S4K2U-5C Series Industrial On-Line UPS

230 V, 1000 VA–3000 VA User Manual

SolaHD S5KC Series

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

User Manual — 5-20kVA Modular UPS

ii | Contents

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

TABLE OF CONTENTS

IMPORTANT SAFETY INSTRUCTIONS 1

SAVE THESE INSTRUCTIONS � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 1

GLOSSARY OF SYMBOLS � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 3

1.0 PRODUCT INTRODUCTION 4

1�1 System Description � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 4

1�2 Features � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 8

1�3 Operating Principle � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 9

1�4 Operating Modes � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 10

1�5 Major Components � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 11

1�5�1 UPS Frame � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 11

1�5�2 User Interface Module � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 12

1�5�3 System Control Module and System Monitor Module � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 12

1�5�4 Power Module� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 13

1�5�5 Battery Module � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 13

1�5�6 Charger Module � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 14

1�5�7 External Battery Cabinet (EBC) � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 14

2.0 INSTALLATION 15

2�1 Unpacking Inspection � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 15

2�1�1 Installation Environment � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 15

2�1�2 Installation Tools � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 15

2�1�3 Installation Site � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 15

2�2 Unloading the UPS � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 16

2�3 Mechanical Installation � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 17

2�3�1 Tower Installation � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 17

2�3�2 Rack Installation � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 18

2�4 Module Installation � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 22

2�4�1 Installing Power Module, Battery Module and Charger Module 22

2�4�2 Installing System Control and System Monitor Modules � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 24

2�5 Cable Connection � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 25

2�5�1 Transformer-Free UPS Cable Connection � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 26

S5KC MBC SERIES USER MANUAL | iii

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

2�5�2 Transformer-Based UPS Cable Connection � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 28

2�5�3 Transformer-Free UPS—Dual Inverter Frames � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 32

2�5�4 Connecting External Battery Cabinet � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 34

2�5�5 Connecting Integrated Power AC Distribution (PAD) � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 36

2�5�6 Commissioning/Startup Procedures � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 37

3.0 COMMUNICATION 39

3�1 IntelliSlot Ports � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 39

3�2 Dry Contact Ports � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 40

3�3 REPO (Remote Emergency Power O) � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 41

3�4 Long Run Time (LRT) Battery Temperature Probe Terminals � � � � � � � � � � � � � � � � � � � � � � � � � 42

3�5 USB Port� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 42

3�6 MultiLink® � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 43

3�7 LCD Port� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 43

4.0 OPERATION AND DISPLAY PANEL 44

4�1 Overview � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 44

4�2 LCD Screen � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 46

4�2�1 Startup Screen� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 46

4�2�2 Main Screen � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 46

4�2�3 Default Screen/Screen Saver � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 51

4�3 LCD Screen Views � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 51

4�3�1 AC Mains Screen � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 51

4�3�2 Battery Screen� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 52

4�3�3 Output Screen� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 52

4�3�4 Load Screen � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 53

4�3�5 UPS Information Screen � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 53

4�3�6 Redundancy Screen � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 54

4�3�7 Settings Screen � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 55

4�4 Entering a Password � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 55

4�5 Setting or Changing a Parameter Setting � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 56

4�5�1 Battery Setting Screen � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 56

4�5�2 Language Selection Screen � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 56

4�5�3 Alarms Screen � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 57

4�5�4 Records Screen � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 57

iv | Contents

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

4�5�5 Module Replacement Screen � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 58

4�5�6 Prompt Window � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 58

5.0 TROUBLESHOOTING 60

5�1 Active Alarms � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 60

5�2 Module Troubleshooting � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 63

5�3 Module Replacement � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 64

5�3�1 Removing Modules � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 64

5�3�2 Replacing the User Interface Module � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 65

6.0 MAINTENANCE 67

6�1 Proper Care � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 67

6�2 Scheduled Maintenance � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 67

6�3 Cleaning Fan Filters � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 67

6�3�1 Top Filter � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 67

6�3�2 Bezel Filter � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 68

6�3�3 Bottom Fan Filter—Transformer-Based Frames Only� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 68

7.0 SPECIFICATIONS 69

7�1 Estimated Battery Run Times � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 72

7�1�1 Tables for UPS Where Model Number Digits 1-4 are S5KA � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 72

7�2 Estimated Battery Run Times � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 75

7�2�1 Tables for UPS Model Number Where Digits 1-4 are S5KB � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 75

7�3 Estimated Battery Run Times � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 78

7�3�1 Tables for UPS model number digits 1-4 are S5KC � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 78

7�4 Estimated Battery Run Times � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 81

7�4�1 Tables for UPS Model Number Where Digits 1-4 are S5KD � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 81

7�5 Estimated Battery Run Times � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 84

7�5�1 Tables for UPS Model Number Where Digits 1-4 are S5KE � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 84

7�6 Estimated Battery Run Times � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 87

7�6�1 Tables for UPS Model Number Where Digits 1-4 are S5KF � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 87

S5KC MBC SERIES USER MANUAL | v

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

FIGURES

Figure 1 — 16-bay transformer-free UPS � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

Figure 2 — 10-bay transformer-free UPS � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

Figure 3 — 12-bay transformer-based UPS � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

Figure 4 — 16-bay transformer-based UPS � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

Figure 5 — Operating principle diagram � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 9

Figure 6 — UPS frames, bezels removed � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 11

Figure 7 — User interface module � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 12

Figure 8 — SolaHD S5KC system control module and the system monitor module � � � � � � � � � � � � � � � � 12

Figure 9 — SolaHD S5KC power module � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 13

Figure 10 — Battery module appearance� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 13

Figure 11 — Appearance of the charger module � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 14

Figure 12 — External battery cabinet� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 14

Figure 13 — Front and rear installation clearances � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 15

Figure 14 — Remove the mounting brackets � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 16

Figure 15 — Connect the ramp and remove UPS � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 16

Figure 16 — Adjust the leveling feet � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 17

Figure 17 — Installation position and drilling hole dimensions for stationary mounting � � � � � � � � � � � � �17

Figure 18 — Install cage nuts � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 18

Figure 19 — Install the tray � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 18

Figure 20 — Install the guide rails � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 19

Figure 21 — Install the brackets � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 19

Figure 22 — Push the UPS frame into the rack � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 20

Figure 23 — Fix the UPS frame � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 20

Figure 24 — Install the metal plate � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 21

Figure 25 — Installation completed � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 21

Figure 26 — Insert the power module, battery module and charger module � � � � � � � � � � � � � � � � � � � 22

Figure 27 — Lever and fastener � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 23

Figure 28 — Remove large display bezel and user interface module � � � � � � � � � � � � � � � � � � � � � � � 24

Figure 29 — Insert the System Control and System Monitor module � � � � � � � � � � � � � � � � � � � � � � � 24

Figure 30 — Lever and fastener on System Control and System Monitor Module � � � � � � � � � � � � � � � � � 25

Figure 31 — Knockouts � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 26

Figure 32 — Connection in single-phase input � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 27

vi | Contents

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Figure 33 — Connection in 3-phase input � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 27

Figure 34 — Setting bypass voltage jumper (default: 208VAC)� � � � � � � � � � � � � � � � � � � � � � � � � � 29

Figure 35 — Setting bypass voltage jumper (200/220/230/240VAC) � � � � � � � � � � � � � � � � � � � � � � � 29

Figure 36 — Conguring the neutral/earth jumper � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 30

Figure 37 — Knockouts � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 30

Figure 38 — Connection method � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 31

Figure 39 — Knockouts � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 32

Figure 40 — Secure cables on cable bridges � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 33

Figure 41 — Wiring connections � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 33

Figure 42 — Connecting external battery cabinet to a transformer-free UPS � � � � � � � � � � � � � � � � � � � 35

Figure 43 — Connecting external battery cabinet (transformer-based UPS) � � � � � � � � � � � � � � � � � � � 35

Figure 44 — Battery screen � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 36

Figure 45 — IntelliSlot communication port location � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 39

Figure 46 — Pin layout of the dry contacts � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 40

Figure 47 — REPO connector pin layout � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 41

Figure 48 — REPO switch connections � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 41

Figure 49 — Pin layout of the temperature sensor terminal � � � � � � � � � � � � � � � � � � � � � � � � � � � 42

Figure 50 — LCD port � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 43

Figure 51 — Operation and display panel � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 44

Figure 52 — User interface module layout � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 45

Figure 53 — Startup screen � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 46

Figure 54 — Main screen � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 46

Figure 55 — Default screen/screen saver � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 51

