Solar Frontier SolarSet 2.0, SolarSet 2.4, SolarSet 4.1, SolarSet 4.8, SolarSet 5.1 Installation And Operating Manual

...Page 1

Solar Frontier Europe GmbH

Installation and Operating Manual

SolarSet 2.0 / SolarSet 2.4 / SolarSet 3.1 / SolarSet 3.6 / SolarSet 4.1 /

SolarSet 4.8 / SolarSet 5.1 / SolarSet 6.1 / SolarSet 7.1 / SolarSet 8.2

ENGLISH

Page 2

2

Page 3

3

Table of contents

1. Preface 5

2. Identication 5

3. General Safety Advice 6

3.1 Safety advice for photovoltaic modules of type Solar Frontier SF170-S 6

3.2 Safety advice for the inverter SF-WR 6

4. Proper Usage 7

5. Scope of Delivery 8

6. About this Manual 9

6.1 Contents 9

6.2 Target group 9

6.3 Markings 9

6.3.1 Symbols 9

6.3.2 Keywords 9

6.3.3 Markings used in the text 9

6.3.4 Abbreviations 10

7. Composition of the Solar Frontier SolarSets 11

8. Installation 12

8.1 Mounting system/ substructure 12

8.2 Mechanical installation of Solar Frontier SF170-S photovoltaic modules 12

8.2.1 Site location 12

8.2.2 Module handling instructions 12

8.2.3 Module mounting instructions 13

8.3 Electrical installation photovoltaic generator 17

8.3.1 Electrical wiring safety precautions 17

8.3.2 Cabling 17

8.3.3 Procedures for electric cabling 20

8.3.4 Grounding 20

8.3.5 Electrical wiring 21

8.4 Installation inverter SF-WR 24

8.4.1 Safety measures during installation 24

8.4.2 Mounting the inverter 25

8.4.3 Preparing the AC-connection 26

8.4.4 Preparing the DC-connections 27

8.4.5 Connecting the inverter and switching on the AC-power 28

8.4.6 Initial commissioning of the inverter 28

8.4.7 Switching on the DC-supply 32

8.4.8 De-installing the inverter 32

Page 4

4

9. Structure and Function of the Inverter SF-WR 33

9.1 Casing 33

9.2 Operating buttons 33

9.3 Display 34

9.3.1 General information 34

9.3.2 Information 34

9.3.3 Settings 36

9.3.4 Service menu 38

9.4 Cooling 40

9.5 Grid monitoring 40

9.5.1 Data communication 40

9.6 Operation 44

9.6.1 Overview of operating functions 44

9.6.2 General operating functions 45

9.6.3 Main operating functions 45

9.7 Self test (mandatory in Italy) 48

9.8 Troubleshooting 50

10. Registration and warranty 53

11. Maintenance 53

11.1 Maintenance Solar Frontier SF170-S photovoltaic modules 53

11.2 Maintenance DC-System 53

11.3 Maintenance inverter SF-WR 53

12. Accessories 54

13. Transport and Storage 54

14. Disposal 54

14.1 Disposal of Solar Frontier SF170-S photovoltaic modules 54

14.2 Disposal of Solar Frontier inverter SF-WR 54

14.3 Disposal of DC-cabling 54

15. Technical Data, Data Sheets and Certicates 55

15.1 Solar Frontier SF170-S photovoltaic module 55

15.1.1 Technical data 55

15.1.2 Certicates for Solar Frontier SF170-S 58

15.2 Inverter 59

15.2.1 Technical data inverter 59

15.3 Technical data AC-cable and line circuit breakers 61

15.4 Table of countries 61

15.5 EU – Declaration of conformity inverter SF-WR 63

15.6 Plugs and Sockets 65

15.6.1 Product information plugs and sockets 65

15.6.2 TÜV certicate plugs and sockets 66

15.6.3 Product information DC-cable 67

15.6.4 EU declaration of conformity DC-cable 68

15.6.5 TÜV certicate DC-cable 69

16. Exclusion of Liability 70

17. Contact 70

18. Notes 71

19. Appendices 72

19.1 Installation SF-WR 72

19.2 AC-plug SF-WR 73

Page 5

5

1. Preface

Thank you for choosing a SolarSet with CIS photovoltaic modules from Solar Frontier. Solar Frontier (SF) oers the highest standards in

creating electrical power from solar energy, and in customer service.

This manual contains important information with regards to the installation, operation, maintenance, cabling and use of the SolarSet,

and the safety instructions involved. To ensure a proper and safe use of the SolarSet, all tips and warnings in this document, as well as

the advice of the manufacturers of the system components should be carefully read, understood and applied. Please make sure that

the installer and operator of the plant obtain a copy of this manual. Please save this document for future use. All applicable local and

national laws and norms should be obeyed during installation, cabling, operation and maintenance of the SolarSet. In case of further

questions please get in touch with your dealer or with Solar Frontier directly.

2. Identication

Type plate of the Solar Frontier inverter Type plate of the SF module

SF-WR

1

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

Barcode for internal purposes

Technical Data –DC-input

Article number and product designation

Manufacturer

Protection Class II and CE symbols

Country of manufacture

Technical Data – AC-output

Protection classication and grid-monitoring standard

Serial number (and barcoded serial number)

2

3

4

5

6

7

1

2

3

4

5

6

7

Certications and protection classes

Serial number (and barcoded serial number)

Name of product

Technical data at STC

Manufacturer and country of manufacture

General product characteristics

Serial number on frame

Figure 1 Figure 2

Manufacturer:

Steca Elektronik GmbH

DC Input:

AC Output:

Voltage: 350 - 845V

MPP Voltage: 350 - 700V

Current: max. 10A

Voltage: 230V, 50/60Hz

Power Factor: 0,95 - 1,0

Current: max. 16A

Power: max. 3600W

Model:

SF-WR-3600, StecaGrid 3600

Art. number:

KIT10001, 749.591

IP classification: IP 21

Overvoltage category: III

According to:

VDE 0126-1-1:A1,

VDE AR N 4105

50,8

57

Made in Germany

SD-010-023-05

MADE IN JAPAN

SF170-S

XXXXXXXXXXXXXX

BARCODE

112

2.20

20.0

2400 33.4

170

87.5

1.95

+10 -5

Page 6

6

3. General Safety Advice

Please ensure all necessary measures are taken to prevent accidents. The use of SolarSets in applications that may endanger human

lives is prohibited, including in air and road transport systems. SolarSets must not be used for anything other than their expressed

purpose.

Solar Frontier strongly advises you to follow the instructions below in order to avoid bodily injury, damage to property and/or death.

SolarSets sold by Solar Frontier GmbH may only be installed by authorized professionals (see 6.2). As soon as it becomes

evident that safe operation is no longer possible (e.g. visible damage), remove the SolarSet immediately from the grid.

3.1 Safety advice for photovoltaic modules of type Solar Frontier SF170-S

• Installation, wiring, and maintenance of SF modules must only be carried out by licensed and trained persons.

• Ensure that all instructions and information related to SF modules and other balance of system components are fully understood

prior to handling and installing a PV solar system.

• The front surface of SF modules should be covered with an opaque material during installation to decrease the potential of electri-

cal shock.

• SF modules only generate direct current (DC) electricity.

• SF modules do not have the ability to store electricity.

• SF modules will experience higher voltage when connected in series and higher electrical current when connected in parallel.

• Only interconnect SF modules with similar electrical characteristics in series or in parallel to prevent system imbalance conditions

and module damage.

• The PV array open-circuit voltage must never exceed the maximum system voltage (including in low temperature conditions).

• Leakage currents could create a shock hazard or re.

• Do not disconnect operational modules or electrical arcing may occur. This may result in serious bodily harm or death.

• Do not use SF modules for purposes other than terrestrial power generation to prevent electrical shock, re or other accidents.

• Do not articially concentrate sunlight on modules using lenses or mirrors.

• Do not use light sources other than natural sunlight and general illumination for power generation.

• Do not use SF modules in water or liquid. There is a serious risk of electric shock, an electric leak or an accident.

• The level of leakage current must be limited in accordance with local regulations for safety reasons.

• Carefully check the polarity of the wiring before installing. Incorrect wiring may damage SF modules or appliances.

• Only use equipment, connectors, wiring and support frames suitable for solar electric systems.

• Wear appropriate protection and take all necessary precautions to prevent electric shock, especially when DC-voltage exceeds

30 VDC.

3.2 Safety advice for the inverter SF-WR

• Install and use the device only after reading and understanding this document.

