Page 1

SUNSYS B15-B20

Installations- und bedienungsanleitung

Manuel d’installation et d’utilisation

Installation and operating manual

Manuale di installazione e uso

DE

FR

GB

IT

Page 2

MANUFACTURER'S WARRANTY

Warranty on products in the SUNSYS B

Sicon S.r.l., which is part of the SOCOMEC group with registered headquarters at Via Sila 1/3 – Z. I. Scovizze, 36033 Isola Vicentina

(Vicenza), guarantees that itsSUNSYS B series products are compliant with technical specifications and applicable quality standards.

series

1) Conditions of Warranty

Sicon S.r.l. guaranteesSUNSYS B series products for a period of 5 years following purchase for manufacturing or material defects only.

The warranty commences on the date the new product was purchased by the end user at the showroom of an official dealer

(date as shown on the receipt).

This warranty applies only to products installed in Italy.

The warranty covers:

a) the repair or replacement of the defective product or component free of charge, whereas the cost of installing the replacement

product or component is the responsibility of the customer or end user;

b) the shipment of the defective product to Sicon S.r.l. (or to an authorised centre), with the cost of dismantling and transport

and related expenses borne by the customer or end user.

The decision to repair or replace the defective product or component will be taken at the complete discretion of Sicon S.r.l.

Replacement or repair of parts and any modifications to the product or components during the warranty period shall not extend

the duration of the warranty.

This standard warranty supplements, but does not replace, all other rights of the consumer or purchaser of the product and, in

particular, does not affect statutory consumer rights under Italian Legislative Decree no. 206 of 06/09/2005 (Consumer Code).

Sicon S.r.l. reserves the right to extend this warranty, which must be agreed in writing

2) Procedure

I.

Defects must be reported to Sicon S.r.l., SOCOMEC after sales service (via Sila 1/3 – Zona Industriale Scovizze – 36033 Isola

Vicentina - VI), in writing by registered post or electronic mail (assistenza@socomec.com), or fax (+390444-598626).

In all cases the report submitted to the above Department must be accompanied by a brief description indicating the type

of fault, product serial number, and all details on the ID plate.

A copy of the proof-of-purchase document must be attached to the written report (delivery note, invoice, till receipt, stating

the purchase date and product ID information — model, serial number etc.). If it is not possible to provide proof of purchase,

the serial number and date of manufacture will be used to calculate the probable warranty expiry date.

The defective product can only be returned to Sicon S.r.l. after the acceptance number has been received; this will be issued

by the service centre on receipt of the written report.

II.

The defective product must be returned to Sicon S.r.l. in the original packaging, or equivalent, attaching the return acceptance number.

III. If the goods are acknowledged as being defective and under warranty, Sicon S.r.l. will send the new or repaired product

and/or component to the end user at the address provided in the fault report or, if no address was provided, to the location

where the goods were delivered originally when new, as specified in the sales contract.

IV. Sicon S.r.l will cover the cost of shipping the replacement product and/or component.

V. Installation of the replacement product and/or component must be carried out by a skilled person or authorised service

centre and the relative cost borne by the customer or end user.

VI. Sicon S.r.l. shall be reimbursed for all activities carried out on products and/or components not covered by the warranty, in

accordance with standard company rates and conditions.

VII. Sicon S.r.l. reserves the right to supply a different product and/or component model provided it offers equivalent performance,

if the original defective model under warranty is out of production.

VIII. If on-site assistance from qualified Sicon S.r.l. personnel is requested, labour costs and travel expenses will be borne by the

customer/end user, applying current Sicon S.r.l. rates.

2

2

SUNSYS B15-B20 - Ref.: IOMSUNPRXX03-GB 00

Page 3

MANUFACTURER'S WARRANTY

3) Warranty Exclusions

a) The warranty does not cover product and/or component defects consisting of and/or resulting from:

I. accidental damage.

II. negligent, improper or inadequate use of the product or component (for example, use outside tolerance limits: temperature,

humidity, poor ventilation).

III. failure to comply with instructions for installation, use and maintenance described in the Installation and Operating Manuals.

IV. modifications or repairs attempted by persons not authorised by the Sicon S.r.l. After Sales Service.

V. damage due to atmospheric discharges, floods, fires, earthquakes, uprisings, wars or other instances of force majeure or

resulting from any circumstances other than normal inverter operating conditions and beyond the control of Sicon S.r.l..

VI. damage caused by overvoltages.

VII. damage due to corrosion.

VIII. inadequate transport.

IX. failure of the user to comply with current regulations and standards.

b) Similarly, the warranty will be invalidated:

I. if the defective product and/or component is not returned to Sicon S.r.l. in its original packaging or equivalent.

II.

if the serial number identifying the products has been tampered with or is not clearly identifiable.

III. if the defect concerns aesthetic or construction aspects that do not affect normal product operation.

c) The warranty does not cover claims not included under warranty conditions, and in particular, claims for the refund of damages

due to loss of production, loss of earnings, or attributable to product defects or installation/dismantling costs.

SOCOMEC retains full and exclusive ownership rights over this document. Only a personal right to use the document for the application indicated by SOCOMEC is granted to the recipient of the document. The reproduction, modification or disclosure of this

document, either entirely or partially and by whatever means, is expressly prohibited except with the prior written consent of Socomec.

This document is not a contract. SOCOMEC reserves the right to make any changes to this information without prior notice.

ENGLISH

SUNSYS B15-B20 - Ref.: IOMSUNPRXX03-GB 00

3

Page 4

Page 5

INDEX

1. GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1. SAFETY SYMBOLS AND INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2. UNPACKING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1. REMOVAL OF PACKAGING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2. CONTENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3. IDENTIFICATION DATA PLATE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3. DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.1. DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.2. GENERAL DESCRIPTION OF COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . . 10

4. INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.1. WARNINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.2. CONDITIONS FOR INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.3. WALL FIXING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5. CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.1. DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.2. AC CONNECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.3. DC CONNECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.4. COMMUNICATION MODULE CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . 16

6. COMMISSIONING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.1. PHOTOVOLTAIC MODULE SETUP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.2. AC GRID VOLTAGE REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.3. FIRST START-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

7. CONTROL PANEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

8. MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

8.1. DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

8.2. SETTINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

9. MEASUREMENTS AND MESSAGES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

9.1. MEASUREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

9.2. ERROR MESSAGES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

9.3. WARNING MESSAGES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

9.4. FAULT MESSAGES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

10. MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

10.1. REMOVAL OF FAN MOUNTING PLATE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

10.2. FAN REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

10.3. REMOVAL OF AIR OUTLET VENT GRILLES . . . . . . . . . . . . . . . . . . . . . . . . . . 35

11. REMOVAL OF INVERTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

12. TECHNICAL SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

ENGLISH

SUNSYS B15-B20 - Ref.: IOMSUNPRXX03-GB 00

5

Page 6

1. GENERAL INFORMATION

This user manual specifies installation and maintenance procedures, technical data and safety instructions for SOCOMEC solar

inverters. For further information visit the Socomec website: www.socomec.com.