Figure 56 — Mains screen � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 51

Figure 57 — Battery screens � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 52

Figure 58 — Output screen � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 52

Figure 59 — Load screen � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 53

Figure 60 — UPS info screen � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 53

Figure 61 — Redundancy screen � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 54

Figure 62 — Settings screens � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 55

Figure 63 — Battery settings screen � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 56

Figure 64 — Language selection screen � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 56

Figure 65 — Alarms screen � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 57

Figure 66 — Records screen � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 57

S5KC MBC SERIES USER MANUAL | vii

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Figure 67 — Module replacement screen� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 58

Figure 68 — Example of prompt window� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 58

Figure 69 — Module LED location � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 63

Figure 70 — Lever and fastener � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 64

Figure 71 — Pull out a battery module, a power module or a charge module � � � � � � � � � � � � � � � � � �65

Figure 72 — Replacing the user interface module� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 66

Figure 73 — Replace/clean the top lter � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 67

Figure 74 — Replace/clean the bezel lter � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 68

Figure 75 — Replace/clean the bottom fan lter � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 68

viii | Contents

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

TABLES

Table 1 — Frame designation � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 4

Table 2 — Cable connection method reference � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 25

Table 3 — Input cable selection list—60Hz � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 26

Table 4 — Input cable selection list—50Hz � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 26

Table 5 — Input cable selection for transformer-based frames (60 Hz) � � � � � � � � � � � � � � � � � � � � � � 28

Table 6 — Key to Figures 32 and 33 UPS wiring � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 28

Table 7 — Input cable selection for transformer-based frames (50 Hz) � � � � � � � � � � � � � � � � � � � � � � 29

Table 8 — Key to Figure 38 UPS input wiring � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 31

Table 9 — Key to Figure 38 UPS output wiring � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 31

Table 10 — Maximum load capacity of the output winding � � � � � � � � � � � � � � � � � � � � � � � � � � � 31

Table 11 — Input cable selection for transformer-free dual inverter frames (50/60 Hz) � � � � � � � � � � � � � � 32

Table 12 — Input cable selection for transformer-free dual inverter frames (50/60 Hz) � � � � � � � � � � � � � � 32

Table 13 — EBC DIP switch settings � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 36

Table 14 — Pin denition of dry contact port � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 40

Table 15 — Pin denition of the REPO dry contact � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 41

Table 16 — Pin denition of the temperature sensor terminal � � � � � � � � � � � � � � � � � � � � � � � � � � 42

Table 17 — LED descriptions� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 44

Table 18 — Audible alarm descriptions � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 45

Table 19 — Control buttons functions � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 45

Table 20 — Function descriptions of menu button � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 45

Table 21 — Item description of system information window � � � � � � � � � � � � � � � � � � � � � � � � � � 46

Table 22 — Item description of menu window and data window � � � � � � � � � � � � � � � � � � � � � � � �47

Table 23 — Function descriptions of menu buttons � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 50

Table 24 — Information and actions required for the prompt window � � � � � � � � � � � � � � � � � � � � � � 59

Table 25 — Alarm message list � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 60

Table 26 — Descriptions of module LEDs� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 63

Table 27 — SolaHD S5KC specications � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 69

Table 28 — Rated input voltage range (Unit: VAC)� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 71

Table 29 — SolaHD S5KC external battery cabinet specications � � � � � � � � � � � � � � � � � � � � � � � �71

Table 30 — 10-bay, single-phase, no transformer unit Type N (& UPS model number digit 9 = N) � � � � � � � � � 72

Table 31 — 10-bay, single-phase, no transformer unit Type R (& UPS model number digit 9 = R) � � � � � � � � �73

Table 32 — 10-bay, single-phase, no transformer unit Type F (& UPS model number digit 9 = F)� � � � � � � � � � 74

S5KC MBC SERIES USER MANUAL | ix

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Table 33 — 16-bay, single-phase, no transformer unit Type N (& UPS model number digit 9 = N) � � � � � � � � � 75

Table 34 — 16-bay, single-phase, no transformer unit Type R (& UPS model number digit 9 = R) � � � � � � � � �76

Table 35 — 16-bay, single-phase, no transformer unit Type F (& UPS model number digit 9 = F)� � � � � � � � � � 77

Table 36 — 12-bay, single-phase, transformer-based unit Type N (& UPS model number 9 = N) � � � � � � � � � � 78

Table 37 — 12-bay, single-phase, transformer-based unit Type R (& UPS model number 9 = R) � � � � � � � � � � 79

Table 38 — 12-bay, single-phase, transformer-based unit Type F (& UPS model number 9 = F) � � � � � � � � � �80

Table 39 — 16-bay, single-phase, transformer-based unit Type N (& UPS model number 9 = N) � � � � � � � � � � 81

Table 40 — 16-bay, single-phase, transformer-based unit Type R (& UPS model number 96 = R)� � � � � � � � � � 82

Table 41 — 16-bay, single-phase, transformer-based unit Type F (& UPS model number 9 = F) � � � � � � � � � �83

Table 42 — 10-bay, two-phase, no transformer unit Type N (& UPS model number 9 = N) � � � � � � � � � � � � � 84

Table 43 — 10-bay, two-phase, no transformer unit Type R (& UPS model number 9 = R) � � � � � � � � � � � � � 85

Table 44 — 10-bay, two-phase, no transformer unit Type F (& UPS model number 9 = F) � � � � � � � � � � � � � 86

Table 45 — 16-bay, two-phase, no transformer, unit Type N (& UPS model number 9 = N) � � � � � � � � � � � � � 87

Table 46 — 16-bay, two-phase, no transformer unit Type R (& UPS model number 9 = R) � � � � � � � � � � � � � 88

Table 47 — 16-bay, two-phase, no transformer unit Type F (& UPS model number 9 = F) � � � � � � � � � � � � � 89

S5KC SERIES USER MANUAL | 1

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

This manual contains important safety instructions� Read all safety, installation and operating instructions before

operating the SolaHD S5KC modular UPS system� Adhere to all warnings on the unit and in this manual� Follow all

operating and user instructions� Individuals must fully understand this equipment to install and operate it�

This product is designed for commercial/industrial use only� It is not intended for use with life support or other

designated critical devices� Maximum load must not exceed that shown on the rating label� Install and operate the

unit only in an indoor clean environment, free from conductive contaminants, moisture, ammable liquids, gases and

corrosive substances� This SolaHD S5KC contains no user serviceable parts other than the user replaceable modules� Refer

all faults to your local dealer, local representative or the Emerson SolaHD service group�

The SolaHD S5KC UPS system is designed for use on a properly earthed (grounded) “TN” electrical supply, for installation

by qualied personnel� A qualied electrician must review and approve customer supplied wiring, circuit breakers, and

intended loads and verify correct input, output, and earth connections to ensure compliance with the technical standards

and local electrical codes of practice� Installation instructions and warning notices are found in this manual�

!

WARNING

Risk of electric shock. Can cause equipment damage, injury and death.

The battery can present a risk of electrical shock and high short circuit current� The following precautions should be

observed before replacing the battery pack:

• Wear rubber gloves and boots

• Remove rings, watches and other metal objects�

• Use tools with insulated handles�

• Do not lay tools or other metal objects on the batteries�

• If the battery kit is damaged in any way or shows signs of leakage, contact your local representative immediately�

• Do not dispose of batteries in a re� The batteries may explode�

• Handle, transport and recycle batteries in accordance with local regulations�

!

WARNING

Risk of electric shock and re. Can cause equipment damage, injury and death.

Although the SolaHD S5KC UPS has been designed and manufactured to ensure personal safety, improper use can result

in electrical shock or re� To ensure safety, observe the following precautions:

• Clean the UPS with a dry cloth� Do not use liquid or aerosol cleaners�

• Never block or insert any objects into the ventilation holes or other openings of the UPS�

• Do not place the SolaHD S5KC where it might be damaged�

!

WARNING

Risk of electric shock. Can cause equipment damage, injury and death.

