Surge Protective Devices

SPD50K Series

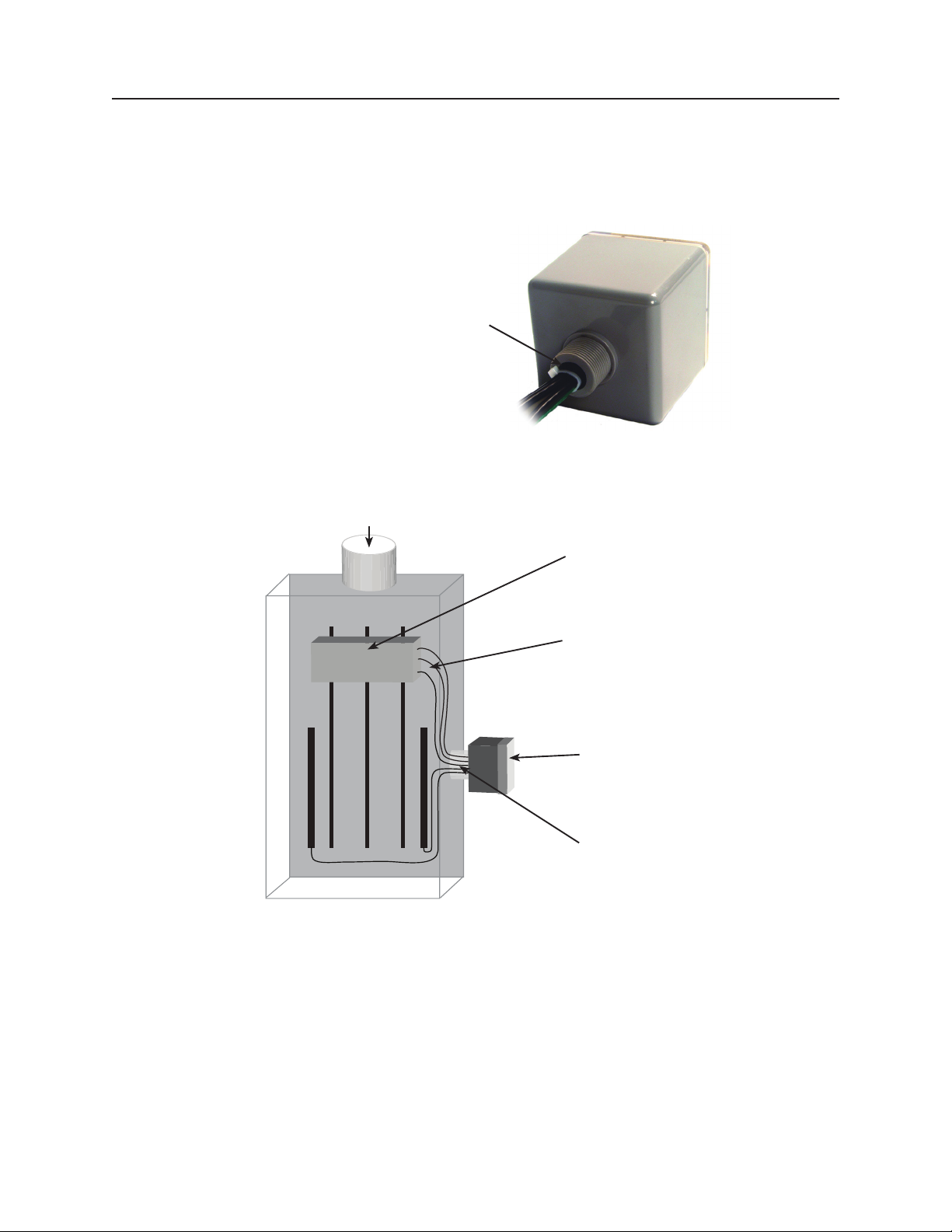

SPD50K

Safety Information

Important Information

Read these instructions carefully and look at the equipment to become

familiar with the device before trying to install, operate, service or maintain it.

The following special messages may appear throughout this bulletin or on the

equipment to warn of potential hazards or to call attention to information that

clarifies or simplifies a procedure.

The addition of either symbol to a “Danger” or “Warning” safety label

indicates that an electrical hazard exists which will result in personal

injury if the instructions are not followed.

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that follow this

symbol to avoid possible injury or death.

