Hardware Manual

commModule MBP

Version: EN-022018-1.00

© Softing Industrial Automation GmbH

Disclaimer of liability

The information contained in these instructions corresponds to the technical status at the time of printing of it and is passed on with the

best of our knowledge. The information in these instructions is in no event a basis for warranty claims or contractual agreements

concerning the described products, and may especially not be deemed as warranty concerning the quality and durability pursuant to Sec.

443 German Civil Code. We reserve the right to make any alterations or improvements to these instructions without prior notice. The

actual design of products may deviate from the information contained in the instructions if technical alterations and product

improvements so require.

It may not, in part or in its entirety, be reproduced, copied, or transferred into electronic media.

Softing Industrial Automation GmbH

Richard-Reitzner-Allee 6

85540 Haar / Germany

http://industrial.softing.com

+ 49 89 4 56 56-340

+ 49 89 4 56 56-488

info.idn@softing.com

support.automation@softing.com

The latest version of this manual is available in the Softing download area at: http://industrial.softing.com/en/downloads.html

Table of Contents

Table of Contents

Chapter 1

Chapter 2

Chapter 3

Chapter 4

Introduction

commModule MBP

Interface

Electrical specifications

...................................................................................... 5

............................................................................................................... 51.1 About this document

............................................................................................................... 51.2 Related documentation

............................................................................................................... 51.3 Conventions used

............................................................................................................... 51.4 Document history

...................................................................................... 6

............................................................................................................... 62.1 Diagram

............................................................................................................... 62.2 Intended use

...................................................................................... 7

............................................................................................................... 73.1 Orientation

............................................................................................................... 73.2 Pin number and signal description

............................................................................................................... 93.3 Pullups and pulldowns

............................................................................................................... 93.4 Flash programming and debugging interface

............................................................................................................... 93.5 Fault Disconnect Equipment

............................................................................................................... 93.6 Simulate enable

...................................................................................... 10

Chapter 5

Chapter 6

Chapter 7

............................................................................................................... 104.1 Protocol select

............................................................................................................... 104.2 Operating conditions

............................................................................................................... 104.3 Port input and output

Environmental specifications

Mechanical specification

Special conditions for safe use

...................................................................................... 12

............................................................................................................... 125.1 Temperature

............................................................................................................... 125.2 MTBF calculation

............................................................................................................... 135.3 Certifications

...................................................................................... 14

............................................................................................................... 146.1 Module dimensions

............................................................................................................... 156.2 Host PCB layout

............................................................................................................... 176.3 Mounting process

............................................................................................................... 176.4 ESD handling precautions

............................................................................................................... 176.5 Packaging and labeling

...................................................................................... 18

............................................................................................................... 187.1 Galvanic isolation

............................................................................................................... 187.2 Safety block diagram

............................................................................................................... 197.3 Installation

............................................................................................................... 197.4 Isolation and creepage distances

© Softing Industrial Automation GmbH 3

Table of Contents

............................................................................................................... 207.5 Label

............................................................................................................... 207.6 Maintenance and spare parts

Chapter 8

CE Compliance

............................................................................................................... 228.1 ATEX EC type examination certificate

............................................................................................................... 278.2 IECEx Certificate of Conformity

............................................................................................................... 358.3 Declaration of Conformity

...................................................................................... 21

4

© Softing Industrial Automation GmbH

Chapter 1 - Introduction

CAUTION

This symbol indicates a potentially hazardous situation which, if not avoided, may result in

minor or moderate injury.

Note

This symbol is used to call attention to notable information that should be followed during

installation, use, or servicing of this device.

Hint

This symbol is used when providing you with helpful user hints.

Document version

Modifications compared to previous version

1.00 - initial version

none

1

Introduction

1.1 About this document

This document is addressed to hardware engineers, giving them a detailed description about the electrical,

mechanical and functional specifics of the single-sided communication module, commModule MBP.

1.2 Related documentation

For further details about the commModule MBP and the configuration workflow of the firmware see the

following document:

commScript PD Customization Guide

1.3 Conventions used

The following conventions are used throughout Softing customer documentation:

1.4 Document history

© Softing Industrial Automation GmbH

5

commModule MBP - Hardware Manual

CAUTION

The commModule MBP is certified for the use in hazardous areas when used in accordance

with its specification and operating conditions. See also Operating conditions for use in

hazardous environment .

