Page 1

CONTROLLER

ATyS C40

Notice d’utilisation - Operating instructions

F

GB

SOCOMEC GROUP SWITCHING PROTECTION & UPS

MAKE YOUR BUSINESS SAFE

Page 2

SOCOMEC - Réf.: 532 929 B

2

THE A

TyS RANGE _______________________________35

GENERAL PRESENTATION _______________________36

Product introduction ____________________________36

INSTALLATION __________________________________37

Mounting _____________________________________37

Dimensions ___________________________________37

Characteristics_________________________________37

CONNECTIONS _________________________________38

Control circuits_________________________________38

OPERATION ____________________________________42

Presentation___________________________________42

Operational modes _____________________________43

Programming __________________________________44

Operation _____________________________________56

Visualisation ___________________________________60

Automatic sequences ___________________________62

TROUBLESHOOTING GUIDE _____________________64

Summary

GB

Page 3

35

SOCOMEC - Réf. : 532 929 B

The ATyS family proposes a complete motorised

changeover range including electrical and mechanical

interlocking. Manual operation is always possible on all

the products in case of emergency.

The electric command is realised via a motorised

module, electronically driven by 2 types of logic:

• Remote controlled: ATyS 3 products are controlled by

volt free contacts allowing the switch to be driven in 1,

0 or 2 position. These contacts can come from an

external control logic.

• Automatic control: AtyS 6 products integrate all

controls, timers and relays required to realise a

Normal/ Emergency application.

ATyS 6e and 6m versions also integrate the remote

controlled feature.

The motorised and control modules can easily be

replaced without disconnecting the power cables.

Controller

ATyS

THE

ATyS

RANGE

>

This instruction manual applies to following

product:

• Controller ATyS C40

>

Following products are delivered with their own

instruction manual:

• ATyS 3s

• ATyS 3e, 6e

• ATyS 6m

• Remote interfaces ATyS D10 & D20

• ATyS C20/ C30 controller

For personnel and product safety, please

read the contents of these operating

instructions carefully before connecting.

ATyS 3s ATyS 3e ATyS 6e ATyS 6m ATyS C30 ATyS C20 ATyS C40

MOTORISED CHANGEOVER

Dual power supply

Metering

Changeover controller Dual gensetIntegrated control relay

Communication optionCom option

2 I/2 O option

2 inputs / 2 outputs option

Remote interfaces ATyS D10 & D20

Page 4

Product introduction

Controller

ATyS

GENERAL PRESENTATION

ATyS C40

36

SOCOMEC - Réf. : 532 929 B

>

ATyS C40

LCD

Voltage sensing and

power supply terminals

Keypad

Control terminals Modular frame

ATYS 466 B

Page 5

Mounting

>

Mounting rail DIN

Dimensions

Characteristics

37

SOCOMEC - Réf. : 532 929 B

Controller

ATyS

INSTALLATION

ATyS C40

>

IP

IP2 and class II on front face

>

Operation

• Temperature: -20 °C to +60 °C

• Humidity: 80 % at 55 °C

95% at 40 °C

>

Consumption

7.5 VA max

>

Measurement category

Cat III

ATYS 528 B

106

26,5

48

58

90

93

45

62

ATYS 529 A

Page 6

Control circuits

400 Vac (P-P) APPLICATION WITH NEUTRAL CONDUCTOR

SWITCHING TYPE TECHNOLOGY

Controller

ATyS

CONNECTIONS

ATyS C40

38

SOCOMEC - Réf. : 532 929 B

13 14 23 24 33 34 43 44 53 54

CA1

+-

CA2

I1I3 I2

301 302 303 304305 306

DC-

DC+

103

F1, F2

Fuse protection

230 Vac 5 A

205

L3

203

L1

106

L1

105104

L3

III

0C

O1

L1

L2

L3

GE1

N

L1

L2

L3

N

F2F1

LOAD

Ph

Double power

Supply option

Power

230 Vac

Control

N

N

DPS

GE2

ATYS 467 B GB

• Configure the type of control logic in impulse mode

(see Programming chapter).

Maximum control cables lenght = 10 m.

In case of longer distance, insert control

relays.

Page 7

Controller ATyS

CONNECTIONS

39

SOCOMEC - Réf. : 532 929 B

Control circuits

400 Vac (P-P) APPLICATION WITH NEUTRAL CONDUCTOR

CONTACTOR TYPE TECHNOLOGY

I1I3 I2

F1, F2

Fuse protection

230 Vac 5 A

LOAD

III

O1

L1

L2

L3

N

L1

L2

L3

N

F2F1

K1

K1

K2

K1

K2

K2

13 14 23 24 33 34 43 44 53 54

+-

301 302 303 304305 306

DC-

DC+

103 205

L3

203

L1

106

L1

105104

L3

GE1

NL2

GE2

ATYS 468 B GB

• Configure the type of control logic in contactor (see

Programming chapter).

Maximum control cables lenght = 10 m.

In case of longer distance, insert control

relays.