DANGER

DANGER indicates a hazardous situation which, if not avoided,

will result in death or serious injury.

WARNING

WARNING indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

Please Note

CAUTION

CAUTION indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

NOTICE

NOTICE is used to address practices not related to physical injury. The safety

alert symbol shall not be used with this signal word.

Electrical equipment should be installed, operated, serviced, and maintained only

by qualified personnel. No responsibility is assumed by Appleton Grp LLC d/b/a

Appleton Group for any consequences arising out of the use of this material.

A qualified person is one who has skills and knowledge related to the

construction, installation, and operation of electrical equipment and has received

safety training to recognize and avoid the hazards involved.

SPD50K

Precautions

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Apply appropriate personal protective equipment (PPE) and follow safe electrical work practices. See NFPA 70E,

NOM-029-STPS or CSA Z462.

• This equipment must only be installed and serviced by qualied electrical personnel.

• Turn o all power supplying this equipment before working on or inside equipment.

• Always use a properly rated voltage sensing device to conrm power is o.

• Replace all devices, doors and covers before turning on power to this equipment.

• This equipment must be eectively grounded per all applicable codes. Use an equipment-grounding conductor to

connect this equipment to the power system ground.

• Conrm the SPD voltage rating on the module or nameplate label is not less than operating voltage the operating

voltage.

Failure to follow these instructions will result in death or serious injury.

WARNING: This product can expose you to chemicals including DINP, which is known to the State of

California to cause cancer, and DIDP which is known to the State of California to cause birth defects or

other reproductive harm. For more information go to: www.P65Warnings.ca.gov.

NOTICE

LOSS OF BRANCH CIRCUIT POWER / LOSS OF SURGE SUPPRESSION

• Perform periodic inspection of the surge protective device status indicator lights as part of the preventative

maintenance schedule.

• Promptly replace the surge protective device when an alarm state exists.

• Use dry contacts to signal an alarm state to the central supervisory system for unmanned, inaccessible, or

critical installations.

• Use multiple surge protective devices to achieve redundancy for critical applications.

Failure to follow these instructions can result in equipment damage.

At end-of-life conditions, Surge Protective Devices (SPDs) can lose their ability to suppress power system

transient voltage spikes and attempt to draw excessive current from the line. This SPD is equipped with

overcurrent and overtemperature components that will automatically disconnect the surge suppression

elements from the mains should the surge suppression elements reach end of life. Tripping of the branch

circuit breaker or fuse feeding the SPD can occur. Mitigate the tripping of the branch circuit breaker or fuse

feeding the SPD by coordinating the surge suppression elements with the branch circuits.

Page: 1

SPD50K

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Do not energize the surge protective device until the electrical system is completely installed, inspected and

tested.

• Ensure all conductors are connected.

• Verify the voltage rating of the device and system prior to energizing.

• Perform high-potential insulation testing, or any other tests where surge protective device components will be

subjected to voltages higher than their rated turn-on voltage, with the neutral and surge protective device disconnected from the power source

Failure to follow these instructions will result in death or serious injury.

Introduction

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Apply appropriate personal protective equipment (PPE) and follow safe electrical work practices. See NFPA 70E,

NOM-029-STPS or CSA Z462.

• This equipment must only be installed and serviced by qualied electrical personnel.

• Turn o all power supplying this equipment before working on or inside equipment.

• Always use a properly rated voltage sensing device to conrm power is o.

• Replace all devices, doors and covers before turning on power to this equipment.

• This equipment must be eectively grounded per all applicable codes. Use an equipment-grounding conductor to

connect this equipment to the power system ground.

Failure to follow these instructions will result in death or serious injury.

Proper installation is imperative to maximize the SolaHD SPD50K's effectiveness and performance. Follow

the steps outlined in this instruction manual to ensure proper installation. Read the entire instruction manual

before beginning the installation. These instructions are not intended to replace national or local electrical

codes. Check all applicable electrical codes to verify compliance. Installation of these surge suppressors must

only be performed by qualied electrical personnel.

Unpacking and Preliminary Inspection

Inspect the shipping container for damage before unpacking the device. Remove the packing material and

further inspect the device for shipping damage. If any damage is found, immediately le a claim with the

shipping company.

