC supply lines you should design a freely

accessible area of approx. 0.5 metres in height below the inverter.

An excessive amount of dust as well as salt and ammonia vapors in the inverter’s

ambient air must be avoided. Unsuitable installation locations increase the risk of

corrosion and reduce the service life of the inverter.

Make sure there is sufcient ventilation if the inverter is installed inside a building

or plant room. Maximum useful life requires that the ambient temperature is never

higher than 30°C.

Due to possible noise emissions, we do not recommend installation in or near

residential rooms or workplaces.

The ambient air should be dust-free to avoid excessive dirt on the heat sink and

fans. Rooms with heavy concentrations of dust (e.g. in cabinetmaking or metal

workshops, hay storage buildings) are not suitable installation locations.

4.3 Lightning protection

The requirements for appropriate lightning protection for a PV plant depend on many different factors (plant size, how the cables are run, the modules used, the surroundings,

etc). A project-specic protection concept must be developed by a qualied person.

15

en

4.4 Scope of delivery

Inverter

AC connector

Installation plate for wall installation

Instruction manual and quick guide

Accessory kit (installation material for wall installation and earth connection)

4.5 Installation

The inverter can be installed easily using the included installation plate and installation

material on a level installation base. You will nd more information about how to properly

install the inverter in the quick guide included in the delivery.

1. Drill four holes, Ø 8mm in diameter and with a depth of 60mm (drill hole pattern

shown in the gure “Installation plate”; page 16).

2. Insert the dowels.

3. Attach the installation plate using the four 6 x 50 screws and washers.

4. Mount the inverter carefully from above into the holder.

NOTE

As soon as the inverter is completely mounted, you can secure it additionally with the

included splint or a padlock (not included in the delivery).

16

Installation plate

235

[mm]

100

10

7

2

1

1

For the other measurements see Section 3.2.

1

Holes for padlock (against theft)

2

Recesses for lock with splint

4.6 Electrical connection

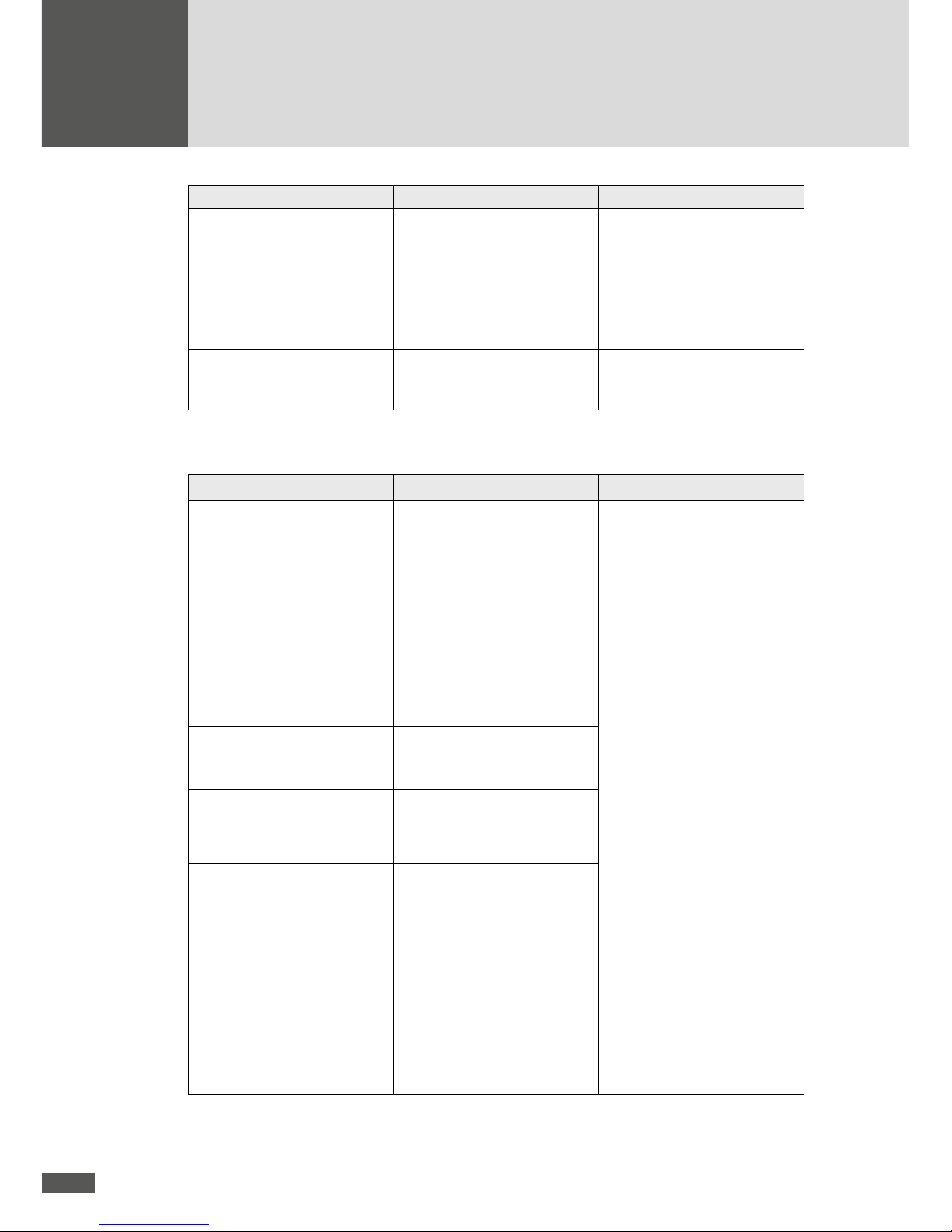

The MT series inverters have the following connection options:

1 2 3 44 5 6 7

17

en

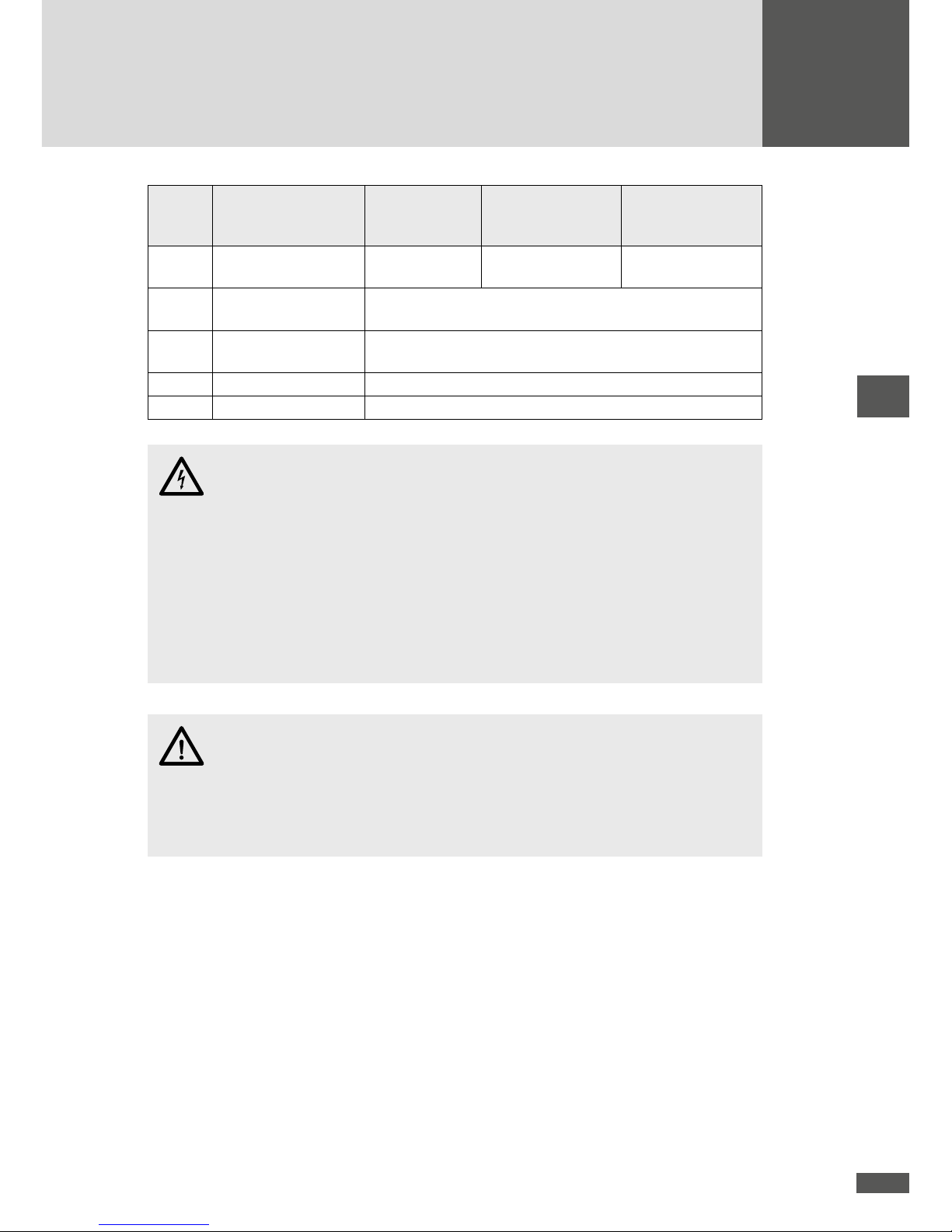

No. Connection

SM8MT2 /

SM6MT2

SM10MT2 /

SM13MT2 /

SM15MT2

SM13MT3 /

SM15MT3

1 - 3 DC

1 x 2 / 1 x 1

strings MC4

2 x 2 strings MC4 3 x 2 strings MC4

4

External protective

conductor

2 x thread M6

5

Status signalling

contact

M12 plug with potential-free switch contact

6 AC 5-pole Amphenol plug-in connector

7 Communication 2 x RJ45 (sealed tight by protective caps)

DANGER

Before you start the installation work, make sure that all the provided DC and AC

feed lines to the inverter are de-energised. The installation work must be performed by a qualied electrician who adheres to the recognised rules of electrical

installations and personal health and safety regulations.

All the feed lines to the inverter must be appropriate for the expected voltages,

currents, and ambient conditions (temperature, UV load, etc.).

Make sure that all lines are laid tension-free.

