Solahart PV Systems must be installed and serviced by a suitably qualified person.

Installation Instructions

Single-Phase PV Systems

PATENTS

This PV System may be protected by one or more patents or registered designs in the name of

Solahart Industries Pty Ltd.

TRADE MARKS

™ Trademark of Solahart Industries Pty Ltd.

Note: Every care has been taken to ensure accuracy in preparation of this publication.

No liability can be accepted for any consequences, which may arise as a result of its application.

Warning: For continued safety of this PV System, it must be installed, operated and maintained in

accordance with these instructions and the installation guide supplied with the PV inverter.

Caution: Only qualified and accredited personnel should perform work on PV systems, such as design,

installation, commissioning, maintenance and repairs. Be sure to follow the safety instructions for all system

components. It is also important to observe relevant local codes and regulations for health and safety and

accident prevention.

Only Solahart parts and Solahart approved parts may be used. No substitute parts may be used without

prior approval from Solahart Industries Pty Ltd. Only parts supplied by Solahart Industries Pty Ltd are

covered by the Solahart warranty.

The warranty can become void if safety devices are tampered with or if the installation is not in

accordance with these instructions.

3

CONTENTS

Contents ....................................................................................................................................... 3

Overview ....................................................................................................................................... 4

Wiring Diagrams .......................................................................................................................... 6

Earthing Arrangements – All Systems .................................................................................... 10

Installation Procedure ............................................................................................................... 11

Planning ..................................................................................................................................... 12

Racking ....................................................................................................................................... 17

Rooftop Isolator ......................................................................................................................... 24

Wiring ......................................................................................................................................... 25

Power Optimizers (SolarEdge only) ........................................................................................ 27

PV Modules ................................................................................................................................ 30

Inverter ....................................................................................................................................... 35

Meter (SolarEdge Only) ............................................................................................................. 39

Labelling ..................................................................................................................................... 42

Commissioning .......................................................................................................................... 44

Engineering Certification .......................................................................................................... 51

Solahart PV System Warranty - Australia Only ...................................................................... 53

4

OVERVIEW

The following installation instructions detail installation procedures for photovoltaic modules, power optimizers,

inverter, module racking systems and balance of system (BOS) components.

Prior to the installation of any grid connected PV system, a Site Visit shall be performed in accordance with

the Clean Energy Council’s “Grid-Connected Solar PV Systems - Design Guidelines for Accredited Installers”.

SAFETY REQUIREMENTS

The voltages and currents produced by a single module or modules connected in series (voltages added

together) or in parallel (currents added together) can be dangerous.

Although module DC plug connectors are insulated to provide touch safe protection, the following points must

be observed when handling modules in order to avoid the risk of sparking, fire hazard, burn risk, and lethal

electric shocks:

Exercise extreme caution when wiring modules and look out for damaged or split cable ends.

Do not perform wiring work in rainy or damp conditions.

Never insert metallic or otherwise conductive objects into plugs or sockets.

Ensure that all electrical connections are completely dry and free from contaminants before they are

assembled.

Ensure that connections are tight and correctly made.

Keep all materials, tools and work areas clean and dry.

Always use appropriate safety equipment such as insulated tools and wear personal protective equipment

such as insulated gloves.

Solar modules produce current when exposed to sunlight. It is recommended that the system is shielded

with an opaque cover during installation, maintenance or repair work.

INSTALLER RESPONSIBILITIES

The installer is solely responsible for:

Observing and conforming to all relevant Australian Standards, all relevant Clean Energy Council

Accreditation guidelines and all applicable laws, ordinances, regulations, codes of practice and local or

national building codes, including any that may have superseded these Installation Instructions.

Ensuring that the installation complies with AS/NZS 3000, AS/NZS 5033, AS/NZS 1170.2,

AS/NZS 1562.1, AS 4777.1, AS/NZS 1768, AS/NZS 3008, AS 2050 and any relevant electrical service

and installation rules for the state or territory where the system is installed.

Ensuring that the PV System and associated components are appropriate for the particular installation

and the installation environment.

Ensuring that the roof, roof rafters, battens, purlins, connections, and other structural support members

can support the total assembly under building live load conditions. The roof on which the PV system is to

be installed must have the capacity to resist the combined Design Dead Load and Live Load at each

mounting point.

Ensuring only parts supplied by Solahart Industries and installer supplied parts as specified by Solahart

Industries are utilised (substitution of parts may void the warranty and invalidate certification).

Ensuring that lag screws have adequate pull-out strength and shear capacities to suit the installation.

Maintaining the waterproof integrity of the roof, including selection of appropriate flashing.

Ensuring safe installation of all electrical aspects of the PV system.

OVERVIEW

5

DISCLAIMER OF LIABILITY AND WARRANTY

Solahart assumes no responsibility for loss, damage or expense resulting from improper installation, handling

or misuse of PV modules. Refer to “Solahart PV System Warranty - Australia Only” on page 53 for full warranty

terms and conditions.

IEC 61730 INFORMATION

Modules supplied by Solahart are designed to fulfil the criteria of application Class A requirements according

to IEC 61730. Modules are qualified for application Class A: Hazardous voltage (Higher than 50 V DC) and

hazardous power (higher than 240 W) applications where general contact access is anticipated. For the

purposes of AS/NZS 3000, modules are classified as Class I equipment.

FIRE GUIDELINES

Utilise the following fire safety guidelines when installing modules supplied by Solahart:

Modules supplied by Solahart have a Class C Fire Rating.

Check with local authorities for guidelines and requirements concerning fire safety for any building or

structure on to which the modules will be installed.

The system design should ensure that fire fighting personnel can access the system in the event of a

building fire. Check with local authorities for any applicable regulations concerning setbacks or other

placement restrictions that may apply for roof-mounted PV arrays.

Any electrical equipment can pose a fire risk. Modules must therefore be mounted over a fire retardant

roof covering rated for the application and a distance of 60mm between the module and the mounting

surface must be respected to allow free circulation of air beneath the module.

ENVIRONMENTAL FACTORS

Solahart’s limited warranty is based upon modules being installed in accordance with the following conditions:

Modules are not suitable for installation in potentially hazardous locations.

Modules should not be installed in locations:

near sources of flammable gases, vapours or open flames.

in direct contact with salt water/spray. Avoid installing in areas subject to high salt mist content.

which experience extreme hail and/or snow.

where they may be exposed to sulphur e.g. near sulphur springs or volcanoes

where they may be exposed to harmful chemicals.

WARNINGS

Warning: This document provides sufficient information for system installation heights up to 10 m. If the

installation site is more than 10 m in height contact Solahart Industries for further advice.

Warning: This system has not been certified for, and should not be installed in, wind region D.

Warning: During installation and when working on the roof, be sure to observe the appropriate OH&S safety

regulations and relevant regulations of your local region.

Warning: Ensure electrical connection/ disconnection is performed only when the relevant circuit is isolated.

Do not connect / disconnect wiring under load conditions.

Warning: Do not expose the PV modules to artificially concentrated light.

Warning: Do not drill holes in the modules as this will void product warranty.

6

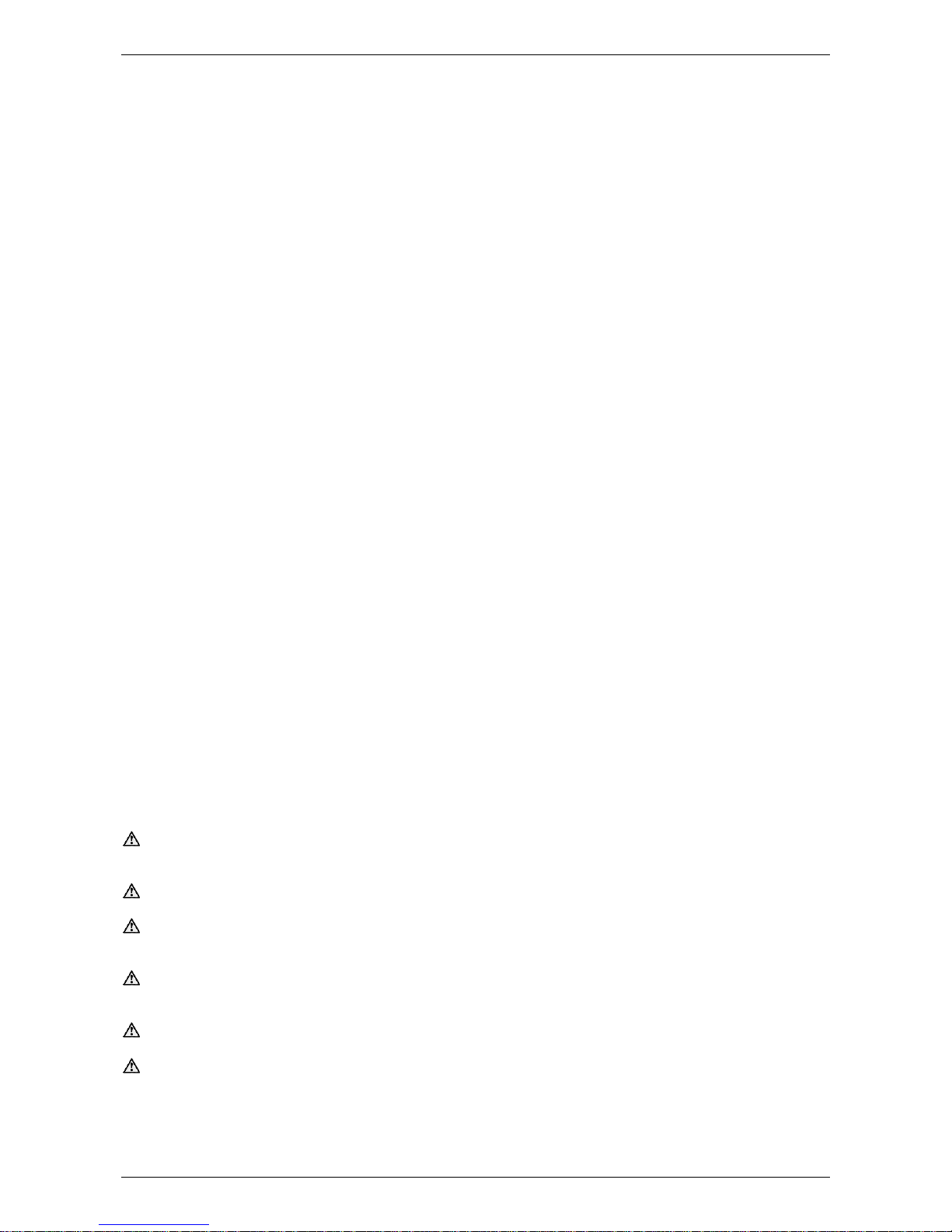

WIRING DIAGRAMS

SINGLE INPUT INVERTER SYSTEMS

For DC Isolator Wiring refer to “DC Isolator Wiring” on page 26.