Parts List

• 1 - SPD50K Surge Protective Device (SPD) including 3 ft (approximately 1m) conductors

• 1 - 3/4 in. conduit nut

• 1 - L bracket mounting kit with two pan head screws

Page: 2

SPD50K

Storage

The device should be stored in a clean, dry environment. Storage temperature is -67 °F to +149 °F (-55°C to

+65°C). All of the packaging materials should be left intact until the device is ready for installation.

Identification Nameplate

The identication nameplate is located on the side of the unit.

Figure 1: SPD 50K Identification Nameplate

E335146

44BV

SolaHD

CW

50-60Hz

UL 1449-4

MCOV: ______

In: ________

VOLTAGE

PROTECTION RATING

L-N _______

L-G _______

N-G _______

L-L _______

MODEL: SPD50K-____

VOLTAGE: _________V

MAX RATED AMBIENT

AIR TEMP: ________

MFG DATE: _________

ENC TYPE: 1, 12, 4X

SPD TYPE: 1

UL

HOLOGRAM

Suitable For Use on a Circuit Capable of Delivering

Not More Than 200,000 rms symmetrical Amperes.

IMPORTANT: Verify the SPD is properly rated for installation on your distribution system. Conrm the surge

protective device voltage rating on the nameplate label exceeds the voltage of the distribution system

(operating system voltage) it will be installed in.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Conrm the SPD voltage rating on the module or nameplate label is not less than operating voltage the operating

voltage.

Failure to follow these instructions will result in death or serious injury.

For any questions, contact SolaHD Technical Support. See the last page of this manual for

contact information.

SPD Location Considerations

Environment

The device is designed to operate in an ambient temperature range of -40 °F to +140 °F (-40°C to +60°C) with a

relative humidity of 0 to 95% non-condensing. This device has a Type 4X housing.

Audible Noise

The device background noise is negligible and does not restrict the location of the installation.

Mounting

The device has been designed to be DIN-rail, bracket or surface mounted.

Service Clearance

The service clearance should meet all applicable code requirements.

Page: 3

SPD50K

Equipment Performance

To obtain optimum surge suppression, locate the SPD as close as possible to the circuitry being surge-limited to

minimize the wire length. Minimizing the wire length reduces the impedance between the circuitry and the SPD.

Refer to the Voltage Protection Rating (VPR) values on the SPD nameplate. These VPR values were obtained by

testing the SPD with six-inch long leads (per UL1449). For every additional foot of wire beyond six inches, the

effective VPR increases by approximately 160 volts.

Technical Data Sheet

Performance Specifications Diagnostic Monitoring

• 50kA per phase

• UL 1449 tested Inominal: 20kA

• UL 1449 tested SCCR: 200kA

• Individually fused & thermally protected MOVs

• Repetitive impulse: 5000 - 3kA - 8 x 20µs;

1000 - 10kA - 8 x 20µs

Physical Specifications Features

• Relative humidity range: 0 - 95% non-condensing

• Operating frequency: 47 - 63 Hz

• Operating temperature: -40° C (-40° F) to

+85° C (185° F)

• Response time: < 1 nanosecond

• Solid state bi-directional operation

• NEMA 4X polycarbonate enclosure—UL746C(f1),

UL 94-5VA

• Pre-wired with 3 feet (0.9 meter) of

#10 AWG conductor

• Typical connection: 30A breaker

• Weight:1.60 lbs (0.73 kg)

Quality, Standards & Validation

• cULus Listed

• Type 1: UL 1449, CSA 22.2 No. 269.1

• ANSI/IEEE C62.41.1-2002, C62.41.2-2002,

C62.45-2002, C62.62-2010 and C62.72-2016

• IEC 61643, CE

• RoHS compliant

• Green LED visible = okay,

Green LED off, with power present = replace SPD

• Every MOV is monitored as opposed to

‘power is present’

• Dry contacts & audible alarm

• Dry contact connection leads exit through nipple

via 18 AWG

• Standard, 35 mm DIN-Rail or Bracket (at surface)

Mount Installation

• Audible alarm with relay contacts, dry contact

leads provided

Page: 4

Dimensions (in./mm)

SPD50K

(L-BRACKET IS INCLUDED)

Electrical

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Conrm the surge protective device voltage rating on the module or nameplate label is not less than the

operating voltage.

Failure to follow these instructions will result in death or serious injury.

Voltage Rating

Prior to mounting the SPD, verify that the device has the same voltage rating as the power distribution system

in which it is installed. Compare the nameplate voltage or model number on the SPD with the nameplate of

the electrical distribution equipment.

The specier or user of the device should be familiar with the conguration and arrangement of the power

distribution system in which the SPD is to be installed. The system conguration of any power distribution

system is based strictly on how the secondary windings of the transformer supplying the service entrance

main or load are congured. This includes whether or not the transformer windings are referenced to ground

via a grounding conductor. The system conguration is not based on how any specic load or equipment is

connected to a particular power distribution system. See Table 1 for the service voltage of each SPD.

Page: 5

SPD50K

Table 1: Model SPD50K Service Voltages

SPD 50K ooo

Surge Protective Device 50kA Rating Per Phase Voltage Codes

10S – 120V/240V

10Y – 208Y/120V

27Y – 480Y/277V

24D – 240V Delta

48D – 480V Delta

34Y – 600Y/347V

60D – 600V Delta

System

Conguration

Phase A (Black)

v

}

Neutral (White)

}

v

Phase B (Black)

Model L-N L-L N-G L-G I

Ground (Green)

2 POLE

Reference

Diagram

Black

White

Black

Green

UL 1449 Test Data

n

SCCR MCOV

SPD50K10S 120/240V 700 1200 600 1200 20kA 200kA 150

Phase A (Black)

Phase B (Black)

A

B

Neutral (White)

N

v

Phase C (Black)

C

Models L-N L-L N-G L-G I

SPD50K10Y 208Y/120V 700 1200 600 1200 20kA 200kA 150

Ground (Green)

WYE

Black

Black

White

Black

Green

n

SCCR MCOV

SPD50K27Y 480Y/277V 1200 2000 1000 1800 20kA 200kA 320

SPD50K34Y 600Y/347V 1500 2500 1200 2500 20kA 200kA 420

Phase A (Black)

v

Phase B (Black)

Phase C (Black)

Ground (Green)

Models L-N L-L N-G L-G I

SPD50K24D* 240V Delta - 1500 - 1200 20kA 200kA 320

DELTA

Black

Black

Black

Green

n

SCCR MCOV

SPD50K48D* 480V Delta - 3000 - 1800 20kA 200kA 552

SPD50K60D* 600V Delta - 2500 - 2500 20kA 200kA 690

* Does not include N-G protection

Page: 6

SPD50K

Location of Surge Protective Device (SPD)

UL 1449 Type 1 SPDs have been designed and approved for line side applications prior to the main service disconnect without supplemental overcurrent protection. Type 2 SPDs must be installed on the load side of the

main Overcurrent Protective Device (OCPD). All installations should either provide or include a disconnecting

means.

Type 1 SPDs can also be used in Type 2 applications (load side of OCPD). When used on the load side, they

must be installed per local codes.

Locate the SPD as close as possible to the circuit mains being surge-limited to minimize the wire length

and optimize SPD performance. Avoid long wire runs so that the device will perform as intended. To reduce

the impedance that the wire displays to surge currents, the phase, neutral, and ground conductors (wye

congurations), or phase and ground conductors (delta congurations), must be routed within the same

conduit and tightly bundled or twisted together to optimize device performance. Avoid sharp bends in the

conductors. See Figures 2 and 3.

Figure 2: SPD Wiring for Wye Configuration

Phases

Neutral

Ground

Neutral bus

Ground bus

To load(s)

Panel

Phase A

Phase B

Phase C

Neutral

Ground

Interconnect wiring

– Minimize length

– Avoid sharp bends

SPD

Page: 7

SPD50K

Figure 3: SPD Wiring for Delta Configurations

Phases

Ground

To load(s)

Phase A

Phase B

Phase C

Ground

Interconnect wiring

– Minimize length

– Avoid sharp bends

SPD

System Grounding

CAUTION

SPD DAMAGE AND POWER SYSTEM OVER VOLTAGE

• Ungrounded power systems are inherently unstable and can produce excessively high line-to-ground voltages

during certain fault conditions. During these fault conditions any electrical equipment, including an SPD, may

be subjected to voltages which exceed their designed ratings. This information is being provided to the user

so that an informed decision can be made before installing any electrical equipment on an ungrounded power

system.

• Resistance-grounded power systems must be maintained in a over-damped state to limit voltage overshoot and

duration during operation.

• Verication and adjustment of correct power system damping should be done following power system

modications and periodically, as part normal system maintenance.

Failure to follow these instructions can result in injury or equipment damage.

NOTICE

LOSS OF SURGE SUPPRESSION

• Verify that the service entrance equipment is bonded to ground in accordance with all applicable codes.

Failure to follow these instructions can result in equipment damage.

The SPD50K has SPD elements connected from phase to ground. It is critical that there be a robust and

effective connection to the building grounding structure. The grounding connection must utilize an

equipment grounding conductor run with the phase and neutral connection of the power system. Do not

connect the SPD to a separate isolated ground. For proper voltage suppression by the SPD50K, use a singlepoint ground system where the service entrance grounding electrode system is connected to, and bonded

to, all other available electrodes, building steel, metal water pipes, driven rods, etc. (for reference, see NEC

Art 250). The ground impedance measurement of the electrical system must be as low as possible and in

compliance with all applicable codes for sensitive electronic and computer systems.

Page: 8

SPD50K

NOTICE

INADEQUATE RACEWAY ELECTRICAL CONTINUITY

• Install an insulated grounding conductor inside a metallic raceway when the raceway is used as an additional

grounding conductor. Size the conductor in accordance with all applicable codes.

• Maintain adequate electrical continuity at all raceway connections.

• Do not use isolating bushings to interrupt a metallic raceway run.

• Do not use a separate isolated ground for the surge protective device.

• Verify proper equipment connections to the grounding system.

• Verify ground grid continuity by inspections and testing as part of a comprehensive electrical maintenance

program.

Failure to follow these instructions can result in equipment damage.

Wiring and Installation

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Apply appropriate personal protective equipment (PPE) and follow safe electrical work practices. See NFPA 70E,

NOM-029-STPS or CSA Z462.

• This equipment must only be installed and serviced by qualied electrical personnel.

• Turn o all power supplying this equipment before working on or inside equipment.

• Always use a properly rated voltage sensing device to conrm power is o.

• Replace all devices, doors and covers before turning on power to this equipment.

• This equipment must be eectively grounded per all applicable codes. Use an equipment-grounding conductor to

connect this equipment to the power system ground.

• Conrm the surge protective device voltage rating on the module or nameplate label is not less than the operating voltage.

Failure to follow these instructions will result in death or serious injury.

Parts List

1 - SPD50K suppressor including 3' (~1m) conductors

1 - 3/4” conduit nut

1 - L bracket mounting kit; includes two pan head screws

1 - Instructions

Page: 9

SPD50K

Table 2: Wire Color

Wye and Delta Systems

Wire Color

Phase 1-3 Black

Neutral White

Ground Green

Delta Systems

Wire Color

Phase 1-3 Black

Ground Green

Follow steps 1 through 10 to make wiring connections:

1. Turn off all power supplying this equipment before working on or inside any enclosure containing

this equipment.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Turn o all power supplying this equipment before working on or inside equipment.

Failure to follow these instructions will result in death or serious injury.

2. If Dry Contacts are to be used, pre-plan the installation of the relay wires.

3. Conrm SPD is rated for your system by comparing voltage measurements to the Line Voltage (L-L, L-N)

on the product label.

4. Identify proper location for the SPD. Locate as close as possible to the mains of the panel being surgelimited so the wires are as short as possible. Mount unit securely. See Figure 5.

• Note: The SPD must be installed in an accessible location.

5. Mount SPD. For weather resistant applications additional sealing, O-ring is required (not included). See

Figure 4 and 5.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• For outdoor installation use and appropriate weather sealing at the nipple (o-ring, sealing conduit, etc).

Failure to follow these instructions will result in death or serious injury.

6. Install in accordance with national and local electrical codes and match the branch circuit Overcurrent

Protection Device (OCPD) to the wire size.

7. For all wires Twist conductors 1/2 turn or more for every twelve inches of length.

8. Do not loop or coil wires. Be sure to maintain adequate wire bending space per NEC. Trim excessive

wire length.

9. Use on solidly grounded systems unless the SPD model is designed for installation on ungrounded/

HRG systems.

10. Energize and conrm proper operation of green LED indicator.

Page: 10

Figure 4: Nipple

A

BC

GN

BREAKER

Sealing gasket:

Two choices

1) At 3/4 in. nom. thread: ID is 1.05 in.