Page 8

Controller

ATyS

CONNECTIONS

ATyS C40

40

SOCOMEC - Réf. : 532 929 B

Control circuits

400 Vac (P-P) APPLICATION WITH NEUTRAL CONDUCTOR

CIRCUIT BREAKER TYPE TECHNOLOGY

>

Electrical interlocking via external control relays

13 14 23 24 33 34 43 44 53 54

I1I3 I2

301 302 303 304305 306

103

F1, F2

BRE. 1

Closing

POS 1

Opening

POS 2

BRE. 2

Fuse protection

230 Vac 5 A

LOAD

205

L3

203

L1

106

L1

105

L2

104

L3N

III

O1

L1

L2

L3

N

L1

L2

L3

N

F2F1

K1

K1

K2

K1

DC-

DC+

K2

K2

1 2

Closing

POS 2

Opening

POS 1

+-

ATYS 530 B GB

Maximum control cables lenght = 10 m.

In case of longer distance, insert control

relays.

* Only on DC versions.

• Configure the type of control logic in contactor (see

Programming chapter).

Page 9

Controller ATyS

CONNECTIONS

41

SOCOMEC - Réf. : 532 929 B

Control circuits

Denomination

Terminals

Description Characteristics

Recommended

section

Power supply L3 (104) Phase 3 440 V ac (phase-phase) 1.5 mm

2

Source L1 (106) Phase 1 maximum, 50/ 60 Hz

Power supply L1 (203) Phase 1 440 V ac (phase-phase) 1.5 mm

2

Source L3 (205) Phase 3 maximum, 50 / 60 Hz

Power supply DC

DC- Power supply 0 V From 9 V dc to 30 V dc 1.5 mm

2

12Vdc, 24Vdc

DC+ Power supply + V dc maxi.

Genset 13 Genset start/ stop relay - 2 stable positions Dry contact 1.5 mm

2

start signal

(1)

14 Programmable state - factory setting = NO, close to start 5A AC1/250 V

Control 23 Impulse mode: order to close source 5 A AC1/ 250 V

(impulse, 24 Contactor mode: order to close contactor source

contactor Breaker mode: order to close breaker source

and breaker 33 Impulse mode: order to close source 5 A AC1/ 250 V 1.5 mm

2

mode to 34 Contactor mode: order to close contactor source

programm) Breaker mode: order to open breaker source

43 Impulse mode: order to close position 0 5 A AC1/ 250 V 1.5 mm

2

44 Contactor mode: programmable relay O1

Breaker mode: order to close breaker source

Genset 53 Genset start/ stop relay - 2 stable positions 5 A AC1/ 250 V 1.5 mm

2

start signal

(1)

54 Programmable state - factory setting = NO, close to start

Information 301 Auxiliary contact information position 1 CA1 Do not connect to 1.5 mm

2

auxiliary 302 Programmable input 3 any power supply

contacts 303 Auxiliary contact information position 2 CA2

Programmable 304 Programmable input 1 Do not connect to 1.5 mm

2

Inputs 305 Programmable input 2 any power supply

Common 316 Specifique voltage supply Do not connect to 1.5 mm

2

input Common terminals 301 to 310 any power supply

(1) Refer to programming, Setup, to modify relay state.

22

2

1

2

2

1

1

1

11

2

1

Page 10

Presentation

The product allows:

• sources control,

• automatic transfer control in AUT mode,

• parameters configuration,

• voltage and frequency metering,

• system state display,

• alarm or fault indication,

Controller

ATyS

OPERATION

ATyS C40

42

SOCOMEC - Réf. : 532 929 B

Presentation

Operational modes

Programming

Operation

Visualisation

Automatic sequences

7 digits + 14 pointers

LCD

Green led is on when product is

powered

POWER led

Led is on when product is faulty.

Disconnect power supplies to reset

FAULT led

- Led is on: source = OK

- Led is off: source is not available

- Led is blinking: order to start is running

Sources state

2 green leds:

- switch I state

- switch II state

Switch state

- Active source: to force the next active source

- Partial counter reset

- Genset remote start (test of load)

Operational modes

Keypad

Escape Navigation

Validation

LCD & leds test

Operations

ATYS 469 A GB

Page 11

Presentation

Controller ATyS

OPERATION

43

SOCOMEC - Réf. : 532 929 B

SOFTWARE VERSION

Displayed after reset.

(3 minutes power off action to allow reset).

Version

number

ATYS 428 A GB

Operational modes

VISUALISATION

Measured values & parametered timers display. Always

accessible without code.

PROGRAMMING

Parameters configuration. Password access (code 1000

from factory).

OPERATION

Test sequences. Password access (code 4000).

Page 12

Programming

Controller

ATyS

OPERATION

ATyS C40

44

SOCOMEC - Réf. : 532 929 B

Presentation

Operational modes

Programming

Operation

Visualisation

Automatic sequences

• This mode allows product parameters configuration

• Always accessible in mode (when programmed on

an input)

• Always accessible in AUT mode, changeover switch on

priority source, priority source being available

• Not accessible when “test off load”, “test on load”

functions are active or during automatic sequence.

Parameters requiring programming before

use:

• type of network

• nominal voltage

• nominal frequency

• control logic

• number of auxiliary contact.

