PART P MULTIFUNCTION DIGITAL LOOP TESTER

Tests no-trip loop, PFC, socket, mains voltage & polarity

PDL 310

USER MANUAL 06/06

2

Caution

We strongly advise reading and understanding this guide

before the instrument is used. In particular note the safety

issues that follow:-

l Although fully protected up to 600V AC this tester is for

use on 230V AC circuits only.

l Always check the tester on a known correctly wired live

socket outlet before and after use.

l Before use - check your tester for any damage to

the plug, lead and cabinet.

BS EN

61010-1

PDL 310

At Socket & See our Engineers constantly look for improvement.

If there is any aspect of your Socket & See tester you would like

to comment on please visit our website at

www.socketandsee.co.uk

or email davidh@kewt.co.uk or Free Fax at 0800 7831385

with any suggestions.

We promise all communications will be acknowledged.

We value YOUR opinion.

Important calibration/check box note

l Because of the Super Smart Loop Test System the test is

immune to sudden value changes (such as voltage spikes).

l As a result when changing calibration or check box loop

values the unit must be switched off between changes.

3

Operation overview

Your Socket & See tester has a special polarity test function.

It is a little known fact that a system can be reverse wired with Live (Phase) to

earth/neutral and earth/neutral to Live (Phase) The sockets will all work and

conventional loop testers will show and test that everything is correct despite

this very dangerous wiring condition.

Although extremely rare, this miswire condition can exist so if your test shows

this fault do not proceed - if in any doubt advise your customer to contact their

supply company immediately.

overview

FUSE 100A

FUSE 100A

From Supply

Company

Live (Phase)

to Meter

Neutral to Meter

To Main

Earthing

Terminal

Neutral to Meter

Live (Phase)

to Meter

To Main

Earthing

Terminal

From Supply

Company

Correct Polarity

REVERSE POLARITY

Typical Supply Service

Cut-Out Fuse

LIVE (Phase)

NEUTRAL

Typical Supply Service

Cut-Out Fuse

NEUTRAL

LIVE (Phase)

Solid Brass

Connecting

Block

Solid Brass

Connecting

Block

4

PDL 310

Operation overview continued

The PDL 310 is a multifunction tester testing for no trip loop, no-trip PFC (Prospective

Fault Current), mains voltage (L-N), correct socket wiring, and polarity.

Correct socket wiring and correct polarity

At the Socket Test stage the PDL 310 also accurately measures and displays the mains

voltage in the LCD (Liquid Crystal Display).

A reminder of the correct voltage range 207-253V AC (Harmonised Standard BS 7697

HD 42S1) is given above the display.

If the Voltage Range is outside of this standard, stop testing - your customer should notify

their electricity supply company of the problem.

If the three socket LED’s are GREEN (correct) and the correct voltage is displayed you

can proceed to Polarity Test.

The reasons for Polarity Test are covered in detail on the previous page of this User Guide.

To carry out the test apply firm (thumb) pressure to the Polarity Test Pad, note this pad

does not depress. The three Socket Test LED’s should remain GREEN - everything is

correctly wired including Polarity (live and earth/neutral are in the right place).

If the LED’s change to RED when you operate the Touch Pad - it is possible a very

dangerous condition is present and the relevant electricity supply company should be

informed immediately of this indication.

If everything in this section is a good test result you can proceed to the next sequence

of testing (see page 7).