CAUTION

The inverter must be installed in a suitable location (see Section 4.2).

Make sure that all the lines into the inverter are laid so as to avoid earth leakage

or short circuits.

4.6.1 Integrated overvoltage protection

The MT series inverters have integrated surge arresters (varistors) on both the DC and

AC ends.

On the DC end, each MPP tracker has a surge arrester from the plus and minus pole

to the earth. The surge arresters comply with requirement class C as dened in VDE

0675-6 or type 2 as dened in EN 61643-11.

On the AC end, each grid phase (L1/L2/L3) has a surge arrester to the earth. The

surge arresters comply with requirement class D as dened in VDE 0675-6 or type 3

as dened in EN 61643-11.

18

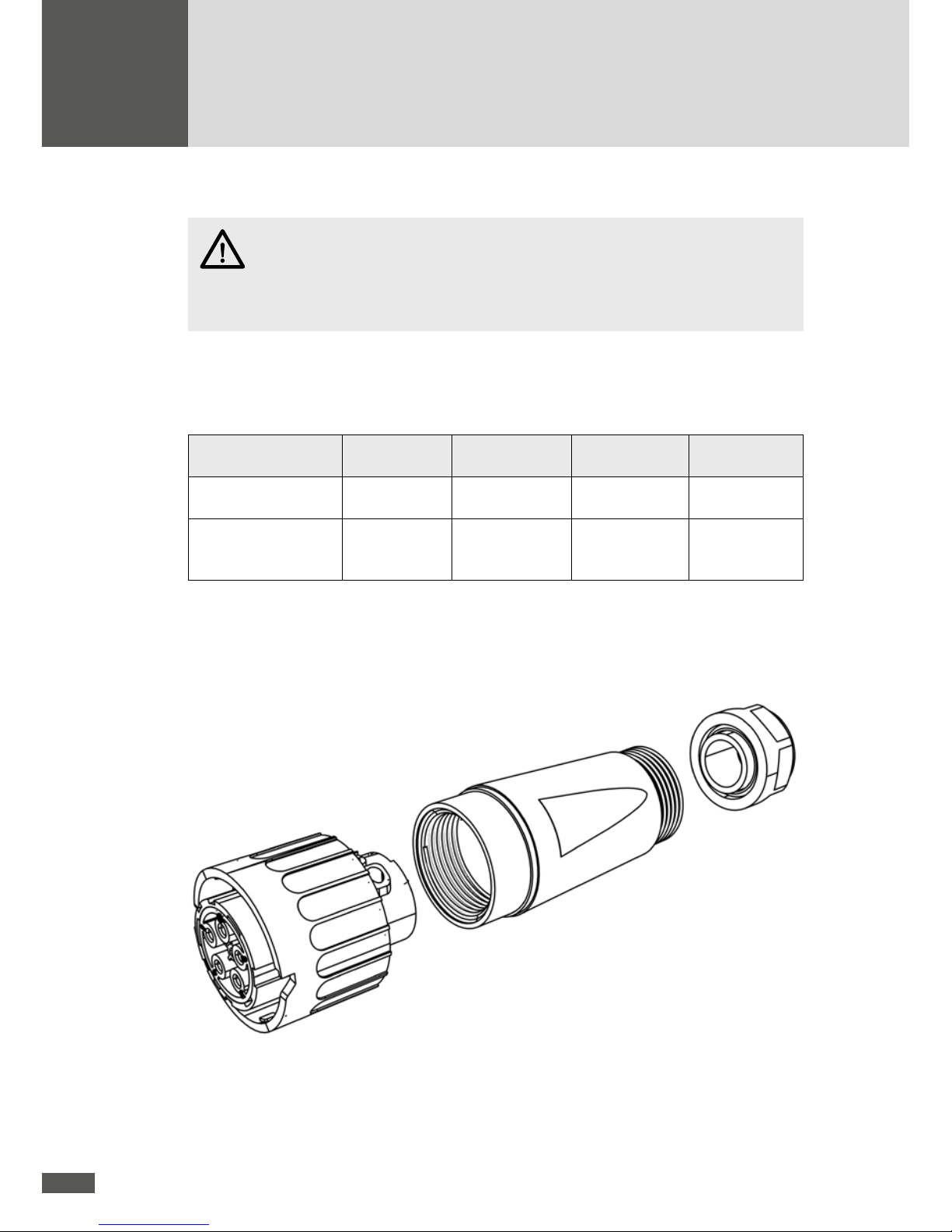

4.6.2 AC connection

CAUTION

The MT series inverters must be connected to a mains connection point meeting

at least the requirements of overvoltage category 3.

Mains fuses and cable cross-sections

The following table contains information about the recommended mains fuses and the

minimum required line cross-sections necessary for the AC feed line:

SM8MT2 /

SM6MT2 SM10MT2

SM13MT2/

SM13MT3

SM15MT2/

SM15MT3

Mains fuses

(C characteristic)

16 A 20 A 25 A 25 A

Minimum line

cross-section AC and

protective conductor

2.5 mm

2

4 mm

2

4 mm

2

4 mm

2

Confectioning the AC connector

The AC feed line is connected to the inverter using the included Amphenol AC connector:

Casing

Retainer ring

Contact base

19

en

The AC connector must be connected using a exible cable as described in

EN 60309-2/VDE 0623.

The permissible cable diameter is 11 to 20mm.

Cable strands with a maximum cross-section of 6mm² can be connected.

Procedure

1. If the cable diameter is > 16mm, remove the blue inlay from the retainer ring.

2. Slide the retainer ring and the casing over the cable.

3. Press the appropriate ferrules on the stripped strands.

4. Connect the individual cores one after another to the contact base:

– Phase L1 to the screw terminal with the number 1

– Phase L2 to the screw terminal with the number 2

– Phase L3 to the screw terminal with the number 3

– Neutral conductor N to the screw terminal with the number 4

– Protective conductor PE to the screw terminal with the earth symbol

– Tightening torque: 0.7 Nm

5. Check that each individual core is securely connected.

6. Screw the casing onto the contact base.

– Tightening torque: 1-2 Nm

7. Screw the retainer ring onto the casing.

– Tightening torque: 5 Nm

The AC feed line can now be connected with a twisting movement to the AC connection

of the inverter (bayonet connector with locking pin). As soon as the correct position is

reached, the connector slips onto the AC connection. The inverter is now rmly connected

to the AC grid.

DANGER

Connect the protective conductor as carefully as possible.

CAUTION

As soon as the bayonet connector has slipped in, the AC connection can only be

re-opened using a tool (slotted screwdriver size 2).

Open the AC connection carefully by pressing down the locking pin on the contact

insulator and turning the AC connector counter-clockwise to break the

connection.

20

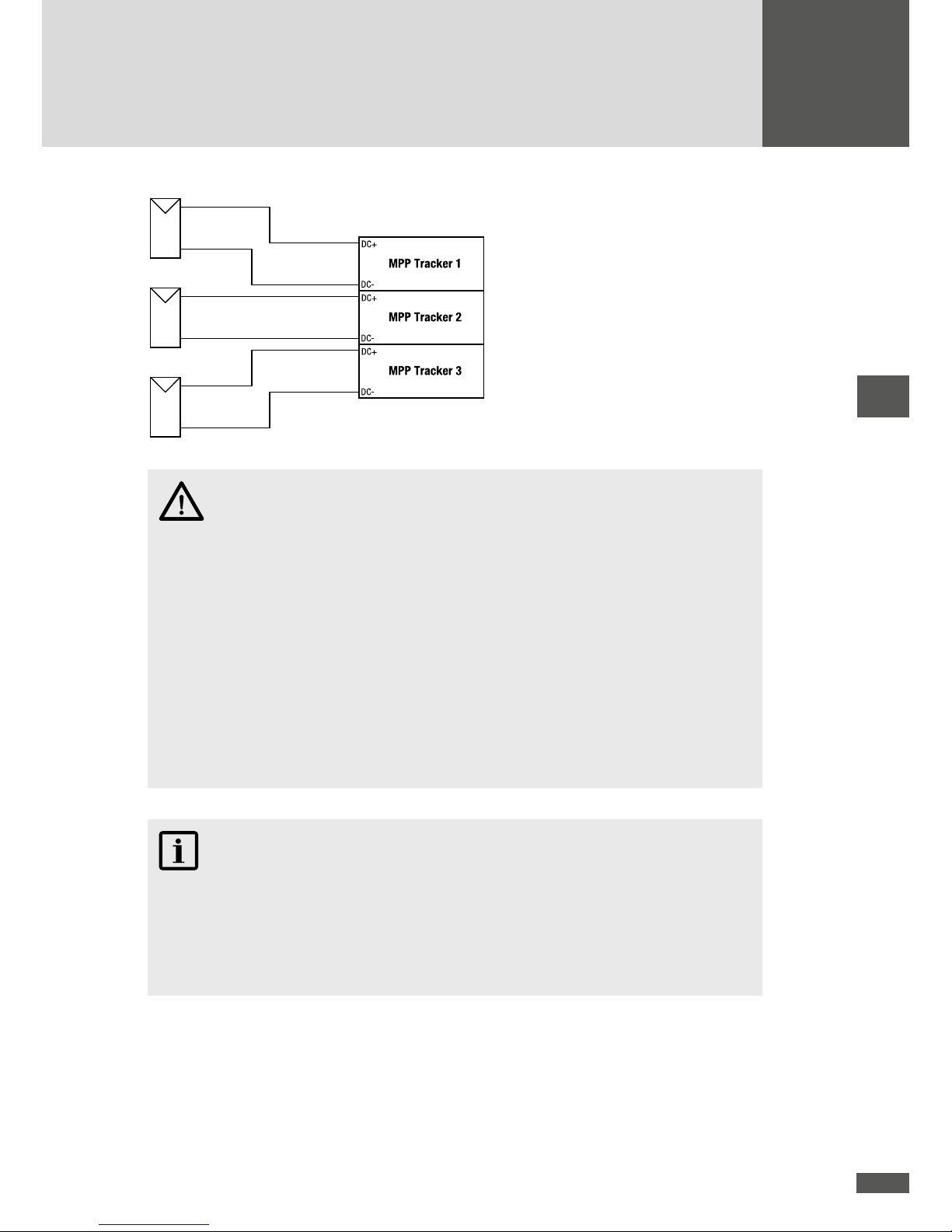

4.6.3 DC connection

The inverters are quipped with 2 (SolarMax 6MT2 / 8MT2 /10MT2 / 13MT2 / 15MT2)

resp. 3 (SolarMax 13MT3 / 15MT3) MPP trackers. Each tracker has two plus and minus

poles for the connection of two strings per tracker input. A string can be connected at

tracker 2 of each of the inverters SM6MT2 and SM8MT2.