• Always perform the measures described in this document in the sequence specied.

• Keep this document in a safe place for the entire service life of the device. Pass the document on to subsequent owners and opera-

tors of the device.

• Improper operation can reduce the yields of the photovoltaic system.

• The device must not be connected to the DC- or AC-cables if it has a damaged casing.

Page 7

7

• If one of the following components is damaged, immediately take the device out of operation and disconnect it from the mains

grid and solar modules.

- Device (not functioning, visible damage, smoke, etc.)

- Cables

- Solar modules

• The system must not be switched on again until:

- The device has been repaired by a dealer or the manufacturer.

- Damaged cables or solar modules have been repaired by a technical specialist.

• Never cover the cooling ns.

• Do not open the casing. This will void the warranty and could result in serious bodily harm or death.

• Factory labels and markings must never be altered, removed or rendered unreadable.

• Observe the respective manufacturer‘s manual when connecting an external device that is not described in this document (e.g.

external data logger). Incorrectly connected devices can damage the inverter.

Safety advice on the inverter

4

1

2

3

10min

Isoler les deux sources

avant toute

intervention

Attention

Présence de deux sources

de tension

- Réseau de distribution

- Panneaux photovoltaïques

4. Proper Usage

The SolarSet may only be used in grid-connected photovoltaic systems. The modules, inverter, cables, and connectors have been

mutually calibrated for best performance. The connections may not be grounded.

Potential curves of the photovoltaic voltage V

PV

at 350V and 550V

VPV = Potential between plus and minus poles at the DC-input

1

Dangerous voltages can remain present on the compo-nents up

to 10 minutes after switching o the DC circuitbreaker and the

line circuit breaker.

2

Warning. There are 2 voltage sources present:

powergrid, solar modules.

3

Disconnect both voltage sources from the device beforeworking

on the device: the solar modules via the DC circuit breaker and

the power grid via the line circuitbreaker.

4

Disconnect both voltage sources from the device before

working on the device:

The solar modules via the DC-circuit breaker and the power

grid via the line circuit breaker.

5

Read and follow the instructions!

Figure 3

Figure 4

175 V

175 V

275 V

275 V

320 V

0 V

320 V

U

t

UPV = 550 V

DC (+)

DC (−)

175 V

− 175 V

− 275 V

275 V

320 V

U

t

0 V

− 320 V

U

PV

= 350 V

DC (+)

DC (−)

175 V

− 175 V

− 275 V

275 V

320 V

0 V

− 320 V

U

t

UPV = 550 V

DC (+)

DC (−)

Page 8

8

5. Scope of Delivery

The Solar Frontier SolarSet comprises the following components. The number of components required can be determined using the

list below based on the type of SolarSet you have:

1

Photovoltaic module Solar Frontier SF170-S

2

Solar Frontier inverter SF-WR (incl. Inverter, Mounting plate and AC-plug)

3

Connecting cable (Versions for + and -, with either 2, 3 or 4 outputs)

4

DC-cable (in 50m or 100m)

5

DC-plugs und DC-sockets (5 of each in each package unit)

6

Unlocking tool

7

Installation Manual

2.0 2.4 3.1 3.6 4.1 4.8 5.1 6.1 7.1 8.2

1

SF170-S

12 14 18 21 24 28 30 36 42 48

2

SF-WR-XXXX

1 1 1 1 1 2 2 2 2 2

3

Connecting cable

2 2 2 2 2 4 4 4 4 4

4

DC-cable [m]

50 50 50 50 50 100 100 100 100 100

5

Plugs & Sockets

5 5 5 5 5 10 10 10 10 10

6

Unlocking tool

1 1 1 1 1 2 2 2 2 2

7

Installation Manual

1 1 1 1 1 1 1 1 1 1

Table 1

Not scope of the delivery are:

• Installation scaolding and installation materials

• Tools for installation and confectioning of the cables

Page 9

9

6. About this Manual

6.1 Contents

This manual contains all the necessary information that an installer or professional requires to install the SolarSet and put it into operation. Please note the instructions provided by component manufacturers (e.g. AC-cable, substructures).

6.2 Target group

The target group for this manual are professionals and installers, unless otherwise stated.

„Professionals“ means the persons that:

• Have the necessary expertise and knowledge with regards to the terms and skills needed to install and operate photovoltaic systems.

• Have sucient experience, professionally trained, knowledgeable, and aware of the safety work regulations, applicable laws and

norms of the following:

- Installation of electrical appliances

- Assembly and connection of data cables

- Assembly and connection of power supply lines

6.3 Markings

6.3.1 Symbols

Symbol Description Location

General safety advice Manual

Danger from electricity

Manual

Device

Read manual before use. Device

6.3.2 Keywords

Keyword Description

Danger Immediate danger of death or serious injury

Warning Possible danger of death or serious injury

Caution Possible danger of light or medium injury

Notice

Possible damage to property

Note

Tips on operation or usage of the manual

6.3.3 Markings used in the text

Marking Description

√

Condition for action

Single step

1., 2., 3., ... Several steps in series

cursive

light emphasis

bold

strong emphasis

Courier

Designation of product elements such as buttons, displays, operating state

Page 10

10

6.3.4 Abbreviations

Abbreviation Description

A Current in Amperes

AC Alternating current

ca. circa

i.e.

that is

DC

Direct current

Derating

Power reduction

MSD

Internal grid monitoring of the inverter (Mains monitoring with allocated Switching

Devices).

tot.

total

l

Current

l

k

Short circuit current

I

mpp

MPP circuit current

incl.

inclusive

kVA

Kilovoltampere

kW

Kilowatt

kWh

Kilowatthour

m

Meter

m

2

Square meter

MPP

maximum power point

Nm

Newtonmeter

P

Electrical power

Pa

Pascal

PV

Photovoltaic

SELV Safety Extra Low Voltage

SF

Solar Frontier

STC

Standard Test Conditions

U

Voltage

et al

and others

U

L

Open circuit voltage

U

mpp

Voltage im Maximum Power Point

U

PV

Voltage of the generator at the DC-connection (photovoltaic voltage)

etc.

and so on

V

Volt

W/m

2

Watt per square meter

e.g.

for example

η

Eciency

Page 11

11

7. Composition of the Solar Frontier SolarSets

Solar Frontier currently oers ten dierent Solarsets with nominal power outputs from 2.0 kW to 8.2 kW. The SolarSets consist of Solar

Frontier modules, Solar Frontier inverter(s), the necessary connecting cables, DC-cable and plugs and sockets.

Table shows the exact composition of each SolarSet, including the electrical structure:

Position

Description 2.0 2.4 3.1 3.6 4.1 4.8 5.1 6.1 7.1 8.2

Module

SF170-S 12 14 18 21 24 28 30 36 42 48

Inverter

SF-WR-3000 1 1 1 1 2 2 1

Inverter

SF-WR-3600 1 1 2

Inverter

SF-WR-4200 1

Roof Area

Area in m

2

15,6 18,2 23,4 27,3 31,2 36,4 39 46,8 54,6 62,4

Module

Number in Series 6 7 6 7 6 7 6 6 7 6

Strings

Number parallel 2 2 3 3 4 4 5 6 6 8

Connecting cable

2+ 1 1 2 1

Connecting cable

2- 1 1 2 1

Connecting cable

3+ 1 1 1 2 2

Connecting cable

3- 1 1 1 2 2

Connecting cable

4+ 1 2

Connecting cable

4- 1 2

DC-cable

50 Meter 1 1 1 1 1

DC-cable

100 Meter 1 1 1 1 1

Plugs

5 pces. 1 1 1 1 1 2 2 2 2 2

Sockets

5 pces 1 1 1 1 1 2 2 2 2 2

Unlocking tool Number

1 1 1 1 1 2 2 2 2 2

Table 2

Schematic structure based on SolarSet 3.1

Figure 5 shows the schematic structure of the SolarSet. The modules are connected serially to strings. The outputs of each single string

are drawn together using the appropriate connecting cable. The connecting cables have to be assembled on the spot, and serve to

extend the connection to the inverter.

The connecting cables have two, three or four

outputs depending on the plant size. Cables are

provided for each polarity (plus and minus).

Figure 5

Page 12

12

8. Installation

For a safe installation, all relevant national and local laws, regulations and directives, especially for accident avoidance,

as well as all relevant technical standards are to be adhered to.

