Page 1

Quick Startup Guide

FG-200 HSE/FF Modbus

Version: EN-102018-1.31

© Softing Industrial Automation GmbH

Page 2

Disclaimer of liability

The information contained in these ins tructions corresponds to the technical status at the time of

printing of it and i s pas sed on with the best of our knowledge. The information in these

instructions is in no event a basis for warranty claims or contractual agreements concerni ng the

described products, and may especially not be deemed as warranty concerning the quality and

durability pursuant to Sec. 443 German Civil Code. We reserve the right to make any alterations or

improvements to these instructions without prior notice. The actual design of products may

deviate from the information contained in the instructions if technical al terations and product

improvements s o require.

Softing Industrial Automation GmbH

Richard-Reitzner-Allee 6

85540 Haar / Germany

http://industrial .softing.com

+ 49 89 4 56 56-0

+ 49 89 4 56 56-488

info.automation@softing.com

support.automation@softing.com

Scan the QR code to find the latest documentation on the product

web page under Downloads.

Page 3

Table of Contents

Chapter 1 ................................................................................... 6About this guide

................................................................................................................ 61.1 Read me first

................................................................................................................ 61.2 Target audience

................................................................................................................ 61.3 Typographic conventions

................................................................................................................ 71.4 Document feedback

Chapter 2 ................................................................................... 8About FG-200 HSE/FF Modbus

................................................................................................................ 82.1 Intended use

................................................................................................................ 82.2 Scope of delivery

................................................................................................................ 92.3 System requirements

................................................................................................................ 92.4 Safety precautions

Chapter 3 ................................................................................... 11Installation

................................................................................................................ 113.1 Hardware ins tallation

Mounting and dis mounting 3.1.1

.................................................................................................. 11

Connection diagram 3.1.2

.................................................................................................. 13

Connecting the power suppl y 3.1.3

.................................................................................................. 14

Connecting to the network 3.1.4

.................................................................................................. 15

Modbus serial connection 3.1.5

.................................................................................................. 17

FG-200 redundancy 3.1.6

.................................................................................................. 17

FF-H1 interface connection 3.1.7

.................................................................................................. 20

Powering up the device 3.1.8

.................................................................................................. 22

Adding a second FG-200 for redundancy 3.1.9

.................................................................................................. 22

................................................................................................................ 233.2 Software instal lation

Tabl e of Con tents

© Softing Industrial Automation GmbH 3

Page 4

Tabl e of Con tents

Chapter 4 ................................................................................... 24Configuration

................................................................................................................ 244.1 Confi guring the IP address

................................................................................................................ 254.2 Setting up a ComConf project

Chapter 5 ................................................................................... 26Status indicators - LEDs

................................................................................................................ 275.1 PWR - power supply

................................................................................................................ 275.2 Device LED statuses in stand-a lone mode

................................................................................................................ 285.3 RUN/ERR/RDL - LED statuses in redundant mode

................................................................................................................ 325.4 H1 channel status indicators

Chapter 6 ................................................................................... 33Technical data

................................................................................................................ 336.1 Specifications

................................................................................................................ 346.2 Installation positions

Chapter 7 ................................................................................... 36European and International Approval

Chapter 8 ................................................................................... 37North American Approval

Chapter 9 ................................................................................... 38Declaration of conformity

© Softing Industrial Automation GmbH4

Page 5

This page is intentionally left blank.

© Softing Industrial Automation GmbH 5

Page 6

FG-200 HSE/FF Modbu s - Qui ck Startup Gu ide

Keys, buttons, menu items, commands and

other elements involving user interaction are

set in bold font and menu sequences are

separated by an arrow

Open Start Control Panel Programs

Buttons from the user interface are enclosed

in brackets and set to bold typeface

Press [Start] to start the application

Coding samples, file extracts and screen

output is set in Courier font type

MaxDlsapAddressSupported=23

Fil e names and directories are written in

italic

Device description fi les are located in C:

\<Application name>\delivery\software

\Device Description files

1

About this guide

1.1 Read me first

Please read this guide carefull y before using the device to ensure safe and proper us e.

Softing does not ass ume any liabil ity for damages due to improper installa tion or

operation of this product.

1.2 Target audience

This Qui ck Startup Guide is i ntended for experienced operation personnel and network

specialists responsible for configuring and maintai ning field devices in process

automation networks. Any person using an FG-200 HSE/FF Modbus must have read and

fully understood the safety requirements and working ins tructions in this guide.

1.3 Typographic conventions

The following conventions are used throughout Softing customer documentation:

6 © Softing Industrial Automation GmbH

Page 7

Chapte r 1 - Abo ut thi s gu ide

CAUTION

This symbol indicates a potential ly hazardous si tuation which, if not avoided,

may result in minor or moderate injury

Note

This symbol is used to call attention to notable information that should be

followed during installation, use, or servi cing of this device.

1.4 Document feedback

We would li ke to encourage you to provide feedback and comments to help us improve the

documentation. If you have a PDF copy of thi s document si mply write your comments and

suggestions to the PDF fil e usi ng the editing tool i n Adobe Reader and email your feedback

to support.automation@softing.com.