Detailed view of DC connections

1

2

1

Plus connections

2

Minus connections

The position of the plus and minus connections is identical for all DC inputs (1 to 3).

Trackers 1 to 3 operate independently of each other, thus enabling simultaneous connection of strings with different characteristics (orientation, dimensioning, module type)

to a shared inverter. The plus and minus connections of different trackers must not be

connected to each other:

MPP Tracker 2

MPP Tracker 1

MPP Tracker 3

DC+

DCDC+

DCDC+

DC-

Wrong connection!

The plus and minus feed lines for trackers 1 to 3 must be run to the inverter separately

from each other:

21

en

Correct connection!

CAUTION

Only use MC4 connectors by MultiContact or connectors compatible with these

for the connection of the DC supply lines.

Due to the transformerless circuit type of the MT series inverters, the plus or

minus pole of the PV generator must not be earthed under any circumstances.

Otherwise, the isolation monitoring in the inverter prevents a mains connection.

Select cable cross-sections for the DC feed lines corresponding to your plant con-

guration and in conformance with the valid local installation regulations.

Remember that the shared plus and minus pole of a string must always be con-

nected to the same tracker.

The position of the DC disconnector Q1 must be “O” (Off).

NOTE

If required, it is possible to oversize the PV generator output with respect to the inverter

output. The oversize factor should not exceed 1.5. For example, for the SM15MT3 a

PV generator output of 22.5 kW is possible. Please contact us if you are intending to

oversize your PV generator output by a larger factor.

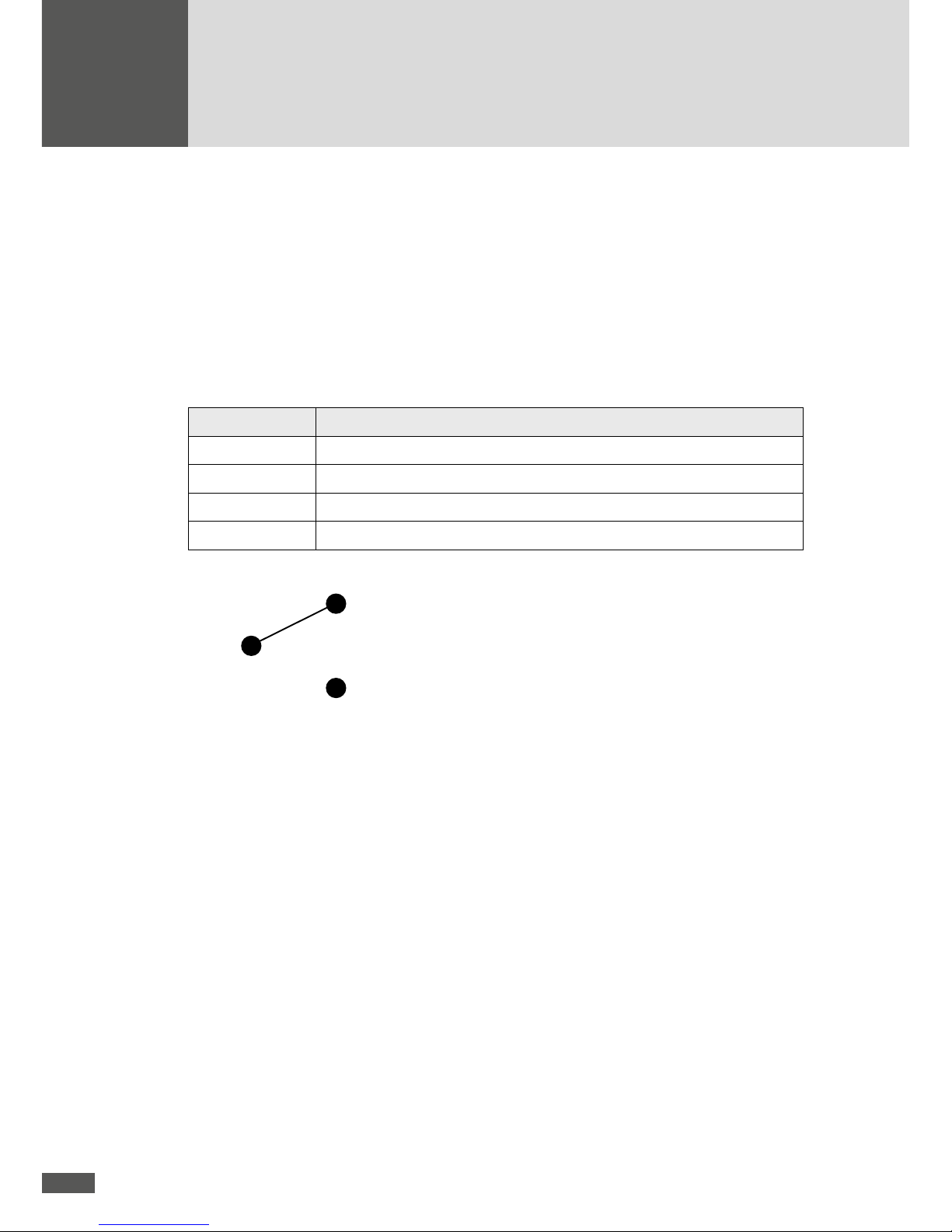

4.6.4 Status signalling contact

The status signalling contact enables remote retrieval of the operating status of the

inverter. The status signalling contact is located in the connection area of the inverter, see

22

Section 4.6. A suitable M12 mating connector to connect to the status signalling contact

can be ordered from the SolarMax Service Centre.

Remote retrieval of the operating status can be congured, see Section 6.8.2.

Connecting conditions

V

Max

250VAC / 30VDC

I

Max

1.5 A

Pinout

Contact Description

1 NO (normally open: open when idle)

2 COM

3 NC (normally closed: closed when idle)

4 Not used

Contact diagram (idle)

COM

NC

NO

4.6.5 Monitoring external input

This interface can be used to connect the inverter to an external grid monitoring system

which will disconnect the inverter from the mains grid from a remote location when this

is needed.

If the “Monitoring external input” function is activated, the grid relays of the inverter can

be used as interconnection circuit breakers of the central G/P protection. The function

is activated during initial start-up (see Section 5.2) or subsequently using the service

software MaxTalk 2 Pro. Remote retrieval of the operating status, as described in Section

4.6.4, is no longer possible when monitoring of the external input is activated.

Functionality

The contacts 1 and 4 of the status signalling contact are used to monitor the external

input. When there is phase voltage between contact1 and contact4, the grid relays K1

and K2 are closed (see Section 3.3). If phase voltage is not present between contacts 1

and 4, the grid relays are open and the inverter disconnects from the grid.

23

en

Contact 1 / contact 4 Grid relays K1 and K2

Phase voltage (L1, L2, or L3) present closed

no phase voltage present open

Connecting conditions

See Section „4.6.4 Status signalling contact“

Pinout

Contact Description

1 Phase (L1, L2 or L3)

2 Not used

3 Not used

4 Neutral conductor N

4.6.6 Communications sockets

The SolarMax MT series inverters have two RJ45 sockets for data communication within

a MaxComm network:

The left-hand RJ45 socket is only an RS485 interface. The RS485 interface is used

for connections to other SolarMax inverters or accessories with MaxComm

interface.

The right-hand RJ45 socket can be used both as an RS485 and as an Ethernet inter-

face; the desired function can be toggled in the “Settings” menu. The Ethernet interface is used for connecting an inverter directly to a PC or to MaxWeb xp. However, if

both sockets are congured as RS485 interfaces, a network containing several

RS485 nodes can be set up.

NOTE

If the RJ45 sockets are used and the inverter is exposed to the weather, please use

products from the VARIOSUB-RJ45 range with IP67 protection class from Phoenix

Contact. This ensures that the installation meets the requirements of IP65.

RJ45 plug-in connector, 8-pin (item no. 1658493)

Available from www.phoenixcontact.com.

24

4.6.7 External protective conductor

The inverter’s stray current to earth can reach values of more than 3.5mA (AC) or 10mA

(DC) during operation. In accordance with IEC/EN 62109-1, a second protective conductor

must therefore be connected. This can be connected to one of the two M6 threaded connections (see Section 4.6).

Connecting conditions

Minimum conductor cross-section: 10 mm²

M6 screw tightening torque: 10.0 Nm

4.6.8 External residual-current device (RCD)

The SolarMax MT series inverters have an integrated AC/DC sensitive fault current

sensor. This sensor is able to distinguish between the operational capacitive stray currents (caused by capacities of the PV modules to the earth) and fault currents (caused by

touching a pole of the PV generator). The inverter disconnects immediately from the grid

as soon as an exceedance of the absolute limit value (300 mA, important in relation to re

protection) or a sudden increase in the DC-end fault current (30 mA, important to protect

against personal injury) has been detected.

If an additional external residual current device (RCD) is wanted, an RCD of type A should

be chosen. The residual current rating of the RCD depends on the number of inverters in

the PV power plant. For each inverter, a residual current rating of at least 100 mA should

be allowed for. For example, in a PV power plant with three inverters an RCD with a

residual current rating of at least 300 mA should be used.

4.6.9 External output control

The MaxWebxp data logger and its MaxRemote extension can be used to set the set

values for active and reactive power (e.g. for remote controlled output limitation). The

MaxWeb xp is connected via the Ethernet or via the inverter’s RS485 interfaces (see Section 4.6.6), i.e. via a MaxComm network.

You can download the installation instructions for the MaxWebxp and MaxRemote accessory components from our website: www.solarmax.com/en/downloads/

data-communication/maxweb-xp.

25

en

5 Commissioning

5.1 Switching on and off

All SolarMax inverters work completely automatically. When the PV generator supplies

enough power, the inverter switches on and then starts mains feed operation. At night,

or when the DC end is shut down, the inverter is disconnected from the grid. Operating

the inverter and the ability to communicate via the interfaces are only possible when the

inverter is switched on.