Any work carried out on the equipment must be performed by skilled, qualified technicians.

1.1. SAFETY SYMBOLS AND INSTRUCTIONS

WARNING!

Failure to observe safety standards could result in fatal accidents or serious injury, and damage equipment or the

environment.

WARNING! RISK OF ELECTRIC SHOCK!

The equipment includes capacitors that store energy. After disconnecting all power sources wait for the capacitors

to discharge.

WARNING! RISK OF BURNS!

During operation the temperature of the casing may exceed 70 °C. Do not touch the surfaces!

Keep this manual safe for future reference.

Before carrying out any operations on the inverter read the Installation and Operating Manual carefully.

The following precautions must be taken in order to avoid risks of overheating, fire. electric shock, mechanical shock, and collateral

damage (persons and/or property):

• Do not cover or obstruct the air outlet vents.

• Do not install the inverter inside a cabinet in an enclosed, non-ventilated area.

• When installing the inverter comply the recommended clearances (see chapter 4.2).

• Only use accessories recommended or sold by the manufacturer.

• Ensure the wiring is in good condition and not undersized.

• Do not operate the inverter with damaged or substandard wiring.

• Do not operate the inverter if it has suffered a violent mechanical shock of any kind (fall, impact, etc.)

• Before cleaning or performing maintenance work on the inverter or connected appliances, disconnect the power sources. After

disconnecting wait for the internal capacitors to discharge completely (15 minutes approx).

• Inverter earth connection. See Chapter 5.

6

6

SUNSYS B15-B20 - Ref.: IOMSUNPRXX03-GB 00

Page 7

2. UNPACKING

2.1. REMOVAL OF PACKAGING

Materials can be disturbed during transport. Check the packaging is not damaged.

After removing the packaging ensure that:

• the data plate details on the left hand side of the inverter correspond to those of the model purchased;

• all accessories are included in the package.

WARNING!

If the inverter is found to be damaged externally or internally, or any of the accessories are damaged or missing,

contact SOCOMEC.

2.1-1

1 2 3

67,2 kg

2.2. CONTENTS

2.2-1

WARNING!

The inverter must be lifted

by two persons.

INSTALLATION AND

OPERATING MANUAL

ENGLISH

SUNSYS B15-B20 - Ref.: IOMSUNPRXX03-GB 00

7

Page 8

2.3. IDENTIFICATION DATA PLATE

2.3-1

2 GENERAL INFORMATION

2.3-2

Model

DC Input Voltage

Current

AC Output Voltage

Current

Power

)0CLASSIlCATION

Over voltage category

Safety class

S/N:

Model

DC Input Voltage

Current

AC Output Voltage

Current

Power

)0CLASSIlCATION

Over voltage category

Safety class

S/N:

: SUN-PR24KTL65RP

: 200-1000Vdc, Max. power: 350-800 Vdc

: max. 30A X 2

: 400 Vac 3PH, 50 Hz

: max. 32 A

: 20 kVA, max. 21 kVA, cosM 0.8 ind - 0.8 cap

: IP 65

: 3

: 1

WD12230012

WE12230012

20 kW model

: SUN-PR18KTL65RP

: 200-1000Vdc, Max. power: 350-800 Vdc

: max. 23A X 2

: 400 Vac 3PH, 50 Hz

: max. 25 A

: 15 kVA, max. 15.75 kVA, cosM 0.8 ind - 0.8 cap

: IP 65

: 3

: 1

WD12230012

WD12230012

15 kW model

Assembled in China

Assembled in China

Model

Technical data

Serial number

8

8

SUNSYS B15-B20 - Ref.: IOMSUNPRXX03-GB 00

Model

DC Input Voltage

Current

AC Output Voltage

Current

Power

)0CLASSIlCATION

Over voltage category

Safety class

S/N:

: SUN-PR24KTL65RP

: 200-1000Vdc, Max. power: 350-800 Vdc

: max. 30A X 2

: 400 Vac 3PH, 50 Hz

: max. 32 A

: 20 kVA, max. 21 kVA, cosM 0.8 ind - 0.8 cap

: IP 65

: 3

: 1

WD12230012

WE12230012

Assembled in China

Page 9

3. DESCRIPTION

3.1. DIMENSIONS

3.1-1

952

1047,5

288,1

208,5

336,2

Front view Side view Rear view

View from above View from below

ENGLISH

SUNSYS B15-B20 - Ref.: IOMSUNPRXX03-GB 00

9

Page 10

3.2. GENERAL DESCRIPTION OF COMPONENTS

3.2-1

3. DESCRIPTION

Output

connection

Communication

port

Input

connection

connection

FansEarth

data and standards

LCD display and

control panel

Air outlet ventLabel showing

10

10

SUNSYS B15-B20 - Ref.: IOMSUNPRXX03-GB 00

Page 11

4. INSTALLATION

4.1. WARNINGS

The inverter is designed for wall-mounting. The wall must be sound and completely smooth.

Install the inverter in an equipment room where only skilled technicians have access. The room must be:

• of a suitable size;

• clean;

• free from inflammable items;

• not exposed directly to sunlight;

• maintained at a temperature between -18 °C and 40 °C.

4.2. CONDITIONS FOR INSTALLATION

4.2-1

ENGLISH

SUNSYS B15-B20 - Ref.: IOMSUNPRXX03-GB 00

11

Page 12

4.2-2

Suitable installation clearances

4. INSTALLATION

4.3. WALL FIXING

4.3-1

Parete

60 cm

60 cm 60 cm

60 cm

60 cm

60 cm

60 cm

192,8

30

97,8

30

129°

3

82 x 6 = 492

127,7

6 viti M6

82

6 viti M6

Unità di misura: mm

14

12

12

SUNSYS B15-B20 - Ref.: IOMSUNPRXX03-GB 00

Page 13

5. CONNECTIONS

WARNING!

Before connecting the power supply connect the earth cable (PE).

Before connecting any cables to the inverter, check that the polarity, voltage and sequence of the phases are correct.

Check that the input and output cables of the photovoltaic system are clearly identified.

5.1. DESCRIPTION

5.1-1

Three-phase AC output,

with connections L1,

L2, L3, and PE

External

communication

interface

External earth

connection (PE)

PV module inputs 1~4

DC1 = 2 strings in parallel

DC2 = 2 strings in parallel

ENGLISH

Inverter cooling

fans

SUNSYS B15-B20 - Ref.: IOMSUNPRXX03-GB 00

13

Page 14

5.1-2

Connection of the system without earth terminal

5. CONNECTIONS

Photovoltaic panels

AC connections

Parallel or Separate

DC connections

1L1

2L2

3L3

4N

PE

External

communication interface

DC distribution panel

DC1 DC2

Note: with a floating DC input (no earth connection) no isolating transformer is required.