This UPS contains no user-serviceable parts except for the user-replaceable module assemblies� The UPS On/O push

button does not electrically isolate internal parts�

All service and maintenance operations must be performed by properly trained and qualied personnel� Under no

2 | IMPORTANT SAFETY INSTRUCTIONS

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

circumstances should unqualied or unauthorized personnel attempt to gain access to the internal portions of the

SolaHD S5KC�

ELECTROMAGNETIC COMPATIBILITY

The SolaHD S5KC complies with the limits of Category C2, pursuant to IEC/EN/AS 62040-2, and for a Class A digital device,

pursuant to Part 15 of FCC rules� Operation is subject to the following conditions:

• The output cables shall be no longer than 10m (32ft)�

• This device may not cause harmful interference�

• This device must accept any interference received, including interference that may cause undesired operation�

Operating this device in a residential area is likely to cause harmful interference that users must correct at their own

expense�

The SolaHD S5KC complies with the requirements of EMC Directive 2004/108/EC and the published technical standards�

Continued compliance requires installation in accordance with these instructions and use of accessories approved by

Emerson�

Operate the UPS in an indoor environment only in an ambient temperature range of 0-40°C (32-104°F)� Install it in a clean

environment, free from moisture, ammable liquids, gases and corrosive substances�

Do not continue to use the UPS if the front panel indications are not in accordance with these operating instructions or

the UPS performance alters in use� Refer all faults to your local service dealer�

Servicing of batteries should be performed or supervised by personnel knowledgeable of batteries and the required

precautions� Keep unauthorized personnel away from the batteries� Proper disposal of batteries is required� Refer to your

local laws and regulations for disposal requirements�

Never block or insert any object into the ventilation holes or other openings�

DO NOT CONNECT equipment that could overload the UPS or demand DC current from the UPS, for example: electric

drills, vacuum cleaners, laser printers, hair dryers or any appliance using half wave rectication�

Storing magnetic media on top of the UPS may result in data loss or corruption� Turn O and isolate the UPS before

cleaning it� Use only a soft dry cloth; never use liquid or aerosol cleaners�

Information for the Protection of the Environment

UPS SERVICING—This UPS makes use of components dangerous for the environment (electronic cards, electronic

components)� The components removed must be taken to specialized collection and disposal centers�

NOTICE TO EUROPEAN UNION CUSTOMERS: DISPOSAL OF OLD APPLIANCES—This product has been supplied from an

environmentally aware manufacturer that complies with the Waste Electrical and Electronic Equipment (WEEE) Directive

2002/96/CE�

The crossed-out trash bin symbol at right is placed on this product to encourage users to recycle

components and units whenever possible� Please be environmentally responsible and recycle this

product through your recycling facility at its end of life� Do not dispose of this product as unsorted

municipal waste� Follow local municipal waste ordinances for proper disposal provisions to reduce the

environmental impact of waste electrical and electronic equipment (WEEE)�

For information regarding the scrapping/disposal of this equipment, please browse Sola Hevi Duty

website (Products section or Contact us section) or call Emerson’s worldwide technical support�

• Toll-Free: 00 80011554499

• Toll Number Based in Italy: +39 0298250222

• GLOSSARY OF SYMBOLS

!

-

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Risk of electrical shock

Indicates caution followed by important instructions

AC input

AC output

S5KC SERIES USER MANUAL | 3

i

PbH2SO4

R

Requests the user to consult the manual

+

Indicates the unit contains a valve-regulated lead acid battery

Recycle

DC voltage

Equipment grounding conductor

Bonded to ground

AC voltage

Toggle between On and O

Standby

Do not dispose of in normal waste stream

4 | 1�0 Product Introduction

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

1�0 Product Introduction

Congratulations on your purchase of the SolaHD S5KC Uninterruptible Power System (UPS)� As with every other SolaHD

product, we stand behind our quality� If you have any questions concerning this UPS, please feel free to contact your local

dealer or SolaHD representative or call the appropriate Technical Support number listed on the back of this manual�

To ensure proper installation and operation of this unit, please read this manual thoroughly� The installation must be

completed by trained professionals and follow all local codes� General operation of the units can be conducted without

any specialized training�

This chapter provides the system description, features, operating principle, operating mode, main components and

specications of the SolaHD S5KC UPS�

1.1 System Description

The SolaHD S5KC power system is a modular UPS designed to provide high reliability� It is intended for use with

workstations, servers, networks, telecoms and other sensitive electronic equipment� It provides continuous, high-quality

AC power to your equipment, protecting it from any power disturbance due to blackouts, brownouts, surges or noise

interference�

The SolaHD S5KC UPS is an easily adaptable UPS system� By simply installing additional power or battery modules, you

can expand your current system capacity, extend your backup runtime, or provide redundancy� The SolaHD S5KC UPS

user interface enables the user to congure the operation according to application requirements� It also informs the user

on the status of the UPS and keeps a log of events�

The SolaHD S5KC series UPS contains both transformer-free and transformer-based UPS frames� The use of the

transformer-free or transformer-based frames is dependent upon the specic application requirements� The appearance

of the dierent frames is shown in Figures 1 through 4.

Table 1: Frame designation

UPS Model Number Digits 1-4 Frame Type Frame Rating

S5KCA or S5KE 10 Bay Transformer-free 15kVA redundant

S5KCB or S5KF 16 Bay Transformer-free 20kVA redundant

S5KC 12 Bay Transformer-based 15kVA redundant

S5KD 16 Bay Transformer-based 20kVA redundant

S5KC SERIES USER MANUAL | 5

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Manual Bypass Breaker

(under the cover)

User Interface

Module

Input Breaker

(under the cover)

Power, Battery

or Charger

Modules

Battery

Modules

Front View - Bezels Removed

Figure 1: 16-bay transformer-free UPS

PAD Ports

RS-232

Port

Dry

Contacts

USB Port

Intelligent Card

Slots

Rear View

Power Input and

Output Terminals

System Enabling

Breaker

Output Breaker

External Battery

Cabinet

Connector

PAD Breakers

User Interface

Input Breaker

(under the cover)

Power, Battery

or Charger

Modules

Battery

Modules

Manual Bypass Breaker

(under the cover)

Module

Front View - Bezels Removed

System Control Module

Figure 2: 10-bay transformer-free UPS

(under the cover)

RS-232

Contacts

USB Port

PAD Port

Intelligent Card

Port

Dry

Slots

Power Input and

Output Terminals

System Enabling

Breaker

Output Breaker

External Battery

Cabinet

Connector

PAD Breakers

Rear View

6 | 1�0 Product Introduction

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Manual Bypass Breaker

(under the cover)

User Interface

Module

Power, Battery

or Charger

Modules

Battery

Modules

Front View - Bezels Removed

Figure 3: 12-bay transformer-based UPS

Intelligent Card

Slots

S5KC

RS-232

Port

Dry

Contacts

USB Port

PAD Port

Output Breaker

System Enabling

Breaker

PAD Breaker

External Battery

Cabinet

Connector

Input Breaker

Power Input

and Output

Terminals

Rear View

S5KC SERIES USER MANUAL | 7

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

User Interface

Power, Battery

or Charger

Modules

Battery

Modules

Manual Bypass Breaker

(under the cover)

Module

PAD Port

RS-232

Port

Dry

Contacts

USB Port

Output

Breaker

Intelligent Card

Slots

System Enabling

Breaker

PAD Breakers

External Battery

Cabinet

Connector

Input

Breaker

Power Input

and Output

Terminals

Front View - Bezels Removed

Figure 4: 16-bay transformer-based UPS

Rear View

8 | 1�0 Product Introduction

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

1.2 Features

SolaHD S5KC UPS

• Flexible extension of capacity, up to 15 or 20kVA modular power, depending upon frame rating

• N + 1 redundancy, improving availability

• Module design, modules hot-swappable by user

• Redundant intelligent module, providing redundant communication path

• Intelligent battery management

• External large battery assemblies can be connected

• Internal automatic and manual bypass

• Transformer-based UPS frames provide output isolation transformer

• Optional 10A battery charger module

• Continuous system monitoring

• User-friendly interface with audible alarms and event logs

• Supporting hot-pluggable and online update

• Compatible with backup generators

Standard Components

• UPS frame

• User interface module: for comprehensive user indications and programmable controls

• System control modules and system monitor module: for system monitoring and communications

• Power modules: for power conditioning

• Battery modules: for backup power

• Charger module: option for charging batteries and long run time applications

• External battery cabinet: extends system run time

Communications

• Dry contacts

• IntelliSlot® communication ports

• USB port

1.3 Operating Principle

have an output isolating

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

The operating principle of the SolaHD S5KC UPS is shown in Figure 5.