REC280TP Modules

Inverter

Min No

of

Modules

Max No of

Modules

per String

Max

No of

Strings

Max No

of

Modules

per

Inverter

Max

System

Power

Rating

(W) *

I

sc

(A)*

per

String

V

oc

(V)*

UNO-DM-2.0-TL-PLUS-B

3 8 1 8 2240

9.4

Check

Voltage

Tables on

page 9

SB1.5-1VL-40

3 7 1 7 1960

9.4

SB2.5-1VL-40

3

11 1 11

3080

9.4

REC290TP2 Modules

Inverter

Min No

of

Modules

Max No of

Modules

per String

Max

No of

Strings

Max No

of

Modules

per

Inverter

Max

System

Power

Rating

(W) *

I

sc

(A)*

per

String

V

oc

(V)*

UNO-DM-2.0-TL-PLUS-B

3 8 1 8 2320

9.58

Check

Voltage

Tables on

page 9

SB1.5-1VL-40

3 6 1 6 1740

9.58

SB2.5-1VL-40

3

11 1 11

3190

9.58

* Values measured at standard test conditions (STC) defined as: irradiance of 1000 W/m2, Spectrum AM 1.5

and cell temperature 25ºC. Variations from STC values will affect actual Isc and Voc and should be allowed for.

Note: -10oC used to calculate maximum V. If minimum temperatures are expected to be lower than -10oC,

maximum number of modules must be re-evaluated.

For earthing arrangement and wiring diagram refer to “Earthing Arrangements – All Systems” on page 10.

WIRING DIAGRAMS

7

MULTIPLE INPUT INVERTER SYSTEMS

For DC Isolator Wiring refer to “DC Isolator Wiring” on page 26.

REC280TP Modules

Inverter

Min No

of

Modules

Max No of

Modules

per String

Max

No of

Strings

Max No of

Modules

per

Inverter

Max

System

Power

Rating

(W) *

I

sc

(A)*

per

String

V

oc

(V)*

SB3.0-1AV-40

5

13 2 14

3920

9.4

Check

Voltage

Tables on

page 9

SB4.0-1AV-40

5

13 2 19

5320

9.4

SB5.0-1AV-40

5

13 2 23

6440

9.4

PVI-3.0-TL-OUTD

4

13 2 14

3920

9.4

PVI-4.2-TL-OUTD

4

13 2 20

5600

9.4

PVI-5000-TL-OUTD

4

13 2 21

5880

9.4

UNO-DM-3.3-TL-PLUS-B

4

13 2 15

4200

9.4

UNO-DM-4.0-TL-PLUS-B

4

13 2 19

5320

9.4

UNO-DM-5.0-TL-PLUS-B

4

13 2 23

6440

9.4

REC290TP2 Modules

Inverter

Min No

of

Modules

Max No of

Modules

per String

Max

No of

Strings

Max No of

Modules

per

Inverter

Max

System

Power

Rating

(W) *

I

sc

(A)*

per

String

V

oc

(V)*

SB3.0-1AV-40

5

13 2 13

3770

9.58

Check

Voltage

Tables on

page 9

SB4.0-1AV-40

5

14 2 18

5220

9.58

SB5.0-1AV-40

5

14 2 22

6380

9.58

PVI-3.0-TL-OUTD

4

13 2 13

3770

9.58

PVI-4.2-TL-OUTD

4

14 2 19

5510

9.58

PVI-5000-TL-OUTD

4

14 2 21

6090

9.58

UNO-DM-3.3-TL-PLUS-B

4

14 2 15

4350

9.58

UNO-DM-4.0-TL-PLUS-B

4

14 2 18

5220

9.58

UNO-DM-5.0-TL-PLUS-B

4

14 2 22

6380

9.58

WIRING DIAGRAMS

8

* Values measured at standard test conditions (STC) defined as: irradiance of 1000 W/m2, Spectrum AM 1.5

and cell temperature 25ºC. Variations from STC values will affect actual Isc and Voc and should be allowed for.

Note: -10oC used to calculate maximum V. If minimum temperatures are expected to be lower than -10oC,

maximum number of modules must be re-evaluated.

For earthing arrangement and wiring diagram refer to “Earthing Arrangements – All Systems” on page 10.

SE5000 INVERTER SYSTEMS

For DC Isolator Wiring refer to “DC Isolator Wiring” on page 26.

REC280TP Modules

Inverter

Min No

of

Modules

Max No of

Modules

per String

Max

No of

Strings

Max No of

Modules

per

Inverter

Max System

Power Rating

(W) *

Max

Inverter

Current

(A)*

Max

Inverter

Voltage

(V)*

SE5000

SE5000-xxxxxxx **

8

18 2 23

6440

19.5

500

SE5000H

8

20 2 23

6440

13.5

480

REC290TP2 Modules

Inverter

Min No

of

Modules

Max No of

Modules

per String

Max

No of

Strings

Max No of

Modules

per

Inverter

Max System

Power Rating

(W) *

Max

Inverter

Current

(A)*

Max

Inverter

Voltage

(V)*

SE5000

SE5000-xxxxxxx **

8

18 2 22

6380

19.5

500

SE5000H

8

19 2 22

6380

13.5

480

WIRING DIAGRAMS

9

* Values measured at standard test conditions (STC) defined as: irradiance of 1000 W/m2, Spectrum AM 1.5

and cell temperature 25ºC. Variations from STC values will affect actual Isc and Voc and should be allowed for.

** This model may have suffixes indicating different options and functionality.

Note: -10oC used to calculate maximum V. If minimum temperatures are expected to be lower than -10oC,

maximum number of modules must be re-evaluated.

For earthing arrangement and wiring diagram refer to “Earthing Arrangements – All Systems” on page 10.

VOLTAGE TABLES FOR SMA AND ABB SYSTEMS

Voc of REC280TP = 39.2V

REC280TP

No of Modules per String

Voc of the String

No of Modules per String

Voc of the String

3

117.6

9

352.8

4

156.8

10

392

5

196

11

431.2

6

235.2

12

470.4

7

274.4

13

509.6

8

313.6

Voc of REC290TP2 = 38.8V

REC290TP2

No of Modules

per String

Voc of the

String

No of Modules per

String

Voc of the

String

3

116.4

9

349.2

4

155.2

10

388

5

194

11

426.8

6

232.8

12

465.6

7

271.6

13

504.4

8

310.4

14

543.2

VOLTAGE TABLES FOR SOLAREDGE SYSTEMS

Note: SolarEdge Inverters operate on a fixed string voltage. The V

oc

of the string is fixed to the nominal DC

voltage of the inverter regardless of the panel Voc.

Voc of REC280TP = 39.2V

Voc of REC290TP2 = 38.8V

Inverter Model

Nominal DC Voltage

Voc of string

SE5000

350 Vdc

350 Vdc

SE5000-xxxxxxxxx *

400 Vdc

400 Vdc

SE5000H

380 Vdc

380 Vdc

* This model may have suffixes indicating different options and functionality.

10

EARTHING ARRANGEMENTS – ALL SYSTEMS

Earthing connections must be made so the removal of one component (e.g. a module) does not interrupt the

earthing to other parts of a system (e.g. other modules). Daisy chaining is not permitted. The PV system earth

connection must be directly connected to the switchboard earth link, not via the inverter earth connection. If

the earth cable could be exposed to direct sunlight, it must have a physical barrier to protect the earth cable

from this exposure.

Earth wires must be sized in accordance with requirements set out in Earthing and bonding arrangements of

AS/NZS 5033.

Solahart approved earthing plates may be used to earth modules via the racking, instead of wiring directly to

the module frames. Refer to “Earthing” on page 31 for more information.

Warning: Do not drill holes in the modules as this will void product warranty.

The racking may be earthed by means of a rooftop isolator bracket. Refer to “Rooftop Isolator” on page 24 for

details.

Where it is necessary to make an earthing connection to a rail that does not have a rooftop isolator bracket

fitted, a rail splice piece will provide a suitable surface for connection. In this case, the splice should be attached

to the end of the rail using both fixing bolts, and then the earth lug connected to the splice as shown in the

figures below:

1. Slide rail splice onto end of rail, ensuring an overhang of approximately 50 mm.

2. Secure rail splice by tightening both Allen head bolts to 15 Nm.

3. Drill a hole in the centre of the rail splice, attach the earth cable using the earthing set supplied, and tighten

to 5 Nm.

Rail splice attached to rail with both Allen head bolts

Earth cable connected to splice

11

INSTALLATION PROCEDURE

1. Planning – Design the system and layout. Refer to “Planning” on page 12.

2. Determine the spacing of the Rail Supports using the “Maximum Rail Support Spacing Tables” on page

18 and considering the following factors (refer to “Planning” on page 12):

a. Wind Region

b. Terrain Category

c. Roof Type

d. Roof Area

e. Building Height

f. Array Orientation

3. Install the Racking (Rail and Rail Supports). Refer to “Racking” on page 17.

4. Install the remainder of the roof top components as follows:

a. Rooftop Isolator. Refer to “Rooftop Isolator” on page 24.

b. Rooftop Wiring. Refer to “Wiring” on page 25.

c. Power Optimizers. Refer to “Power Optimizers (SolarEdge only)” on page 27.

d. PV modules. Refer to “PV Modules” on page 30.

5. Install the inverter. Refer to “Inverter” on page 35.

6. Install the energy meter (optional component). Refer to “Meter (SolarEdge Only)” on page 39.

7. Install the system labels. Refer to “Labelling” on page 42.

8. Commission the PV system. Refer to “Commissioning” on page 44.

12

PLANNING

INSTALLATION TOOLS

4,5 & 6 mm Allen keys or 4,5 & 6 mm Allen Key fittings to suit torque adjustable drill (for racking

components and inverter)

Torx T20 screwdriver (ABB inverter systems only)

Cordless torque adjustable drill

Angle grinder with stone disk (for tile cutting if required)

Electricians hand tools (screwdrivers, pliers etc.)

String line

Timber to shim tile roof interfaces (if required)

STRUCTURAL ASSESSMENT

The installer is responsible for ensuring that the building and building structures are capable of withstanding

the additional loads and forces generated as a result of installing the PV system. For domestic dwellings, it is

recommended that a structural engineering assessment is completed. For all other installations, a structural

assessment is required to be completed by a qualified structural engineer.

COMMUNICATIONS DEVICES

Complete installation of inverter communications devices requires the installer to register the communication

device and inverter on the inverter manufacturer’s web portal. Hence, to complete the communications

equipment installation, the installer must have access to the PV system owner’s internet connection. An

example of items that should be organised prior to onsite installation are:

Confirmation that an internet accessible network port is available

Length of networking cable required from inverter to networking port

Wi-Fi access including SSID and password

PV system owner’s network administrator permission and assistance to adjust firewall, network

address translation (NAT) and port forwarding settings.