2

commModule MBP

The commModule MBP is a surface mountable fieldbus communication module with minimum footprint.

It is typically integrated into an intelligent field device mapping industrial intrinsic safe fieldbus Profibus PA

and Foundation Fieldbus to the field device.

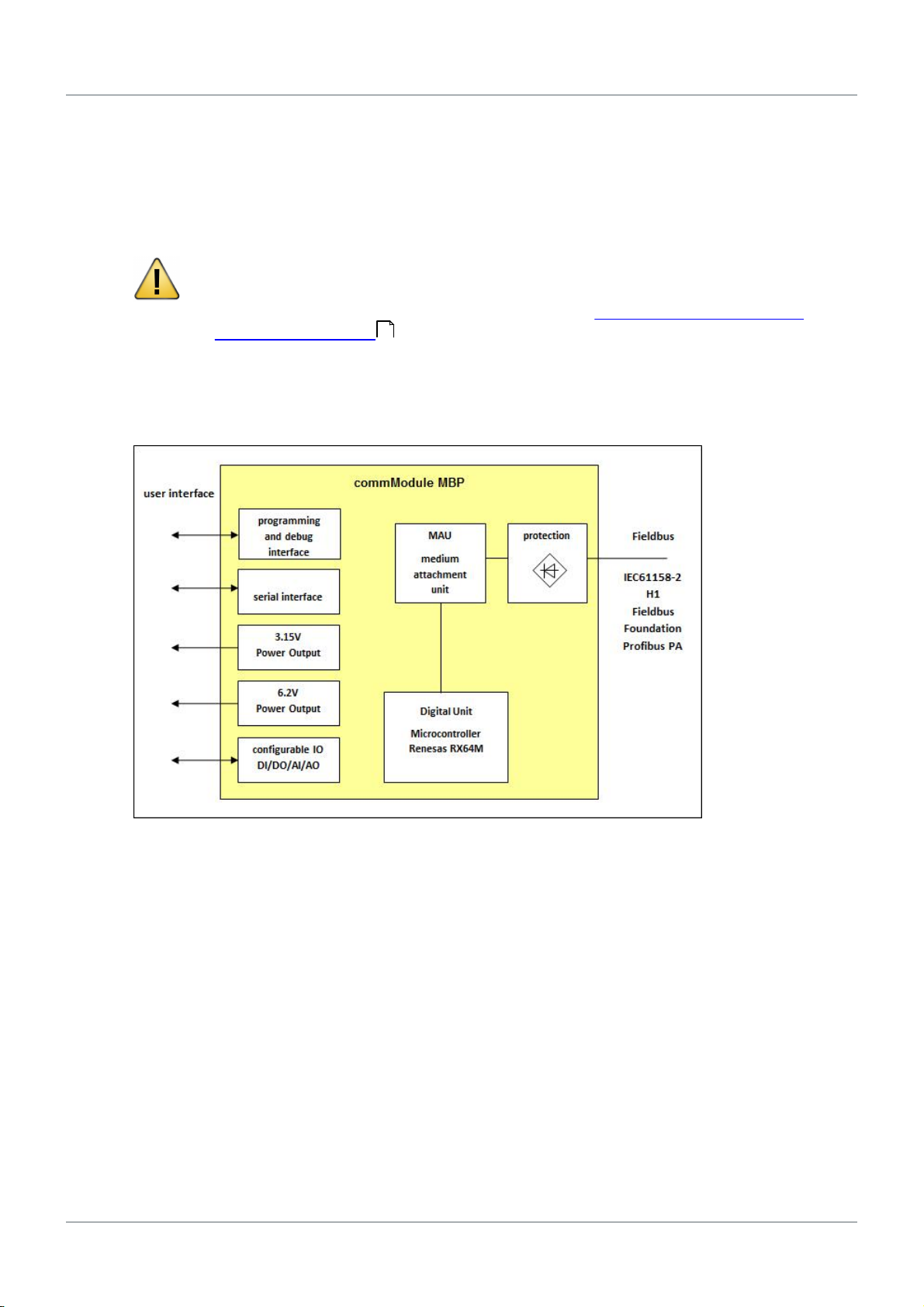

2.1 Diagram

The block diagram below shows the design of the commModule MBP:

12

2.2 Intended use

This product has been designed to be integrated as a system component by a qualified hardware engineer.

6

© Softing Industrial Automation GmbH

Chapter 3 - Interface

Signal Name

Pin No.

I/O*

Description

TXD9_PB7

1DOTX Interface signal for HART

#RTS9_PB5

2DOLow active RTS signal for HART

RXD9_PB6

3DIRX Interface signal for HART

GPIO_PA4

4

GPIO

For future use

GPIO_PE6

5

GPIO, AI

For future use

#CTS9_PB4

6DILow active CTS signal for HART

3V15

7

VCC

Do not use. Internal supply voltage

GND

8

Ground

Ground

GPIO_PE2

9

GPIO

For future use

GPIO_PE5

10

GPIO, AI

For future use

GPIO_PE7

11

GPIO, AI

For future use

GPIO_PE1

12

GPIO

For future use

PROT_SEL_P27 / TCK

13DIProtocol Select: FF/PA, Programming interface

TDO14DBG

Programming interface

GND

15

Ground

Ground

3

Interface

This section describes the signals available on the module via the PCB solder pads on the edge of the PCB.

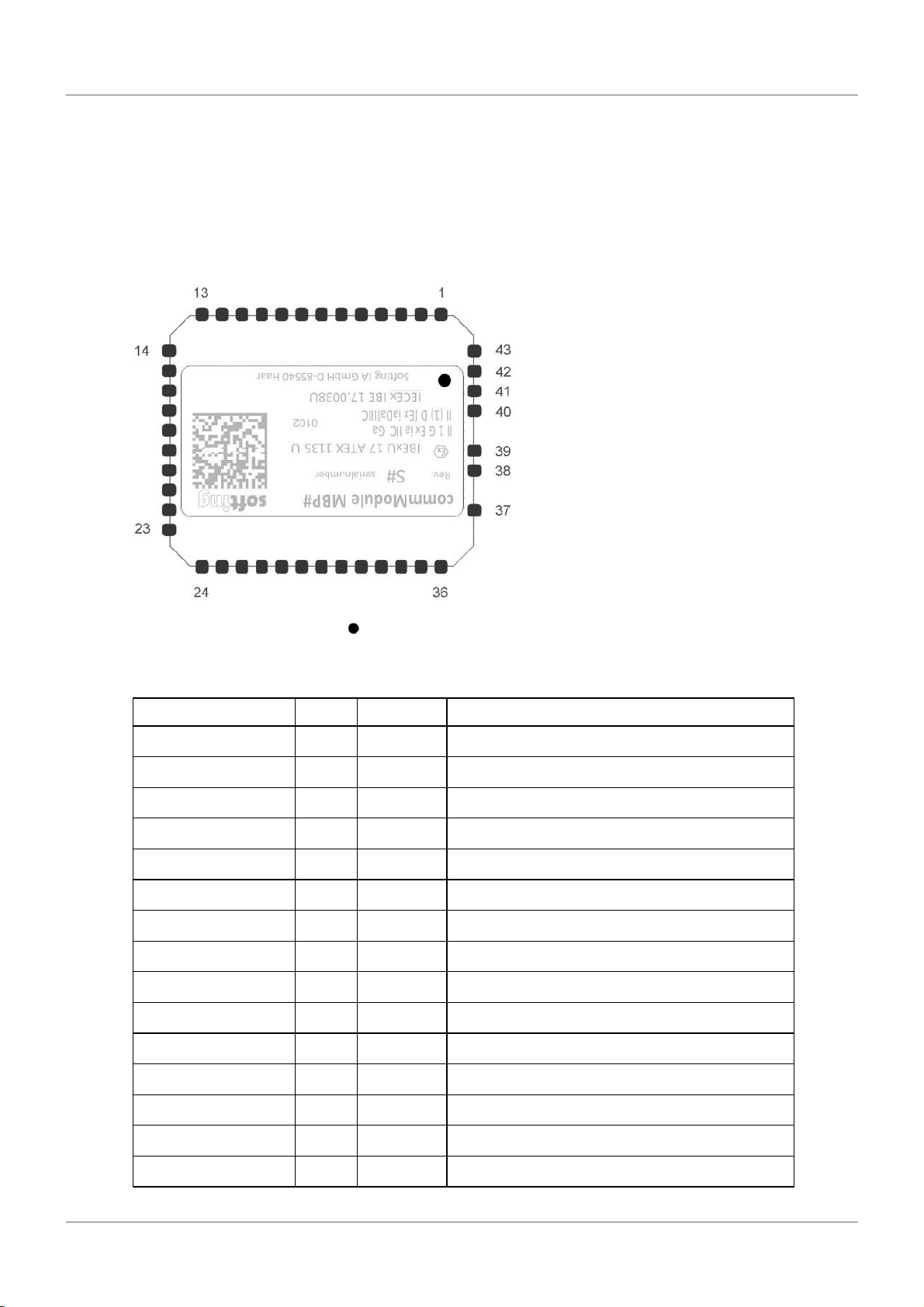

3.1 Orientation

Top view on commModule

The position of Pin 1 is marked on the label.

3.2 Pin number and signal description

© Softing Industrial Automation GmbH

7

commModule MBP - Hardware Manual

RXD7_P92

16DIRX Interface signal for Debug Console (PD 33k)

TXD7_P90

17DOTX Interface signal for Debug Console

DA118AO

For future use

GND

19

Ground

Ground

3V_OUT

20POPower Output 3.15V

6V2_OUT

21POPower Output 6.2V

SIM_EN_P31

22

DBG

Simulate Enable

GPIO_P23

23

GPIO

For future use

GPIO_P22

24

GPIO

For future use

GPIO_P21

25

GPIO

For future use

GPIO_P20

26

GPIO

For future use

GPIO_PC6

27

GPIO

For future use

GPIO_PC7

28

DBG/GPIO

For future use

GPIO_PC5

29

GPIO

For future use

GPIO_PC4

30

GPIO

For future use

EMLE

31

DBG

Programming Interface

TDI32DBG

Programming interface

GPIO_PD2

33

GPIO

For future use

#RESET

34

DBG

Programming interface

FINED

35

DBG

Programming interface (do not pullup)

GND

36

Ground

Ground

FB_P_NF

37FBDo not use

FIELDBUS_N

38FBFieldbus

FIELDBUS_P

39FBFieldbus

FDE_PO

40FBFDE, connect to Pin 41

FDE_PI

41FBFDE, connect to Pin 40

FDE_NO

42FBFDE, connect to Pin 43

FDE_NI

43FBFDE, connect to Pin 42

* AI = Analog Input, AO = Analog Output, DI = CMOS Digital Input, DO = CMOS Digital Output, GPIO = General

Purpose CMOS Digital Input/Output, PO = Power Output, DBG = Programmer Interface, FB = Fieldbus, PD

Pulldown, PU Pullup

8

© Softing Industrial Automation GmbH

3.3 Pullups and pulldowns

Signal Name

Description

14-pin Renesas Fine

Interface

TDO

Not required for debugging.

Only used for internal flash programming with

Renesas Flash Programmer

5

TDI

Not required for debugging.

Only used for internal flash programming with

Renesas Flash Programmer

11

FINEC

Programming Interface

1

FINED

Programming Interface

7

PC7

Programming Interface

10

#RESET

Programming Interface

13

GND

Ground

2, 12, 14

3V15

Internal supply voltage

8

EMLE

Programming Interface

4

CAUTION

The memory blocks are reserved for the firmware. They must not be modified as this will

invalidate the software license and damage the commModule MBP. Only programming project

files provided by Softing shall be used to reprogram the module.

Weak pullups are provided on all GPIO pins. Pullups for TDO and TDI are not included on the CommModule

MBP and must be included on the application base board (pullup to Pin 7 of CommModule MBP).

RXD7_P92: internal pulldown 33k

3.4 Flash programming and debugging interface

The following signals of the microcontroller are required for flash programming.

See the commModule MBP Evaluation Kit manual for details. The usage of this interface is detailed in

document "E1/E20 Emulator – additional document for User’s Manual (RX User System Design) from

Renesas".