If you prefer to write your feedback directly as an email, pl ease include the following

information with your comments:

document name

document versi on (as shown on cover page)

page number

© Softing Industrial Automation GmbH 7

Page 8

FG-200 HSE/FF Modbu s - Qui ck Startup Gu ide

Note

The FG-200 is availabl e in two vari ants. They have identical technical

specifi cations. Their only di fferentiating characteris tic is their mount direction

that is mirrored, i.e. rotated by 180°.

2

About FG-200 HSE/FF Modbus

The Softing FG-200 HSE/FF Modbus is a gateway connecting Modbus RTU, Modbus TCP or

FOUNDATION fieldbus High Speed Ethernet (HSE) to FOUNDATION fieldbus H1 field devices.

It provides fast access to process data, while maki ng use of FOUNDATION Fieldbus

adva ntages s uch as reduced cabli ng, central field device parametrization, comprehensive

diagnos tics or intrinsicall y safe device segments. For s imple installation it is compatible

with the R. STAHL bus-Carrier Series 9419 and Fi eldbus power suppli es Seri es 9412.

2.1 Intended use

The FG-200 ca n be used for integrating up to four FF H1 links into a Modbus control system

(TCP or RTU) or for communication between FF H1 devices and FF HSE network. The gateway

can be operated in both hazardous and non-hazardous areas. Any other use is not

intended. Follow the instructions in this guide on how to use the FG-200.

2.2 Scope of delivery

The delivery of this gateway includes the foll owing parts:

FG-200 HSE/FF Modbus device

CD including ComConf, PACTware firmware and manuals

Quick Startup Guide

IP a ddress label

8 © Softing Industrial Automation GmbH

Page 9

Chapte r 2 - Abo ut FG-200 HSE/FF Modbus

2.3 System requirements

24V power supply

power condi tioner

PC with operating system Windows 7 or Windows 8.1 (both 32 bi t or 64 bit supported)

Web browser (Microsoft Internet Explorer version 8.0 or higher, Mozil la Fi refox version

versi on 35 or higher)

2.4 Safety precautions

Use in hazardous areas

The FG-200 is an electrical equipment with degree of protection Ex nA, approved for use in

Zone 2 hazardous areas or i n the safe area. The four FF-H1 interfaces are designed

according to the protection method Ex ic. Onl y certified circuits with an accordi ng

protection method shall be connected to these FF-H1 interfaces.

© Softing Industrial Automation GmbH 9

Page 10

FG-200 HSE/FF Modbu s - Qui ck Startup Gu ide

Before setting the FG-200 i nto operation, the corresponding field has to be

maked (e.g. if the device is used in an IC environment, mark the upper field on

the type label).

Use an appropri ate permanent pen for si gning, e.g. an etching pen.

More than one marking is not allowed. If you need a second marking, you must

replace the exis ting equipment with a new one.

An equipment which has been operated under non-intri nsical ly safe

condi tions i s no longer permitted to be used under intrinsi cally safe

condi tions.

CAUTION

During operation, the device's surface wil l be heated up. Avoid di rect contact.

When servicing, turn off the power supply and wai t until surface has cooled

down.

Note

Do not open the housing of the FG-200. It does not contain any parts that need

to be maintained or repaired. In the event of a fault or defect, remove the device

and return it to the vendor. Opening the device wil l void the warranty!

Special hints for safe use

The FG-200 HSE/FF Modbus is only approved for intended and appropriate use. In ca se of

noncompliance, the warranty and manufacturer’s l iabi lity do no longer apply!

10 © Softing Industrial Automation GmbH

Page 11

Chapte r 3 - Ins tal lation

Note

With an ambient temperature above 55 °C at the place of installation it is l ikely

that the temperatures of connecting cables wil l increase if the cables are

install ed in an unfavourable position. In such cases, measure the temperature

to ensure that the service temperature of the cables i s not exceeded (i.e. 80 °C),

or use cables sustaining high temperatures of at least 90 °C.

Note

Make sure the FG-200 is mounted in a manner that the power supply

disconnecting device or interrupt faci lity can always be reached easil y.

Note

Depending on the installation pos ition, the maxi mum ambient operating

temperature may differ. Refer to Technical Data for detai led information.

Installation and inspection

Instal lation and inspection must be carried out by quali fied personnel only

(personnel qual ified accordi ng to the German standard TRBS 1203 or similar

(Technical Regulations for Operational Safety). The defini tion of terms can be

found in IEC 60079-17.

3

Installation

3.1 Hardware installation

3.1.1 Mounting and dismounting

33

© Softing Industrial Automation GmbH 11

Page 12

FG-200 HSE/FF Modbu s - Qui ck Startup Gu ide

1. Hook the upper notch of the cut-out on the

back of the FG-200 into a 35 mm DIN rail .

2. Press the FG-200 down towards the rail

until it sl ides into place over the lip of the

locking bar.

Note

Do not put stress on the device by bending or tors ion.

1. Slide a screwdri ver diagonal ly under the

housing into the locki ng bar.

2. Lever the screwdriver upwards, pull the

locking bar downwards - without tilting the

screwdriver - and move the gateway upwards

off the rai l.

Mounting

Dismounting

12 © Softing Industrial Automation GmbH

Page 13

3.1.2 Connection diagram

The following connection diagram shows the physical interfaces of the FG-200.