The inverter can be configured either with parallel inputs (1 MPPT) or with two separate inputs (2 MPPT).

5.1-3

Connecting the system to positive or negative earth

Photovoltaic panels

Must be

connected in parallel

A transformer must be

installed

Isolating transformer

Load

3 Ph +N

400 Vac

Inverter

3 Ph +N

400 Vac

DC distribution panel

(GND+ or GND-)

o

z

z

Note: with a floating DC input (no earth connection) no isolating transformer is required.

All strings of the photovoltaic field must be connected in parallel (1 MPPT).

14

14

SUNSYS B15-B20 - Ref.: IOMSUNPRXX03-GB 00

Page 15

5. CONNECTIONS

5.2. AC CONNECTION

• Before wiring the AC side ensure the three-phase AC mains supply is disconnected.

• Check that the connection cable used matches the specifications in the table.

Sizing of AC cables

Model Rated current Cross-section Fastening Circuit breaker Residual current protection

SUNSYS-B15

SUNSYS-B20

22 A 6 mm

29 A 6 mm

The AC connection is made with a three-phase plug (L1, L2, L3, N, PE - see drawing).

5.2-1

PE

1 : L1

2 : L2

3 : L3

1 2

4 : N

: PE

L2L1

L3N

2

≥ 0.9 Nm MCCB rated 32 A 3P+N curve C 0.3 A type A or AC

2

≥ 0.9 Nm MCCB rated 40 A 3P+N curve C 0.3 A type A or AC

2

3

1

3

4

36

L2

L1

L3

N

12

35

4 5

ENGLISH

SUNSYS B15-B20 - Ref.: IOMSUNPRXX03-GB 00

15

Page 16

5.3. DC CONNECTION

• Before wiring the DC side ensure the three-phase AC power supply is disconnected.

• Check that the connection cable used matches the specifications in the table.

Sizing of DC cables

Model Rated current Cross-section

SUNSYS-B15

SUNSYS-B20

DC connections are divided into positive and negative poles.

5.3-1

2 x 23 ADC 6 mm

2 x 30 ADC 6 mm

red

2

2

5. CONNECTIONS

black

5.4. COMMUNICATION MODULE CONNECTIONS

5.4-1

Communication module

Dry contact (10 A/250 V)

EPO - Emergency Power Off

RS485

Terminal resistor

RS485

PIN Layout

PIN FUNCTION

4 DATA 5 DATE +

7 GND

5.4.1. EPO

Connector CNS3 performs an emergency power-off function (EPO).

When the external breaker is short-circuited the inverter shuts down immediately.

5.4.2. Dry contact

The voltage-free contact is available on connector CNS2 (Dry Contact) With the inverter connected to the grid, the contact is closed.

16

16

SUNSYS B15-B20 - Ref.: IOMSUNPRXX03-GB 00

Page 17

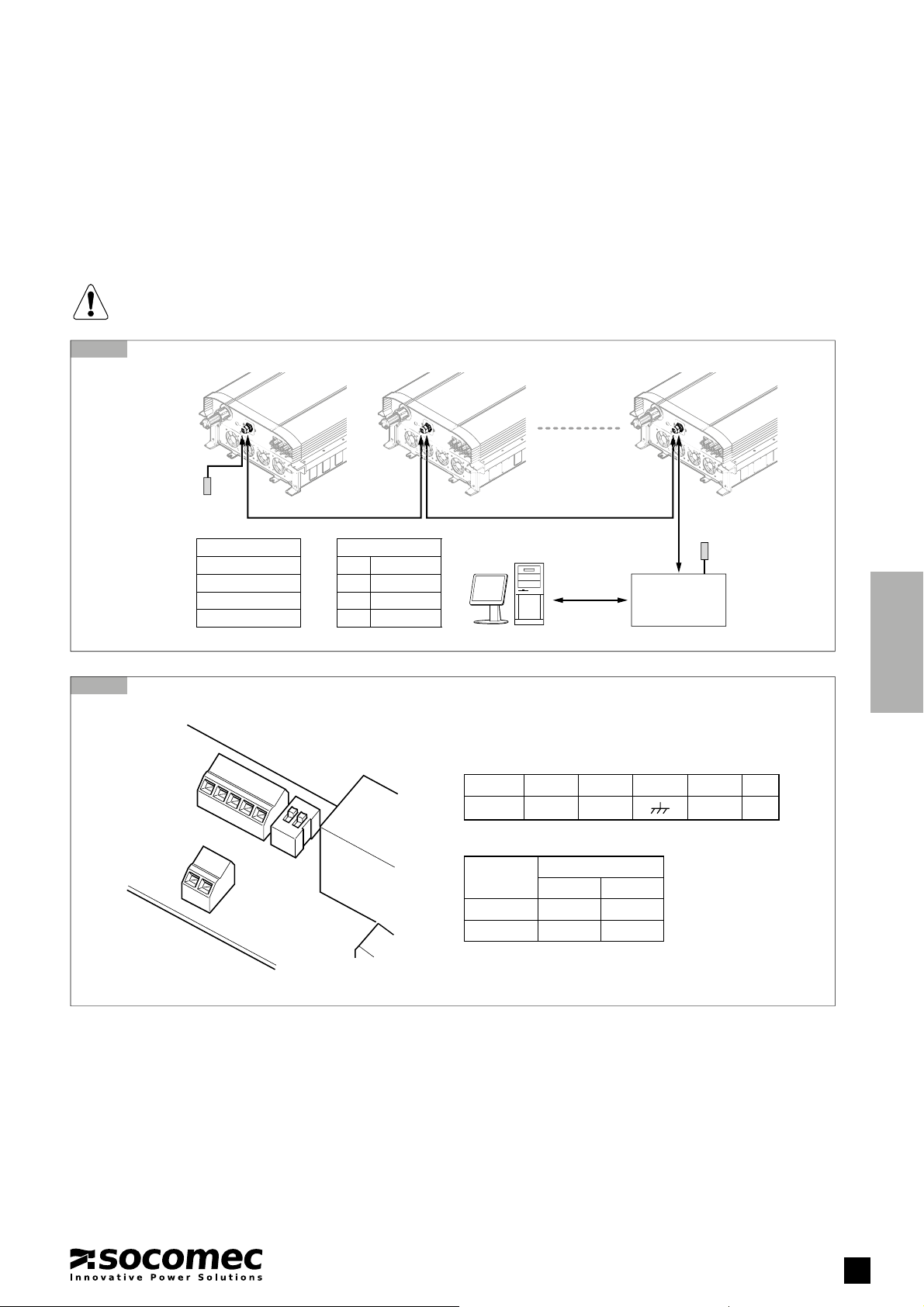

5.4.3. RS-485

The RS-485 function enables connection of the inverter in parallel.

Installation:

• set the dip-switch SWS1 of the first and last machine in the series to the ON position;

• this same dip switch must be set to the OFF position on all other machines.

WARNING!