Input

S5KC SERIES USER MANUAL | 9

Manual Bypass

Output

EMI

Filter

Wiring

Power

Control

Figure 5: Operating principle diagram

The SolaHD S5KC UPS is composed of AC input, EMI lter, power module(s), battery module(s), user interface, control

interface, system control module, output and bypass contactor, manual bypass, output transformer (certain frames only)

and AC output�

Power

Module(s)

Battery

Module(s)

User

Interface

EMI

Filter

Control

Interface

Communication

Output and

Bypass

Contactor

System Control

Module

System Monitor

Module

Output

Transformer

Transformer models

transformer

10 | 1�0 Product Introduction

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

1.4 Operating Modes

The SolaHD S5KC UPS is a true online double-conversion system, having the following operating modes:

• Normal Mode

• Backup Mode

• Auto Restart Mode

• Bypass Mode

Normal Mode

The power module rectiers derive power from a utility AC source and supply regulated DC power to the inverter� The

module’s inverter regenerates precise AC power to supply the connected equipment� The battery charger is in the power

module and maintains a oat-charge on the batteries of the UPS; additionally, the optional charger module can also

charge the batteries to maintain a quicker recharge time for long backup time applications�

Backup Mode

When AC utility fails, the connected equipment is supplied power by the inverter, which obtains energy from the battery

modules� The output power will not be interrupted during the failure or restoration of the AC utility/mains source�

Auto Restart Mode

After a power outage and complete battery discharge, and once AC utility is restored, the UPS will automatically restart

and resume supplying power to connected equipment� This feature is enabled at the factory, but can be disabled by the

user� The user can also program two auto restart delay settings from the LCD:

• Battery capacity level (%)

• Countdown timer

Bypass Mode

The bypass provides an alternate path for power to the connected equipment and operates in the following manner:

• Automatic: In the event of an internal fault or should the inverter overload capacity be exceeded, the UPS performs

an automatic transfer of the connected equipment from the inverter to the bypass source�

• Manual: Should the UPS need to be taken out of service for limited maintenance or repair, manual activation of the

bypass will cause an immediate transfer of the equipment from the inverter to the bypass source�

S5KC SERIES USER MANUAL | 11

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

1.5 Major Components

This section provides a general description of each component and its functions� Please review this section carefully, as it

will give you a better understanding of how the UPS operates�

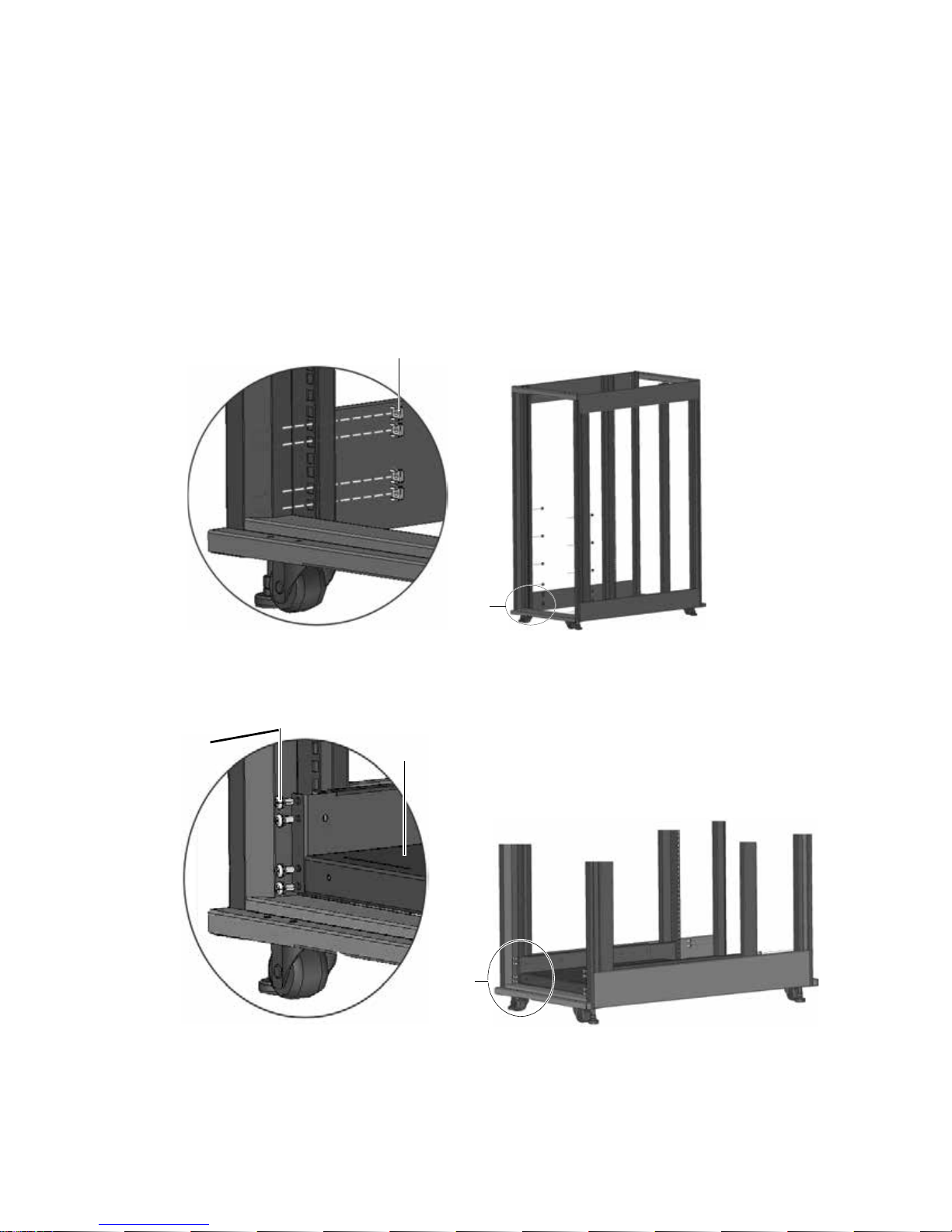

1.5.1 UPS Frame

The UPS frames are shown in Figure 6.

Manual

Bypass

Breaker

Fan

(behind

display

bracket)

Manual

By

pass

aker

Bre

Fan

(behind

display

bracket)

10-Bay Transformer-Free UPS

16-Bay Transformer-Free UPS

Fan (behind

display

Fan

(behind

display

bracket)

Manual

Bypass

Breaker

Fans

12-Bay Transformer-Based UPS

bracket)

Manual

Bypass

Breaker

Fans

16-Bay Transformer-Based UPS

Figure 6: UPS frames, bezels removed

NOTE

In Figure 6, the power module and battery module are extended for illustration purposes only. Extending more than one

module at a time could cause the unit to tip over.

All UPS components are located in the SolaHD S5KC frame� The front of the UPS consists of a series of metal bezels� By

grasping these bezels from the sides and pulling straight out, you can remove the bezel to reveal the battery/power

module bays� The standard-model frame provides cooling fans and a manual bypass breaker on its top; the transformermodel frame provides a manual bypass breaker on its bottom and fans on both top and bottom� The user interface

module is located above the power/battery module bays for easy access, operation and for viewing UPS operating

information� On the lower right part of the user interface module, you will see the system control module bays�

12 | 1�0 Product Introduction

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

1.5.2 User Interface Module

The user interface module is shown in Figure 7.

Figure 7: User interface module

The user interface module is the primary source of communication between the UPS and the user� The user interface

module permits:

• Viewing the UPS status

• Conguring the system

• Reviewing the event log

• Silencing the audible alarm

Refer to 4.0 - Operation and Display Panel for details on operating the user interface module�

1.5.3 System Control Module and System Monitor Module

The system control module and the system monitor module are the communication backbone of the UPS� They gather

input from all modules and process the data to control the operation of the system, including monitoring the condition

of each module� Except for the silkscreen, the appearance of the system control module and the system monitor module

is as shown in Figure 8.

Handle

Green Status LED

Yellow Fault LED

Figure 8: SolaHD S5KC system control module and the system monitor module

Under normal operation, the green status LED will blink and the yellow fault LED will be O� For any other condition, refer

to 5�0 - Troubleshooting�

Securing Hole

Locking Lever

S5KC SERIES USER MANUAL | 13

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

1.5.4 Power Module

The power module is shown in Figure 9.

Fan

Green Status LED

Yellow Fault LED

Locking Lever

Front View

Figure 9: SolaHD S5KC power module

Each power module is an independent 5kVA unit, consisting of a power factor corrected rectier, battery charger and

inverter, with associated monitoring and control circuitry� The modules are connected in parallel for greater capacity and/

or redundancy�

The power modules may be added or replaced on-line with no interruption or danger to the connected equipment or

user�

1.5.5 Battery Module

The battery module is shown in Figure 10.