2) At 0.14 in. high 'base step': ID is 1.25 in.

SPD50K

Figure 5: Typical panel Installation

To Protected Loads

(Type 1 or individual equipment

installations may vary)

Use closest breaker to SPD

Locate SPD close to intended

breaker

Keep Leads Short as Possible

Avoid Sharp Bends

Rotate Model SPD50K

such that LED indicator is

most visible

Outdoor installation requires

appropriate weather sealing

at nipple (gasket, sealing

conduit, etc.)

Page: 11

SPD50K

Figure 6: Single-Phase, Three-Wire Installation

Phase A (Black)

v

}

Neutral (White)

}

v

Black

White

Black

Phase B (Black)

Ground (Green)

Figure 7: Three-Phase, Three- or Four-Wire, Grounded WYE Installation

Phase A (Black)

A

N

Phase B (Black)

B

Neutral (White)

Green

Black

Black

White

v

Phase C (Black)

C

Ground (Green)

Black

Green

1

Note 1: The neutral conductor is not present on three-wire Wye grounded power systems.

Figure 8: Three-Phase, Three-Wire, Delta Installation

Black

Black

Black

Green

Page: 12

Phase A (Black)

v

Phase B (Black)

Phase C (Black)

Ground (Green)

Figure 9: Mounting the SPD50K

• 3/4" pipe nipple (conduit nut included)

• With L-bracket mounting kit accessory

- Standard 35mm DIN-Rail (not included)

• L-bracket tightens onto DIN-Rail

- Standard at mounting surface

• Attach L-bracket to surface via mounting holes

SPD50K

Std. 3/4”-14

Nipple

DIN-Rail Mount

(rail not incl.)

Bracket Mount

for at surfaces

Surface-Mount Installation

Note: Mount the unit as close as possible to the protected panel.

1. Make perforations on the wall according to the screw holes located on the enclosure. (Rotate dimensions

90° as appropriate depending on orientation).

2. Congure the electrical conductor and conduit connection consistent with the installation instructions

in this manual.

Page: 13

SPD50K

Operation

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Apply appropriate personal protective equipment (PPE) and follow safe electrical work practices. See NFPA 70E,

NOM-029-STPS or CSA Z462.

• This equipment must only be installed and serviced by qualied electrical personnel.

• Turn o all power supplying this equipment before working on or inside equipment.

• Always use a properly rated voltage sensing device to conrm power is o.

• Replace all devices, doors and covers before turning on power to this equipment.

• This equipment must be eectively grounded per all applicable codes. Use an equipment-grounding conductor to

connect this equipment to the power system ground.

Failure to follow these instructions will result in death or serious injury.

LED Status Indicators

Diagnostic LEDs are located on the front of the SPD50K device. They operate as follows:

• Verify that all phase voltages are present. If the LED is not illuminated, the device may not be installed

correctly. Check the power supply and service voltage. Upon energizing the SPD, check the LED status. If

LED is illuminated, surge suppression is operating.

• If one LED is illuminated, there is a loss of surge suppression.

• If an inoperative condition occurs the device must be replaced by a qualied electrical personnel.

Figure 10: Diagnostic Operation

Indicator LED is GREEN = OK

Indicator LED OFF = loss of

surge suppression, replace as required.

Page: 14

SPD50K

Dry Contacts

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Use 600VAC rated dry contact wiring.

• Dry contact wiring must have less than 1/16 in. (1.6mm) exposed wire from the dry contact block.

• Do not supply more than 24VDC / 24VAC and no more than a current of 2 A.

Failure to follow these instructions will result in death or serious injury

This SPD50K device is provided with dry contacts. The unpowered state shall be closed between the common

wire and the normally closed wire. This is also the alarm condition. The opposite state, closed between the

common wire and the normally open wire, indicates that power is on to the unit and that no alarm condition

exists. These dry contact leads can be used for remote indication of the SPD operating status to a computer

interface board or emergency management system.

The dry contacts are designed for a maximum voltage of 24VDC / 24VAC and a maximum current of 2 A.

Higher energy applications may require additional relay implementation outside the SPD. Damage to the

SPD’s relay caused by use with energy levels in excess of those discussed in this instruction bulletin are not

covered by warranty. For application questions, please contact SolaHD Technical Services.