5.1.1 Switching on

1. Switch on the DC disconnector Q1

– The inverter switches on; after a couple of seconds, the graphics display is acti-

vated (assuming there is enough power coming from the PV generator)

2. Switch on the external AC disconnector

– The inverter switches to mains feed operation after roughly 30 seconds

5.1.2 Switching off

DANGER

The DC-end MC connectors may only be disconnected from the inverter if the DC

disconnector (Q1) is open. If the disconnector is not open, disconnecting the DC feed

lines during operation can result in dangerous arcs.

1. Switch off external AC disconnector (optional)

– The inverter is disconnected from the grid

2. Switch off the DC disconnector Q1

– The inverter shuts off after a few seconds

26

5.2 Initial start-up

When the inverter is started up for the rst time, initial setup starts automatically. This

procedure must only be carried out once during initial start-up. You can nd information

on the operation of the graphics display in Section 6.

5.2 .1 Requirements

Correctly connected DC supplies (AC connection is not required)

Sufcient solar irradiation

NOTE

Entering the country incorrectly may lead to problems regarding inverter operation

and to the withdrawal of the operating license by the respective grid operator.

You can restart initial start-up on the graphics display by pressing at any

time.

Thoroughly read the manual before starting initial start-up. Contact your grid ope-

rator or the SolarMax Service Centre if you have any doubt regarding the settings

you must select.

5.2.2 Procedure

1. Switch on the inverter as described in section 5.1.1. The “Initial setup” menu will be

displayed:

2. Select the display language from the “Language” menu.

3. If necessary, update the time and the date.

– The inverter saves the date entered as the initial start-up date.

– The “Country” menu will be displayed:

27

en

4. Select the correct country setting.

– Press

to conrm your entry.

– Depending on the country setting selected, additional menus may be displayed

(see Section 5.2.3).

– The “Monit. ext. input” menu is then displayed.

5. If appropriate, activate the function:

Menu Setting Description

Monit. ext. input Inactive

The function “Monitoring external input” is

switched off (default setting).

On

The function “Monitoring external input” is

switched on. The status signaling contact serves

as interface for the remote controlled deactivation

of the inverter via external grid monitoring (see

Section 4.6.5).

– The “Conrmation” menu is then displayed.

6. Check the data in the “Conrmation” menu.

7. To complete initial start-up, press

.

– The main menu will then be displayed (see Section 6.4).

– Should commissioning be taking place in Italy, the auto-test must be carried out

after the initial start-up (see Section 6.10).

5.2.3 Description of country-specic menus

Depending on the country setting, additional menus will be displayed during the initial

set-up.

Country setting “Belgium”

Menu Setting Description

Plant type ≤ 10kVA The maximum plant system rating is 10 kVA.

> 10kVA The plant system rating is higher than 10 kVA.

28

Country setting “Denmark”

Menu Setting Description

Plant type

≤ 13.8 kVA

The maximum plant system rating is 13.8 kVA.

> 13.8 kVA – ≤ 30 kVA

The plant system rating is higher than 13.8 kVA

and/or does not exceed 30 kVA.

> 30 kVA

The plant system rating is higher than 30 kVA.

Country setting “Germany”

Menu Setting Description

Grid connection Medium voltage

The inverter is connected to the mediumvoltage mains.

Low voltage

The inverter is connected to the low-voltage

mains.

Plant type*

< 13.8kVA The plant system rating is lower than 13.8 kVA.

13.8–30kVA The plant system rating is between 13.8 kVA

and 30kVA.

> 30 kVA The plant system rating is higher than 30 kVA.

An external grid monitoring and remote shutdown will be used.

VDE 0126-1-1 Required setting if the inverter is commissioned

within a PV plant connected to the grid before 1

January 2012. Note: The setting “VDE 0126-11” is inadmissible for PV plants connected to the

grid after 31 December 2011.

cosφ(Pac)

Inactive

No reactive power feed-in (cosφ=1)

On

Standardised reactive power feed-in

* the menu is only displayed at the “Low-voltage” grid connection.

Country setting “Great Britain”

Menu Setting Description

Standard G83/2 Inverter settings in accordance with grid con-

nection G83/2.

G59/3 Inverter settings in accordance with grid con-

nection G59/3.

Country setting “Italy”

Menu Setting Description

Grid connection Medium voltage

The inverter is connected to the mediumvoltage mains.

Low voltage

The inverter is connected to the low-voltage

mains.

29

en

Menu Setting Description

Standard*

Guida Connessioni Required setting if the inverter is commissioned

within a PV plant connected to the grid before

1 July 2012.

CEI 0-21 Required setting if the inverter is commissioned

within a PV plant connected to the grid after 30

June 2012.

* the menu is only displayed at the “Low-voltage” grid connection.

Country setting “Spain”

Menu Setting Description

Standard RD 1699

The inverter is connected to the low-voltage

grid.

RD 1699 & PO 12.3 Large PV Systems

The inverter is connected to the low-voltage

grid. The FRT function is activated.

RD 661 & PO 12.3

The inverter is connected to the medium-voltage grid. The FRT function is activated.

5.3 Conguration of the data communication interfaces

In order to use the RS485 and Ethernet communications interfaces, you must enter the

following settings in the “Settings” menu (see Section 6.8):

Device address

If you connect several inverters into one network, you must assign each device its own

address.

NOTE

You can assign addresses between 1 and 249. It is very important to remember to give

a unique address to each individual device in the network!

When connecting to a LAN network, the following settings are required in addition to the

device address:

Ethernet

If you want to operate the right RJ45 communications socket on the terminal block as an

Ethernet interface, enter “on” at this point.

IP

If you want to access your inverter from a local area network (LAN), enter an unassigned

IP address from your LAN here.

30

Netmask

Please enter the pertinent subnet mask for your IP address here.

TCP Port

Enter the desired TCP port for communications with the inverter. Remember that the TCP

port must be greater than 1023 since this range is reserved for predened applications

(referred to as “well known services”).

NOTE

You will nd more details about data communication in the technical

information “MaxComm network”. This document can be downloaded from our website at: www.solarmax.com/en/downloads/data-communication/maxcomm/.

31

en

6 Operation

6.1 Graphics display

The graphics display on the front of the inverter shows the inverter’s system variables,

status information, and failure messages. The display allows you to learn the current

device status, access the integrated data logger, and enter various settings for the

inverter. Navigate the various menus using the three buttons under the display.

The display is backlighted to improve readability when lighting is poor. Activate the backlight by pressing any of the buttons. The backlight remains active for 180 seconds after

the buttons were last used.

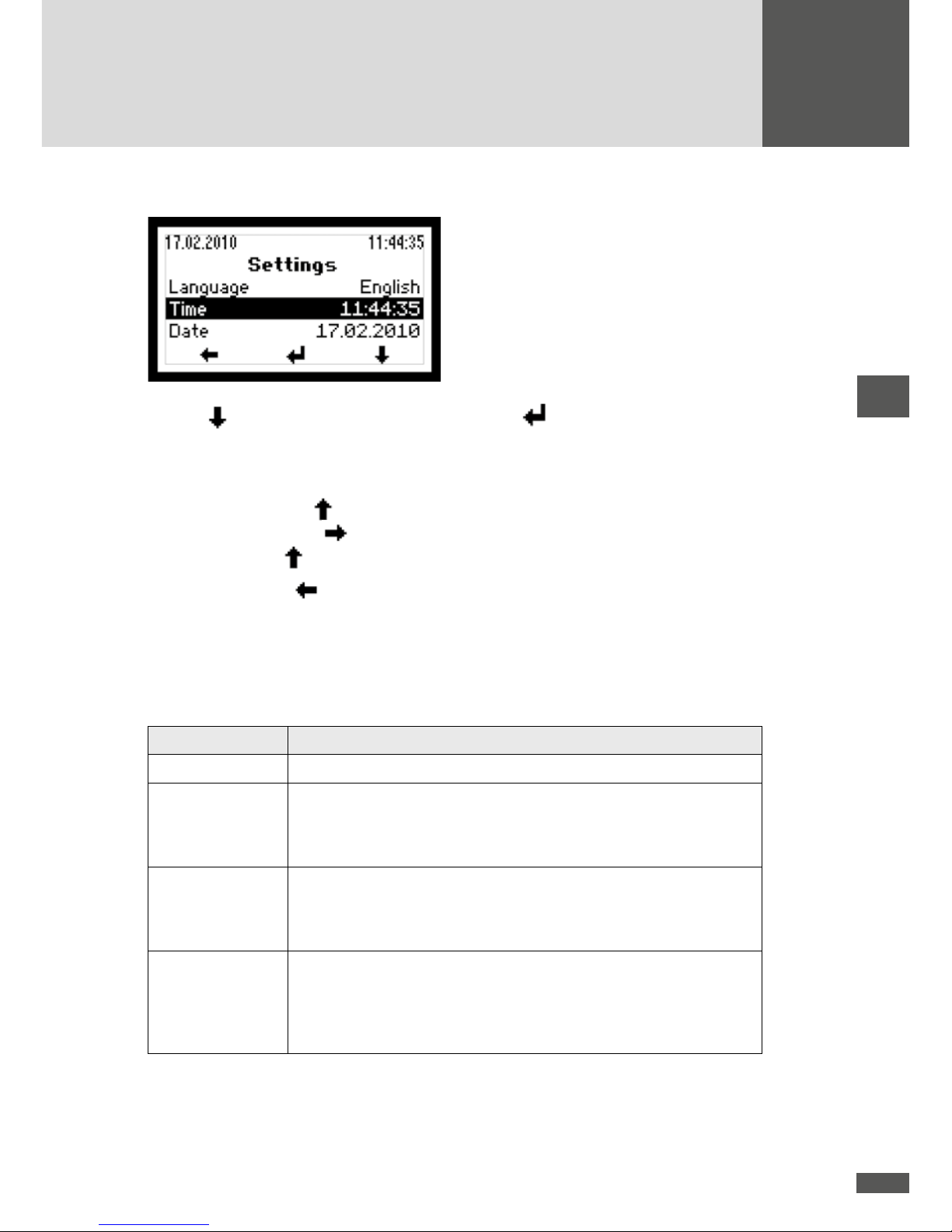

Menu button symbols

With the help of the symbols shown here you can navigate the various menus and functions visible in the display. The current button function may change from one menu to

the next and corresponds to the symbol appearing directly over the button in each case:

Symbol Function

Scroll up, increase number, or next element

Scroll down, or previous element

Back to higher level menu

Select next number

Display selected sub-menu or conrm changes

Launch edit mode for selection

Abort

32

6.2 Menu structure

* only for country setting “Italy”.