Green Status LED

Yellow Fault LED

Locking Lever

Front View

Figure 10: Battery module appearance

When AC utility fails, the battery module will supply power to the load� Each battery module contains six individual 12V,

valve-regulated lead-acid (VRLA) battery blocks� Two battery modules are connected in series to form a battery string�

Each battery module has monitoring and controls to isolate the battery module in the event of a battery failure� The

battery strings are connected in parallel to provide backup time and/or redundancy�

NOTE

Two battery modules must be installed in the same row to make a complete battery string.

The battery modules may be added or replaced on-line with no interruption or danger to the connected equipment,

provided that the UPS is not operating on battery�

Under normal operation, the green status LED will blink continuously and the yellow fault LED will be O� For any other

condition, refer to 5.0 - Troubleshooting.

14 | 1�0 Product Introduction

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

1.5.6 Charger Module

Figure 11 shows the charger module�

Green Status LED

Yellow Fault LED

Figure 11: Appearance of the charger module

In AC mains mode, the charger module charges the system battery modules or external battery cabinet� Each charger

module is rated to deliver 10A charging current� The charger module has an independent control function and maintains

real-time communication with the system and the battery modules to ensure stable charging and fault protection�

The charger module may be added or replaced on-line with no interruption or danger to the user, connected battery

system or connected equipment�

1.5.7 External Battery Cabinet (EBC)

The external battery cabinet is divided into nine rows: the upper seven rows are for use with the intelligent battery

modules, and the lower two are used for overcurrent protection for each battery cabinet� For normal operation, two

battery modules must be inserted in the same row of the frame to create a complete string� The battery module strings

work in parallel to provide longer backup time for the UPS� A SolaHD S5KC can be congured with, at most, four external

battery cabinets� An external battery cabinet is shown in Figure 12.

EBC Breaker

Figure 12: External battery cabinet

12in. (305mm)

S5KC SERIES USER MANUAL | 15

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

2�0 INSTALLATION

This chapter describes UPS installation, including installation preparation, unloading the UPS, mechanical installation,

installing modules and cable connection�

2.1 Unpacking Inspection

Upon receiving the UPS, uncrate it and conduct the following checks:

• Inspect the UPS appearance for shipping damage� Report any shipping damage to the carrier and send a copy to

your Emerson® representative�

• Check against the delivery list to ensure that the package contains the correct number and type of accessories� If

there is any discrepancy, contact the distributor immediately�

2.1.1 Installation Environment

NOTE

Operating the UPS in temperatures above 77° F (25° C) will reduce battery life.

The UPS environment must be free of conductive contaminants and excessive moisture (water and condensation),

ammable vapors, chemical fumes, corrosive gases and liquids�

2.1.2 Installation Tools

The tools required to properly set up your UPS are listed below:

• Pallet jack

• 17mm (11/16”) wrench or socket

• 13mm (1/2”) wrench or socket

• 10mm wrench or socket

• #1 and #3 Phillips screwdrivers

• Torque wrench

2.1.3 Installation Site

Consider the weight and size of the SolaHD S5KC when deciding where to install the unit� Verify that the oor can support

the weight of a fully loaded unit, any accessories and external cabinets�

Verify that the UPS will be in a well-ventilated area with at least 12 inches (305mm) clearance behind it� The UPS is

air-cooled, utilizing internal fans� Air is drawn into the front of the UPS and is exhausted through ventilation grilles in the

back� The UPS should also have at least 39 inches (1m) clearance in front for service and to meet many local and national

building codes�

Figure 13: Front and rear installation clearances

39in. (1000mm)

16 | 2�0 INSTALLATION

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

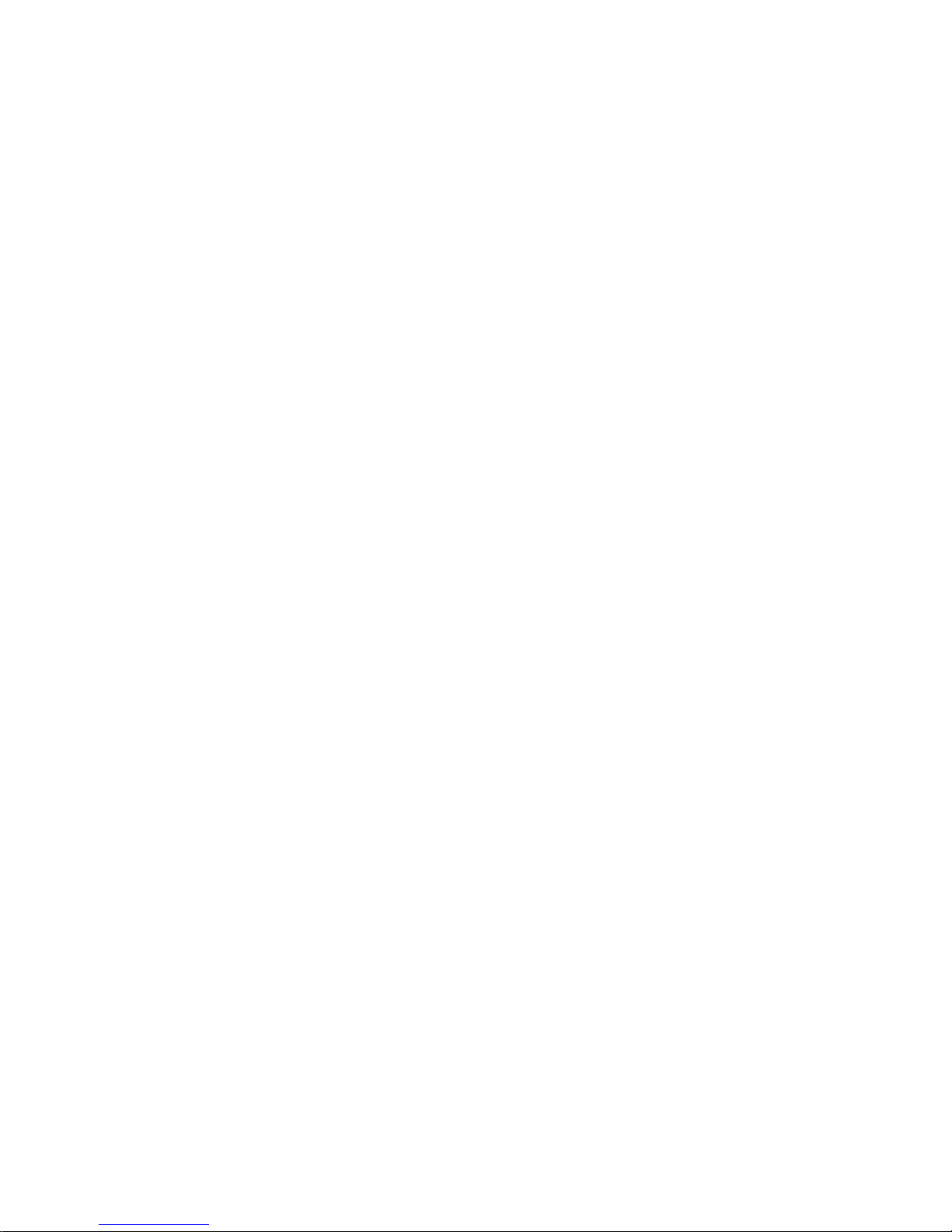

2.2 Unloading the UPS

The unit frame is bolted to the shipping pallet to ensure safety during shipping� Emerson recommends keeping the unit

bolted to the pallet and using a pallet jack to transport the unit to its installation location�

NOTE

This UPS is very heavy. At least two people should assist in unloading it from the pallet.