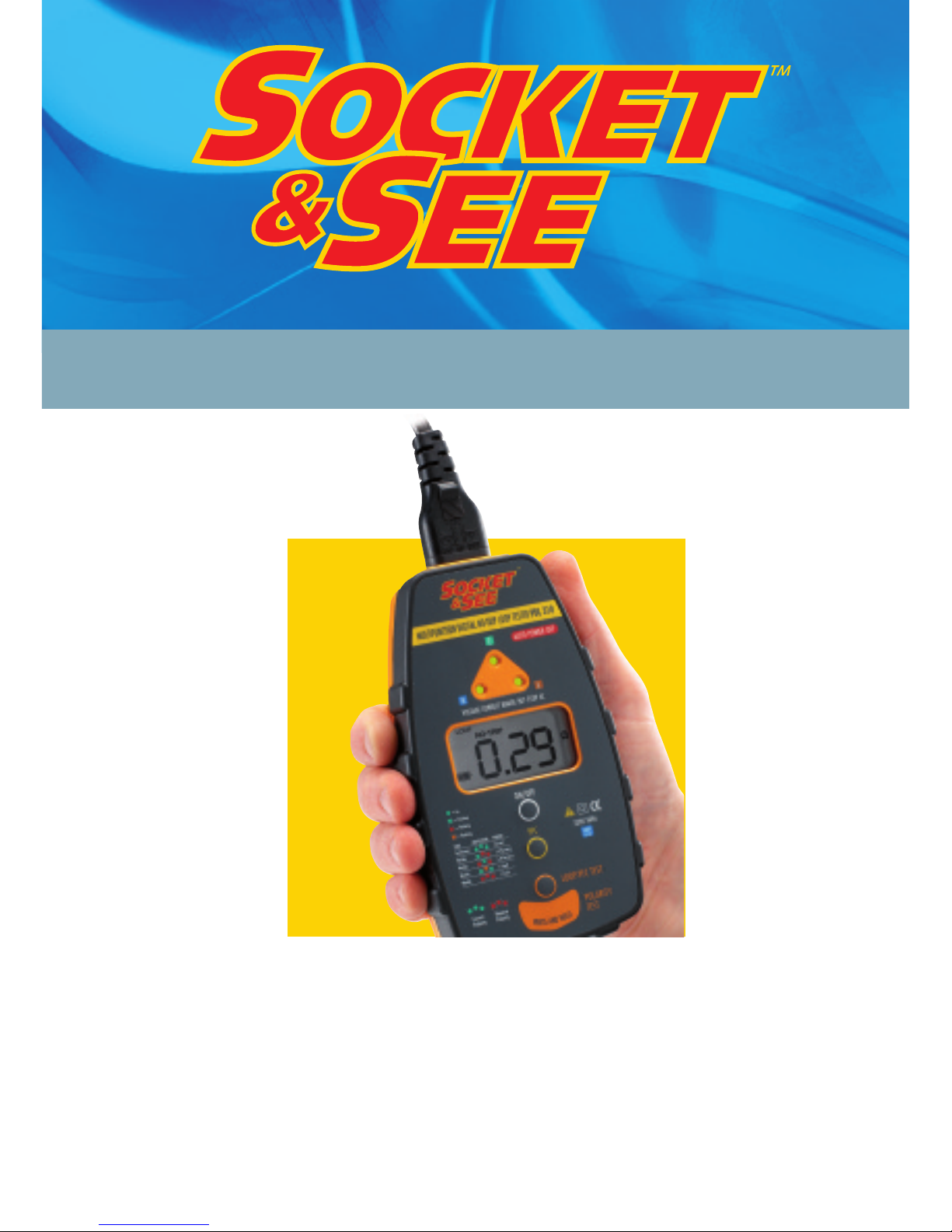

2.

Three LED’s

show socket

wiring status

3.

LCD (Liquid

Crystal Display)

display (default

L-N voltage

measurement)

1.

On/off button

7.

PFC

(Prospective

Fault Current

Result)

5/6.

Test push

button (loop

test reading

default)

Operation - a detailed view of the PDL 310

Note numbers also indicate sequence of test.

5

overview

4.

Polarity test pad

A. (No-trip) loop test function selected

B. PFC-PSC (prospective fault current - prospective short circuit

current selected)

C. HANDSFREE operation

D. Ohms symbol

E. Volts (AC) (L-N)

F. Fault current

G. Wait - result calculation in progress

H. Tester has gone over operating temperature

I. Greater than (>) less than (<) indication

J. Battery Condition ( =good)

6

PDL 310

Overview of the display

G

CBA

D

E

F

H

I

J

Plug the tester in and switch on the mains supply.

1. Power ON/OFF - Pressing and releasing this button turns the

PDL 310

on holding down for longer than two seconds turns the unit off (plus intelligent

Auto Power Off is incorporated).

2. All three LEDs GREEN = CORRECT wiring status, any other indication

(see back cover) - DO NOT PROCEED -investigation is required.

