WATTrouter Mx - user manual

How to fit and setup the device

Page 1 from 82

WATTROUTER MX - USER MANUAL

FOR MODELS:

WATTROUTER MX (WRMX 01/08/17 AND WT 02/10)

WATTROUTER MX 100A (WRMX 01/08/17 A WT 03/11)

HOW TO FIT AND SETUP THE DEVICE

Document version: 1. 1

Last revision: 10. 9. 2018

Company: SOLAR controls s.r.o.

WATTrouter Mx - user manual

How to fit and setup the device

Page 2 from 82

TABLE OF CONTENTS

General information ................................................................................................................................................ 4

Description of basic function .................................................................................................................................. 5

Packaging contents ................................................................................................................................................. 7

Safety warning ........................................................................................................................................................ 8

Fitting the device ..................................................................................................................................................... 9

Inserting the SC-Gateway module .................................................................................................................... 19

Device configuration ............................................................................................................................................. 20

USB driver installation ....................................................................................................................................... 20

WATTconfig Mx control software installation .................................................................................................. 22

Setting up main function ................................................................................................................................... 23

Setting up CombiWATT mode ........................................................................................................................... 26

Setting up time schedules ................................................................................................................................. 27

ANDI input configuration .................................................................................................................................. 27

Wireless comunication settings ........................................................................................................................ 27

Finishing the configuration ............................................................................................................................... 28

Description of WATTconfig Mx items ................................................................................................................... 29

Main window .................................................................................................................................................... 29

Measured parameters and statuses ............................................................................................................. 30

Input settings tab .......................................................................................................................................... 33

Output settings tab ....................................................................................................................................... 35

Time schedules tab ....................................................................................................................................... 40

Other settings tab ......................................................................................................................................... 42

Statistics tab .................................................................................................................................................. 46

Log tab ........................................................................................................................................................... 48

Options and buttons ..................................................................................................................................... 49

USB/COM driver configuration window ............................................................................................................ 50

LAN/UDP driver configuration window ............................................................................................................. 50

LED statuses .......................................................................................................................................................... 52

Configuration examples ........................................................................................................................................ 53

Example No. 1 – one load only .......................................................................................................................... 53

Example No. 2 – 6 loads, control mode = sum of all phases ............................................................................. 55

Example No. 3 – 7 loads, control mode = each phase independently .............................................................. 57

Example No. 4 – 5 loads, control mode = each phase independently .............................................................. 59

WATTrouter Mx - user manual

How to fit and setup the device

Page 3 from 82

Ethernet network configuration ........................................................................................................................... 61

Local network connection settings ................................................................................................................... 61

Setting up Internet access ................................................................................................................................. 62

Description of web interface and XML communication ........................................................................................ 63

Troubleshooting .................................................................................................................................................... 72

Maintenance and repairs ...................................................................................................................................... 78

Technical specifications......................................................................................................................................... 79

Recycling ............................................................................................................................................................... 81

Declaration of conformity ..................................................................................................................................... 82

WATTrouter Mx - user manual

How to fit and setup the device

Page 4 from 82

GENERAL INFORM ATI ON

WATTrouter Mx is a programmable controller to optimize self-consumption of energy produced by

photovoltaic or wind power plant (hereinafter referred to as PV-plant). It is a smart home energy management

system. After correct installation and configuration, the controller perfectly optimizes self-consumption of

energy produced by your PV-plant. WATTrouter Mx consists of a current sensing module and the regulator

itself.

WATTrouter Mx offers the following functionalities:

Three-phase indirect current measurement.

Single phase detection of voltage necessary to determine the power direction in phase L1, for other

phases it is determined by software.

Evaluation of active power outputs in individual phases, necessary to determine the surplus of

produced electric power.

Regulation based on the sum of power outputs (summary surplus) from all three phases or based on

surplus in each phase.

Switching for up to 8 outputs (2 relays and 6 external solid state relays SSR) based on configured

priorities.

Optimal use of surplus energy produced by PV-plant on SSR outputs through the application of

proportional synchronous regulation of resistive loads, compliant to European standards EN 61000-3-2

and EN 61000-3-3. This regulation modulates connected load's power exactly according to the

available surplus energy.

Very short average dynamic response of the controller (up to 10 s)

Optional CombiWATT function used for switching loads under a combined mode where energy is

taken both from PV-plant and public grid (especially suitable for water heating and also for swimming

pool filtering system).

Input for low tariff signal (nightly low price electricity) for CombiWATT. This is for households where

double tariff rates will apply.

4 multi-purpose ANDI inputs for connection of external current transformers, impulse outputs of

external energy meters, and analog temperature sensors of type NTC or PT1000.

DQ input to connect up to 4 digital temperature sensors of type DS18x20.

Separated current sensing module and regulator for easy installation into existing household wiring.

WATTconfig software designed for Microsoft Windows, Linux and MAC OS X, provides comfortable

controller configuration and monitoring via USB, Ethernet or RS485 interfaces.

Integrated web interface allows comfortable controller configuration and monitoring using regular

Internet browser.

Real-time module backed with a lithium battery for advanced management of outputs and

CombiWATT function.

Daily, weekly, monthly and annual statistics.

Integrated MicroSD card.

Firmware update.

WATTrouter Mx - user manual

How to fit and setup the device

Page 5 from 82

DESCR IPTION OF BASIC FUN CTI ON

The current sensing module measures electric current in real time and on all phases. The regulator evaluates

the measured electric currents and if it determines the available surplus energy produced by the PV-plant, it

will switch on connected loads according to adjustable priorities, while constantly trying to maintain zero

energy flow through the current sensing module, the so called "virtual zero" (the sum of active power outputs

on all three phases = 0) or optionally, on each phase separately, so called "phase zero".

Switching according to priorities is done in the following way:

By default (during night), all loads are turned off. If surplus energy generated by PV-plant is determined in the

morning, the output with the first (highest) priority is switched on.

The switching time is different according to selected output function.

SSR/PWM outputs (proportional outputs) are switched on almost immediately after surplus energy is

detected and the controller is gradually (synchronous control or PWM modulation) maintaining

"virtual zero" or "phase zero", according to the control settings.

Relay outputs are switched on only if the surplus energy exceeds the preset load‘s nominal power.

Alternatively, relay outputs may be operated in "prepend" mode if there is sufficient power at any

proportional output with nearest higher priority. This allows for maximum utilization of the produced

surplus power even for relay outputs - refer to the "Prepend before SSRs" function.

When load with 1st priority is switched on (for proportional output it means switching on the maximum

power), the system waits until the power output of PV-plant increases again (beginning of dawn). If electric

production is determined even when this load is switched on, load with second priority in the same mode is

switched on as well.

If the power output of PV-plant is still increasing, additional connected loads are switched on in the same

mode.

If the power output of the PV-plant decreases, or if another load - not connected to the WATTrouter device is

switched on, the switched (active) outputs are disconnected - again according to preset priorities but in reverse

order (the load with lower priority is disconnected first).

For relay outputs there may be set a minimum switching time. If, simultaneously with a relay output the

proportional output with higher priority is switched on, and the available surplus energy is reduced, then this

proportional output will reduce the power output of the of the load (even down to zero) in order to maintain

virtual zero or phase zero on the current sensing module, if possible.

Except for the situation specified in the paragraph above, the controller never violates the established

priorities.

The above specified principle applies only to standard connection of the current sensing module, connected

right behind the facility’s main energy meter, so the WATTrouter device uses only the actual PV-plant surpluses

(recommended settings). However, WATTrouter controller is versatile device and can be connected according

to your needs. For example, you can place the current sensing module just next to the PV inverter and then you

can maintain the virtual or phase zero on that line.

The above specified basic control mode may be combined with another mode of output switching, provided

that low tariff signal (double tariff rate) is available (CombiWATT mode), or with switching based on preset time

conditions (time schedules).

WATTrouter Mx - user manual

How to fit and setup the device

Page 6 from 82

This device is not designed for precise active power measurement (it is not a replacement for a

wattmeter or electricity meter). Active power is measured with sufficient precision in order to

maintain all control functions.

WATTrouter Mx - user manual

How to fit and setup the device

Page 7 from 82

PACKAGING CONTENTS

Contents of packaging:

1 WATTrouter Mx regulator

1 WATTrouter Mx current sensing module

1 USB cable

1 short manual with links to this manual, software and firmware updates.

WATTrouter Mx - user manual

How to fit and setup the device

Page 8 from 82

SA FET Y W ARN ING

When you receive your package, inspect the packaging unit for damages. After opening

your package, inspect the regulator and the current sensing module for damages. Do not fit

the regulator or the current sensing module if you see signs of mechanical damages!

Always have the regulator and the current sensing module fitted by a person with the

necessary electrical certificate and qualifications. It is necessary that you read this manual

thoroughly and observe all safety warnings and requirements specified herein.

The regulator and the current sensing module must be fitted in a dry room without

excessive dust level. The room must be protected from direct sunlight and the ambient

temperature must be maintained within the range mentioned in chapter Technical

specifications. Do not place the regulator or other electronic components of this system

near flammable objects!

