USER MANUAL

MODEL PMA2100 PHOTOMETER / RADIOMETER

Part Number: 210092

Revision Level: D

100 East Glenside Avenue • Glenside, PA 19038 • USA • P 1.215.517.8700 • F 1.215.517.8747

1

www.solarlight.com • info@solarlight.com • www.youtube.com/user/SolarLightCoInc

2

TABLE OF CONTENTS

1 INTRODUCTION......................................................................................................................................................................4

1.1 PMA2100 Design Concept...........................................................................................................................................4

1.2 Major Features.............................................................................................................................................................4

1.3 Currently Supported Detectors....................................................................................................................................4

2 QUICK START GUIDE...............................................................................................................................................................5

2.1 Selection Of The Detector............................................................................................................................................5

2.2 Measuring With PMA2100...........................................................................................................................................5

3 CONTROLS & INDICATORS...........................................................................................................................6

3.1 Display..........................................................................................................................................................................6

3.2 Keypad..........................................................................................................................................................................7

3.3 Audible Signals............................................................................................................................................................7

3.4 Error Messages............................................................................................................................................................7

4 SETUP......................................................................................................................................................................................8

4.1.1 LCD Contrast

4.1.2 Line Frequency Rejection

4.1.3 Real Time Clock and Calendar

4.2.1 Low Pass Digital Filter

4.2.2 Automatic Datalogging

4.2.3 Scale

4.2.4 Offset

4.2.5 Alarms

4.2.6 Mode Of Operation

4.1 Meter Setup..................................................................................................................................................................8

4.2 Detector Setup...........................................................................................................................................................8

5 DATA MANAGEMENT......................................................................................................................................................11

5.1 Data Logging..............................................................................................................................................................11

5.2 Downloading The Data.............................................................................................................................................11

5.3 Data Processing.......................................................................................................................................................12

6 INTERFACES.........................................................................................................................................................................13

6.1 Detector Interface......................................................................................................................................................13

6.2 Serial and Extension Port.........................................................................................................................................14

6.3 Digital Control Lines................................................................................................................................................14

7 TECHNICAL SPECIFICATIONS...............................................................................................................................................15

8 MAINTENANCE....................................................................................................................................................................16

8.1 Meter Calibration.......................................................................................................................................................16

8.2 Battery Charging......................................................................................................................................................16

9 TABLE OF FIGURES...............................................................................................................................................................16

10 INDEX...................................................................................................................................................................................17

3

1

The Personal Measurement Assistant model PMA2100 is a sophisticated, multipurpose measuring instrument combining the user-friendliness of

simple meters with the capabilities of an advanced data logger.

INTRODUCTION

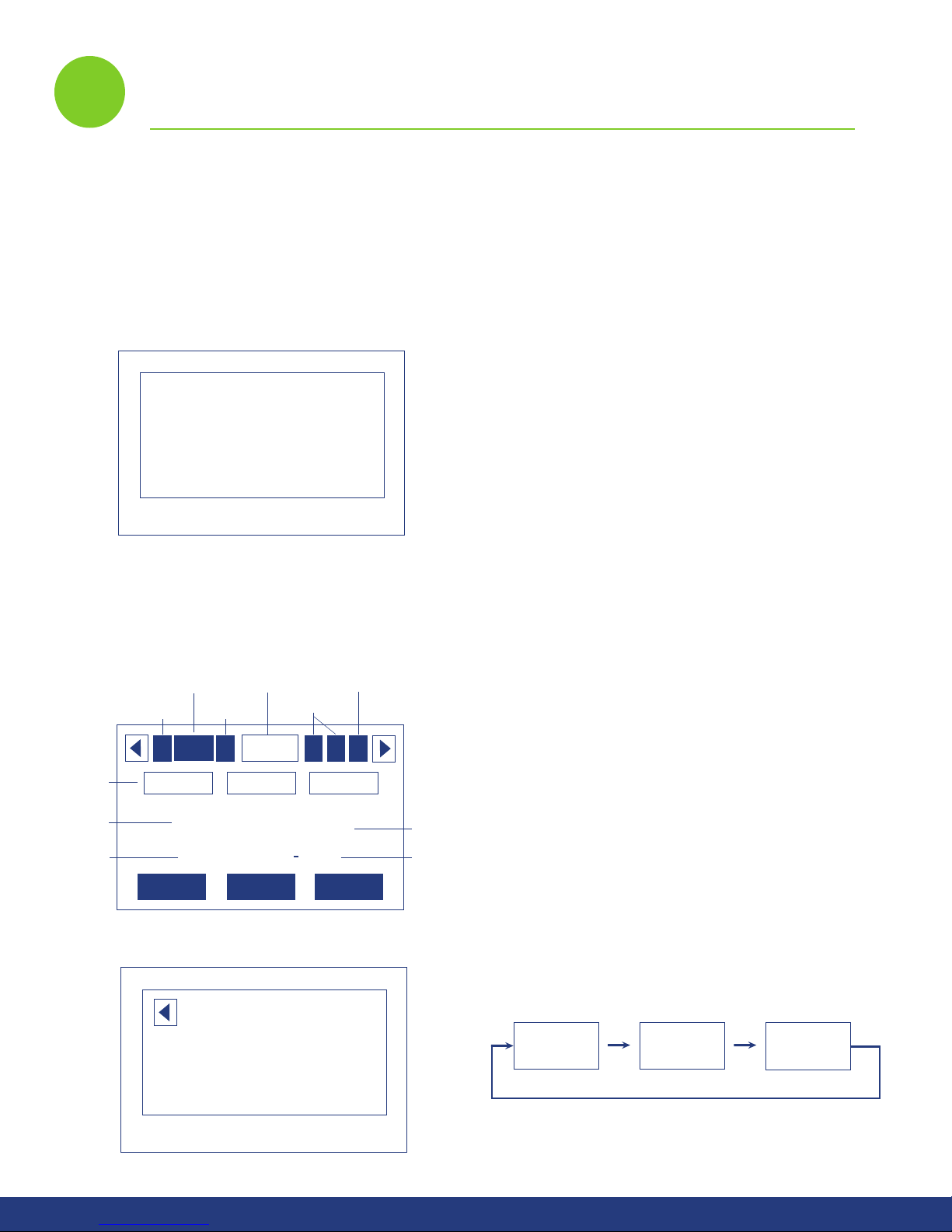

1.1 PMA2100 DESIGN CONCEPT

The meter itself is programmed to perform the tasks common to most

detectors. The information specific for a particular detector is stored in

a nonvolatile memory built into the detector itself. It includes

identification information, signal processing algorithms, a description of

the data presentation and the current setup of the detector.