PV MODULE ORIENTATION AND INCLINATION

To maximize system output, install modules at optimum orientation and inclination (tilt) angles. The specifics

of this will depend on the installation location and must be calculated by a qualified system designer. The ideal

angle for mounting a module should result in the sun’s rays falling perpendicular (i.e. at a 90° angle) to the

module surface.

Note: All modules in each series string must have the same orientation and inclination to ensure that modules

do not underperform due to a mismatching of each module’s output.

Modules should be installed in a shade free position. Even minor or partial

shading of the modules/array will reduce array/system output. A module is

considered shade free when it is both:

Free from shade or shadows all year round.

Exposed to several hours of direct sunlight, even during the

shortest days of the year.

Note: The following information is provided as a guide only:

Modules should be installed facing toward true north. Where this

orientation is not practical, a system facing up to 45° (NW or NE)

from true north is satisfactory however losses of up to

approximately 6% will occur. A module facing due east or due

west will experience a loss in performance of approximately 18%.

Inclination of modules should be approximately equal to the local latitude angle. The latitude of some

Australian cities is shown in the “Latitude of Some Australian Cities” on page 13. Modules may be

PLANNING

13

installed at the roof angle for simplicity of installation and appearance, however, if inclination varies by

±15º or more from the correct inclination, performance losses of 4% or more will occur.

Modules should be inclined at an angle of at least 10° to support the self-cleaning function of the

glass.

Losses for incorrect orientation and incorrect inclination will be compounded.

If the roof angle is flat, adjustable or fixed tilt legs should be considered to optimise inclination

depending upon area.

For an installation at right angles to (across) a tile roof pitch, landscape tile roof hooks are required.

Each module and its fittings including racking weighs approximately 25 kg.

LATITUDE OF SOME AUSTRALIAN CITIES

Adelaide

35°S

Cairns

17°S

Hobart

42°S

Port Hedland

20°S

Alice Springs

24°S

Canberra

35°S

Mildura

34°S

Rockhampton

24°S

Brisbane

27°S

Darwin

12°S

Melbourne

38°S

Sydney

34°S

Broken Hill

31°S

Geraldton

28°S

Perth

32°S

Townsville

19°S

WIND REGION

Use the wind region diagram shown below to determine the wind region of the installation site.

Wind region notes:

Wind regions are predefined for all of Australia by Australian Standard AS/NZS 1170.2. The Wind

Region has nothing to do with surrounding topography or buildings.

Most of Australia is designated Region A which indicates a Regional Ultimate Basic Wind Velocity of

45 m/s.

Some areas are designated Region B (57 m/s). Local authorities will advise if this applies in your

area.

Region C areas (66 m/s) are generally referred to as Cyclonic and are generally limited to northern

coastal areas. Most Region C zones end 100 km inland.

Region D (80 m/s) Australia's worst Cyclonic Region between Carnarvon and Pardoo in WA.

PLANNING

14

TERRAIN CATEGORY

The terrain over which the approaching wind flows towards a structure must be assessed on the basis of the

following category descriptions:

Terrain Category 2: Open terrain, including grassland, with well-scattered obstructions having heights

generally from 1.5 m to 5 m, with no more than two obstructions per hectare, e.g. farmland and cleared

subdivisions with isolated trees and uncut grass.

Terrain Category 3: Terrain with numerous closely spaced obstructions having heights generally from 3 m to

10 m. The minimum density of obstructions shall be at least the equivalent of 10 house-size obstructions per

hectare, e.g. suburban housing or light industrial estates.

ROOF TYPE

Determine the roof type of the building where the PV modules are to be installed and select the appropriate

rail support.

Rail support systems are available as follows:

Roof Type

Roof Pitch

Rail Support Category

Rail Support Name (Options)

Standard tile

10 - 30º

Tile roof interface

Tile interface (Portrait)

Tile interface (Landscape)

Low profile tile

Flat tile interface

Slate

Slate interface

Metal

10 - 30º

Metal roof interface

Metal roof interface

Metal

Corrugated

< 10 º

or

< Latitude minus 15º

Tilt leg interface

10 - 15° adjustable tilt legs

15 - 30° adjustable tilt legs

30° fixed tilt legs

30 - 60° adjustable tilt legs

ROOF AREA

Determine the installation area on the roof (roof position area). The diagrams below show roof position areas

designated as “Edge Zone” areas and “Centre Zone” areas according to interface type.

Edge zone areas are subject to higher wind loadings and therefore will require closer rail support spacing.

Warning: If any part of the system array is located in one of the edge zones, the entire array must use the

support spacing specified for the edge zones.

PLANNING

15

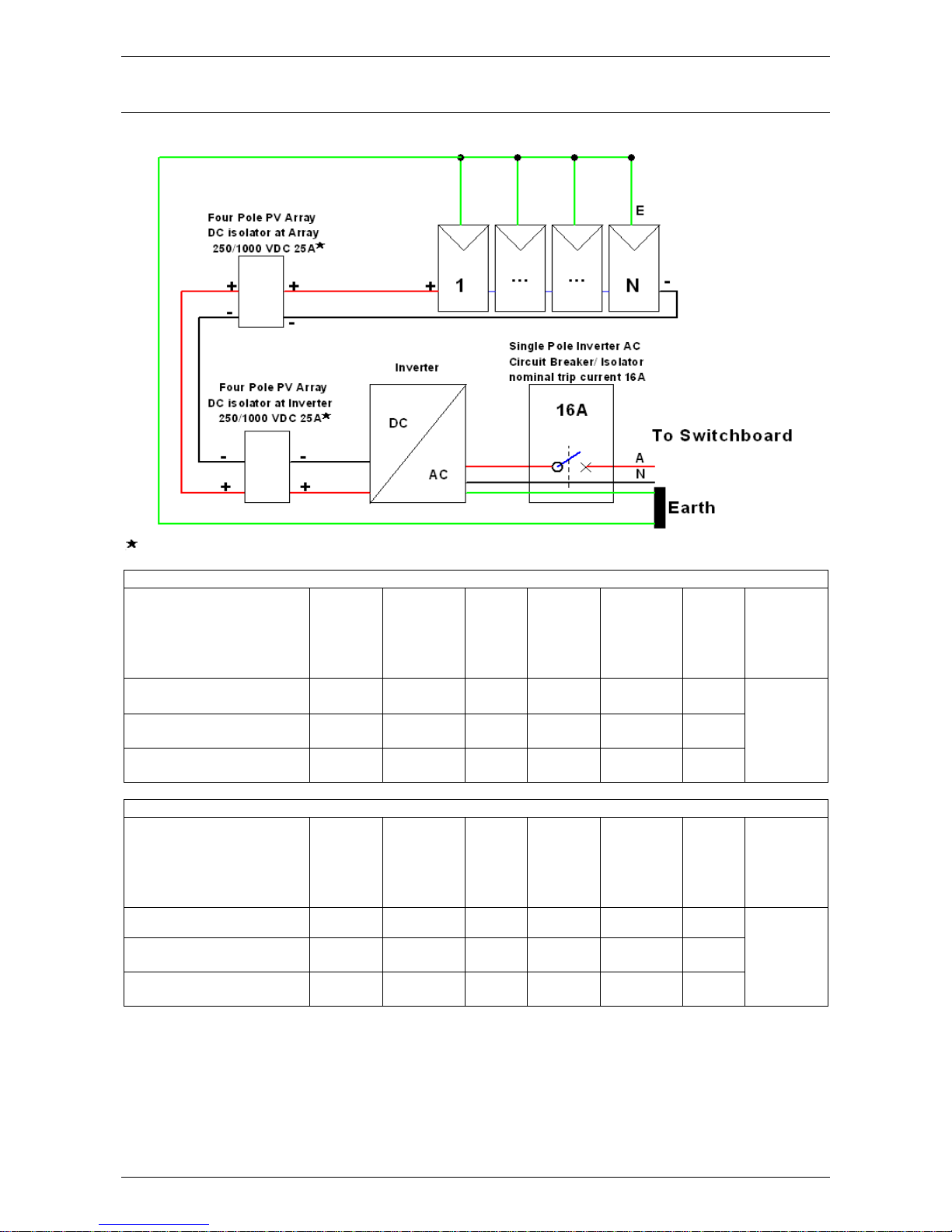

Use the following diagram, tables and worked example to determine the minimum required roof area for

the array when designing and installing with REC280TP modules.

REC280TP spacing and dimensions

Worked Example:

Number of rows: 2

Number of modules per row: 10

Total number of modules = 20

Calculating H:

H=N

rows

×(1,665+20

)

-20

H=2×1,685-20

H=3,350 mm

Calculating W:

W=

N

modules/row

×(991+18)+(2×25

)

-18

W=10×1,009+50-18

W=10,122 mm

Calculating Area

Roof

in mm2:

Area

Roof

=H×W

Area

Roof

=3,350×10,122

Area

Roof

=33,908,700 mm

2

Converting Area

Roof

in mm2 to m2:

Area

Roof

=

33,908,700

1,000,000

=33.91 m

2

Calculating Area

Roof

in m2:

Area

Roof

=

H

1,000

×

W

1,000

Area

Roof

=

3,350

1,000

×

10,122

1,000

Area

Roof

=3.35×10.122

Area

Roof

=33.91 m

2

Notes:

Modules installed in portrait as per diagram

For tilt leg systems, row spacing must prevent shading of one row by another and needs to be calculated on

an individual site basis, taking into account orientation, roof pitch and module inclination

All dimensions are in mm, unless otherwise stated.

Number of modules per row – REC280TP

1 2 3 4 5 6 7 8 9 10

…

Number of rows

H 1665

1665

1665

1665

1665

1665

1665

1665

1665

1665

1 X X X X X X X X X X X W 1041

2050

3059

4068

5077

6086

7095

8104

9113

10122

H 3350

3350

3350

3350

3350

3350

3350

3350

3350

3350

2 X X X X X X X X X X X W

1041

2050

3059

4068

5077

6086

7095

8104

9113

10122

…

Number of modules per row – REC280TP

1 2 3 4 5 6 7 8 9 10

…

Number of rows

Roof 1

Area

1.73

3.41

5.09

6.77

8.45

10.13

11.81

13.49

15.17

16.85

(m2)

Roof

2

Area

3.49

6.87

10.25

13.63

17.01

20.39

23.77

27.15

30.53

33.91

(m2)

…

PLANNING

16

Use the following diagram, tables and worked example to determine the minimum required roof area for

the array when designing and installing with REC290TP2 modules.