Connecting Optional Form C Dry Contact & Audible Alarm

The dry contacts are designed for a maximum voltage of 24VDC / 24VAC and a maximum current of 2 A.

Higher energy applications may require additional relay implementation outside the SPD. Damage to the

SPD’s relay caused by use with energy levels in excess of those discussed in this instruction bulletin are not

covered by warranty. For application questions, call the SolaHD technical support at 1-800-377-4384 or email

us at solahd.technicalservices@emerson.com.

Three 3 ft. (~1 m) 18 AWG wires are included through the nipple with this option. See Figure 12. Gray is

Common, Blue is Normally Open and Red is Normally Closed when energized in its expected installation.

(When not energized, the SPD is no longer in its ‘Normal’ state and contacts will be reversed.)

If the dry contacts are not utilized, insulate lead ends, coil and secure. Audible Alarm will still

function correctly.

The contact is rated 24VDC / 24VAC and a maximum current of 2 A. Higher energy applications require

supplemental relaying. This option monitors the suppression elements condition and is not intended for use as

phase loss or phase detection monitoring.

Page: 15

SPD50K

Figure 11: Leads

• Normally Closed (suggested): Use Gray and Red

• Normally Open: Use Gray and Blue

Blue

Red

Gray

Preventive Maintenance

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Apply appropriate personal protective equipment (PPE) and follow safe electrical work practices. See NFPA 70E,

NOM-029-STPS or CSA Z462.

• This equipment must only be installed and serviced by qualied electrical personnel.

• Turn o all power supplying this equipment before working on or inside equipment.

• Always use a properly rated voltage sensing device to conrm power is o.

• Replace all devices, doors and covers before turning on power to this equipment.

• This equipment must be eectively grounded per all applicable codes. Use an equipment-grounding conductor to

connect this equipment to the power system ground.

Failure to follow these instructions will result in death or serious injury.

Inspect the SPD periodically to maintain system performance and continued transient voltage surge

suppression. During this inspection, check the state of the display LED status indicators.

Page: 16

Technical Support

Website: www.solahd.com

Technical Support E-Mail: solahd.technicalservices@emerson.com

Toll-Free: (800) 377-4384

USA: (847) 268-6651

Warranty

Please see the “Terms & Conditions of Sale” document.

SPD50K

While every precaution has been taken to ensure accuracy and completeness in this manual, Appleton Grp LLC d/b/a Appleton Group

assumes no responsibility, and disclaims all liability for damages resulting from use of this information or for any errors or omissions.

Page: 17

SPD50K Series

A272-329 Rev. 2 03/2021

The Emer son logo is a trademark and ser vice mark of Emerson Elect ric Co.

Appleton Grp LLC d/b/a Appleton Group. SolaH D is a registered t rademark of App leton Grp LLC.

All othe r marks are the proper ty of their respec tive owners. © 2021 Emerson Elec tric Co. All rig hts reserved.

United States

(Headquarters)

Appleton Grp LLC

9377 W. Higgins Road

Rosemont, IL 60018

Unite d States

T +1 800 621 1506

Australia Sales Office

Bayswater, Victoria

T +61 3 9721 0387

Korea Sal es Offic e

Seoul

T +82 2 3483 1555

PN# 96 44_rB

Europe

ATX SAS

Espace I ndustriel N ord

35, rue André Durouchez,

CS 980 17

80084 A miens Cedex 2

France

T +33 3 2254 1390

China Sa les Offic e

Shanghai

T +86 21 3338 7000

Canada

EGS Electrical Group Canada

Ltd.

99 Unio n Street

Elmira O N, N3B 3L7

Canada

T +1 888 765 2226

Middle East Sales Office

Dammam, Saudi Arabia

T +966 13 510 3702

Asia Pac ific

EGS Priv ate Ltd.

Block 4 008, Ang Mo Ki o

Ave 10,

#04 -16 TechPlace 1,

Singapore 569625

T +65 6556 1100

Chile Sa les Offi ce

Las Condes

T +56 2928 4819

Latin America

EGS Comercializadora

Mexi co S de RL de CV

Calle 10 N° 145 Piso 3

Col. San P edro de los Pin os

Del. Álvaro Obregon

Ciudad d e México. 01180

T +52 55 5809 5049

India Sales Office

Chennai

T +91 44 3919 7300

Loading...

Loading...