Upon connection of the detector, the PMA2100 identifies it, downloads

the contents of the detector’s memory into operating memory, updates

its setup and executes the downloaded code, if appropriate.

PMA2100

DISPLAY

CONNECTOR

AND CABLE

CENTRAL

PROCESSOR

& MEMORY

SYSTEM

CONVERTER

This approach allows for an unlimited number of detectors to be

handled by the PMA2100. It configures itself to the specific features of

each detector and the custom setup of the measurement process.

DETECTOR

AMPLIFIERS

SENSOR

KEYPAD

Figure 1 Architecture of the PMA2100

1.2 MAJOR FEATURES

Measuring with the PMA2100 is as simple as with the usual single

detector and meter. Plug in the detector to either of the two input

sockets, turn ON the power and read the display. The many additional

capabilities of the PMA2100 are added through menu driven setup.

These capabilities of the PMA2100 Version 1.21 include:

• User Selectable System Of Units

• Integration Of The Accumulated Dose

• Tracking Of The Extremes Of The Signal (Min., Max., Avg.)

• Automatic & On-Demand Data Storage And Printout

• Digital Low Pass Filter

•

Programmable Alarms Triggered By The Signal Level Or The Dose Level

• Line Interference Rejection For Both 50 & 60Hz

• Two Simultaneously Serviced Detector Inputs

• Serial Interface

• Digital Inputs & Outputs To Control External Devices

• Dose Control System (DCS) Capability

DETECTOR

MEMORY

1.3 CURRENTLY SUPPORTED DETECTORS

The PMA2100 family currently includes a variety of detectors for such

parameters as:

• UVA Radiation

• UVB Biologically Effective UV Radiation

• UVC Germicidal Radiation

• Visible Light (Photopic and Scotopic)

• Full Spectrum Pyranometers

• UV Safety

• Biliruben Phototherapy

• PAR Photosynthetically Active Radiation

• Laser Power

• Temperature/Humidity

*For a complete list of detectors see

www.solarlight.com/product_category/products/sensors

4

The PMA2100 can be used in any application where an accurate

measurement is required, especially if multiple quantities are measured

or the enhanced functionality of the meter is desired.

Potential applications include:

• Laboratory Measurements

• Environmental Monitoring

• Industrial Safety

• UV-curing, Printing and Photolithography

• Photodermatology and Photobiology

• Cosmetic Industry, SPF Testing

• Materials Testing, Light Degradation Studies

• Agriculture

Any sensor producing up to 4 analog signals can be quickly and

inexpensively accommodated by the PMA2100, making it attractive to

sensor manufacturers who would like to offer a state of the art meter

with their product.

2

While sophisticated and powerful, the PMA2100 is a user-friendly instrument allowing for simple “plug-and-play” operation.

2.1 SELECTION OF THE DETECTOR

A critical part of every measurement process is the sensor selection.

The criteria that need to be addressed when making that decision are:

• Anticipated signal characteristics

• Environmental factors such as temperature range and humidity

The PMA2100 family includes detectors for both indoor and permanent

outdoor operation, satisfying virtually any operating environment.

QUICK START GUIDE

detector setup is shown or edited. Upon power-up the PMA2100

automatically enters the “data mode”.

5 In order to turn the PMA2100 OFF, return to the “display mode”

and press the On/Off key. If the LCD is in a mode other than

“display mode,” the On/Off key is inactive. To return to the “data

mode,” press the Start/Stop/Escape key repeatedly. If unit is

connected to external power, it will remain powered up and an

On/Off will have no effect.

2.2 MEASURING WITH PMA2100

To perform measurements with a PMA2100 the following steps should

be followed:

1 Remove the PMA2100 from its carrying case

2 Power it ON by pressing the ON/OFF button. If the meter does not

respond, attach the battery charger to operate from external power

or charge the batteries. Refer to page 16 for battery maintenance

instructions. The unit will be powered ON whenever connected to

the external power supply. The PMA2100 will turn itself OFF after 3

minutes of inactivity if no detector is attached.

Refer to “Controls and Indicators” on page 6 for detailed

description of the PMA2100 “data mode” display.

3 Plug the selected detector into one of the two detector inputs

located on the side of the meter. The meter will indicate the

connection by a beep and the display will show the measurement

result. Squeeze the locking arms of the detector plug while

connecting or disconnecting it.

4 If only one detector is attached, the meter’s display will

automatically switch to the only occupied channel. If two detectors

are simultaneously operating, use thekeys to switch between

the channels. While displaying the measurement result, the PMA is

in a “data mode,” as opposed to a “setup mode” when the meter or

Figure 2 The PMA2100

5

3

CONTROLS & INDICATORS

3.1 DISPLAY

The graphical Liquid Crystal Display (LCD) of the PMA2100 offers great

flexibility of the data presentation. It shows the measurement results

and allows easy setup of the meter via a series of menus.

When the meter is turned ON, it displays a start-up screen (Figure 3)

while performing the hardware test. The model number, version number

and the serial number of the meter are briefly displayed.

SOLAR LIGHT CO., INC.

PMA2100

S/N: 07587 VER: 1.21

Figure 3 Start-up Screen Of The PMA2100 Meter

Then, the display goes into the “data mode.” If at least one detector is

attached, the measurement results are shown (Figure 4). Otherwise the

screen indicates that there is no detector connected (Figure 5).

LOW, HIGH AND

AVERAGE VALUES

INSTANTANEOUS

READING

INTEGRATED DOSE

DATA STORAGE

INTERVAL IN MINUTES

HOLD INDICATOR

H F D! J! CS015

L0.123 H1.245 A0.948

DETECTOR NAME

LOW PASS DIGITAL

FILTER INDICATOR

UVA

1.234 mW/cm

∑2.354 J/cm

UNITS PRINT SETUP

Figure 4 Display In The “Data Mode” With A Detector Connected

2

DOSE AND VALUE

ALARM INDICATORS

41m 23

BATTERY

CHARGING INDICATOR

2

s

SELECTED UNITS

TIME OF INTEGRATION

The complete contents of the LCD are described in Figure 4 (referred to

several times in the following pages). The two arrows in the top left and

right corners indicate the currently selected detector. Pressing the

keys changes the selection.