8.1 Mounting system/ substructure

The SolarSets are delivered without mounting systems. In general, all mounting systems commercially available, are suitable (e.g. Novotegra (MHH), HatiCon, K2 Mounting Systems, Easy Roof (IRFTS), Schletter, Tritec) provided that the installation is in accordance with

the requirements indicated in 8.2.3. Your installer will be able to suggest a suitable solution.

8.2 Mechanical installation of Solar Frontier SF170-S photovoltaic modules

8.2.1 Site location

• Ensure that the maximum wind and snow loads in local conditions do not exceed the SF module maximum load ratings.

• Avoid installing SF modules in areas where they are exposed to oil vapour and /or corrosive gas.

• Avoid accumulation of grit or dust on the SF modules as it may inuence the output yield.

• Do not expose SF modules to sulphurous atmospheres.

• Do not install SF modules in locations where ammable gases accumulate or ow as there is a risk of sparks from SF PV modules.

• Do not install SF modules near re.

• Avoid installing SF modules in locations where they may be covered by permanent shadows. This may adversely aect their perfor-

mance.

• Do not install SF modules in locations where temperatures exceed the temperature range indicated in the module’s technical

specications

8.2.2 Module handling instructions

• Do not disassemble or modify SF modules. This may result in an electric shock, re or other accidents. Solar Frontier cannot be held

responsible for any loss or damage caused by unauthorized disassembling, modication or misuse of SF modules.

• Do not drill additional mounting holes into the aluminum frame. Only pre-drilled holes should be used.

• Avoid placing any stress onto the SF modules, cables or connectors.

(Minimum bending radius of 39 mm for module cables is recommended)

• Do not stand or step on SF modules. This may result in damage to the module and/ or bodily harm by falling.

• Do not drop SF modules or drop objects onto them. Both sides of the module (the glass surface and the back sheet) are fragile.

• Do not strike the terminal box or pull the cables. The terminal box can crack and break, while the output cable may unplug and

cause electricity leakage or an electric shock.

• Do not scratch the back sheet or cables of the SF modules. Rubbing or scratching may result in an electric shock, electric leakage or

an accident.

• Do not scratch the insulation coating of the frame (except for the grounding connection). This may weaken the strength of the

frame or cause corrosion.

• Do not cover the water drain holes of the frame. Doing so may cause frost damage.

• Do not use glue when closing the cover of the junction box. Similarly, do not use a sealant to bond the junction box lid to its base.

Page 13

13

8.2.3 Module mounting instructions

Mounting structures cautions

• Pay attention to the electrochemical series when selecting support structure material to avoid galvanic corrosion.

• Fasten and lock bolts completely. Inadequate mounting may result in SF modules falling or other accidents.

• Ensure that the SF modules are securely fastened to the mounting support structure that is durable, made of UV and corrosion

resistant material, and follow the applicable local and civil codes.

• Ensure that your mounting support structure is designed to withstand the SF module design snow and wind loads applicable for

the chosen site. Solar Frontier will not be responsible if the SF modules are damaged due to the durability of the mounting support

structure. Please consult your mounting structure manufacturer.

Mounting the solar modules

• PV modules should typically face South in the Northern Hemisphere and North in the Southern Hemisphere for optimal power

production.

• Modules can be installed horizontally (landscape) or vertically (portrait).

• Maintain a space between SF modules and the roof. This will allow air to circulate, cooling the module, and allowing condensation

to dissipate. Solar Frontier recommends a distance of at least 100 mm (3.94 in).

Mounting with Screws

SF modules should be fastened to the support structure using the mounting holes on the frame. The support structure should be

securely fastened to a non-corrosive roof. Tighten the screws with an adequate torque value. Please refer to further instructions and

adequate torque value provided by the screw manufacturer.

Mounting with Inner Holes

Each module will require four M6 (or 1/4 in) bolts with washers, lock washers and nuts. Tighten the screws with an adequate torque value.

UL: Recommended tightening torque is 8 Nm (70.8 lb in) minimum.

TUV: 2,400 Pa (50 lbs/ft2) to the front and back of the module

UL: 1,600 Pa (33.4 lbs/ft

2

) to the front and back of the module

1.5 times the design load is applied to the module during UL testing. 2,400 Pa (50 lbs/ft

2

) is applied to test 1,600 Pa

(33.4 lbs/ft

2

) UL design load.

Landscape (horizontal)

256 mm ±1 mm

745 mm

Portrait (vertical)

256 mm ±1 mm

745 mm

Page 14

14

Mounting with Outer Holes

Each module will require four M8 (or 5/16 in) bolts with washers, lock washers and nuts. Tighten the screws with an adequate torque value.

UL: Recommended tightening torque is 15 Nm (132.8 lb in) minimum.

TUV: 2,400 Pa (50 lbs/ft2) to the front and back of the module

UL: 1,600 Pa (33.4 lbs/ft

2

) to the front and back of the module

1.5 times the design load is applied to the module during UL testing. 2,400 Pa (50 lbs/ft

2

) is applied to test 1,600 Pa

(33.4 lbs/ft

2

) UL design load.

Please refer to further instructions and adequate torque value provided by the screw manufacturer.

Landscape (horizontal)

256 mm ±1 mm

745 mm

Portrait (vertical)

Portrait (vertical)

256 mm ±1 mm 745 mm

174 mm ±1 mm

909 mm

909 mm

174 mm ±1 mm

Landscape (horizontal)

Page 15

15

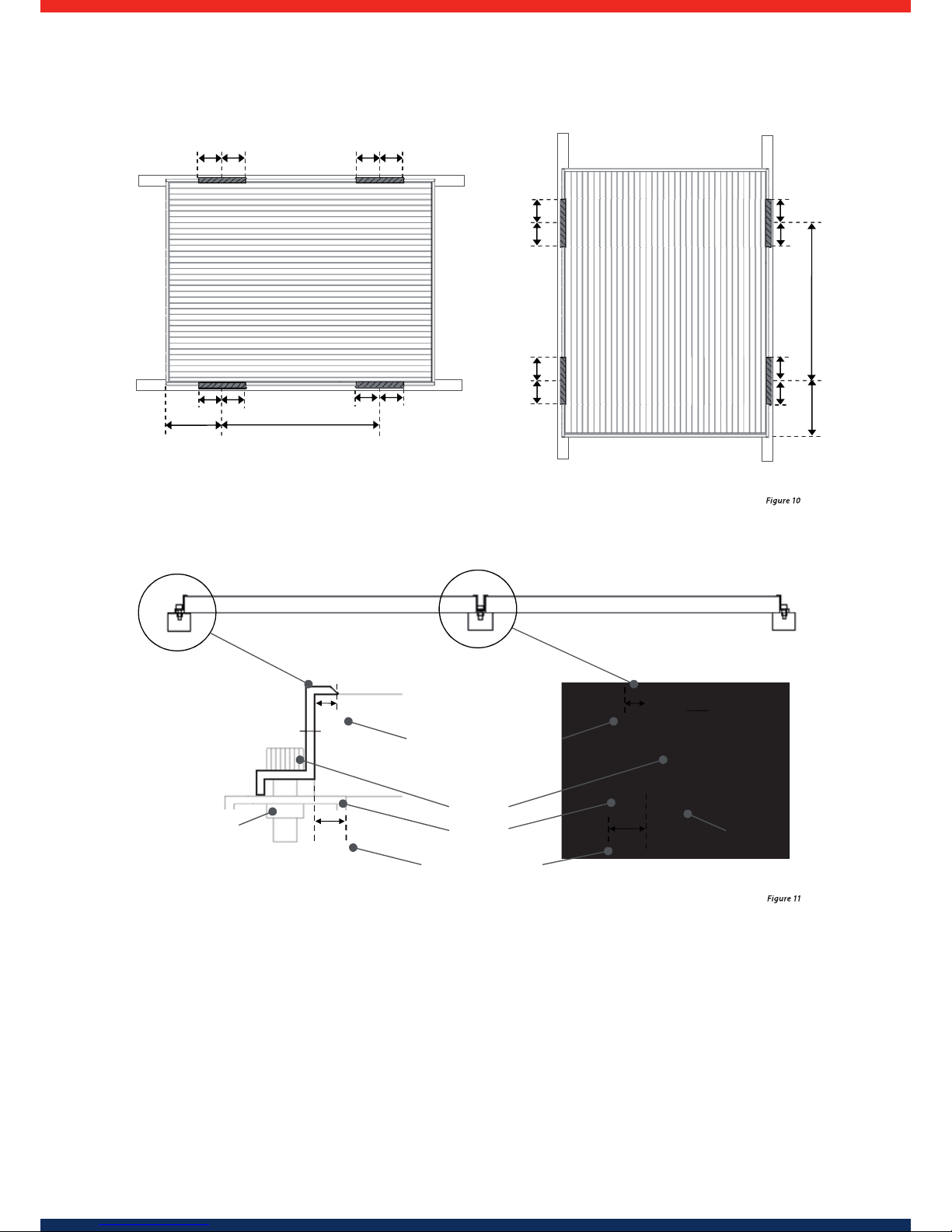

Mounting with clamps

Four or more corrosion-proof aluminum clamps should be used to fasten SF modules to the support structure. Center-line of the

clamps shall be secured within the indicated clamping zone (256 mm +/- 75 mm) from the corners of the longer side of the module

frame using stainless-steel M8 bolts with a minimum length of 20 mm. Tighten the clamps with an adequate torque value.