To unload the UPS:

1. Move the UPS to its installation site and remove the package paper�

2. Use a 17mm (11/16”) wrench, to remove the four mounting bolts from the pallet brackets (see Figure 14).

3. Remove the mounting brackets from the UPS with a 10mm wrench or socket or a #3 Phillips screwdriver�

Figure 14: Remove the mounting brackets

4. Raise the four leveling feet to provide clearance between the pallet and the UPS frame�

5. Connect the ramp to the UPS pallet, as shown in Figure 15�

6. Roll the UPS slowly down the ramp until it is on a level surface, as shown in Figure 15�

Figure 15: Connect the ramp and remove UPS

S5KC SERIES USER MANUAL | 17

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

2.3 Mechanical Installation

Two installation modes are available for the SolaHD S5KC UPS: tower installation and rack installation�

2.3.1 Tower Installation

1. Once the UPS is in the desired location, adjust the leveling feet to secure its position, as shown in Figure 16.

a. Use an open end wrench to turn the lower nut to raise or lower the leveling foot�

b. After the unit is level, tighten the upper nut against the frame to prevent the height from changing�

Upper nut is threaded on

leveling foot; used to hold

foot height

Lower nut is bonded to

leveling foot; used to raise

and lower foot

Figure 16: Adjust the leveling feet

2. For added stability or earthquake-resistant installations, the shipping brackets can be used to secure the unit to the

oor�

a. Drill holes 10�3mm (13/32”) in the oor for stationary mounting; these will accommodate the mounting bolts

removed from the pallet� Refer Figure 17 for the layout�

b. Use the mounting screws to install the mounting brackets on the front and rear of the UPS�

c. Secure the mounting brackets to the oor with the mounting bolts (see Figure 17)� For greater stability, use a

higher-grade bolt�

716 mm

(28�19 in�)

Mounting Bolt

Mounting Bracket

340 mm

(13�39 in�)

Figure 17: Installation position and drilling hole dimensions for stationary mounting

M10 Screw

Floating Nut

Screw,16 places

18 | 2�0 INSTALLATION

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

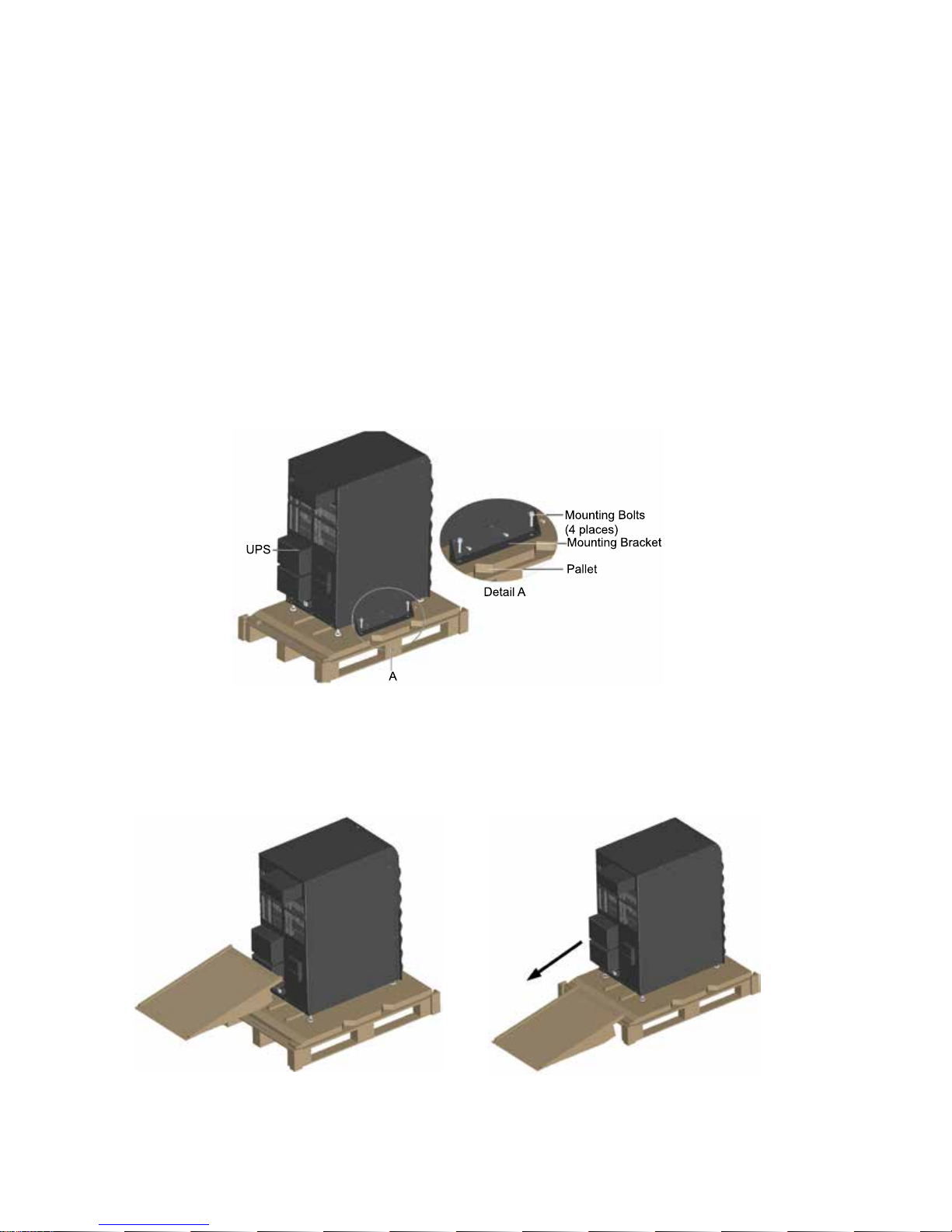

2.3.2 Rack Installation

1. Install the cage nuts on the corresponding positions in the rack, as shown in Figure 18�

a. Install cage nuts in the two lower square holes of 1U space and in the two upper square holes of 2U space of all

four rack posts� These cage nuts will secure the optional shelf that will support the weight of the SolaHD S5KC�

b. Install a cage nut in the middle square hole of 4U, 6U, 10U, 12U spaces, respectively, again in all four posts� The

cage nuts will help secure the UPS in the rack�

Floating Nut

A

Detail A

Figure 18: Install cage nuts

2. Install the rack-mount shelf on the corresponding position between 1U space and 2U space on the bottom of the

rack, as shown in Figure 19�

Screw

(16 places)

Tray

B

Detail B

Figure 19: Install the tray

3. Install the guide rails (ramp) in the mounting slot at the front of the tray, as shown in Figure 20�

C

Guide

Rail

Insert one end

of the guide rail

into the mounting

slot on the tray

Mounting

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Slot

S5KC SERIES USER MANUAL | 19

Detail C

Figure 20: Install the guide rails

4. Unscrew the 10 screws on the front of the two side panels of the UPS frame�

5. Use those screws to attach the brackets to each side of the UPS frame, as shown in Figure 21.

Bracket

D

Screw

(8 places)

Bracket

Detail D

Figure 21: Install the brackets

Guide Rails

Panel Screw (8 Places)

20 | 2�0 INSTALLATION

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

6. Push the SolaHD S5KC frame slowly into the enclosure from the front, as shown in Figure 22. The rear of the UPS goes

into the rack rst when installing through the front of the rack�

Figure 22: Push the UPS frame into the rack

7. Use eight panel screws to secure the UPS frame to the rack posts, as shown in Figure 23.

NOTE

It might be necessary to use the leveling feet to get the holes to align

Panel Screw

(8 places)

E

Detail E

Figure 23: Fix the UPS frame

S5KC SERIES USER MANUAL | 21

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Use four screws to install the metal plate (accessory in the rack-mount kit) on the corresponding position on the lower

front part of the UPS frame

9� Insert the provided bezel into the square holes of the metal plate, as shown in Figures 24 and 25.

Square Hole

(2 places)

Detail F

Metal Plate

Figure 24: Install the metal plate

The installation is complete, as shown in Figure 25.

Screw

(4 places)

F

Bezel

Figure 25: Installation completed

22 | 2�0 INSTALLATION

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

2.4 Module Installation

The SolaHD S5KC ships from the factory congured (modules prepopulated) and tested as a system to the customer’s

requirements� If any modules were removed to facilitate ease of installation, follow the steps below to reinsert them

properly�

2.4.1 Installing Power Module, Battery Module and Charger Module

1. Lift module to appropriate bay, resting end of module on bay shelf�

NOTE

Use caution not to rest the module on any of the bezels, this could damage the bezel.

Two battery modules must be installed in the same row to complete the battery string.

2. Push the module into the bay slowly� The module will not be locked until 1/3 is in�

a. At this point, lift the module up and continue pushing it until about 5cm of the module is still out of the bay�

b. Push it rmly and smoothly to ensure that the module is fully inserted, as shown in Figure 26�

1� Push module slowly into

the bay until it is 1/3 in�

4� Push module quickly and

rmly into the bay�

2� Raise the face

of the module�

50mm

3� Continue pushing module slowly|

until about 2” (50mm) remains out�

Figure 26: Insert the power module, battery module and charger module

3. Use a #2 Phillips screwdriver to install the module-securing bracket, and then press the lever down into the bracket,

as shown in Figure 27.

Side View

Side View

Locking

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Lever

Fastener

S5KC SERIES USER MANUAL | 23

Pull Out

Press

Downward

Before Pressing the Lever

After Pressing the Lever

Figure 27: Lever and fastener

NOTE

If the lever of the module cannot be pressed down smoothly, remove the module and reinstall it.