33

en

6.3 Overview

If none of the three buttons is pushed for 120 seconds, the display returns automatically

to the Overview menu showing the three most important values as well as the current

operating status.

6.4 Main menu

The Main menu provides access to other menu levels. Use the arrow keys and to

select the desired menu. Click

to conrm your selection.

6.5 Measured values

The current inverter measured values can be accessed in the “Measured values” menu.

Use the arrow buttons and to navigate the measured values.

Press the left button

to return to the Main menu.

34

NOTE

The inverter measured values are not suitable for billing purposes or calculating efciency. The measuring error may amount to up to ±5% depending on the measured

value. Only the measured values of a calibrated electricity meter are decisive for billing

purposes.

The following measured values can be accessed:

Measured value Description

Vdc1 / Vdc2 / Vdc3

DC input voltages trackers 1, 2, and 3

Idc1 / Idc2 / Idc3

DC input currents trackers 1, 2, and 3

Pdc Input power

Pdc1 / Pdc2 / Pdc3

Input power trackers 1, 2, and 3

VacL1 / VacL2 /VacL3 Mains voltage phases L1, L2, and L3 (voltage to neutral)

IacL1 / IacL2 / IacL3 AC feed-in current phases L1, L2, and L3

Pac Active output power

Q Reactive power (+: overexcited / −: underexcited)

S Apparent output power

cosφ

Power factor (OEX: overexcited / UEX: underexcited)

Frequency Mains frequency

Temperatur e Temperature of the heat sinks

Fan Operating conditions of the fans (on/off)

35

en

6.6 Statistics

In the Statistics menu you can access the inverter’s internal data logger. The accessible

statistics are for the most recent 31 days, 12 months or 10 years. The “Total” sub-menu

contains the accumulated yield and operating data since initial start-up of the inverter.

Use the button to highlight a statistic category. Select a category by pressing the

button.

Press the left button

to return to the Main menu.

6.6.1 Daily statistics

This menu provides access to the data from the most recent 31 days.

Use the buttons and to select a daily statistic. Press the left button to return

to the Statistics menu.

36

6.6.2 Monthly statistics

This menu provides access to the data from the most recent 12 months.

Use the and buttons to select a monthly statistic. Press the left button to

return to the Statistics menu.

6.6.3 Yearly statistics

This menu provides access to the data from the most recent 10 years.

Use the and buttons to select a yearly statistic. Press the left button to return

to the Statistics menu.

6.6.4 Total

This menu lists the total yield and the total number of operating hours of the inverter since

initial start-up.

Press the left button to return to the Statistics menu.

37

en

6.6.5 Reset

In this menu you can delete all the entries in the Statistics menu.

NOTE

Once deleted this data is irretrievably lost!

Press the button to conrm the deletion of all the statistics entries. Use the

button to enter the Statistics menu without deleting the statistics entries.

6.7 Conguration

All available operating parameters and advanced functions of the inverter are listed in

the “Conguration” menu. The settings displayed for the limit values and the functions

depend on the country selected during initial start-up.

NOTE

MaxTalk 2 Pro, the extension to the standard MaxTalk 2 software, allows authorised

skilled workers to individually adjust the operating parameters. The required “MT

series parameter conguration using MaxTalk 2 Pro” instruction manual can be found

on our website www.solarmax.com (Downloads area). You can request MaxTalk 2 Pro

from the SolarMax Service Centre. The contact details can be found overleaf.

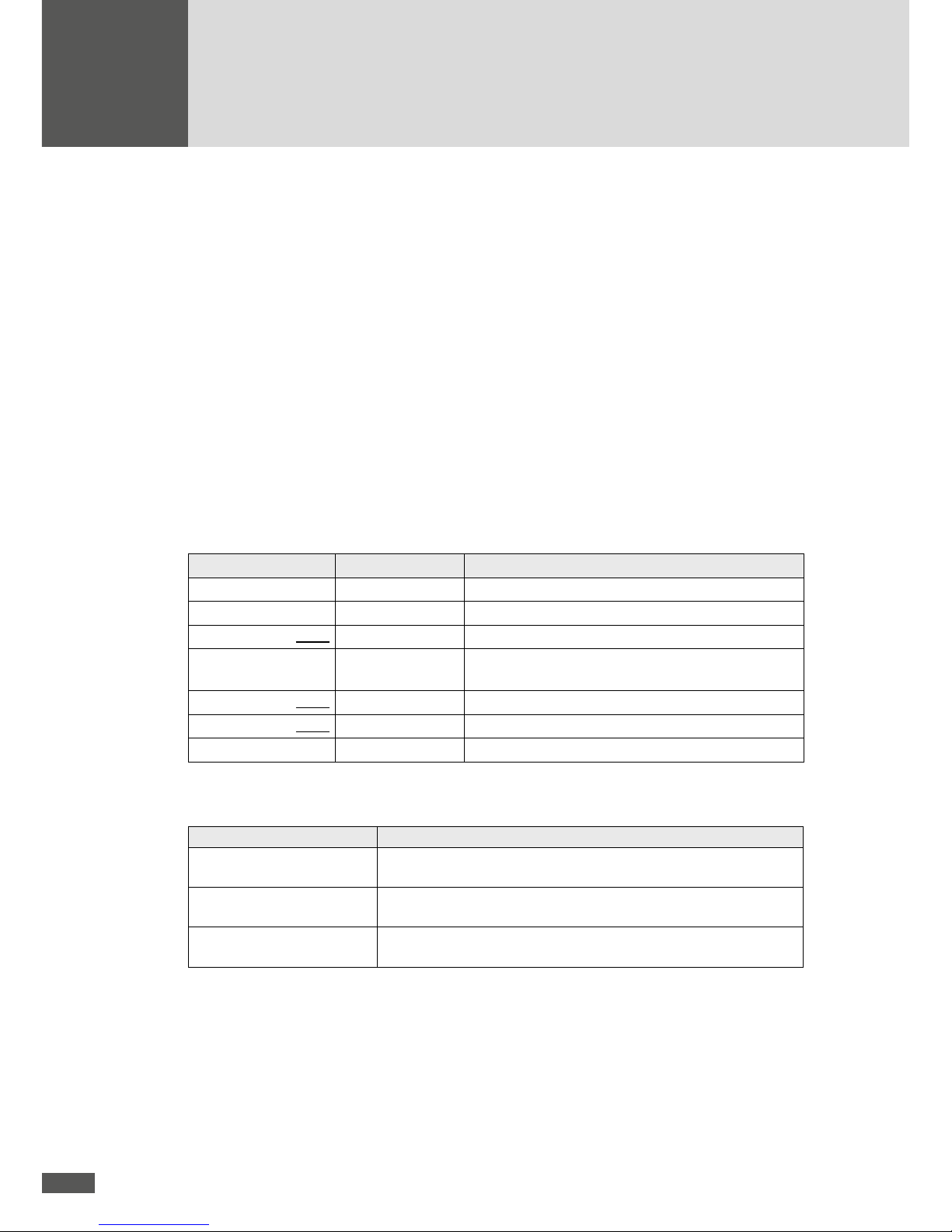

Function / Parameter Description Unit

Country Country setting selected during initial start-up -

Plant type Plant type selected during initial start-up -

Standard Grid connection selected during initial start-up

Vac min 1 Minimum admissible mains voltage (rst limit) V

t Vac min 1 Release time for minimum admissible mains voltage ms

Vac max 1 Maximum admissible mains voltage (rst limit) V

38

Function / Parameter Description Unit

t Vac max 1 Release time for maximum admissible mains voltage ms

Vac min 2 Minimum admissible mains voltage (second limit) V

t Vac min 2 Release time for minimum admissible mains voltage ms

Vac max 2 Maximum admissible mains voltage (second limit) V

t Vac max 2 Release time for maximum admissible mains voltage ms

Vac 10 min max Maximum admissible average value of the mains volt-

age over the last 10 minutes

V

Iac mean max Maximum permissible DC component in the mains

current

A

f min 1 Minimum admissible mains frequency (rst limit) Hz

t f min 1 Release time for minimum admissible mains frequency ms

f max 1 Maximum admissible mains frequency (rst limit) Hz

t f max 1 Release time for maximum admissible mains frequency ms

f min 2 Minimum admissible mains frequency (second limit) Hz

t f min 2 Release time for minimum admissible mains frequency ms

f max 2 Maximum admissible mains frequency (second limit) Hz

t f max 2 Release time for maximum admissible mains frequency ms

df/dt max Maximum admissible change of the mains frequency Hz/s

Ierr max Maximum admissible leakage current (effective value)

on the DC end

mA

Island detection Immediate grid disconnection when island operation

detected (Anti-Islanding)

Inactive/

on

Monit. ext. input The status signalling contact is congured for monitor-

ing an external input.

Inactive/

on

Restart delay Delay time before grid reconnection upon previous

failure-related grid disconnection.

s

Pac progression Maximum increase of the effective power during grid

reconnection upon previous failure-related grid disconnection.

%/min

Soft Start Maximum increase of the effective power at grid con-

nection. This gradient, if activated, is always effective,

as opposed to “Pac Progression” (even during restart

in the morning).