*1

All selected module clamps must be at least 50 mm long, 3 mm thick, and overlap the module frame by 8 mm or more.

Clamps must not create shadow nor cover the front glass, and shall not deform the module frames during installation. Please refer to

the instructions provided by the clamp manufacturer for further instructions.

*1 UL: Recommended tightening torque is 15 Nm (132.8 lb in) minimum.

TUV: 2,400 Pa (50 lbs/ft2) to the front and back of the module

UL: 1,600 Pa (33.4 lbs/ft2) to the front and back of the module

1.5 times the design load is applied to the module during UL testing. 2,400 Pa (50 lbs/ft2) is applied to test 1,600 Pa

(33.4 lbs/ft2) UL design load.

Module perpendicular to support rails

Landscape (horizontal) Portrait (vertical)

256 mm 745 mm

75 mm 75 mm

75 mm

75 mm

75 mm 75 mm 75 mm 75 mm

75

mm

75

mm

75

mm

75

mm

75

mm

75

mm

7

4

5

mm

25

6

mm

75

mm

75

mm

Array Installation (section)

Landscape (horizontal) Portrait (vertical)

End clamp

Middle clamp

Module

support rail

Bolt

Module

Module

Nut

Module Module

Module

Clamp to module overlap

min 8 mm

8mm

8 mm

3 mm

3 mm

256 mm 745 mm

75 mm 75 mm

75 mm

75 mm

75 mm 75 mm 75 mm 75 mm

75

mm

75mm

75

mm

75

mm

75

mm

75

mm

7

4

5

mm

25

6

mm

75

mm

75

mm

Page 16

16

For alternative mounting methods, please consult Solar Frontier.

Module parallel to support rails

Landscape (horizontal) Portrait (vertical)

256 mm

75 mm

745 mm

75 mm 75 mm 75 mm

75 mm 75 mm

75 mm

75 mm

75 mm 75 mm

75 mm 75 mm

745 mm

256 mm

75 mm 75 mm

75 mm 75 mm

Landscape (horizontal) Portrait (vertical)

Middle clamp

Module

support rail

Bolt

End clamp

Module Module Module

Module

Module

Module to rail overlap,

min 10 mm

10 mm

10 mm

Nut

Nut

8 mm

Clamp to module overlap,

min 8 mm

8 mm

3 mm

3 mm

256 mm

75 mm

745 mm

75 mm 75 mm 75 mm

75 mm 75 mm

75 mm

75 mm

75 mm 75 mm 75 mm 75 mm

745 mm

256 mm

75 mm 75 mm 75 mm 75 mm

Page 17

17

8.3 Electrical Installation photovoltaic generator

8.3.1 Electrical wiring safety precautions

• The sum of Voc of modules in series must not exceed the maximum system voltage of the module under any condition.

Reverse current applied to the modules must not exceed 7 A.

• Do not touch or handle the PV module, terminal box or the end of output cables with bare hands.

• Do not carry out installation when PV modules, installation tools or installation area are exposed to water.

• Ensure that the connection parts between SF modules and power receiving devices are isolated and waterproof.

Using SF modules with insucient isolation and waterproong could result in an electric shock, an electric leak or an accident.

• Keep the wiring box (junction box) and the module connector away from any liquids until connectors are mated. Failure to do this

may cause faulty wiring.

• Components interconnecting the modules must be compatible with the connectors, and must provide system operation and fault

protection.

• Inverters must meet the technical requirements of SF modules.

• Do not connect the PV modules directly to loads such as motors. Variation in output power may damage the motor.

• Observe and understand the safety instructions of batteries. Their misuse can result in serious bodily harm due to high electrical

current.

• Cables should be adequately protected from damage by wildlife

8.3.2 Cabling

Solar Frontier places great value on delivering as many components as possible pre-assembled in order to help avoid sources of error.

Since roof and PV installation has its own specialities, it may be necessary to adapt certain cables on site to t them best (e.g.: connections cables to the inverter shall be cut and assembles on site, and/or extension cable will be necessary to wire around interrupted

strings on the roof of obstacles exist such as chimneys). The DC-cable, sockets and plugs which are included in the SolarSet are for this

purpos. A suitable crimping tool is necessary but excluded of the SolarSet).

Please ensure a clean and proper assembly of the cables to avoid error sources and to ensure safe cabling.

To assemble the cables the following tools are necessary:

- Mounting key (not scope of the delivery)

- Crimping tool for twisted contacts (not scope of the delivery)

- Insulation stripping pliers (not scope of the delivery)

Shortening and stripping the insulation from cables

First, the cable has to be shortened to the proper length. Then the outer insulation is removed with a suitable insulation stripping

pliers to a length of 7 mm.

Ensure that the wires are not damaged – a reduction of the cross-sectional area can result in electrical errors.

Page 18

18

See Figures 12 and 13:

Crimping the twisted contacts

Push the stripped end of the cable into the crimp sleeve as shown in Figure 14 Make sure that all wires are inside the crimp sleeve. The

wires must be visible in the small opening.

To crimp the sleeves use the „hex“ or „4-ident“ crimp die. Put the crimp sleeve with the cable in the respective slot on the crimp pliers.

The crimping tool must be suitable for drilled crimp contacts of the type Amphenol Helios H4. For more detailed information on using

the crimp pliers please consult the operations manual of the pliers manufacturer.

See Figures 15 and 16:

Checking the crimping results

A visual check of the crimping results, and a pull test are needed to ensure a correct crimping.

Figure 17 and Figure 19 show a good result for a „hex“ crimping; Figure 18 and Figure 20 show a good result for a „4-ident“ crimping:

The pull test should be for at least 310 Newton.

Inspection hole

Fig ur e 12

Fig ure 13

Page 19

19

Assembling the plugs and sockets

To assemble the plugs and socket the respective cover should be pushed over the contact until a clear click is heard or felt. The click

shows that the contact is in the right position in the plug/socket. Contacts cannot be released when they have been positioned.

See Figures 21 to 24:

The covering cap is to be tightened with 2.6 to 2.9 Nm. A suitable installation spanner can be used for this purpose.

Connecting and disconnecting the plug/socket combination

Connect the plug and socket to each other. A click shows that the connection has been successful. To open and disconnect the plug/

socket combination a suitable tool is necessary. This could be a disconnecting tool as delivered or another suitable tool.

See Figure 27.

Never disconnect plug/socket combinations when the plant is in operation in order to avoid light arcing, which can lead to

serious injury or death.

Page 20

20

8.3.3 Procedures for electric cabling

The electrical cabling of Solar Frontier SolarSets has to be done as described in Chapter 7, Table 2. Take care that the exact number of

modules in series are connected in accordance with Table 2, and that the respective number of parallel strings is adhered to.

String connection

The serial connection of modules should be done in accordance with 8.3.5, Figure 31 and 32.

Procedure by interrupted strings:

If it isn’t possible to connect modules directly, the plugs, sockets and DC-cable provided can be used to bridge gaps.

An exemplary approach is shown in 8.3.5, Figure 33 and 34. The basics on assembling an extension cable can be found in Chapter 8.3.2

Assembly. Please note that only a limited number of plugs/sockets are provided in the set, and that the cable provided is primarily for

the extension from the generator to the inverter.

If you should need extra material, please ensure that the compatibility to the SolarSet products is conrmed. If in doubt

please contact Solar Frontier.

Connecting the strings

The string connecting cable in the set is used to connect the strings and lead them to a mutual collection point. The number of strings

can be determined in Chapter 7, Table 2.