The HOLD indicator is activated by pressing the HOLD key. When

highlighted, the contents of the display are frozen; however, the

measurements and data logging, dose integration, or min/max/avg (if

enabled) will continue in the background. Pressing the HOLD key again

reactivates the continuous data display.

Data storage interval indicator displays the interval (in minutes) for

automatic data logging for the currently selected detector. If not

displayed, then data logging is not enabled for the currently selected

sensor. The data logging interval can be set independently for each

detector. See “Automatic Data Logging” on page 9 for further details

about setting the interval. The interval is stored in the detector, and will

be restored the next time it is connected to the PMA2100.

The low pass digital filter can be turned on to reduce the fluctuations of

a noisy signal. This feature can be activated independently for each

detector and is preserved in the internal detector’s memory. Refer to

“Low Pass Digital Filter” on pages 8 and 9 for further details.

Dose and high value alarm indicators show whether the alarms are

activated. The alarm thresholds are set independently for each detector

and stored in the detector’s memory. They are restored the next time

the detector is connected. When the instantaneous signal level

exceeds the value alarm setting then an audible and visual signal is

generated. The dose alarm is triggered by the integrated dose value.

See “Alarms” on page 10 for further information.

The battery charging indicator displays “C” when the battery is charged

and “B” when the battery is low. Refer to “Battery Charging” on page 16

for further details about battery maintenance.

The Low, High and Average tracking can be initiated by pressing the

Min/Max key. The same key clears the setting. The tracking of

extremes starts from the moment the feature is activated. To re-start

the tracking, turn the feature OFF and then back ON by pressing the

Min/Max key twice.

NODET

Figure 5 Display In The “Data Mode” With No Detector Connected

6

F1 F1

MED/HR

Figure 6 Pressing The F1 Function Key Converts The Measurement Result

Into One Of The Available Unit Systems. UVB Detector Display Units Shown

uW/cm

2

Time/MED

The instantaneous reading is displayed in a large font for improved

readability. The currently selected units are displayed to the right of the

measurement result. If alternative units are available, then the UNITS

indicator appears above the F1 function key indicator. By pressing the

F1 key the measurement result will be converted to alternative units.

There can be more than two unit systems. They can be selected by

pressing the F1 repeatedly. After the last unit selection is reached,

pressing the F1 key will bring the display back to the initial unit

selection.

If the measured quantity can be integrated over time, then integration

can be initiated by pressing the Start/Stop key. The integrated value

and a corresponding time of the integration are displayed in the space

below the instantaneous measurement value (Figure 4.) During

integration the clock icon, shown next to the time integration, will

indicate integration in process. The integration is stopped by pressing

the Start/Stop key again. The integration timer and the dose display

freeze but the information is displayed on the LCD until the Start/Stop

key is pressed again. When restarted, the integrated value and the time

will be reset to zero. If data logging has been enabled, pressing the

Start/Stop key will affect the value stored for the next logged data

point. The average value is logged when the dose integration is

activated. Instantaneous values are stored otherwise.

The assignment of the function keys, F1-F3, can change dynamically

depending on the mode of operation. The indicators displayed along

the bottom of the LCD describe the function of the keys. If the key

indicator is blank, then the key has no assigned function.

be edited. They are inactive in the “display mode.”

Pressing the HOLD key freezes the information on the LCD without

affecting the measurement and data collection process. An “H” will be

displayed in the upper left-hand corner. While in the “hold mode”

pressing HOLD reactivates display updating.

The Min/Max key initiates the Low, High and Average tracking. The

same key clears the setting. The tracking of extremes starts from the

moment the feature is activated. To re-start the tracking turn the feature

OFF and then back ON by pressing the Min/Max key twice (See

“Display” on page 10). High, low and average values will be reset to

zero on restart of the Min/Max function.

F1

Hold

On/Off

F2 F3

Min/Max

INCR

DECR

Start/Stop Menu

Escape Enter

3.2 KEYPAD

The keys of the PMA2100 (Figure 7) have a tactile feel and an audible

signal is generated when the key is pressed.

The On/Off key toggles the power to the meter. It is only active in the

display mode.

The Start/Stop button enables the dose integration. The integrated

dose and a corresponding time of the integration are displayed in the

space shown below the instantaneous measurement result (Figure 4.)

The Start/Stop key works also as an Escape key in menu and setup

mode. In general, it reverts to the previous menu level or leaves the

“menu mode” and enters the “display mode.”

The Menu/Enter key transfers control to the “menu mode” allowing for

the meter setup. Settings for LCD contrast, line frequency rejection, or

real time clock can be altered in that mode. Refer to “Meter Setup” on

page 8 for further details.

Thekeys allow for the selection of the displayed channel while in the

“display mode”. In “edit mode” (when a numerical value is changed,)

these keys select the digit to be changed. When a menu is shown

thekeys allow navigation through menu list.

Figure 7 Keypad Configuration Of The PMA2100

3.3 AUDIBLE SIGNALS

Certain conditions cause the generation of an audible signal to attract

the attention of the user. The conditions generating an audible signal

are listed in Table 1.

TABLE 1 CONDITIONS CAUSING

A GENERATION OF AN AUDIBLE SIGNAL

Power On 1 Long Beep

Activation Of Any Key

Acceptance Of An Newly Connected Detector

Detector Disconnected

Activation Of A Value Or Dose Alarm

1 Short Beep

1 Short Beep

3 Short Beeps

5 Short Beeps

3.4 ERROR MESSAGES

When an erroneous condition is detected by the PMA2100 an error

number and a brief message are displayed to indicate the nature of the

problem.

Thekeys allow navigation through a list of menu items and

decrement/increment the selected digit allowing a numerical value to

7

TABLE 2 ERROR CODES AND MESSAGES

Code Message On LCD Description Of The Problem

01 Detector Conflict

02

Upgrade Software

03 Out Of Calibration

Some detectors use all 4 analog inputs available in the PMA2100 and cannot be used simultaneously with other

detectors. This message will appear when 2 incompatible detectors are connected to the PMA2100.

The detector requires higher version of the software controlling the PMA2100. This message is displayed

immediately after the new detector is connected. Contact Solar Light for upgrade.

The detector is due for calibration. The detector should be returned to Solar Light for re-calibration. Various detectors have different calibration intervals, depending on their inherent long-term stability.

4

SETUP

4.1 METER SETUP

The “meter setup mode” is accessed from the “display mode” by

pressing the MENU key. To return back to the “display mode,” the

Escape key should be pressed.