If the terminal resistor is installed in the converter do not set the inverter.

5. CONNECTIONS

5.4.3-1

5.4.3-2

Terminal

Resistor

120 Ω (1/2 W)

DATA + to DATA –

Data Format

Baud Rate: 9600

Data bits: 8

Stop bit: 1

Parity: N/A

Connection

NO

PIN Layout

PIN FUNCTION

4 DATA 5 DATA +

7 GND

2

1

RS485/USB

or

RS485/RS232

RS485

Pin 1 2 3 4 5

Function DATA - DATA +

Terminal resistor

Resistor Pin

12

ON ON OFF

OFF OFF OFF

GND

Terminal

Resistor

ENGLISH

SUNSYS B15-B20 - Ref.: IOMSUNPRXX03-GB 00

17

Page 18

6. COMMISSIONING

6.1. PHOTOVOLTAIC MODULE SETUP

• The maximum no-load DC voltage of the photovoltaic field must be no higher than 1000 V.

• The maximum connection power going to the inverter must be no greater than 24 kW (SUNSYS B20) or 18 kW (SUNSYS B15).

• The breaker device must have a maximum rated voltage of > 1000 Vdc and maximum short-circuit current > 32A (SUNSYS-B20)

or > 24 A (SUNSYS-B15).

• The voltage range of the MPPTs must be between 350 V and 800 V.

6.2. AC GRID VOLTAGE REQUIREMENTS

Nominal voltage and current. See Chapter 5.

•

An AC1 automatic circuit breaker must be installed and allocated to each of the solar inverters, independently of the system (see heading 5.2).

Grid voltage values

L1-L2 400 Vac L1-N 230 Vac

L1-L3 400 Vac L2-N 230 Vac

L2-L3 400 Vac L3-N 230 Vac

• Type B output residual current device integrated into inverter.

1. or similar protection on the basis of current regulations

18

18

SUNSYS B15-B20 - Ref.: IOMSUNPRXX03-GB 00

Page 19

6. COMMISSIONING

6.3. FIRST START-UP

Check that the AC, DC and communication connections are made and secured correctly.

1. Power up the inverter

2. Set the country (confirm twice).

Note: low voltage (LV) and medium voltage (MV) systems are mutually distinct.

3. Set the language (confirm once)

6.3-1

Country selection menu

6.3-2

Language selection menu

Select Country

Netherlands

Bèlgium

France

Spain

Italy LV

Italy MV

12. Lug 2012 14:37

SET SET

EXIT

Select Language

English

Deutsch

Français

Italiano

Español

Nederlands

&RQðUP&RXQWU\

No Yes

12. Lug 2012 14:37

WARNING!

If the country setting is wrong SOCOMEC must be contacted for assistance.

12. Lug 2012 14:37

Are you sure xxxxxx Country?

SET

ENGLISH

If the level of sunlight is sufficient the inverter will come into operation.

After the first kWh produced the installation date is updated automatically.

During subsequent start-ups the device will show the main page of the menu.

6.3-3

Main menu

Menu

E-Today

Power Meter

Energy Log

Event Log

Operation Data

Inverter Information

Settings

12. July 2012 14:37

Description of menus and settings. See Chapter 8.

Daily energy produced

Electrical measurements

Energy data log

Event log

Operating data

About the inverter

Machine settings

SUNSYS B15-B20 - Ref.: IOMSUNPRXX03-GB 00

19

Page 20

7. CONTROL PANEL

WARNING! RISK OF ACCIDENT OR SERIOUS INJURY!

Do not touch the terminal of the photovoltaic module when exposed to sunlight

7.1-1

LCD display

Back to previous page

Scroll down

Scroll up

Confirm

LED

green/red

LED indicator

Condition Green LED Red LED

Countdown FLASHING OFF

On grid LIT OFF

Error or fault OFF LIT

Standby or night-time (no DC supply) OFF OFF

One DC input only (during countdown)

1

OFF FLASHING

One DC input only (inverter delivering) LIT FLASHING

Fan fault

2

LIT FLASHING

FW update FLASHING FLASHING

1. Solar Low alert (inverter not connected to grid)

2. HW Fan alert

20

20

SUNSYS B15-B20 - Ref.: IOMSUNPRXX03-GB 00

Page 21

8. MENU

WARNING!

The menus and settings described are visible only after the appliance has been started up for the first time. See

Chapter 6.

8.1. DESCRIPTION

8.1-1

Daily energy

8.1-2

Measurements

Energy produced

Daily hours of operation

Inverter status

Power curve

Input DC2

Input DC1

Power

Voltage

Current

E-Today: 47kWh

Runtime: 8.2 Hrs Power: 12103 W

On Grid

20

15

10

5

0

4 8 12 16 20 24

Power Meter

Input 1 Input 2 Output

1002 825 1754 WP

600 620 230 V

V

1.7 1.3 7.6 A

I

Today Energy:

Today Runtime:

Today Earning:

Today CO2 Saved:

12. July 2012 14:37

12. July 2012 14:37

47

8.2

24

87.42

kWh

Hours

€

kg

Instantaneous power output

AC output

ENGLISH

SUNSYS B15-B20 - Ref.: IOMSUNPRXX03-GB 00

21

Page 22

8.1-3

Annual, monthly and daily energy generation log

8. MENU

Energy Log-Year

kWh

4500

3750

3000

2250

1500

750

0

EXIT

1 2 3 4 5 6 7 8 9 10 11 12 Month

E-Year:

17033

2354

kWh

kWh

Peak Month:

Exit 2009 Month

Energy Log-Year

4500

3750

3000

2250

1500

750

0

1 2 3 4 5 6 7 8 9 10 11 12 Month

E-Year:

29200

2490

kWh

kWh

Peak Month:

Esci 2008 2010 Mese

EXIT

2010

Year Earning:

Year CO2 Saved:

2009

Year Earning:

Year CO2 Saved:

12. July 2012 14:37

8516

31681€kg

12. July 2012 14:37

14600

54312€kg

Energy Log-Total

Life Energy:

Life Runtime:

Total Earning:

Total CO2 Saved:

12. July 2012 14:37

29200

kWh

3651

Hours

14600

€

54312

kg

SET

EXIT

Cronologia

Energy Log-Month

kWh

180

SET SET SET

150

120

90

60

30

0

1 5 10 15 20 25 30 Day

E-Month:

144792kWh

Peak Day:

Exit 2010.05 Day

EXIT

kWh

Energy Log-Month

180

150

120

90

60

30

0

EXIT

1 5 10 15 20 25 30 Day

E-Month:

248095kWh

Peak Day:

Exit 2010.04 2010.06 Day Exit 2010.06.19 2010.06.21 Year

EXIT

kWh

12. July 2012 14:37

2010.06

Month Earning:

Month CO2 Saved:

12. July 2012 14:37

2010.05

Month Earning:

Month CO2 Saved:

1240

2690€kg

1240

4612€kg

Energy Log-Day

20

kWh

15

10

E-Day:

Peak Hours:8014

Exit 2010.06.20 Year

EXIT

2010.06.21

5

0

4 8 12 16 20 24 Hour

kWh

kWh

Energy Log-Day

2010.06.20

4 8 12 16 20 24 Hour

kWh

kWh

EXIT

E-Day:

Peak Hour:8014.1

EXIT

20

15

10

5

0

12. July 2012 14:37

Day Earning:

Day CO2 Saved:40149€kg

12. July 2012 14:37

Day Earning:

Day CO2 Saved:40149€kg

SETSETSET

This page displays the last thirty events (error or fault) recorded by the system. The first event displayed is the most recent.