DC-cable

The DC-cable is used to extend the connecting cables in the PV generator with the inverter. Basics on assembling the cable can be

found in chapter 8.3.2

Connecting to the inverter

The connection of the PV generator to the inverter is described in detail in chapter 8.4. Please ensure that the instructions and procedures described there are strictly adhered to to avoid possible danger sources and to ensure a safe installation.

8.3.4 Grounding

Grounding cautions

• Be aware of the necessary grounding requirements prior to installation. Your local authorities can help you further.

• Install arrestors, surge absorbers or any other appropriate lightning protection tools as needed.

• Module frames, mountings, connection boxes and metal conduits should be connected to an earth ground as lightning protection,

in accordance with local, regional and national standards and regulations.

• Grounding holes (ф 4 mm) on the aluminum frame of the SF modules are provided to accommodate grounding. Use a grounding

wire made of copper, not smaller than 2 mm² (14AWG). Temperature rating of the conductors must be between -40 °C to 85 °C. Ensure that the crimping terminal is tightly tied to the module frame with a rolling thread screw and a lock washer to ensure electrical

contact.

• Grounding devices such as module clamps with an integrated grounding pin, serrated washers, grounding clips or lugs, designed

for bonding photovoltaic modules to the mounting structures may also be used for grounding as described in NEC section 250.

These grounding devices shall be made in conformance with the grounding device manufacturer instructions. Consult the grounding device manufacturer to identify the appropriate grounding and bonding device for your mounting structure or design.

For alternative grounding methods please consult Solar Frontier.

UL: The module with exposed conductive parts is considered to be in compliance with UL 1703 only when it is electrically grounded

in accordance with the instruction presented below and the requirements of the NEC.

Page 21

21

Earth by connecting from

to earth.

Use M4 bolt (torque value 1.5 Nm) or standard gauge size M6 bolt (torque value 1.0 Nm). Tighten the bolts or screw with an adequate

torque value. Please refer to further instructions provided by the screw or bolt manufacturer.

UL: Recommended tightening torque is 1.5 Nm and 1.0 Nm minimum for M4 and standard size M6 bolt respectively.

8.3.5 Electrical wiring

• A set of cables with a plastic connector for each polarity is supplied with SF modules. Use these to connect modules.

• Do not open the junction box.

• Fasten the module cable to the frame or to the mounting system in order to avoid any stress to the connector.

• Cables drooping from the terminal box are hazardous and must be avoided.

• Cables should be secured so they are not exposed to direct sunlight (such as behind the module).

• The sum of Voc of modules in series must not exceed the maximum system voltage rating of the module under any condition, even

at low temperature.

• Reverse current applied to the modules should not exceed 7 A under any condition.

• Minimum cable diameter: 2.5 mm

2

.

Carry out installation and wiring work in compliance with all relevant health, safety and environment laws and regulations.

Grounding (IEC)

Edelstahl-Schraube

Rolling Thread Screw

Lock Washer

Crimping Terminal

Grounding Cable

PV module frame

Grounding with washer (UL)

stainless-steel cupped washer

stainless-steel star washer

stainless-steel nut

stainless-steel bolt

Series connection Parallel connectionJunction box

Page 22

22

Schematic structure of standard module cabling

The standard module cabling is applicable for modules mounted in portrait and landscape direction. Modules connected in series

make up a string. The string cabling can be done as shown in Figure 31 and Figure 32. The strings are picked up with the delivered

connecting cables one on each side and led to a mutual collection point.

Landscape:

Portrait:

Schematic structure of standard cabling with interruption

If obstacles such as windows and chimneys exist on site, it is not possible to mount the modules directly next to each other. In cases

like these, DC-cable, plugs and sockets, which are provided with the kit, could be used as a bridge connection. A simple example is

shown in Figure 33 and Figure 34:

Landscape:

Portrait:

Roof window

Extension Cable

Roof window

Extension Ca ble

Page 23

23

Schematic structure of cross cabling

Those modules connected in series make up a string. The string cabling should be done as shown in Figure 35:

Cross cabling is used only for a portrait installation of the modules, whereby modules are alternately cross connected in series to

optimize the use of the cable length. The serially connected modules make up a string. The strings are picked up with the delivered

connecting cable and led to a mutual collection point. The number of strings and the number of parallel strings can be found in Table 2

on page 11.

Schematic structure of cross cabling with interruptions

If obstacles such as windows and chimneys exist on site, it is not possible to mount the modules directly next to each other. In cases

like these, DC-cable, plugs and sockets, which are provided with the kit, could be used as a bridge connection. A simple example is

shown in Figure 36:

Roof window

Extension Cable

Extension Cable

Page 24

24

8.4 Installation Inverter SF-WR

8.4.1 Safety measures during installation

Observe the following safety notes when performing the work described in section Installation.

Danger

Risk of electrocution!

• Only technical professionals may perform the work described in section Installation.

• Always disconnect all DC- and AC-cables as follows before starting work on the inverter:

1. Turn the AC-circuit breaker to o. Take measures to prevent the system from being unintentionally switched on again.

2. Set the DC-circuit breaker on the inverter to position 0. Take measures to prevent the system from being unintentionally

switched on again.

3. Disconnect the Amphenol Helios H-4 connections of the DC-cables according to the manufacturer‘s instructions. A special tool is

required for this. Warning: DC-cables carry voltage when the solar modules are subjected to sunlight.

4. Pull out the AC-plug from the inverter as described in section 8.4.8.

5. Check that all pins of the AC-plug are free of voltage. Use a suitable voltmeter for this (do not use a simple neon phase checker).

• Do not connect cables to the inverter until explicitly asked to do so in the instructions.

• Do not open the casing of the inverter.

• Connect only SELV circuits to the RJ45 sockets (RS485 interface).

• Lay the cables such that the connection cannot come loose accidentally.

• When laying cables, ensure that no damage occurs to any of the constructional re safety measures in the building.

• Make sure that no inammable gases are present.

• Observe all applicable installation regulations and standards, national laws and connection values specied by the regional power

supply company.

Notice

Danger of damage to the inverter or derating!

• The mounting location must satisfy the following conditions:

- The mounting surface and immediate environment are permanently xed, vertical, at, non-inammable and not subject to

constant vibration.

- The permissible ambient conditions are conformed to; see Technical data Inverter, 15.2.1.

- The following free spaces must be present around the inverter:

Above/below: at least 200 mm:

At the sides/in front: at least 60 mm

• Do not install the inverter in areas where animals are kept.

• Observe the connection ratings specied on the type plate.

• The DC-cables must not be connected to an earth potential (DC-inputs and AC-output are not galvanically isolated).

• Avoid exposing the inverter to direct sunlight.

• The display must be readable on the installed device.

Notice

When transmitting data over a public network:

• Transmitting data over a public network can incur additional costs.

• Data transmitted over a public network is not protected from unauthorised access by third-parties.

Page 25

25

8.4.2 Mounting the inverter

Fastening the mounting plate

Screw the mounting plate to the mounting surface using 4 screws:

• Use screws (and dowels etc.) appropriate for the weight of the

inverter.

• The mounting plate must lie at on the mounting surface and

the metal strips at the sides must point forwards (Figure 37).

• Install the mounting plate vertically with the retaining plate

1

at the top (Figure 37).

Notice

More information on determining the optimum position for the

mounting plate is provided in the attached information sheet.

For Australia only:

Mask o the Protection Class II symbol on the type plate

Notice

When the inverter is used in Australia, the national regulations do

not permit the Protection Class II symbol to be displayed on the type

plate. The inverter is therefore supplied with a smallsticker in the

same bag as the AC plug.

Completely cover the Protection Class II symbol using the small

sticker provided, as shown in Figure 38.

Mounting the inverter on the mounting plate

1. Mounting the inverter on the mounting plate 1, position it 2

in the middle of the mounting plate

1

and press lightly (Figure 39).

2. Lower the inverter into place

3

:

· The hooks on the rear side of the inverter slide over matching

protrusions on the mounting plate.

· The retaining plate on the mounting plate clicks audibly into

place.

3. The inverter must now sit securely on the mounting plate and

can no longer be slid upwards.

Note

The procedure for removing the inverter from the mounting plate is

described in 8.4.8

1

2

3

1

1

1

Page 26

26

8.4.3 Preparing the AC-connection

Line circuit breaker

Information on the required line circuit breaker and the cables to be used between the inverter and the line circuit breaker is provided

in chapter 15.3.