W/s

Mains check Additional mains check before connecting to the grid Inactive/

on

- Vac MC max Maximum admissible mains voltage V

- Vac MC min Minimum admissible mains voltage V

39

en

Function / Parameter Description Unit

- f MC max Maximum admissible mains frequency Hz

- f MC min Minimum admissible mains frequency Hz

- t MC Monitoring Duration of the mains check s

P(f)-Mode Frequency-dependent power reduction Inactive/

on

- f start Starting frequency Hz

- f stop Stop frequency Hz

- P(f) MC f max Maximum admissible mains frequency Hz

- P(f) MC f min Minimum admissible mains frequency Hz

- P(f) MC Vac max Maximum admissible mains voltage V

- P(f) MC Vac min Minimum admissible mains voltage V

- P(f) MC t monitoring Duration of mains check in P(f) mode s

- Reduction Reduction gradient %/Hz

- Re-increase Increase gradient to the maximum possible power

output (in % of rated output power Pac nom/min)

%/min

P(V)-Mode Output reduction dependent on grid voltage Inactive/

on

- Vac threshold Limit of grid voltage (average value) V

- Pac reduction Reduction gradient (% of Pac nom/min) %/min

- Pac recovery Increase gradient to the maximum possible power

output (% of Pac nom/min)

%/min

- Monitoring time Monitoring time s

Q-Mode

Reactive power mode: inactive (cosφ =1), cosφ,

cosφ(Pac), Q, Q( Vac) mode 1 or Q(Vac) mode 2

-

- Vac Lock Grid voltage-dependent on/off switch for the reactive

power modes cosφ and cosφ(Pac).

Inactive/

on

- Vac Lock-In High Value at which the reactive power mode is switched on.

Upper value at which the reactive power mode "Q(Vac)

mode 2" is switched on.

V

- Vac Lock-Out Low Value at which the reactive power mode is deactivated

(cosφ =1). Lower value at which the reactive power

mode "Q(Vac) mode 2" is switched off.

V

- QR 1 Fixed reactive power in reactive power mode "Q(Vac)

mode 2" (when grid voltage is too high; in % of

Pac nom)

%

- Vac Lock-Out High Upper value at which the reactive power mode Q(Vac)

mode 2" is deactivated (cosφ =1).

V

40

Function / Parameter Description Unit

- Vac Lock-In Low Lower value at which the reactive power mode "Q(Vac)

mode 2" is activated.

V

- QR 2 Fixed reactive power in reactive power mode "Q(Vac)

mode 2" (when grid voltage is too low; in % of

Pac nom)

%

- Pac Lock Active power-dependent on/off switch for the reactive

power modes cosφ and Q.

Inactive/

on

- Pac Lock-In Value at which the reactive power mode is activated. W

- Pac Lock-Out Value at which the reactive power mode is deactivated

(cosφ =1).

W

FRT Fault ride through function for dynamic grid support Inactive/

on

- K-Factor Reactive current static factor for voltage support with

reactive current during mains drops

-

Iac max Maximum admissible mains current (per phase) A

Pac max Maximum effective power to be fed W

S max Maximum apparent power to be fed. VA

6.8 Settings

This menu can be used to set different communication parameters and monitoring functions. All settings can also be implemented with MaxTalk.

Parameter Description

Language Selection of the display language (German, English, French, Italian, or

Spanish). The display language can be selected independently of the

selected specic country settings.

Time Setting the internal clock

Date Setting the displayed date

Device address Denition of the device address between 1 and 249. If you connect

several inverters and accessory components to become one MaxComm

communication network, each device within the network must have an

individual address.

IP

Conguration of the Ethernet interface. Details see Section 5.3.Netmask

TCP Port

Status relay delay Setting the switching delay of the status signalling contact

Pinst tot Rated output of the PV generator (entry only possible in MaxTalk).

41

en

6.8.1 Implementing the settings

Use the button to select a parameter. Press the button to select a highlighted

parameter and switch into the editing mode to change it.

In the editing mode each individual number is changed.

Example: Using the button, the highlighted number can be increased. After editing

this number, use the

button to go to the next number which in turn can be incre-

ased using the

button.

Press the left button

to return to the Main menu.

6.8.2 Status relay

The functions of the status signalling contact can be adjusted. There are four different

functional settings.

Setting Description

Off The status signalling contact is always open.

Mains When the inverter starts mains operation, the status signalling contact

closes immediately and remains closed as long as the inverter is feeding

in. If the inverter is no longer feeding into the grid, the status signalling

contact opens after the adjustable delay time has expired.

Error If a warning, failure, or device error occurs with the inverter, the status

signalling contact closes after the adjustable delay time has expired (the

events are listed in 10.2 “Diagnosis & measures”). The status signalling

contact opens immediately when the error is no longer present.

On This setting is designed for controlling an external motorised AC discon-

nector, for example. When the inverter is switched on (sufciently high

DC input voltage), the status signalling contact closes. The status signalling contact will only re-open when the inverter is switched off (DC input

voltage too low).

The monitoring electronics are supplied by the PV generator, in other words during the

night and when the DC end is switched off, the status signalling contact is open.

42

6.9 Information

This menu contains the following information:

Device type

Serial number

Firmware version

Status message and two-digit number code (if a device error occurs)

Warning (alternating display if several warnings are active at the same time)

Date of initial start-up

Accumulated operating hours

Date

Time

Use the

and keys to move through the menu. Press the left button to return

to the Main menu.

6.10 Auto Test according to DK 5940

During mains operation, the Auto Test procedure according to DK 5940 (only for country

setting “Italy”) varies the trigger threshold for AC voltage and frequency monitoring linearly with a ramp of ≤ 0.05Hz/s and/or ≤ 0.05Vn/s (Vn = 230Vac). This way, at some

point during the test, the threshold will coincide with the current measured value, leading

to triggering of the monitoring intervention. After each test step the values of the trigger

thresholds, delay times, current measured frequency and AC voltage values, and the

standard threshold trigger value are displayed.

6.10.1 Start Auto Test

The Auto Test can be activated only if there is sufcient irradiance, the inverter is connected to the grid, and is in feed mode.

1. Wait until the inverter has connected to the grid.

2. Select the “Auto Test” menu item in the Main menu.

3. Answer the question whether the Auto Test should be executed with YES.

4. The Auto Test now runs automatically.

NOTE

If an error occurs during the test or the irradiance is too low, the Auto Test is aborted

and the message “Auto Test aborted” appears in the display together with an associated error message.

43

en

6.10.2 Procedure

Maximum voltage

The set voltage monitoring threshold Vac max is displayed.

The threshold value is decremented linearly until it reaches the current mains voltage

value and grid monitoring is triggered.

The trigger value, the trigger time, the current value, and the default value of voltage

monitoring (Vac max) are displayed.

Minimum voltage

The set voltage monitoring threshold Vac min is displayed.

The threshold value is incremented linearly until it reaches the current mains voltage

value and grid monitoring is triggered.

The trigger value, the trigger time, the current value, and the default value of voltage

monitoring (Vac min) are displayed.

Maximum frequency

The set frequency monitoring threshold f max is displayed.

The threshold value is decremented linearly until it reaches the current mains fre-

quency value and grid monitoring is triggered.

The trigger value, the trigger time, the current value, and the default value of frequency

monitoring (f max) are displayed.

Minimum frequency

The set frequency monitoring threshold f min is displayed.

The threshold value is incremented linearly until it reaches the current mains fre-

quency value and grid monitoring is triggered.

The trigger value, the trigger time, the current value, and the default value of frequency

monitoring (f min) are displayed.

After the Auto Test is complete, the inverter returns to normal operation.

44

7 Operating status

7.1 Status messages and status LED

The status message in the graphics display describes the current operating status of the

inverter. Each inverter status message belongs to one of the ve possible operating statuses. The status LED always displays one of these operating statuses through a variety

of colours. In addition to the status messages, the inverter can also display warnings.

Warnings result from device errors or external failures which, however, do not affect the

mains operation of the inverter. Losses of yield are possible, however.

Warnings have no relation to the operating status and are displayed on the graphics display alternately with the current status message.

The status messages of the “Failure”, “Error”, and “Blocked” operating statuses, as well

as the warnings, usually require certain measures to be taken, see Section 8.2.

LED status Operating status Description

Off -

Inverter is switched off → grid disconnection

Flashing green – – – Booting

Inverter starts → grid disconnection

Green

Mains operation Grid feed-in (normal operation)

Flashing

orange – – –

-

Warning → no grid disconnection

Orange

Failure

External failure → grid disconnection

Red

Error

Internal device error → grid disconnection

Flashing red – – – Blocked

Inverter is blocked → grid disconnection

7.2 Booting

Status message Description

Irradiance too low The solar irradiation or rather the available output is too low for

mains operation.

Startup… The inverter checks the internal hardware and software

components before connecting to the grid.

Restart delay The inverter has disconnected itself from the grid and is

delaying re-connection to the grid.

45

en

7.3 Mains operation

Status message Description

Mains operation The inverter has been switched to the grid and is feeding power

into the grid.

Maximum power The inverter limits the output power to the maximum permissible

level. Limiting the power can occur when the PV generator has

been oversized or in the event of high irradiation.

Idc limitation The inverter limits the DC input current to the maximum permis-

sible value. This can occur if the PV generator was designed so

that the current in the MPP is higher than the maximum permissible DC current of the inverter.

Iac limitation The inverter limits the fed-in mains current to the maximum

permissible value. This can occur in response to major uctuations

in irradiation, low mains voltage or due to an over-dimensioned PV

generator.

Restart limitation The inverter increases the active power after the conclusion of an

external limitation with a dened progression (Pac progression

and/or Soft Start).

Frequency limitation The inverter temporarily limits the active power due to an active

frequency-dependent reduction in power - P(f) mode.

External limitation The output power of the inverter is limited by a remote command.

7.4 Communications activity

The communications activity of the inverter is displayed via two different symbols on the

graphics display.

Symbol Description

This symbol is displayed when the inverter sends or receives data

(via RS485 or Ethernet).

This symbol appears when there is an Ethernet connection (corresponds with

the “Link” display on network cards).

46

8 Troubleshooting

SolarMax Produktions GmbH delivers only SolarMax inverters which have stood up to our

extensive quality testing regime. Moreover, each inverter is subjected to several hours of

endurance testing under full-load conditions.

If, despite this, your PV plant suffers a failure or an error we recommend these procedures:

DANGER

Work on the PV plant must be performed by qualied electricians only.

1. Check whether the inverter and PV generator have been installed correctly. Check the

cable connections using the instructions and information contained in the “Installation” section of this manual.

2. Determine the cause of the failure by checking the message in the graphics display.

Section 10.2 “Diagnosis & measures” explains possible ways of correcting failures.

If you cannot correct the failure using the recommended measures, or you are not sure

what sort of error is involved, please contact our SolarMax Service Centre.

8.1 SolarMax Service Center

If you have technical questions or difculties, our Service Center would be happy to help

you. If you have questions about failures, please provide us with the following details:

Device type

Serial number S/N

Installation location

Information about the failure you are experiencing (status message, etc.)