>

Navigation in the menus

• Parameters access: Press “up”, “down”, “left” & “right” push buttons

• Parametermodification: press “left” & “right” push button to access the parameter to modify

Press “up’’ and “down” push buttons to modify the parameter

and “validate”

• Return to main menu: press “ESC” push button

Value is only modified after validation

+

or

+

>

Programming exit

• Press and hold for 5 s

“validation” push button

>

Programming access

• Step 1: press and hold for 5 s

“validation” push button

• Step 2: enter code (factory code = 1000)

using navigation push buttons

• Step 3: press validation

push button

Page 13

Programming

Controller ATyS

OPERATION

45

SOCOMEC - Réf. : 532 929 B

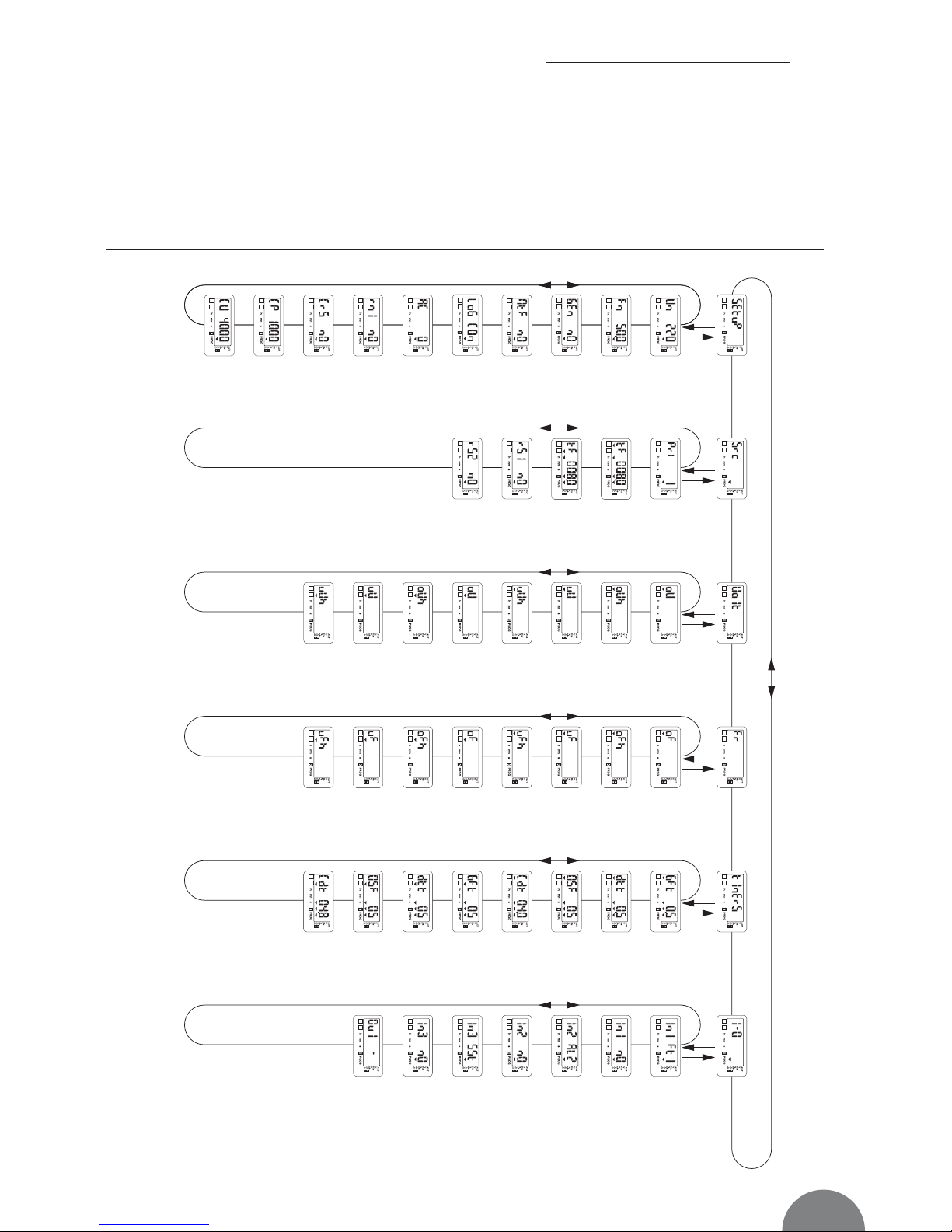

PROGRAMMING MENU ARCHITECTURE

1 2

1 2

1 2

1 2

1 2

1 2

1 2

1 2

1 2

1 2

1 2

1 2

1 2

1 2

1 2

1 2

1 2

1 2

1 2

1 2

1 2

1 2

1 2

1 2

1 2

1 2

1 2

1 2

1 2 1 2 1 2 1 2 1 2

1 2

1 2

1 2

1 2

1 2

1 2

1 2

1 2

1 2

1 2

1 2

1 2

1 2

1 2 1 2

1 2

1 2

1 2

1 2

Phase-Phase

nominal

voltage

ESC

See page 47 See page 48 See page 49 See page 50 See page 51 See page 52

Setup Source Voltage Frequency

Timer

2I/2O

ESCESCESC

ESC

ESC

Priority source

if no automatic

choice is

possible

Partial working

time for

source 1

Network 1

over voltage

threshold

Network 1

over voltage

threshold

hysteresis

Network 1

under voltage

threshold

hysteresis

Network 1

under voltage

threshold

Network 2

over voltage

threshold

Network 2

over voltage

threshold

hysteresis

Network 2

under voltage

threshold

hysteresis

Network 2

under voltage

threshold

Network 1

over frequency

threshold

Gen Failure

Timer source 1

Option 1

input 1

(variable

selection)