When power SSRs are connected to SSR outputs, it is absolutely necessary to fit these into a

distribution box equipped with adequate heat dissipation system (with ventilation grid or

vents)!

Make sure that unauthorized persons, mainly children, cannot access the location where

the controller is fitted. There is a serious risk of electric shock!

Only connect outputs of the controller to electrical loads which have been designed for this

operation mode and for which the manufacturer does not explicitly prohibit connection via

switching element!

The manufacturer is not liable for any damages occurred due to improper fitting or

operation of the device! The owner is fully responsible for operation of the entire system.

WATTrouter Mx - user manual

How to fit and setup the device

Page 9 from 82

FI TTING THE DEVICE

WATTrouter Mx regulator may be fitted in a regular electrical distribution box onto a 35 mm DIN rail or

attached to a wall using 2 screws with round or countersink head and with diameter up to 6 mm.

WATTrouter Mx current sensing module may be fitted in a regular electrical distribution box onto a 35 mm DIN

rail.

Measuring inputs of the current sensing module may be connected as single, double, or triple-phase

connections.

The recommended maximum distance of the current sensing module and the regulator is 2 meters. Bigger

distance is acceptable, but it will slightly affect the measuring accuracy.

If CYKY or other thick and hard cables cannot pass through current transformers easily, use flexible cables to

extend the existing connections. When fitting the current sensing module do not press hard on it. You may

damage the module.

Tip: Individual phase wires may pass through the current sensing module from either direction. The direction of

currents may be configured in the control software.

To connect power supply to the regulator (L1 and N) use wires with a minimum cross-section of 0.5 mm2, for

example CYKY 1.5.

To connect loads to the relay outputs use wires with adequate cross-section corresponding with the power

ratings of the connected loads.

To connect loads to the power SSRs again use wires with adequate cross-section corresponding with the power

ratings of the connected loads.

To interconnect the current sensing module and regulator (inputs Y and ILx) use 4-wire cable with cross-section

from 0.5 to 1.5 mm2. If these wires are longer than 2m or are placed in a cable tray together with other power

cables/wires, we recommend using a shielded cable. Similar recommendation applies for connecting external

current transformers to the ANDI inputs.

To interconnect power SSR control inputs and/or 0-10VDC control signals with SSR outputs use wires with

cross-section from 0.5 to 1.5 mm2. If these wires are longer than 2m or are placed in a cable tray together with

other power cables/wires, we recommend using a shielded cable.

To interconnect S0 impulse signals from external energy meters with ANDI inputs use 2-wire cable with crosssection from 0.5 to 1.5 mm2, connected between GND and respective ANDI terminal. If these wires are longer

than 2m or are placed in a cable tray together with other power cables/wires, we recommend using a shielded

cable.

To interconnect analog temperature sensors with ANDI inputs use 2-wire shielded cable with cross-section

from 0.5 to 1 mm2, connected between GND and respective ANDI terminal.

To interconnect digital temperature sensors of type DS18x20 to DQ bus use 3-wire shielded cable with crosssection from 0.5 to 1 mm2, connected between GND (ground), +5V (power supply) and DQ terminal (data bus).

When connecting other sensors to the DQ data bus always connect shielding. Total length of the bus including

all branches should not exceed 50m.

Connect shielding of all shielded cables to the GND terminal as close as possible to the regulator.

If you use shielded cables then use for each type of signal a standalone shielded cable, i.e. do not mix signals

from analog and digital sensors in one cable, especially when making the cables longer. There might be

crosstalk which will decrease measurement accuracy.

WATTrouter Mx - user manual

How to fit and setup the device

Page 10 from 82

Figure 1: Connector and LED description (top view).

Regulator terminals - description:

Top left terminal block (this only accepts voltage from public grid!):

L1 – regulator power supply and voltage detection L1, 230VAC/50Hz (must always be connected)

N – neutral wire (must always be connected)

R1_1 – relay output 1 – terminal 1

R1_2 – relay output 1 – terminal 2

R2_1 – relay output 2 – terminal 1

R2_2 – relay output 2 – terminal 2

Top right pluggable terminal block:

GND – signal ground

S1- – external output for SSR 1 – negative electrode (open collector)

S2- – external output for SSR 2 – negative electrode (open collector)

S3- – external output for SSR 3 – negative electrode (open collector)

S4- – external output for SSR 4 – negative electrode (Sallen-Key filter)

S5- – external output for SSR 5 – negative electrode (Sallen-Key filter)

S6- – external output for SSR 6 – negative electrode (Sallen-Key filter)

+12V – external SSR outputs – common positive electrode (+12V with respect to GND)

+5V – power supply for digital temperature sensors DS18x20 (+5V with respect to GND)

Left bottom communication connectors:

USB – USB interface connector (USB B)

LAN – Ethernet interface connector (RJ45, 10/100 Mbit/s)

Left bottom pluggable terminal block:

RS485 A – non-inverting RS485 line

RS485 B – inverting RS485 line

DQ – data bus for digital temperature sensors of type DS18x20

Right bottom pluggable terminal block:

Y – common wire coming from the current sensing module (must always be connected)

IL1 – electric current measuring input L1 from the current sensing module (must always be connected)

IL2 – electric current measuring input L2 from the current sensing module

IL3 – electric current measuring input L3 from the current sensing module

ANDI1 – multi-purpose ANDI 1 input

ANDI2 – multi-purpose ANDI 2 input

ANDI3 – multi-purpose ANDI 3 input

ANDI4 – multi-purpose ANDI 4 input

LT – low tariff signal detection (0V or +5V)

LED description:

PWR – regulator power on light (green)

WATTrouter Mx - user manual

How to fit and setup the device

Page 11 from 82

USB – communication light - USB interface (yellow)

ERR – error status light (red)

S1– external output for SSR 1 - activity indication light

S2– external output for SSR 2 - activity indication light

S3– external output for SSR 3 - activity indication light

S4– external output for SSR 4 - activity indication light

S5– external output for SSR 5 - activity indication light

S6– external output for SSR 6 - activity indication light

R1– relay output No. 1 - activity indication light

R2– relay output No. 2 - activity indication light

RJ45 connector – Ethernet connection indication light (left yellow LED – carrier frequency, right green

LED - connection speed)

Wireless PWR – SC-Gateway power LED (optional accessories)

Wireless LINK – SC-Gateway link LED (optional accessories)

Other connectors:

Micro SD – slot with integrated MicroSD card

Figure 2: Connection terminals of current sensing module WT 02/10 (for WATTrouter Mx ) and WT 03/11 for WATTrouter Mx 100A. The

GND terminal of the WT 03/11 module must be connected to the Y terminal of the controller.

Current sensing module terminal description (the terminals are described directly on the motherboard of the

Mx 100A module):

Y– common wire (must always be connected), on the WT 03/11 module it is marked as GND.

I_L1 – current measuring output L1 (must be always connected)

I_L2 – current measuring output L2

I_L3 – current measuring output L3

Connect the controller according to sample connection diagrams shown on figures below. If you observe basic

principles, connections may be combined in various ways. You may connect any number of loads to any

outputs; in certain cases you may remove certain phase cable from the measuring, etc.