4. Replace the small bezels�

24 | 2�0 INSTALLATION

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

2.4.2 Installing System Control and System Monitor Modules

NOTICE

Risk of unintended shutdown� Can cause equipment damage�

Do not remove both the control and the monitor modules at the same time� Removing both the control module and

monitor module at the same time will cause the UPS to shut down and remove power from the load� Replace these

modules one at a time�

1. Remove the display bezel and the user interface (LCD) module on top of the frame, as shown in Figure 28.

Large Display Bezel

User Interface Module

Figure 28: Remove large display bezel and user interface module

2. Push the module slowly until about 1cm (2�54 in�) of the module is still out of the bay, and then press it rmly to

ensure that the module is fully inserted, as shown in Figure 29�

10mm

Insert

module

here

Figure 29: Insert the System Control and System Monitor module

3. Use a #2 Phillips screwdriver to install the screws into the holes on each end�

Pull

Out

Lever

Press and Slide

Mounting

Mounting

Hole

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

4. Slide the lever toward the right, as shown in Figure 30�

Lever

S5KC SERIES USER MANUAL | 25

Hole

to the Right

Before Pressing

After Pressing

Lever

Figure 30: Lever and fastener on System Control and System Monitor Module

5. Replace the LCD module and display bezel�

2.5 Cable Connection

!

WARNING

Risk of electric shock. Can cause injury or death.

Disconnect local and remote power supplies before working within.

Read this section thoroughly before attempting to install wiring to this unit.

Ensure that all the UPS input sources are disconnected o before attempting to install wiring to this unit.

This UPS cables should be connected by a properly trained and qualied electrician.

Refer to the unit model number in Table 2 to determine which instructions to use for installation�

Table 2: Cable Connection Method Reference

UPS Model #

Digits 1-4 Frame Type

S5KA 10 Bay Transformer-free 2�5�1

S5KB 16 Bay Transformer-free 2�5�1

S5KC 12 Bay Transformer-based 2�5�2

S5KD 16 Bay Transformer-based 2�5�2

S5KE 10 Bay Transformer-free 2�5�3

S5KF 16 Bay Transformer-free 2�5�3

Manual

Section

26 | 2�0 INSTALLATION

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

2.5.1 Transformer-Free UPS Cable Connection

A junction box is factory-installed on each model of the SolaHD S5KC to ease cable connection� Select the appropriate

input cables according to Table 3 and Table 4 based on the UPS rating and mains frequency; however, it is recommended

that you size the over current protection and wiring for the frame rating to easily allow upgrades to the UPS system�

Table 3: Input cable selection list—60Hz

Input voltage - 200VAC Input voltage - 208VAC Input voltage - 240VAC

Maximum System

Rated Load

5kVA 27A 50A 26A 50A 23A 50A

10kVA 53A 63A 51A 63A 45A 63A

15kVA 80A 100A 77A 100A 67A 100A

20kVA 106A 125A 102A 125A 90A 125A

The power input and output terminals accept a maximum cable cross-sectional area of 35mm2 (2AWG); the minimum cable

cross-sectional area is 16mm2 (6AWG); the rated torque is 4�52Nm (40 in-lb)�

Use of 90°C copper wire is recommended

Maximum

Current in UPS

Mode

Table 4: Input cable selection list—50Hz

Input Voltage - 220VAC Input Voltage - 230VAC Input Voltage - 240VAC

Maximum System

Rated Load

5kVA 25A 50A 24A 50A 23A 50A

10kVA 49A 63A 47A 63A 45A 63A

15kVA 73A 100A 70A 100A 67A 100A

20kVA 97A 125A 93A 125A 90A 125A

The power input and output terminals accept a maximum cable cross-sectional area of 35mm2 (2AWG); the minimum cable cross- sectional area is

16mm2 (6AWG); the rated torque is 4�52Nm (40 in-lb)�

Use of 90°C copper wire recommended

Maximum

Current in UPS

Mode

Recommended

Input Protection

Circuit Breaker

Recommended

Input Protection

Circuit Breaker

Maximum

Current in UPS

Mode

Maximum

Current in UPS

Mode

Recommended

Input Protection

Circuit Breaker

Recommended

Input Protection

Circuit Breaker

Maximum

Current in UPS

Mode

Maximum

Current in UPS

Mode

Recommended

Input Protection

Circuit Breaker

Recommended

Input Protection

Circuit Breaker

To connect the cable:

NOTE

Input and output cables must be run in separate conduit before cable connection.

1. Remove the knockouts at the junction box (see Figure 31) and pull the cables through them, leaving some slack for

installation�

Output Cable Knockout

16-Bay SolaHD S5KC

No Transformer

Input Cable Knockout

10-Bay SolaHD S5KC

No Transformer

Output Cable Knockout

Input Cable Knockout

Figure 31: Knockouts

200/208/220/230/240V

S5KC SERIES USER MANUAL | 27

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

2. Connect the cables to the corresponding terminal of the power input and output terminals�

3. Tighten the screws to 4�52Nm (40 in-lb) with a 13mm (1/2”) torque wrench�

4. Respectively, secure the conduit of the input/output cables through the cable bridges on the rear panel of the UPS

(see Figure 31)�

The connection methods in the single-phase input mode and the 3-phase input mode are shown in Figures 32 and

33, respectively� Installation of the factory-provided copper bar is essential in the single-phase input mode� The copper

busbar is in the accessory bag included with the UPS�

OUTPUT INPUT

200/208/220/230/240V

Figure 32: Connection in single-phase input

OUTPUT INPUT

200/208/220/230/240V 380/400/415V

Figure 33: Connection in 3-phase input

PE 4PE 21 23

PE 4PE 21 23

1

1

28 | 2�0 INSTALLATION

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Table 5: Key to Figures 32 and 33 UPS Wiring

System

Voltage

200 60 L1 * L1 * L1 * L2 GND L1 L2 GND

208 60 L1 * L1 * L1 * L2 GND L1 L2 GND

220 60 L1 * L1 * L1 * L2 GND L1 L2 GND

230 60 L1 * L1 * L1 * L2 GND L1 L2 GND

240 60 L1 * L1 * L1 * L2 GND L1 L2 GND

200 50 L * L * L * N PE L N PE

220 50 L * L * L * N PE L N PE

230 50 L * L * L * N PE L N PE

240 50 L * L * L * N PE L N PE

380 50 L1 L2 L3 N PE L N PE

400 50 L1 L2 L3 N PE L N PE

415 50 L1 L2 L3 N PE L N PE

* This connection requires the factory-provided three-position busbar to connect the three terminal block positions

System

Nominal

Frequency

1 2 3 4 PE 1 2 PE

Input Terminal Block Output Terminal Block

2.5.2 Transformer-Based UPS Cable Connection

NOTE

After the output transformer is installed, if the startup is on bypass, the UPS has a six-cycle inrush current that is up to 20 times

the rated output current. This must be taken into account when selecting the input overload protection device at the AC input

supply distribution point.

To avoid random tripping on startup, Emerson® recommends that the AC input supply be protected with a circuit breaker

capable of withstanding this initial inrush (the MCB is derated according to the D curve or TYPE 4).

This UPS is tted with EMI lters. Earth leakage current is less than 40mA. Transient and steady state earth leakage currents may

occur when starting the UPS. This should be taken into account when selecting transient RCCB or RCCD (leakage current devices

of the UPS and load).

The MCB of the AC power supply connected to the UPS input must bear this warning:

Disconnect the connection with UPS before maintaining this circuit.

The warning is required because the UPS has no autofeeding protection device. The UPS grounding should be in accordance

with local regulations.