Chapte r 3 - Ins tal lation

© Softing Industrial Automation GmbH 13

Page 14

FG-200 HSE/FF Modbu s - Qui ck Startup Gu ide

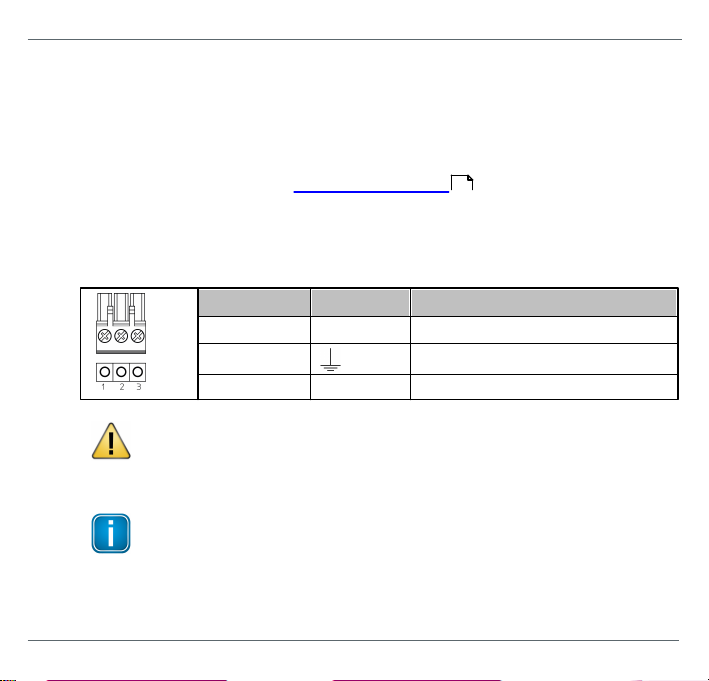

Pin

Signal

Description

1

GND

Ground

2

Functional earth

3

L+

Positive supply voltage

CAUTION

The Functional Earth (FE) connection of the device has to be connected at low

inductance with the Protective Earth (PE) of the system.

Note

As indicated in the connection diagram, the power can be appl ied alternatively

by a speci al DIN rail connector (Rail Power Suppl y). For further information

contact Softing Industri al Automation.

3.1.3 Connecting the power supply

1. Connect the FG-200 to a 24 V DC power supply.

2. Use different or redundant power supplies for redundant FG-200s.

3. Turn on the power supply. The boot process takes approx. 50 seconds. For indica tion

of proper operation of a FG-200 acting in non-redundant mode or as pri mary device

in redundant mode refer to Status i ndicators - LEDs .

The suppl y voltage (18 VDC .... 32 VDC) is connected by a 3-pole terminal block. The power

supply is connected to the plug connector vi a flexi ble wires with a cross s ection of 0.75 to

1.5 mm². The ground connection wire must have a cross section of 1.5 mm².

14 © Softing Industrial Automation GmbH

26

Page 15

Chapte r 3 - Ins tal lation

Note

When using the FG-200 as li nking device you can broadcast High Speed Ethernet

(HSE) and Modbus TCP over the same Ethernet port.

3.1.4 Connecting to the network

1. Connect the FG-200 to the Modbus TCP network to one of the two Ethernet ports (ETH1

or ETH2).

2. Connect each link of your FOUNDATION fieldbus H1 network via a power conditioner

to a Fieldbus Channel port of your gateway (CH0 to CH3).

FG-200 with redundancy connection

© Softing Industrial Automation GmbH 15

Page 16

FG-200 HSE/FF Modbu s - Qui ck Startup Gu ide

Note

Your FG-200 cannot operate in both Modbus TCP and Modbus RTU mode at the

same time.

Note

When you connect your FG-200 to a Modbus RTU Mas ter you cannot operate

the device in redunda ncy mode.

FG-200 with Modbus connection

16 © Softing Industrial Automation GmbH

Page 17

Chapte r 3 - Ins tal lation

Pin

Signal

Description

6RXReceiver eXchange

5TXTrans mitter eXchange

4

GND

Ground

Note

If you are working with two FG-200 in redundant mode, the seri al connection

cannot be used (s ee next Section).

Note

As the interface is not galvanicall y isolated make sure that there is no potential

difference between the two connected devices.

3.1.5 Modbus serial connection

When connecting the FG-200 via s erial connection (RTU) use the connector from your

delivery with the following pin ass ignment:

3.1.6 FG-200 redundancy

If you intend to use two FG-200s as a redundant set, connect the redundancy link

interfaces (RDL) of both FG-200s (primary and secondary) by a cable before you power up

the devices. If the redundancy l ink is not installed before start-up, the FG-200 wil l operate

in non-redundant mode.

© Softing Industrial Automation GmbH 17

Page 18

FG-200 HSE/FF Modbu s - Qui ck Startup Gu ide

Pin

Signal

Description

6RXReceives data from redundant device

5TXTrans mits data to redundant device

4

GND

Ground

Note

The receive (RX) and transmit (TX) signals must be cross-l inked.

The maximum cabl e length is 0.5 m according to EMC requirements. The pin as signment is :

Do not power up devices when serial link is missing

If the two FG-200 s forming a redundant set are powered while the serial link is missing,

both devices will behave like independent, non-redundant Pri mary Devices. If they

operated in redundant mode before and therefore have identical configuration

information, both will use the same H1 node address es, which will cause problems on the

H1 links. The ERR (error) LED will blink. In thi s case, remove the power, install the serial

li nk and apply the power again.

18 © Softing Industrial Automation GmbH

Page 19

Chapte r 3 - Ins tal lation

Primary device vs. secondary device

When using a redundant set of two FG-200 s , the device which is powered first will operate

as primary device. If both devices are powered at the same time, the one with the lower IP

address will operate as primary device.

Removing the power supply

Before you remove the power supply from the primary device make sure the secondary

device is operational . In a redundant set of FG-200s, removing the power suppl y, the

Ethernet cable or the redundancy l ink interface cabl e from the primary device caus es a

redundancy change-over. Before doing so, make sure that the secondary device is

operational (and not still booting due to a prior change-over). Otherwise the system breaks

down or the configuration i nformation might get lost. Therefore wait at least one minute

between such checks .

© Softing Industrial Automation GmbH 19

Page 20

FG-200 HSE/FF Modbu s - Qui ck Startup Gu ide

CH1

Pin

Signal

Description

7+Fieldbus +

8SFieldbus shield

9-Fieldbus -

CH2

Pin

Signal

Description

10+Fieldbus +

11SFieldbus shield

12-Fieldbus -

3.1.7 FF-H1 interface connection

Connect the H1 li nks to the terminal blocks of the H1 interfaces. Since the FG-200 does not

provi de power to the H1 links, a power condi tioner and a bus termination is required for

each H1 link. When using a redundant set of two devices, make sure to connect each H1

li nk to the same channel (CH 1 .. CH 4) on both FG-200s.

The FG-200 provides four Founda tion Fieldbus H1 i nterfaces. These interfaces are named

CH1 to CH4 and are used to connect an FF-H1 bus to the FG-200.

FF H1 bus line channel 1

FF H1 bus line channel 2

20 © Softing Industrial Automation GmbH

Page 21

Chapte r 3 - Ins tal lation

CH3

Pin

Signal

Description

13+Fieldbus +

14SFieldbus shield

15-Fieldbus -

CH4

Pin

Signal

Description

16+Fieldbus +

17SFieldbus shield

18-Fieldbus -

Note

The fieldbus shield is not connected directly to functiona l earth. For EMC

reasons, it is onl y connected via a capacitor. If a direct connection to

functional earth or protective earth is required, you need to implement this

separately.

FF H1 bus line channel 3

FF H1 bus line channel 4

© Softing Industrial Automation GmbH 21

Page 22

FG-200 HSE/FF Modbu s - Qui ck Startup Gu ide

Hint

Refer to Section FG-200 redundancy for more information on the

redundancy concept.

3.1.8 Powering up the device

Turn on the power supply. The boot process takes a few seconds. For indication of proper

operation of a FG-200 refer to Status indica tors - LEDs .

26

3.1.9 Adding a second FG-200 for redundancy

For adding a second FG-200 to an already commiss ioned FG-200 that is operating in the

role "Primary, no backup", the foll owing steps are required:

1. Set the IP configuration (IP address and subnet mask) of the second FG-200 usi ng the

same IP subnet as the primary device (see Configuring the IP address ).

2. Connect the H1 li nks to the terminal blocks of the H1 interfaces. Make sure to connect

each H1 link to the same channel (CH 1 .. CH 4) on both FG-200s.

3. Connect the second FG-200 to the Ethernet switch or hub.

4. Connect both RDL interfaces as mentioned in Section FG-200 redundancy.

5. Connect the second FG-200 to a 24 V DC power supply. Use different or redunda nt

power supplies for redundant FG-200s .

6. After turni ng on the power supply the boot process takes approx. 50 seconds.

7. The second FG-200 will take over the configuration data from the primary device and

will start operation in the role "secondary". For more detail s about proper operation

as a secondary device see also the Status indicators - LEDs .

17

26

24

17

22 © Softing Industrial Automation GmbH

Page 23

Chapte r 3 - Ins tal lation

3.2 Software installation

When you i nstall a Softing product for the first time, you will be asked in a di alogue

window if you trust the publi sher. Activate the option Always trust software from Softing

AG if you do not want to be asked in s ubsequent instal lations and select [Install] to start

the installation.

1. Insert the CD "Gateways for Process Industries" into the CD drive.

a. If Autorun is enabled on your system, the startup page is opened.

b. If Autorun i s disabled, open an Explorer window, select your CD drive and

double-click the file start.exe in the CD's root directory.

2. Select Installation of FG-200 Software and Documentation in the startup page.

3. Select the ins tallation setup fil es required.

4. Instal l the SearchAnd Configure software.

With the SearchAndConfigure function you will be abl e to detect and modify device IP

addresses. See the User Guide for more detail s.

5. Instal l PACTware if no other FDT frame application is used.

PACTware and the Softing FFdtm will be installed.

6. Instal l FFdtm if you prefer using a different FDT frame application such as FieldCare,

FieldMate or others to allow usi ng a CommDTM in another FDT frame appli cation. See

the User Guide for more details .

© Softing Industrial Automation GmbH 23

Page 24

FG-200 HSE/FF Modbu s - Qui ck Startup Gu ide

Note

Before connecting the FG-200 to your LAN network, make sure that its IP

address is not used by another network station.

To assign a new IP address to your PC, you must have adminis trator rights.

4

Configuration

When your PC and FG-200 have an IP connection, start a web browser to access the

gateway from your PC.

4.1 Configuring the IP address

The FG-200 is deli vered with the pre-confi gured IP address 192.168.0.10.