REC290TP2 spacing and dimensions

Worked Example:

Number of rows: 2

Number of modules per row: 10

Total number of modules = 20

Calculating H:

H=N

rows

×(1,675+20

)

-20

H=2×1,695-20

H=3,370 mm

Calculating W:

W=

N

modules/row

×(997+18)+(2×25

)

-18

W=10×1,015+50-18

W=10,182 mm

Calculating Area

Roof

in mm2:

Area

Roof

=H×W

Area

Roof

=3,370×10,182

Area

Roof

=34,313,340 mm

2

Converting Area

Roof

in mm2 to m2:

Area

Roof

=

34,313,340

1,000,000

=34.31 m

2

Calculating Area

Roof

in m2:

Area

Roof

=

H

1,000

×

W

1,000

Area

Roof

=

3,370

1,000

×

10,182

1,000

Area

Roof

=3.37×10.182

Area

Roof

=34.31 m

2

Notes:

Modules installed in portrait as per diagram

For tilt leg systems, row spacing must prevent shading of one row by another and needs to be calculated on

an individual site basis, taking into account orientation, roof pitch and module inclination

All dimensions are in mm, unless otherwise stated.

Number of modules per row – REC290TP2

1 2 3 4 5 6 7 8 9 10

…

Number of rows

H 1675

1675

1675

1675

1675

1675

1675

1675

1675

1675

1 X X X X X X X X X X X

W 1047

2062

3077

4092

5107

6122

7137

8152

9167

10182

H 3370

3370

3370

3350

3370

3370

3370

3370

3370

3370

2 X X X X X X X X X X X W 1047

2062

3077

4092

5107

6122

7137

8152

9167

10182

…

Number of modules per row – REC290TP2

1 2 3 4 5 6 7 8 9 10

…

Number of rows

Roof

1

Area

1.75

3.415

5.15

6.85

8.55

10.25

11.95

13.65

15.35

17.05

(m2)

Roof 2

Area

3.53

6.95

10.37

13.79

17.21

20.63

24.05

27.47

30.89

34.31

(m2)

…

17

RACKING

OVERVIEW OF RACKING COMPONENTS

Overview of components for tile roof

Rail

(a)

Rail splices

(c)

Tile roof

Interfaces (b)

Z-modules with

Allen head bolt

Wood screws M6

x 80

Overview of components for metal roof

Rail

(a)

Rail splices

(c)

Metal roof

interfaces (b)

Z-modules with

Allen head bolt

Wood screws M6

x 90 *

Overview of components for adjustable tilt legs

Rail

(a)

Rail splices

(c)

Z-modules with

Allen head bolt

Front rail &

leg foot (d)

Adjustable

tilt leg (e)

Wood Screws

M6x90 *

Overview of components for 30º fixed tilt legs

Rail

(a)

Rail splice

(c)

Z-modules with

Allen head bolts

Front rail &

leg foot (d)

Fixed

tilt leg (e)

Wood Screws

M6x90 *

* Note: Screws must be fit for purpose e.g. screws used in metal purlins must be suitable for metal structures

and have a TPI (threads per inch) of 14.

Tile & Metal Roof Diagram (Tile Roof shown)

Tilt Leg Diagram (Adjustable Tilt Leg shown)

Rail Support Spacing

Rail Support Spacing

Rail

Spacing

Rail

Spacing

Rail Overhang

RACKING

18

RAIL SUPPORT SPACING

Use the following tables to determine the rail support spacing for the relevant roof type based on the previously

determined wind region, terrain category, roof position area (Edge Zone or Centre Zone) and maximum height

of the installation.

MAXIMUM RAIL SUPPORT SPACING TABLES

Wind Region A

Terrain Category 2 3

Roof Area

Edge Zone

Centre Zone

Edge Zone

Centre Zone

Roof Height (m)

5

10 5 10 5 10 5 10

Tile Roof (Timber Rafters only)

1200

950

1575

1275

1475

1800

Metal Roof with Timber Battens

1505

1247

1700

1600

1675

1800

Metal Roof with Steel Battens

1075

890

1523

1261

1432

1800

Tilt Legs – PV Module Angle 15°

1325

1025

1500

1254

1400

1575

Tilt Legs – PV Module Angle 30°

1089

902

1400

1350

1325

1500

Wind Region B

Terrain Category 2 3

Roof Area

Edge Zone

Centre Zone

Edge Zone

Centre Zone

Roof Height (m)

5

10 5 10 5 10 5 10

Tile Roof (Timber Rafters only)

825

675

1100

875

1025

1350

Metal Roof with Timber Battens

938

777

1329

1101

1250

1759

Metal Roof with Steel Battens

670

555

949

786

893

1265

Tilt Legs – PV Module Angle 15°

927

768

944

782

1235

1257

Tilt Legs – PV Module Angle 30°

679

562

1078

892

904

1435

Wind Region C

Terrain Category 2 3

Roof Area

Edge Zone

Centre Zone

Edge Zone

Centre Zone

Roof Height (m)

5

10 5 10 5 10 5 10

Tile Roof (Timber Rafters only)

525

450

700

575

650

850

Metal Roof with Timber Battens

582

526

825

745

910

735

1289

1042

Metal Roof with Steel Battens

416

375

589

532

650

525

921

744

Tilt Legs – PV Module Angle 15°

576

520

586

529

850

727

915

740

Tilt Legs – PV Module Angle 30°

421

380

669

604

658

532

1045

845

Roof interfaces must be fixed to rafters or purlins under the roof cladding. Screw minimum embedment into

timber rafters is 50 mm and 35 mm for timber battens.

Steel purlins must meet the following minimum requirements:

Roof interface

Minimum steel purlin specification

Metal roof interface

0.55 mm BMT 550 Grade or 0.75 mm BMT 450 Grade

Tilt leg interface

1.0 mm BMT 500 Grade

Note: Screws supplied with the roof interfaces are wood screws suitable for timber only. Screws used in metal

purlins must be suitable for metal structures and have a TPI (threads per inch) of 14.

RACKING

19

RAIL SPACING

Rails should be spaced so that the module is clamped in the correct positions.

In general, the rails may be spaced between 833 mm and 1249 mm apart for REC280TP modules and 843 mm

and 1259 mm apart for REC290TP2 modules.

RAIL OVERHANG

Rail end overhang must be no greater than 50% of rail support spacing. For example; if rail support spacing is

1200 mm, rail end overhang can be up to 600 mm. In this case, two rail support brackets can support a rail up

to 2400 mm in length (1200 mm between brackets and 600 mm of overhang at each end).

Note: Drawings not to scale

Rail Spacing:

REC280TP: 833 – 1249 mm

REC290TP2: 843 – 1259 mm

Rail Support

Spacing = x

Rail Overhang < x/2

RACKING

20

TILE ROOF INSTALLATION

Note: The tile roof interface is only suitable for installation on timber rafters.

1. Determine and mark the position of the

tile roof interfaces according to your

plans. Remove the roof tiles at marked

positions or, if possible, simply move the

tiles up slightly.

2. Fix the tile roof interfaces to rafters

using two M6 X 80 mm wood screws.

Ensure a 50 mm minimum screw

embedment into the rafters.

3. Warning: Tile roof interfaces must not

press against roof tiles and must be

fixed parallel with rafters. If necessary,

pack underneath tile roof interfaces with

timber.

Incorrect

Correct

4. Warning: Do not use tile roof interfaces

as a climbing support as extreme

loading of this point could cause

damage to the tile below.

5. For thin tiles (such as slate, shingles)

proceed directly to step 6.

For thick tiles (such as grooved tiles), if

necessary, use an angle grinder to

chase a recess (or remove raised

groves) on the tile that covers the tile

roof interface at the point where the

interface protrudes through so that the

tile lies flat.

For thick tiles it may also be necessary

to cut a recess into the tile located below

the tile roof interface.

Now proceed to installation of the rails.

Refer to “Rail Installation” on page 23.

RACKING

21

6. For thin tiles (such as slate, shingles), a

portion of tile must be cut and removed

from the tile above the tile roof interface,

creating a recess.

Suitable flashing must then be installed

around the tile roof interface, with an

overlap of at least 150mm at the edges

of the recess.

Now proceed to installation of the rails.

Refer to “Rail Installation” on page 23.

METAL ROOF INSTALLATION

Note: Screws supplied with the roof interfaces are wood screws suitable for timber only. Screws used in metal

purlins must be suitable for metal structures and have a TPI (threads per inch) of 14.

1. Determine and mark position of the metal roof

interfaces according to your plans. Pre drill

through roof cladding (on top of crest) at planned

locations. Place the supplied rubber gasket under

the metal roof interface and ensure that a

weatherproof seal is made between the interface

and the roof cladding.

2. Fix the metal roof interface to the timber batten or

rafter using the M6 x 90 mm screw supplied.

Ensure a 50 mm minimum screw embedment for

rafters or 35 mm for timber battens.

If the interface is being fixed to metal purlins use

screws suitable for metal structures with a TPI of

14.

3. Check the metal roof interface to ensure that the

fastening screw tightly fixes sealing gasket

without damaging roof cladding.

Now proceed to installation of the rails. Refer to

“Rail Installation” on page .

RACKING

22

TILT LEG INSTALLATION

Note: Screws supplied with the tilt legs are wood screws suitable for timber only. Screws used in metal purlins

must be suitable for metal structures and have a TPI (threads per inch) of 14.

1. Determine and mark position of feet according

to your plans. Pre drill through roof cladding (on

top of crest) at planned locations. Place the

supplied rubber gaskets under each foot and

ensure that a weatherproof seal is made

between the foot and the roof cladding.

2. Fix the foot to the timber batter or rafter using a

minimum of two M6 X 80 mm screws.

Ensure a minimum screw embedment of

35 mm for timber battens and 50 mm for rafters.

If the interface is being fixed to metal purlins

use screws suitable for metal structures with a

TPI of 14.

Check the foot to ensure that the fastening

screws tightly fix the sealing gaskets without

damaging roof cladding.

Adjustable tilt leg foot

30º fixed tilt leg foot

3. Adjustable tilt legs only: Insert feet U

brackets into front feet and loosely fasten Allen

head bolt and nut to allow for later adjustment.

Allen head bolt and Z-module on top of U

bracket is utilised to attach rails in next step.

4. For adjustable tilt legs: Place rear legs into

feet, insert Allen head bolt, washer, retaining

washer and nut and fasten loosely to allow for

later adjustment.

For 30º fixed tilt legs: Place rear legs onto

feet, insert Allen head bolt, washer, retaining

washer and nut and tighten to 15-20 Nm.

Adjustable tilt legs

30º fixed tilt legs

5. Loosen the leg telescopic section Allen head

grub screws. Adjust the leg length according to

your plans and tighten the grub screws to

17 Nm.

6. Fix the leg L bracket to the leg using the Allen

head bolt, washer, retaining washer and nut

and fasten loosely to allow for later adjustment.

RACKING

23

RAIL INSTALLATION

1. Install rails onto the roof interfaces. If the

assembly consists of rails of different

lengths, always begin with the shortest

piece. Install the rail loosely onto the roof

interfaces using the Allen head bolt,

washer, retaining washer and Z-modules

supplied (2 to 3 turns of the bolt are

adequate for loose installation). Refer to

step 2 for method of inserting Z-module

into rail.

2. For easy use of Z-modules ensure that

Allen head bolt threads do not project

through lower side of Z-module so that

the Z-module is free to move. Position Zmodules in rail channel as shown and

fasten loosely with 2 to 3 turns of Zmodule Allen head bolt. The rail can then

be freely moved along Z-modules.

3. Adjust the vertical and horizontal position

of the rail by taking advantage of the long

hole in the tile and metal roof interfaces

and the still loose connection of the rail

Z-modules.

4. Align all rail ends.

For adjustable tilt legs: align the rail tilt

orientation (use a string line if

necessary).

Tighten all previously loosely installed

rail and feet Z-module Allen head bolts to

a torque of 21 Nm.

5. To connect multiple rails together, slide

a splice on to the rear side of the

previously assembled rail. Tighten the

first splice Allen head bolt to 15 Nm.

Slide the next rail segment into the

splice. An expansion gap at the rail joints

is recommended. Leave a gap of

approximately 10 mm between the rail

joints and then tighten the second Allen

head bolt to 15 Nm.

24

ROOFTOP ISOLATOR

When installing the rooftop DC isolator, a Solahart Rooftop Isolator Subassembly must be used and must be

mounted to the rail by following the steps below. To help prevent UV degradation, the Rooftop Isolator

Subassembly should be mounted as far from the north side of the array as possible.

When installing the rooftop isolator the following points should be observed:

Ensure the IP rating of the isolator enclosure is maintained and that no moisture can enter. The conduit

entry points must be on the lower end of the enclosure (i.e.: facing downwards) so that any water will run

away from and not towards enclosure entry points. Screw cover caps must be installed and all mounting

holes should be sealed with silicone to help prevent water ingress.

Cable glands and conduit adapters must be chosen to suit the type of cable or conduit used. E.g. cable

glands designed for figure-8 cables must be chosen where figure-8 type solar DC cables are utilised.

Any conduit adapters should be installed so that the conduit slopes downwards from the enclosure to

prevent water ingress in adverse weather conditions.

If water and/or condensation can form in the isolator enclosure, provision must be made for its harmless

escape through suitably located drainage points in accordance with AS/NZS 3000 Clause 3.3.2.3. Conduit

entering the isolator enclosure must have a drainage hole installed at the lowest point to facilitate the

escape of any moisture.

Note: Install Rooftop Isolator Subassembly before installing any PV modules.

1. Determine where the Rooftop Isolator

Subassembly is to be attached.

a. The Rooftop Isolator Subassembly is

configured for installation on the array as

shown above.

b. If the Subassembly is to be fitted in the other

orientation, move the cover (with the Solahart

logo) from position A to position B as shown

above.

c. If in doubt, slide the subassembly into the rail at

the point of attachment (see Step 4) and check

whether the Solahart logo is facing up.

2. Identify the earth connection point on the bracket,

as shown above.

3. Connect the earthing wire to the connection point,

as shown above, using a tightening torque of

5 Nm.

4. Slide the subassembly into the rail making sure

that the Solahart logo is facing up (see Step 1)

5. Tighten both M8 bolts to 15 Nm, ensuring good

connection between the bolts and rail.

25

WIRING

WIRING

Only UV-resistant cables and connectors approved for outside use should be used. PV cable must be marked

or labelled in accordance with AS/NZS 5033.

To minimise the risk of indirect lightning strikes, avoid forming closed loops when designing the system. Check

to ensure that system wiring is correct before commissioning modules. If the measured open circuit voltage

(Voc) and short circuit current (Isc) differ from specifications, a wiring fault may be present.

Recommended cable size for plug connectors is 4 – 6 mm2, with an operating temperature range of -40 to

+120ºC. Plug connectors are polarised and should be firmly connected. All connections should be secure, tight

and electrically and mechanically sound. Correct DC polarity should be observed at all times. Plug connectors

should never be used to turn the system on or off (i.e. do not connect or disconnect plug connectors under

load conditions).

Only use plug connectors supplied with your Solahart PV system, or which are the same type/model and from

the same manufacturer as those on the PV module. Ensure that all plug connectors and plug wiring are in

good electrical and mechanical condition and are not subjected to mechanical stress.

Ensure that all materials meet system requirements such as maximum voltage, current, moisture and

temperature when exposed to sunlight.

Electrical ratings of the PV modules are within 3% of measured values at Standard Test Conditions (STC).

Under normal conditions, a photovoltaic module may experience conditions that produce more current and/or

voltage than that reported under STC. When designing a system, allow for increased output of a module as a

result of conditions different to STC in accordance with the Clean Energy Council’s “Grid-Connected Solar PV

System - Design Guidelines for Accredited Installers” and AS/NZS 5033.

Ensure cables are fixed to the mounting structure and are not in contact with the roof or rear surface of

module(s) by using restraining devices which are sunlight and UV-resistant.

Note: Plastic cable ties are not to be used as primary means of support.

A roof flashing such as a Dektite® must be used where wiring penetrates tile or metal

roofing. Flashings must be sealed using an appropriate waterproofing compound such

as silicone.

All wiring must be protected from mechanical damage and external wiring must be

protected from UV and mechanical damage in such a manner that it will last the life

of the system. All conduits shall comply with AS/NZS 2053.1 and if exposed to sunlight

must be suitably UV rated and marked with the letter “T”. Do not install wiring such

that it is subject to permanent tension.

COMPONENT PLUG AND DC CABLE SIZING TABLE

Cabling

Plug

Cable Size

Plug Rating

Module fly leads

Pre crimped on fly leads

4 mm2

IP67

Module DC extension leads

Supplied in BOS Kit

Min 4 mm2

IP67

Wiring – Roof isolator to inverter isolator

(a)

Not required – hard wired

Min 4 mm2

N/A

Wiring – Inverter isolator to inverter

(b)

Supplied in BOS Kit for

ABB and SolarEdge inverters or as

supplied with SMA inverters.

Min 4 mm2

IP67

(a)

= DC cable supplied by installer.

(b)

= DC cable supplied by installer for SMA inverters only.

All cables/wiring are double insulated Solar DC type cable.

It is recommended the maximum voltage drop between the PV array and the inverter is 3%.

Dektite

WIRING

26

DC ISOLATOR WIRING

The DC isolators utilised in Solahart PV Systems are not polarity sensitive (non polarised type) however for

uniformity they should be wired as shown in the DC isolator wiring diagram below.

Warning: DC isolator terminal screws must be tightened by hand only. Do not use power tools.

DC isolator wiring

diagram

Once wired, the DC isolator should be left in the open position until system commissioning.

27

POWER OPTIMIZERS (SOLAREDGE ONLY)

Warning: Input and output connectors are not watertight until mated. Open connectors should be mated to

each other or plugged with appropriate watertight caps.

Warning: Cutting the power optimizer input or output cables is prohibited and will void product warranty.

Warning: Do not connect / disconnect DC connectors or wiring while under load.

Warning: Only connectors of the same make and model may be connected together.

Note: Modules with SolarEdge power optimizers output a low safety voltage before the inverter is turned ON.

As long as the power optimizers are not connected to the inverter or the inverter is turned OFF, each power

optimizer will output a safe voltage of 1V (±0.1V).

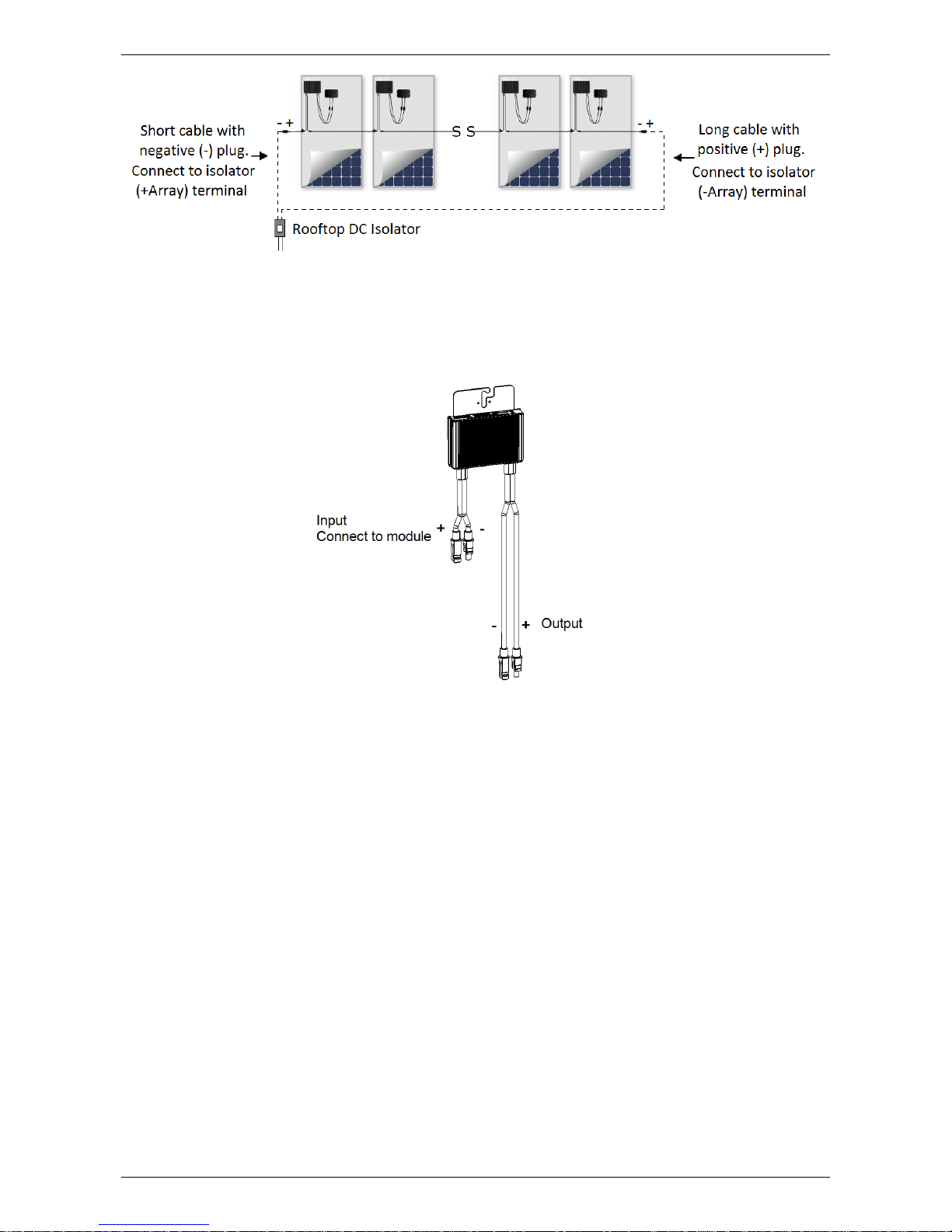

MOUNTING THE POWER OPTIMIZERS

1. Determine and mark the power optimizer mounting locations on the rail:

a. Power optimizers should be spaced approximately 1009 mm (for REC280TP) or 1015mm (for

REC290TP2) apart on the rail. See figure below.

b. Power optimizers must be positioned so that they maintain a 25 mm clearance distance

between the power optimizer and other surfaces to allow for heat dissipation.