Residual current circuit breaker

If the local installation regulations require the installation of an external residual current circuit breaker, then a Type A residual current

circuit breaker as per IEC62109-1, §7.3.8. is sucient.

Wiring the AC-plug

Danger

Risk of electrocution! Observe the warning notes in 8.4.1!

Grid voltage 220 V ... 240 V

Wire the AC-plug provided as described in 19.2.

Grid voltage 100 V … 127 V

Danger

Risk of electrocution! Never connect one of the phases L1, L2 or L3 to PE or N on the mains grid side.

Note

With a mains grid voltage of 100V ...127V, the inverter can be connected between the L1, L2 and L3 external conductors as follows:

2-phase mains grids

• N and L are connected between the L1–L2 external conductors at the inverter side. See 2 and 3 Figure 40.

• One of the two connected external conductors is connected to PE at the inverter side. This connection can be made within the

AC- plug or in an external junction box.

• Figure 40 shows an example of an inverter-side connection between L1 and PE:

Above: Connection

1

in the AC-plug 5

Below: Connection

4

in an external junction box 6).

3-phase mains grids

• N and L are connected between the L1–L2 or L1–L3 or L2–L3 external conductors at the inverter side.

• Connect the external conductor on the inverter side to PE: as above.

• The external conductor voltages are shown in Figure 40.

Connect the external conductor on the inverter side to PE: as Figure 41.

1. Wire the AC-plug supplied to match the selected external conductors, as described in chapter 19.2. Do not yet close the AC-plug.

2. Connect one of the two connected phases to PE at the inverter side. Make this connection inside the AC-plug or use an external

junction box; see Figure 40.

Page 27

27

1

Connection cable between N and PE with the connection point inside the AC-plug

2

External conductor L1

3

External conductor L2

4

Connection cable between N and PE with the connection point inside the junction box

5

Casing of the AC-plug

6

Junction box

8.4.4 Preparing the DC-connections

Danger

Risk of electrocution!

Opposing Amphenol Helios H4 connectors must be attached to the DC-cable to suit the Multi-Contact MC4 DC-connections

(opposing connectors included in Set).

Observe the warning notes in 8.4.1

Notice

Danger of damage to the inverter and the modules.

Connect the opposing connectors for the DC-connections to the DC-cable, observing the correct polarity.

Attach the Amphenol Helios H4 opposing connectors to the DC-cable according to 8.3.2

33

L1

L2

L3

N

PE

2

5

2

1

33

L1

L2

L3

N

PE

2

5

2

1

3

2

4

5

3

2

6

L1

L2

L3

N

PE

L2

L3

L1

N

100 - 127 V

100 - 127 V

100 - 127 V

L1

L2

N

100 - 127 V

100 - 127 V

Page 28

28

8.4.5 Connecting the inverter and switching on the AC-power

Danger

Risk of electrocution! Observe the warning notes 8.4.1.

1. Push the Amphenol Helios H4 opposing connector of the DC-cable rmly into the DC-connection of the inverter until it audibly

clicks into place.

2. Insert the AC-plug into the socket on the inverter until it audibly clicks into place.

3. Switch on the AC-line circuit breaker. The start page for initial commissioning is shown on the display.

Perform initial commissioning and switch on the DC-supply, as described in 8.4.6 and 8.4.7.

8.4.6 Initial commissioning of the inverter

• Before connecting the PV-system to the grid, ensure that the complete system has been checked, tested and approved in ac-

cordance with the relevant laws, norms, and regulations.

• Depending on local regulations only accredited personnel may connect the PV-system to the grid, and commission it.

Function

Conditions for starting initial commissioning

Initial commissioning starts automatically when at least the AC-connector has been installed and switched on as described previously.

If initial commissioning is not fully completed then it starts anew the next time the device is switched on.

Guided initial commissioning

• Initial commissioning is a guided procedure that sets the following information:

• Display language

• Date / Time

• Country

• Reactive power characteristic curve (if prescribed for the selected country)

Setting the country

The following applies when setting the country:

• The country set must always be the same as the country where the inverter is installed. This causes the inverter to load the prescri-

bed grid parameters for the selected country; more information on this is provided in Table of countries, chapter 15.4.

• The country can only be set once!

• Contact your installer if you have set the wrong country.

• Contact your installer if you cannot select the country where your inverter is installed.

• The country setting does not aect the language used on the display. The display language is set separately.

Page 29

29

Operation

Starting initial commissioning

√ The check list for initial commissioning is displayed.

• The default display language is English.

• The Language entry is selected.

• The check boxes are not selected.

NOTICES

• When a check list item is called up the corresponding check

box is automatically selected.

• The following items are only displayed when the use of a re-

active power characteristic curve is prescribed for the country

currently selected in the Country item:

–Reac. pwr. ch. c. (type of reactive power characteristic curve)

–No. of nodes

1)

–Node 1

1)

–Node 2

1)

–Node n

1) 2)

–Display char. curve

1)

: Is only displayed for reactive power characteristiccurve type

Enter char. curve.

2)

: Is only displayed when no. of nodes has been set to avalue > 2.

• Initial commissioning is completed by calling up the

Finish item.

• Finish can only be performed when all other checkboxes

are selected.

1. Press

to select a check list item.

2. Press SET to call up the item.

The items are described in detail below.

Language

1. Press to select a display language.

2. Press SET. The language is adopted.

3. Press ESC. The check list is shown.

Date format

1. Press to select a date format.

2. Press SET. The date format is adopted.

3. Press ESC. The check list is shown.

Page 30

30

Date

1. Press SET. The date ashes.

2. Press

to change the day

3. Press SET. The change is adopted.

4. Press

. The month is selected.

5. Repeat steps 1 to 3 for the month.

6. Press

. The year is selected.

7. Repeat steps 1 to 3 for the year.

8. Press ESC. The check list is shown.

Time format

1. Press to select a time format.

2. Press SET. The time format is adopted.

3. Press ESC. The check list is shown.

Time

1. Press SET. The hour display ashes.

2. Press

to change the hour.

3. Press SET. The change is adopted.

4. Press

. The minutes are selected.

5. Repeat steps 1 to 3 for the minutes.

6. Press ESC. The check list is shown.

Country selection

Note

The country can only be set once!

1. Press

to select a country.

2. Press SET.

3. Press ESC. The dialogue shown at the left is displayed.

4. Press ESC to select a dierent country by performing step

1and step 2, or

Press SET for a longer period of time (> 1 s) to conrm the

currently selected country.

The check list is shown.

Reactive power characteristic curve

1. Press to select the reactive power characteristic curve

corresponding to to the local regulations.

2. Press SET. The power characteristic curve type is adopted.

3. Press ESC. The check list is shown.

Page 31

31

Number of nodes

1. Press SET. The value ashes.

2. Press

to change the number of nodes.

3. Press SET. The value is adopted.

4. Press ESC. The check list is shown.

Node n

1. Press to select a parameter for the node.

Notice

P % cannot be changed at the rst and last nodes (000 %,100 %).

2. Press SET. The parameter value ashes.

3. Press

to change the value.

4. Press SET. The change is adoptted.

5. Repeat steps 1 to 4 for the other parameters.

6. Press ESC. The check list is shown.

Display characteristic curve

1. The previously set reactive power characteristic curve is

displayed graphically (example in Fig. left).

2. Press ESC. The check list is shown.

Finish

√ Finish has been selected in the check list and SET has been

pressed. One of 2 possible dialogues is displayed.

1. Proceed as follows, depending on the respective dialogue:

• Dialogue Settings are incomplete: Press SET and and work

through the open items in the check list.

• Dialogue Are all settings correct?: Press ESC to correct

settings or

Press and hold SET (> 1 s) to nish initial commissioning.

2. If SET was pressed for a longer time then the inverter starts

anew and synchronises itself with the grid (Fig. left).

Page 32

32

8.4.7 Switching on the DC-supply

Set the DC-circuit breaker on the inverter to position I (Figure42).

After testing via the internal MSD (approx. 2 minutes), the power fed into the grid

can be shown on the display (assuming that sunlight is present).

8.4.8 De-installing the inverter

Danger

Risk of electrocution!

Only technical professionals may perform the work described in section Deinstalling the inverter.

Observe the warning notes in chapter 8.4.1.

Switching o AC- and DC-supplies

1. Turn the AC-circuit breaker to o.

2. Set the DC-circuit breaker on the inverter to position 0 (Figure 43).

Disconnect DC-connections from the inverter

Disconnect the Amphenol Helios H4 to Multi-Contact MC4 connections of the

DC-cable in accordance with the instructions of the manufacturer.