GND I_L1 I_L2 I_L3

WATTrouter Mx - user manual

How to fit and setup the device

Page 12 from 82

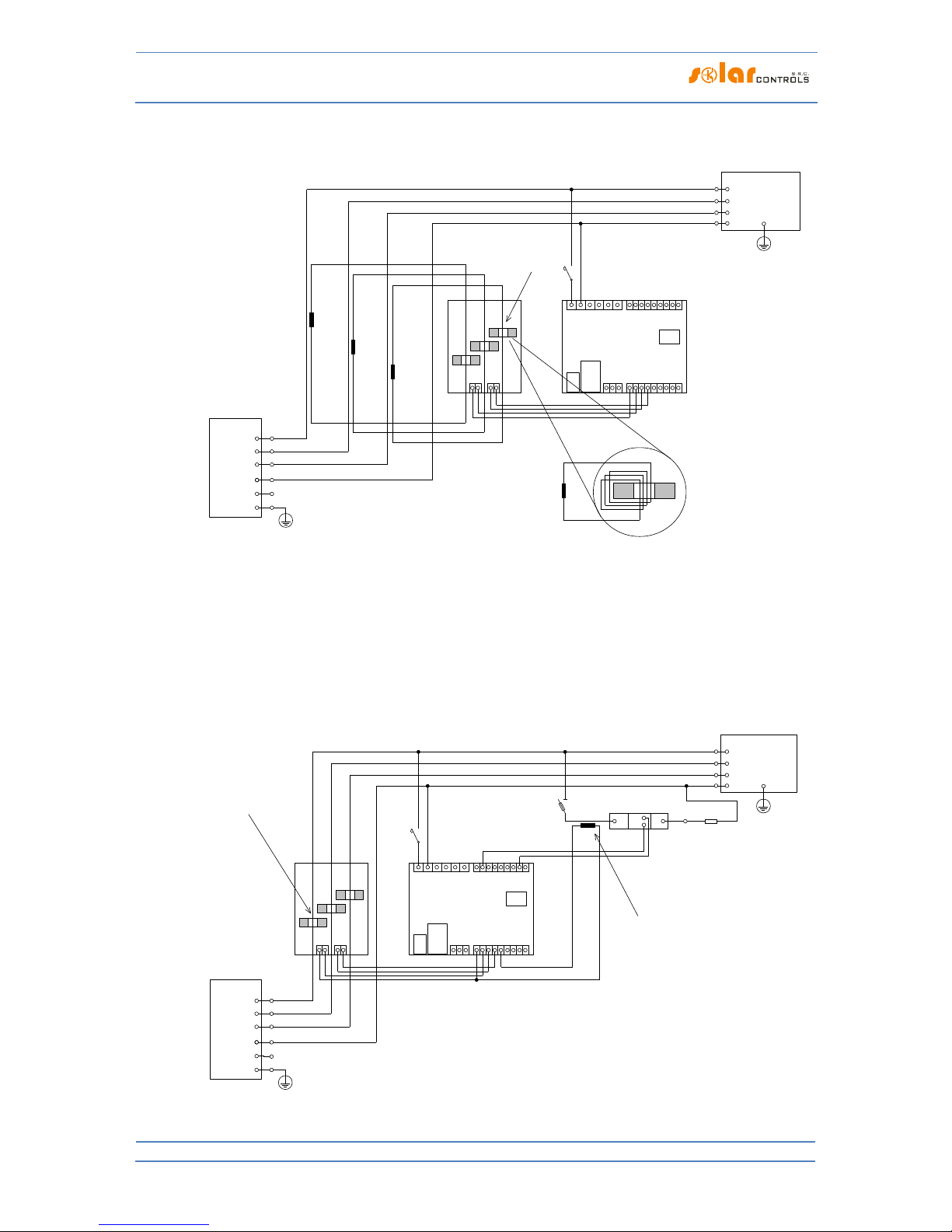

Figure 3: Three-phase connection with low tariff signal circuit for CombiWATT mode, or time schedules. Current sensing module is

placed at the facility’s supply cable coming from the distribution box where main energy meter is located. The connected loads use only

real surpluses produced by PV-plant. 5 loads are connected, 3 of them through the recommended SSRs, RGS1A series manufactured by

Carlo Gavazzi.

Figure 4: Single-phase connection with optional low tariff signal circuit for CombiWATT mode, or time schedules. Current sensing

module is placed at the facility’s supply cable coming from the distribution box where main energy meter is located. The connected

loads use only real surpluses produced by PV-plant. Only 1 load is connected through the recommended SSR, RGS1A series

manufactured by Carlo Gavazzi.

L1

Current sensing module

N

Regulator

IL1

IL2

IL3

B

DQ

Y

LT

ANDI3

ANDI4

ANDI2

R2_1

R2_2

L1

N

ANDI1

R1_1

R1_2

IL3

IL2

IL1

Y

Load 1

(only resistive)

House wiring

+ PV plant

PE

PE

Public grid

connection point

(main energy meter)

Wire goes through

current transformer

Relay 230VAC

LT (low tariff signal)

I > I >

Load 2

(only resistive)

M

1

Load 4

(e.g. motor*)

M

1

Load 5

(e.g. motor*)

Load 3

(only resistive)

I >

B6A

USB

LAN

micro

SD

GND

S2-

S1-

S4-

S3-

S6-

S5-

+12V

+5V

A

RS485

*) Always use separated contactor

for motors and loads with cos(φ)<>1!

L2

L3

L1

N

L2

L3

L1

T1

A1+

A2-

RGS1A60D..

L1

T1

A1+

A2-

RGS1A60D..

L1

T1

A1+

A2-

RGS1A60D..

L1

Current sensing module

N

Regulator

IL1

IL2

IL3

B

DQ

Y

LT

ANDI3

ANDI4

ANDI2

R2_1

R2_2

L1

N

ANDI1

R1_1

R1_2

IL3

IL2

IL1

Y

Load 1

(only resistive)

House wiring

+ PV plant

PE

PE

Public grid

connection point

(main energy meter)

Wire goes through

current transformer

Relay 230VAC

LT (low tariff signal)

I >

B6A

USB

LAN

micro

SD

GND

S2-

S1-

S4-

S3-

S6-

S5-

+12V

+5V

A

RS485

L2

L3

L1

N

L2

L3

L1

T1

A1+

A2-

RGS1A60D..

WATTrouter Mx - user manual

How to fit and setup the device

Page 13 from 82

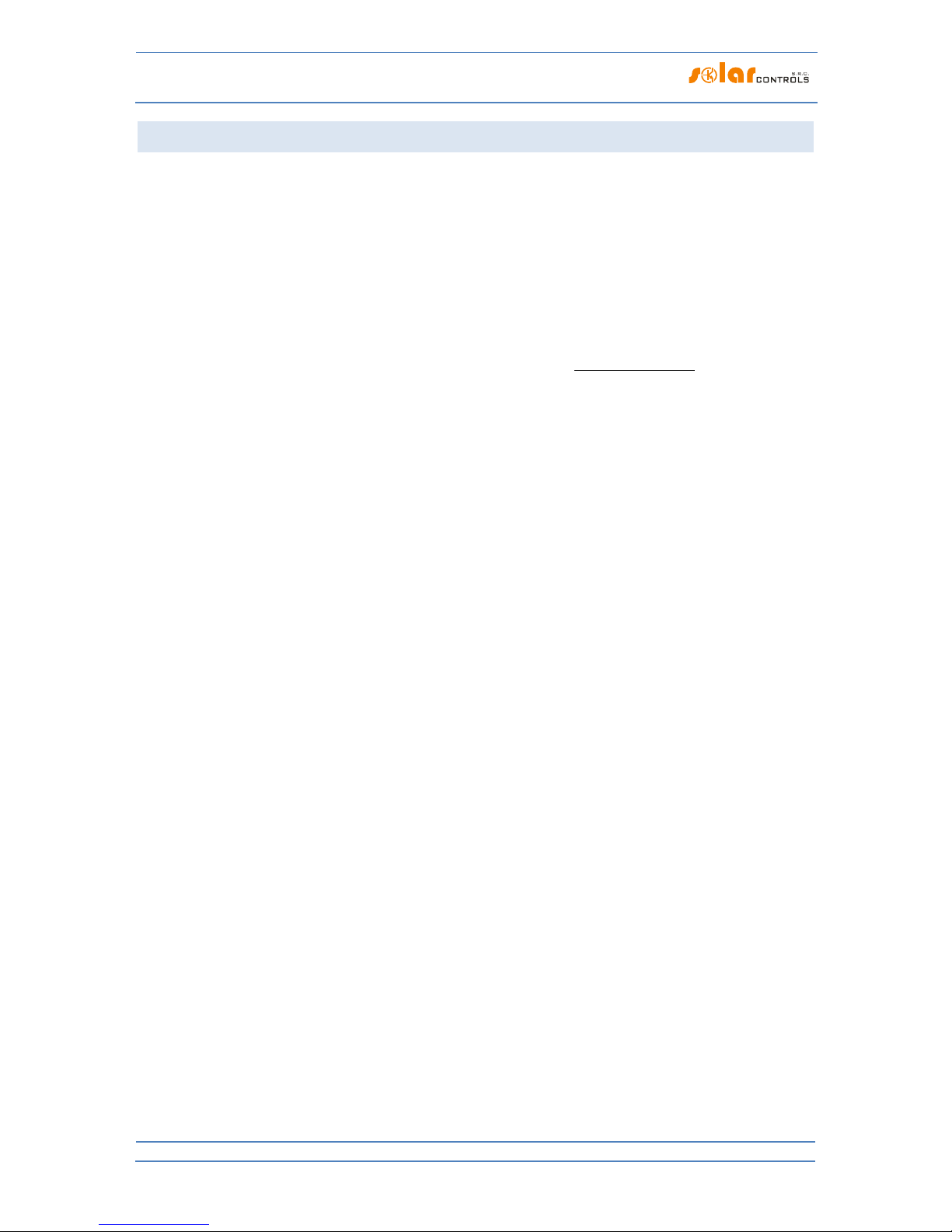

Figure 5: Three-phase connection with 2 current sensing modules and with low tariff signal circuit for CombiWATT mode, or time

schedules. This connection is necessary if the PV-plant output is connected directly to a sealed distribution box, accessible only to the

electricity provider. This may be the case for PV-plants made originally only for feed-in tariff, without self-consumption possibility.

Current sensing module 1 is connected to the household wiring branch; current sensing module 2 is connected to PV-plant branch. The

accuracy of measurement is reduced down to ± 10% in this connection because of the finite impedance of current transformer

secondary winding. Caution: Current flow through current sensing modules must always be subtracted in this connection (marked with

arrows on the picture). The same phase sequence must be observed in the regulator and in both current sensing modules!