A junction box is factory-installed on all models of the SolaHD S5KC to ease cable connection�

Select the appropriate input cables according to Table 6 and Table 7 based upon the UPS rating and mains frequency�

Emerson recommends sizing the frame’s overcurrent protection and wiring to permit easier UPS system upgrades�

Table 6: Input Cable Selection for Transformer-Based Frames (60 Hz)

Input Voltage - 200VAC Input Voltage - 208VAC Input Voltage - 240VAC

Maximum System

Rated Load

5kVA 27A 50A 26A 50A 23A 50A

10kVA 53A 63A 51A 63A 45A 63A

15kVA 80A 100A 77A 100A 67A 100A

20kVA 106A 125A 102A 125A 90A 125A

The power input and output terminals accept a maximum cable cross-sectional area of 70mm2 (2/0AWG); the minimum cable cross-sectional area is

16mm2 (6AWG)� The rated torque is 12�43Nm (110 in-lb)�

90°C copper wire recommended�

Maximum

Current in UPS

Mode

Recommended

Input Protection

Circuit Breaker

Maximum

Current in UPS

Mode

Recommended

Input Protection

Circuit Breaker

Maximum

Current in UPS

Mode

Recommended

Input Protection

Circuit Breaker

S5KC SERIES USER MANUAL | 29

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Table 7: Input cable selection for transformer-based frames (50 Hz)

Input Voltage - 220VAC Input Voltage - 230VAC Input Voltage - 240VAC

Maximum System

Rated Load

5kVA 25A 50A 24A 50A 23A 50A

10kVA 49A 63A 47A 63A 45A 63A

15kVA 73A 100A 70A 100A 67A 100A

20kVA 97A 125A 93A 125A 90A 125A

The power input and output terminals accept a maximum cable cross-sectional area of is 70mm2 (2/0AWG); the minimum cable

cross-sectional area is 16mm2 (6AWG)� The rated torque is 12�43Nm (110 in-lb)�

90°C copper wire recommended�

Maximum

Current in UPS

Mode

Recommended

Input Protection

Circuit Breaker

Maximum

Current in UPS

Mode

Recommended

Input Protection

Circuit Breaker

Maximum

Current in UPS

Mode

Recommended

Input Protection

Circuit Breaker

Conguring the Bypass Voltage

The UPS bypass voltage is factory-set and the copper busbar jumper has been factory-installed� If the jumper setting does

not match the input source, the bypass voltage jumper may need to be changed to ensure the correct output voltages

are provided when operating in bypass mode� Refer to Table 9 for the proper setting location according to the AC mains

voltage available and to Figures 34 and 35 for the jumper setting location�

Jumper

Figure 34: Setting bypass voltage jumper (default: 208VAC)

Jumper

Figure 35: Setting bypass voltage jumper (200/220/230/240VAC)

1 2

1

2

30 | 2�0 INSTALLATION

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Conguring the Neutral/Earth Jumper

The UPS contains an isolation transformer that generates a neutral conductor for the connected load� The UPS is a

separately derived source and contains a neutral/earth jumper� A factory-installed neutral/earth jumper copper bar may

require removal to comply with local codes and regulations�

Neutral/Earth Jumper

Neutral/Earth Jumper

2

1

Figure 36: Conguring the neutral/earth jumper

Connecting Cables

To connect the cable:

NOTE

Input and output cables must be run in separate conduit before cable connection.

1. Remove the knockouts at the junction box (see Figure 37) and pull the cables through them, leaving some slack for

installation�

Output Cable Knockout

16-Bay SolaHD S5KC

With Transformer

Input Cable Knockout

12-Bay SolaHD S5KC

With Transformer

Output Cable Knockout

Input Cable Knockout

Figure 37: Knockouts

2. Connect the cable to the corresponding terminal of the power input and output terminals� Using a torque wrench,

tighten the screws to 12�43Nm (110 in-lb)� The connections are shown in Figure 38.

S5KC SERIES USER MANUAL | 31

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

1 2

Figure 38: Connection Method

Refer to Table 7 for conguring the output cable� For standard voltages, make the connections shown in Table 9�

Table 8: Key to Figure 38 UPS Input Wiring

System

Voltage

200 60 L1 L2 GND

208 60 L1 L2 GND

220 60 L1 L2 GND

230 60 L1 L2 GND

240

200

220 50 L N PE

230 50 L N PE

240 50 L N PE

System Nominal

Frequency

60

50

Input Terminal Block

1 2 PE

L1 L2 GND

L N PE

Table 9: Key to Figure 38 UPS Output Wiring

Output

Voltage

200/100 200 — OK 100 100

220/110 220 — OK 110 110

230/115 230 — OK 115 115

220/127 220 OK — 127 127 220

240/120 240 — OK 120 120 208 240

208/120 208 OK — 120 120 208 240

If the bypass voltage jumper copper bar is connected incorrectly, the system will report a fault alarm�

When wiring to single-phase panels, connect to output terminals 1, 3, 4 and PE (GND) only�

Set Output

Voltage by LCD

Bypass Voltage Jumper Output Voltage (Between Terminals)

208V TAP (1-2) 240V TAP (2-3) 1-4 3-4 2-3 1-3

173

(Do Not Use)

190

(Do Not Use)

199

(Do Not Use)

Table 10 shows the maximum load capacity of the output winding of the transformer-based UPS�

Table 10: Maximum Load Capacity of the Output Wiring

Maximum Output Capacity, kVA

(Between Terminals)

UPS Model

16-bay Transformer-based UPS 10 10 20 20

12-bay Transformer-based UPS 7�5 7�5 15 15

1-4 3-4 2-3 1-3

200

220

230

254

(Do Not Use)

32 | 2�0 INSTALLATION

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

2.5.3 Transformer-Free UPS—Dual Inverter Frames

A junction box is factory-installed on all models of the SolaHD S5KC to ease cable connection� Select the appropriate

input cables according to Tables 11 and 12 based on the UPS rating and mains frequency� Emerson recommends sizing

the overcurrent protection and wiring for the frame rating for easing upgrades to the UPS system�

Table 11: Input Cable Selection for Transformer-Free Dual Inverter Frames (50/60 Hz)

Input Voltage – 200/100VAC Input Voltage – 208/120VAC Input Voltage – 240/120VAC

Maximum

System Rated

Load

5kVA 28A 50A 27A 50A 27A 50A

10kVA 56A 63A 54A 63A 54A 63A

15kVA 84A 100A 80A 100A 80A 100A

20kVA 112A 125A 107A 125A 107A 125A

The power input and output terminals accept a maximum cable cross-sectional area of 35mm2 (2AWG); the minimum cable cross- sectional area is

16mm2 (6AWG); and the rated torque is 4�52Nm (40 in-lb);�

90°C copper wire is recommended�

Table 12: Input cable selection for transformer-free dual inverter frames (50/60 Hz)

Maximum System

Rated Load

5kVA 28A 50A 28A 50A 27A 50A

10kVA 56A 63A 56A 63A 54A 63A

15kVA 84A 100A 84A 100A 80A 100A

20kVA 112A 125A 112A 125A 107A 125A

The power input and output terminals accept a maximum cable cross-sectional area of 35mm2 (2AWG); the minimum cable

cross-sectional area is 16mm2 (6AWG); and the rated torque is 4�52Nm (40 in-lb);

90°C copper wire is recommended�

Maximum

Current in UPS

Mode

Input Voltage – 220/110VAC Input Voltage – 230/115VAC Input Voltage – 220/127VAC

Maximum

Current in UPS

Mode

Recommended

Input Protection

Circuit Breaker

Recommended

Input Protection

Circuit Breaker

Maximum

Current in UPS

Mode

Maximum

Current in UPS

Mode

Recommended

Input Protection

Circuit Breaker

Recommended

Input Protection

Circuit Breaker

Maximum

Current in UPS

Mode

Maximum

Current in UPS

Mode

Recommended Input

Protection Circuit

Breaker

Recommended

Input Protection

Circuit Breaker

To connect the cable:

NOTE

Input and output cables must be run in separate conduit before cable connection.

1. Remove the knockouts at the junction box (see Figure 31) and pull the cables through them, leaving some slack for

installation�

Output Cable Knockout

Input Cable Knockout

10-Bay SolaHD S5KC

No Transformer

Output Cable Knockout

Input Cable Knockout

16-Bay SolaHD S5KC

No Transformer

Figure 39: Knockouts

2. Connect the cables to the corresponding terminal of the power input and output terminals�

3. Tighten the screws to 4�52Nm (40 in-lb) with a 13mm (1/2 in) torque wrench�

S5KC SERIES USER MANUAL | 33

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

4. Respectively secure the input/output cables through the cable bridges on the rear panel of the UPS (see Figure 40)�

Cable Bridge

Figure 40: Secure cables on cable bridges

PE NL2L1PENL2 L1

Cable Bridge

OUTPUT INPUT

Figure 41: Wiring connections

34 | 2�0 INSTALLATION

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

2.5.4 Connecting External Battery Cabinet

Up to four external battery cabinets may be connected to the SolaHD S5KC Series UPS to provide longer battery run

times�

The external battery cabinet (EBC) requires the use of one of the optional EBC cable kits for connection to the UPS� The

optional cable kits each contain the power and communication cables required for proper operation and monitoring of

the battery modules� The standard cable kit lengths are 1, 3, and 5 meters (3�2, 9�8 and 16�4 ft�) to accommodate dierent

site installation requirements�

To connect an external battery cabinet: