Page 1

© Copyright 2014 - 2016 Softing Industrial Automation GmbH

User Manual

Version: MMA-NN-006005-EN-062016-1.30

PROFIBUS Tester 5 (BC-700-PB)

Page 2

The information contained in these instructions corresponds to the technical status at the time of printing of it and is passed on with the

best of our knowledge. The information in these instructions is in no event a basis for warranty claims or contractual agreements

concerning the described products, and may especially not be deemed as warranty concerning the quality and durability pursuant to Sec.

443 German Civil Code. We reserve the right to make any alterations or improvements to these instructions without prior notice. The

actual design of products may deviate from the information contained in the instructions if technical alterations and product improvements

so require.

It may not, in part or in its entirety, be reproduced, copied, or transferred into electronic media.

Disclaimer of liability

Softing Industrial Automation GmbH

Richard-Reitzner-Allee 6

85540 Haar / Germany

http://industrial.softing.com

The latest version of this manual is available in the Softing download area at: http://industrial.softing.com/en/downloads.html

+ 49 89 4 56 56-0

+ 49 89 4 56 56-488

info.automation@softing.com

support.automation@softing.com

Page 3

Copyright 2016 Softing Industrial Automation GmbH 3

Table of Contents

Table of Contents

Chapter 1

.......................................................................................... 7

Introduction

...................................................................................................................... 7

1.1

About the PROFIBUS Tester 5 (BC-700-PB)

...................................................................................................................... 7

1.2

About this document

.................................................................................................................. 7

Purpose 1.2.1

.................................................................................................................. 7

Target group 1.2.2

.................................................................................................................. 8

Conventions used 1.2.3

.................................................................................................................. 9

Document history 1.2.4

...................................................................................................................... 9

1.3

Delivery scope

...................................................................................................................... 10

1.4

Optional accessories

.................................................................................................................. 10

D-sub adapter cable for testing live systems 1.4.1

.................................................................................................................. 11

Adapter Set for M12 Connection Technology 1.4.2

.................................................................................................................. 11

Fieldbus Shield Digital Leakage Current Clamp 1.4.3

.................................................................................................................. 11

Adapter for testing PROFIBUS PA networks 1.4.4

.................................................................................................................. 12

Spare battery 1.4.5

.................................................................................................................. 12

Service interfaces for PROFIBUS DP 1.4.6

.................................................................................................................... 12

Connection Type D-sub

1.4.6.1

.................................................................................................................... 13

Connection Type M12

1.4.6.2

...................................................................................................................... 13

1.5

System requirements

...................................................................................................................... 14

1.6

Connectors and controls

Chapter 2

.......................................................................................... 15

Power up and down the device

...................................................................................................................... 15

2.1

Power-up

...................................................................................................................... 15

2.2

Power-on behaviour without USB connection

...................................................................................................................... 16

2.3

Power-on behaviour when USB connected

...................................................................................................................... 16

2.4

Power-off and sleep mode

Chapter 3

.......................................................................................... 18

Connection to PROFIBUS-DP

...................................................................................................................... 18

3.1

Basics

.................................................................................................................. 18

Note when testing a live bus 3.1.1

.................................................................................................................. 18

Connection types 3.1.2

.................................................................................................................. 18

Adapter cable 3.1.3

.................................................................................................................. 19

Strain relief 3.1.4

.................................................................................................................. 19

Using the security lock port 3.1.5

.................................................................................................................. 19

Test Locations 3.1.6

Page 4

Copyright 2016 Softing Industrial Automation GmbH

Table of Contents

4

...................................................................................................................... 20

3.2

Simple connection for tests during system shutdown

...................................................................................................................... 20

3.3

Connection for testing a live bus (DP)

.................................................................................................................. 21

Connection via D-sub connector with service socket 3.3.1

.................................................................................................................. 22

Direct cable connection 3.3.2

.................................................................................................................. 23

Connection Type M12 3.3.3

...................................................................................................................... 23

3.4

Master simulator, topology scan and cable test

...................................................................................................................... 25

3.5

Connecting to PROFIBUS PA networks

.................................................................................................................. 25

Requirements for analyzing a live bus 3.5.1

.................................................................................................................. 25

PA adapter BC-700-H1 – before you start 3.5.2

.................................................................................................................. 25

Connecting PA-adapter to test device 3.5.3

.................................................................................................................. 26

Bus connection 3.5.4

.................................................................................................................. 27

Test Locations 3.5.5

.................................................................................................................. 28

Analyzing during shutdown 3.5.6

Chapter 4

.......................................................................................... 29

Display and control in stand-alone mode

...................................................................................................................... 29

4.1

Start display

...................................................................................................................... 29

4.2

User interface

...................................................................................................................... 30

4.3

Operating functions and softkeys

...................................................................................................................... 31

4.4

Device status

...................................................................................................................... 32

4.5

Menu functions

...................................................................................................................... 36

4.6

Organize and store test results

Chapter 5

.......................................................................................... 38

Data import into the PC

Chapter 6

.......................................................................................... 39

Device management

...................................................................................................................... 39

6.1

Licenses

.................................................................................................................. 39

Which license is activated? 6.1.1

.................................................................................................................. 39

How to activate a license 6.1.2

...................................................................................................................... 40

6.2

Firmware update

Chapter 7

.......................................................................................... 41

Maintenance and Servicing

Chapter 8

.......................................................................................... 42

Troubleshooting

Chapter 9

.......................................................................................... 44

Tips and tricks for cable testing

...................................................................................................................... 44

9.1

Assessment criteria

...................................................................................................................... 44

9.2

Cable test - fault indications and remedial measures

...................................................................................................................... 47

9.3

Metering the cable segment length correctly

Chapter 10

.......................................................................................... 49

Quality index compatibility between BC-600-PB and BC-700-PB

...................................................................................................................... 49

10.1

What does the quality index indicate and how is the index determined?

...................................................................................................................... 49

10.2

Why might the BC-700-PB display different quality indexes?

Page 5

Copyright 2016 Softing Industrial Automation GmbH 5

Table of Contents

Chapter 11

.......................................................................................... 50

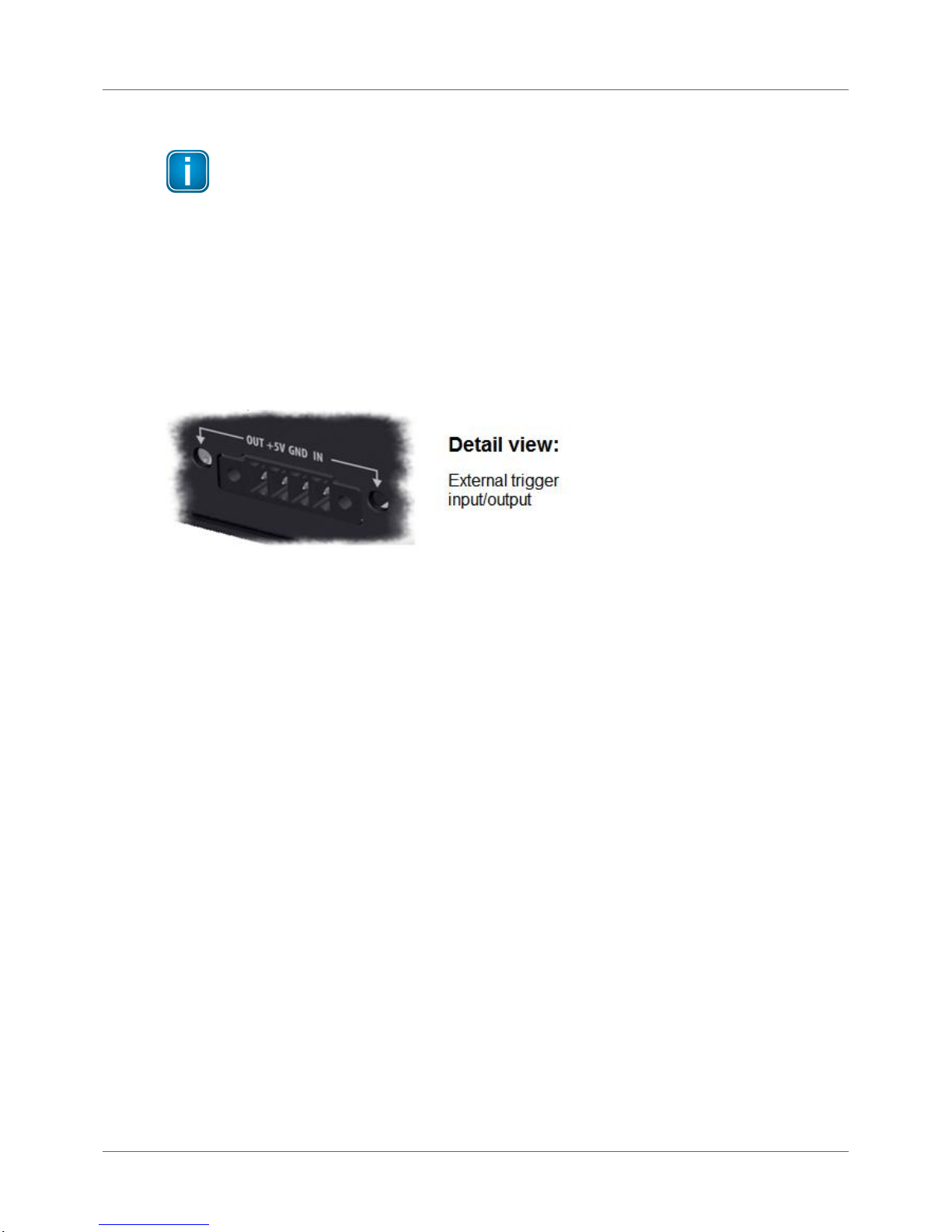

Notes on external trigger input and output

Chapter 12

.......................................................................................... 51

Notes on battery use

...................................................................................................................... 51

12.1

General hints and warnings on rechargeable battery use

...................................................................................................................... 52

12.2

Charge battery

...................................................................................................................... 53

12.3

Replace battery

...................................................................................................................... 53

12.4

Discharge battery

...................................................................................................................... 53

12.5

Storage and transportation

...................................................................................................................... 54

12.6

Battery lifetime

...................................................................................................................... 54

12.7

Battery warranty

...................................................................................................................... 54

12.8

Lithium backup battery

Chapter 13

.......................................................................................... 55

Technical Data

Chapter 14

.......................................................................................... 56

Declarations by the manufacturer

Index ................................................................................................................ 57

Page 6

This page is intentionally left blank.

6 Copyright 2016 Softing Industrial Automation GmbH

Page 7

Chapter 1 - Introduction

Copyright 2016 Softing Industrial Automation GmbH

7

1

Introduction

1.1 About the PROFIBUS Tester 5 (BC-700-PB)

The PROFIBUS Tester 5 (BC-700-PB) is a powerful tool that allows full testing of the bus physics and bus

communication on PROFIBUS DP and PROFIBUS PA segments (option). Using the integrated master

simulator, you can also test the bus physics if the PLC is currently not in operation. In addition you can

check individually check "suspicious" bus stations. The cable test function examines the cabling in

PROFIBUS DP segments. It locates unwanted reflections on the line and verifies proper termination of

cable segments. The tool is powered either by its built-in battery or through an external AC adapter.

The PROFIBUS Tester 5 (BC-700-PB)s the first battery-powered tester, which combines the assessment

of bus physics and bus communication as well as cable testing in one device. It is therefore the only and

truly mobile PROFIBUS diagnostic tool.

1.2 About this document

Read this manual before starting

For damages due to improper connection, implementation or operation Softing refuses any

liability according to our existing guarantee obligations.

CAUTION

Refer also to the safety precautions for battery and battery pack in Section Notes on

battery use .

1.2.1 Purpose

This document describes the BC-700-PB. It provides information about putting into service and also

provides detailed information regarding its safe and correct operation.

1.2.2 Target group

This document is addressed to operating staff which is adept in operating PROFIBUS-systems such as:

Maintenance personnel

Commissioniers

Application engineers and developpers

Trainers

51

Page 8

PROFIBUS Tester 5 (BC-700-PB) - User Manual

8

Copyright 2016 Softing Industrial Automation GmbH

1.2.3 Conventions used

The following conventions are used throughout Softing customer documentation:

Keys, buttons, menu items, commands and

other elements involving user interaction are

set in bold font and menu sequences are

separated by an arrow

Open Start Control Panel

Programs

Buttons from the user interface are enclosed in

brackets and set to bold typeface

Press [Start] to start the application

Coding samples, file extracts and screen output

is set in Courier font type

MaxDlsapAddressSupported=23

Filenames and directories are written in italic

Device description files are located in C:

\<productname>\delivery\software

\Device Description files

CAUTION

CAUTION indicates a potentially hazardous situation which, if not avoided, may result in

minor or moderate injury.

Note

This symbol is used to call attention to notable information that should be followed during

installation, use, or servicing of this device.

Hint

This symbol is used when providing you with helpful user hints.

Page 9

Chapter 1 - Introduction

Copyright 2016 Softing Industrial Automation GmbH

9

1.2.4 Document history

Document version

Modifications compared to previous version

Version 1.00

none - initial publication

Version 1.01

Editorial modifications following internal review

Order numbers for optional accessories added

New device status icons added

New cable test note added

Version 1.10

Revised and enhanced PA-specific topics

Internal battery is installed upon delivery - new section "Replace battery"

inserted.

Added a recommendation with respect to cable shield

Added reference about Softing License Manager

Version 1.11

New optional accessory

Modified battery descriptions

Document structure optimized

Version 1.20

Note regarding providing device serial number when ordering the PA-H1Adapter and activating the license

New section describing how to work with the PA-Adapter BC-700-H1

Version 1.30

New test function Locate Stations

New oscilloscope functionality in stand-alone mode with result display

and without need to use PROFIBUS Diagnostics Suite (requires additional

license, refer to Licenses )

Segments, locations and networks can be created in the PROFIBUS

Diagnostics Suite and then be downloaded to the BC-700-PB (refer also to

the PROFIBUS Diagnostics Suite online help for more information)

1.3 Delivery scope

The BC-700-PB carrying case contains:

Test tool with RS485 interface

Rechargeable battery pack (internal battery)

Wide-range power supply with European and US mains power cables

RS485 D-sub adapter cable BC-600-PB-CB-DSUB-2 “Standard” (cable petrol blue, light connector) for

PROFIBUS DP

USB cable, 2 m

Terminal block for trigger input/output

CD-ROM with driver software, PC software and detailed integrated help system in English and

German

Documentation for BC-700-PB and for the PROFIBUS Diagnostics Suite PC software

33

33

39

33

Page 10

PROFIBUS Tester 5 (BC-700-PB) - User Manual

10

Copyright 2016 Softing Industrial Automation GmbH

Figure 1: BC-700-PB in carrying case

The carrying case comprises cut-outs for optional accessories (leakage current clamp, adapter for

testing PROFIBUS PA networks, spare rechargeable battery)

1.4 Optional accessories

1.4.1 D-sub adapter cable for testing live systems

This D-sub adapter cable is optimized for reduced influence on live PROFIBUS DP segment operation.

Thereby it is most suitable for testing of running plants. The risk of critical influences on bus operation

which can cause a plant standstill is significantly reduced.

Note

Using this cable it is not possible to use both active functions master simulator and topology

detection (see Master simulator and topology scan ).

Figure 2: D-sub adapter cable with reduced influence on bus operation

Softing Order No.: BC-600-PB-CB-DSUB-1

23

Page 11

Chapter 1 - Introduction

Copyright 2016 Softing Industrial Automation GmbH

11

1.4.2 Adapter Set for M12 Connection Technology

Using the M12 adapter set, you can connect the PROFIBUS Tester 5 to field devices with M12

connectors. The set comprises an M12 adapter cable with special pin layout and an M12 terminating

resistor that you can screw on, if required.

Figure 3: Special adapter set for M12

Softing Order No.: BC-600-PB-CB-M12

1.4.3 Fieldbus Shield Digital Leakage Current Clamp

When routing PROFIBUS cables in high-interference environments, electromagnetic interference can

affect the signal quality. By measuring the shield currents with the digital leakage current clamp, you

can locate EMC problem areas and take appropriate countermeasures. The digital leakage current

clamp is supplied in a handy case, including measuring cables. There is also an empty compartment for

the fieldbus shield digital leakage current clamp in the carrying case of the PROFIBUS Tester 5 (BC-700PB).

Figure 4: Fieldbus shield digital leakage current clamp

Softing Order No.: PB-LSZ-CHB3

1.4.4 Adapter for testing PROFIBUS PA networks

The optional plug-in adapter (including test equipment set) for PROFIBUS PA networks enables the BC700-PB to analyze electrical signal quality and data communication in PROFIBUS PA installations. The

BC-700-PB in conjunction with the adapter BC-700-H1 is the proper test tool for identifying basic

installation errors and defective PROFIBUS PA stations.

License for PA option

If you want to use the PA-Adapter BC-700-H1 with your BC-700-PB you need a

corresponding license (upgrade). This license is related to the serial number of your device.

When ordering the PA option we kindly ask you to provide us with the serial number of

your BC-700-PB (see also Licenses) .

Before using the PA adapter

Before using the PA adapter for the first time read carefully section PA-Adapter BC-700-H1

– before you start . Activate the PA license on your device and preform the required

updates.

39

25

Page 12

PROFIBUS Tester 5 (BC-700-PB) - User Manual

12

Copyright 2016 Softing Industrial Automation GmbH

Note

Note the PROFIBUS PA-specific notes in sections Connecting to PROFIBUS PA-networks ,

Display and controls in stand-alone mode and Licenses .

Figure 5: BC-700-H1 adapter

Figure 6: Supplied test equipment set for connecting to PROFIBUS PA segments

Softing order number: DDL-NL-006010 (adapter, license and test equipment)

1.4.5 Spare battery

Intensive use of BC-700-PB during the work day may exhaust the rechargeable battery faster than

expected. In addition charging and discharging will typically wear out the battery pack over the time

(refer to Notes on battery use ). BC-700-PB has an internal energy management. If the measures for

energy saving are not sufficient or are perceived as a disturbance it is recommended operating on the

device in conjunction with an external power supply. Alternatively the user may use a spare

rechargeable battery.

Figure 7: Rechargeable battery pack, Softing Order No.: ABA-NN-006012

1.4.6 Service interfaces for PROFIBUS DP

1.4.6.1

Connection Type D-sub

The D-sub service interface provides a PROFIBUS access point for testing if the existing D-sub

connectors have no service socket or if the bus stations are connected via a terminal block. The service

interface can power the terminating resistor of the D-sub connector. You can thus use it as an active

bus termination at the beginning or end of the bus.

If the PLC allows dropping and adding bus stations on the live bus, you will need this external bus

termination to be able to exchange the first and last bus stations without causing problems on the bus.

The compact unit is rail mounted like a terminal block and powered by an external 24 VDC power

supply. The package includes an 90° angled PROFIBUS connector with a switchable terminating resistor.

25

29 39

51

Page 13

Chapter 1 - Introduction

Copyright 2016 Softing Industrial Automation GmbH

13

Figure 8: D-sub service interface for testing a live bus, Softing Order No.:BC-PBMB-PB-S

1.4.6.2

Connection Type M12

The M12 service interface comprises an IP68 rated T piece, an end cap for the service output of the T

piece, and a 1m PROFIBUS DP cable fitted with a male/female M12 connector on each end.

Figure 9: M12 service interface, Softing order No.: BC-M12DP-PB

1.5 System requirements

Hardware

PC

USB 2.0 Port

operating system

Windows 7, Windows 8, Windows 8.1 and Windows 10 (each in 32 bit and 64 bit version)

Hardware

PC

Page 14

PROFIBUS Tester 5 (BC-700-PB) - User Manual

14

Copyright 2016 Softing Industrial Automation GmbH

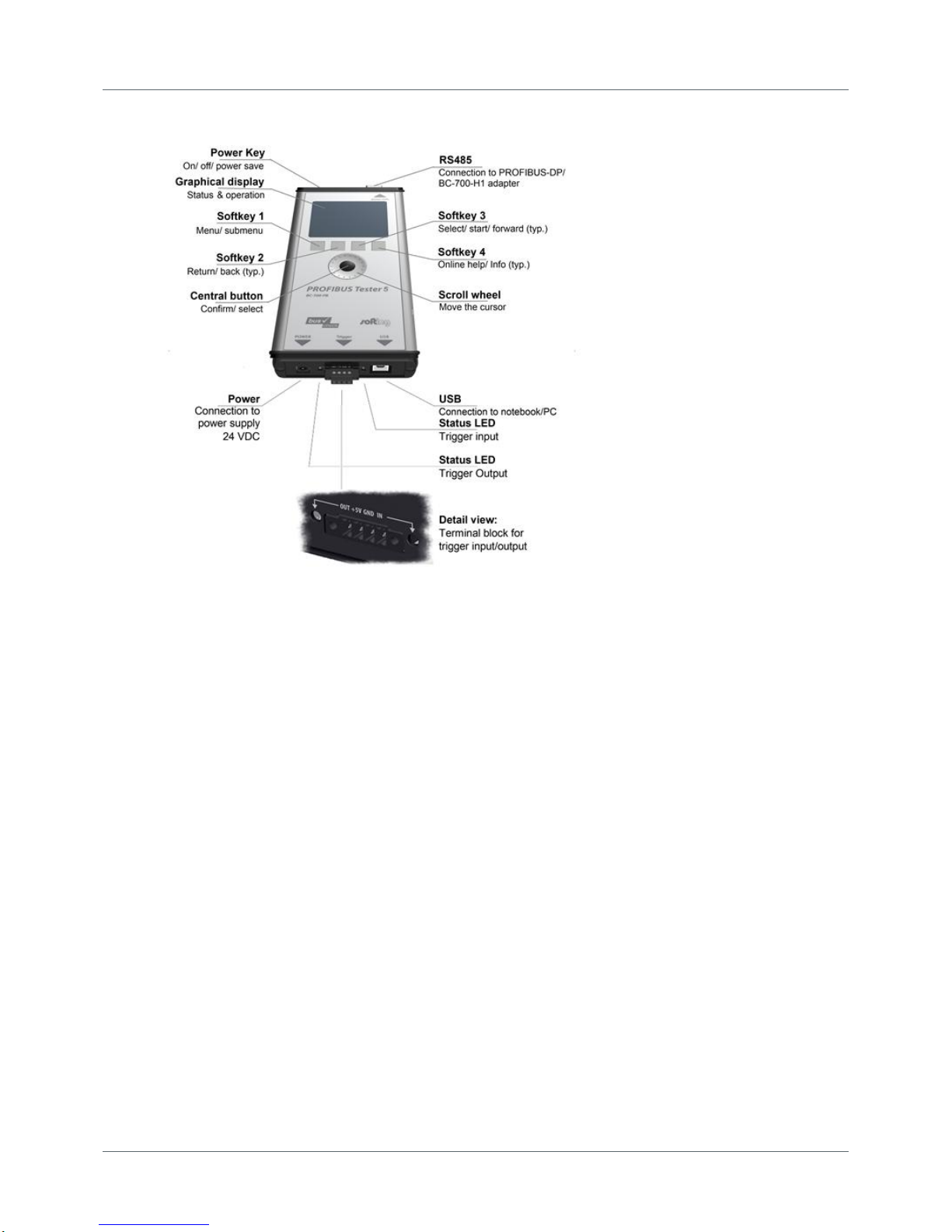

1.6 Connectors and controls

Figure 10: Connectors, buttons and status displays on the BC-700-PB

Page 15

Chapter 2 - Power up and down the device

Copyright 2016 Softing Industrial Automation GmbH

15

2

Power up and down the device

Install PROFIBUS Diagnostics Suite before connecting to a PC

Before connecting the BC-700-PB for the first time with a PC make sure the latest PROFIBUS

Diagnostics Suite and the required drivers are installed on your PC. For detailed installation

instructions refer to the Quick Startup Guide supplied with your PROFIBUS Diagnostics Suite

CD-ROM.

Always connect device directly to an USB port

Use the included USB cable to connect the tool to a PC or notebook. When you use external

USB hubs, notebook docking stations or USB 3.0 ports for connection, problems may occur.

2.1 Power-up

1. Acclimate to room temperature

Before being connected to the AC mains power, the PROFIBUS Tester and the AC adapter must be

acclimated to room temperature to avoid condensation. This may take up to 60 minutes.

2. Power-up

Make sure that you have either connected it to a power supply, or that you have inserted the

battery. Then switch on the tool by pressing the power key at the upper front edge. The display

lights up and self-test starts.

3. Check battery charge level

The display shows the battery charge level indicator ( , , ). If the charge level is too low,

recharge the battery as described in Charge battery .

Hint

We recommend operating the device solely using the wide-range power supply supplied or

using the integrated battery to avoid equalizing currents which can falsify the test results.

The tool is powered by a built-in three cells lithium ion accumulator with 11.1 VDC. Alternatively the

tool can be powered by 24 VDC through the external wide-range power supply.

2.2 Power-on behaviour without USB connection

If not connected to an USB port, the BC-700-PB starts up in stand-alone mode (see Display and controls

in stand-alone mode ) and is immediately ready for testing. During program start-up the splash

screen is shown for a few seconds and displays "USB NOT CONNECTED":

Figure 11: Splash screen – starting without USB connection

31

52

29

Page 16

PROFIBUS Tester 5 (BC-700-PB) - User Manual

16

Copyright 2016 Softing Industrial Automation GmbH

2.3 Power-on behaviour when USB connected

Install drivers before connecting to USB

Install the PC software "PROFIBUS Diagnostics Suite" and the corresponding drivers before

connecting for the first time to a PC or to a notebook. You will find software and drivers on

the PROFIBUS Diagnostics Suite CD-ROM.

The internal battery of BC-700-PB is NOT charged when being connected to a USB port.

On successful completion of the self-test, the BC-700-PB displays:

Figure 12: Power-up display when USB connected

When you start the PROFIBUS Diagnostics Suite control and evaluation software on your computer and

select the PROFIBUS Tester and a network for testing in its user interface, the test tool switches to PC

mode. At this point, a firmware update instead of using the control and evaluation software might be

started automatically. See Firmware update .

The display shows:

Figure 13: Display during test with PC software

Do not connect/disconnect the USB while the device is booting.

2.4 Power-off and sleep mode

Power-down

Press power key for more than three seconds in order to power-down the device. There is no power

consumption if the device is powered down. The device can be stored for long a period of time.

40

Page 17

Chapter 2 - Power up and down the device

Copyright 2016 Softing Industrial Automation GmbH

17

Activate sleep mode

If you want to change manually to sleep mode, shortly actuate the power key. During sleep mode the

BC-700-PB is saving energy and the power key will blink slowly. If a measurement function is currently

active, it is not possible to switch to sleep mode. Depending on the settings in energy management, the

BC-700-PB may automatically change to sleep mode after a predefined period of time.

Return to normal operation mode

You can recover normal operation very quickly by shortly actuating the power key a second time. The

lastly shown menu screen will be displayed which was active before changing to sleep mode.

Automatic power-down

If the BC-700-PB is in sleep mode for more than 2 hours, it will automatically power down.

Page 18

PROFIBUS Tester 5 (BC-700-PB) - User Manual

18

Copyright 2016 Softing Industrial Automation GmbH

3

Connection to PROFIBUS-DP

3.1 Basics

3.1.1 Note when testing a live bus

Test tool side effects

When you connect a test tool, side effects on the system under test are generally

unavoidable. If the PROFIBUS is already disturbed to a certain degree or if Simatic

Diagnostic Repeaters are used, the operation of the PROFIBUS might nevertheless be

affected occasionally. Observe the following connection notes.

3.1.2 Connection types

There are several ways to connect a bus station to a PROFIBUS network:

Using connectors

o D-sub connectors , most of which have an integrated terminating resistor and, optionally, an

additional service socket

o M12 connectors for environments requiring increased IP ratings

o Special vendor-specific hybrid connectors; they are used in combination with special cables to

supply power via the bus

Using terminals for direct connection

Due to the typical daisy-chain topology, the connection points of the bus stations are the only possible

points for connecting the test tool in most cases.

3.1.3 Adapter cable

The BC-700-PB is supplied with the D-sub adapter cable BC600-PB-CB-DSUB-2 Standard (light

connector). For testing on live systems the optional D-sub adapter cable BC-600-PB-CB-DSUB-2 is

recommended. An M12 adapter set is optionally available, see D-sub adapter cable for testing live

systems .

Only use original short cables

Use only the original short cables with special pin layout to connect the unit to a PROFIBUS

network. Do not cascade more than two D-sub connectors with service sockets at the same

time:

Figure 14: Unallowed cascading of D-sub connectors

21

23

10

Page 19

Chapter 3 - Connection to PROFIBUS-DP

Copyright 2016 Softing Industrial Automation GmbH

19

3.1.4 Strain relief

Avoid stress on connectors and bus stations

Avoid stress on connectors and bus stations which might be caused by the device's own

weight.

Possible measures to avoid stress are

support,

strain relief using cable ties or

using a retaining hand strap. Fastening eyes are premounted at the bottom of the tester. You can fix

them either at the bottom or at the top of the tester. The retaining hand strap is not part of the

delivery.

If avoiding stress is not possible, you need to select a different connection point to avoid damage.

3.1.5 Using the security lock port

When using trend logging, the BC-700-PB is typically operated in an unattended manner over a

prolonged period of time. You can connect a Kensington lock to the security lock port to prevent your

device being stolen. The Kensington lock is not part of the product delivery and must be purchased

separately. To use the Kensington lock, refer to the product manual. Tie the Kensington lock cable to a

fixed object and install the other end of the cable to the security lock port.

Figure 15: Using a Kensington lock

3.1.6 Test Locations

Basically you can carry out tests anywhere on a physical PROFIBUS segment using the BC-700-PB. Note

that the use of repeaters creates separate physical segments that each needs to be measured

individually.

For the best and most informative signal quality results, perform the tests at the beginning and end of

each physical segment. If these test results indicate problems that cannot be clearly classified

immediately, you should carry out one or more additional tests at the center.

Page 20

PROFIBUS Tester 5 (BC-700-PB) - User Manual

20

Copyright 2016 Softing Industrial Automation GmbH

3.2 Simple connection for tests during system shutdown

If all bus stations provide D-sub connectors with an additional service socket, you can simply plug in the

BC-700-PB at that socket. If a D-sub connector does not provide a service socket, you can plug in the

Dsub adapter cable underneath. Keep in mind that you do not cascade more than two D-sub

connectors (see Adapter cable ).

When using M12 connection technology, the M12 adapter cable is looped into the bus. It is essential to

ensure proper termination at the beginning and end of the bus by using the terminating resistor

provided with the M12 adapter set.

Shut down complete installation before connecting

All these simple connection types will divide the bus. You therefore need to shut down the

PLC and all the devices connected to the PROFIBUS; in other words, you need to shut down

the whole installation.

Figure 16: Connection points at system shutdown

3.3 Connection for testing a live bus (DP)

To test a live PROFIBUS with the BC-700-PB during operation, appropriate connection possibilities have

to be provided. If no suitable connection points are available in the existing installation, it is

recommended installing them during system shutdown. This will make future maintenance work much

easier.

Shut down complete installation before connecting

Shut down the PLC and all the devices connected to the PROFIBUS as all these simple

connection types will divide the bus.

18

Page 21

Chapter 3 - Connection to PROFIBUS-DP

Copyright 2016 Softing Industrial Automation GmbH

21

Use D-sub adapter cable BC-600-PB-CB-DSUB-1 for testing on live systems

For testing on live systems we highly recommend using the optional D-sub adapter cable

BC-600-PB-CB-DSUB-1 with reduced influence on bus operation. Refer to D-sub adapter

cable for testing live systems .

3.3.1 Connection via D-sub connector with service socket

If all bus stations provide D-sub connectors with an additional service socket, you can simply plug in the

BC-700-PB at that socket.

Figure 17: Connection points for the D-sub adapter cable

10

Page 22

PROFIBUS Tester 5 (BC-700-PB) - User Manual

22

Copyright 2016 Softing Industrial Automation GmbH

3.3.2 Direct cable connection

To test a live PROFIBUS, you will need additional D-sub service interfaces of the type BC-PBMB-PB-S

(see Service interfaces for PROFIBUS DP ).

Figure 18: Service interfacesprovide connection points at direct cable connection

12

Page 23

Chapter 3 - Connection to PROFIBUS-DP

Copyright 2016 Softing Industrial Automation GmbH

23

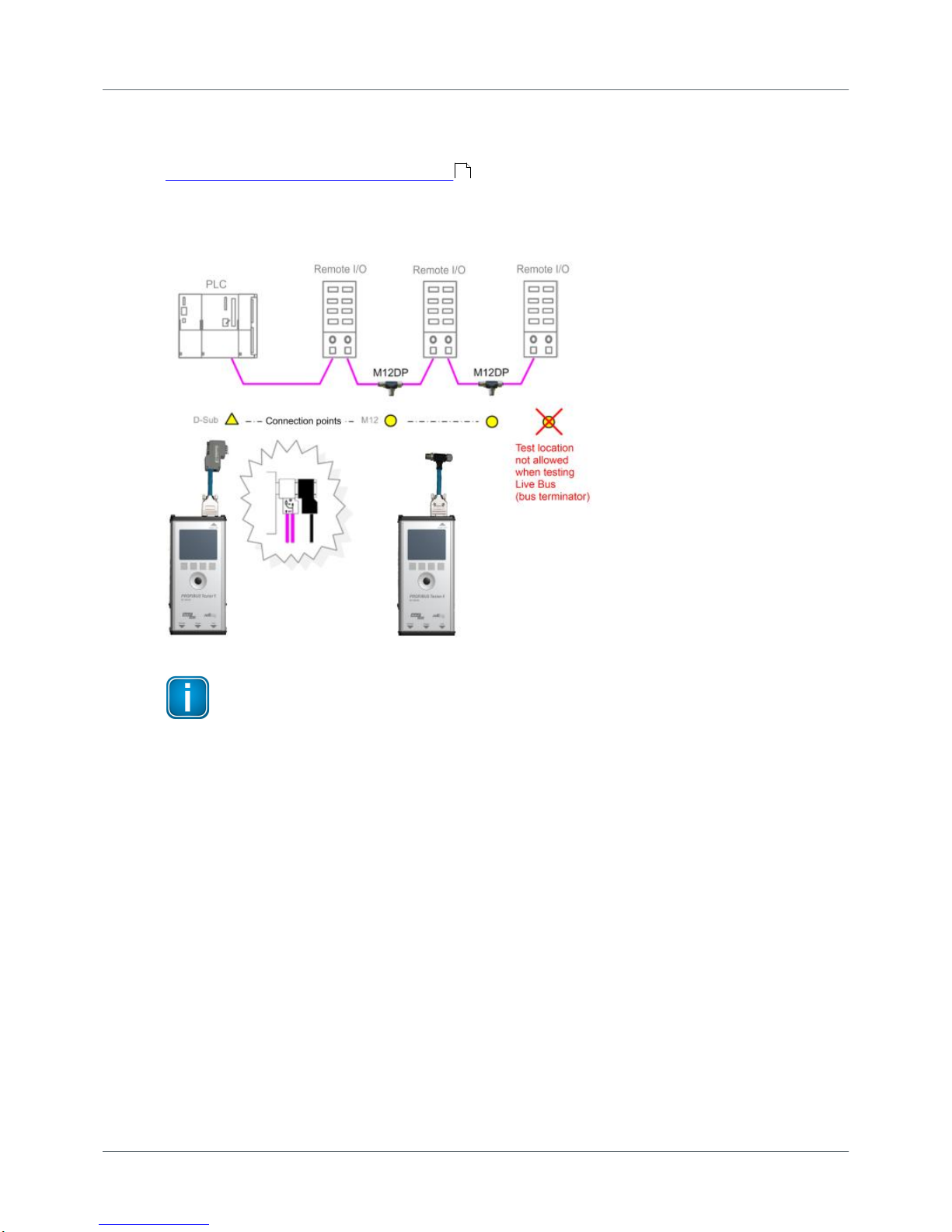

3.3.3 Connection Type M12

To test a live PROFIBUS, you will need additional service interface of the type BC-M12DP-PB (see

Adapter set for M12 connection technology ).

Tests on a live PROFIBUS are only allowed on bus segments providing D-sub connection technology.

Only D-sub connectors with service socket can be used as connection points for the test tool. For this

reason, tests can often only be performed at a bus end.

Figure 19: Connection points for the M12 adapter cable

Connect T-fitting between existing cable and 1 meter connection cable

Always connect one end of the T-fitting to the already existing cable and the other end to

the 1 meter connection cable which is supplied with the service interface.

Do not screw the T-fitting of the M12 service interface directly onto a slave.

3.4 Master simulator, topology scan and cable test

Master simulator

The master simulator allows checking the bus cabling and the station addresses during installation and

commissioning, when the PLC (master) is not in operation yet. In addition, you can use this mode to

check individual suspicious bus stations that have been disconnected from the bus.

Topology scan

The topology scan determines the sequence and distances of all passive bus stations (slaves). This

feature requires correct bus cabling, a very good signal quality, and a connection point located directly

at the beginning or end of the bus.

11

Page 24

PROFIBUS Tester 5 (BC-700-PB) - User Manual

24

Copyright 2016 Softing Industrial Automation GmbH

Cable test

The cable test assesses the wiring and can be used to determine a faulty cable location (e.g. short

circuit) by means of reflection test. All three features can only be used during shutdown of the

installation. The D-sub cable BC-600-PB-CB-DSUB-2 which is included in the standard scope of supply

must be used. As long as communication is detected on the bus, i.e. at least one device is an active

master, the functions are disabled. Check If necessary, disconnect every single active device (PLC, MPI

and, if necessary, diagnostic repeaters) from the power supply or the bus. If an active device is at the

end of the bus you want to test, its PROFIBUS connector needs to be unplugged and connected directly

to the PROFIBUS Tester 5 (BC-700-PB). The bus termination in the device connector will then be

powered by the BC-700-PB.

Figure 20: Connection points for topology scan and cable test

Bus stations must only be disconnected from the power supply or the bus during shutdown

of the installation.

The three functions can be started also when the BC-700-PB is disconnected from the bus. If

you then connect the BC-700-PB to a live bus despite the yellow bus status bar indicated by

the PC software, this can cause bus communication problems or a shutdown of the

installation.

Special case: active devices at both ends o the bus during topology scan

On the very rare occasion when there is an active device at each end of the bus, do the following:

1. When using D-sub connection:

a. Additionally switch on the terminating resistor in the D-sub connector of the last slave.

b. Make sure the outgoing cable to the active device at the bus end is connected to the outgoing

connector (marked with "OUT", an outgoing arrow, or "A2/B2").

Page 25

Chapter 3 - Connection to PROFIBUS-DP

Copyright 2016 Softing Industrial Automation GmbH

25

Figure 21: Checking the connection direction at the D-sub connector - topology scan only

2. When using M12 connection:

a. Connect the cable from the bus start or test tool to the incoming M12 connector of the last

slave.

b. A bus termination is required at the outgoing M12 connector of the last slave.

3.5 Connecting to PROFIBUS PA networks

3.5.1 Requirements for analyzing a live bus

When using the BC-700-PB and the BC-700-H1 adapter to carry out measurements on an MBP segment

during operation, it is preferable to connect the tool via free bus connection terminals of the DP/PA

fieldbus coupler. If the bus begins at the coupler, you can simply use the second terminal block at the

DP/PA coupler or at the SK1 or SK2 to sample the bus signal. If the couplers mentioned above are not

located at the beginning of the bus or if the bus begins with an SG3 coupler or if you are interested in

the PROFIBUS PA signal at another test location, we recommend connecting a short spur cable to rail

mounted terminals during system shutdown. This gives you an appropriate connection point and makes

future maintenance work much easier.

3.5.2 PA adapter BC-700-H1 – before you start

Before using the PA adapter BC-700-H1 with the BC-700-PB for the first time make sure the following

preconditions are fulfilled:

PROFIBUS Diagnostics Suite version 3.11 or higher is installed on your PC.

The PA option on the BC-700-PB is activated (refer to Which license is activated?) .

Firmware version on your BC-700-PB is 01.01.02.00 or higher.

3.5.3 Connecting PA-adapter to test device

Mounting

Mount the D-sub connector (male, 9-pin) of the PROFIBUS PA-adapter BC-700-H1 directly to the D-sub

connector (female, 9-pin) of the PROFIBUS Tester 5. If applicable, you may need to remove a mounted

D-sub adapter cable. Optionally you may fix the PA-adapter to the BC-700-PBby means of the two

screws, which are part of the D-sub connector (male, 9-pin). It is possible to stow the BC-700PBtogether with the mounted PA-adapter in the carrying case after use.

Disassembly

Disassemble the PA adapter as described above but in reverse order.

Please note also the PROFIBUS PA-specific information in section Display and controls in stand-alone

mode .

39

29

Page 26

PROFIBUS Tester 5 (BC-700-PB) - User Manual

26

Copyright 2016 Softing Industrial Automation GmbH

Stop running tests prior to mounting or disassembling the PA-adapter

To prevent loss of test data and in terms of a structured mode of operation you should

solely mount or disassemble the PROFIBUS PA-adapter BC-700-H1 when there is no running

test function.

Two light emitting diodes directly give a check-back indication with respect to the operational state of

the PA-adapter and to the DC voltage (supply voltage), see figure.

Figure 22: Connecting PA-adapter to test device

3.5.4 Bus connection

The supplied test equipment set allows to easily connect the BC-700-H1 adapter to the PROFIBUS PA

segment. Alternatively you can use a short length of PROFIBUS PA standard cable to connect the tool to

the bus.

In general it is sufficient to use PA+ and PA-

Protocol analysis, testing DC voltage level (supply voltage) and AC signal levels (MPB peakpeak voltage) require only a proper connection to signal wires PA+ and PA-. To guard

against and prevent errors in test and parasitic coupling (EMC) it is additionally

recommended using cable shielding or interconnecting the shield connector.

Figure 23: PROFIBUS-PA pin assignment

Do not use in hazardous areas

The BC-700-PB and BC-700-H1 adapter must not be used in hazardous areas and must not

be connected to an intrinsically safe MBP-IS segment (blue terminals of fieldbus coupler; in

some cases blue bus cables).

Page 27

Chapter 3 - Connection to PROFIBUS-DP

Copyright 2016 Softing Industrial Automation GmbH

27

3.5.5 Test Locations

There are several ways to connect bus stations to PROFIBUS PA:

Using terminals for direct connection

Using M12 connectors in the field (unfortunately there is no rule defining on which sides the male

and female connectors are to be used)

Field distributors and T pieces are widely used. As opposed to PROFIBUS DP, spur cables are allowed to

a limited extent for PROFIBUS PA.

The following types of DP/PA fieldbus couplers are the most common:

Simatic DP/PA couplers from Siemens, also as part of DP/PA links

SK1, SK2 and SK3 segment couplers, e.g. from Pepperl+Fuchs (or sometimes under a different label)

Irrespective of the connection types used for the field devices, the fieldbus couplers are usually

installed in a control cabinet, and the PA output is connected there via terminals.

Connection to MBP-IS is not allowed.

You can use the connection points of bus stations or access points inside the field distributors as

connection points. Establishing the electrical connections required for measuring may vary from system

to system and might not be possible during operation.

Figure 24: Connection points for PROFIBUS PA

Hint

An appropriate connection point is located directly at the DP/PA coupler. At this point, the

tool can continue to analyze the bus communication even when lines are interrupted. The

measurements are not affected by repeaters or field barriers.

Page 28

PROFIBUS Tester 5 (BC-700-PB) - User Manual

28

Copyright 2016 Softing Industrial Automation GmbH

3.5.6 Analyzing during shutdown

If there is no possibility for connection, you need to improvise in order to pick up the bus signal at an

existing terminal block of the fieldbus coupler, the field distributor, segment protector or a field device.

For example, you can try a double assignment of bus terminals.

Shut down the system before you divide the bus.

Disconnect all bus stations from the power supply.

Page 29

Chapter 4 - Display and control in stand-alone mode

Copyright 2016 Softing Industrial Automation GmbH

29

4

Display and control in stand-alone mode

The BC-700-PB always starts in stand-alone mode unless it is USB connected to a PC or notebook. The

readings are shown on the graphical display. You can control the tool with the four softkeys, the scroll

wheel and the push button in center of the scroll wheel (see Connectors and controls ).

When you establish a USB connection during stand-alone mode while a test is running, the test will be

aborted and the tool will be reset (restart). The display briefly shows: "Switching to PC mode".

4.1 Start display

The start display appears after start-up in stand-alone mode (or when all dialogs or functions have been

stopped and you have been returned to the main menu). The start display (with main menu) is your

starting point where you can open any of the test functions or additional administrative functions.

Figure 25: Start display

4.2 User interface

The user interface of BC-700-PB comprises four parts:

Device Status

The device status in the upper right corner provides information such as the battery charge level

indicator, system load status, memory information, state of master simulator, connected interfaces

and adapters,…

Application status

The application status at the upper edge on the left displays which function or sub-function is

currently selected.

Workspace

The Workspace in the center of the graphical user interface contains the start page, detail views for

the bus analyzes and views for administrative purposes. At a glance the user views the most

important information with respect to the selected test function.

Control information

Control information is shown at the lower edge of the user interface. The meaning of the four

softkeys is explained in Operating functions .

14

30

Page 30

PROFIBUS Tester 5 (BC-700-PB) - User Manual

30

Copyright 2016 Softing Industrial Automation GmbH

Figure 26: Division of screen areas

The presentation of dialog information uses four layouts:

Additional information which is typically less important is shown on user request in Info-dialogs.

Access to this read-only function or information is subjected to a sub-menu function or to the

[Info]-softkey.

Other functions may require appropriate user input by means of input dialogs. The colors light blue

and blue indicate, which elements are selectable or changeable by means of the input focus

(cursor).

Error messages are displayed in error dialogs.

The BC-700-PB provides a context-sensitive online help. Their content is shown in quick reference

dialogs using a smaller font size.

Figure 27: User interface dialogs

4.3 Operating functions and softkeys

Use the scroll wheel, in order to move the cursor within lists, tables, dialogs and alphabetic strings.

Selected elements are highlighted in blue. Press the central button of the scroll wheel or press the

Selection- or [Info]-softkey in order to call functions or to request additional information. The

appearance of controls will change in a context-sensitive manner. If a softkey is grayed out, the

corresponding operating function is disabled.

Page 31

Chapter 4 - Display and control in stand-alone mode

Copyright 2016 Softing Industrial Automation GmbH

31

Icon

Function

Open menu/ submenu

Browse backwards, quit menu function

Browse tab to the left

Browse tab to the right

Confirm/ select (central button in scroll wheel)

Start a previously stopped function

Stop a running function

Request details for selected elements (press briefly) or

Open context-sensitive reference (press button approx. for 2 seconds)

Open context-sensitive reference

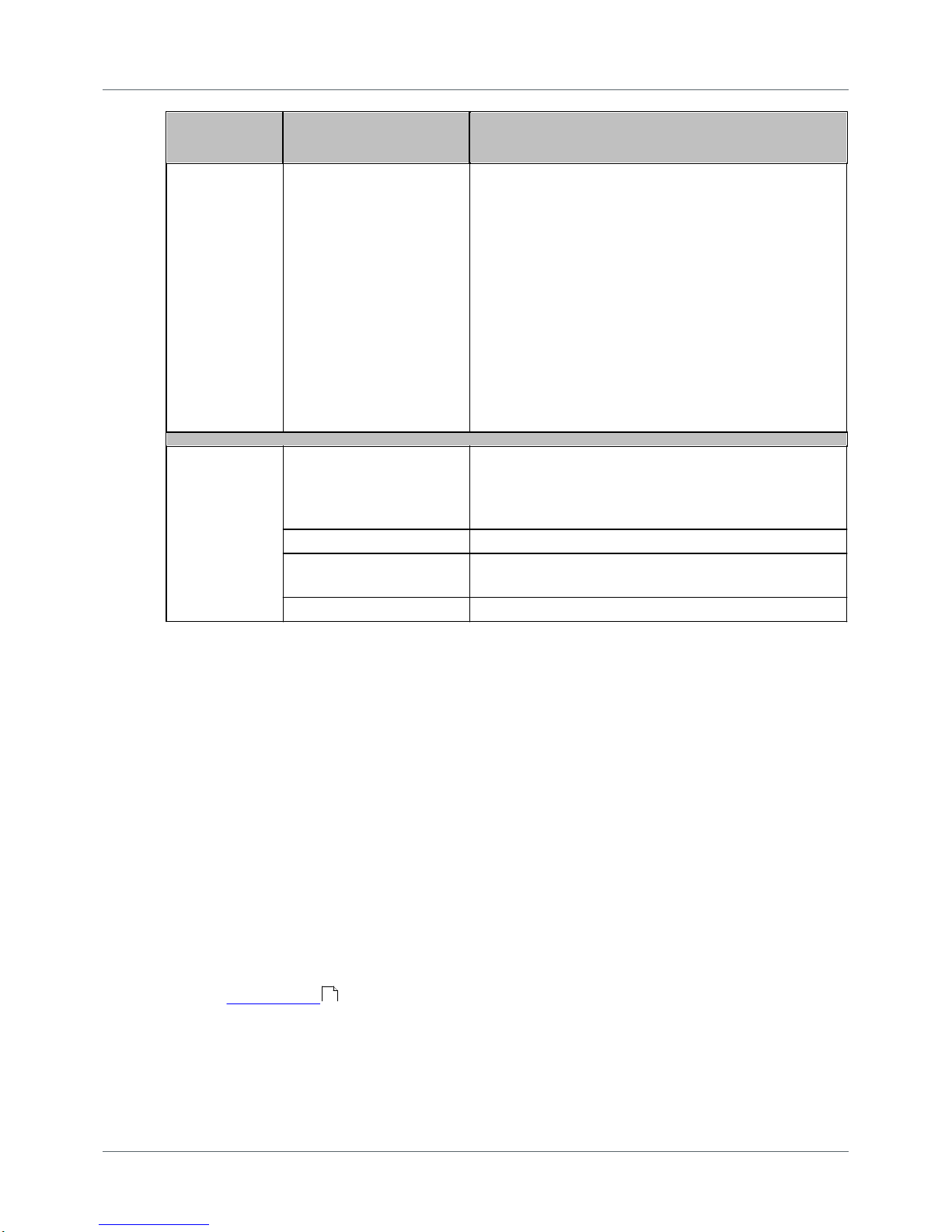

4.4 Device status

The following table contains the meaning of the device status icons. Device status information is

available and visible at any time of device operation in stand-alone mode.

Battery charge level (internal battery with/without AC adapter connected)

Icon

Description

, ,

Internal battery charge level (approx. 100 %, 66 %, 33 %)

Critical battery charge level. BC-700-PB is going to shut down

automatically in a couple of minutes. Connect BC-700-PB to the AC

adapter.

AC adapter connected and battery is charging

Battery completely charged - without AC adapter connected

Battery completely charged - with AC adapter connected

Battery not found or defective. The device runs with external power

supply.

Page 32

PROFIBUS Tester 5 (BC-700-PB) - User Manual

32

Copyright 2016 Softing Industrial Automation GmbH

Testing and measurement status

Icon

Description

PROFIBUS DP:

There is bus activity. If the LED is green, but no baud rate is displayed (e.g. in

Bus Status function), the bus activity results from disturbances and not from

regular frames.

PROFIBUS PA:

There is bus activity (31.25 kbit/s) and the DC voltage level (fieldbus supply

voltage) is clearly keeping the limit values.

PROFIBUS DP:

No bus activity, open circuit voltage within correct range between 0.8 V and

1.4 V. The bus termination is correct, but no frames are transmitted on the

bus. To run a test, you have to either switch on the PROFIBUS master or

activate the master simulator.

PROFIBUS PA:

Either there is no activity on the bus or the DC voltage level is below the

adjustable critical limit. Use the Bus Status function in order get more details

about bus communication and DC voltage level.

PROFIBUS DP:

No bus activity, open circuit voltage below 0.8 V or above 1.4 V. If an open

circuit voltage greater than 0 V is displayed in Bus Status function, the bus has

not been properly terminated. An open circuit voltage of about 0.5 V to 0.6 V

indicates that no power is supplied to one of the two bus terminations.

PROFIBUS PA:

The DC voltage level is either below the fixed error limit of 9 V or above the

maximum allowable fixed error limit of 32 V. Use the Bus Status function in

order get more details about bus communication and DC voltage level.

Master simulator is active. You can start the master simulator from the "Extras

> Master simulator" menu.

The BC-700-PB has detected the mounted PA-adapter BC-700-H1 and the

license "PA Test" has been appropriately activated on the PROFIBUS Tester.

The test system is ready to operate for testing PROFIBUS PA networks.

4.5 Menu functions

The following table gives a brief overview about the menu functions of BC-700-PB in stand-alone mode.

The device help contains a more detailed description of operating functions (use the [ ] softkey in the

corresponding context).

The operating philosophy and the user interface for analyzing PROFIBUS DP- and PROFIBUS PAnetworks are identical and thus, eliminating the need to learn the operating philosophy of an additional

device. The PA-specific information will be explained in [square brackets in italic type].

Page 33

Chapter 4 - Display and control in stand-alone mode

Copyright 2016 Softing Industrial Automation GmbH

33

Main menu

Submenu(s)

(> Submenu function)

Short description

Test functions

Bus status

> Overview

Bus Status function (Overview) assesses bus physics and

bus communication and displays the test result in a

simplified view.

Bus status

> Detail view

Bus Status function (Overview) assesses bus physics and

bus communication and displays the test result in a

simplified view.

Signal quality

[PA: Signal Level]

The signal quality [PA: signal level] test determines the

signal quality index [PA: signal level] for each bus

station and displays the test result in a bar diagram. The

test location is particularly important when you are

testing the signal quality [PA: signal level].

Additional information is available such as

PROFIBUS DP: Signal/ Noise ratio, rise time and

numerical values with respect to signal quality testing.

PROFIBUS PA: Deviation of bitrate, signal polarity and

numerical values with respect to signal level testing.

Signal quality

[PA: Signal Level]

> Select test location

The test location is particularly important when you are

testing the signal quality [PA: signal level]. We

recommend performing at least two signal quality [PA:

signal level] tests per physical segment (at both ends of

the corresponding segment).

Signal quality

[PA: Signal Level]

> Settings evaluation

The signal quality evaluation settings contain limit

values for

PROFIBUS DP: quality index, signal-to-noise ratio, rise

time and timeout.

PROFIBUS PA: DC voltage level and AC signal level

Locate Stations

> Select test location

Detects the topological order of the stations on the bus

line by measuring the distances between masters and

their related slaves. The measurement is purely passive

and does not disturb a running system.

Locate Stations

> Delete location data

Allows to delete data from test locations.

Oscilloscope

Using the Oscilloscope dialog you can analyze the

waveform on the PROFIBUS cable.

Page 34

PROFIBUS Tester 5 (BC-700-PB) - User Manual

34

Copyright 2016 Softing Industrial Automation GmbH

Main menu

Submenu(s)

(> Submenu function)

Short description

Cable test

[PA: not available]

The cable test functionality examines the cabling in

PROFIBUS segments. It detects the cable segment

length, scans for unwanted reflections on the line and

verifies proper termination of the cable. In case of a

fault you will get an error description and a distance

indication (if possible) for troubleshooting actions. You

can only perform a cable test starting at one end of a

PROFIBUS line; during the test no active stations

(Master, MPI panel, ...) must be connected to the

related cable segment.

For further information and starting points in order to

correctly interpret the fault indication see List of fault

indications and remedial measures .

Cable test

[PA: not available]

> Edit Configuration

In the context of cable testing we recommend providing

additional information about the corresponding cable

segment (physical segment); this is important for

proper detection of line length, compliance with

maximum allowed segment length as well as for proper

documentation of test results. Give full particulars with

respect to the configuration of each cable segment.

Cable test

[PA: not available]

> Cable Segment List

The cable segment list shows all segments which belong

to the currently selected network in a tabular overview;

an OK- or error-message is displayed (if available).

Particularly in the context of acceptance control the

commissioner can get a survey over the cabling of the

network.

Recording

Functions

Quick Test

[PA: not available]

The Quick Test allows full testing of bus physics and bus

communication. The test data is stored in the currently

selected net (see submenu "Network Management")

and can be imported by the PROFIBUS Diagnostics Suite

software application.

A progress label is displayed during the quick test. After

completion of the test, a tabular overview is displayed

which informs you about existing and missing quick

tests respectively.

44

Page 35

Chapter 4 - Display and control in stand-alone mode

Copyright 2016 Softing Industrial Automation GmbH

35

Main menu

Submenu(s)

(> Submenu function)

Short description

Trend

[PA: not available]

Trend logging is used for detecting rare or sporadic

faults over a prolonged period of time. The function

monitors both the bus physics and critical events in the

bus communication. The test data is stored in the tool

and can be imported by the PROFIBUS Diagnostics Suite

software application. The tool displays the duration of

the running trend test.

After completion of the test, a tabular overview is

displayed which informs you about existing and missing

quick tests respectively. The Trend Test runs until it is

manually stopped, ends when the power supply is

interrupted or when the maximum logging time of 99

hours and 59 minutes is reached.

Network

Management

You can easily create networks, segments and test locations in

PROFIBUS Diagnostics Suite and then load this data onto your

test tool. For more information refer to the onlinehelp of

PROFIBUS Diagnostics Suite in section "Prepare stand-alone

tests".

Networks

Select network - The test tool stores the test results

that are associated with a real PROFIBUS network in a

separate file folder for that network. Three configurable

directories are available. The radio button shows which

network is currently selected.

Each network contains at least one physical segment

and test location.

Networks

> Edit Network

Segment list - The signals of stations located behind a

repeater are regenerated and transmitted by the

repeater. Therefore, all stations behind the same

repeater will have identical test results. When using

repeaters, you will thus have to test each segment

separately.

One test location belongs exclusively to one segment.

Networks > Segment List

> Edit Segment

Assign test locations to segments: Those test locations

are particularly important which are located within the

currently tested physical segment. We recommend

performing at least two signal quality tests per physical

segment (at both ends of the corresponding segment).

Test Locations

Manage test locations: Particularly when testing signal

quality, the test location has a major influence on the

test result.

To find these faults, it is recommended to measure the

signal quality at different locations on the bus, at least

at both line ends. If a PROFIBUS network comprises

multiple segments connected through repeaters, you

have to measure each segment separately.

Page 36

PROFIBUS Tester 5 (BC-700-PB) - User Manual

36

Copyright 2016 Softing Industrial Automation GmbH

Main menu

Submenu(s)

(> Submenu function)

Short description

Extras

Master simulator

[PA: not available]

Using the master simulator, you can even test the signal

quality while you are still setting up a PROFIBUS

installation and the actual master (controller) is not

operational yet.

The master simulator is disabled by default when you

switch on the tool. You can only select a baud rate on

the display and thus start the master simulator if no

other master is active.

If you use the master simulator in a trend test, quick

test recording or when running the Bus Status function,

the values for the critical events will not be informative

because the master simulator does not execute a

regular DP protocol.

Settings

Energy Management

The energy management settings have a considerable

bearing on battery life of the test device with respect to

one battery charge. We recommend activating the

automatic profile "economy".

Language

Select language

Hardware Information

Hardware information is displayed here (version- and

serial numbers).

License

Displays license information

4.6 Organize and store test results

BC-700-PB comprises three predefined network folders: a default network folder and two empty

folders.

A network folder is a directory containing all the test results assigned to a network. The name of the

network folder is the same as the network name displayed during the data import into the PC.

The default network is provided for spontaneous tests and is a fixed component of the project

management and cannot be deleted. However, you can rename and edit the default network and start

testing using this network. If you are deleting all networks, automatically the default network including

a default segment and a default test location will be generated in the network folder.

A network in BC-700-PB comprises one or more segments, and one or more test locations. A minimum

network configuration (default network) comprises one segment (default segment) and one test

location (default test location).

The test location has a major influence on the test result, particularly when testing signal quality, using

the oscilloscope function or using the cable test function. To store all test results within a network in

the BC-700-PB, you have to set the radio button to the corresponding network in the networks function

(see also User interface ).

29

Page 37

Chapter 4 - Display and control in stand-alone mode

Copyright 2016 Softing Industrial Automation GmbH

37

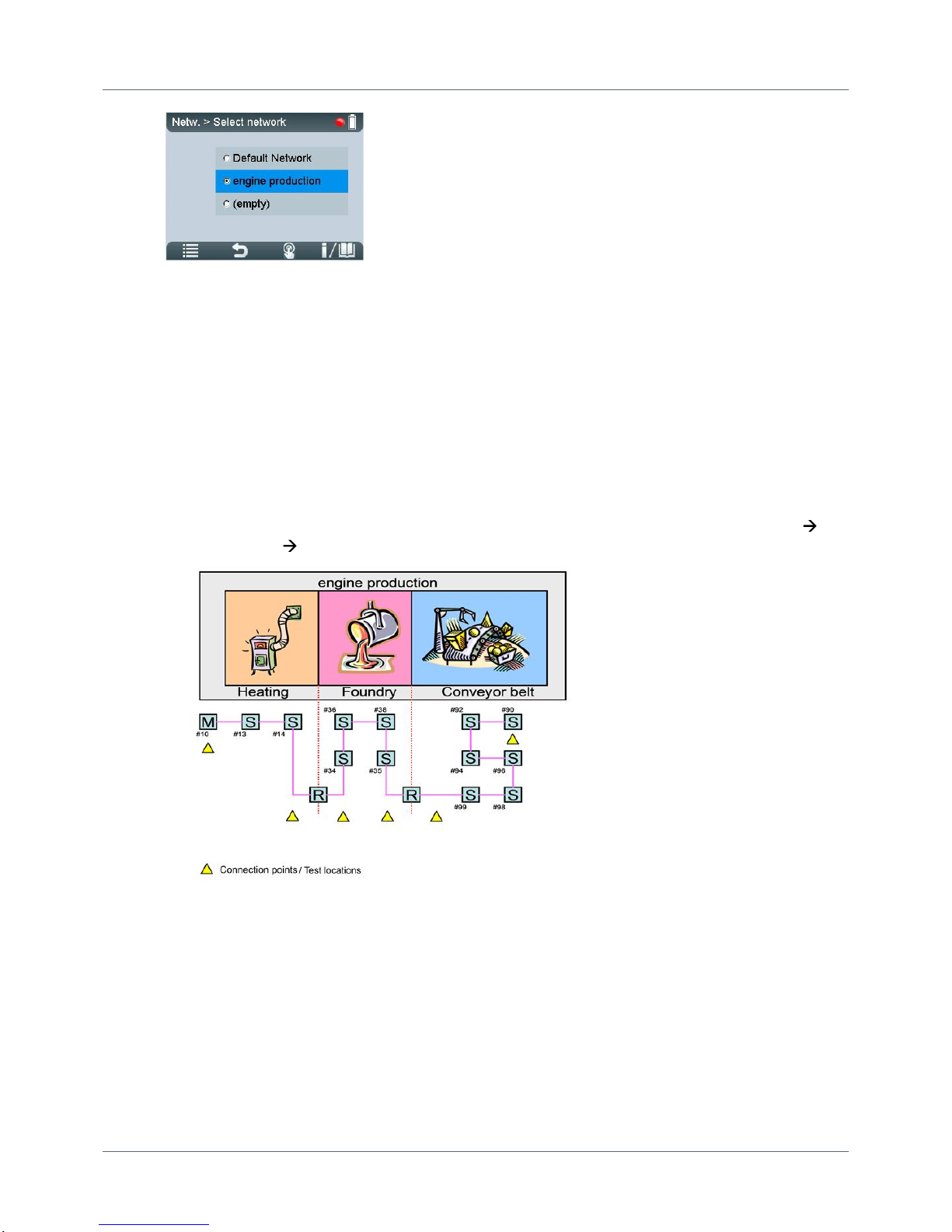

Figure 28: Select Network – the radio button is set to "engine production"

Test results in stand-alone mode are stored under the specified test location in the network you have

defined as the storage location. Thus, test results will be organized and stored in BC-700-PB according

to their test location. Refer to the figure below to see an example network which could be organized as

follows in BC-700-PB (recommendation):

1. Use the Networks/ Select network function and select an empty network folder. Enter the network

name (e.g. "engine production").

2. Use the Edit network function and rename the default segment (e.g. to "heating") and add two new

segments (e.g. "foundry" and "conveyor belt").

3. Use the Test locations function and generate six test locations.

4. Assign test location to segments. To do so, use the Test locations function or select Networks

Edit Networks Edit Segment.

Page 38

PROFIBUS Tester 5 (BC-700-PB) - User Manual

38

Copyright 2016 Softing Industrial Automation GmbH

5

Data import into the PC

You can import quick tests, trend logs and cable test results from the test tool into the PC software.

Proceed as follows:

1. Start the PROFIBUS Diagnostics Suite.

2. Connect the PROFIBUS Tester 5 (BC-700-PB). An additional Import Test Data dialog box appears

automatically showing the test data previously saved:

Figure 29: Importing test data

3. The Import test data dialog box has been filled in advance and contains already the network

designations, segment designations and the test location designations, which have been derived

from the network management of BC-700-PB.

4. For ALL the stored data, you need to fully select the action to be performed, the network/project

and the test location to which you want to store the data. The default action "Import and Delete"

deletes the test data in the tool after the import is completed. This frees the allocated memory

locations for new tests.

The imported Quick Tests and Trend logs are fully compatible with the test data that can be acquired

using the PC software.

Page 39

Chapter 6 - Device management

Copyright 2016 Softing Industrial Automation GmbH

39

6

Device management

6.1 Licenses

Some test functions of the BC-700-PB require activating a license.

Licenses are related to the serial number of your device and can only be used together with

this device. Please include the serial number of your device when ordering a license.

If you already have licensed an option and you want to purchase an additional license

please send your license key to Softing. This key contains both, the serial number and the

license(s) already bought.

You can read the license key that is currently being used by the device from the License

Manager (see How to activate a license ). To do so select Softing Interface, the select tab

Interface Licenses. The connected device together with its serial number and its license key

is displayed. Copy the license key with a right mouse click and then insert it into a

document.

6.1.1 Which license is activated?

Activated licenses are displayed in the BC-700-PB in menu Settings License.

Disabled functions or functions without a license will be grayed out or are not visible in the main menu

in stand-alone mode.

Hint

When USB is connected you can view the license activation status in PC-software PROFIBUS

Diagnose Suite (Help Hardware Info).

6.1.2 How to activate a license

I. Install the PROFIBUS Diagnostics Suite (from your delivery CD-ROM or from the Softing download

area in http://industrial.softing.com/en/downloads.html).

II. Perform a firmware update:

1. Connect the BC-700-PB with the USB cable to the PC and power on the test tool.

2. Start the PROFIBUS Diagnostics Suite. The software verifies whether the firmware needs to be

updated. If your firmware needs to be updated, a firmware update window appears. Click

[Automatic Update], to update the firmware.

3. Close the PROFIBUS Diagnostics Suite after a successful firmware update.

III. Activate your license in BC-700-PB:

39

Page 40

PROFIBUS Tester 5 (BC-700-PB) - User Manual

40

Copyright 2016 Softing Industrial Automation GmbH

1. Connect the BC-700-PB with the USB cable to the PC and power on the test tool.

2. Start the License Manager with Start All Programs Softing License Manager License

Manager V4.

3. <t0/>The Softing Interface button in the left area must be activated<t6/>. If it is deactivated,

click the reload arrow ( ) in the upper right corner.

4. Click the Softing Interface button. Then select tab Interface Licenses. the BC-700-PB and its

serial number are displayed.

5. Enter the license key from the supplied certificate into the field License Key.

6. Click [Enable license]. The license acquired s now displayed in the information area.

7. Close the Softing License Manager.

6.2 Firmware update

Firmware updates are made available as required. They are provided with the updates to the PC

software on our website download area (http://industrial.softing.com/en/downloads.html) They allow

access to new or improved functionality (see also how to activate a license or User Manual

"PROFIBUS Diagnostics Suite - first steps".

39

Page 41

Chapter 7 - Maintenance and Servicing

Copyright 2016 Softing Industrial Automation GmbH

41

7

Maintenance and Servicing

The BC-700-PB is maintenance-free and does not require calibration. We recommend excluding this

device from control of measuring and monitoring of devices. Repairs may only be carried out by the

device manufacturer. All returns must be made without supplied carrying case and accessories (unless

otherwise agreed). Please also include a brief fault description and a phone number at which we can

contact you should we need further details. Please also include a brief fault description and a phone

number at which we can contact you should we need further details. In case of returns within the

warranty period, please also enclose a copy of the invoice or delivery note.

The built-in battery is subjected to normal wear and tear. The battery capacity decreases in the course

of years; this is typical for specified normal operation. Exhaustive discharge and overcharge or

exhaustive operation of the device in conjunction with very high or low temperatures will accelerate

the battery aging process (refer to Notes on battery use) .

51

Page 42

PROFIBUS Tester 5 (BC-700-PB) - User Manual

42

Copyright 2016 Softing Industrial Automation GmbH

8

Troubleshooting

Problem

Possible causes and remedies

The display of the BC700-PB remains blank.

Possible cause:

The BC-700-PB always needs an additional external power

supply or the internal battery is not installed.

Remedy:

Use the supplied external AC adapter to connect the tool to the

mains power supply.

Charge the built-in battery

Alternative cause:

The tool is defective.

The rechargeable battery is defective.

Remedy:

Return the tool to the manufacturer.

Replace the rechargeable battery.

The display shows the

error message "USB

ERROR - Refer to manual

or disconn. for standalone mode".

Possible cause:

This error message can be caused by poor physical connection

via USB (loose contact).

Remedy:

Check the USB cable and connector.

Alternative cause:

The device may be connected via external USB hub, notebook

docking stations or USB 3.0 port which could evoke problems

during driver installation.

Remedy:

We recommend connecting the unit directly to a USB 2.0 port.

The baud rate is not

detected automatically

on a live PROFIBUS.

Possible cause:

Massive disturbances in the bus physics.

Remedy:

Manually set the baud rate and repeat the test.

A main menu function is

grayed out or is not

visible respectively

Possible cause:

Missing license.

Outdated firmware version in use.

Remedy:

Please check your bill of delivery if the license is included in

your order.

Please download the latest firmware version.

It is not possible to

activate the sleep mode

for energy saving

Possible cause:

A test function is currently active.

Remedy:

Page 43

Chapter 8 - Troubleshooting

Copyright 2016 Softing Industrial Automation GmbH

43

Problem

Possible causes and remedies

Stop running test functions before activating the sleep mode.

After some minutes the

display becomes dark

Possible cause:

Backlight was switched off automatically in the context of energy

saving settings.

Remedy:

Press any push button or push the scroll wheel.

Alternative cause:

The tool automatically entered the sleep mode/ powered off in

the context of energy saving settings.

Remedy:

Press the power key in order to power up the device.

The device is running but

does not react to any

user input

Possible cause:

The program has crashed.

Remedy:

Press the power key for at least three seconds to turn off the

device.

Interrupt the power supply. You may need to open head screws

on the back of the device and remove the connecting plug of the

rechargeable battery.

After switching on the

device, the splash screen

persists and shows

"Selftest failed! System

halted"

Possible cause:

Self-testing has identified faulty device components.

Remedy:

Return the tool to the manufacturer.

Optional: Press the key combination [Softkey 1] + [Softkey 4]

during switch-on of the device. Detailed information about selftesting is shown.

You can find support contact data on the cover sheet's back side of this document.

Page 44

PROFIBUS Tester 5 (BC-700-PB) - User Manual

44

Copyright 2016 Softing Industrial Automation GmbH

9

Tips and tricks for cable testing

Perform cable test in stand-alone mode without mains adapter connected

When using the cable test function we recommend removing the mains adapter and

operating on the BC-700-PB by means of the built-in battery in stand-alone operation

mode.

9.1 Assessment criteria

The cable test function examines the cabling in PROFIBUS DP segments and summarizes the test result

in a single statement ("Ok" or "Error"). Amongst technical criteria with respect to the cabling the overall

assessment incorporates additional criteria with respect to the workflow and to plant planning. Under

certain conditions a user may not be able to successfully finish cable testing in a dedicated segment

(e.g. at a very early installation phase of a facility, when there is no possibility to power the bus

terminators). In such a case it is recommended adding a comment to the corresponding test report

which clarifies the circumstances that lead to the negative cable test result. Not all errors will inevitably

lead to downtimes or represent under the specific circumstances a severe error. At last, the

commissioner or maintenance personnel decides, if a PROFIBUS-network is functioning properly or

notl. The corresponding person gets necessary information and recommendations by means of using

appropriate PROFIBUS diagnostic tools. The table below contains assessment criteria which must be

fulfilled in order to successfully complete the cable testing function.

Failed, if at least one of the following criteria is

fulfilled

Passed, if all of the following criteria are fulfilled

Substatial troubleshooting effort was carried out

unsuccessfully and there are still errors on the

cabling

All cabling errors have been successfully

eliminated

The corresponding PROFIBUS DP segment is still

affected by reflections on the cable

The corresponding PROFIBUS DP cable segment is

free of reflections

The user did not run through the tree steps of

cable testing

The user has run through each of the three steps

of cable testing successfully

Detection of the cable segment length fails

The cable segment length has been successfully

detected

Bus termination is not as expected

The terminators at both ends of the cable

segment are switched on and properly powered

The detected cable segment length exceeds the

limit value specified by PI (PROFIBUS PROFINET

International)

The baudrate (entered by user) and the detected

cable segment length fit together according to PI

recommendation (PROFIBUS PROFINET

International)