Figure 6: Three-phase connection of WATTrouter Mx with 2 regulators and with low tariff signal circuit for CombiWATT mode, or time

schedules. Using this connection you may extend the number of outputs up to 16. Current sensing module is placed at the facility’s

supply cable coming from the distribution box where main energy meter is located. Connected loads use only the actual surpluses

L1

Current sensing module 1

N

Regulator

IL1

IL2

IL3

B

DQ

Y

LT

ANDI3

ANDI4

ANDI2

R2_1

R2_2

L1

N

ANDI1

R1_1

R1_2

IL3

IL2

IL1

Y

Load 1

(only resistive)

House

wiring

PE

PE

Wire goes through

current transformer

Relay 230VAC

LT (low tariff signal)

I > I >

Load 2

(only resistive)

M

1

Load 4

(eg. motor*)

M

1

Load 5

(eg. motor*)

Load 3

(only resistive)

I >

B6A

USB

LAN

micro

SD

GND

S2-

S1-

S4-

S3-

S6-

S5-

+12V

+5V

A

RS485

*) Always use separated contactor

for motors and loads with cos(φ)<>1!

L2

L3

L1

N

L2

L3

L1

T1

A1+

A2-

RGS1A60D..

L1

T1

A1+

A2-

RGS1A60D..

L1

T1

A1+

A2-

RGS1A60D..

Public grid

connection point

(main energy meter)

Only accessible to

provider, PV plant

connected inside.

L1L2L3

N

Current flow

Current sensing module 2

IL3

IL2

IL1

Y

L1

N

PV plant

PE

L2

L3

Current flow

Wire goes through

current transformer

L1

Current sensing module

N

Regulator L1

IL1

IL2

IL3

B

DQ

Y

LT

ANDI3

ANDI4

ANDI2

R2_1

R2_2

L1

N

ANDI1

R1_1

R1_2

IL3

IL2

IL1

Y

Load 1 (L1)

(only resistive)

House wiring

+ PV plant

PE

PE

Public grid

connection point

(main energy meter)

Wire goes through

current transformer

Relay 230VAC

LT (low tariff signal)

I > I >

Load 2 (L2)

(only resistive)

M

1

Load 4 (L1)

(eg. motor*)

M

1

Load 5 (L2)

(eg. motor*)

Load 3 (L3)

(only resistive)

I >

B6A

USB

LAN

micro

SD

GND

S2-

S1-

S4-

S3-

S6-

S5-

+12V

+5V

A

RS485

*) Always use separated contactor

for motors and loads with cos(φ)<>1!

L2

L3

L1

N

L2

L3

L1

T1

A1+

A2-

RGS1A60D..

L1

T1

A1+

A2-

RGS1A60D..

L1

T1

A1+

A2-

RGS1A60D..

Regulator L2+L3

IL1

IL2

IL3

B

DQ

Y

LT

ANDI3

ANDI4

ANDI2

R2_1

R2_2

L1

N

ANDI1

R1_1

R1_2

USB

LAN

micro

SD

GND

S2-

S1-

S4-

S3-

S6-

S5-

+12V

+5V

A

RS485

I >

B6A

WATTrouter Mx - user manual

How to fit and setup the device

Page 14 from 82

produced by PV-plant. To make things simple, again only 5 loads are connected, but you may use all 16 outputs. Similarly, you may also

connect 3 regulators to 1 current sensing module. In such scenario, each regulator works on one phase and you will get 24 outputs.

Figure 7: Increasing of current measurement range of the device for facilities where main circuit breaker is larger than 3x40A.

Transformers 200/5A, or even 400/5A may be used, based on the main circuit breaker value. Secondary coil of current transformers is

shorted through the current sensing module (the secondary circuit passes through measuring transformers in the current sensing

module). Additional increase of current measurement range may be done if you take the secondary circuit of the current transformer

and make several turns through the measuring transformer in the current sensing module (for transformers 200/5A, the best option is

to make 4 turns in order to reach optimum transfer ratio 200/20A). For this purpose we recommend using lines, which are not overrated

for the nominal secondary current, just to be able to make more turns through the hole of measuring transformer. When connected

through external current transformers, the conversion ratio must be set correctly in the control software - see the item Conversion ratio

of external CT‘s in the main window of the WATTconfig software.

L1

Current sensing module

N

Regulator

IL1

IL2

IL3

B

DQ

Y

LT

ANDI3

ANDI4

ANDI2

R2_1

R2_2

L1

N

ANDI1

R1_1

R1_2

IL3

IL2

IL1

Y

House wiring

+ PV plant

PE

PE

Public grid

connection point

(main energy meter)

Wire goes through

current transformer

LT (low tariff signal)

I >

B6A

USB

LAN

micro

SD

GND

S2-

S1-

S4-

S3-

S6-

S5-

+12V

+5V

A

RS485

L2

L3

L1

N

L2

L3

TR

200/5A

Improving range for

current transformer to 200/20A

(make 4 turns through our CT)

TR2

200/5A

TR1

200/5A

TR3

200/5A

L1

Current sensing module

N

Regulator

IL1

IL2

IL3

B

DQ

Y

LT

ANDI3

ANDI4

ANDI2

R2_1

R2_2

L1

N

ANDI1

R1_1

R1_2

IL3

IL2

IL1

Y

Load 1

(only resistive)

House wiring

+ PV plant

PE

PE

Public grid

connection point

(main energy meter)

Wire goes through

current transformer

LT (low tariff signal)

I >

B6A

USB

LAN

micro

SD

GND

S2-

S1-

S4-

S3-

S6-

S5-

+12V

+5V

A

RS485

L2

L3

L1

N

L2

L3

L1

T1

A1+

A2-

RGS1A60D..

TR

Wire goes through

current transformer

WATTrouter Mx - user manual

How to fit and setup the device

Page 15 from 82

Figure 8: Connection of an external current transformer (marked as TR, this may be another current sensing module or other compatible

current transformer) to measure the current flow through the appliance. The secondary transformer circuit is connected between the Y

terminal and any ANDIx input, which must be configured correctly in WATTconfig. In this example, ANDI1 function must be set to power

measurement and the Measurement Source option must be set to SSR1. It is also possible to use an external impulse output meter and

connect this output to the ANDI input, which must then be set to the S0 pulse counter function.

Figure 9: Connection of external meter with S0 impulse output. The meter can measure, for example, the energy produced from the PV

plant. The S0 output of the meter is connected between the GND terminal and the ANDIx input, which must be further configured

correctly in WATTconfig. In this example, the ANDI1 input must be set to the S0 pulse counter function, and the Measurement Source

option must be set to one of the Lx items if the meter measures the PV power produced.

Figure 10: Connection of supported types of temperature sensors to the regulator. The DS18x20 digital sensors are connected three-wire

to the GND, DQ and +5V terminals, analog sensors are connected two-wire between the GND terminals and the corresponding ANDIx

input, which must be correctly configured in WATTconfig. In this example, ANDI3 must be set to NTC and ANDI4 to PT1000.

L1

Current sensing module

N

Regulator

IL1

IL2

IL3

B

DQ

Y

LT

ANDI3

ANDI4

ANDI2

R2_1

R2_2

L1

N

ANDI1

R1_1

R1_2

IL3

IL2

IL1

Y

House wiring

+ PV plant

PE

PE

Public grid

connection point

(main energy meter)

Wire goes through

current transformer

LT (low tariff signal)

I >

B6A

USB

LAN

micro

SD

GND

S2-

S1-

S4-

S3-

S6-

S5-

+12V

+5V

A

RS485

L2

L3

L1

N

L2

L3

Auxilliary energy meter

with S0 impulse output

L1

Current sensing module

N

Regulator

IL1

IL2

IL3

B

DQ

Y

LT

ANDI3

ANDI4

ANDI2

R2_1

R2_2

L1

N

ANDI1

R1_1

R1_2

IL3

IL2

IL1

Y

House wiring

+ PV plant

PE

PE

Public grid

connection point

(main energy meter)

LT

I >

B6A

USB

LAN

micro

SD

GND

S2-

S1-

S4-

S3-

S6-

S5-

+12V

+5V

A

RS485

L2

L3

L1

N

L2

L3

DS18x20

NTC

PT1000

WATTrouter Mx - user manual

How to fit and setup the device

Page 16 from 82

Figure 11: Example for 0-10V signal output from the regulator. The corresponding SSR outputs must be set to the PWM function, and the

desired PWM modulation frequency must be set. The outputs SSR 4 to 6 generate the desired signal directly (but the signal may have a

significant output ripple at slow PWM modulation), SSR outputs 1 to 3 generate only PWM, so you must use external PWM/0-10V

converter to get the desired signal.

Figure 12: Connection of positive SSR anodes (typically A1 +) to an external DC source + 12V when the internal power supply of the

controller is heavily loaded. SSR control circuit can be normally powered by + 12V or + 5V terminals. We recommend the + 12V (must be

used if the control voltage >5V is required). However, using the two built-in relays, the voltage at the + 12V terminal can drop to + 8V

and will not fully drive the SSR 4 to SSR 6 outputs in the PWM / 0-10V function, and some of the built-in relays does not need to be

switched on. In this case, connect all SSRs to an external power source as shown in the figure. Firmware since version 1.5 already checks

the voltage drop at + 12V terminal and also enables software optimization of the built-in relay consumption. For details, see chapter

Measured parameters and statuses and chapter Other settings tab.

L1

Current sensing module

N

Regulator

IL1

IL2

IL3

B

DQ

Y

LT

ANDI3

ANDI4

ANDI2

R2_1

R2_2

L1

N

ANDI1

R1_1

R1_2

IL3

IL2

IL1

Y

House wiring

+ PV plant

PE

PE

Public grid

connection point

(main energy meter)

LT

I >

B6A

USB

LAN

micro

SD

GND

S2-

S1-

S4-

S3-

S6-

S5-

+12V

+5V

A

RS485

L2

L3

L1

N

L2

L3

0-10V

+12V

GND

PWM+

PWM-

+

-

0-10V

(through converter)

+

-

0-10V

(direct output)

PWM function

PWM function

L1

Current sensing module

N

Regulator

IL1

IL2

IL3

B

DQ

Y

LT

ANDI3

ANDI4

ANDI2

R2_1

R2_2

L1

N

ANDI1

R1_1

R1_2

IL3

IL2

IL1

Y

Load 1

(only resistive)

House wiring

+ PV plant

PE

PE

Public grid

connection point

(main energy meter)

Wire goes through

current transformer

Relay 230VAC

LT (low tariff signal)

I > I >

Load 2

(only resistive)

M

1

Load 4

(e.g. motor*)

M

1

Load 5

(e.g. motor*)

Load 3

(only resistive)

I >

B6A

USB

LAN

micro

SD

GND

S2-

S1-

S4-

S3-

S6-

S5-

+12V

+5V

A

RS485

*) Always use separated contactor

for motors and loads with cos(φ)<>1!

L2

L3

L1

N

L2

L3

L1

T1

A1+

A2-

RGS1A60D..

L1

T1

A1+

A2-

RGS1A60D..

L1

T1

A1+

A2-

RGS1A60D..

12VDC

WATTrouter Mx - user manual

How to fit and setup the device

Page 17 from 82

The controller may be connected only to 230VAC, 50 Hz public electric grids. Regulator must be

protected with a circuit breaker - recommended rating is B6A - and connected loads must also be

adequately protected! Installation may only be done when the facility’s main circuit breaker is

turned off!

Upon completion of the installation process make sure to check thoroughly the connection of the

regulator and the current sensing module. Also check connection of all pluggable terminal blocks,

where NO power grid voltage or voltage outside of tolerances specified in the chapter Technical

specifications may be connected! NO other than resistive (heating) loads may be connected to

power SSRs! Regular relays CANNOT be connected to SSR outputs! It is prohibited to connect

loads with higher than the maximum allowed nominal power! If you fail to observe these rules it

is almost guaranteed that you will damage the regulator and lose your warranty!

For the correct operation of the controller, it is absolutely necessary to ensure proper phasing of

the measured currents with the internal voltage detector. This can be done by selecting the

appropriate phase in the Input Settings tab. It is strongly recommended to connect the controller

so that the phase conductor fed to terminal L1 corresponds to the phase conductor wired

through the measuring transformer corresponding to the IL1 input, which will allow the

measurement to match the default settings of the controller (and therefore the same as required

for older models). The IL2 and IL3 current inputs can be connected arbitrarily, the respective

phases for these inputs must be set up correctly in the WATTconfig control software.

We strongly advise you to protect your loads connected to the power SSRs with fuses suitable for

protection of semiconductors, rather than regular circuit breakers. Please note that SSRs

damaged by overcurrent or short-circuit most likely cannot be claimed under warranty. Make

sure that solid state relays are correctly connected, as required by their user manual.

No electronic devices (various measuring and protective elements, such as sub-meters and

residual current circuit breakers) may be installed between the SSRs and the appliance, since

they may be damaged by impulse power! Always install these devices on the line between the

fuse and the solid-state relay where constant power is available.

If your facility is located in an area with higher risk of overvoltage spikes due to atmospheric

discharge (lightning), we strongly recommend fitting a suitable overvoltage/lightning protection

between the distribution box with the main energy meter and the current sensing module!

If any sensors are connected to the ANDI multi-purpose inputs, it is imperative to properly

configure their function, otherwise these and/or even the ILx inputs may not work properly!

The current sensing module supplied with the WATTrouter Mx controller is fully compatible with

the current sensing module supplied with older types of WATTrouter CWx, WATTrouter CWx

SSR, WATTrouter ECO, WATTrouter M and vice versa. The current sensing module installed with

these controllers can be used with the WATTrouter Mx controller (and vice versa). However,

please note: The terminal marked GND for these older measuring modules must be connected to

the Y terminal of the Mx controller, not to the GND terminal!

If the regulator is constantly connected to PC via USB interface (mostly if long cable is used), we

strongly recommend using an USB isolator!

WATTrouter Mx - user manual

How to fit and setup the device

Page 18 from 82

Note: It is allowed to connect only pure resistive loads to power SSRs. These loads cannot be fitted with own

electronic control system nor with built-in motors (e.g. fans - see the note below). These loads may only have

regular mechanically controlled thermostats and indication LEDs or neon lamps. Almost any regularly produced

boilers, immersion heaters, infra radiators, heating floor pads, motor-free dryers (infra dryer), oil heaters,

cartridge heaters in a solar tanks, etc. may be used.

Note: Each SSR output is capable of providing power to heating loads with built-in fan for longer time (such as

hair dryer, heat radiator). These loads are fitted with a built-in thermal protection, which, if synchronous SSR

control mode is used for that load, will disconnect the load for low power of SSR output (in this scenario, the

built-in fan’s power is not sufficient to cool down the heating element of the load). Therefore, consider fitting

these loads to SSR outputs carefully.

Note: Heating loads connected via residual-current circuit breaker may be connected to SSR outputs.

Note: Heating loads with nominal power up to 2 kW may be connected to relay outputs directly, without using

external contactor.

Carefully examine connection of the controller and then turn off all circuit breakers and deactivate fuse

switches for connected loads. Then turn on the main circuit breaker and the regulator circuit breaker (L1 power

supply). The LED PWR lights up (power on indication). If the light is off, or if it does not shine permanently, or if

the LED ERR starts to flash (error status), proceed according to instructions specified in the Troubleshooting

chapter. In default status no output is active and therefore, no load will be turned on.

Now the controller is fitted and ready for configuration.

WATTrouter Mx - user manual

How to fit and setup the device

Page 19 from 82

IN SER TIN G T HE SC-GATEWAY MODUL E

The SC-Gateway module is an optional accessory that provides wireless communication with wireless endpoints. Insert the module to sockets in the regulator according to the images below. Before insertion you must

lift the regulator cover with a small screwdriver or similar tool.

Make sure the regulator is turned off before inserting the module!

Keep the proper orientation of the module. Reverse orientation can damage the module!

Insert the module gently, without unusual force!

Figure 13: Insert the module to sockets on regulator

mainboard, use vertical movement as the arrow indicates.

Figure 14: Resulting position of the module inside the regulator.

After regulator power on, the blue LED on the module must indicate the module initialization sequence, refer

to chapter LED Statuses. In case that does not happen, refer to chapter Troubleshooting.

WATTrouter Mx - user manual

How to fit and setup the device

Page 20 from 82

DEVIC E CONFIGURATION

You will need notebook or regular PC (placed closely enough to the regulator) with USB interface (hereinafter

referred to as a computer only). The controller is configured using the WATTconfig Mx control software. The

installation package for this software is available on manufacturer’s web pages. Before installing the

WATTconfig Mx control software you need to install the driver for USB interface.

In order to connect to the USB interface, it is necessary - due to safety reasons - to turn off the

entire distribution box before manipulation.

Tip: After you configure Ethernet network connection you may perform all settings including firmware update

over the Ethernet interface. You do not need to use the USB interface at all, provided that the parameters of the

connected LAN are the same as the default controller parameters (see below), and if there is no conflict

between IP addresses or conflict between physical MAC addresses.

Tip: The controller can be monitored and configured via the RS485 interface using the WATTconfig Mx software.

An appropriate USB/RS485 converter is required to connect to this interface using a PC. The RS485 interface is

reserved for various other protocols (such as MODBUS RTU) which might be implemented in future.

If you cannot continue with the settings (due to any reasons), proceed according to instructions specified in the

Troubleshooting chapter.

US B D RIV ER INS TAL LAT I ON

The installation procedure is described for Windows XP, English locale. The procedure is similar for newer

systems, or it is much simpler (Windows 7).

1. Insert the attached USB cable to the USB connector of the regulator and then to the computer.

2. Turn on the controller. The green LED PWR must light up (power on indication). Also the yellow LED

USB light will or should flash briefly (communication process indication) as the USB device will start to

register in your computer.

3. After a moment, following window must appear confirming that a new device was found:

WATTrouter Mx - user manual

How to fit and setup the device

Page 21 from 82

4. Select: No, not this time. In the following window select: Install from a list or specific location

(Advanced).

5. Select the path to the driver file:

WATTrouter Mx - user manual

How to fit and setup the device

Page 22 from 82

6. The driver has been installed successfully, if this window appears:

7. During the installation there might appear a warning about an invalid digital driver signature. Just

ignore it. The device is registered in your system device manager as USB serial converter (menu

Universal Serial Bus Controllers)

8. You must perform the same installation process for the second USB serial port device.

WATTC ONF IG MX CONTRO L SO FTWARE INSTA LLATIO N

WATTrouter Mx - user manual

How to fit and setup the device

Page 23 from 82

1. Turn on the PC.

2. Run WATTconfig_Mx_Setup.exe which you may download from manufacturer’s web pages.

3. Follow the on-screen instructions.

SE TTI NG UP MAI N F UNC T ION

1. Click on START button in your PC and run the WATTconfig Mx control software. The system will display

the main software window.

2. Make sure that the controller is turned on and connected to your computer. Make sure that USB

interface driver is correctly installed.

3. Select USB interface connection mode (field next to the "Connect" button).

4. Select correct port for connection. This can be done in the dropdown menu Port in USB/COM driver

configuration window, which will show up by clicking on button Configure connection.

Note: Unlike WATTrouter CWx or WATTrouter M devices the WATTrouter Mx uses a serial port connection

(COMx). This port is always virtual port because the controller is connected via USB. Once more ports are

displayed, it is necessary to check in Windows device manager, which port is assigned to USB Serial Port.

5. Click the "Connect" button. The controller should be now connected and the connection indicator (a

stripe) should be displayed in green. If it is not, and the system displays an error message, wait until

the USB driver is ready for use in your PC, or inspect the settings in the USB driver configuration

window. You may display the window by pressing the Configure button.

6. After establishing successful communication, you should be able to see the current measured values

(power outputs on individual phases, etc.). No outputs should be active ("unused" priority). Also no

time schedules should be used.

7. Now you can configure measuring inputs. This can be done on the "Input settings" tab. First, you set

the phase sequence and then the direction of current flows through the current sensing module.

a. Setting up phase sequence: Turn off the PV-plant and turn on a resistive load on each phase

which will be involved in the measuring process. The system will display measured active

power on each individual phase. For now, you may ignore the signs of the measured power

values. Now, in the Phase field select corresponding phase, based on the actual status

recognized by the controller, and press Write button. The configuration will be saved in the

controller. If the output values measured on individual phases differ too much from the

reality, change the phase for given input and again press the Write button. Repeat these

steps for all 3 inputs IL1, IL2 and IL3 until all measured powers are displayed correctly.

b. Setting up the direction of current flows through the current sensing module: As specified in

the previous steps, leave loads on measured phases switched on. When the PV-plant is

turned off, all measured power output values must be smaller than 0 or equal to 0. If any of

the measured power outputs is positive it means that the phase wire is passing through the

current sensing module in a reverse direction. Use the Current orientation field for the

relevant phase, select the reversed option and press the Write button. The configuration will

be saved in the controller. Now, all measured power outputs must be <= 0. Turn the PV-plant

on and turn off all loads. Now, measured outputs must be positive (>=0). If they are not, or if

the measured values do not correspond with nominal power ratings of the connected loads,

or if they do not correspond with the power output of the PV-plant, you have either still

connected another loads (which you don‘t know about, such as various loads in stand-by

mode, etc.), or the phase sequence in voltage or in current inputs does not match, or you may

WATTrouter Mx - user manual

How to fit and setup the device

Page 24 from 82

have a defect in household wiring. In any case, make sure to inspect the entire electric

wiring.

c. You can verify the correctness of measurement input configuration by using the chart "Input

checking oscilloscope". This chart shows measured current waveforms in selected phase,

values are given in units of the built-in A/D-converter (digits), these are not normalized to

amps due to performance. This feature should only aid the fitter when configuring the

measuring inputs. Always verify with a resistive (heat) load only, so that the phase shift

between voltage and current is zero ( )! Moreover, in order to verify the

measuring inputs the amplitude of current half-wave should always be greater than 1000

digits (to be sure about the correctness of the settings).

Note: During normal operation there may be shown even "exotic" waveforms. Be sure this is

the real current flowing through the phase wire, a superposition of currents flowing through

the connected appliances which are not always sinusoidal or their power factor varies from

one.

Figure15: Input is fitted correctly - sine wave of the current flowing through a resistive (heat) load is in phase with the voltage.

WATTconfig shows negative values on selected phase (consumption). Left image appears when there is normal (default) current flow

direction, right image appears for opposite direction. Note: The PV-inverter throughput appears exactly as the opposite, because the

current is anti-phased with the voltage. If the inverter performs power factor compensation you can observe corresponding phase

shifts.

Figure 16: Input is fitted incorrectly - sine wave of the current flowing through a resistive (heat) load is not in phase with the voltage and

either precedes (image left) or lags behind (image right) the voltage by 1/3 of mains half-wave. Measuring inputs are fitted incorrectly

and you need to select correct option in the Phase field for respective input.

8. After a successful setup of measuring inputs you may begin to test outputs. This can be done on the

"Output settings" tab. Each connected load must be tested separately. Turn on circuit breaker or

activate fuse switch for the first output, and press the TEST button for the corresponding output. The

load should switch on. When the load is switched on, the active power drawn by connected load must

be detected by the current sensing module on the relevant phase.

WATTrouter Mx - user manual

How to fit and setup the device

Page 25 from 82

9. After you have successfully tested all outputs, you may begin to configure the control mode in the

Control settings field. This can be done on the "Other settings" tab. Set this mode either to "sum of all

phases" or to "each phase independently", based on the configuration of your 4-quadrant energy

meter. If you are not sure how your energy meter is configured, please contact your electricity

provider or use the "each phase independently"-mode, which works for any configuration of the

energy meter.

In order to use the "each phase independently"-mode, it is necessary to select correct phase for each

output, i.e. phase where the corresponding load is really connected. Controller will then try to

maintain zero energy flow in each phase ("phase zero"). You may check correct phase assignment

again through the TEST button. Within a short time after pressing the button the active power drawn

by connected load must be detected by the current sensing module on relevant phase.

As far as your energy meter is configured to evaluate sum of powers in all phases, you may use the

mode "sum of all phases". Here the controller will try to maintain virtual zero energy flow. This means

that for output switching it takes the sum of measured powers from all 3 phases ("virtual zero"). Here

you may try experimenting with both methods, but it is recommended to use "sum of all phases"mode, because it is more effective for the user.

10. After a correct setup of the control mode, you may start to assign priorities and power ratings for

individual outputs. This can be done on the "Output settings" tab. Select priorities of individual loads.

The switching process based on priorities may be described as follows:

By default (during night), all loads are turned off. If PV-plant production (available surplus energy) is

determined in the morning, the output with the first (highest) priority is switched on. The switching

time is different for proportional outputs (their function equals to proportional or PWM) and relay

outputs. Proportional outputs are switched on almost immediately (this is the proportional switching),

but relay outputs are switched on only if the available surplus energy exceeds the value specified in

the Connected power field (there is also a different solution available – see the "Prepend before SSR"

function). When the load is switched on (for proportional output it means the load is switched to the

value specified in the Maximum power field), the system waits until the power output of PV-plant

increases again (sunrise). If additional available surplus energy is determined when the load with first

priority is switched on, then load with second priority is switched on in the same mode. The same

applies to all outputs. If the available surplus energy decreases, or if another load in the household is

switched on, active outputs are disconnected according to preset priorities but in reverse order (first,

the load with the lowest priority gets disconnected).

The value in the "Connected power" field should be equal to the power rating of the connected load.

For relay output it must be higher or equal to the power rating of the load, otherwise the controller

will not operate correctly, and the load will be repeatedly turned on and off. For proportional output

this value only configures the control dynamics, but it should be also equal to the actual power rating

of the load.

The fields On-delay time and Off-delay time for relay outputs specify the time delay to switch the relay

on or off after a condition has been detected to do so. This feature is necessary for loads which cannot

be switched on frequently.

Set outputs according to the connected loads and based on your priorities and then press the Write

button. The configuration will be saved in the controller. Now the main function of the controller

should be configured.

11. Test the main function of the controller, or possibly, modify priorities for outputs and power settings

of connected loads.

WATTrouter Mx - user manual

How to fit and setup the device

Page 26 from 82

SE TTI NG UP COM BIW ATT MOD E

After you have successfully tested the main function, you may start to configure CombiWATT mode, provided a

low tariff signal is connected to the controller (it may be used even if single tariff rate is present – see notes

below). This can be done on the "Output settings" tab. CombiWATT mode provides constant daily energy

supply to the connected loads. This mode is indispensable if you need to heat up water but also e. g. if you use

a swimming pool filtering system during cloudy days or when your PV-plant is temporarily out of order. In

CombiWATT mode, energy is taken both from PV-plant and from public grid.

Determine the optimal value of energy in kWh for the connected load (for example for a boiler or immersion

heater), which you plan to supply the load with every day. For example, for a boiler it is suitable to determine

the value of electric energy based on the average consumption of hot water. Usually, electric energy necessary

to increase the temperature of hot water by 40°C equals to:

3600000

][*][*

][

KTlVc

kWhE

V

. If you enter it

into the formula you will get:

][*0464.0][ lVkWhE

. For a 180 liter boiler it will be 8.36 kWh. We

recommend to increase this value by the daily heat loss of the boiler and also to modify (reduce) the value

based on the actual average consumption of hot water.

Note: If you are heating water for example, the controller does not "know" how hot the water in the boiler is

and therefore, the assumed values of the supplied electric energy may be higher than the actual delivered

energy (the boiler thermostat may shut it off at any time). If you want to count only real supplied energy to the

boiler then connect additional measurement for it according to Figure 8.