Warning

DC-cables are under current if light falls on the modules.

Disconnect the AC-connection from the inverter

1. As described in chapter 19.2, disconnect the AC-plug from the socket on the inverter.

2. Make sure that all poles have zero voltage – use a suitable voltmeter to do this (do not use a simple neon phase tester).

Removing the inverter from the mounting plate

1. Use one hand to press the retaining plate on the mounting plate

approx. 5mm towards the mounting surface

1

(Figure 44)

2. Use the other hand to push the inverter upwards, far enough so

that the retaining plate no longer latches

2

Release the retaining

plate.

3. Lift the inverter with both hands until the hooks on the rear side of

the inverter are free

3

4. Remove the inverter from the mounting surface

4

3

1

2

4

Page 33

33

9. Structure and Function of the Inverter SF-WR

9.1 Casing

1

Hood

2

Display (monochrome, 128 x 64 Pixel)

3

Type plate, warning notices

4

Operating buttons: ESC, , , SET (from left to right)

5

1x AC-connection

6

2x RJ45-sockets (RS485 bus)

7

1x Minus DC-connection (−) for solar modules

(Multi-Contact DC-socket MC4, contact proof )

8

1x RJ45 socket (Ethernet)

9

1x Plus DC connection (+) for solar modules

(Multi-Contact MC4 DC socket, contact proof )

10

DC circuit breaker (interrupts the plus and minus inputs

simultaneously)

The casing components are explained below.

9.2 Operating buttons

The operating buttons (4 in Figure 45) have the following functions:

Button Action Function general Guided conguration

ESC

Press briey

Jumps up one level Goes back one step

Discards any changes

Press longer (≥ 1 Sec)

Jumps to status display Jumps to the start of the guided conguration

Press briey

Moves the selection bar or the display content upwards

When performing numerical settings, moves the selection 1 position to the left

Increases the value setting by one step

Press briey

Moves the selection bar or the display content downwards

When performing numerical settings, move the selection one position to the right

Decreases the value setting by one step

SET

Press briey

Jumps down one level –

A selected numerical value starts ashing and can be changed; accepts a change;

Changes the state fo a control element (check box/ radio button)

Press longer (≥ 1 Sec) Answers a query dialogue with yes Navigates one step forward

Table 3

11

2

3

14

168 7

10

151

9

Page 34

34

9.3 Display

9.3.1 General information

For information shown in the display (2 in Figure 45) the following generally applies:

• Symbol

: the inverter is processing large amounts of data and is not able to process any user input at this times. The resulting

waiting time is indicated by the animated sun symbol.

• Errors are indicated by a red ashing backlighting. An event message is also displayed at thesame time.

9.3.2 Information

The information shown on the display is described below using illustrative examples.

Status display

3

4

2

2

7 8

9

5 6

1

F

_

The status display shows the following values:

1

Measurement name

2

Measurement in units

3

Date

4

Symbol non-conrmed event messages;

more information on this is provided in 9.11.

5

Animated Connect symbol with 2-digit inverter address;

indicates data trac on the RS485 bus.

6

Derating symbol

7

Symbol Fixed voltage mode activated

8

Time

9

IP address of the device when a network connection has

been established, display alternates with

3

-

7

The following applies to the status display:

• The measurements shown in the status display are dened

under Settings/Measurements.

Some measurements are always displayed (default setting).

• Current values are not displayed at night (solar irradiation too

low; example in Figure left).

• The CO

2

savings shown in the staus display are calculated

using the savings factor of 508g/kWh

Numeric Yield (day, month, year)

2

1

Daily, monthly and annual yield can be shown numerically in a list.

1

Yield period (day/month/year)

2

Individual yields with period and value (one per row)

The yield periods contain the following numbers of individual

entries:

Day yield: last 31 days

1)

Monthly yield: last 12 months

1)

Annual yield: last 30 years

1)

1)

A yield value of 0 is shown when the inverter has not yet been

installed.

Page 35

35

Graphical Yield (day, month, year)

2

2

3

1

4

Daily, monthly, and annual yields can be displayed in a graph.

1

Period for a single yield value

(here: day yield).

2

y-axis:

- Yield in kWh

- With an extra M: yield in MWh

- The scaling changes depending on the maximum value

3

x-axis: time in hours / days/ months/ years.

4

Total of all individual yields shown in the graph, in kWh;

The graphical representation can show annual yields for

the last 20 years.

Event messages (See section 9.8.).

Generator characteristic curve

1

2 3

1

x-axis: input voltage in V

2

y-axis: power in kW

3

Peak = MPP

When the Generator characteristic curve menu item is called, the

inverter records the generator chracteristic curve of the generator and then displays it (see left). The following applies:

• The inverter traverses the input voltage range and records

the power generated over this range. Duration: a few seconds,

is displayed.

• The MPP is the peak of the generator characteristic curve.

• This peak and the generator characteristic curve change with

the level of solar irradiation.

• Multiple peaks are a sign of partial shading (see example on

the left).

• If the top of the curve is at then the inverter may possibly no

longer feed power into the grid.

Information

1

The information menu item contains the following

submenu items:

- Contact information

- Systeminformation (see left):

· Product designation

· Serial number of the inverter

· Information on the software and hardware versions of the

inverter (see example

1

on the left)

· Country setting

· Version of the relevant operating instructions for the inverter.

- Country setting:

currently set country and country-specic grid parameters.

- React.pwr.char.curve: reactive power characteristic

curve (only when prescribed for currently set country

- Network: network parameters, partially congurable under

Settings > Network

· DHCP status: DHCP on/o

· Link status: Network connection state

· IP address: IP address of the inverter

· Gateway: IP address of the network gateway

· Subnet mask: subnet mask of the inverter

· MAC address: hardware address of the inverter

Page 36

36

9.3.3 Settings

The control elements shown on the display, which are used for performing settings in the inverter, are described below using illustrative

examples:

Numerical settings

2

2

1

2

2

2

2

1

Designation of the numerical setting.

2

Value to be set; the selected value to be set is highlighted

in black.

When performing numerical settings of remuneration and dates,

the following applies:

Remuneration

• Possible currencies: £ (pound), € (Euro), kr (Krone), none.

• The maximum value that can be set for remuneration is limi-

ted for technical reasons. The remuneration must be set using

dierent units as required. Example: dollars instead of cents

(set a currency of none).

Date

When setting the month/year, a check is performed to ensure

that the selected day is valid. If not, then the day is automatically

corrected.

Example: 31.02.2011 is corrected to 28.02.2011.

Selection of the measurements

Selection of the measurements to be shown in the status.

The following measurements can be selected:

• Output power: output power of the inverter

1)

• Act. day yield: daily yield from 0:00 until now

• PV-Voltage: voltage supplied by the PV-modules

• PV-Current: current supplied by the PV-modules

• Grid voltage

1)

• Grid current: current fed into the mains grid

• Grid frequency

• Internal temperature: internal temperature of the

inverter.

• Derating: reason for the derating

2)

• Max. daily power: maximum power supplied in the

current day.

3)

• Absolute max. power: maximum power ever fed into

the grid.

3)

• Max. daily yield: max. daily yield achieved

3)

• Operating hours: the operating

hours during which the device has been connected to the

grid (including nighttime hours)

• Total yield: yield since commissioning

• CO

2

saving: CO2-savings achieved since commissioning

1)

Measurement is always displayed (cannot be switched o)

2)

Possible causes:

- internal temperature too high

- User default Power limiter

- frequency too high

- controlled by grid operator (feed-in management)

- delayed increase in power after starting

3)

can be reset to 0 via: settings/reset max. values

Page 37

37

Acoustic Alarm

An acoustic alarm sounds (approx. 4,5kHz) when an event message is displayed.

• Sounds twice: Warning

• Sounds three times: Error

The acoustic alarm is switched of with the factory default

settings.

Backlighting

• o

• automatic: switches on for 30 seconds when a button is

pushed.

• Grid feed:

- Not feeding: switches on for 30 seconds when a button is

pushed; then switches o.

- Feeding: switches on for 30 seconds when a button is

pushed; then dims.

Note:

The following section assumes that you know the parameters required for setting up the TCP/IPnetwork connection. Consult (further)

technical professionals if required.