3. Check mains voltage is correct 207-253VAC

Important note:

All tests are inhibited until the mains voltage appears in the display

4. Polarity Test - this important test is discussed in full on pages three and

four of this manual, please read.

5/6. The push to test switch must be operated to initiate test (except if this button

is held down for approx two seconds HANDSFREE testing is selected which is

very useful for testing at DB’s (Distribution Boards), luminaires or similar

connecting strips.

Your tester defaults to no-trip loop testing when you first switch on button five re-selects no-trip loop test (and retests) if you have selected

other functions.

7. Having carried out a (no-trip) loop test - pressing this button calculates the PFC

(Prospective Fault Current) by dividing the measured loop result into the

measured L-N voltage.

Loop-PFC testing

7

Loop-PFC testing

8

PDL 310

Specifications

Wiring Test

Detects missing E or N (>15kΩ)

Detects L-E or L-N swap

Detects Live - Earth/Neutral reversal by use of Polarity Test Pad

Fault indicated by chart on front of instrument

Phase - Neutral voltage measurement ± 1% ± 1V

Loop Test

No trip mode 3 wire testing Phase - Neutral - Earth all connected

Test current <15mA at 253V AC

Range Accuracy

0.00 to 9.99Ω ± 5% ± 5 digits

10.00 to 99.9Ω ± 4% ± 4 digits

100.00 to 500Ω ± 4% ± 4 digits

PFC Measurement

10A - 9.99kA This is a calculated measurement whose accuracy is

derived from the Loop Test result

Over Voltage Protection

440V AC No damage - complete recovery

Power

4 x AA batteries (not included)

Battery life (BS EN 61557) > 10,000 test (or shelf life of batteries installed)

Environmental

Operating Temperature Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 00C to 400C

Storage Temperature Range. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -10

0

C to 600C

Operating Humidity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80% @ 31˚C to 50% @ 40˚C

Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157mm x 89mm x 39mm

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 400g

9

Loop-PFC testing

Socket Test Technology

The PDL 310 uses our well proven Socket Testing patented technology to

indicate the socket is correctly wired.

Plugging the unit in and switching on mains supply automatically initiates the

socket test sequence.

If the socket is correctly wired the LED’s will be GREEN on this check.

If the socket is incorrectly wired one or more LED’s will go to FLASHING RED to

indicate there is a a socket miss-wire or other fault.

If flashing red (or orange) occurs using the touch pad at this stage, this should

show where the socket wiring problem is – as per the example below.

A unique feature of your tester is the ability to display by the position of the red

LED(s) where the problem is, EARTH, LIVE (Phase) or NEUTRAL.

A full list of wiring faults is shown on the back cover of this User Guide.

This is an example of ‘Fault Locate’ showing Live (Phase), neutral reverse.

10

PDL 310

Socket & See Industrial

www.socketandsee.co.uk

Unit 4, Century Road, High Carr Business Park,

Newcastle, Staordshire, UK, ST5 7UG

T +44 (0)1782 567096

F +44 (0)1782 567095

© Socket & See Limited (A division of the Kew Technik Group of companies)

11

LED’s will flash to indicate fault condition

NC=No Connection

Condition Wiring Supply LED

Buzzer

Number Condition Terminal Display

NEL

Socket Wiring

1 Correct NEL Continuous

2 L-E reverse NLE Warble

3 L-N-E miswire ELN Warble

4 L-N reverse LEN Warble

5 L-N-E miswire LNE Warble

6 Faulty N / L-E miswire NC L N Warble

7 Faulty N / E miswire NC N L Warble

8 Faulty N NC E L Warble

9 Faulty N / L-E reverse NC L E Warble

10 Faulty E / L-N reverse LNCN Warble

11 Faulty E NNCL Warble

12 Faulty E / N miswire ENCL Warble

13 Faulty E / L-N miswire LNCE Warble

14 Faulty L / N-E miswire LNNC Warble

15 Faulty L / E miswire NLNC Warble

16 Faulty L / N-E miswire ELNC Warble

17 Faulty L / N miswire LENC Warble

18 No Mains NC NC NC None

Loading...

Loading...