Availability

The contact details of the SolarMax Service Center can be found on the back of this

instruction manual.

SolarMax Produktions GmbH

Zur Schönhalde 10

D-89352 Ellzee

47

en

8.2 Diagnosis & measures

The following tables describe possible measures for remedying failures. If the measures suggested do not correct the failure, please contact the SolarMax Service Centre

immediately.

8.2.1 General troubleshooting

Cause Steps

The display remains blank DC disconnector Q1 is

switched off.

Switch on DC disconnector

Q1.

Irradiation too low. Wait until the irradiation is

sufcient.

Strings disconnected. Check PV generator and

correct disconnection.

Internal failure. Notify the SolarMax Service

Centre.

The PV generator is connected

incorrectly (plus and minus

connections have been mixed

up).

Connect the PV generator

properly.

8.2.2 Warnings

Warning Cause Measure

Failure fan A fan is defective or dirty. Contact the SolarMax Service

Centre.

Temperature limitation The feed-in power has been

temporarily reduced to

limit the temperature of the

inverter.

Clean the fan grids and

improve ventilation in the

operations room.

Failure temp. sensor A temperature sensor in the

inverter has failed.

Contact the SolarMax Service

Centre.

Burst error The inverter disconnected

from the grid ve times or

more on the same day. The

warning is displayed for the

remainder of the day. The error

counter will be reset when

the system is restarted in the

morning.

Check your plant’s status logger in MaxWeb xp (if present)

or check the grid parameters.

If this happens repeatedly,

contact our SolarMax Service

Centre.

48

Warning Cause Measure

RTC error The RTC (real-time clock) in

the inverter is malfunctioning,

the date and time have been

reset.

If this problem happens frequently, contact the SolarMax

Service Centre. Set the time

and date correctly.

Flash error A ash error has occurred.

Inverter mains operation continues to be guaranteed.

Contact the SolarMax Service

Centre.

Firmware mismatch The rmware versions of the

inverter controllers do not

match.

Contact the SolarMax Service

Centre.

8.2.3 Failures

Status message Cause Measure

Vdc too high (VDC3, VDC2,

VDC1)

The DC input voltage at the

specied inverter DC connection is too high.

Switch off the DC disconnector Q1 immediately and

disconnect the PV generator

from the inverter. Check

the dimensioning of the PV

generator.

No mains

No mains BP

There is no mains voltage

or the AC supply has been

interrupted.

Check the AC supply.

Mains error

Mains error BP

The grid has been switched

off.

If this problem continues to

occur, contact the responsible

grid operator.

Frequency too high

Frequency too high BP

The mains frequency is

outside of the f max 1 or f max

2 limit values.

Frequency too low

Frequency too low BP

The mains frequency is

outside of the f min 1 or f min

2 limit values.

Vac too high (L1 L2 L3)

Vac too high BP (L1 L2 L3)

The mains voltage at the

specied phase is outside of

the Vac max 1 or Vac max 2

limit values.

Vac too low (L1 L2 L3)

Vac too low BP (L1 L2 L3)

The mains voltage at the

specied phase is outside of

the Vac min 1 or Vac min 2

limit values.

49

en

Status message Cause Measure

Vac 10min too high (L1 L2 L3)

Vac 10min too high BP

(L1 L2 L3)

The maximum 10-minute

average value of the mains

voltage ( Vac 10 min max.)

at the specied phase is too

high.

If this problem continues to

occur, contact the responsible

grid operator.

df/dt too high The change in the mains

frequency per second has

exceeded the maximum

admissible value df/dt max.

Insulation fault DC

Insulation fault DC BP

The insulation resistance of

the PV generator against earth

is too low.

Check the PV generator.

Ierr too high

Ierr too high BP

The DC leakage current has

exceeded the admissible

absolute limit value lerr max.

Ierr step too high

Ierr step too high BP

The DC leakage current has

exceeded the admissible step

value.

L and N interchanged A phase and the neutral

conductor are incorrectly connected (interchanged).

Connect the AC supplies

correctly.

Error DC polarity One or more DC connections

are connected incorrectly

(incorrect polarity).

Connect the DC supplies

correctly.

Error ext. input 1 The external grid monitoring

and/or remote shutdown has

disconnected the inverter from

the grid.

If this problem continues to

occur, contact the responsible

grid operator.

8.2.4 Error

Status message Cause Measure

Device error (+ error code) An internal error has occurred

in the inverter.

Check the two-digit error code

displayed and contact the

SolarMax Service Centre.

8.2.5 Blockings

Status message Cause Measure

External blocking There is a 0% command from

MaxRemote (coming from the

grid operator).

None. Wait until the grid

operator suspends the

blocking of the inverter via

MaxRemote.

50

Status message Cause Measure

Program Firmware The inverter rmware is cur-

rently being updated.

The inverter automatically

resumes mains operation

once the rmware update is

complete.

9 Maintenance

SolarMax inverters are basically maintenance-free. However, in order to ensure perfect

operation over the course of several years, in addition to regular controls of the operating

and yield data via the inverter display or remote monitoring, we also recommend performing the simple maintenance work described below at regular intervals. The maintenance intervals must be set keeping the ambient conditions in mind (especially exposure

to dust).

The following checks can be performed by the plant operator. If you discover problems

while performing these checks, contact the electrician in charge of maintenance or our

SolarMax Service Centre.

Functional check of the inverter using the graphics display

On-site check of visible traces of wear and tear (damage, rain, snow, rodents, etc.)

Cleaning and check of plant room

Cleaning the fan screens

10 Disposal

Please dispose of the inverter at the end of its service life in compliance with the disposal

regulations then valid where it is installed. You can also return the inverter at your own

cost for professional disposal to SolarMax Produktions GmbH.

51

en

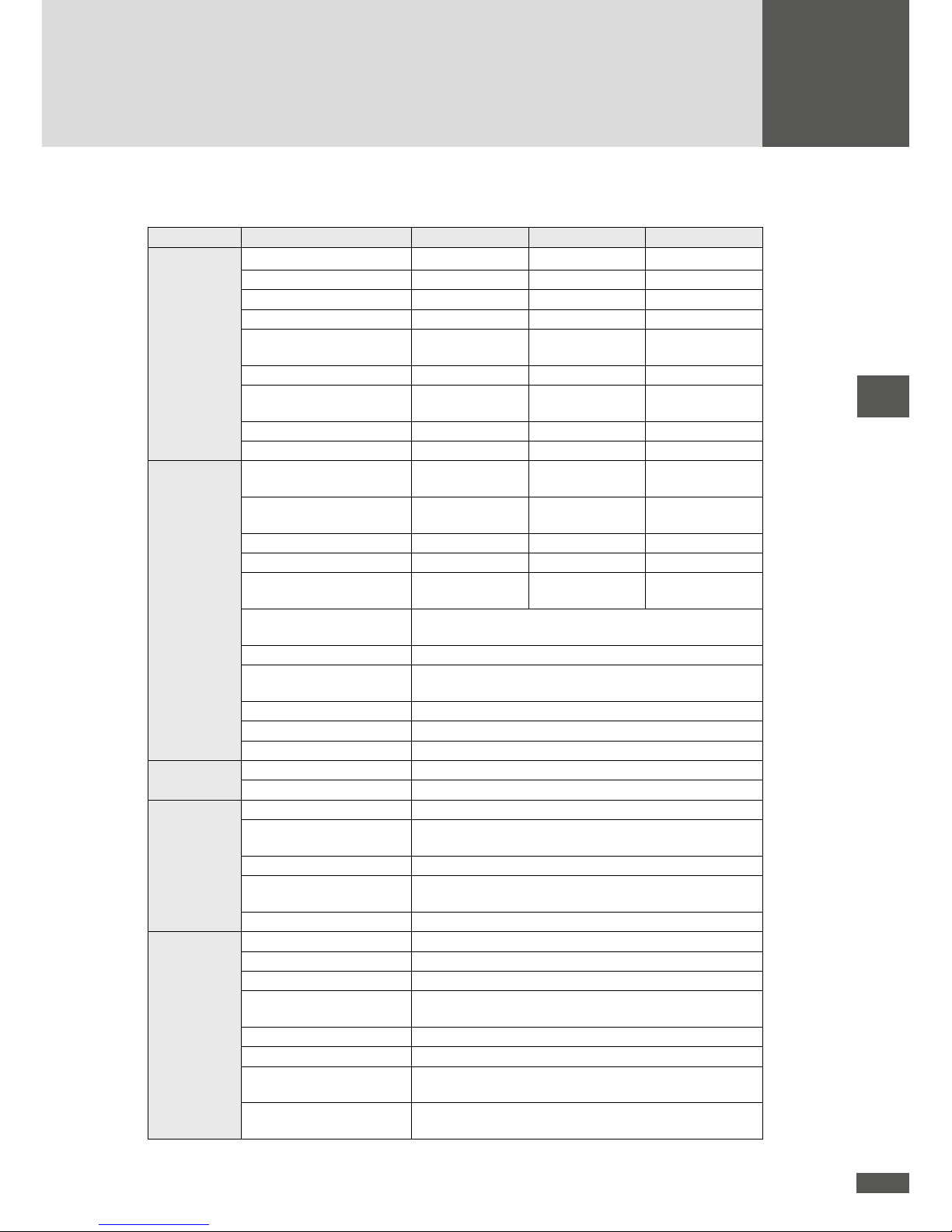

11 Technical data

6MT2 8MT2 10MT2

Input

values

MPP voltage range

1)

340… 750 V

2)

300… 750 V

2)

290… 750 V

2)