Option 1

input 1

(contact state

selection)

Option 2

input 2

(contact state

selection)

Option 2

input 2

(variable

selection)

Option 3

input 3

(contact state

selection)

Output

(variable

selection), if

Log ≠ ìimp ”

Option 3

input 3

(variable

selection)

Delay on

transfer timer

source 1

0 Secours

timer source

1

to source 2

Cool down

timer source 1

Gen Failure

Timer source 2

Delay to

transfer timer

source 2

0 Secours

timer source 2

to source 1

Cool down

timer source 2

Network 1

over frequency

threshold

hysteresis

Network 1

under

frequency

threshold

hysteresis

Network 1

under

frequency

threshold

Network 2

over frequency

threshold

Network 2

over frequency

thres

hold

hysteresis

Network 2

under

frequency

threshold

hysteresis

Network 2

under

frequency

threshold

Source 1

global working

time counter

reset

Source 2

global working

time counter

reset

Partial working

time for

source 2

Nominal

frequency

Genset start

signal state

retransfert

Manual

Impulse or

contactor

logic

Number of

auxiliary

contacts

Return to

position 0

Number of

permutation

counter Reset

Programming

partial code

modification

(global code

except rS1

and rS2)

Programming

code

modification

ATYS 470 B GB

Page 14

Programming

Controller

ATyS

OPERATION

ATyS C40

46

SOCOMEC - Réf. : 532 929 B

Presentation

Operational modes

Programming

Operation

Visualisation

Automatic sequences

PARAMETER MODIFICATION

>

Example:

Modify network nominal voltage from 400 to 230 V.

1

ATI 074 A

Press to access first digit (blinking)

Press

2X to display 2 (blinking)

Press

to access second digit (blinking)

Press

3X to display 3 (blinking)

Press to validate

Page 15

Programming

Controller ATyS

OPERATION

47

SOCOMEC - Réf. : 532 929 B

PARAMETERS CHARACTERISTICS

Network

nominal

frequency

Network nominal frequency 50 Hz or 60 Hz 50 Hz

1 2

>

Menu Setup

LCD Denomination Definition Setting Default

range values

1 2

Network

nominal voltage

Phase-Neutral voltage or Phase-Phase voltage From 100 V to

440 V

220 V

Manual

retransfer

“impulse” or

“contactor”

logic

Outputs control logic: impulse (IMP) or contactor (Con)

Activation of the feature YES or nO nO

Imp or con IMP

Restricted

access code

modification

Restricted access (counters rS1 and rS2) code modification

From 0000 to

9999

5000

Number of

auxiliary contact

Depends on changeover technology

(switch, contactor, breaker)

0 or 2 2

1 2

12

1 2

Genset start

signal state

Normally opened or closed. The same state for the 2

sources.

nO or nC nO

1 2

12

Return to 0

position

Allows to go to position 0 in case of network loss

(contactor logic type)

YES or nO nO

12

Number of

permutation

counter Reset

Automatic sequences counter reset YES or nO nO

1 2

Programming

code

Programming code modification From 0000 to

9999

1000

1 2

1 2

Page 16

Controller

ATyS

OPERATION

ATyS C40

48

SOCOMEC - Réf. : 532 929 B

Presentation

Operational modes

Programming

Operation

Visualisation

Automatic sequences

Programmation

>

Source Menu

LCD Denomination Definition Setting Default

range values

Priority source Priority source to start (1 or 2) if the internal logic could not

make any choice (rS1 = rS2 for exemple)

Partial working

time for source

1

Partial working

time for source

2

Reset of the

global working

time counter for

source 1

Partial workingtime counter for the source 1

Partial workingtime counter for the source 2

Reset of the global working time counter for source 1

1 or 2

from 000.1 to

999.9 hours

from 000.1 to

999.9 hours

nO or YES

1

008.0 hours

008.0 hours

nO

1 2

1 2

12

Reset of the

global working

time counter for

source 2

Reset of the global working time counter for source 2 nO or YES nO

12

1 2

1 2

Page 17

Programming

Controller ATyS

OPERATION

49

SOCOMEC - Réf. : 532 929 B

>

Volt Menu

Threshold detection starts from the loss of source

or source return sequence.

LCD Denomination / Definition Setting Default

range values

t100

Available source

Controlled value (voltage)

Over voltage threshold (oU)

Under voltage threshold (uU)

Over voltage hysteresys

threshold (oUh)

Under voltage hysteresys

threshold (uUh)

%

ATYS 243 A GB

Network 1 over voltage threshold From 102

to 120%

115%

Network 1 over voltage threshold hysteresis From 101

to 119% (< oU)

110%

Network 1 under voltage threshold From 80

to 98%

85%

Network 1 under voltage threshold hysteresis From 81

to 99% (> uO)

95%

Network 2 over voltage threshold From 102

to 120%

115%

Network 2 over voltage threshold hysteresis From 101

to 119% (< oU)

110%

Network 2 under voltage threshold From 80

to 98%

85%

Network 2 under voltage threshold hysteresis From 81

to 99% (> uU)

95%

1 2

1 2

1 2

1 2

1 2

1 2

1 2

1 2

1 2

Values definition: % of nominal values

Hysteresis values range is limited by thresholds values.

Page 18

Controller

ATyS

OPERATION

ATyS C40

50

SOCOMEC - Réf. : 532 929 B

Presentation

Operational modes

Programming

Operation

Visualisation

Automatic sequences

Programming

>

Frequency Menu

Threshold detection starts from the loss of source

or source return sequence.

LCD Denomination / Definition Setting Default

range values

t100

%

Available source

Controlled value (frequency)

Over frequency threshold (oU)

Under frequency threshold (uU)

Over frequency hysteresys

threshold (oUh)

Under frequency hysteresys

threshold (uUh)

ATYS 286 A GB

Network 1 over frequency threshold From 101

to 120%

105%

Network 1 over frequency threshold hysteresis From 100.5

to 119.5% (< oF)

103%

Network 1 under frequency threshold From 80

to 99%

95%

Network 1 under frequency threshold hysteresis From 80.5

to 99.5% (> uF)

97%

Network 2 over frequency threshold From 101

to 120%

105%

Network 2 over frequency threshold hysteresis From 100.5

to 119.5% (< oF)

103%

Network 2 under frequency threshold From 80

to 99%

95%

Network 2 under frequency threshold hysteresis From 80.5

to 99.5% (> uF)

97%

1 2

1 2

1 2

1 2

1 2

1 2

1 2

1 2

1 2

Values definition: % of nominal values

Hysteresis values range is limited by thresholds values.

Page 19

Programming

Controller ATyS

OPERATION

51

SOCOMEC - Réf. : 532 929 B

>

Menu Timer

LCD Denomination Definition Setting Default

range values

Gen Failure

Timer source 1

Delays source 1 failure detection

Delay to transfer

timer source 1

0 Secours Timer

source 1 to

source 2

Cool down

timer source 1

Standby network stability validation before transfer source 1 ->

source 2

Rest in zero position (open position) when transferring from

source 1 to source 2

Allows generator cooling down period after load’s retransfer

from source 1 -> source 2

From 0 to 60 s

From 0 to 60 s

From 0 to 20 s

From 0 to

30 mn

5 s

5 s

0 s

4 mn

1 2

1 2

1 2

Gen Failure

Timer source 2

Delays source 2 failure detection From 0 to 60 s 5 s

1 2

Delay to transfer

timer source 2

Standby network stability validation before transfer source 2 ->

source 1

From 0 to 60 s 5 s

1 2

0 Secours Timer

source 2 to

source 1

Rest in zero position (open position) when transferring from

source 2 to source 1

From 0 to 20 s 0 s

1 2

Cool down

timer source 2

Allows generator cooling down period after load’s retransfer

from source 2 -> source 1

From 0 to

30 mn

4 mn

1 2

1 2

12

Page 20

LCD Denomination/ Definition Setting range Default values

Input 1 SSt, Ft1, AL1, Ft2, AL2, /

MAn, MtF, /

Input 1 state nO or nC nO

Input 2 SSt, Ft1, AL1, Ft2, AL2, /

MAn, MtF, /

Input 2 state nO or nC nO

Input 3 SSt, Ft1, AL1, Ft2, AL2, /

MAn, MtF, /

Input 3 state nO or nC nO

Output* S1A, S2A, ScA, / /

* Non available in IMP logic (see LOG in SETUP menu).

Controller

ATyS

OPERATION

ATyS C40

52

SOCOMEC - Réf. : 532 929 B

Presentation

Operational modes

Programming

Operation

Visualisation

Automatic sequences

Programming

Output relays are NO type (construction) and

can not be configured as NC.

1 2

>

Inputs/Outputs Menu

Input state can be configured: NC or NO.

1 2

1 2

1 2

1 2

1 2

1 2

1 2

1 21 2

Page 21

Programming

Controller ATyS

OPERATION

53

SOCOMEC - Réf. : 532 929 B

>

Inputs/Outputs Menu

Inputs

1 2

Variable Description

SSt Start/stop transfer cycle.

Ft1 Fault input source 1. The fault led is blinking as soon as the input is active and Ft1 is displayed on LCD.

Reset when the input is de-actived (see diagram 2).

AL1 Alarm input source 1 (see diagram 1).

Ft2 Fault input source 2. The fault led is blinking as soon as the input is active and Ft2 is displayed on

LCD. reset when the input is de-actived (see diagram 2).

AL2 Alarm input source 2 (see diagram 1).

Man Information transfer system in manual mode. All automatic commands and test are inhibited as soon

as the input is activated.

MtF Remote manuel re-transfer. Feature identical to manual transfer on keypad. Re-transfer from priority

source to backup source is allowed from input activation (1s front). The Mtf variable in the setup menu

must be selected (Yes) to allow input recognition.

Variable Description

S1A Source 1 available.

Output activated as soon as source 1 is considered available (similar to front led source 1).

S2A Source 2 available.

Output activated as soon as source 2 is considered available (similar to front led source 2).

ScA Source 1 or Source 2 available.

Output activated as soon as source 1 or Source 2 considered available (similar to one of front led

source 1or Source 2).

* Non available in IMP logic (see LOG in SETUP menu).