The statistics of the selected event can be displayed by pressing SET.

8.1-4

Event log

Event Log

1. 15/02/2010 17:02

2. 02/12/2009 09:13

3. 23/11/2009 15:28

4. 03/10/2009 06:02

5. 27/05/2009 05:52

6. 18/02/2009 16:46

12. July 2012 14:37

AC Freq High

No Grid

HW Fan

Insulation

Insulation

HW DC Injection

Summary

SET

EXIT

Event Summary

Event

HW DC Injection

Temperature

HW NTC1 Fail

HW NTC2 Fail

HW NTC3 Fail

HW NTC4 Fail

12. July 2012 14:37

Count

1

0

0

0

0

0

22

22

SUNSYS B15-B20 - Ref.: IOMSUNPRXX03-GB 00

Page 23

8.1-5

Operating data (maximum values measured)

8. MENU

Operating Data - 1/4

Input 1

Voltage (Vdc)

Current (A)

Power (W)

Input 2

Voltage (Vdc)

Current (A)

Power (W)

SET

Operating Data - 4/4

Temperature

Inside

Heatsink-1

Heatsink-2

Heatsink-3

(°C)

(°C)

(°C)

(°C)

12. July 2012 14:37

Maximum

811

25.2

11200

785

26.3

10301

12. July 2012 14:37

Max.

Min.

59.3

15.7

75.5

15.3

74.2

15.2

73.6

15.2

SET

SET

To reset the data on this menu press

hold for approximately 10 seconds.

Operating Data - 2/4

Voltage (Vdc)

Current (A)

L1

Power (W)

Voltage (Vdc)

Current (A)

L2

Power (W)

Voltage (Vdc)

Current (A)

L3

Power (W)

Operating Data - 3/4

Output

Voltage

Current

Power

Frequency

(Vdc)

(A)

(W)

(Hz)

SET

simultaneously and

12. July 2012 14:37

Maximum

247

30.5

6810

244

30.3

6756

245

30.1

6745

SET

12. July 2012 14:37

Maximum

247

30.5

20311

5010

8.1-6

Inverter information

Inverter Information

Serial Number

DSP-Version

Red.-Version

Comm.-Version

Installation Date

Inverter ID

Country

ENGLISH

12. July 2012 14:37

WE08450003

1.80

1.17

91.23

19.Apr.2012

001

Italy LV

SUNSYS B15-B20 - Ref.: IOMSUNPRXX03-GB 00

23

Page 24

8.2. SETTINGS

8.2-1

8. MENU

8.2-2

Personal settings

5–60 minutes

automatic shut-down

1-5

Settings

3HUVRQDO6HWWLQJV

&RHIðFLHQWV6HWWLQJV

,QVWDOO6HWWLQJV

$FWLYH5HDFWLYH3RZHU&RQWURO

)57

Personal Settings

Language

Date

Time

Screen Saver

Brightness

Contrast

[ ]

12/07/2012

(DD/MM/YYYY)

13:50

[ ]

[ ]

[ ]

12. July 2012 14:37

12. July 2012 14:37

English

5 min

3

2

8.2-3

Coeffi cient settings

&RHIðFLHQW6HWWLQJV

(DUQLQJ9DOXHZN:K

&26DYHG.JN:K

&XUUHQF\

12. July 2012 14:37

0.50

> @

1.86

> @

€

> @

24

24

SUNSYS B15-B20 - Ref.: IOMSUNPRXX03-GB 00

Page 25

8. MENU

8.2.1. Installation settings

WARNING! DAMAGE CAN BE CAUSED TO THE MACHINE AND SYSTEM!

The following settings are enabled and managed by the grid operator, installer or specialist technician.

Wrong settings are liable to damage the photovoltaic system.

To access the Installation Settings menu enter the password 5555 (the password cannot be changed).

• Inverter ID

Address of each inverter.

• Insulation

This function measures the impedance between grid and earth. In the event of a fault, prevents connection to the grid. The

following insulation measurement methods can be adopted depending on the type of photovoltaic system: positive to earth,

negative to earth, DC1 only, DC2 only, not active.

• RCMU

This function monitors current leakage to earth. If the set limit is exceeded the inverter shuts down.

8.2.1-1

Installation settings - User mode

Password

Insulation

Mode

Resistance

12. July 2012 14:37

12. July 2012 14:37

1200[ ] Kohm

ON[ ]

SET

EXIT

Install Settings

Inverter ID

Insulation

RCMU

Grid Settings

Reconnection Time

Ramp-up Power

12. July 2012 14:37

[ ]

001

[ ]

ON

[ ] S300

20[ ] %/m

• Grid setting

The operating voltage and frequency thresholds of the inverter are displayed.

8.2.1-2

Grid settings

ENGLISH

Grid Settings - 1/4

Vac High Off [ ] 52.00 Hz

Vac High On

Vac High Off T

Vac Low Off

Vac Low On

Vac Low Off T

12. July 2012 14:37

[ ] 276.0 V

[ ] 253.0 V

[ ] 0.5 S

[ ] 184.0 V

[ ] 195.5 V

[ ] 5.0 S

Grid Settings - 2/4

Vac High Off Slow

Vac High On Slow

Vac High Off Slow T

Vac Low Off Slow

Vac Low On Slow

Vac Low Off Slow T

12. July 2012 14:37

[ ] 276.0 V

[ ] 253.0 V

[ ] 1 S

[ ] 184.0 V

[ ] 195.5 V

[ ] 0.5 S

Grid Settings - 3/4

Fac High Off

Fac High On

Fac High Off T

Fac Low Off

Fac Low On

Fac Low Off T

12. July 2012 14:37

[ ] 50.10 Hz

[ ] 1.5 S

[ ] 47.00 Hz

[ ] 49.90 Hz

[ ] 5.0 S

Grid Settings - 4/4

Reconnection Time

12. July 2012 14:37

[ ] 300 S

• Reconnection time

This function varies the waiting time for the inverter to restart (factory setting 300 s).

• Ramp up Power

Percentage of rated power put onto the grid during start-up (factory setting 20%).