Meter setup allows for adjustments specific to the contrast of the LCD,

the line rejection frequency and the real time clock. The settings of

measurement parameters are available through the Detector Setup

menu (see page 8), since they are specific for a particular detector.

4.1.1 LCD CONTRAST

The contrast of the LCD changes with the ambient temperature.

To assure a legible display, the contrast can be adjusted for best

visibility.

To change the LCD contrast, follow these steps:

1 Press the Menu/Enter key to enter the “menu mode.”

2 Select the Contr: X item on the menu pressing or keys.

4.1.3 LINE REAL TIME CLOCK AND CALENDAR

The real time clock and calendar provides the information for time

stamping of the recorded data.

To set the real time clock, follow these steps:

1 Press the Menu/Enter key to enter the “menu mode.”

2 Select the Clock... item on the menu pressing or keys.

3 Press the Menu/Enter key to start the time setting procedure. The

LCD will show the current date and time. The item selected

for modification is listed by theicon, such as in this

example:change month. Press theorkey to decrement

or increment the selected item. When this item is properly set use

theto select next item for editing. The items available are: year,

month, day, hour, minutes, and seconds.

4 When the date and time is properly set, press either Enter or

Escape key to leave the time setting menu.

3 Keep pressing the Menu/Enter key until optimal contrast of the

LCD is selected.

4 Press the Escape key to return to the “display mode.”

4.1.2 LINE FREQUENCY REJECTION

The PMA2100 has an ability to discriminate against the 50 or 60 Hz

interference from power lines. To achieve the best performance, the

local line frequency must be set manually.

To set the line frequency, follow these steps:

1 Press the Menu/Enter key to enter the “menu mode.”

2 Select the Line: XXHz item on the menu pressing or keys.

3 Press the Menu/Enter key until appropriate frequency is selected.

4 Press the Escape key to return to the “display mode.”

8

5 Press the Escape key to return to the “display mode.”

4.2 DETECTOR SETUP

The detectors are equipped with a non-volatile memory to store

configuration information specific to a particular detector. When the

detector is connected, these configuration parameters are read from

the detector and used to set up the PMA. Among the parameters stored

are user-configurable settings such as: low pass filter ON/OFF, data

logging parameters, scale and offset values, alarm settings and

operating mode.

4.2.1 LOW PASS DIGITAL FILTER

The low pass digital filter is used to reduce the fluctuations of a noisy

signal. Due to its averaging nature it will smooth the signal and allow

the measurement of the average.

To change the setting of the low pass filtering follow these steps:

1 Select the detector to be set up with keys if two detectors are

attached.

2 Press the SETUP key to enter the “detector setup mode.” The SETUP

key is one of the function keys annotated by the word SETUP on the

LCD. A menu of available settings will be presented on the LCD. The

SETUP annotation only appears when the detector is attached.

3 Use thekeys to select the Fltr: XXX item. The XXX will indicate

either ON or OFF.

4 Press the Menu/Enter key to set the status of the digital filter to a

desired state.

5 Press the Escape key to return to the display mode. At this time the

current setup of the detector is written to the detector’s memory.

Skipping this step or disconnecting the detector beforehand is

equivalent to ignoring the changes made.

4.2.2 AUTOMATIC DATA LOGGING

The PMA2100 is capable of storing the measurement data either in

manual or automatic mode. Refer to “Data Logging” on page 11 for

more information about data logging.

In the automatic mode one record of data is logged in memory per

user-selected interval, ranging from 1 minute to 1 hours. If two sensors

are attached at the same time, the data logging interval can be set

independently for each.

To initiate the automatic data logging, follow these steps:

1 Select the detector to be set up with keys if two are attached.

2 Press the SETUP key to enter the “detector setup mode.” The

SETUP key is one of the function keys annotated by the word

SETUP on the LCD. A menu of available settings will be presented

on the LCD.

3 Use thekeys to select the Sav: XXm item. The XX represents

the currently selected interval in minutes. If automatic data logging

is not activated then Sav: 0m (zero) will be shown.

4.2.3 SCALE

An additional user-preset scale factor can be applied to the

measurement. Normally the scale factor is set to 1.00 to accept the

factory calibrated scale factor of the detector.

To change the scale factor follow these steps:

1 Select the detector to be set up with keys if two are attached.

2 Press the SETUP key to enter the “detector setup mode.” The

SETUP key is one of the function keys annotated by the word

SETUP on the LCD. A menu of available settings will be presented

on the LCD.

3 Use thekeys to select the Scal: X.XX item. The X.XX

represents the currently set scale factor, typically 1.00.

4 Press the Menu/Enter key to enter the scale editing mode. The

name of the currently selected detector is shown on the LCD.

5 Use thekeys to move the cursor between the digits of the scale

value. Usekeys to increment or decrement the selected digit.

If the cursor is placed underneath the sign of the number then

pressing thekeys will toggle the sign between + and -.

6 Press Menu/Enter to accept the new scale value. The LCD will

revert back to the “detector setup menu.”

7 Press the Escape key to return to the display mode. At this time

the updated scale factor for the detector is written to the detector’s

memory. Skipping this step or disconnecting the detector

beforehand is equivalent to ignoring the changes made.

4.2.4 OFFSET

The measurement made by the PMA2100 can be offset by a user

entered value in order to compensate for the drifts in the detector or to

compensate for a background signal.

The offset setting is unit-sensitive, i.e. it takes the unit conversions into

account and converts the offset values accordingly.

To modify the offset follow these steps:

1 Select the detector to be set up with keys if two are attached.

4 Press the Menu/Enter key to enter the logging interval selection

menu. The currently set interval is shown on the header of the

menu.

5 Use thekeys to navigate through the list of valid intervals

and to select the desired one. Select NONE to disable data logging.

6 Press Menu/Enter to accept the selected interval. The LCD will

revert back to the “detector setup menu.”

7 Press the Escape key to return to the display mode. At this time

the updated logging configuration parameters are written to the

detector’s memory. Skipping this step or disconnecting the

detector beforehand is equivalent to ignoring the changes made.

2 Press the SETUP key to enter the “detector setup mode.” The

SETUP key is one of the function keys annotated by the word

SETUP on the LCD. A menu of available settings will be presented

on the LCD. The SETUP annotation only appears when the detector

is attached.

3 Use thekeys to select the Ofs: X.XXX item. The X.XXX

represents the currently set offset, typically 0.000.