Chapter 3 - Interface

3.5 Fault Disconnect Equipment

External fault disconnect equipment (FDE) can be optionally added using the assigned FDE pins.

If not in use, connect signal FDE_PO to FDE_PI and signal FDE_NO to FDE_NI.

3.6 Simulate enable

Fieldbus conformance testing requires switching the application to simulation mode.

Simulation mode is enabled by signaling low on pin SIM_EN_P31.

For the registration of the final device by the FieldComm Group this signal must be accessible to the

fieldbus testing personnel.

© Softing Industrial Automation GmbH

9

commModule MBP - Hardware Manual

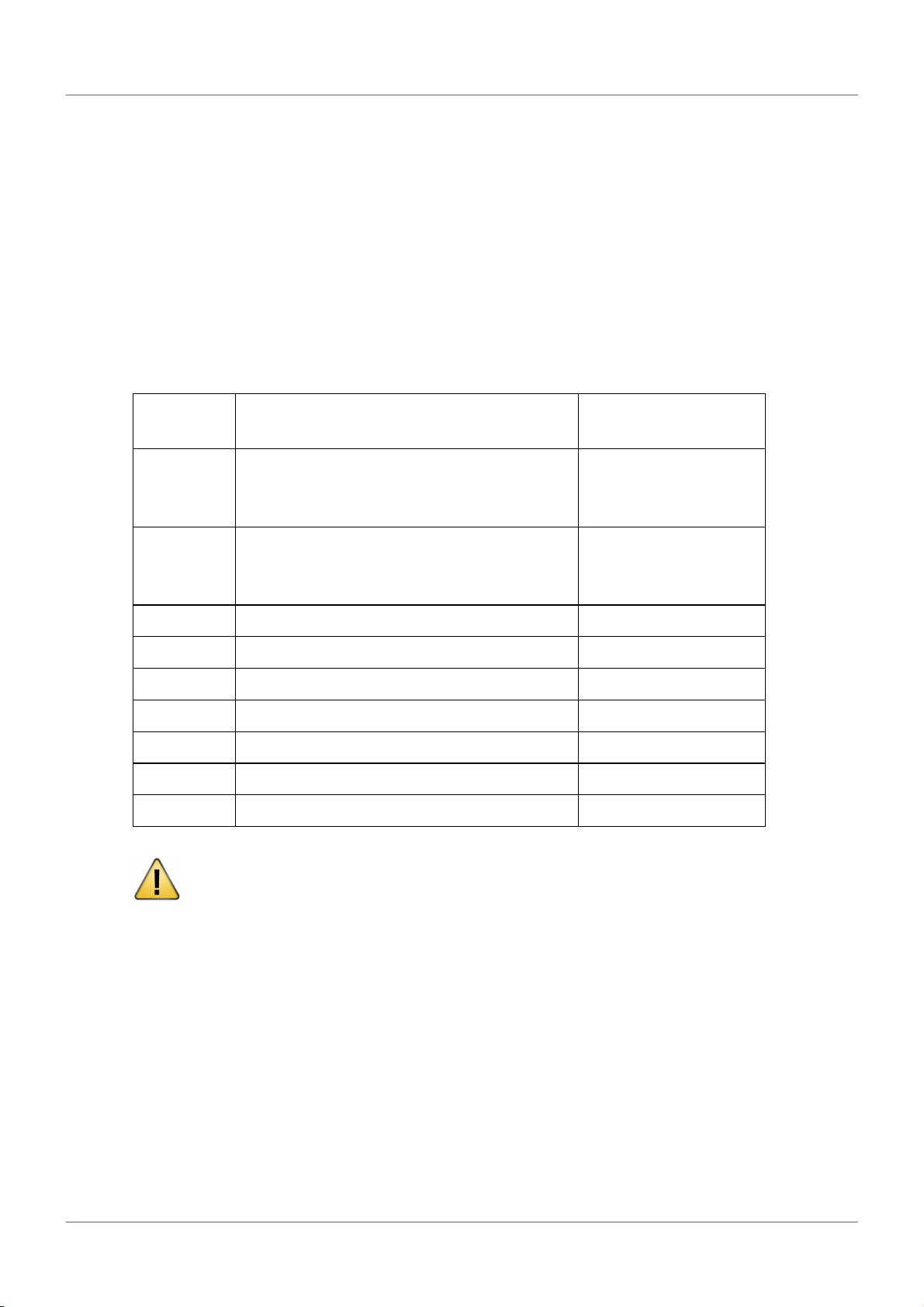

Fieldbus Protocol

PROT_SEL_P27

description

Fieldbus Foundation FF

High

(internal pullup)

Leave open

The commModule MBP is operating in

Foundation Fieldbus (FF) mode.

Profibus PA

Low

connect to GND

The commModule MBP is operating in Profibus

PA mode.

Parameter

Symbol

Min

Max

Unit

Test Conditions

DI: input low voltage

V

IL

Vcc x 0.2

V

DI: input high voltage

VIHVcc x 0.8

V

DO: output low voltage

V

OL

0.5

V

IOL = 1mA

DO: output high voltage

VOHVcc – 0.5

V

IOH = -1mA

4

Electrical specifications

4.1 Protocol select

This pin is scanned during start-up.

4.2 Operating conditions

Unless otherwise noted, all specifications apply over the specified operating temperature range.

4.3 Port input and output

The communication module has the following port input and port output specification at Vcc = 3.2V± 4%.

Analog Input

The commModule MBP incorporates a 12bit-A/D converter with a reference voltage of 3.0V

Power Output:

The power budget to supply a connected system from fieldbus is limited.

It is dependent on the rated current from fieldbus, which is adjustable in software

from IN = 10mA to 26mA.

Available output power:

P

= approx. 90mW on 6V2_OUT, with I

omax

or:

P

= approx. 70mW on 3V_OUT, with I

omax

When both power outputs are used, the available power budget is between 70 and 90mW. The slew rate

is controlled. The rise time is 1.43ms. The output current is not limited on the commModule MBP.

10

PO_6V2

PO_3V_OUT

= I

– 10mA

N

= (IN – 10mA) / 0.7

© Softing Industrial Automation GmbH

Chapter 4 - Electrical specifications

Note

If the available power budget is exceeded the commModule MBP may reset.

Parameter

Nom

Min

Max

Unit

3V_OUT

Io = 1mA

3.2

3.1

3.3

V

6V2_OUT (internal series resistance 10 Ohms)

Io = 1mA

6.2

6.05

6.3

V

Fieldbus:

Physical Layer according to IEC 61158-2 type 3 voltage mode, 31.25kBit/s.

Rated current adjusted in software to In = 10mA up to 26mA.

Powered from Fieldbus 9V to 32V (non hazardous location).

Use in hazardous locations:

Limitation on fieldbus power supply applies for different use cases. See also Operating conditions for use

in hazardous environment .

12

© Softing Industrial Automation GmbH

11

commModule MBP - Hardware Manual

Parameter

Units

Min

Max

Note

operating temperature

°C

-40

80

storage temperature

°C

-40

85

humidity

°rH1090

non condensing

Use Case

Input Supply

Temperature

Class

Ambient

Temperature Range

commModule

Internal fused with

62mA

FISCO

or:

EX ia IIB, Ui =17.5V, Ii =380mA

or:

EX ia IIC, Ui = 24V, Ii = 250mA

T4

-40°C to +80°C

5

Environmental specifications

5.1 Temperature

Absolute Maximum Ratings:

Storage temperature: -40°C to + 85°C.

Stresses exceeding maximum ratings may damage the device. Maximum ratings are stress ratings only.

Functional operation above the recommended operating conditions is not implied. Extended exposure to

stresses above the recommended operating conditions may affect device reliability.

Normal Operating Conditions (module soldered):

Fieldbus current adjustable from 10mA to 26mA.

Operating conditions for use in hazardous environment:

Operating temperature is dependent on intrinsic safe input parameters.

Operating Conditions for use in hazardous environment with external fuse.

Additional requirements apply for the design of the host PCB.

For further information see the ATEX EC type examination certificate .

5.2 MTBF calculation

MTBF calculated according to SN29500:

@40°C: 3.655.879 hours

@70°C: 1.142.849 hours

Conditions: Standard SN29500, continuous operation

12

22

© Softing Industrial Automation GmbH

5.3 Certifications

ROHS

The commModule MBP is ROHS compliant.

ATEX / IECEx:

IECEx IBE 17.0038U

Ex ia IIC Ga

[Ex ia Da] IIIC

IBExU17ATEX1135 U

II 1G Ex ia IIC Ga

II (1) D [Ex ia Da] IIC

Chapter 5 - Environmental specifications

© Softing Industrial Automation GmbH

13

commModule MBP - Hardware Manual

6

Mechanical specification

The weight of a potted variant (commModule MBP#STD) is approximately 15 gram. The weight of the non-

potted variant (commModule MBP#STD_NOP) is 8 gram.

6.1 Module dimensions

The dimensions below are shown in millimeters.

14

Bottom view

© Softing Industrial Automation GmbH

6.2 Host PCB layout

Note

The host PCB footprint must not contain any exposed copper under the module except the

pads interfacing the CommModule MBP to avoid any contact with traces on the module.

Recommended footprint

Chapter 6 - Mechanical specification

The PCB footprint dimensions may be modified based on user experience and/or process capability.

Routing under the CommModule MBP

© Softing Industrial Automation GmbH

15

commModule MBP - Hardware Manual

Note

It is recommended to include 4 vias on the host PCB near the corners (not in keep out area) to

avoid tilting of the CommModule MBP during soldering.

Note

The recommended stencil thickness is 0.12 to 0.15mm.

Note

The schematic library and PCB library for the Altium Designer can be download here:

Intrinsic safety:

1. Ensure there is no copper within 0.5mm of the marked Keep Out Area on the host PCB.

2. Ensure a clearance of 2mm between signals on Pin 40 – 43 to all other pins.

3. Ensure a clearance of 2mm between fieldbus on Pin 37 – 39 to all other pins and Pin 37 to Pin 39.

Solderpaste

16

© Softing Industrial Automation GmbH

6.3 Mounting process

Note

It is recommended to perform electrical, climate, stress and vibration tests on the final

assembled product to verify that the manufacturing process has not damaged the

commModule MBP. CommModule MBP are moisture sensitive devices.

Note

Variant commModule MBP #STD must be soldered by hand.

The commModule MBP contains highly sensitive electronic circuitry and is an Electrostatic

Sensitive Device (ESD). Observe precautions for safe handling! Failure to observe these

precautions can result in severe damage to the module.

The PCB is made of FR4 and has a NiAu surface finish. We strongly recommend that commModule MBP

modules are not soldered more than once after shipping by Softing.

The soldering of the communication module is compliant with RoHS directive 2011/65.

Reflow recommendations

The following temperatures and times are recommended for variant commModule MBP #STD_NOP:

Ramp up rate 3°C/second max

Maximum time maintained above 217°C 40 -60 seconds

Peak reflow temperature 245°C

Ramp down rate 4°C/second max

Chapter 6 - Mechanical specification

6.4 ESD handling precautions

6.5 Packaging and labeling

CommModule MBP are moisture sensitive devices. They are shipped in ESD safe trays measuring

approximately 136 x 315 mm.

Storage and Drying

The packaging may not exceed the max. temperature of 60°C.

Labeling

© Softing Industrial Automation GmbH

17

commModule MBP - Hardware Manual

7

Special conditions for safe use

Please read and follow the instructions in this manual.

If the notes stated in this excerpt are not observed or in case of inappropriate handling of the device,

our liability is waived.

The details of this user manual have to be observed as have to be the conditions for use and the

applicable details stated on the marking, type labeling and accompanying documentation of each device.

The device is only approved for intended and appropriate use. In case of non-compliance, the warranty

and manufacturer’s liability do no longer apply!

It has to be ensured that only such equipment is installed which complies with the types of protection

applicable to the relevant zones!

All connected electrical equipment has to be suitable for the respective intended use.

Equipment Protection Level Ga requires an enclosure according to IEC 60079-0. Mechanical strength tests

on enclosures, e.g. degree of protection (IP), thermal endurance tests, impact test, fall test are not

applicable for the commModule MBP as a bare module.

7.1 Galvanic isolation

The circuits of the commModule MBP have no galvanic isolation. All signals are galvanically connected

together.

7.2 Safety block diagram

The following block diagram shows the commModule MBP:

18

© Softing Industrial Automation GmbH

7.3 Installation

Pin

Signal

Creepage and clearance

Pin 1 to 36

GPIO, GND, DBG

No requirement on creepage distances between these

signals.

Clearance and creepage distance to all other signals

with level of protection 10V according to table 5 in

IEC 60079-0

Pin 37

FB_P_NF

Clearance and creepage distance to all other signals

except FIELDBUS_N

with level of protection 30V according to table 5 in

IEC 60079-0

Pin 38, 39

FIELDBUS_P, FIELDBUS_N

No requirement on creepage distances between these

signals.

Clearance and creepage distance to all other signals

The commModule MBP must be installed by qualified personnel only.

Ensure that the equipment installed complies with the types of protection relevant to the applicable zones

and categories and with local requirements for electrical equipment used in explosive areas associated

with explosive atmosphere.

The following points must be considered when deploying the unit:

The device must be used as intended by the manufacturer

Do not use this device when damaged.

Do not use this device when certification information is illegible.

Observe storage conditions.

Clean installation space.

Installation done according to instructions.

Do not put stress on the system by bending or torsion.

Connecting improper or non Ex certified equipment invalidates Ex approval of device.

Chapter 7 - Special conditions for safe use

Electrical parameters of connected devices must match the values described in the technical section.

Local requirements for electrical equipment for use with hazardous location associated with explosive

atmosphere shall be considered for installation.

This device has no housing and must be protected in a cabinet against splash water, dirt, moisture

mechanical force exceeding pollution degree 1.

7.4 Isolation and creepage distances

Following creepage and clearance distances and separations must be observed when integrating

commModule MBP.

© Softing Industrial Automation GmbH

19

commModule MBP - Hardware Manual

with level of protection 30V according to table 5 in

IEC 60079-0

Pin 40 to 43

FDE_PO, FDE_PI,

FDE_NO, FDE_NI

No requirement on creepage distances between these

signals.

Clearance and creepage distance to all other signals

with level of protection 30V according to table 5 in

IEC 60079-0

7.5 Label

The commModule MBP is marked with a label similar to the example below.

7.6 Maintenance and spare parts

The device does not require any maintenance.

In case of malfunctioning or failure, disassemble the device or the affected part and return this device to

Softing for repair.

20

© Softing Industrial Automation GmbH

Chapter 8 - CE Compliance

8

CE Compliance

This device complies with the following EC directives:

EC directive 2014/30/EU "EMC directive”

EC directive 2014/34/EU "ATEX"

EC directive 2011/65/EU "RoHS"

© Softing Industrial Automation GmbH

21

commModule MBP - Hardware Manual

8.1 ATEX EC type examination certificate

22

© Softing Industrial Automation GmbH

Chapter 8 - CE Compliance

© Softing Industrial Automation GmbH

23

commModule MBP - Hardware Manual

24

© Softing Industrial Automation GmbH

Chapter 8 - CE Compliance

© Softing Industrial Automation GmbH

25

commModule MBP - Hardware Manual

26

© Softing Industrial Automation GmbH

8.2 IECEx Certificate of Conformity

Chapter 8 - CE Compliance

© Softing Industrial Automation GmbH

27

commModule MBP - Hardware Manual

28

© Softing Industrial Automation GmbH

Chapter 8 - CE Compliance

© Softing Industrial Automation GmbH

29

commModule MBP - Hardware Manual

30

© Softing Industrial Automation GmbH

Chapter 8 - CE Compliance

© Softing Industrial Automation GmbH

31

commModule MBP - Hardware Manual

32

© Softing Industrial Automation GmbH

Chapter 8 - CE Compliance

© Softing Industrial Automation GmbH

33

commModule MBP - Hardware Manual

34

© Softing Industrial Automation GmbH

8.3 Declaration of Conformity

Chapter 8 - CE Compliance

© Softing Industrial Automation GmbH

35

Softing Industrial Automation GmbH

Richard-Reitzner-Allee 6

85540 Haar / Germany

http://industrial.softing.com

Tel: + 49 89 45 656-340

Fax: + 49 89 45 656-488

info.idn@softing.com

Loading...

Loading...