SUNSYS B15-B20 - Ref.: IOMSUNPRXX03-GB 00

25

Page 26

8.2.2. Active/Reactive Power

8. MENU

8.2.2-1

Menu

E-Today

Power Meter

Energy Log

Event Log

Operation Data

Inverter information

Settings

Password

12. July 2012 14:37

SET

EXIT

12. July 2012 14:37

SET

EXIT

Settings

Personal Settings

&RHIðFLHQWV6HWWLQJV

Install Settings

Sctive/Reactive Power Control

FRT

Active/Reactive Power

Power Limit

Power vs. Frequency

Constant cosM

cosM(P)

Constant Reactive Power

Q(U)

12. July 2012 14:37

SET

EXIT

12. July 2012 14:37

• Active Power Control

If activated, the Active Power Limitation function will reduce the power output.

This depends on:

- the configured Set Point percentage;

- sunlight conditions.

8.2.2-2

Active/Reactive Power

Power Limit

Power vs. Frequency

Constant cosM

cosM(P)

Constant Reactive Power

Q(U)

12. July 2012 14:37

SET

EXIT

Active Power Control

Set Point

Actual/Rated Power

Mode

12. July 2012 14:37

100[ ] %

Rated[ ]

OFF[ ]

• Frequency-determined Active Power Control

This function limits the active power output level automatically (in the event of frequency transients higher than the set value).

8.2.2-3

Active/Reactive Power

Power Limit

Power vs. Frequency

Constant cosM

cosM(P)

Constant Reactive Power

Q(U)

12. July 2012 14:37

SET

EXIT

Active Power Control

Actual/Rated Power

Start Frequency

Stop Frequency

Recovery Frequency

Statism

Recovery Time

Mode

12. July 2012 14:37

Actual

[ ]

50.30

[ ] Hz

-----

[ ] Hz

-----

[ ] Hz

2.4

[ ] %

300

[ ] s

ON

[ ]

26

26

SUNSYS B15-B20 - Ref.: IOMSUNPRXX03-GB 00

Page 27

8. MENU

• Operation at constant cos

This function selects a fixed cos setting between 0.8 inductive and 0.8 capacitive.

8.2.2-4

Active/Reactive Power

Power Limit

Power vs. Frequency

Constant cosM

cosM(P)

Constant Reactive Power

Q(U)

12. July 2012 14:37

SET

EXIT

Reactive Power Control

cosM

Mode

12. July 2012 14:37

1.00[ ]

[ ]OFF

• Power-regulated Cos monitoring

If activated, this function generates a cosφ variable as a function of power (instantaneous power factor regulated automatically by the inverter).

8.2.2-5

Active/Reactive Power

Power Limit

Power vs. Frequency

Constant cosM

cosM(P)

Constant Reactive Power

Q(U)

12. July 2012 14:37

SET

EXIT

Reactive Power Control

Upper limit - cosM

Lower Power

Lower limit - cosM

Upper Power

Lock-in Voltage

12. July 2012 14:37

[ ]

1.00

[ ] %

45

[ ]

Ind 0.90

[ ] %

90

[ ] V

241.5

ENGLISH

Upper limit

(cosφ =1)

Lower limit

(cosφ =0.9)

inductive

Lower

power

Higher

power

P/Pn

Reactive Power Control

Lock-out Voltage

Mode

12. July 2012 14:37

230.0[ ] V

[ ]OFF

SUNSYS B15-B20 - Ref.: IOMSUNPRXX03-GB 00

27

Page 28

8. MENU

• Operation at constant reactive power

This function selects a reactive power percentage up to 48.43 % of the rated power.

8.2.2-6

Active/Reactive Power

Power Limit

Power vs. Frequency

Constant cosM

cosM(P)

Constant Reactive Power

Q(U)

12. July 2012 14:37

SET

EXIT

Reactive Power Control

Reactive Power (Q/Sn)

Mode

12. July 2012 14:37

0

[ ] %

OFF

[ ]

• Operation at voltage-regulated reactive power (Q)

This function generates reactive power determined by the voltage registered at the output terminals.

8.2.2-7

Active/Reactive Power

Power Limit

Power vs. Frequency

Constant cosM

cosM(P)

Constant Reactive Power

Q(U)

12. July 2012 14:37

SET

EXIT

Controllo potenza reattiva

V1s

V2s

Qs limit

V1i

V2i

Qi limit

12. July 2012 14:37

248.4

[ ] V

253.0

[ ] V

Ind 44

[ ] %

[ ] V

211.6

[ ] V

207.0

[ ] %

Cap 44

Reactive Power Control

Delay Time

Lock-in Power

Lock-out Power

Mode

12. July 2012 14:37

10.00

[ ] s

[ ] %

20

[ ] %

5

OFF

[ ]

28

28

SUNSYS B15-B20 - Ref.: IOMSUNPRXX03-GB 00

Page 29

8. MENU

• FRT (Low Voltage Fault Ride Through)

This function ensures that the inverter will not shut down during dips in grid voltage.

8.2.2-8

Settings

3HUVRQDO6HWWLQJV

&RHIðFLHQWV6HWWLQJV

,QVWDOO6HWWLQJV

$FWLYH5HDFWLYH3RZHU&RQWURO

)57

12. July 2012 14:37

3DVVZRUG

SET SET

EXIT

12. July 2012 14:37

EXIT

)57

'HDGEDQG9K

'HDGEDQG9,

NIDFWRU

9GURS

W

8

W

)57

t3

Mode

12. July 2012 14:37

> @

> @

> @

> @

> @PV

> @

> @V

12. July 2012 14:37

> @V

ON

> @

ENGLISH

SUNSYS B15-B20 - Ref.: IOMSUNPRXX03-GB 00

29

Page 30

9. MEASUREMENTS AND MESSAGES

9.1. MEASUREMENTS

Description of measurement messages

Measurement Description

Energy today Total energy generated during the day

Op time Total PV inverter operating time during the day

Power Actual power generated

Input 1 P Power at DC input 1

Input 1 V Voltage at DC input 1

Input 1 I Current at DC input 1

Input 2 P Power at DC input 2

Input 2 V Voltage at DC input 2

Input 2 I Current at DC input 2

P output Power at AC output 1

V output Voltage at AC output (star voltage)

I output Current at AC output (current of one phase)

Energy today Total energy generated today

Op time today Total operating time today

Earnings today Total amount earned today (US dollars)

CO2 saved today Total reduction in CO2 emissions today

Tot Energy Prod. Total energy generated since the system went into operation

Total op time Total operating time since the system went into operation

Total earnings Total earnings since the system went into operation

Total CO2 saved Total reduction in CO2 emissions since the system went into operation