4 Press the Menu/Enter key to enter the offset editing mode. The

name of the currently selected detector is shown on the LCD.

5 Use thekeys to move the cursor between the digits of the

offset value. Usekeys to increment or decrement the selected

9

digit. If the cursor is placed underneath the sign of the number

then pressing thekeys will toggle the sign between + and -.

6 Press Menu/Enter to accept the new offset value. The LCD will

revert back to the “detector setup menu”.

7 Press the Escape key to return to the display mode. At this

time the updated offset of the detector is written to the detector’s

memory. Skipping this step or disconnecting the detector

beforehand is equivalent to ignoring the changes made.

4.2.5 ALARMS

The PMA2100 can generate an acoustic and visual alarm whenever the

value of the measured quantity or the accumulated dose exceeds

the preset threshold. The thresholds for “value alarm” and the

“dose alarm” are set independently. The two alarms can also be

independently enabled or disabled.

4 Press the Menu/Enter key to enter the alarm-editing mode. The

name of the currently selected detector is shown on the top of the

LCD and the settings of the alarms are displayed as shown in

Figure 9.

5 One item is marked as currently selected by a frame around it. If

change in settings is needed, then use thekeys to select the

item to modify.

6 If the ON/OFF status of the alarm needs to be changed, simply

press the Menu/Enter key. It toggles the ON/OFF setting.

7 If a threshold value must be changed, then press the Menu/Enter

key in order to enter the number editing mode. Use thekeys to

move the cursor between the digits of the threshold value.

Use keys to increment or decrement the selected digit. If the

cursor is placed underneath the sign of the number, then pressing

thekeys will toggle the sign between + and -.

8 Press Menu/Enter to accept the new threshold value. The LCD will

revert back to the alarm settings.

9 Press the Escape key twice to return to the display mode. At this

time, the updated alarm settings of the detector are written to the

detector’s memory. Skipping this step or disconnecting the

detector beforehand is equivalent to ignoring the changes made.

Figure 8 Generation Of Value & Dose Alarms

Figure 8 illustrates the conditions in which the alarms are generated.

Each time the measured value crosses over the value alarm threshold

the value alarm is generated. Since the accumulated dose cannot

decrease, the dose alarm is generated only once in each integration

cycle, unless the dose threshold was increased during that cycle.

The alarm is indicated by a series of 5 short beeps and an alarm

message appears on the screen with an arrow pointing to the detector

port that triggered the alarm. In addition, the alarm system generates a

pulse on the digital output (See “Digital Control Lines” on page 14).

The status (ON or OFF) and threshold of both value and dose alarm are

preserved in the detector’s memory and automatically applied when the

detector is connected to the PMA2100.

To view or modify the alarm settings, follow these steps:

1 Select the detector to be set up with keys if two are attached.

2 Press the SETUP key to enter the “detector setup mode.” The

SETUP key is one of the function keys annotated by the word

SETUP on the LCD. A menu of available settings will be presented

on the LCD. The SETUP annotation only appears when the detector

is attached.

UVBIO ALARMS

Value Alarm: ON

@ 5.500 uW/cm

Dose Alarm: OFF

@ 20.000 mJ/cm

Figure 9 Example Of Alarm Settings Displayed On

The PMA2100’s LCD For A Detector Identified As “UVBIO”.

2

2

4.2.6 MODE OF OPERATION

Starting with Version 1.13 of the PMA2100 the Mode setting was

introduced that toggles between 2 possible values: Meter and DCS

(Dose Control System). The Meter mode is the primary mode of

operation and all information in this manual is related to this mode.

In the DCS mode the PMA2100 is configured to control the Solar

Simulators manufactured by Solar Light Company.

Any detector whose signal can be integrated with respect to time

can operate either in the traditional “Meter” mode or in the “DCS”

mode. Refer to the PMA2100 Dose Control System Users Manual for

operation in the DCS mode.

3 Use thekeys to select the Alrm... item.

10

5

DATA MANAGEMENT

5.1 DATA LOGGING

The data measurement results can be logged (stored) in the

PMA2100’s non-volatile memory either in automatic or manual mode.

In automatic mode, the data record is logged in user-selectable

intervals. The storage interval for each detector can be set

independently. Refer to “Automatic Data Logging “ on page 9 for

information about setting the data storage interval. When data logging

is enabled the symbol “SXXX” will be displayed in the upper left hand

corner of the LCD display, with XXX indicating the number of minutes

between samples.

In the manual mode, one record of data is logged each time the PRINT

key is pressed. Only the data record for the currently selected detector

is stored and printed. The detector selection can be changed using

the and keys while in the display mode. The data record is then

simultaneously saved in memory and transmitted via the serial port. A

printer or a computer attached to the serial port can print or capture the

data on-line. The manual data logging can also be used at the same

time automatic mode is activated.

The PMA2100 is capable of logging up to 1,024 data records. Table

3 illustrates how the logging interval translates to the maximum

recording time for a single detector. After the data buffer is filled, the

new records will start overwriting the oldest records in memory. Logged

data is preserved when the PMA is powered down or if the battery runs

down since the memory is non-volatile.

If data from two sensors are being logged, maximum recording length

will be 1/2 that shown in Table 3.

Along with the measurement result the following information is stored:

• Date & Time

• Type Of Detector

• Serial Number Of Detector

• Units Used During The Measurement

• User Pre-Set Scale Factor

• Detector Setup Flags

• Detector Calibration Due Date

NOTE: If the integration mode is active, the PMA stores the average

value over the period since the last data point was logged. Otherwise

the instantaneous value is logged.

5.2 DOWNLOADING THE DATA

The data stored in the non-volatile memory can be downloaded to a

computer via a serial communication port (RS232.)

To download the data from the PMA2100 follow these steps:

1 Connect the PMA2100 to an available serial port on the computer

using the cable provided with the meter.

2 Turn the PMA2100 ON.

3 Start the communication software on your computer, such as

Procomm or Windows Terminal.

4 Set the communication parameters of the appropriate serial port

to: 2400,N,8,1. Set the communications program to the ANSI

Terminal Emulation mode.

If the INTEGRATION mode is active, the PMA will store the average value

of the data over the period since the last data point was logged. The

average is based on 1 second samples of the signals. Pressing the

PRINT key will store the average value calculated up to the point

the key was pressed. In both cases the data value averaging will

begin again after the point is logged and will represent the period

between logged samples only. If INTEGRATION is not activated then

instantaneous values are stored.