Minimum DC voltage 250 V 250 V 250 V

Maximum DC voltage 900 V 900 V 900 V

Maximum DC current 1 x 9 A / 1 x 9 A 1 x 18 A / 1 x 9 A 2 x 18 A

Maximum DC short-circuit

current

1 x 9 A / 1 x 9 A 1 x 18 A / 1 x 9 A 2 x 18 A

Number of MPP trackers 2 2 2

Max. PV generator output

per MPP tracker

5 000 W MPPT1: 9 000 W

MPPT2: 5 000 W

9 000 W

String connections 1 x 2 / 1 x 1 1 x 2 / 1 x 1 2 x 2

Connection type MC 4 MC 4 MC 4

Output values Rated output power at

cosφ = 1

6 000 W 8 00 0 W 10 000 W

Maximum apparent output

power

6 000 VA 8 000 VA 10 0 00 VA

Nominal mains voltage 3 x 400 V 3 x 400 V 3 x 400 V

Maximum AC current 3 x 9 A 3 x 12 A 3 x 16 A

Maximum AC short-circuit

current

42 A

peak

42 A

peak

42 A

peak

Mains nominal frequency

/ range

50 Hz / 45 Hz…55 Hz

Power factor cosφ

adjustable from 0.8 overexcited to 0.8 underexcited

Distortion factor at rated

output power

< 3 %

Connection type Connector (locking)

Grid connection three-phase (3 /N / PE)

Power input at night 0 W

Efciency Max. efciency 98.0 %

European efciency 9 7.5 %

Ambient

conditions

Protection type IP65

Ambient temperature range

(at rated output power)

−20 °C…+60 °C (−20 °C…+50 °C)

Relative humidity 0…100 % (condensation)

Maximum altitude above

sea level

2 000 m

3)

Noise emissions (↔ 1.5 m)

51 dB(A) fan off / 58 dB(A) fan on

Conguration Display Graphic LC display with backlight and status LED

DC disconnector integrated (cat. DC-21 or higher)

Circuit type two-stage, transformerless

Data logger Data logger for energy yield, peak output, and operating dura-

tion for the last 31 days, 12 months and 10 years

Fault current monitoring internal, AC/DC sensitive

Casing Aluminium

Overvoltage conductor DC Requirement class C (VDE 0675-6) and/or type 2

(EN 616 43 -11)

Overvoltage conductor AC Requirement class D (VDE 0675-6) and/or type 3

(EN 616 43 -11)

52

6MT2 8MT2 10MT2

Standards &

guidelines

EMC EN 61000-3-2 / EN 61000-3-3 / EN 61000-3-11 / EN 61000-

3-12 / EN 61000-6-2 / EN 61000-6-3

Grid connection

2)

VDE-AR-N 4105 / VDE 0126-1-1 A1:2012 / BDEW MS-

Richtlinie / CEI 0-21 / CEI 0-16 / RD 661 / RD 1699 / G59/3 /

G83/2 / PPC Guide / C10/11 / EN 50438 / AS 4777

Device safety

IEC / EN 62109-1/-2

Interfaces Data communication RS485 / Ethernet

Status signalling contact M12 connector with relay as N/C contact / N/O contact

Connection of external grid

monitoring

M12 connector

Weight &

dimensions

Weight 39 kg 39 kg 39 kg

Dimensions in mm

(W x H x D)

550 x 750 x 200

Warranty Standard 5 years / extension to 10, 15, 20, or 25 years possible

1) for AC rated power output

2) max. 700 V with external power limitation

3) contact us if the installation location is at a higher level

4) certicates are not available for all models. Details can be found at www.solarmax.com

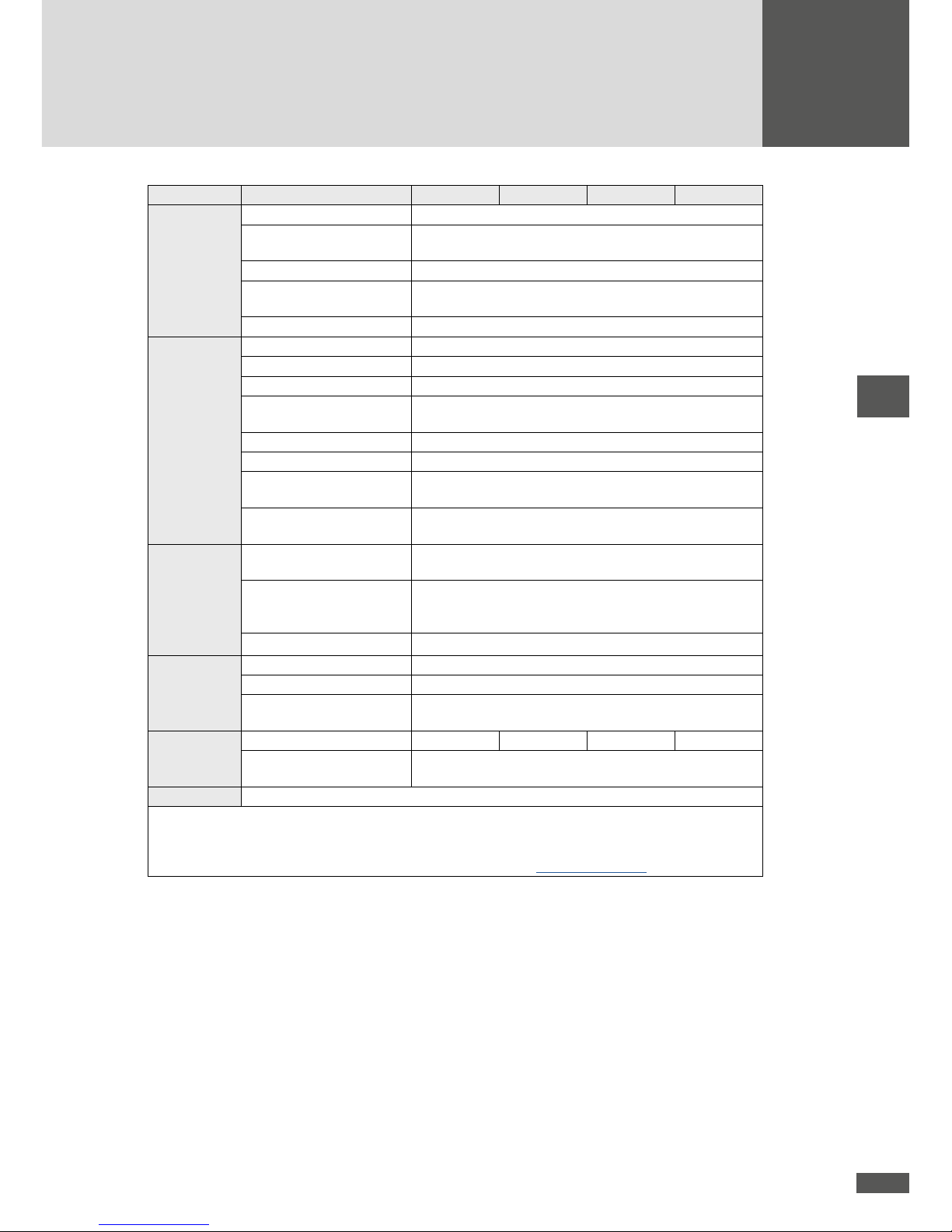

13MT2 15MT2 13MT3 15MT 3

Input

values

MPP voltage range

1)

370… 750 V2)430… 750 V2)280… 750 V2)320… 750 V

2)

Minimum DC voltage 250 V 250 V 250 V 250 V

Maximum DC voltage 900 V 900 V 900 V 900 V

Maximum DC current 2 x 18 A 2 x 18 A 3 x 16 A 3 x 16 A

Maximum DC short-circuit

current

2 x 18 A 2 x 18 A 3 x 16 A 3 x 16 A

Number of MPP trackers 2 2 3 3

Max. PV generator output

per MPP tracker

9 000 W 9 0 00 W 9 00 0 W 9 000 W

String connections 2 x 2 2 x 2 3 x 2 3 x 2

Connection type MC 4 MC 4 MC 4 MC4

Output values Rated output power at

cosφ = 1

13 000 W 15 000 W 13 00 0 W 15 000 W

Maximum apparent output

power

13 000 VA 15 000 VA 13 00 0 VA 15 00 0 VA

Nominal mains voltage 3 x 400 V 3 x 400 V 3 x 400 V 3 x 400V

Maximum AC current 3 x 20 A 3 x 22 A 3 x 20 A 3 x 22 A

Maximum AC short-circuit

current

42 A

peak

42 A

peak

42 A

peak

42 A

peak

Mains nominal frequency

/ range

50 Hz / 45 Hz…55 Hz

Power factor cosφ

adjustable from 0.8 overexcited to 0.8 underexcited

Distortion factor at rated

output power

< 3 %

Connection type Connector (locking)

Grid connection three-phase (3 /N / PE)

Power input at night 0 W

Efciency Max. efciency 98.0 %

European efciency 9 7.5 %

53

en

13MT2 15MT2 13MT3 15MT 3

Ambient

conditions

Protection type IP65

Ambient temperature range

(at rated output power)

−20 °C…+60 °C (−20 °C…+50 °C)

Relative humidity 0…100 % (condensation)

Maximum altitude above

sea level

2 000 m

3)

Noise emissions (↔ 1.5 m)

51 dB(A) fan off / 58 dB(A) fan on

Conguration Display Graphic LC display with backlight and status LED

DC disconnector integrated (cat. DC-21 or higher)

Circuit type two-stage, transformerless

Data logger Data logger for energy yield, peak output, and operating dura-

tion for the last 31 days, 12 months and 10 years

Fault current monitoring internal, AC/DC sensitive

Casing Aluminium

Overvoltage conductor DC Requirement class C (VDE 0675-6) and/or

type 2 (EN 61643-11)

Overvoltage conductor AC Requirement class D (VDE 0675-6) and/or

type 3 (EN 61643-11)

Standards &

guidelines

EMC EN 61000-3-2 / EN 61000-3-3 / EN 61000-3-11 / EN 61000-

3-12 / EN 61000-6-2 / EN 61000-6-3

Grid connection

2)

VDE-AR-N 4105 / VDE 0126-1-1 A1:2012 / BDEW MS-

Richtlinie / CEI 0-21 / CEI 0-16 / RD 661 / RD 1699 / G59/3 /

G83/2 / PPC Guide / C10/11 / EN 50438 / AS 4777

Device safety

IEC / EN 62109-1/-2

Interfaces Data communication RS485 / Ethernet

Status signalling contact M12 connector with relay as N/C contact / N/O contact

Connection of external grid

monitoring

M12 connector

Weight &

dimensions

Weight 39 kg 39 kg 42 kg 42 kg

Dimensions in mm

(W x H x D)

550 x 750 x 200

Warranty Standard 5 years / extension to 10, 15, 20, or 25 years possible

1) for AC rated power output