Energy/year Total energy produced in one year

Earnings/year Total earnings in one year

Monthly peak Peak production per month

CO2/year Total reduction in CO2 emissions over one year

Energy/month Total energy produced in one month

Earnings/month Total earnings in one month

Daily peak Peak production per day

CO2/month Total reduction in CO2 emissions over one month

Energy/day Total energy produced in one day

Earnings today Total earnings in one day

Peak today Peak production per hour

CO2 saved today Total reduction in CO2 emissions on one day

Max voltage input 1 Maximum voltage registering at input 1

Max current input 1 Maximum current registering at input 1

Max power input 1 Maximum power registering at input 1

Max voltage input 2 Maximum voltage registering at input 2

Max current input 2 Maximum current registering at input 2

Max power input 2 Maximum power registering at input 2

Max voltage L1 Maximum output voltage on L1

Max current L1 Maximum output current on L1

Max power L1 Maximum output power on L1

Max voltage L2 Maximum output voltage on L2

Max current L2 Maximum output current on L2

30

30

SUNSYS B15-B20 - Ref.: IOMSUNPRXX03-GB 00

Page 31

9. MEASUREMENTS AND MESSAGES

Max power L2 Maximum output power on L2

Max voltage L3 Maximum output voltage on L3

Max current L3 Maximum output current on L3

Max power L3 Maximum output power on L3

Max output voltage Maximum output voltage

Max output current Maximum output current

Max output power Maximum output power

Temperature

Max internal Maximum internal temperature of the inverter

Min internal Minimum internal temperature of the inverter

Max heatsink 1 Maximum temperature at heatsink 1

Min heatsink 1 Minimum temperature at heatsink 1

Max heatsink 2 Maximum temperature at heatsink 2

Min heatsink 2 Minimum temperature at heatsink 2

Max heatsink 3 Maximum temperature at heatsink 3

Min heatsink 3 Minimum temperature at heatsink 3

9.2. ERROR MESSAGES

Description of error messages

Message Description Solutions

AC Freq High

AC Freq Low

Grid Quality

HW Connected Fail

No Grid

AC Volt Low

AC Volt High

Solar1 High

Solar2 High

1) Grid frequency higher than nominal

2) Country configuration incorrect

3) Measuring circuit failure

1) Grid frequency lower than nominal

2) Country configuration incorrect

3) Measuring circuit failure

1) Excessive distortion caused by loads

connected to grid or near inverter

2) Measuring circuit failure

1) AC plug wrongly connected

2) Measuring circuit failure

1) No AC power

2) AC switch contacts open

3) Plug not connected

4) Internal fuses blown

1) AC voltage lower than nominal

Country configuration or grid setting incorrect

2)

3) AC plug wrongly connected

4) Internal fuses blown

1) AC voltage higher than nominal

2)

Country configuration or grid setting incorrect

3) AC plug wrongly connected

4) Internal fuses blown

1) Input voltage 1 higher than 1000 V

2) Measuring circuit failure

1) Input voltage 2 higher than 1000 V

2) Measuring circuit failure

1) Check the grid frequency value

2) Check the country setting

3) Contact the technician

1) Check the grid frequency value

2) Check the country setting

3) Contact the product technician

1) Check for the existence of non-linear loads

connected to the grid

2) Contact the technician

1) Check the wiring as described in the manual

2) Contact the technician

1) Check the grid voltage value

2) Close the AC breaker contacts

3) Check the connection and wiring

4) Contact the product technician

1) Check the grid voltage value

2) Check the country/voltage limits setting

3) Check wiring in the manual

4) Contact the technician

1) Check the grid voltage value

2) Check the country/voltage limits setting

3) Check wiring in the manual

4) Contact the technician

1) Reduce the no. of panels to obtain an open

circuit voltage VOC < 1000 V

2) Contact the technician

1) Reduce the no. of panels to obtain an open

circuit voltage VOC < 1000 V

2) Contact the technician

ENGLISH

SUNSYS B15-B20 - Ref.: IOMSUNPRXX03-GB 00

31

Page 32

9. MEASUREMENTS AND MESSAGES

9.3. WARNING MESSAGES

Description of error messages

Message Description Solutions

Solar1 Low

Solar2 Low

HW FAN

1) Input voltage 1 below limits

2) Measuring circuit failure

1) Input voltage 2 below limits

2) Measuring circuit failure

1) One or more fans jammed

2) One or more fans faulty

3) One or more fans disconnected

4) Measuring circuit failure

1) Check the DC voltage value

2) Contact the product technician

1) Check the DC voltage value

2) Contact the technician

1) Remove the object obstructing the fan

2) Remove the faulty fan

3) Check the fan connections

4) Contact the chnician

9.4. FAULT MESSAGES

Description of error messages

Message Description Solutions

1) Check for the existence of non-linear loads

connected to the grid

2) Contact the technician

1)

Check the installation environment and ventilation

2) Contact the technician

1) Check the installation environment

2) Contact the technician

1) Check the installation environment

2) Contact the technician

1) Check the installation environment

2) Contact the technician

1) Check the installation environment

2) Contact the technician

1) Check that DC voltage > 150 V

2) Contact the technician

1) Check that DC voltage > 150 V

2) Contact the technician

1) Check that DC voltage > 150 V

2) Contact the technician

1) Input power too low

2) Contact the technician

1) Input power too low

2) Contact the technician

Check the current measurements between inverter

1)

and system

2) Contact the technician

1) Switch off the inverter and switch on again

2) Contact the technician

1) Switch off the inverter and switch on again

2) Contact the technician

HW DC Injection

Temperature

HW NTC1

Fail

HW NTC2

Fail

HW NTC3

Fail

HW NTC4

Fail

HW DSP

ADC1

HW DSP

ADC2

HW DSP

ADC3

HW RED

ADC1

HW RED

ADC2

HW Efficiency

HW COMM2

HW COMM1

1) Abnormal grid voltage

2) Measuring circuit failure

1) Ambient temperature > 60 °C or < -30 °C

2) Measuring circuit failure

1) Ambient temperature > 90 °C or < -30 °C

2) Measuring circuit failure NTC1

1) Ambient temperature > 90 °C or < -30 °C

2) Measuring circuit failure NTC2

1) Ambient temperature > 90 °C or < -30 °C

2) Measuring circuit failure NTC3

1) Ambient temperature > 90 °C or < -30 °C

2) Measuring circuit failure NTC4

1) Insufficient input power

2) Measuring circuit failure

1) Insufficient input power

2) Measuring circuit failure

1) Insufficient input power

2) Measuring circuit failure

1) Insufficient input power - Input 1

2) Measuring circuit failure

1) Insufficient input power - Input 2

2) Measuring circuit failure

1) Calibration incorrect

2) Measuring circuit failure

1) Problems with internal communication between

RED and CPU

1)

Problems with internal communication between DSP

and COMM

32

32

SUNSYS B15-B20 - Ref.: IOMSUNPRXX03-GB 00

Page 33

9. MEASUREMENTS AND MESSAGES

GROUND

CURRENT

INSULATION

HW Connect Fail

RCMU Fail 1) Internal control circuits not working 1) Contact the technician

Relay Test Short

Relay Test Open

Bus Unbalance

HW Bus OVR

AC Current High

HW CT A Fail 1) Internal control circuits not working 1) Contact the technician

HW CT B Fail 1) Internal control circuits not working 1) Contact the technician

HW CT C Fail 1) Internal control circuits not working 1) Contact the technician

HW AC OCR

HW ZC Fail 1) Internal control circuits not working 1) Contact the technician

DC Current High 1) Internal control circuits not working 1) Contact the technician

1) Problems with PV field insulation

2) High stray capacitance of PV field

3) High level of current leakage to earth

1) Problems with PV field insulation

2) High stray capacitance of PV field

1) No internal power supply to the machine

2) Internal control circuits not working

1) Output relays with contacts closed

2) Internal control circuits not working

1) Output relays faulty

2) Internal control circuits not working

3) Grid voltage measurements abnormal

1) Problems with wiring of strings

2) String short-circuiting to earth

3) Internal control circuits not working

1) Problems with wiring of strings

2) String short-circuiting to earth

3) Internal control circuits not working

1) AC grid overvoltage

2) Internal control circuits not working

1) High levels of power system harmonics

2) Internal control circuits not working

1) Check PV field insulation

2) Check that the stray capacitance of each input

to earth is < 2.5 μF.

3) Check system wiring

1) Check PV field insulation

2) Check that the stray capacitance of each input

to earth is < 2.5 μF.

1) Contact the technician

1) Contact the technician

2) Contact the technician

1) Contact the technician

2) Contact the technician

3)

Compare machine and grid measurement values

Check the parallel string setup connected to the

1)

inverter

2) Check the system

3) Contact the technician

Check the parallel string setup connected to the

1)

inverter

2) Check the system

3) Contact the technician

1) Switch off/switch on again

2) Contact the technician

1) Check for the existence of non-linear loads

connected to the grid

2) Contact the technician

ENGLISH

SUNSYS B15-B20 - Ref.: IOMSUNPRXX03-GB 00

33

Page 34

10. MAINTENANCE

WARNING!

Follow the instructions in section 1.2.

The solar inverter should be inspected at six-monthly intervals to ensure continued trouble-free operation.

To ensure the appliance is properly ventilated check the fans are operating correctly and the protective air vent grilles are clean.

10.1. REMOVAL OF FAN MOUNTING PLATE

10.1-1

1

4 5

1

2

2 3

3

4

34

SUNSYS B15-B20 - Ref.: IOMSUNPRXX03-GB 00

Page 35

10.2. FAN REPLACEMENT

10.2-1

10. MAINTENANCE

1

4

2 3

NEW

10.3. REMOVAL OF AIR OUTLET VENT GRILLES

10.3-1

ENGLISH

SUNSYS B15-B20 - Ref.: IOMSUNPRXX03-GB 00

35

Page 36

11. REMOVAL OF INVERTER

If it is necessary to remove the inverter proceed as follows:

1. Open the AC breaker contacts to disconnect the electricity.

2. Isolate the power feed from the photovoltaic field

3. Use a suitable meter to verify the absence of AC and DC voltages.

4. Remove the AC connections immediately

5. Remove the DC connections to isolate the PV field.

6. Remove the RS485 communication module with the computer connection.

Once these steps have been completed remove the inverter.

36

36

SUNSYS B15-B20 - Ref.: IOMSUNPRXX03-GB 00

Page 37

12. TECHNICAL SPECIFICATIONS

Model

Enclosure Powder coated aluminum

Operating temperature -20–60 °C

At maximum power: up to 40 °C 0-90% non-condensing

Relative humidity 0-90% non-condensing

Protection level IP65 (electronic components)

IP54 (other parts)

Galvanic insulation NO

Safety class Class I metal casing

with protective earth connection 965 × 610 × 287.5 mm

Overvoltage category III

Weight 67.2 kg

Dimensions 960 × 612 × 278 mm

Connectors Weather resistant connectors

DC input (solar side)

Maximum input power 24 kWp 18 kWp

Rated voltage 630 VDC

Operating voltage 200–1000 VDC

Start-up voltage > 250 V

Start-up power > 40 W

Absolute maximum voltage 1000 VDC

MPP voltage range

at rated power

Number of inputs 4 (2MPPT)

MPPT

Separate inputs: 2MPPT < 30 A < 23 A

Rated current 2 x 30 A 2 x 23 A

AC output (grid side)

Rated power at 400 V ±10% 20 kVA 15 kVA

Rated power at Cosφ=0.9

Maximum power 21 kVA 15.75 kVA

Voltage 230–400 ±20%

Rated current 29 A 22 A

Max current 32 A 25 A

Frequency 47-52 Hz

Total Harmonic Distortion < 3% at rated power

Power factor

DC current injection Disconnect: 0.5% In in 1 s, 1 A in 200 ms

Night time power < 2 W

Maximum efficiency > 98.05%

European efficiency > 97.5%

AC connector 3 Phases + Neutral + PE

Recommended protection Thermal-magnetic with I = 1.25 x Inom Thermal-magnetic with I = 1.25 x Inom

SUNSYS B20 SUNSYS B15

350–800 Vdc

Parallel inputs: 1MPPT

Separate inputs: 2MPPT

18 kW 13.5 kW

> 0.99 at rated power

Cosφ = 0.8 inductive and capacitive

ENGLISH

SUNSYS B15-B20 - Ref.: IOMSUNPRXX03-GB 00

37

Page 38

12. TECHNICAL SPECIFICATIONS

System information / communication

LCD graphic display, 5” (320 x 240 pixels)

User interface

External communication 2 x RS-485 connection

Standards and Directives

CE compliance Yes

Emissions IEC61000-6-4, IEC61000-6-3

Harmonics EN 61000-3-12

Fluctuations and flicker EN 61000-3-11

Grid interface VDE0126-1-1; RD1663

ESD IEC 61000-4-2

RS IEC 61000-4-3

Immunity

Electrical safety EN 60950, Draft IEC62109 -1& -2

EFT IEC 61000-4-4

SURGE IEC 61000-4-5

CS IEC 61000-4-6

PFMF IEC 61000-4-8

Data logger with 10 year capacity

and real time clock

30 events

38

38

SUNSYS B15-B20 - Ref.: IOMSUNPRXX03-GB 00

Page 39

Page 40

SOCOMEC GROUP

S.A. SOCOMEC capital 11 302 300 € - R.C.S. Strasbourg B 548 500 149

B.P. 60010 - 1, rue de Westhouse - F-67235 Benfeld Cedex

SOCOMEC Strasbourg

11, route de Strasbourg - B.P. 10050 - F-67235 Huttenheim Cedex- FRANCE

Tel. +33 (0)3 88 57 45 45 - Fax +33 (0)3 88 74 07 90

SOCOMEC Isola Vicentina

Via Sila, 1/3 - I - 36033 Isola Vicentina (VI) - ITALY

Tel. +39 0444 598611 - Fax +39 0444 598622

it.pvconsult@socomec.com

www.socomec.com

*IOMSUNPRXX03-GB 00*

IOMSUNPRXX03-GB 00 11.2012

Loading...

Loading...