Note: Figure is not to scale.

Note: Ensure clearance between power optimizers and PV module junction boxes.

REC280TP: 1009 mm

REC290TP2: 1015 mm

REC280TP: 1009 mm

REC290TP2: 1015 mm

POWER OPTIMIZERS (SOLAREDGE ONLY)

28

2. Attach each power optimizer to the mounting rail using the Z-module assembly provided in the BOS kit.

See figure below. Apply a tightening torque of 9.5 Nm.

Z-module assembly

Note: It is recommended that the power optimizers be placed face down to ensure clearance between the

back of modules and power optimizers. See figure below.

Note: Figure is not to scale.

3. Verify that each power optimizer is securely attached to the rail.

4. Record power optimizer serial numbers and locations. This can be achieved through the use of a paper

template or SolarEdge smartphone application. Refer to SolarEdge supplied documentation for more

information.

POWER OPTIMIZER WIRING PROCEDURE

Warning: Use insulated tools and wear appropriate PPE when performing wiring to prevent the risk of

electric shock.

PV Module and power optimizer DC plug connectors are connected as follows:

Firmly push positive (+) plug into negative (-) plug until an audible

“click” is heard, and then try to pull plugs apart. Incorrectly connected

plugs will come apart whilst correctly connected plugs will not come

apart unless the locking latches on either side of the positive (+) plug

are depressed using an unlocking tool whilst plugs are pulled apart.

Note: Pull on plugs, do not pull on wiring.

+ -

Warning: Do not connect / disconnect DC connectors or wiring while under load.

Warning: Only connectors of the same make and model may be connected together.

The following procedure should be adhered to whilst wiring power optimizer strings to prevent the risk of electric

shock or inadvertent short circuiting of live cables whilst wiring the Rooftop DC Isolator:

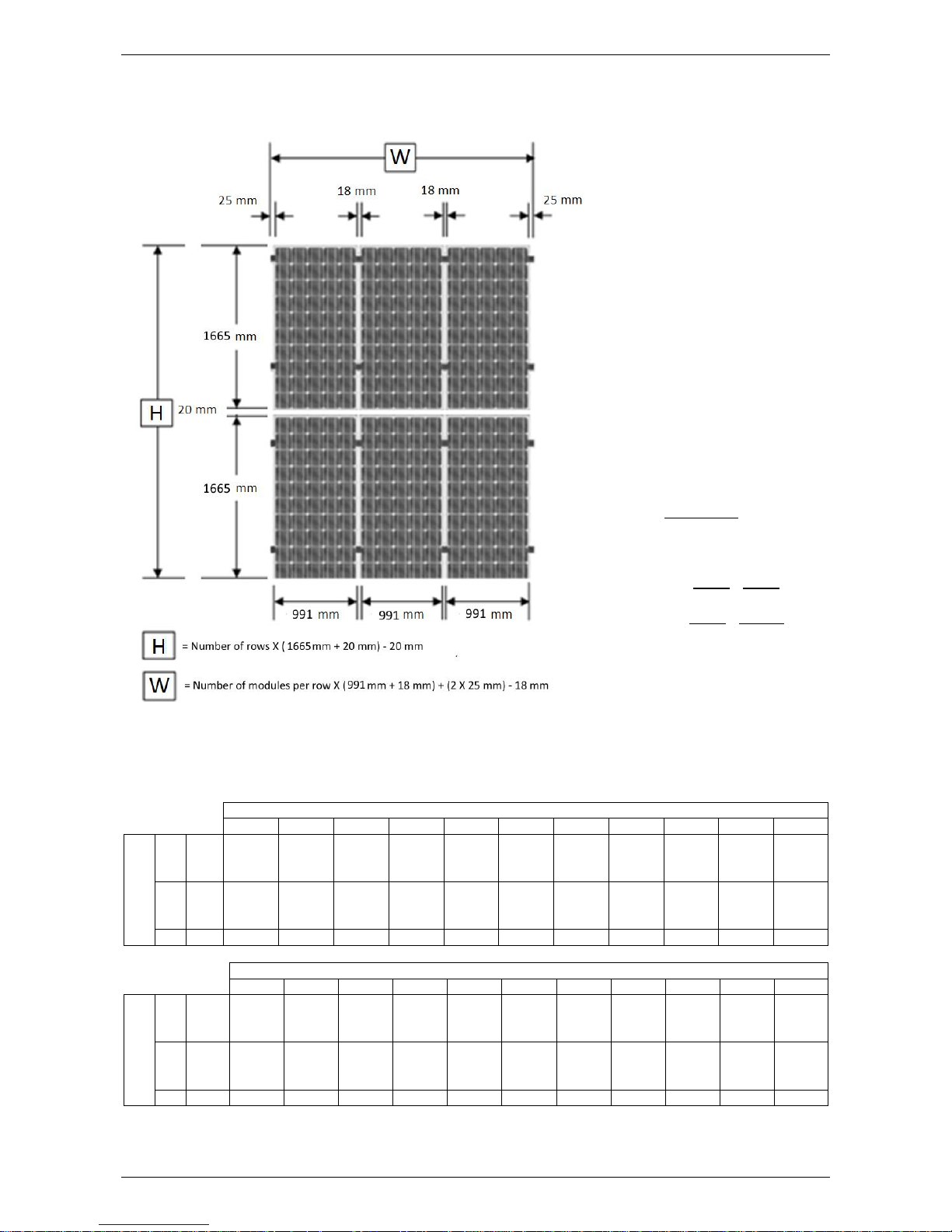

1. Two extension leads per string should be constructed using the DC extension cable provided in the BOS

Kit. One should be short to connect from the first power optimizer in the string to the DC isolator. The other

should be sufficiently long to plug the end power optimizer in the string to the DC isolator (see the example

schematic below).

POWER OPTIMIZERS (SOLAREDGE ONLY)

29

2. Ensure the Rooftop DC Isolator is in the OFF position, strip 12 mm of insulation from the end of each

extension lead and connect the two extension leads to the Rooftop DC Isolator terminals. The Rooftop

DC Isolator should be wired in a consistent manner. Refer to “DC Isolator Wiring” on page 26.

3. Connect the first power optimizer’s positive output (+) cable plug to the Rooftop DC Isolator extension

cable negative (-) plug. See figure below for power optimizer cable plug illustration.

Note: Image is for illustration purposes only. Refer to the label on the product to identify the plus and

minus input and output connectors.

4. Connect each power optimizer’s negative output (-) cable to the following power optimizer’s positive output

(+) cable.

5. Connect the last power optimizer’s negative output (-) cable to the Rooftop DC Isolator extension cable

positive (+) plug.

6. Connect the first power optimizer’s input connectors to the first module’s connectors.

7. Repeat Step 6 for each module and power optimizer in the string.

8. Verify proper power optimizer connection by measuring the voltage of each string individually.

Note: Each power optimizer in the string will output a safe voltage of 1 V (±0.1 V). For example: 9 power

optimizers connected in a single string should output a safe voltage of 9 V (±0.9 V).

Note: Ensure the modules are exposed to sunlight during this process; otherwise, the power optimizers may

not be powered.

9. Repeat Steps 1 - 8 for each string in the PV array.

10. Your PV array wiring is now complete.

Note: The Rooftop DC Isolator should still be in the OFF position at the completion of this stage of the

installation. It should not be turned ON until the correct stage of commissioning. Refer to “Solar Isolation

Device(s) Test – Rooftop DC Isolator(s)” on page 45.

30

PV MODULES

PV MODULES

PV modules generate electricity as soon as they are exposed to sunlight and as such they can represent a

danger. All warnings in this manual must be observed when handling solar modules to avoid the risk of fire,

sparking and/or electrocution.

If modules are connected in series (summing voltage) the combined voltage must not exceed the inverter’s

maximum input voltage rating. For the maximum number of series connected modules permissible, refer to

the relevant wiring diagram in this document for the inverter model installed.

The Solahart mounting system requires the use of modules of equal thickness for correct clamping.

Note: Ensure only modules of the same type (model & thickness) are clamped side-by-side and electrically

connected.

MODULE HANDLING

Modules should be handled with care and protected from damage at all times. All warnings and instructions

on the packaging should be observed. Follow these guidelines when unpacking, transporting or storing the

modules:

Note module serial numbers before installation and record serial numbers in the system documentation.

Carry modules using both hands and do not use the junction box or electrical wiring as a grip.

Do not subject modules or backsheets to loads or stresses.

Do not stand on the modules.

Do not use modules that have been dropped.

Keep all electrical contacts clean and dry.

Store modules in a dry and properly ventilated room.

Do not use sharp or pointed objects to mark module surface or module anodising.

Never apply paints, adhesives, or detergents to the rear laminate of the modules.

Never attempt to disassemble modules, modify or adapt the modules or labels in any way as this will

void the warranty.

Do not drill additional holes in any part of the module. Drilling holes voids the product warranty.

Warning: Do not use modules which are broken or damaged. If the module front glass is broken or laminate

back sheet is damaged in any way, hazardous voltages may be exposed.

STRING WIRING PROCEDURE

Note: If you have completed the “Power Optimizer Wiring Procedure” on page 28, proceed to “Earthing” on

page 31.

Warning: Use insulated tools and wear PPE when performing wiring to prevent the risk of electric shock.

It is suggested that modules be covered with an opaque material during wiring to reduce the voltage generated

by the string.

PV Module DC plug connectors are connected as follows:

Firmly push positive (+) plug into negative (-) plug until an audible

“click” is heard, and then try to pull plugs apart. Incorrectly connected

plugs will come apart whilst correctly connected plugs will not come

apart unless the locking latches on either side of the positive (+) plug

are depressed using an unlocking tool whilst plugs are pulled apart.

Note: Pull on plugs, do not pull on wiring.

+

-

Warning: Do not connect / disconnect DC connectors or wiring while under load.

Warning: Only connectors of the same make and model may be connected together.

