Instruction Manual & Specification

PDL 234Plus

Part P Loop Testing Kit

SS004V2

Sn

2

SS004V2

1. Safety

1.1 Equipment Markings

1.2 Operational Safety

The PDL234Plus is designed to be used by skilled persons in accordance with

safe methods of work. If the PDL234Plus is used in a manner not specified by

Socket and See, the protection provided by it may be impaired.

Inspect the product before using. If any damage is visible; such as cracks in the

casing, damage to any accessories, leads or probes, the unit should not be

used.

Although fully protected up to 600V AC, this tester is is for use on 230V AC 50Hz

circuits only.

This tester has been designed to be used with suitable PPE, including insulated

gloves if required.

Caution - refer to the instruction manual

Construction is double insulated

Product should be recycled as electronic waste

Conforms to EU standards

Measurement Category III is applicable to test and measuring circuits

connected after the source of the building’s low-voltage MAINS

installation. This part of the installation is expected to have a

minimum of two levels of over-current protective devices between

the transformer and connecting points of the measuring circuit.

Examples of CAT III are measurements on devices installed after the

main fuse or circuit breaker fixed within the building installation. Such

as junction boxes, switches and socket outlets.

CAT

3

SS004V2

To maintain safety always check the tester on a known correctly wired live

socket outlet before and after use. Or use a suitable checkbox such as the

Socket and See CB400.

2. Description

The PDL234 is a multi function tester, testing no trip loop, mains voltage correct

socket wiring and polarity.

2.1 Features

● Colour coded and simple to understand LED indication

● Quick and convenient non trip loop impedance test

● Mains voltage indication

● Incoming mains polarity test

● Socket wiring tester

● Carrying case included

● Contains 13A plug to IEC connector for use at 13A socket outlets.

● Contains ITLS 400. Three pole fused test leads that terminate with prods or

crocodile clips. For use at fused spurs or distribution boards.

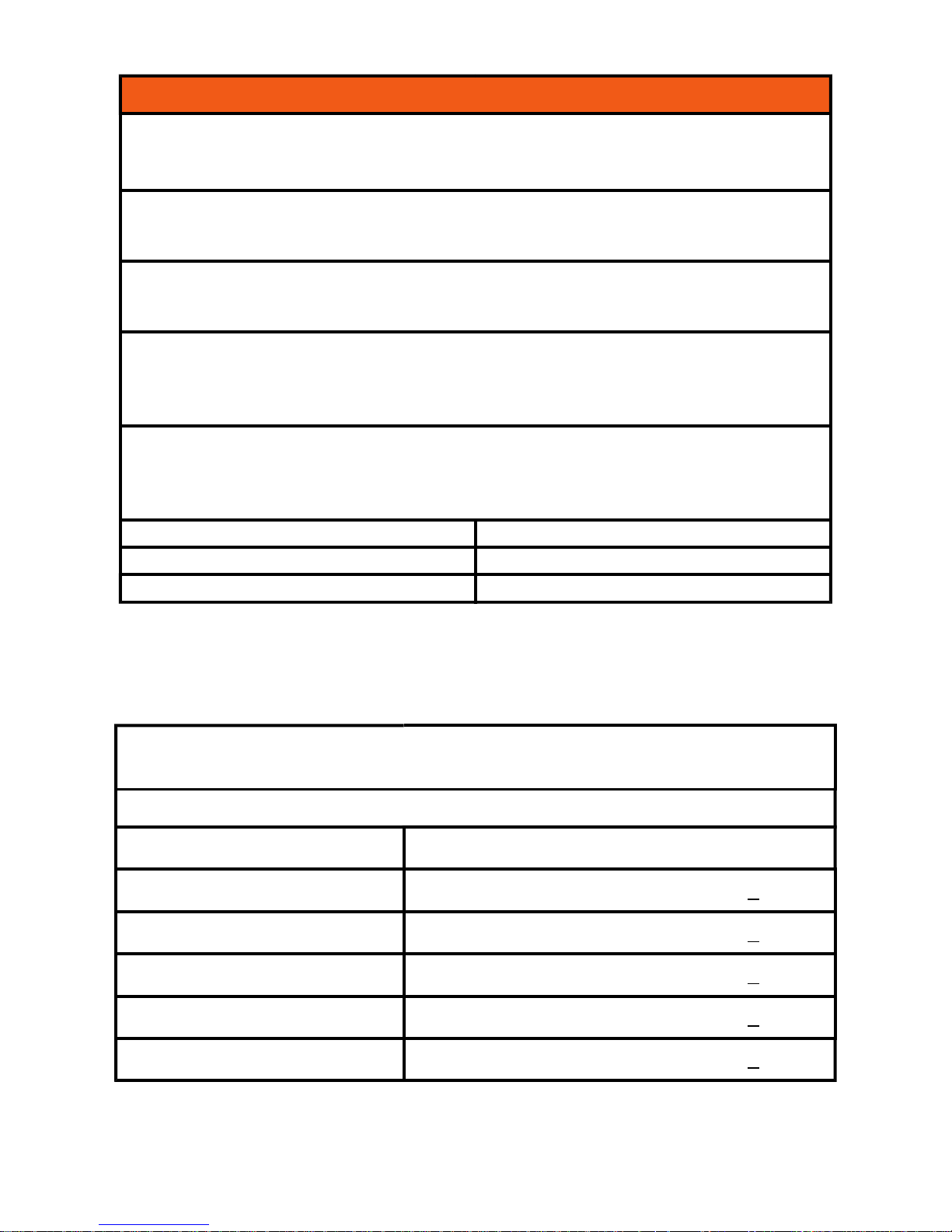

2.2 Indication

The PDL234 uses simple to understand colour coded LED indication.

Loop Testing Indication

Value (Ω) LED INDICATION

< 1 GREEN

< 2 GREEN

< 100 GREEN

< 200 GREEN

> 200 RED

4

SS004V2

3. Usage

Mains Voltage Indication

Value (Volts AC) LED INDICATION

< 207 AMBER

207 - 253 GREEN

> 253 RED

Fault loop result

LED’s

Table of correct

and common

socket wiring

faults

Polarity test

indications

Socket wiring and

Polarity status LED’s

Mains voltage

LED’s

Loop test push

button

Polarity touch

pad

5

SS004V2

5

3.1 Operation

If the tester is to be used with on a fixed 13A socket outlet simply use the IEC 13

Amp lead and plug directly into the socket outlet.

If the tester is connected to a switched or unswitched spur via the fused test

leads it is strongly recommended the supply is isolated before the first

connections are made.

3.1.1 Socket Test

When the PDL234 is first connected to a live socket it will automatically test the

socket wiring to confirm correct installation of the socket. If three GREEN LED’s

illuminate and a continuous tone is emitted the socket wiring is correct and you

may proceed to the incoming supply polarity test, (step 3.2.2).

A fault with the socket wiring will be indicated by an audible alternating tone

and flashing LED’s, at least one of which will be red or orange. If a fault

indication is given DO NOT PROCEED! Investigation and remedial action is

required before any further tests can be carried out.

3.1.2 Incoming Supply Polarity Test

With all three LED’s illuminated green place your thumb over the Polarity test

touch pad. If the incoming supply polarity is correct the socket and wiring

polarity LED’s will flash green. If this indication is correct proceed to incoming

voltage checks (step 3.1.3).

If the supply polarity has been reversed the three LED’s will turn RED and flash. If

this happens stop testing immediately and notify the supply company.

For further information on incoming supply polarity refer to the technical

document on the Socket and See website.

3.1.3 Mains Voltage Test

The mains AC voltage will be displayed automatically on the Mains Voltage

LED’s. Check that the voltage is within the correct range 207 - 253 VAC. If the

mains voltage is within the correct range a no trip loop test can be conducted.

(Step 3.1.4)

If the voltage is outside of this range the electricity supply company should be

contacted.

6

SS004V2

3.1.4 No Trip Loop Testing

A brief press of the test button will initiate the loop test. Three socket test LED’s

will flash orange to indicate a loop measurement is being taken. The result will

then be displayed on the Fault loop results LED’s . For a guide to results please

see the below table.

FOR GUIDANCE ONLY: Refer to the IET Wiring standards BS 7671

< 1

Less than 1 Ohm: A good result and typical of a correctly wired

TN (PME) system.

< 2

Less than 2 Ohm: A result that would be worth pushing the plug

in and out to see if it is just tarnished socket contacts or

checking where the socket is located. If it is at the furthest point

of the end circuit a higher reading may be expected.

<100

Less than 100 Ohms: Now you must check the wiring system

being used. If it is a TT system (earth rod) then it is a good result

but if it is any other system this should cause concern and urgent

investigation is required.

< 200

Less than 200 Ohms: As above. Assuming it is a TT system most

codes of practice accept a Loop Test value of less than 200

Ohms for an earth rod for a system protected by a 30mA RCD

as being acceptable.

>200

There are very real problems with this system and urgent further

investigation is requited

7

SS004V2

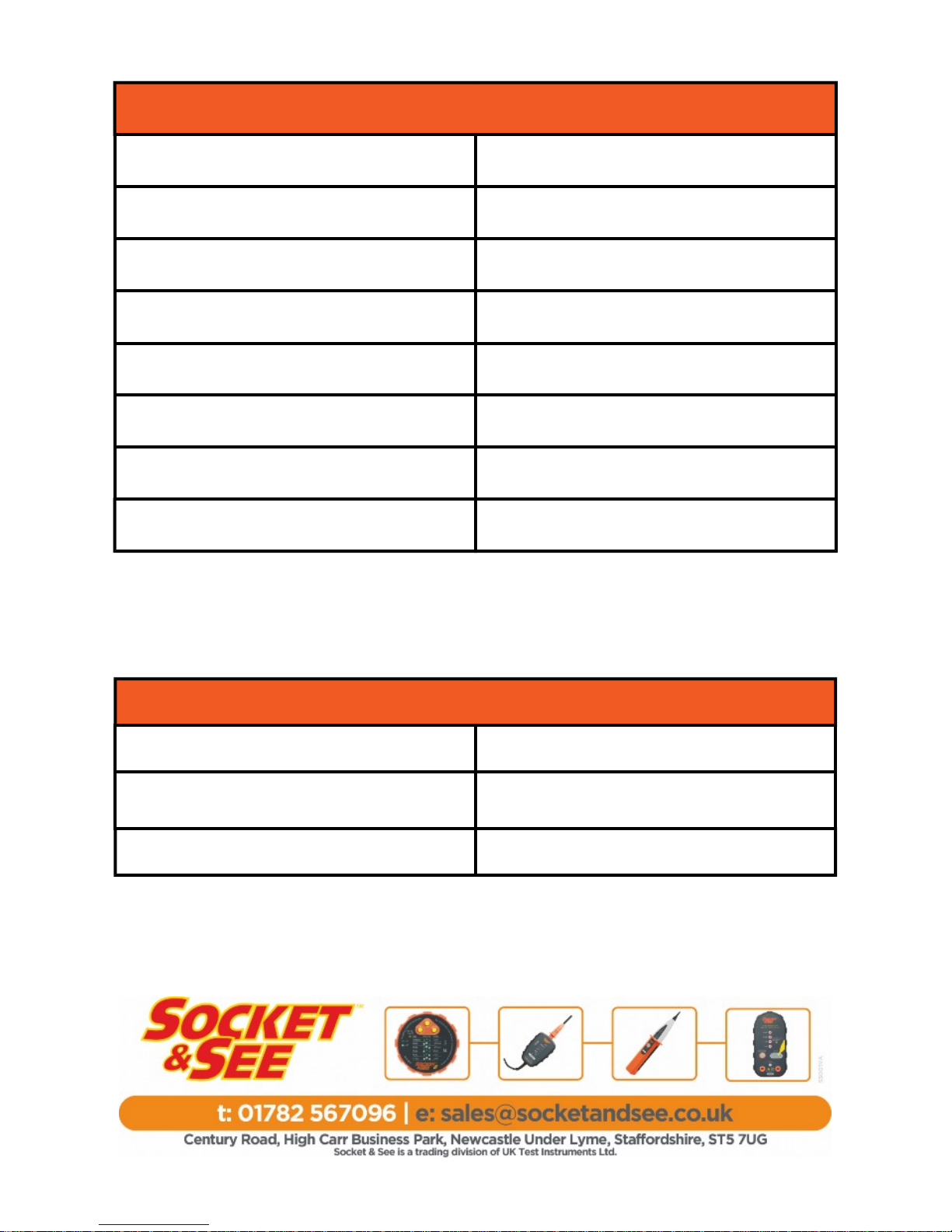

Condition

Number

Wiring

Conditions

Supply Terminal LED Buzzer

N E L

Socket Wiring

1 Correct

N E L

Continuous

2 L-E reverse

N L E

Warble

3

L-N-E

miswire

E L N

Warble

4 L-N reverse

L E N

Warble

5

L-N-E

miswire

L N E

Warble

6

Faulty N/L-E

miswire

NC L N

Warble

7

Faulty N/E

miswire

NC N L

Warble

8 Faulty N

NC E L

Warble

9

Faulty N/L-E

reverse

NC L E

Warble

10

Faulty E/L-N

reverse

L NC N

Warble

11 Faulty E

N NC L

Warble

12

Faulty E/N

miswire

E NC L

Warble

13

Faulty E/L-N

miswire

L NC E

Warble

14

Faulty L/N-E

miswire

L N NC

Warble

15

Faulty L/E

miswire

N L NC

Warble

16

Faulty L/N-E

miswire

E L NC

Warble

17

Faulty L/N

miswire

L E NC

Warble

18 No mains

NC NC NC

None

LED’s will flash to indicate a fault.

NC = No connection

8

SS004V2

4. Maintenance and Service

If required, clean with a damp cloth and mild detergent. Do not use abrasives

or solvents.

There are no user serviceable parts.

Contact Socket and See for parts and technical assistance.

Socket and See

Century Road

High Carr Business Park

Newcastle

Staffordshire, UK

ST5 7UG

Tel: +44 (0) 1782 567096

Fax: +44 (0) 1782 567095

Email: sales@socketandsee.co.uk

Website: www.socketandsee.co.uk

9

SS004V2

Specification

Wiring Test

Detects missing E or N (>15kΩ)

Detects L-E or L-N swap

Detects Network Supply Live - Earth/Neutral reversal by use of Polarity Test

Pad.

Phase - Neutral voltage measurement accuracy to 1% and displayed on 3

LED’s

< 207 VAC LOW

207- 253 VAC STANDARD

< 253 VAC HIGH

Loop Test

(No trip mode, 3 wire testing, Phase - Neutral - Earth all connected)

Test current <15mA at 253V AC

Range Accuracy

<1Ω Each breakpoint has an accuracy of + 10%

<2Ω Each breakpoint has an accuracy of + 10%

<20Ω Each breakpoint has an accuracy of + 10%

<200Ω Each breakpoint has an accuracy of + 10%

>200Ω Each breakpoint has an accuracy of + 10%

SS004V2

Ordering Information

Item Supplier Code

Socket and See PDL234Plus Part P

Loop testing Kit tester

SOC/PDL234Plus

Socket and See fused test leads SOC/ITLS400

Specification Continued

Overvoltage Category CAT III 300 V

Over Voltage Protection

440V AC No damage complete

recovery

Operating Temperature 0ºC to 40ºC

Operating Humidity 80% @ 31ºC to 50% @ 40ºC

Safety Compliance BS EN 61010-2-030:2010

Probes GS38 Compliant

Dimensions

140mm x 80mm x 31mm

Weight 250g

Loading...

Loading...