TCP/IP-Network

Network settings, required for network communication, e. g.

withan Internet portal:

• DHCP: DHCP on/o

• IP adress: IP adress of the inverter

• Subnet mask: subnet mask of the inverter

• Gateway: IP adress of the network gateway

Page 38

38

9.3.4 Service menu

The following section describes the service menu items. Some items have password protection.

You can also obtain the password from our technical support; see chapter 17.

Notice

Risk of reduced yields. Inverter and grid parameters can be changed in the service menu. The service menu may only be used by

professional personnel who can ensure that the changes do not contravene the applicable regulations and standards.

Power limiting

The inverter output power can be manually limited to a minimum of 2000 W. When the power is manually limited, the

Derating symbol is shown in the status display and the

Derating/Cause: User default measurement is displayed.

Fixed voltage

The device can regulate the input voltage to a manually adjustable value. This switches o the automatic setting of the MPP

(MPP tracking). The input voltage can be adjusted over a range

between the maximum and minimum input voltage. Example of

application: fuel cell.

Notice

Before setting a xed input voltage, make sure that the generator is suitable for this.

Otherwise, this may result in yield losses or damage to the system.

Delete country setting

After the country setting has been deleted, the device starts a

new and displays the guided initial commissioning menu.

Factory setting

Resetting the device to the factory setting deletes the following

data:

• Yield data

• Event messages

• Date and time

• Country setting

• Display-language

After the personal settings have been deleted, the device starts

anew and displays the guided initial commissioning menu.

Page 39

39

Voltage limits (peak values)

The following voltage limits can be changed:

• Upper voltage disconnection value

1)

• Lower voltage disconnection value

1)

(Figure left)

1)

The disconnection value relates to the peak value of the voltage.

Frequency limits

The following frequency limits can be changed:

• Upper frequency disconnection value.

• Lower frequency disconnection value (gure left)

• Derating switch-on threshold (because frequency is too high)

• Frequency threshold when switching on again.

Voltage limits Ø (average value)

The following voltage limits can be changed:

• Upper voltage disconnection value

1)

• Lower voltage disconnection value (gure left)

1)

1)

The disconnection value relates to the average value of the voltage.

Reactive power characteristic curve - Overview

4

5

2

2

3

1

The reactive power characteristic curve must be set during initial

commissioning if this is prescribed for the previously selected

country. The following applies:

• 3 characteristic curves are available for selection (see left):

- Default. char. curve (pre-dened)

- Char. curve cos φ = 1 (pre-dened)

- Enter char. curve (manually adjustable)

• After conguration, the characteristic curve is diplayed as a

graph (example left).

1

x-axis, output power P in%

2

y-axis, phase shift cos φ

3

nodes (in example: 4 nodes)

4

arrow symbol overexcitation

5

arrow symbol underexcitation

Page 40

40

Technical details

• Each characteristic curve is dened by 2 to 8 nodes.

• A node is dened by the output power of the inverter (x-axis)

and the associated phase shift (y-axis).

• The phase shift can be set over a range of 0.95 (overexcitati-

on) through 1.00 (no phase shift) to 0.95 (under excitation)

• The type of phase shift is shown in the graph using arrow

symbols dened as follows (dened from the point of view of

the inverter:

Overexcitation - inductive

Underexcitation - capacitive

• The 3 characteristic curves available for selection have the

following properties:

Default char. curve: pre-dened according to the

selected country (example left)

Char. curve cos φ = 1: pre-dened with cosφ =

constantly 1.00. this characteristic curve must be selected if

no reactive power control is to be performed on the device.

Enter char. curve: the number of nodes and their x/y

values can be congured. Exceptions: the rst node is always

located at x(P%)= 0% and the last node is always located at

x(P%) = 100%.

9.4 Cooling

The internal temperature control system prevents excessive operating temperatures. When the internal temperature is too high, the

inverter adjusts the power consumption from the solar modules to reduce the heat dissipation and operating temperature.

The inverter is convection-cooled via ns on the front and rear side. A maintenance-free fan circulates the heat within the closed

casing evenly over the entire surface of the casing.

9.5 Grid monitoring

The inverter constantly monitors the mains grid parameters while feeding the grid. If the grid deviates from the legally prescribed

specications then the inverter automatically switches o. When the grid conforms to the legally prescribed specications then the

inverter automatically switches on again. The legally prescribed specications for the grid parameters are described in the Table of

countries,in chapter 15.4.

9.5.1 Data communication

The device has the following communication interfaces:

• 1x RJ45 socket (Ethernet for TCP/IP network) for communication, e. g. with a central data server

• 2x RJ45 sockets (RS485 bus) for communication with external devices, e. g. a data logger

Data

The inverter can transmit a wide range of data to other devices. Some of this data is shown on thedisplay and certain data is stored in

the internal memory (EEPROM) as described below.

Page 41

41

Displayed data

• Voltage and current of the solar generator

• Power and current fed into the grid

• Voltage and frequency of the power grid

• Energy yields on a daily, monthly and annual basis

• Error conditions, notes

Logged data (EEPROM)

• Event messages with date

• Energy yields on a daily, monthly and annual basis

The storage resolution of the energy yield data is as follows (Table 4):

Energy yield data Storage resolution/Period

10-Minute values 31 days

Daily values 13 months

Monthly Values

30 years

Annual values 30 years

Total yield

permanent

Table 4

Network (TCP/IP)

The device can transfer yield data and event messages via the TCP/IP interface to the Internet portalserver at

http://www.solare-energiewende.de. The yield data can be displayed graphically in theInternet portal as illustrated below.

This service is free of charge for 2 years. The following applies:

• The user must rst register at www.steca.com/portal before the Inter-

net portal can be used.

• The local network settings must be set at the inverter in order to esta-

blish a connection to theInternet portal server. This can be performed

automatically or manually:

Automatically: If IP addresses are automatically assigned in your

network (DHCP), then no settings need to be made at the inverter.

Manually: If IP addresses are not automatically assigned in your

network, then you must manually set the inverter network settings

via Settings > Network, P. 37

• The address of the Internet portal server is permanently stored in the

inverter and cannot bechanged.

• Once the network connection is established, the inverter automati-

cally starts non-encrypted transmission of data to the server.

Notice

The network cable must be disconnected in order to prevent transmission of the data.

Page 42

42

RS485-Bus

The inverter communicates with other devices via an RS485 bus. The following applies:

• The inverter has two RS485 interfaces (RJ45 sockets) on the lower side of the casing.

• The beginning and end of the RS485 bus must be terminated; see P. 43.

• Standard RJ45 cables can be used as bus cables (Cat-5 patch cables, not supplied). Use an alternative data connection cable for

longer connections; see P. 43.

• The inverters connected to the RS485 bus operate as bus slave units.

Notice

The SF-WR has a compatible data interface and can be connected to the RS485 bus as slave.

• If one of the optionally available devices below is connected to the bus, then this device operates as a bus master.

• Only 1 master may be connected to the RS485 bus at any given time.

The following optional available devices support the transfer protocol used by the inverter.

• StecaGrid Vision remote display: display of the data from inverters connected to the RS485 bus.

• Energy management unit StecaGrid SEM

• PC or notebook (with suitable software, for technical professionals only):

– Load rmware updates

– Read inverter information using service software

– An optional RS485nUSB adapter for connecting to the inverter is also available. Theadapter is available from Steca.

• External data loggers, for professional system monitoring:

– WEB‘log (Meteocontrol)

– Solar-Log (Solare Datensysteme)

Note

The correct settings must be made in external data loggers, according to the manufacturer‘sinstructions, before connecting them to the bus.

The wiring diagram of the RS485 bus is shown below.

1

StecaGrid Vision or external data logger

2

First inverter

3

Inverter

4

Last inverter, terminated

5

Standard RJ45 cable (patch cable)

Alternative data connection cable

ATTENTION!

Material damage caused by electrical voltage! The alternative data connection cable may onlybe manufactured by technical professionals.

The alternative data connection cable is a Cat-5 cable for long data connections. The followingapplies to the alternative data connection cable

• The total length of the RS485 bus must not exceed 1,000 m (master/rst inverter to lastinverter)

• Use a 1:1 pin assignment if the alternative data connection cable is connected to the RJ45sockets of the inverters and the data logger

Page 43

43

• Use the pin assignment according to the table below if the alternative data connection cable isconnected to the RJ45 socket of the

rst inverter and to the connector of the data logger.

Device Inverter Solar -Log WEB'log

Signal

Connection RJ45 Terminal strip RJ12

Pin

1 1 1 Data A