PV MODULES

31

The following procedure should be adhered to whilst wiring module strings to prevent the risk of electric shock

or inadvertent short circuiting of live cables whilst wiring the Rooftop DC Isolator:

1. Two extension leads per string should be constructed using the DC extension cable provided in the BOS

Kit. One should be short to connect from the first module in the string to the DC isolator. The other should

be sufficiently long to plug the end module in the string to the DC isolator (see the example schematic

below).

2. Ensure the Rooftop DC Isolator is in the OFF position, strip 12 mm of insulation from the end of each

extension lead and connect the two extension leads to the Rooftop DC Isolator terminals. The Rooftop

DC Isolator should be wired in a consistent manner. Refer to “DC Isolator Wiring” on page 26.

3. Connect the first module positive (+) cable plug to the Rooftop DC Isolator extension cable negative (-)

plug.

4. Connect each module’s negative (-) cable to the following module’s positive (+) cable as modules are

being installed until the halfway point is reached i.e. fourth module in an eight module string.

5. Install and connect the remaining modules, but do not make the halfway connection, i.e. in an eight module

string do not connect the fourth module negative (-) cable to the fifth module positive (+) cable (refer to

wiring diagram below). These two cables will be connected at the end of this procedure.

6. Connect the last module’s negative (-) cable to the Rooftop DC Isolator extension cable positive (+) plug.

7. Complete the circuit by connecting the two string halves together by connecting the positive (+) and

negative (-) cables of the two modules left previously disconnected in step 5.

Note: Modules may be connected in a different order provided that all modules in a string are connected in

series.

Note: The Rooftop DC Isolator should still be in the OFF position at the completion of this stage of the

installation. It should not be turned ON until the correct stage of commissioning. Refer to “Solar Isolation

Device(s) Test – Rooftop DC Isolator(s)” on page 45.

EARTHING

All modules and rails must be earthed. Refer to “Earthing Arrangements – All Systems” on page 10. Earthing

connections must be made by a suitably qualified person according to the relevant standards outlined on page

4. It is also recommended that a reliable lightning protection system be installed.

`Stainless steel serrated washers must be used so the rail anodising is pierced, providing good electrical

continuity. Stainless steel nuts, bolts and washers must be used and all ferrous metal in conductive

connections should be specially treated to prevent corrosion (i.e. by spray painting or coating with a galvanising

paint). Refer also to “Earthing Arrangements – All Systems” on page 10.

Earthing plates

To earth modules and rails, use earthing plates supplied when mounting modules. Install earthing plates in

accordance with the following instructions. When installed correctly, earthing plates will provide earth bond

continuity between rails and modules whilst allowing removal of a module without affecting the earthing

integrity of other components in the system. The rails must then be earthed by connecting a suitably sized

earth wire. Refer to “Earthing Arrangements – All Systems” on page 10.

PV MODULES

32

Warning: Only Solahart approved earthing plates are to be used.

Warning: Module frames must be located on top of earthing plate earth bond protrusions.

Warning: Earthing plates are intended for single use only and must not be reused.

Warning: If rails are not of a continuous length, or rail splices do not provide satisfactory earth continuity,

earth bond jumper cables must be used across rails or rail splices or each section of rail must have an earth

wire connection.

MODULE MOUNTING

Ensure a minimum clearance of 60 mm between the outer surface of the roof and any part of the module to

allow sufficient airflow beneath the modules and adequate cooling of the modules.

Module cables must be installed so that any water will run away from the junction box.

Each corner of the module frame has small drainage holes to allow water caused by rain or snow melt to exit

the frame easily and to minimize damage caused by freezing and thawing. Please note:

The drainage holes must not be used for mounting the module.

Ensure the drainage holes are clear at all times.

Fastening the modules to the mounting structure

Each module must be securely fixed to the mounting structure at a minimum of four points. The distance

between the end clamp and the end of the rail should be a minimum of 25 mm. The mounting clamps must be

fastened so the clamp lies completely within the range of shown below for each type of module.

Note: Figure is not to scale

PV MODULES

33

Module Mounting Procedure

1. Mid clamps and end clamps can be

inserted into the rail by following the

procedure shown, making sure the

spring washer is correctly in place.

For easy use of Z-modules, ensure

Allen head bolt threads do not project

through lower side of Z-module, so the

Z-module is free to move along the rail.

2. In positions where earthing plates are

required, slide the earthing plate over

threaded section of Allen head bolt and

press earthing plate into rail so that rail

retention tabs hold the earthing plate in

position.

3. Install PV module under end clamps.

Ensure end clamps are tight against the

module and are at least 25 mm from the

rail ends. For end clamps with earthing

plates, ensure the frame of the module

is located on top of the protrusions of

the earthing plate. Tighten end clamp

bolts to 21 Nm.

4. Place a mid clamp with Z-module and

Allen head bolt in each rail and slide

into position. Ensure that the mid clamp

is tight against the module. For mid

clamps with earthing plates, ensure the

frame of the module is located on top of

the protrusions of the earthing plate.

Fasten loosely (approx 2 – 3 turns).

5. Place the next module onto the rail and

slide the module into the mid clamps. In

positions where earthing plates are

required, ensure both module frame

edges are located on top of the

protrusions of the earthing plate

6. Tighten each mid clamp Allen head bolt

to 21 Nm.

Repeat steps 4 to 6 for each remaining

module in the row.

PV MODULES

34

7. Place an end clamp into the end of each

rail. Ensure that the end clamps are

tight against the module and are at

least 25 mm from the rail ends. In

positions where earthing plates are

required, ensure the frame of module is

located on top of the protrusions of the

earthing plate. Tighten end clamp bolts

to 21 Nm.

8. Repeat the steps 3 - 7 for each row of

modules.

Mid clamps may be temporarily placed

between rows to ensure 18 mm uniform

spacing between rows.

Module installation is now complete.

35

INVERTER

For inverter installation instructions and warranty exclusions refer to the documents supplied with the inverter.

The following points must also be observed when installing the inverter:

Warning: Inverters have masses between 9 kg and 27 kg. Proper safe handling procedures must be

employed when installing or handling these inverters.

Inverters must be sheltered from direct sunlight and other sources of heat.

Inverters must be installed in a well-ventilated place so as to allow good circulation of air around the

unit. Avoid places where air cannot circulate freely around the unit.

The inverter must not be installed in a location accessible to children.

The mounting structure must be capable of supporting the inverter weight.

If the inverter is to be mounted on a combustible surface such as wood, a heat resistant backing (such

as a fibre cement board) must be installed behind the inverter. Backing must extend a minimum of

20 mm past all edges and sides of the inverter.

Inverter mounting clearances and requirements outlined in the relevant inverter documentation must

be adhered to. Ignoring recommended mounting instructions can cause permanent damage to the

inverter from water ingress and can reduce inverter efficiency due to inadequate heat dissapation..

Sealing plugs provided with the inverter must be inserted into any unused string inputs to maintain the

inverter’s IP rating. For SMA inverters, sealing plugs must inserted into the rear of the Sunclix DC plug

connectors. For ABB and SolarEdge inverters verify the presence of watertight rubber cap seals on

DC input connectors and install them should they be absent.

For the ABB PVI single phase inverters ensure that:

o For multiple string systems, the inverter is configured for ‘independent’ channels (factory

default setting).

o For single string systems, the inverter is configured for ‘parallel’ channels. Refer to inverter

documentation for detailed instructions on configuration of channels.

When installing an inverter with a StorEdge Connection Unit, do not install fuses if a battery is not

installed. Leave all fuses in their original packaging behind the plastic cover inside the StorEdge

Connection Unit, clear from all electrical wires and components.

MULTI-CONTACT DC CONNECTIONS

Multi-Contact Safety Locking Clips must be installed over the negative connectors of all Multi-Contact DC

connections at the inverter. The purpose of these devices is to prevent accidental disconnection of live DC at

the inverter. When the Safety Locking Clip is in place, a custom tool is required to separate the connectors.

Multi-Contact (MC)

Positive (+) Connector: PV-KBT4

Multi-Contact (MC)

Negative (-) Connector: PV-KST4

Multi-Contact (MC)

Safety Locking Clip: PV-SSH4

AC CABLE SIZING TABLE

Inverter AC cabling must be sized and installed in accordance with AS/NZS 3000, AS/NZS 3008 and any

local applicable codes. Cables selected must have an appropriate current carrying capacity for the maximum

fault current output of the inverter, and the Inverter AC isolator, taking into consideration relevant de-rating

factors. For the nominal trip current of the AC breaker, refer to the “Wiring Diagrams” beginning on page 6.

INVERTER

36

Inverter

Model

Maximum AC Fault Current (A)

SB 1.5-1 VL-40

12.0

UNO-DM-2.0-TL-PLUS-B

12.0

SB 2.5-1 VL-40

19.0

PVI-3.0-TL-OUTD

16.0

SB3.0-1AV-40

29.0

UNO-DM-3.3-TL-PLUS-B

16.0

SB4.0-1AV-40

29.0

UNO-DM-4.0-TL-PLUS-B

19.0

PVI-4.2-TL-OUTD

22.0

PVI-5000-TL-OUTD

32.0

SB5.0-1AV-40

29.0

UNO-DM-5.0-TL-PLUS-B

24.0

SE5000-xxxxxxxxx*

27.0

SE5000H

23.0

*This model may have suffixes indicating different options and functionality.

Inverter AC cabling must have a voltage drop or rise less than 1% in accordance with AS/NZS 5033. For

common PVC/PVC cable types operating at 75°C on a 230 V single-phase circuit, the following table provides

for a voltage variation of less than 1%.

Inverter Model

Conductor cross section

2.5 mm2

4.0 mm2

6.0 mm2

10.0 mm2

16.0 mm2

Maximum cable length (m)

SB 1.5-1 VL-40

18.3

29.3

N/A

N/A

N/A

UNO-DM-2.0-TL-PLUS-B

Refer ABB Quick Installation Guide

SB 2.5-1 VL-40

11.6

18.6

N/A

N/A

N/A

PVI-3.0-TL-OUTD

Refer ABB Quick Installation Guide

SB3.0-1AV-40

9.8

15.8

23.5

39.6

N/A

UNO-DM-3.3-TL-PLUS-B

Refer ABB Quick Installation Guide

SB4.0-1AV-40

7.4

11.8

17.6

29.6

N/A

UNO-DM-4.0-TL-PLUS-B

Refer ABB Quick Installation Guide

PVI-4.2-TL-OUTD

Refer ABB Quick Installation Guide

UNO-DM-5.0-TL-PLUS-B

Refer ABB Quick Installation Guide

PVI-5000-TL-OUTD

Refer ABB Quick Installation Guide

SB5.0-1AV-40

5.9

9.4

14.1

23.7

N/A

SE5000-xxxxxxxxx*

4.7

7.6

11.3

19.1

N/A

SE5000H

5.6

8.9

13.3

22.4

N/A

*This model may have suffixes indicating different options and functionality.