Outputs*

Page 22

Controller

ATyS

OPERATION

ATyS C40

54

SOCOMEC - Réf. : 532 929 B

Presentation

Operational modes

Programming

Operation

Visualisation

Automatic sequences

>

AL1 Alarm diagram 1

Position G1

Position O

Position G2

sst

AL1

GFt 1

dtt 2

< tF 1

OSF 2 -> 1 OSF 1 -> 2 OSF 1 -> 2

tF 2 tF 1 < tF 2x

Cdt 2 dtt 2 Cdt 2

Cdt 1 dtt 1 Cdt 1

Start/stop order

Sensing

Start/stop order

Sensing

tG 1 = 0.5xtF1 + 1xtF1 + the old tG 1

tG 2 = 1xtF2 + x + 0.5xtF1 + the old tG 2

Input

dtt 1

ATYS 519 B GB

• An alarm is typically a warning information: fuel tank will

be empty very soon -> the genset will be stopped.

• During the functionning of one supply (G1 for example),

if an alarm AL1 appears, the second supply (G2 in that

case) is started at the end of GFt1 timer. G1 genset

is then stopped after Cdt1 timer. The emergency

genset G2 will then be maintained as long as the alarm

AL1 will be present. After AL1 disappearance, the basic

cycle will take over.

Programming

Page 23

Controller ATyS

OPERATION

55

SOCOMEC - Réf. : 532 929 B

>

Ft1 fault diagram 2

sst

Ft1

dtt 2

< tF 1

OSF 2 -> 1 OSF 1 -> 2 OSF 1 -> 2

tF 2 tF 1 < tF 2x

Cdt 2 dtt 2 Cdt 2

dtt 1 Cdt 1

Input

dtt 1

tG 1 = 0.5xtF1 + 1xtF1 + the old tG 1

tG 2 = 1xtF2 + x + 0.5xtF1 + the old tG 2

Position G1

Position O

Position G2

Start/stop order

Sensing

Start/stop order

Sensing

ATYS 520 B GB

• A fault can cause an important damage -> the genset

must be stopped immediately.

• During one supply operation (G1 for example), if Ft1

appears, the second supply (G2 in that case) is imme-

diately started. The initial G1 genset is then stopped

immediately after the transfer. The emergency genset

G2 will then be maintained as long as Ft1 will be

present. After Ft1 disappearance, the basic cycle will

take over.

Programming

Page 24

Operation

Controller

ATyS

OPERATION

ATyS C40

56

SOCOMEC - Réf. : 532 929 B

Presentation

Operational modes

Programming

Operation

Visualisation

Automatic sequences

PRESENTATION

Enter operation mode:

• Step 1: press and hold

the “TEST” push button for 5 s

• Step 2: enter the operation code (CE) using

navigation push buttons (code 4000)

• Step 3: press “validation”

push button

Exit operation mode:

Press and hold the “TEST” push button for 5 s

or automatic exit without action during around

2 min

Navigate in operation mode:

• Press “TEST” push button to access

different features

• Press “validation” push button to activate

required function

This mode allows in manual mode (not padlocked) to start

a test off load. In automatic mode, it allows to start a test,

on or off load.