TABLE 3 DATA BUFFER CAPACITY OF 1024 RECORDS

TRANSLATED INTO RECORDING DURATION FOR A SINGLE DETECTOR

Data Storage Interval [Minutes] Max Data Record length

1

5

10

15

30

60

17 hours

3.5 days

7.1 days

10.7 days

21.3 days

42.7 days

5 To start the download of the data, press the P key on the

computer’s keyboard. The data will be transmitted in a standard

text format. To stop the transmission, press the C key. The first line

of data will contain the serial number of the PMA and the number

of logged data points. The end of data will be indicated by a line

containing END.

6 If the data is to be stored on your PC’s hard drive, activate the data

capture feature of your communication software before starting the

data transfer. For example, in Procomm press the Alt-F1

combination and enter the filename in the pop-up window. Refer to

the manual of your communication program for detailed

instructions about capturing the incoming data.

After the data are stored on the disk, the data buffer may be cleared.

Otherwise, the new data will be appended to the end of the previously

recorded data, which will also be included in the next downloading.

To clear the data buffer follow these steps:

1 While connected to the PMA2100 via a serial port, press the Ctrl-C

11

key combination (hold the Ctrl key and press C).

2 The PMA2100 responds with the following message: Clear data?

(Y/N): Pressing Y in response clears the contents of the entire data

buffer. Any other response preserves the data. Clearing the data

buffer will ensure that only new data points will be downloaded the

next time data is retrieved from the PMA.

5.3 DATA PROCESSING

The data downloaded from the PMA2100 can be imported into any

commercial spreadsheet or data processing package supporting the

import of data in Comma Separated Format.

As an example the steps necessary to import a PMA2100 file into a

Microsoft Excel worksheet are listed:

The data are downloaded in a text format following the template shown

in Table 4.

TABLE 4 FORMAT OF THE DATA DOWNLOADED FROM PMA2100

Detector

Type

Serial

Number

Record

Date

Record

Time

Recorded

Value

Units Flags Calibration

Due Date

TABLE 5 EXAMPLE OF DATA FILE DOWNLOADED FROM THE PMA2100

SN:07587 Rec#0002

31,”02245”,” 2.06.2005”,”14:00:00”, 48.5,”lux “, 1.000,000,”23.04.2006”

31,”02245”,” 2.06.2005”,”14:20:00”, 56.5,”lux “, 1.000,000,”23.04.2006”

END.

The fields are separated by commas. The non-numerical values, such

as serial number, date, time, and units are enclosed in quotes to comply

with the commonly used Comma and Quote Separated Format. Table

6 contains detailed description of the individual fields of the data

record. Refer to “Data Processing” chapter below for additional

information about importing and processing the data.

1 Download the data from the PMA2100 and save in a file called

PMA.TXT.

2 In Excel, place the cursor on an empty page in a cell where you

want the data block to begin.

3 From the menu select Data then Import External Data then

Import Data...

4 In the file selection box, select the file with the data, in this

example PMA.TXT.

5

In the Text Import Wizard Step #1 select Delimited then click Next.

6 In Step #2 select Comma as the delimiter and “ as the Text

qualifier then click Finish.

The data is imported into the spreadsheet and can be manipulated with

the various tools built into the software. A macro can be created in most

spreadsheet programs to automate the import of downloaded data.

TABLE 6 DESCRIPTION OF THE DATA RECORD FORMAT

Field Contents

Detector Type

Serial Number The string containing the serial number of the detector Enclosed In “”

Record Date The date stamp of the measurement. The date is formatted as follows: dd.mm.yyyy

Record Time The time stamp of the measurement. The time is formatted as follows: hh:mm:ss

Recorded Value The measurement result Numerical

Units Units used for measurement result Enclosed In “”

Scale Factor The scale factor effective during measurement. See “Scale” on page 16 for additional information Numerical

Flags Decimal representation of the detector setup flags:

Calibration Due Date The date the detector is/was due for calibration. The date is formatted as follows: dd.mm.yyyy

The last two digits of the detector type. For example the detector PMA2131 has the type code 31

where:

dd = day, mm = month, yyyy = year

where: hh = hours, mm = minutes, ss = seconds

1 Low Pass Filter Active

2 Dose Integration Active

4 Value Alarm Active

8 Dose Alarm Active

16 DCS On/Off

32 DCS Fixed Time On/Off

The flag codes are additive, so if low pass filter is active together with dose integration the value of flags is (1 + 2) = 3

where: dd = day, mm = month, yyyy = year

(see page 8-9)

(average is stored)

(see p. 10)

(see p. 10)

Type

Numerical

Enclosed In “”

Enclosed In “”

Numerical

Enclosed In “”

12

6

INTERFACES

6.1 DETECTOR INTERFACE

The PMA2100 detector interface provides connections for the

PMA2100 can generate a warning, should a conflict occur.

See “Error Messages” on page 8 for further details.

detector’s analog signals, the power for the detector and the digital

interface for the detector’s memory.

Each of the two PMA2100 detector interfaces (ports) provides 2

independent analog inputs, designated Input0 and Input1. Moreover, the

two inputs are available directly as well as through a 1:10 resistive

divider to accommodate larger signals. The direct inputs accept signals

in a range of -0.4V to +0.4V. The dividers extend that range 10-fold.

Table 7 provides detailed functional description of the individual pins.

The inputs of the other port are also available on the pins of each

detector interface in order to handle detectors generating more than 2

voltages. Both the direct and divided inputs of the other channel are

available. If a detector uses more than two analog inputs, then only one

detector at a time can be connected to the PMA2100. The detector’s

memory has an indication of the inputs used by the detector so the

TABLE 7 PMA2100 DETECTOR INTERFACE CONFIGURATION

(BOTH PORTS HAVE THE SAME CONFIGURATION)

Pin Number Signal Description

1

2

3

4

5

6

7

8

9

10

11 -5V power 5mA Max.,

12 +5V power 20mA Max.,

13

14

Shield POWER AND DIGITAL GROUND (connected to pin 13 inside the PMA2100 meter)

ANALOG INPUT 2 -

High Level (1:10 Divider)

ANALOG INPUT 1 Low Level

ANALOG INPUT 2 -

Low Level

ANALOG INPUT 1 -

High Level (1:10 Divider)

ANALOG GROUND

ANALOG GROUND

OTHER DETECTOR’S ANALOG INPUT 2 -

High Level (1:10 Divider)

OTHER DETECTOR’S ANALOG INPUT 1 -

Low Level

OTHER DETECTOR’S ANALOG INPUT 2 -

Low Level

OTHER DETECTOR’S ANALOG INPUT 1 -

High Level (1:10 Divider)

POWER AND DIGITAL GROUND

(connected to shield inside the PMA2100 meter)

DIGITAL I/O

(connected to memory capsule)

VIEW FROM THE BACK OF THE PLUG

2 4 6 8 10 12 14

1 3 5 7 9 11 13

Figure 10 Detector Input Pin Assignment.