Mark the CombiWATT field for the relevant output (output must be activated, which means that the output

must be assigned with the relevant priority), enter the established value of the daily electric energy in kWh and

press the Write button. The configuration will be saved in the controller.

The CombiWATT mode is activated only if ALL the following conditions are met:

a. The output is activated (priority has been assigned to the output - that means the output is

not in the "not used" status).

b. PV-plant does not produce electric power (active powers at all measured phases are <= (less

or equal to the) CombiWATT production limit field).

c. During the day, PV-plant did not supply the load with the required amount of energy, that is,

the field "Supplied energy" is lower than the value specified in the "CombiWATT [kWh]" field

for the relevant output.

d. Low tariff signal has been detected (the info LED "low tariff" is red). Energy from public grid is

always consumed in CombiWATT only if low tariff is present. See note below to learn how to

configure this mode if you don't have double tariff rate.

e. The "Time to activate CombiWATT"-field shows zero.

The CombiWATT mode is deactivated if some of the following conditions will apply:

a. The value in the field "Supplied energy" reached the "CombiWATT [kWh]" value for the

relevant output.

b. PV production has been detected at some of the measured phases (active power at some

measured phase is > (greater than the) CombiWATT production limit field).

c. The low tariff signal is turned off.

Reset of energy counters (that is reset of values in the fields "Supplied energy")

WATTrouter Mx - user manual

How to fit and setup the device

Page 27 from 82

a. At sunrise. Counters are reset to zero at sunrise time, which is automatically calculated by the

controller.

b. At fixed time. Counters are reset to zero at a preset time.

More information about counter reset processing is available in the chapter Description of

WATTconfig Mx items.

Note: For boilers/immersion heaters or any other hot water tanks the CombiWATT mode "does not care"

during what time of the day the water is heated and used. The CombiWATT function only supplies the

preset minimum daily power to the boiler and thus making sure that there is enough hot water when the

recommended configuration is used. In cases when even under the recommended configuration hot water

is not available in required amount, we recommend to gradually increase the daily energy limit

("CombiWATT [kWh]") for example, by 1 kWh, in order to make sure that hot water is available and at the

same time that not too much energy is consumed from public grid. This is recommended mostly for

households where consumption of hot water is high at the evening. Here it may come to the situation

where water is sufficiently heated during the present day by the PV-plant, but the next day the plant is not

capable of providing the necessary amount of energy (cloudy weather). The CombiWATT mode may also be

aided by enforcing the relevant output with a time schedule. Based on user preferences, time schedules

may even completely replace the CombiWATT mode. For more information see chapter Setting up time

schedules.

If you do not have low tariff signal available (either you don't have double tariff rate or the signal cannot be

utilized) but you still want to use the CombiWATT mode, connect the GND terminal to the LT terminal. In such

scenario, the low tariff signal will be active at all times and the CombiWATT mode will be activated after

production of PV-plant comes to an end (after sundown).

SE TTI NG UP TIM E S CHE D ULE S

Up to 4 independent time intervals may be set for each individual output. During these time intervals the

relevant output may be forced to be switched on, or the switching process may be prohibited (restricted). The

enforcing/restricting process may be further conditioned by the presence of the low tariff signal and / or by the

status of daily energy counters for the relevant output (field "Supplied energy") or temperature conditions.

The actual configuration of time schedules is done on the "Time schedules" tab. For more set up information,

see the chapter Description of WATTconfig Mx items, Time schedules tab.

AN DI INP UT CON FIG URA TION

The controller has 4 multi-purpose ANDI inputs to connect:

1. WATTrouter-compatible external current transformers (e.g. another current sensing module or other

compatible current measuring transformers). These can measure powers exactly as ILx inputs;

2. External meters with impulse output S0, which meets the parameters specified in the technical

specification and its output signal provides information about the measured electrical energy;

3. Analog temperature sensors of NTC type;

4. Analog temperature sensors type PT1000.

ANDI inputs are not required to be used. They play an auxiliary role and provide additional information to the

controller. For more information, see chapter Description of WATTconfig Mx items, Input settings tab.

WIREL ESS CO MUN ICA TIO N SETTINGS

Note: This function is accessible, once SC-Gateway module is inserted.

WATTrouter Mx - user manual

How to fit and setup the device

Page 28 from 82

WATTrouter Mx optionally integrates up to 6 wirelessly controlled devices which can be purchased as

accessories. Wireless connection solution can be applied in buildings, where installation of wire connections

between controller and devices would be too difficult.

Attention: Before ordering of this accessory function, assure that wireless devices will be accessible by the

controller. The accessible distance is based on construction of the building and it is possible to extend this range

by the repeaters. Further information can be obtained from technical support.

This function requires SC-Gateway module which needs to be inserted into regulator. To install this SC-Gateway

module, refer to the SC-Gateway user manual. It is also necessary to buy at least one wireless peripheral

(wireless socket or wireless module to be installed on the DIN rail).

How to activate wireless peripherals:

1. Connect wireless peripheral to electrical network and wait till the device gets registered in wireless

network. SC-Gateway module acts as a coordinator of this wireless network and the controller is being

informed once new device is detected. In such case, WATTconfig software will show the Add wireless

station window. If this dialog does not appear even after longer period (1 minute or longer), the

peripheral is probably out of connection range of regulator – proceed according to chapter

Troubleshooting.

2. In window "Add wireless station", set the name tag of the station and choose the table line where the

new peripheral should be registered.

3. Upon closing the Add wireless station dialog (see Fig. "Other Settings" tab) press the Write button. The

configuration will be saved in the controller.

4. On the "Output settings" tab, assign to the logic output WLS the configured wireless peripheral by

using the Station and Device fields. Press the Write button. The configuration will be saved in the

controller.

5. Test with Test button, respective output on the peripheral should respond. If it does not, proceed

according to Chapter Troubleshooting.

6. In case of usage of more wireless peripherals, repeat this procedure from point one for each one. Do

not connect new stations to power line at the same moment, because otherwise the identification of

new station will be impossible.

FI NIS HIN G T HE CON FIG U RAT ION

After setting up the controller according to previous chapters the controller is fully configured. You may save

the preset configuration by pressing the Save button or you may load it at any time by pressing the Open

button. This way you may create several different configurations and monitor them for some time and

determine which one provides better utilization of energy self-consumption in your facility or household.

After you have completed the settings using the USB port then in case of manipulating within the distribution

box turn off entire distribution box, remove the USB cable and turn on the distribution box again.

Tip: In order to maintain continuous monitoring the controller can be kept connected either via USB or Ethernet.

If you want to use permanent USB connection, then it is recommended using a suitable USB isolator or USB

connection extender via Ethernet (for example Silex 3000GB). To use permanent Ethernet connection you may

connect the network cable directly to your network router or switch.

WATTrouter Mx - user manual

How to fit and setup the device

Page 29 from 82

DESCR IPTION OF WA TTC O NFI G M X I TEM S

This chapter contains a list of all items available in the WATTconfig control software and explains their

meaning. Or you may use the controller web interface, where the items have identical names and meanings.