1. Open a browser (e.g. Internet Explorer or Firefox).

2. Enter the URL address 192.168.0.10 and press Enter.

3. Login with the foll owing data:

login name: administrator

login password: fgadmin

4. Select Configuration Settings Internet Protocol.

5. Change IP Address and Subnet Mask.

6. Cli ck [Change Settings and Reebot]

7. The FG-200 performs a reboot.

24 © Softing Industrial Automation GmbH

Page 25

Chapte r 4 - Configuration

4.2 Setting up a ComConf project

For information on how to set up a project in the Communication Configuration Tool and

working with the FG-200 web server interface refer to the User Guide on CD or download

the lastest document version from the product page. Scan QR code on back page for direct

access .

© Softing Industrial Automation GmbH 25

Page 26

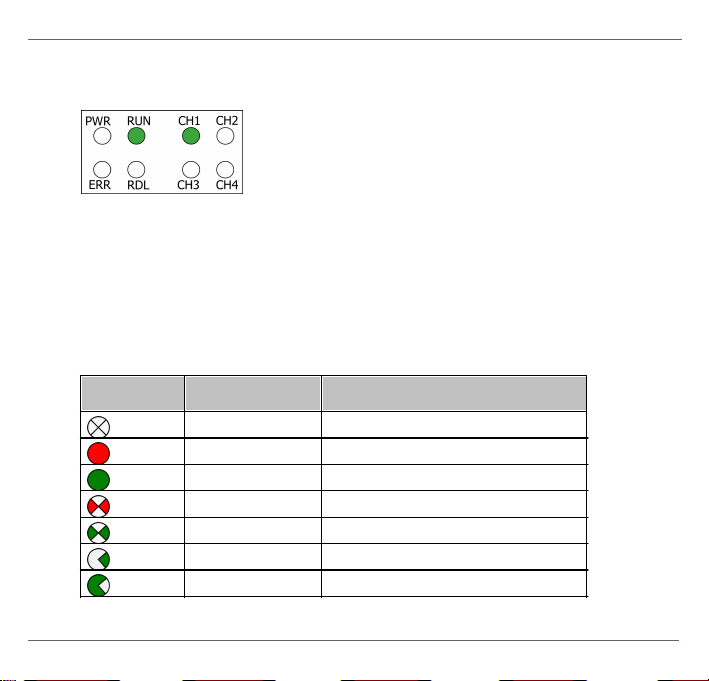

FG-200 HSE/FF Modbu s - Qui ck Startup Gu ide

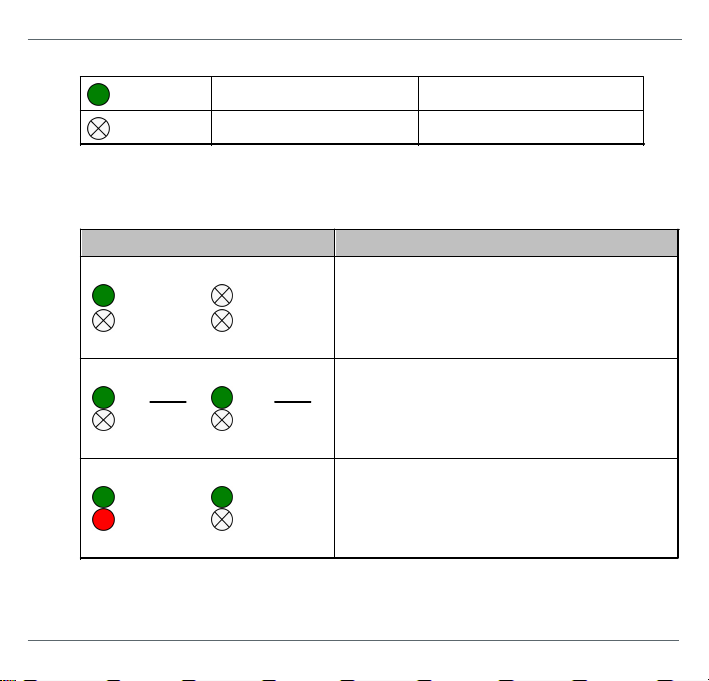

Symbol

Color

Lighting

none

off

red

permanent

green

permanent

red

fla shing

green

fla shing

green

fla shing sl owly (0.5 Hz)

green

fla shing quickly (5 Hz)

5

Status indicators - LEDs

The FG-200 is equipped with eight LEDs on its front side:

PWR stands for power supply

RUN stands for running

ERR stands for error

RDL stands for redundancy link

CH1 to CH4 stands for H1 channel 1 to H1 channel 4

The LEDs may be on permanently or fl ash i n different colors and frequenci es. We use the

following symbols:

26 © Softing Industrial Automation GmbH

Page 27

Chapte r 5 - Sta tus ind icators - LEDs

permanent green

24V DC power suppl y is ok

off

no power supply

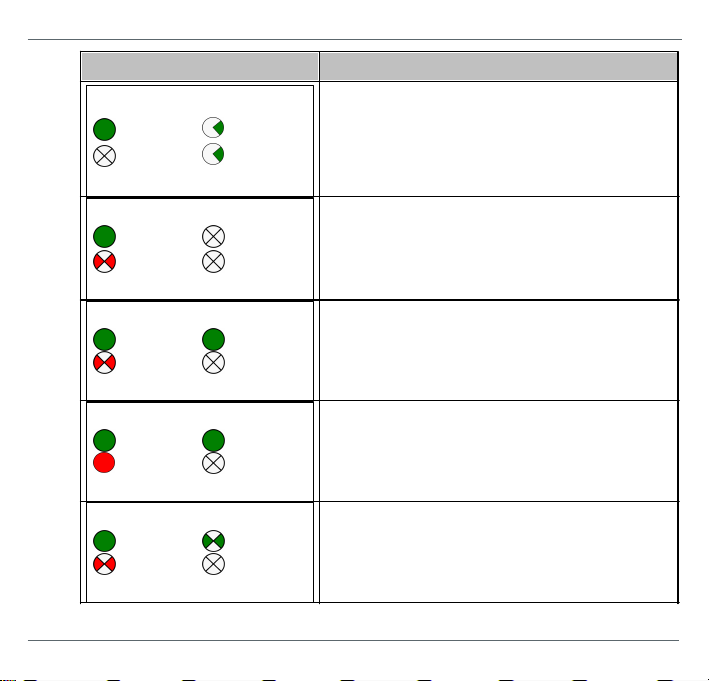

LEDs

Meaning

PWR

RUN

green

ERR

RDL

Startup phase (approximately 7 seconds)

During this phas e redundancy role is determined.

PWR

RUN

green

green

ERR

RDL

Non redundant device, ready.

The device is operational; it is not part of a

redundant set.

PWR

RUN

green

green

red

ERR

RDL

Permanent hardware fault detection during

startup.

A fatal error has been detected.

5.1 PWR - power supply

5.2 Device LED statuses in stand-alone mode

The following table shows possible LED combinations i n stand-a lone mode:

© Softing Industrial Automation GmbH 27

Page 28

FG-200 HSE/FF Modbu s - Qui ck Startup Gu ide

fla shing

green

redundancy l ink communication is ok (triggered by redundancy

li nk packets)

red

li nk communication interrupted or aborted (broken down)

off

no link communication at all

LEDs

Meaning

PWR

RUN

green

ERR

RDL

Start–up phase (approx. 7 seconds )

During this phas e redundancy role is determined.

PWR

RUN

green

green

ERR

RDL

Non redundant device, ready.

The device is operational; it is not part of a

redundant set.

Primary Device is redundant set.

The device is operational, acting as Primary Device

in a redundant set. The secondary device is ready

PWR

RUN

green

green

red

ERR

RDL

Permanent hardware faul t detection duri ng startup.

A fatal error has been detected. Possible failure

coul d be a missi ng Ethernet connection.

5.3 RUN/ERR/RDL - LED statuses in redundant mode

The redundancy link LED is used to indicate if traffic via the serial line is performed. It will

fla sh green if a vali d message is received. It will switch to red if serial communication i s

lost and it will be off if no serial response has been received after startup.

28 © Softing Industrial Automation GmbH

Page 29

Chapte r 5 - Sta tus ind icators - LEDs

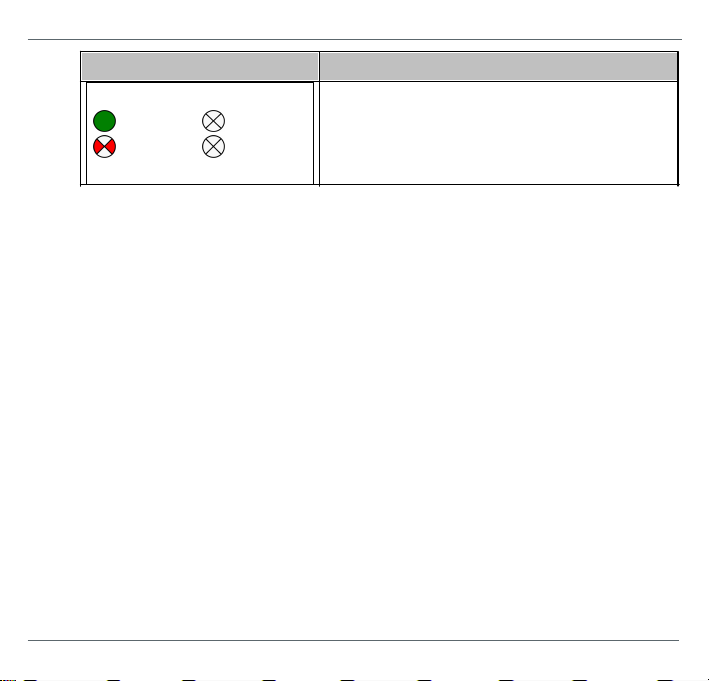

LEDs

Meaning

PWR

RUN

green

green

red

ERR

RDL

Primary device or non-redundant device, hardware

fai lure.

The device is acting as non-redundant device, but a

minor hardware failure has been detected during

start-up.

In the case of a Primary Device on a redundant set,

the secondary device is not ready

PWR

RUN

green

green

red

ERR

RDL

Primary device or non-redundant device, failure.

The device is acting as non-redundant device, but a

fai lure has been detected.

or

Secondary device, not ready.

The device is acting as secondary device in a

redundant set, but it is not ready to take over the

primary rol e due to e.g. not synchroni zed

confi guration information or a non-operational

redundancy l ink.

or

Primary Device or non-redundant device, failure.