±4V Full Scale, 300kΩ Impedance, ESD Protected

±0.4V Full Scale, 29.1 kΩ Impedance, ESD Protected

±0.4V Full Scale, 29.1 kΩ Impedance, ESD Protected

±4V Full Scale, 300kΩ Impedance, ESD Protected

Internally Connected to Power/Digital Ground -

Do not connect to power GND inside the detector

--- As above ---

±4V Full Scale, 300kΩ Impedance, ESD Protected

±0.4V Full Scale, 29.1 kΩ Impedance, ESD Protected

±0.4V Full Scale, 29.1 kΩ Impedance, ESD Protected

±4V Full Scale, 300kΩ Impedance, ESD Protected

80Ω Internal Resistance,

ESD Protected

(THE CABLE END)

Specifications

Short Circuit Protected

22Ω Internal Resistance,

Short Circuit Protected

13

6.2 SERIAL AND EXTENSION PORT

The PMA2100 is equipped with a RS232C serial port allowing

communication with a computer or a serial printer. The serial

communication lines, along with other analog and digital signals,

available on the 25 pin female D-connector located on the bottom of

the meter.

To connect the PMA2100 to a PC, a standard AT modem cable can be

used in place of the one that is provided with the meter. The baud rate

of the serial port is preset at 2400bps, allowing for cable lengths up to

20ft.

Due to the power-saving features built into the PMA2100, the serial

port’s transmitter operates properly only if there is no incoming

transmission, i.e. the receiving line must be in a negative (marking)

state. The PMA2100’s receiver works properly all the time.

TABLE 8 SERIAL COMMUNICATION

AND EXTENSION PORT CONNECTOR

Pin Number Signal Description Specifications

12

24

25

3

3

4

7

RxD -

Data Input

TxD -

Data output

DCD -

Data Carrier Detect Input

GROUND

ANA2

AGND

ANA1

Switching Threshold Approx.

1.5V, with 0.5V Hysteresis;

Accepts Standard RS232C Levels

High State: +5V Low State:

Equal to the RxD’s Low Level

RS232C Levels

Digital Ground

Analog Signal from Right Detector Input

Analog Ground

Analog Signal from Left Detector Input

TABLE 9 PMA2100 TO MODEM CONNECTION

PMA DB25 connector Modem DB25 connector

Pin Number Signal Pin Number Signal

2

3

7

RxD

TxD

GND

3

2

7

TxD

RxD

GND

6.3 DIGITAL CONTROL LINES

The digital control lines of the PMA2100 can be used to control an

external device, such as a relay or valve, acting as a closed loop

feedback system or as a dose controller. An example application is the

monitoring and control of greenhouse temperature and the amount of

light.

The PMA2100’s digital control lines provide 2 optically coupled inputs

and 2 optically coupled outputs designed to connect with control

equipment. The pins of the digital control lines are available on the 25

pin connector, which also accommodates the pins of the serial port.

The outputs DIGO1 and DIGO2 are controlled by the alarm system of

detector port 1 and 2 respectively.

The optically isolated output is normally open (high impedance)

indicated as high state in Figure 11. The output goes low (impedance

of about 3kΩ) when the value alarm is ON and the preset threshold is

exceeded. The output is set high when the signal goes back below this

threshold.

a)

High (Open)

THRESHOLD

VALUE EXCEEDED

The PMA2100 can be controlled from a remote computer via an

external modem. The modem connected to the PMA2100 should be set

to auto-answer in order to pick-up the incoming calls automatically.

The modem’s result codes should be disabled also. For modems

supporting the Hayes AT commands the following programming

sequence is adequate:

AT&D0Q1E0S0=2&C1&W0&Y0

This sequence should be transmitted to the modem from a PC before

this modem is connected to the PMA2100. Only the remote modem

picking up the calls to the PMA2100 has to be set up in this way.

The PMA2100 is not able to dial the telephone number so the calls

cannot originate from the PMA2100. Table 9 shows the cable

connections between the PMA2100 and the modem.

14

Low (Closed)

b)

START PULSE

High (Open)

Low (Closed)

Figure 11 Digital Output Control:

a) From the Value Alarm System b) From the Dose Alarm System

10us<t<100us

DOSE REACHED

50ms<t<200ms

A short pulse (10μs<t<100μs) is generated when the dose integration

is started, either by pressing the START/STOP button or by a pulse on

the digital input. A longer pulse (50ms<t<200ms) is generated if

the dose alarm is ON and the preset dose limit is reached or the

integration is terminated by either pressing the START/STOP key or

applying a pulse (>200ms) to a corresponding digital input.

If both the value and dose alarms are activated, then the value alarm

takes precedence over the dose alarm, i.e. the digital output will be held

low as long as the value threshold is exceeded.

The optically insulated inputs DIGI1 and DIGI2 control the dose

collection on detector port 1 and 2 respectively. A positive pulse at

least 200ms long toggles the dose integration. The minimum pulse

amplitude is 4V. Similarly, the start and stop of dose integration are

flagged at the corresponding digital output (Figure 14.)

7

Figure 12 Digital, Optically Coupled Outputs

Figure 13 Digital, Optically Coupled Inputs

a) Digital Input

High (+4V min)

Low (0)

b) Digital Output

High (Open)

Low (Closed)

Figure 14 Starting Dose Collection From The Digital Input.