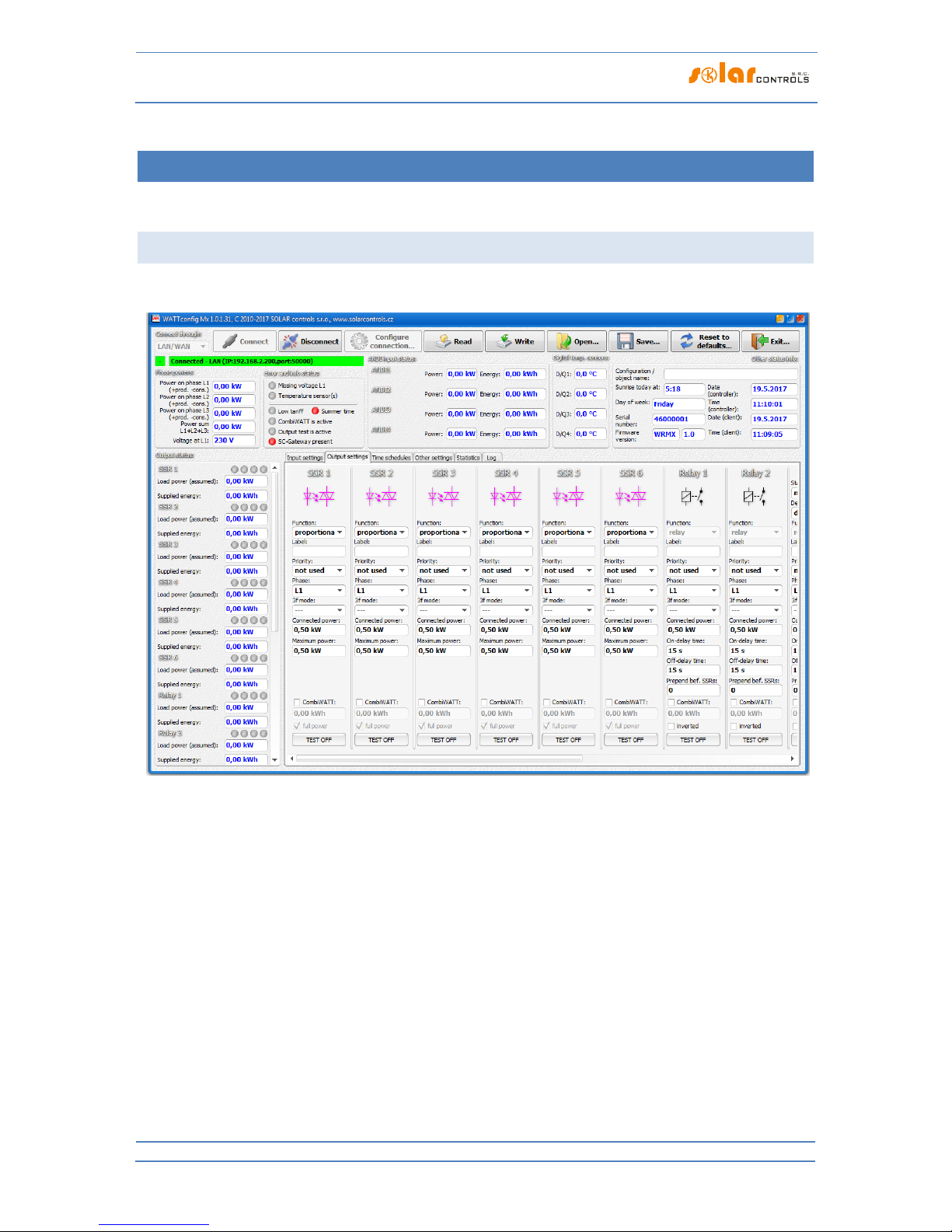

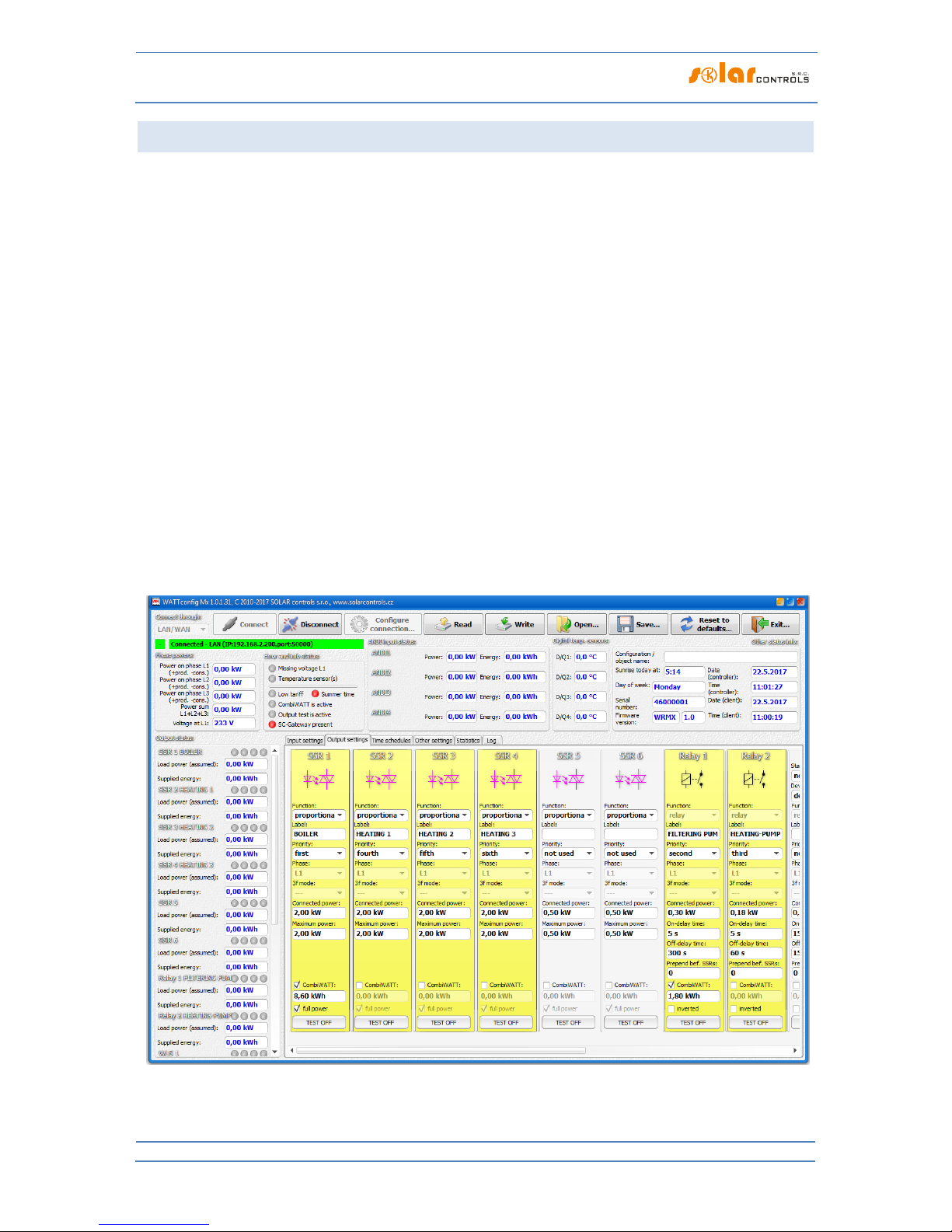

MAIN WIN DOW

The main window displays all basic measured values and statuses. Controller can be configured using

configuration tabs.

Figure 17: Main window of WATTconfig software.

WATTrouter Mx - user manual

How to fit and setup the device

Page 30 from 82

MEASU RED PARAMETERS AND ST ATU S ES

Measured values:

Power on ph. Lx - the actual value of the active power measured on the relevant phase wire. Positive

value means production (PV-plant supplies power to the grid); negative value means that power is

being drawn from the grid.

Power sum L1+L2+L3 – sum of active power outputs in all three phases.

Voltage at L1 – voltage on phase L1 which powers up the regulator. This voltage value is used to more

accurately calculate the power output than for the older WATTrouter models where the voltage was

not measured and a constant value of 230V was assumed. It is also used for calculating the powers on

other phases where a similar voltage value is assumed.

Error and info status (gray in inactive status, red in active status):

Missing voltage L1 – failure of the synchronization circuit that detects the voltage at L1 terminal. This

is a hardware failure of the regulator and it must be replaced or repaired.

Wrong voltage value L1 - grid voltage is too low (<200VAC) or high (> 260VAC). Firmware since version

1.5 signals this fault separately from the previous general state "Missing voltage L1". The controller

will remain functional in this malfunction state, only indicating the problem. Instead of the measured

voltage value, a fixed voltage of 230VAC is assumed (as for previous models CWx, M, ECO). If the

voltage at terminal L1 is within the specified limits, it is a circuit failure that measures the voltage, and

replacement or repair of the controller is recommended.

Temperature sensor(s) – somewhere in time schedules temperature conditions are defined according

to a temperature sensor (ANDI or DQ input) but this sensor does not work. Change the time schedule

configuration or fix the problem with the sensor.

DC source overload - Voltage level at terminal + 12V drops below + 9V relative to GND. This

malfunction can occur when the internal DC voltage source is heavily loaded. The firmware since

version 1.5 checks this and eventually signals this failure. This malfunction lasts for the duration of the

cause and for a further 60s afterwards. Typically, this failure occurs when all 8 internal outputs are

used or there is overload on the + 12V or + 5V terminals may (there can be for example a malfunction

of some digital sensor if powered from + 5V terminal). Please check that the + 12V or + 5V terminals

are not overloaded. When the two internal relays are occupied, connect the control circuits of all used

SSRs to an external source (see Figure 12). You can also enable the Optimize internal relay

consumption feature (see chapter Other settings tab) which might help to reduce the power

consumption of internal relays.

Low tariff – if the low tariff signal is detected the red light comes on, otherwise it is grayed.

Summer time - informs the user that the summer time mode is active. Summer time starts at 2:00 CET,

on the last Sunday in March and ends at 3:00 CEST, on the last Sunday in October. If the option "Use

summer time" is not marked on the "Other settings" tab, the indicator remains inactive.

CombiWATT is active – informs the user that CombiWATT mode is active. This indicator is active if the

condition necessary to run CombiWATT is valid, if the low tariff is active and if the CombiWATT

function has been configured for some output.

Output test is active – informs the user about a status when some of the outputs have been activated

by the TEST button. Output tests done via LAN interface are protected from unauthorized access or

intervention.

WATTrouter Mx - user manual

How to fit and setup the device

Page 31 from 82

SC-Gateway present – informs the user about the presence of the SC-Gateway module in the

regulator.

Output statuses:

Load power - the power drawn by the load connected to the relevant output. It is either:

a. Estimated power based on the output settings and may not correspond with the actual

power output of the load, or:

b. Measured power using an external current transformer connected to the corresponding ANDI

input. If the output is switched on by the controller, but the assigned ANDI input does not

measure any output (for example, the appliance is disconnected by its internal thermostat),

the item flashes.