The device is acting as Primary Device in a

redundant set or as non-redundant device, but a

fai lure has been detected. In the case of a Pri mary

Device in a redunda nt set or as non redundant set,

the secondary device is not ready.

© Softing Industrial Automation GmbH 29

Page 30

FG-200 HSE/FF Modbu s - Qui ck Startup Gu ide

LEDs

Meaning

PWR

RUN

green

green

green

ERR

RDL

Secondary device, operational.

The device is operational as secondary device in a

redundant set. The configuration information has

been successfully transferred from the Primary

Device and the redundancy li nk is operational.

PWR

RUN

green

red

ERR

RDL

Secondary device, hardware failure.

The device is acting as secondary device in a

redundant set, but a ha rdware fai lure has been

detected.

PWR

RUN

green

green

red

ERR

RDL

Primary with H1 error state

PWR

RUN

green

green

red

ERR

RDL

Primary not ready

PWR

RUN

green

green

red

ERR

RDL

Secondary with H1 error

30 © Softing Industrial Automation GmbH

Page 31

LEDs

Meaning

PWR

RUN

green

red

ERR

RDL

Primary, confi guration error

Chapte r 5 - Sta tus ind icators - LEDs

© Softing Industrial Automation GmbH 31

Page 32

FG-200 HSE/FF Modbu s - Qui ck Startup Gu ide

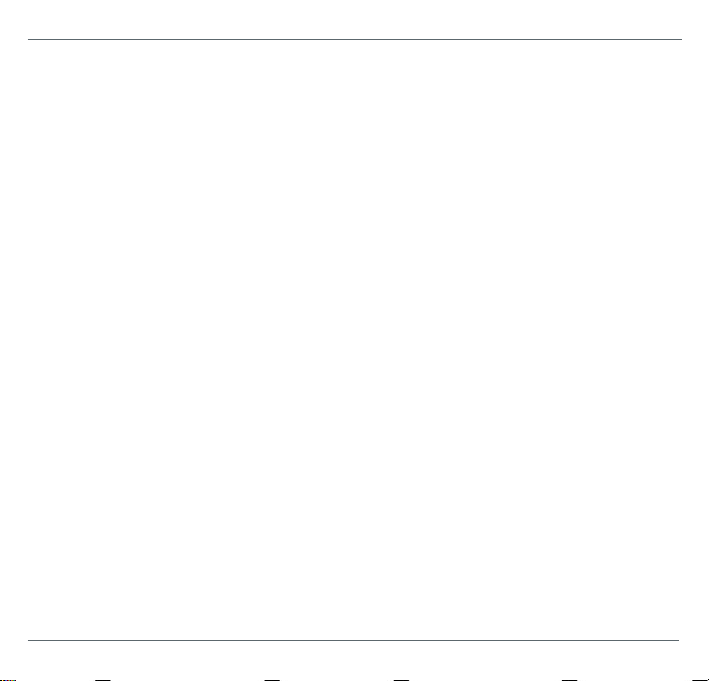

Symbol

Color / frequency

Meaning

green

Visitor address

fla shing sl owly (0.5 Hz)

not in LAS role

fla shing quickly (5 Hz)

LAS role

red

no carrier or H1 l ink is disconnected

fla shing red

no token received

off

H1 link unused

5.4 H1 channel status indicators

The following table shows the channel LEDs and their meaning of al l four channels

(CH1 - CH4):

32 © Softing Industrial Automation GmbH

Page 33

Chapte r 6 - Technical data

Power supply

18 VDC...32 VDC; SELV/PELV supply mandatory

Typical input current is 200 mA; maximum is 1 A (consi dering the

rush-in current at switch-on).

FF-H1

Four FF-H1 channels, compli ant with type 114 of the FF physi cal

layer profile. The Fieldbus voltage range is from 9 VDC...32 VDC.

Preferred value is 24 VDC.

Ethernet

IEEE 802.3 100BASE-TX/10BASE-T

Only ETH 1 is s upported. Do not use ETH 2 (reserved for further us e).

Mini mum ambient

operating

temperature

-40 °C

Storage temperature

-40 °C...+85 °C

Relative humidity

10 %...95 % (non-condensing)

Altitude

Must not exceed 2,000 m

Location

Indoor use only; no direct sunlight

Coating

Conformal Coating based on ANSI/ISA-S71.04 G3

Safety standard

IEC/EN/UL 61010-1 Safety requirements for electrical equipment for

measurement, control and laboratory use - Part 1: General

requirements: IEC/EN/UL 61010-2-201 Sa fety requirements for

electrical equipment for measurement, control and laboratory use Part 2-201: Particular requirements for control equipment (both

with CB scheme).

Ingress protection

IP20

6

Technical data

6.1 Specifications

© Softing Industrial Automation GmbH 33

Page 34

FG-200 HSE/FF Modbu s - Qui ck Startup Gu ide

Minimum distance

Provi de a minimum dis tance of 50 mm to the air inlet and air outlet to ensure

natural convection.

Rotated installation position

The maximum permissi ble ambient temperature values als o apply to a 180°

rotated installation pos ition.