DOSE INTEGRATION

STARTED

START PULSE

GENERATED

AT THE

OUTPUT

10us<t<100us

DOSE INTEGRATION

STOPPED

STOP

PULSE

GENERATED

50ms<t<200ms

TECHNICAL SPECIFICATIONS

Detector Inputs

Input Ranges

Resolution

Dynamic Range

Accuracy

Non-Linearity

Operating Environment

Temperature Coefficient

Power Source

Battery Life

Interfaces

Program Control

Size WxDxH

LCD Size

Weight

SPECIFICATIONS

2 Sockets with Up to 2 Analog Signals Each

±0.4V, ±4V, Auto Ranging

15μV on 0.4V Range

5

>2x10

0.5% FS All Ranges

Max. 0.02% FS Within Each Range

32 to 120°F (0 to +50°C)

Max 50ppm/°C

4 x AA NiCd or Alkaline Batteries, 9-12V AC or DC Charger

Up to 40 Hours Between Charges

RS-232 Serial Interface and Opto-Isolated Digital I/O

12-Button Keypad

4” x 1.75” x 7.5” (10 x 4.3 x 19.2 cm)

2.25” x 1.25” (5.7 x 3 cm)

18 oz. (510 grams)

15

8

MAINTENANCE

8.1 METER CALIBRATION

Both the PMA2100 meter and the detectors must be calibrated to

assure accurate measurements.

The analog inputs of the PMA2100 are initially calibrated with an

accuracy of 0.2% and the calibration factors are stored in its internal

memory. The internal real time clock is accurate to within 1 minute per

month. Since there are no mechanically adjustable components in the

meter, its calibration is extremely stable. Nonetheless, the calibration

should be periodically checked. The recommended calibration interval is

one year. The calibration is done in a computerized tester and must

be performed by Solar Light Company for further information.

The calibration of the detectors is independent from the meter’s

calibration. The detector calibration accuracy depends on the type

of detector. It should be performed at least on a yearly basis. The

calibration can be performed by Solar Light Company.

8.2 BATTERY CHARGING

The PMA2100 meter can operate directly from the AC line or from

either rechargeable NiCd or non-rechargeable alkaline batteries. The

battery compartment holds four AA size cells each with a nominal

voltage of 1.2 or 1.5 volts. The polarity of the batteries inserted into

the battery holder should be observed.

NOTE: The NiCd batteries should be fully charged before first use. Never

attempt to charge alkaline batteries.

To charge the NiCd batteries, an external 9V DC power adapter must

be connected with a current capacity of at least 300mA. The charge

controller built into the PMA2100 assures that the batteries are not

overcharged. During the charging cycle, a letter C is shown in the

battery indicator position. It disappears when the battery reaches full

charge. It takes approximately 6 hours to fully charge the NiCd

batteries. When the battery charge is low, a letter B appears. Only a few

minutes of operation are available after the B indicator is activated.

Typically, fully charged NiCd batteries will support operation of the

PMA2100 for more than 24 hours.

BATTERY

CHARGING INDICATOR

H F D! J! CS015

L0.123 H1.245 A0.948

1.234 mW/cm

∑2.354 J/cm

UVA

2

41m 23

2

s

UNITS PRINT SETUP

Figure 15 Battery Charging Indicator.

9

FIGURE

Figure 1

Figure 2

Figure 3

Figure 4

Figure 5

Figure 6

Figure 7

Figure 8

16

TABLE OF FIGURES

DESCRIPTION PAGE

Architecture of the PMA2100 6

The PMA2100 5

Startup Screen of the PMA2100 Meter 6

Display in the “Data Mode” With a Detector

Connected

Display in the “Data Mode” With No Detector

Connected

Pressing the F1 Function Key Converts the

Measurement Result into One of the Available Unit

Systems.

UVB Detector Display Units Shown

Keypad Configuration of the PMA2100 7

Generation of Value and Dose Alarms 10

FIGURE

Figure 9

6

6

6

Figure 10

Figure 11

Figure 12

Figure 13

Figure 14

Figure 15

Example of Alarm Settings Displayed on the

PMS2100’s LCD for a Detector Identified as

“UVBIO”

Detector Input Pin Assignment 13

Digital Output Control: a) From the Value

Alarm System b) From the Dose Alarm

System

Digital, Optically Coupled Outputs 15

Digital, Optically Coupled Inputs 15

Starting Dose Collection from the Digital Input 15

Battery Charging Indicator 16

DESCRIPTION PAGE

10

14

10

INDEX

Alarms......................................................10

Digital Output.........................................14

Applications.................................................5

Audible Signals..........................................7

Averaging...............................................8, 11

Battery

Charging...............................................16

Calendar....................................................8

Calibration.................................................16

Clearing The Data.......................................12

Clock.......................................................7,8

Communication.....................................11,14

Computer Interface.....................................14

Contrast.....................................................8

Controls.......................................................6

Data

Buffer...............................................11,12

Buffer Capacity......................................11

Clearing................................................12

Downloading.....................................11,12

Format..............................................11,12

Importing...............................................12

Logging.............................................7,8,9

Management........................................11

Processing.............................................12

Storage.............................................4,11

Data Mode...................................................5

Decrementing Numbers................................7

Detector Interface.......................................13

Detectors.....................................................5

Inputs......................................................5

Selection..................................................6

Switching.................................................6

Detectors.....................................................4

Connecting..............................................5

Setup..............................................4,6,8,9

Diagnostic...................................................6

Digital Control Lines....................................14

Digital Filter.............................................8,9

Display........................................................6

Structure.................................................6

Dose.........................................................4,6

Downloading..............................................11

Edit Mode....................................................7

Filter.........................................................8,9

Function Keys...........................................7,9

HOLD......................................................7,12

Importing Data.........................................12

Incrementing Numbers.................................7

Indicators....................................................6

Integration....................................7,11,12,14

Interfaces..................................................13

Keypad.......................................................7

LCD Contrast...............................................8

Line Rejection.............................................8

Logging Data..............................................9

Low Pass Filter.....................................8,9,12

Maintenance..............................................16

Menu/Enter..................................................7

Min/Max

Tracking..................................................6

Model Number.............................................6

Modem Connection....................................14

Offset.........................................................9

ON/OFF.......................................................5

PMA2100

Applications.............................................5

Design Concept........................................4

Detectors.................................................5

Features..................................................4

Measuring With........................................5

Setup...................................................7,8

PRINT.........................................................11

Real Time Clock.........................................8

Scale Factor.................................................9

Serial Number..............................................6

Serial Port.............................................11,14

Cable.....................................................14

Setup....................................................11

Setup..........................................................7

Setup Mode.................................................5

Start/Stop....................................................7

Technical Specifications..............................15

Time........................................................8,9

Tracking Min. and Max...........................4,7,8

Tracking Min/Max.........................................6

Troubleshooting.........................................16

Units.........................................................4,7

Conversion..............................................7

17

Loading...

Loading...