Page 25

Controller ATyS

OPERATION

57

SOCOMEC - Réf. : 532 929 B

Operation

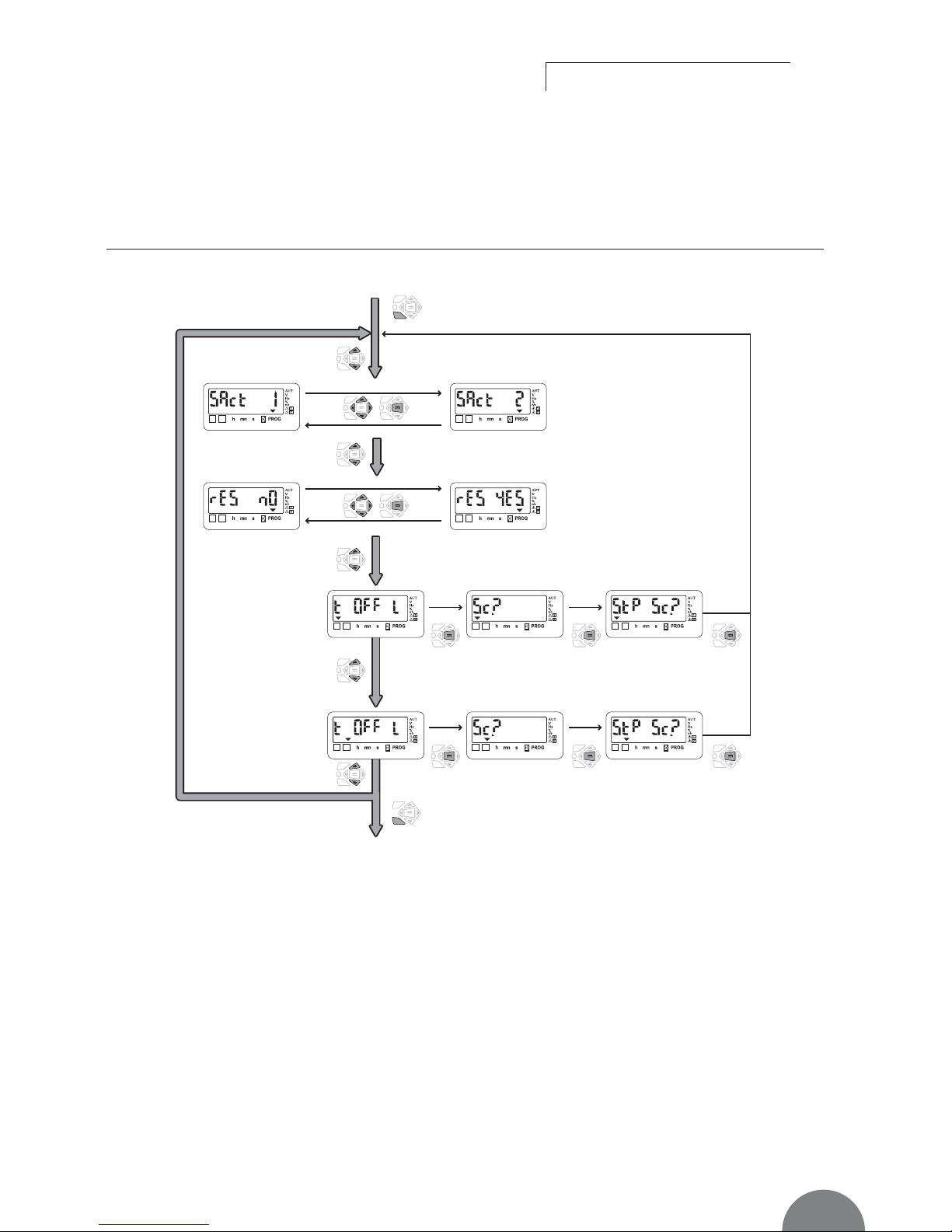

OPERATION MODE ARCHITECTURE

Exit: press 5 seconds

Yes, press

“validation”

Next source active :

source 2

Next source active :

source 1

Reset partial

counter : Yes

Test off Load source 1 Source 1 available ? Stop source 1 ?

Test off Load source 2 Source 2 available ? Stop source 2 ?

Reset partial

counter : No

No, press

“validation”

Yes, press

“validation”

Yes, press

“validation”

No, press

“validation”

Yes, press

“validation”

Enter: press 5 seconds and enter

the operation code (CE)

1 2

1 2

1 2 1 2

1 21 2

1 2

1 2

1 2

1 2

ATYS 523 A GB

Page 26

Controller

ATyS

OPERATION

ATyS C40

58

SOCOMEC - Réf. : 532 929 B

Presentation

Operational modes

Programming

Operation

Visualisation

Automatic sequences

Operation

ACTIVE SOURCES

>

Description

When a basic cycle is started, the first started group is the

one who has the least worked, or the one who is defined

in the menu “source” (in programming mode).

Nevertheless, in a punctual way it is possible to force

this choice of starting up of the next group by “operation” menu

>

Activation

- If the LCD indicate “SAct 1”, then the next “Source

Active”, or the next source which will be started, will be

the source 1.

- If the LCD indicate “SAct 2”, then the next “Source

Active”, or the next source which will be started, will be

the source 2.

RESET OF COUNTER

>

Description

During a basic cycle, each group works during a time

defined in the “source” menu in the programming mode.

This timer can be reset punctually during a running of

the associated genset.

>

Activation

- If the LCD indicate “rES nO”, then the timer is not

reseted.

- If the LCD indicate “rES YES”, then the timer is reseted.

Page 27

Controller ATyS

OPERATION

59

SOCOMEC - Réf. : 532 929 B

Operation

TEST OFF LOAD (ACCESSIBLE IN AUT / MODES)

>

Description

• This mode will start and stop remote by genset operation without load transfer

• The test is not possible during an automatic sequence

>

Keypad activation

After operation mode access, press mode push button

to make a test with the load led blinking and validate to

start the sequence.

Gen stopped

Validate

Yes

No

Gen?

Stop Gen?

Start Gen

1 2

1 2

1 2

1 2

1 2

ATYS 087 C GB

Page 28

Visualisation

Controller

ATyS

OPERATION

ATyS C40

60

SOCOMEC - Réf. : 532 929 B

Presentation

Operational modes

Programming

Operation

Visualisation

Automatic sequences

PRESENTATION

• This mode allows parameters to be displayed independently from mode /AUT (if programmed on

input) switch position

• No code required to access parameters visualisation

• Without any action during 10 seconds on the keypad,

the LCD displays voltage available on active network.

Navigation in visualisation mode:

• Press “up” and “bottom” push buttons to access required parameter

• Press “left” and “right” push buttons to navigate in the different menus

Page 29

Visualisation

Controller ATyS

OPERATION

61

SOCOMEC - Réf. : 532 929 B

VISUALISATION ARCHITECTURE MODE

1 2

1 2

1 2

1 2

1 2

1 2

1 2

1 2

1 2

1 2

1 2

1 2

1 2

1 2

1 2

1 2

1 2

1 2

W

*

orking time for the

next cycle or for the

current cycle

* Displays automatically comes back to this display if no action is performed on the product.