Maximum number

of fieldbus channels

Maximum fieldbus

voltage

Minimum

distance

Maximum permissible

ambient temperature T

a

4

32 VDC

0 mm

55 °C

2

24 VDC

0 mm

60 °C

4

32 VDC

17.5 mm

65 °C

2

24 VDC

17.5 mm

70 °C

6.2 Installation positions

The gateway FG-200 can be mounted horizontally and verticall y. Depending on the

install ation posi tion, different ambient operating temperatures (Ta) are allowed:

Horizontal installation position

34 © Softing Industrial Automation GmbH

Page 35

Vertical installation position

Maximum number of

fieldbus channels

Maximum fieldbus

voltage

Minimum

distance

Maximum permissible

ambient temperature T

a

4

32 VDC

0 mm

40 °C

2

24 VDC

0 mm

50 °C

4

32 VDC

17.5 mm

55 °C

2

24 VDC

17.5 mm

60 °C

Chapte r 6 - Technical data

© Softing Industrial Automation GmbH 35

Page 36

FG-200 HSE/FF Modbu s - Qui ck Startup Gu ide

7

European and International Approval

The equipment meets the following standards:

a) IEC 60079-0:2011 Ed. 6, modified Cor. 2012 + Cor. 2013 / EN 60079-0:2012 + A11:2013

b) IEC 60079-11:2011 Ed. 6 + Corr. 2012 / EN 60079-11:2012

c) IEC 60079-15:2010 Ed. 4 / EN 60079-15:2010

If i ndicated on the device label and in the related documentation, the FG-200 is suitable

for use in gas-Ex atmospheres of Zone 2 in the explosi on groups IIA, IIB and IIC in

temperature cla ss T4, if accommodated in a tested enclosure.

IECEx marking for expl osion protection: Ex nA [ic] IIC T4 Gc.

ATEX marking for explosion protection: II 3G nA [ic] IIC T4 Gc.

The Ex protection method [ic] corresponds only to the FF-H1 fieldbus i nterfaces.

The FG-200 HSE/FF Modbus compli es with the applicable standards and regula tions and

meets the requirements of European Directive 94/9/EC. The requirements for erecting the

device as part of the system in potentially explosive atmospheres (e.g. IEC / EN 60079-14)

must be strictly a dhered.

Certificates

ATEX The EC type examination number for ATEX is: BVS 15 ATEX E 063 X

IECEx The type examination number for IECEx is : IECEx BVS 15.0055X

A copy of the certificate is availabl e in s ection ATEX Type Examination

Certifica te.

The certificate can be downloaded from http://iecex.iec.ch

36 © Softing Industrial Automation GmbH

Page 37

Chapte r 8 - North Ameri can App roval

8

North American Approval

If i ndicated on the device label, the FG-200 i s sui tabl e for use in Cla ss 1, Divi sion 2,

Groups A, B, C and D ha zardous or non-hazardous locations .

The device must be installed in a protective enclosure which meets the requirements for

resi stance to impact and IP54 according to IEC 60529.

Marking for explosion protection: Class I Div.2 Groups A,B,C,D.

Certificate

cULus The cULus l isted Certifi cate of Compli ance number is: 20151215-E356500

See the user manual for a copy of the Certificate of Compliance.

© Softing Industrial Automation GmbH 37

Page 38

FG-200 HSE/FF Modbu s - Qui ck Startup Gu ide

EN 55011

Industri al, sci entific and medical (ISM) devices - radio disturbance

- li mits and methods of measurement

EN 55032

Electromagnetic compatibility of multimedia equipment (MME) and

interference emission

EN 61000-6-4

Electromagnetic compatibility (EMC); Part 6-4: generic standard –

emiss ion for industria l environments

EN 61000-6-2

Electromagnetic compatibility (EMC); Part 6-2: generic standard immunity for i ndustrial environments

Note

To fulfil l the EMC requirements, the other components of your installation

(DC adapter, Industrial Ethernet devices, etc.) als o have to meet the EMC

requirements. A shielded cabl e must be used. In addition, the cable shi eld

must be grounded properly.

CAUTION

This is a Cl ass A product. In a domestic environment this product may cause

radio interference in which case the user may be required to take adequate

measures!

CE

A Declaration of Conformity in compliance with the above standards has

been made and can be requested from Softing Industri al Automation.

9

Declaration of conformity

This device is compliant with EC directive 2014/30/EG for "Electromagnetic Compatibility"

(EMC) and meets the foll owing harmonized standards:

38 © Softing Industrial Automation GmbH

Page 39

Chapte r 9 - De claration of conformi ty

ROHS

This product is ROHS compli ant.

FCC

This equipment has been tested and found to comply with the limits for a

Cla ss A digital device, under part 15 of the FCC Rules. These limits are

designed to provi de reasonable protection against harmful i nterference when

the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not instal led

and used i n accordance with the instruction manual , may cause harmful

interference to radio communications.

VCCI

This Class A product conforms to the regulations of Voluntary Control Council

for Interference (VCCI) by Information Technology Equipment.

WEEE

Electri cal and electroni c equipment must be dis posed of separately from

normal waste at the end of its operational li fetime. Packaging material and

worn components shal l be disposed of accordi ng to the regulations

appli cable in the country of instal lation.

© Softing Industrial Automation GmbH 39

Page 40

Softing Industrial Automation GmbH

Richard-Reitzner-Allee 6

85540 Haar / Germany

http://industrial .softing.com

+ 49 89 45 656-340

+ 49 89 45 656-488

info.idn@softing.com

Loading...

Loading...