Note: If the installation requires different cabling or has installation conditions different to those specified

above, the installer must undertake appropriate calculations to ensure the cabling is correctly sized.

INVERTER

37

EARTH FAULT ALARMS

The installation of an earth fault alarm compliant with AS/NZS 5033 requirements is mandatory for all arrays.

Solahart inverters are able to communicate an earth fault in four different ways:

1. Inverter display

Some Solahart inverters display an Earth Fault Alarm message on the inverter display when

an earth fault is present. Consult the specific inverter installation manual for details of the error

message display on the inverterI

Examples:

o ABB inverter display

o SolarEdge inverter display

2. Inverter Built-in Audible Alarm

Some Solahart inverters come with built-in audible alarm which is triggered when an earth

fault is present.

Examples:

o SMA Smart Connect Series (SB3.0-1AV-40, SB4.0-1AV-40, SB5.0-1AV-40)

3. External alarm – Email Alert

Some Solahart inverters are able to communicate with a web portal that can be configured to

send an email alert to the system owner when an earth fault is present.

Examples:

o SMA Webconnect

o ABB WIFI logger card

o SolarEdge Wi-Fi kit or integrated Ethernet

4. External alarm – Audible or Visual Alarm

Some Solahart inverters can switch a relay when an earth fault is present. The relay can be

connected to an audible or visual alarm that meets AS/NZS 5033 requirements.

Examples:

o SMA multi-function relay

o ABB configurable relay

SMA Webconnect

The SMA Webconnect, SWDM-10, comes factory installed in all our

current SMA single-phase inverters.

The Webconnect is a cable-based type of communication based on the

Ethernet standard. The Webconnect enables the inverter to exchange data

with SMA Sunny Portal which facilitates data monitoring and fault

communication via email.

To set up the Webconnect, proceed as follows:

1. Prior to PV system commissioning, connect the Webconnect to the

PV system owner’s internet connected router through the use of a network cable as described in the

SWDM-10 installation instructions

2. Commission the PV system as outlined in the Solahart Owner’s Guide and Installation Instructions

3. Commission and register the PV system on SMA Sunny Portal through the Plant Setup Assistant. An

internet connected laptop, tablet or smartphone is required.

4. Once the system has been successfully registered, login to Sunny Portal

5. Ensure to activate earth fault alarm reporting on SMA Sunny Portal

SMA multi-function relay

On the occurrence of an inverter fault, the relay can be used to trigger an external audio and/or visual alarm.

Please follow the instructions provided in the inverter product manual for maximum ratings, requirements and

instructions on how to utilise the relay connection.

Note: SB 1.5-1 VL-40, SB 2.5-1 VL-40, SB3.0-1AV-40, SB4.0-1AV-40 and SB5.0-1AV-40 inverters do not

have any relay functionality.

ABB INVERTER DISPLAY

It may be possible to comply with earth fault alarm requirements without additional components. In this

instance, the visual warning light and error information on the graphical display can be relied upon; however,

this method of compliance requires the inverter be installed in a compliant location according to AS/NZS 5033

and/or local regulator.

SMA Webconnect (SWDM-10)

INVERTER

38

ABB Wifi logger card (VSN300)

The ABB Wifi logger card, VSN300, is an add-on card compatible

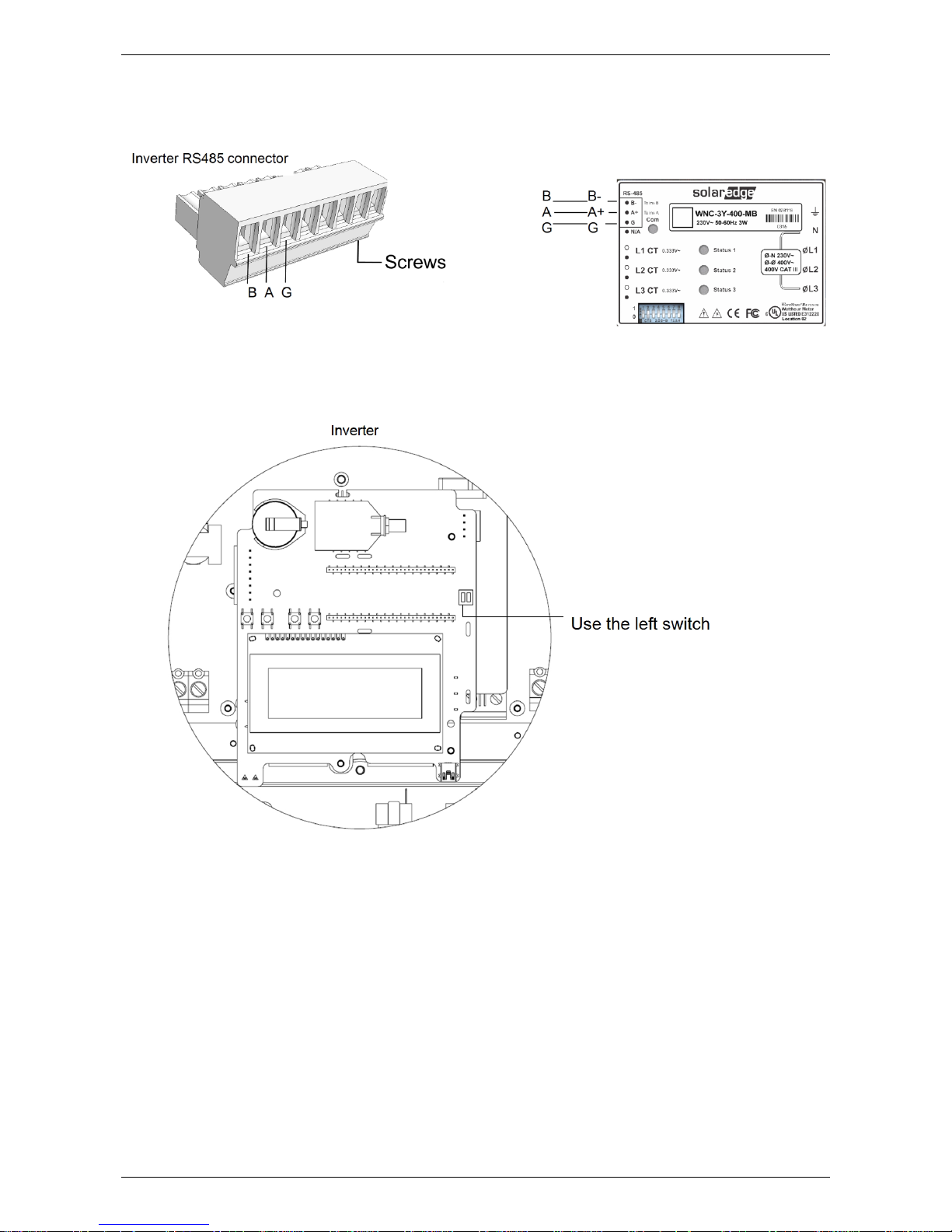

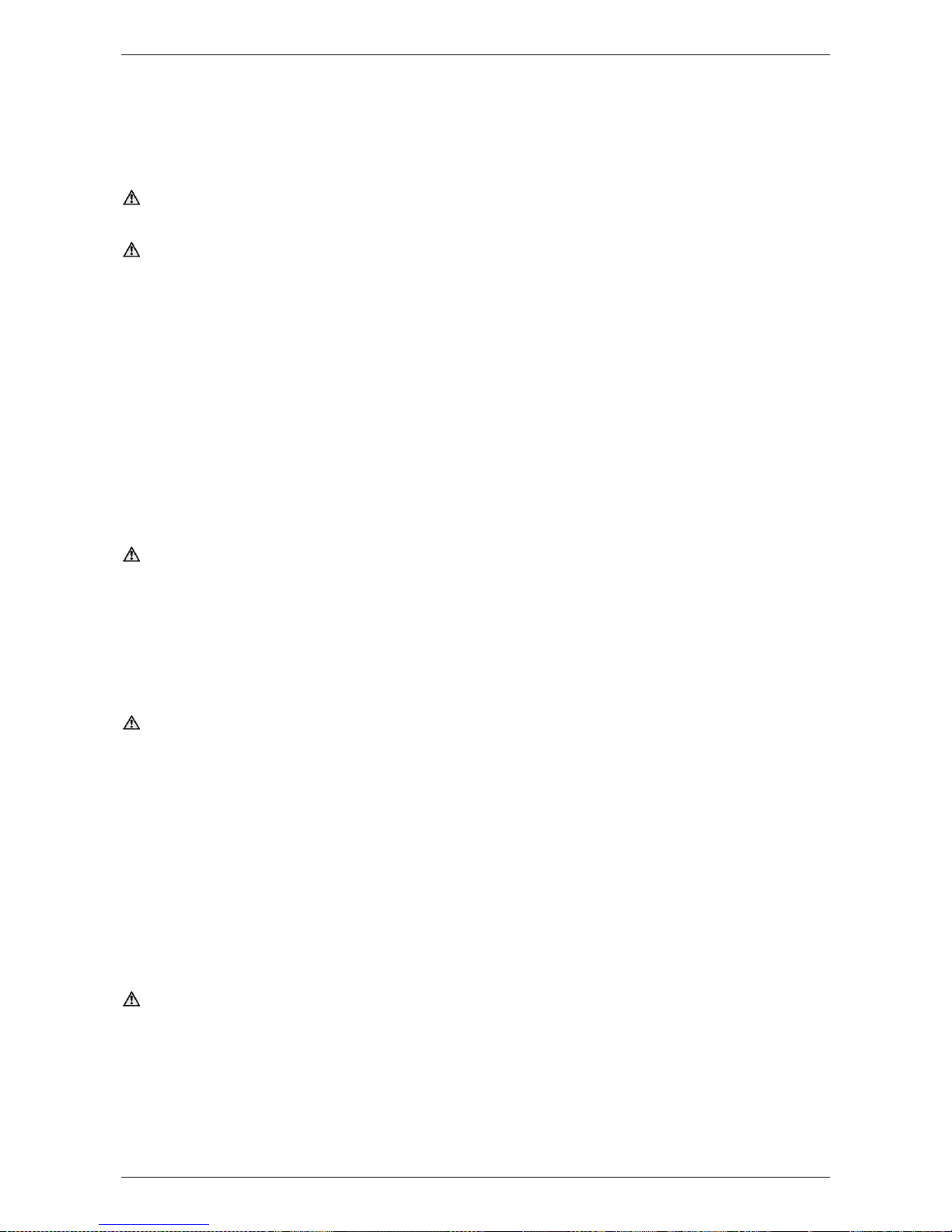

with ABB PVI series inverters (PVI-3.0-TL-OUTD, PVI-4.2-TLOUTD, PVI-5000-TL-OUTD). The Wifi logger card is a Wi-Fi based