Sources Timers Counter Metering

Gen Failure Timer

source 1

Delay to transfer timer

source 2

Source 1 -> source 2

transfer counter

Delay to transfer timer

source 1

Cool down timer

source 2

Voltage

source 1

Frequency

source 1

Frequency

source 2

Voltage

source 2

Cool down timer

source 1

Gen Failure Timer

source 2

0 position stay

Timer from

source 1 to source 2

0 position stay

Timer from

source 2 to source 1

Global working time

for source 1

Global working time

for source 2

Partial working time

for source 1

Partial working time

for source 2

ATYS 524 A GB

Page 30

Controller

ATyS

OPERATION

ATyS C40

62

SOCOMEC - Réf. : 532 929 B

Presentation

Operational modes

Programming

Operation

Visualisation

Automatic sequences

Automatic sequences

OPERATION

>

Operation principle

C40 controler automatically starts and stops 2 gensets

if SSt input is activated (refer to programming).

Each genset has its own operational timer.

• tF1: partial operational timer (on one cycle, refer to

programming)

• tG1: global operational timer (from last counter reset).

>

Start sequence

From SSt start signal:

• If operational time on source 1 is greater than operational time on source 2,

-> Start source 1

• If operational time on source 2 is greater than operational time on source 1,

-> Start source 2

• If next source to start has been selected on HMI,

-> Start the required source.

Rq: In case of “non starting” of priority source, after

1 minute the second source is automatically started.

>

During the sequence

• If partial timer is counted down and sst stil active,

-> The second source is started and the load transferred

• If active source disappears before the end of the

sequence,

-> The second source is started and remains active

until the end of the partial timer (refer to diagrams 2

& 3)

>

Stop sequence

The cycle is stopped

• either when the state of the input (SSt) changes

• or when a fault appears

• or when the “manual” mode is activated.

• Diagram 1

Base cycle

dtt 2

tF 1

OSF 2 -> 1 OSF 1 -> 2 OSF 1 -> 2

tF 2 tF 1 < tF 2

Cdt 2 dtt 2 Cdt 2

Cdt 1 dtt 1 Cdt 1

tG 1 = 2xtF1 + the old tG 1

tG 2 = 1,5xtF2 + the old tG 2

SSt input

dtt 1

Position G1

Position O

Position G2

Start/stop order

Sensing

Start/stop order

Sensing

ATYS 525 B GB

tF1 1

• tG1 = fF1 + tF1 + tF1 + a

• number of cycle already realized by 1 = tG1/tF1 = 3, … cycles

tF1 1 tF1 1 a < tF1 1

Page 31

Controller ATyS

OPERATION

63

SOCOMEC - Réf. : 532 929 B

Automatic sequences

• Diagram 2:

source loss without reappearance before SSt state changeover

Complete genset loss

sst

GFt 1

dtt 2

< tF 1

OSF 1 -> 2

tF 2 x

Cdt 2

Cdt 1

tG 1 = 0.5xtF1 + the old tG 1

tG 2 = 1xtF2 + x + the old tG 2

Input

dtt 1

Position G1

Position O

Position G2

Start/stop order

Sensing

Start/stop order

Sensing

ATYS 526 B GB

• Diagram 3:

source loss and reappearance before SSt state changeover

Partial genset loss

sst

GFt 1

dtt 2

< tF 1

OSF 2 -> 1 OSF 1 ->2

tF 2 tF 1 x

Cdt 2

Cdt 1 dtt 1 Cdt 1

tG 1 = 0.5xtF1 0,5xFt1 + the old tG 1

tG 2 = 1xtF2 + x + 0.5xtF1 + the old tG 2

Input

dtt 1

Position G1

Position O

Position G2

Start/stop order

Sensing

Start/stop order

Sensing

ATYS 527 B GB

NB: in case of source 1 reappearance, it might be preferable not to retransfer immediately the load. Manual

retransfer feature can be activated if required from

keypad or remotely (cf. programming).

Page 32

Controller

ATyS

TROUBLESHOOTING GUIDE

ATyS C40

64

SOCOMEC - Réf. : 532 929 B

STATE ACT IO N

Electrical operation is not working • Verify voltage applied on terminals 9 Vdc to 30 Vdc for DC version

• Verify state of input MAN if selected

Product is faulty (fault is active) • Disconnect power supply and reconnect to reset fault

FT1, AL1, FT2, AL2 • In case of programming inputs FT1 or FT2, verify if external fault is not

active. If the external fault disappear it acquit the fault

• Verify inputs (NO, NC…) configuration

Source available led is never active • Press test lamp to verify led is operational (push 5 seconds)

when available • Verify nominal preset values (voltage and frequency)

• Verify voltage and frequency thresholds

The changeover switch does not transfer • Verify state of input MAN, if selected

after loss of main • Verify emergency source is available (ex: genset is started)

• Verify voltage applied on terminals

Test on load and off load

• Verify password to access test (5000)

can not be activated from keypad

• Verify state of input MAN, if selected

The changeover switch • Verify if dtt is counted down

does not re-transfer after main's return • Verify state of input MAN if selected

• Verify manual retransfer feature is not active

(press validation to allow retransfer)

Retransfer has been realised but • Verify if CDT is counted down

emergency source in still running (did not stop) • Verify Start Gen output relay command,

(contacts 13-14 or 53-54 depending on genset)

Electrical operation not according to commands • Verify control logic (impulse or contactor mode)

• Verify Rn variable in Setup menu

The product is in faulty position • Verify the number of AC in the setup menu. It must be in conformity with the

number of AC connected

• Verify the switch position

Error LCD Err XXXX • Send the product back to the manufacturer

Loading...

Loading...