Socket CF RFID, CF RFID Reader Card 6E, CF RFID Reader-Scan Card 6M, CF RFID Reader-Scan Card 6P User Manual

Page 1

CF RFID Reader Card™

CF RFID Reader-Scan Card™

Series 6

User’s Guide

Page 2

10/2008 Document # 6410-00266 H

Copyright Notice

Copyright © 2008 Socket Mobile, Inc. All rights reserved.

Socket, the Socket logo and Mobility Friendly are registered

trademarks of Socket Mobile, Inc. CF RFID Reader Card, CF RFID

Reader-Scan Card, SoMo, RFID Demo, SocketScan, and

SocketScan Trigger are registered trademarks or trademarks of

Socket Mobile, Inc. All other brand and product names are

trademarks of their respective holders.

The CF RFID Reader Card and CF RFID Reader-Scan Card contains

technology licensed under United States Patent No. 5,902,991

and 7,003,627.

Reproduction of the contents of this manual without the

permission of Socket Mobile is expressly prohibited. Please be

aware that the products described in this manual may change

without notice.

Feel free to contact Socket Mobile at:

Socket Mobile, Inc.

39700 Eureka Drive

Newark, CA 94560-4808

USA

Other than the above, Socket Mobile can assume no

responsibility for anything resulting from the application of

information contained in this manual.

Please refrain from any applications of the CF RFID Reader Card

or CF RFID Reader-Scan Card that are not described in this

manual. Please refrain from disassembling the device.

Disassembly of this device will void the product warranty.

You can track new product releases, software updates and

technical bulletins by visiting the Socket Mobile website at:

www.socketmobile.com.

Page 3

Table of Contents

1 | INTRODUCTION 4

About the Software 4

Package Contents 5

System Compatibility Requirements 5

Accessories 5

Product Registration 6

2 | SETUP FOR WINDOWS MOBILE 7

STEP 1: Uninstall Other Scanning Software 8

STEP 2: Install the Software 9

STEP 3: Assign Trigger Button(s) 11

STEP 4: Start SocketScan 13

STEP 5: Insert the Card 14

STEP 6: Verify Card Mode 15

STEP 7: Open Application 15

STEP 8: Read Data 16

RFID Settings 19

Symbology Selector 22

SocketScan Trigger 23

Dual Device Support 25

3 | RFID DEMO 26

Read an RFID Tag 27

Enable Inventory and Loop Modes 29

Select Tag Type 30

ADVANCED: Write to Tag 31

APPENDICES

A PRODUCT SPECIFICATIONS 34

B HF RFID STANDARDS AND TAG DESCRIPTIONS 36

C BAR CODE LABEL SPECIFICATIONS 45

D CLASS 1 VS. CLASS 2 LASER SCANNERS 46

E ENABLING OR DISABLING SYMBOLOGIES 49

F LASER DECODE ZONE 51

G TROUBLESHOOTING 53

H TECHNICAL SUPPORT 54

LIMITED WARRANTY 55

REGULATORY COMPLIANCE 57

3

Page 4

1 | Introduction

Now you can add high frequency RFID

read/write capability to your Windows Mobile

based data collection application with the CF

RFID Reader Card Series 6. The series includes

the dual function CF RFID Reader-Card 6M and

6P, which offer both RFID and linear bar code

scanning functionality. All three versions read

and write to all ISO 15693 and many

proprietary 13.56 MHz RFID tags.

The CF RFID Reader Card Series 6 includes three versions:

• CF RFID Reader Card 6E: CompactFlash RFID Reader/Writer

• CF RFID Reader-Scan Card 6M: CompactFlash dual-function

RFID Reader/Writer and Class 1 laser bar code scanner

• CF RFID Reader-Scan Card 6P: CompactFlash dual-function

RFID Reader/Writer and Class 2 laser bar code scanner

The CF RFID Reader Cards feature a sleek designed with no

cables or batteries – they draw minimal power from the Pocket

PC. Plus, the card is designed to withstand repeated three-foot

drops to concrete – even when inserted into the Pocket PC.

About the Software

SocketScan™ software enters the RFID tag ID or bar

coded data directly into any open Windows

program, as if the data were manually typed. You

can configure various settings, like Prefix/Suffix,

symbologies, etc.

The RFID Setup utility allows you configure what kinds

of data are returned after reading RFID tags, including

tag ID, tag memory, tag types, tag type prefix, etc.

Socket RFID Demo allows you to read memory blocks

of selected RFID tags in range in either Inventory

4

Page 5

Mode or a continuous Loop Mode. Advanced users

can write data to the RFID memory.

SocketScan Trigger places a software trigger on your

screen that you can tap to trigger the RFID reader or

bar code scanner. Installation is optional.

The Socket Trigger Select program allows you to

press a button to quickly switch between the RFID

and laser scanning modes of the CF RFID ReaderScan Card.

The Read Bar Code program allows you to assign a

button on your device to triggering the bar code

laser scanner.

The Read RFID program allows you to assign a

button on your device to trigger the RFID reader.

For software updates, visit: www.socketmobile.com/support/downloads

Package Contents

• CF RFID Reader Card

• Extra rubber collar for use with non SoMo devices

• SocketScan Installation CD

• Booklet with copyright and warranty information

System Compatibility Requirements

• Any of the following Windows Mobile versions:

− Windows Mobile 2003, 2003SE or 5.0 for Pocket PC

− Windows Mobile 6.0/6.1 Classic

• Available CompactFlash slot

• Software installation requires a host PC with the appropriate

synchronization software (ActiveSync or Windows Mobile

Device Center), both available from the Microsoft website

Accessories

If you plan to use the CF RFID Reader Card with the Socket SoMo

650 handheld computer, Socket offers a FlexGuard silicone cover

that protects both the RFID reader and the handheld computer.

For more information, please visit:

www.socketmobile.com/products/accessories

CHAPTER 1: INTRODUCTION 5

Page 6

Product Registration

Socket highly recommends that all customers register their

products. Registered users receive priority for technical support

and can choose to receive product updates, and special offers.

Register online at: www.socketmobile.com/support/support/new

.

6

Page 7

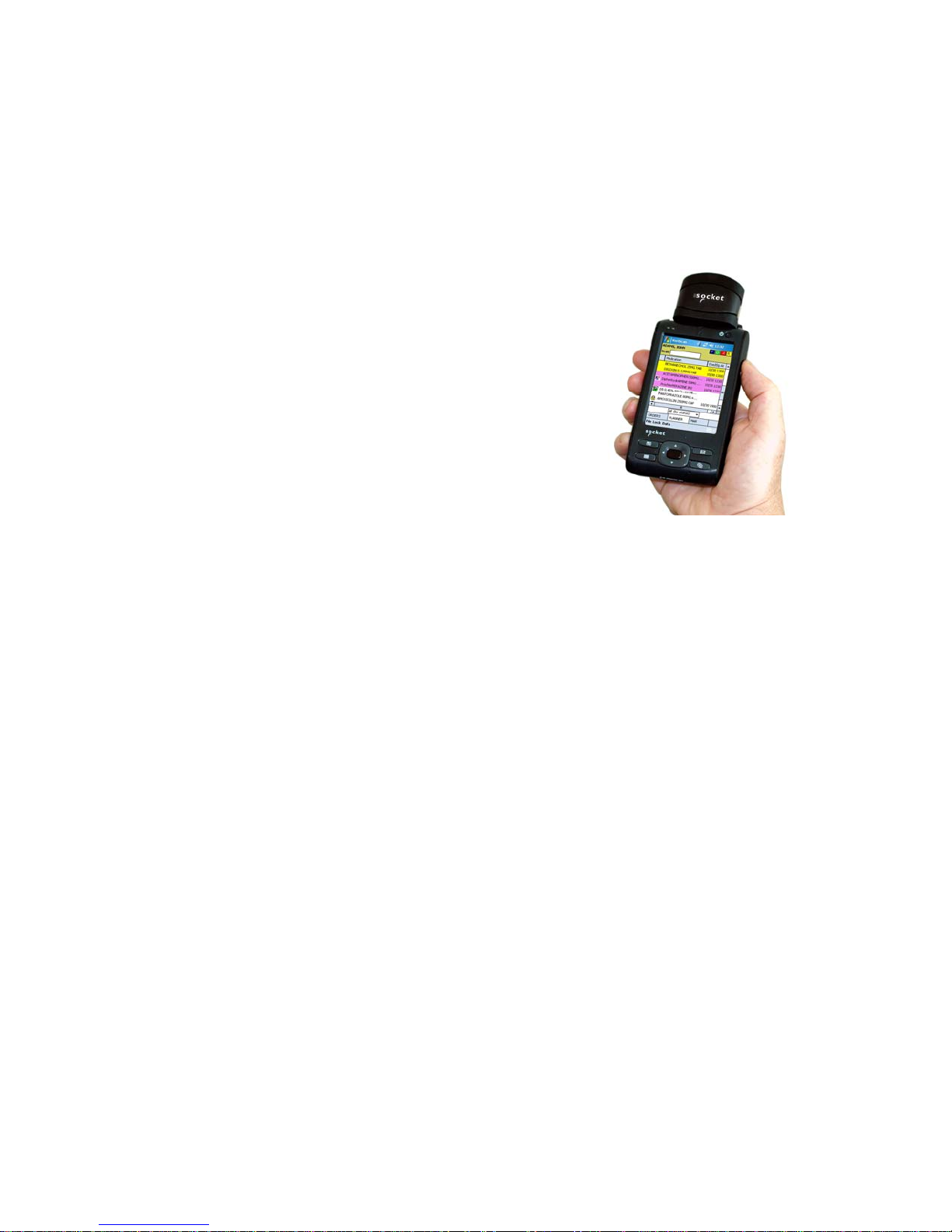

2 | Setup for Windows Mobile

This chapter shows how to install, configure, and

use the CF RFID Reader Card Series 6 on a device

running Windows Mobile.

Setup Summary

STEP 1: Uninstall other scanning software.

STEP 2: Install the software.

STEP 3: Insert the card.

STEP 4: Start SocketScan.

STEP 5: Assign a trigger button.

STEP 6: Read tag IDs into a Windows program.

Application Features

RFID settings

Symbology selector

SocketScan Trigger.

Version information.

Note: The Socket SoMo 650 handheld computer comes preloaded with the SocketScan software suite, so steps 1 and 2 are

not required. The SocketScan software pre-loaded on the SoMo

650 cannot be uninstalled but can be upgraded.

CHAPTER 2: SETUP FOR WINDOWS MOBILE 7

Page 8

STEP 1: Uninstall Other Scanning Software

Uninstall any bar code scanning software already in your

computer, including previous versions of SocketScan™ software.

SoMo 650: The pre-installed SocketScan software cannot be

uninstalled, but it can be upgraded.

1. Make sure the software is not running.

2. Tap Start | Settings | System tab | Remove Programs.

3. Use the utility to delete the software.

8

Page 9

STEP 2: Install the Software

ADVANCED USERS: Refer to the README file for CAB file

installation instructions..

Note: If you are using the SoMo 650, software installation is not

necessary. SocketScan is pre-loaded on the device.

Follow these instructions to install SocketScan. Afterwards, you

can use the same process to install RFID Demo and/or Floating

Trigger.

4. Use a serial/USB cable or cradle and the appropriate Microsoft

synchronization software to make an active connection

between your device and a host PC.

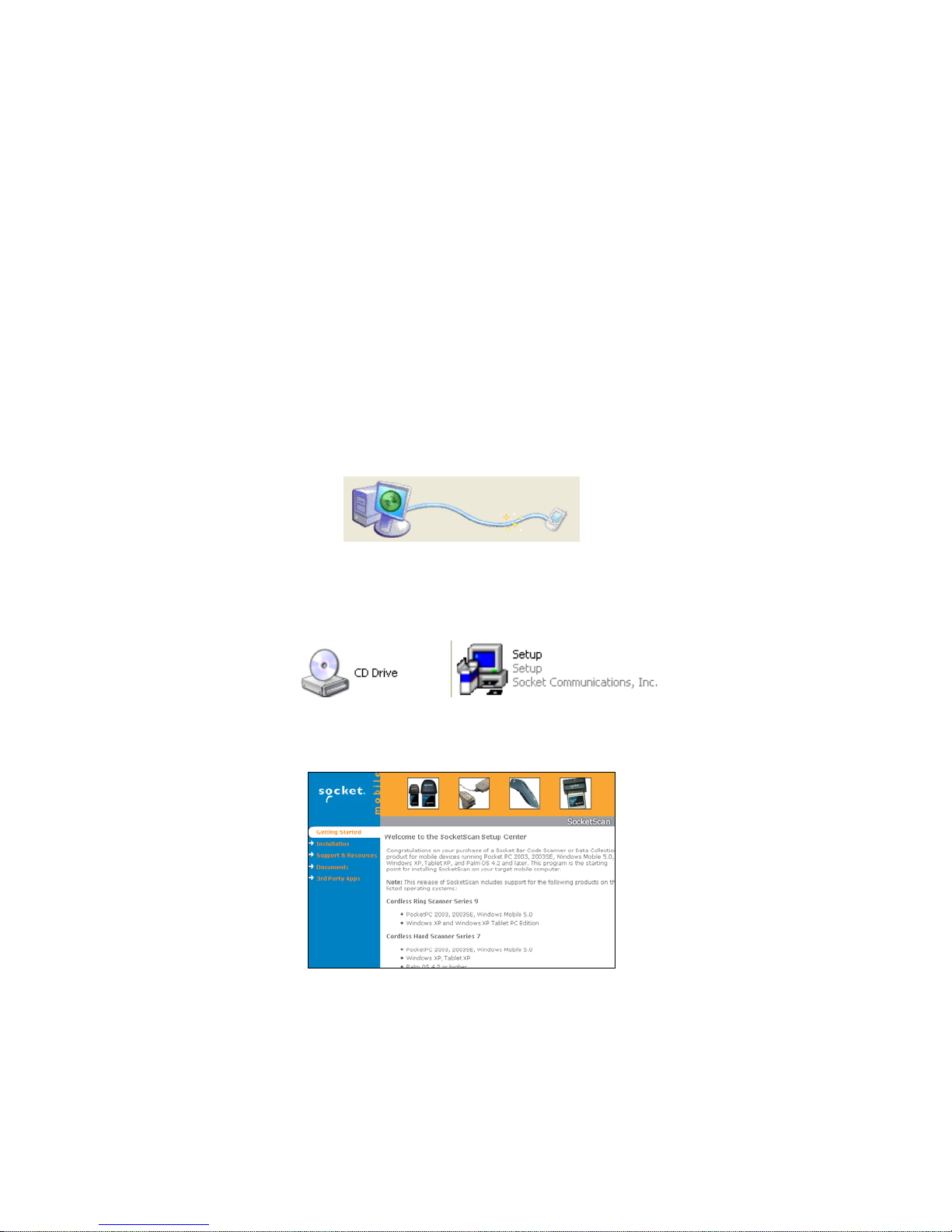

5. Insert the installation CD into your host PC.

6. Use My Computer or Windows Explorer to access your CD-

ROM drive. In the CD, click on SETUP.EXE.

7. The SocketScan Setup Center will appear in your web browser.

Read the first page and click Installation in the left margin.

8. In the SocketScan Installation page, in the Windows CE

section, click Install In the first paragraph.

CHAPTER 2: SETUP FOR WINDOWS MOBILE 9

Page 10

9. Your web browser will present a series of dialogs.

Internet Explorer:

• In the File Download –Security Warning dialog, click Run.

• In the second warning dialog, click Run.

• Internet Explorer will download the file.

Firefox:

• In the file opening dialog, click Save File.

• Firefox will download the file.

• In the Downloads list, next to SocketScanCE.exe, click Open.

• In the warning dialog, click OK to continue.

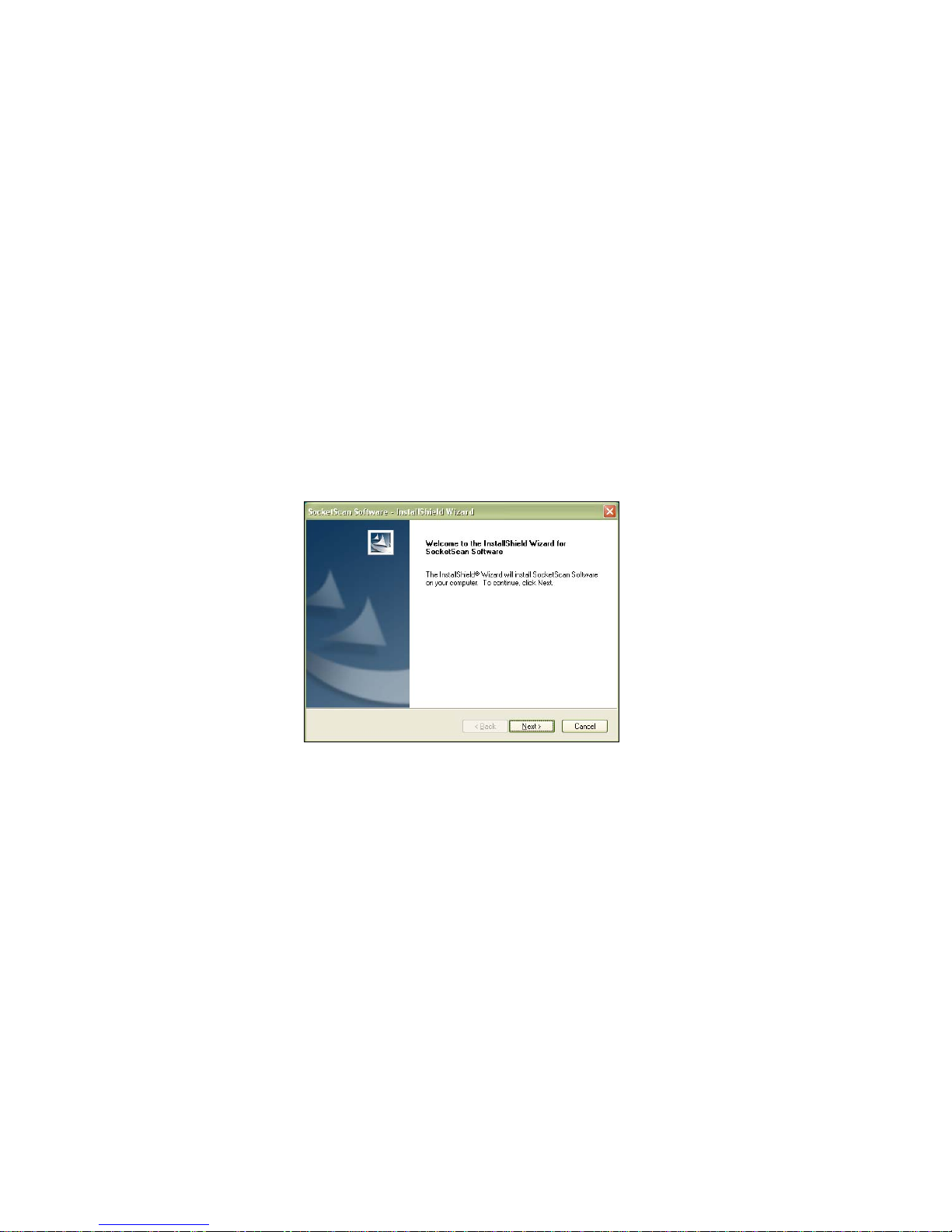

10. The InstallShield Wizard for SocketScan Software will

automatically launch. Follow the wizard to install the software.

11. If your device warns that the software comes from an

unknown publisher, tap Yes to continue installation.

12. When software installation is complete, remove the device

from the cradle. Soft reset the device by pressing the reset

button.

Note: After software installation, several new icons will appear in

the Programs screen.

10

Page 11

STEP 3: Assign Trigger Button(s)

You must set up a mechanism for triggering the CF RFID Reader

Card. Hardware button(s) are the best triggering method from a

handheld device.

If you have the CF RFID Reader-Scan Card 6M/6P, SocketScan allows

you to configure up to four buttons for launching SocketScan

and/or triggering the RFID reader or bar code scanner.

Please refer to the chart below to determine which SocketScan

functions you would like to assign to buttons on your device.

Program

What happens when you press a button assigned

to this program?

If SocketScan is not open, SocketScan will launch.

If SocketScan is open and you have the CF RFID Reader Card

6E, the RFID reader will activate.

If SocketScan is open and you have the CF RFID Reader-Scan

Card 6M/6P, either the RFID reader or the laser scanner will

activate, depending on which mode the card is in.

If you assign only one hardware button for use with

the CF RFID Reader Card, this is the program that

should be assigned.

If you do not assign a button to SocketScan, you can only

start SocketScan by manually tapping through menus.

If you are using the CF RFID Reader-Scan Card 6M/6P, this

program will switch the device from RFID mode to bar code

scanning mode, or vice versa. This is designed to be used

with a trigger button assigned to SocketScan. You can also

use Socket Trigger Select to toggle to other Socket Mobile

bar code scanners that use a software trigger.

The laser bar code scanner will activate. SocketScan must be

running.

The RFID reader will activate. SocketScan must be running.

CHAPTER 2: SETUP FOR WINDOWS MOBILE 11

Page 12

If you do not want to assign a hardware button, you can install

and use SocketScan Trigger software from the installation CD,

which enables you to tap on a software icon to trigger

SocketScan and the RFID reader/bar code scanner.

Refer to your device manual for specific instructions.

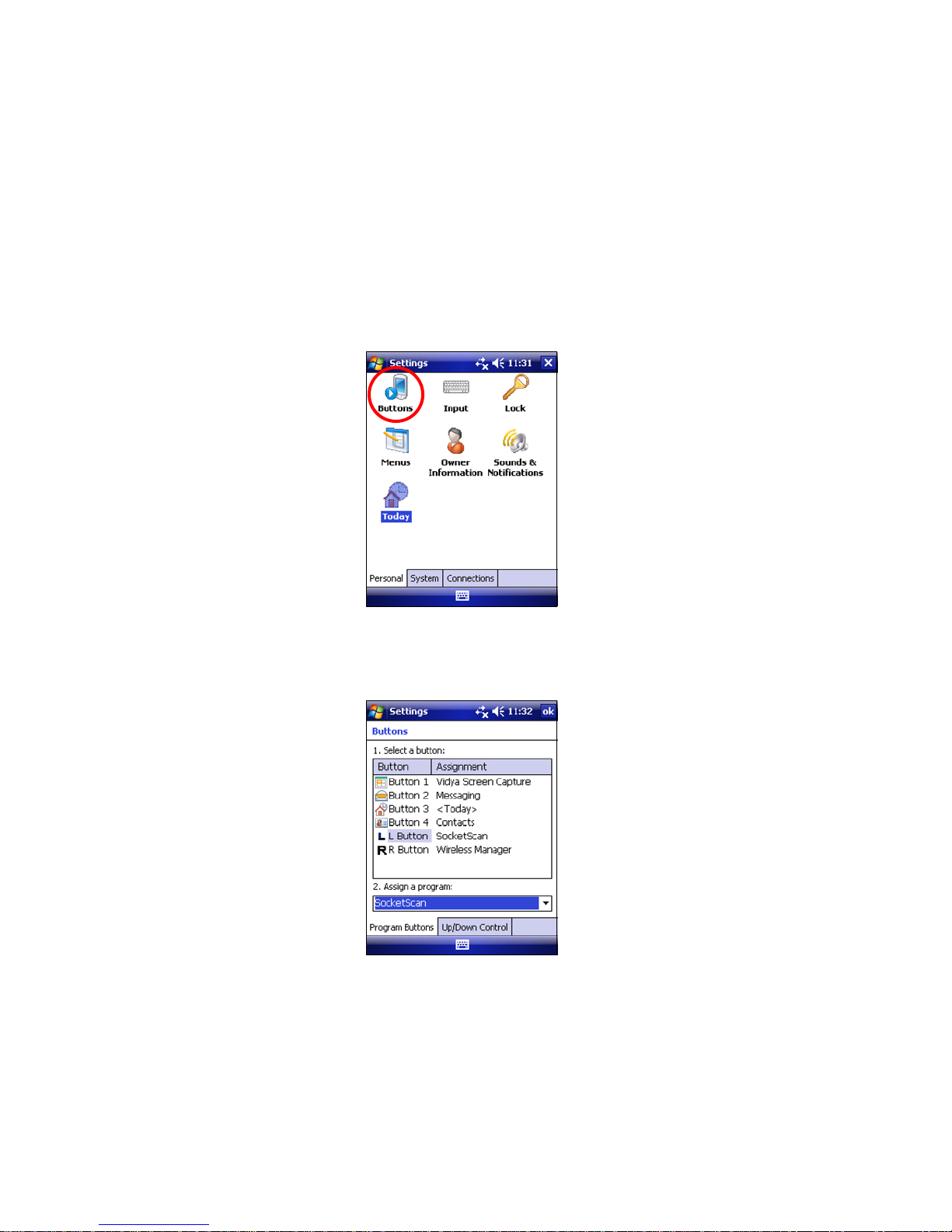

1. Tap Start | Settings | Personal | Buttons.

2. In the Button list, select a button. In the drop-down menu,

select the program. If desired, repeat to assign additional

trigger buttons. When done, tap ok.

Note: For best ergonomics, choose a button located beneath

your thumb or forefinger when you hold the device. For the

Socket SoMo 650, the left and right buttons are ideal.

12

Page 13

STEP 4: Start SocketScan

1. If you assigned a hardware button to SocketScan,

you can press the button to quickly launch the

program. Otherwise, tap Start | Programs |

SocketScan folder | SocketScan.

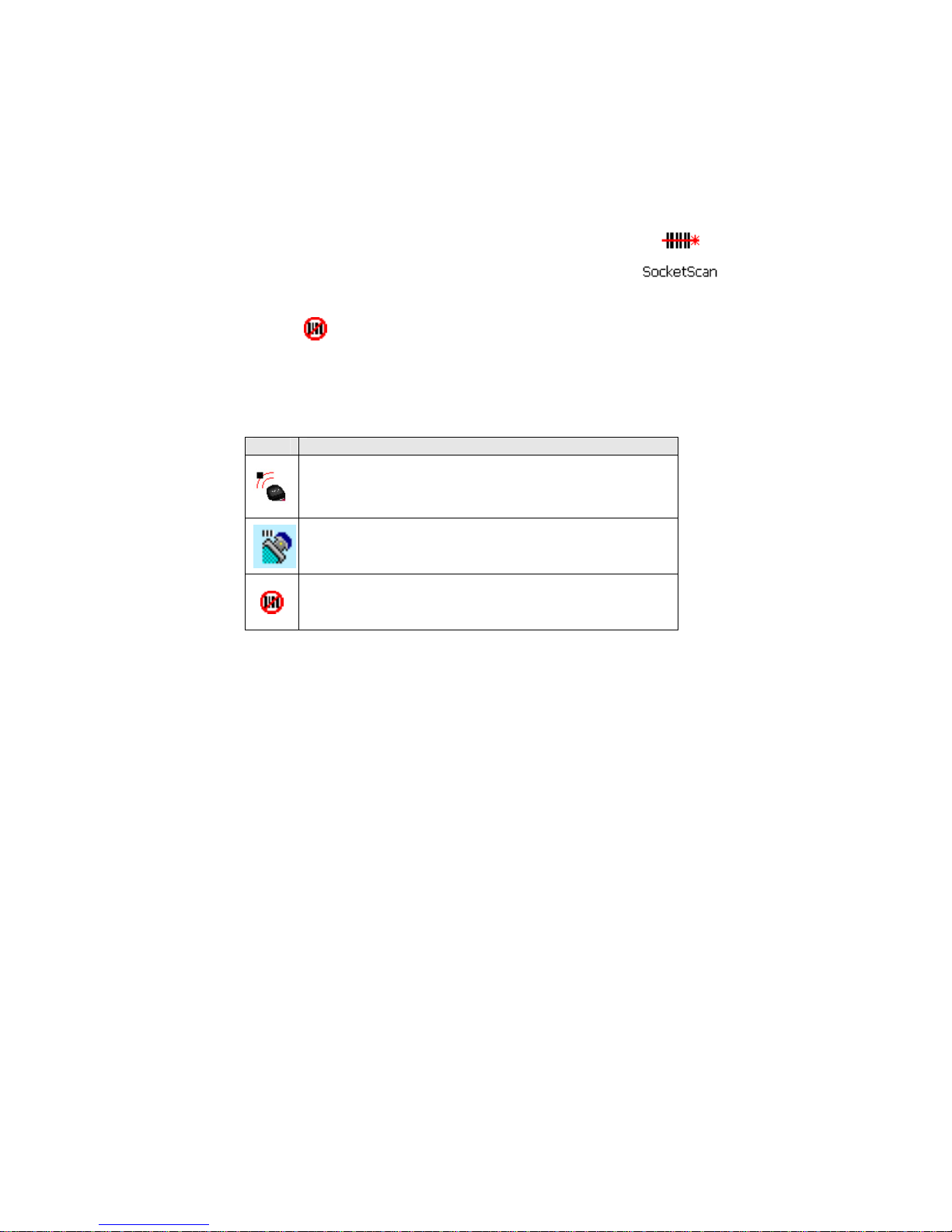

2. An icon

will appear in the task tray of the Today screen

indicating that the system does not detect the RFID reader.

When SocketScan is running, any of the following icons will

appear in the task tray of the Today screen:

Icon Meaning.

Card detected, RFID mode. SocketScan detects the

reader-scan card and is ready to read RFID tags.

Card detected, scanning mode. SocketScan detects the

reader-scan card and is ready to read bar codes.

No RFID Reader Card detected. The reader card is

either missing or improperly inserted.

CHAPTER 2: SETUP FOR WINDOWS MOBILE 13

Page 14

STEP 5: Insert the Card

1. If your device has a cover protecting the CompactFlash slot,

open the cover.

2. Insert the card into the CompactFlash slot of your device.

Make sure the card is right-side up, with the blue label on top.

Push the card all the way into the slot.

14

Page 15

STEP 6: Verify Card Mode

If you are using the dual-function CF RFID Reader-Scan Card

6M/6P, and you did not assign buttons to Trigger ISC or Trigger

RFID, make sure the card is in the correct mode you wish to use.

The SocketScan icon at the bottom of the Today screen indicates

your current mode.

To switch modes, do either of the following:

• If you assigned a button to Trigger Select, press the button.

• Tap on the SocketScan icon. In the pop-up menu, tap to select

the card mode you want.

STEP 7: Open Application

Start the application that you want to receive the data (e.g.,

Excel, Notepad, etc.). Make sure a document or spreadsheet is

open. Place the cursor where you want to enter data.

Note: If reading RFID tags into Excel Mobile, you may want to

widen the cells to fit the full tag ID, which may exceed 20

characters.

CHAPTER 2: SETUP FOR WINDOWS MOBILE 15

Page 16

STEP 8: Read Data

Please note that the correct positions for RFID reading and

bar code scanning are very different!

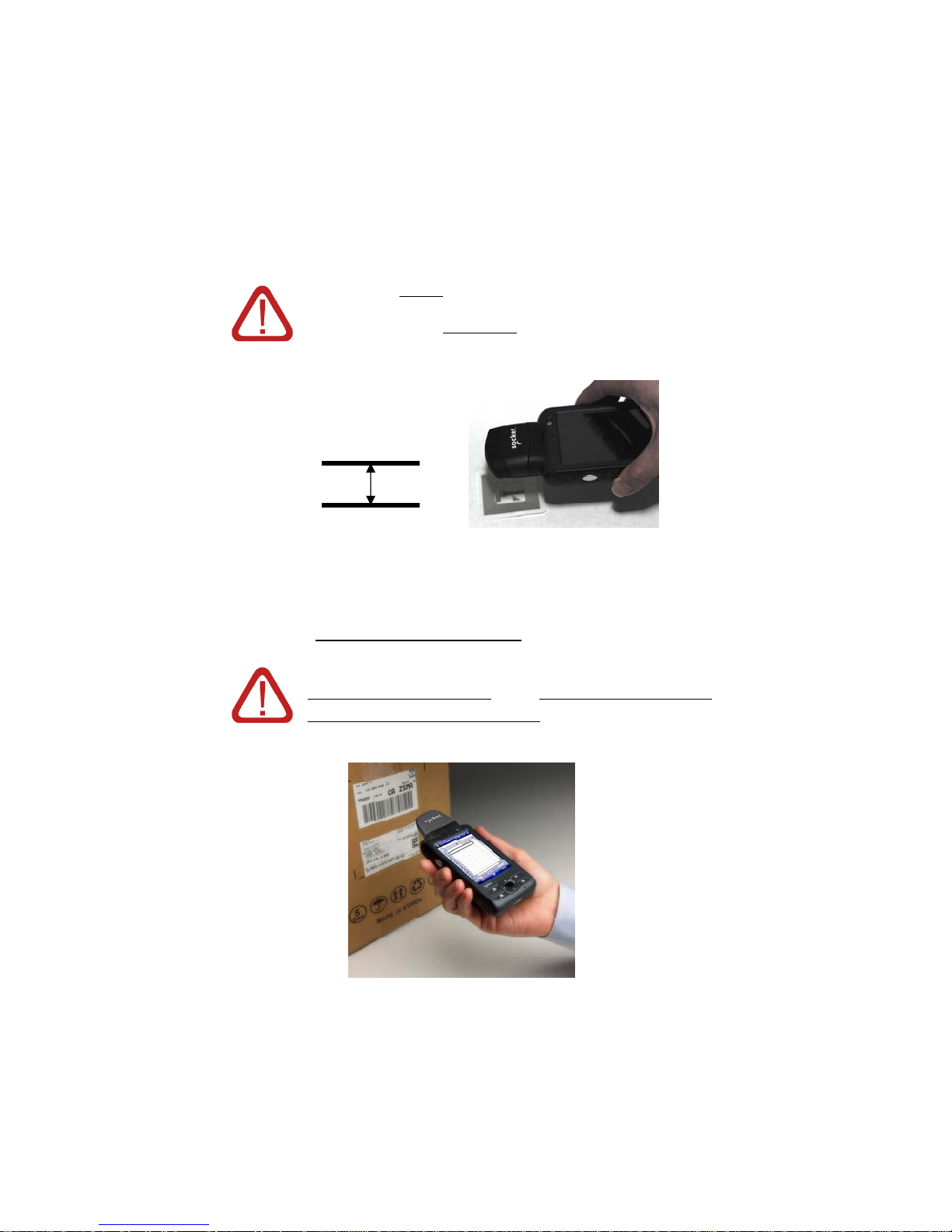

CORRECT RFID POSITION:

Hold the card parallel to and directly above

the tag, at most 3.0 inches above the tag.

Parallel,

3.0 inches (7.6 cm)

maximum

Note: The LED will turn amber to indicate that the card is reading tag

IDs.

CORRECT BAR CODE SCANNING POSITION:

Hold the card so that the lens is angled about

45° to the bar code and at least 2.0 inches

away from the bar code. The red laser line

should cover the entire width of the bar code.

Note: The proper scanning distance and angle vary depending on

the size, type, quality, and print surface of the bar code.

16

Page 17

WRONG RFID POSITION:

DO NOT direct the RFID Reader-Scan Card

at an angle towards the tag.

WRONG RFID POSITION:

DO NOT hold the RFID Reader-ScanCard

perpendicular to the tag.

CHAPTER 2: SETUP FOR WINDOWS MOBILE 17

Page 18

When data is read, a beep should sound indicating a good read,

and data should appear in your application.

For example, in an Excel Mobile spreadsheet, data should appear

in the cell you highlighted. The next cell should now be

highlighted, ready for the next scan/read.

If the card fails to read data within a few seconds, you must

try again.

Note: By default, the RFID reader will return the tag ID. The

RFID Setup utility can be used so that the RFID Reader-Scan

Card returns only the tag data, or the tag ID plus the tag data.

(See the next page for instructions.)

18

Page 19

RFID Settings

Note: These settings are only used with the SocketScan keyboard

wedge programs and Scan Demo.

1. Tap on the SocketScan icon. In the pop-up menu, tap

Settings.

2. In the Prefix/Suffix screen, enter the characters you would like

added to each read/scan of data (128 character maximum).

Note: Only

printable ASCII

characters can be

used as prefixes or

suffixes.

Note:

• The default suffix is a carriage return.

• If in the RFID Setup utility you selected Tag ID & Read Data, the

prefix/suffix is added to both the tag ID and the read data fields.

3. Tap on the Sound tab.

CHAPTER 2: SETUP FOR WINDOWS MOBILE 19

Page 20

4. In the Sound screen, select which sound you would like

SocketScan to make to indicate a good read.

To you want to play a .WAV file, after selecting Play .wav

file, you can search through files by tapping the browse box.

In the Open screen, tap on the file you want:

Note: You can only select a WAV file from the My Documents

folder. If needed, copy the file you need to this folder.

5. After selecting your sound, tap on the RFID tab.

6. In the RFID screen, enter the following settings:

20

Page 21

Trigger mode:

• Tag ID Only: Select to read only the tag ID.

• Read Data Only: Select to read only data from the tag

memory.

• Tag ID & Read Data: Select to read both the tag ID and

tag memory.

Starting block: If you selected a Read Data option, enter

the number of the first block you want to begin reading.

Number of blocks: If you selected a Read Data option,

enter the number of blocks you want to read.

Read error string: Enter the string you want your application

to display in case the RFID reader cannot read the tag data.

Tag type: Select the type of RFID tag you want to read. The

Auto Detect setting enables all tag types to be read.

Choosing a specific tag may result in a longer read range and

faster read.

Inventory mode: Check for the RFID reader to read all tags

present in an RFID field, if supported by the tag type.

Display tag ID prefix: Check to display the RFID tag ID prefix

with each tag ID. The prefix indicates the tag type.

Displayable characters only: Check for the RFID reader to

read only displayable characters while reading data from the

tag memory. Otherwise, the RFID reader will also read “filler”

symbols used in memory blocks that aren’t completely filled

with data. This option is only available if you selected a Read

Data trigger mode.

7. After selecting all of your Prefix/Suffix, Sound and RFID settings, tap ok.

CHAPTER 2: SETUP FOR WINDOWS MOBILE 21

Page 22

Symbology Selector

If you have the dual-function CF RFID Reader-Scan Card 6M/6P,

SocketScan provides an applet that makes it easy to modify which

bar code symbologies the scanner will recognize and attempt to

decode. By default, the scanner is set to recognize several of the

most common symbologies.

1. Tap on the SocketScan icon at the bottom of the Today

screen.

2. In the pop-up menu, tap Symbology Selector. If SocketScan

is currently configured for more than one scanner, then tap

In-Hand Scanner in the submenu that appears.

3. In the screen that appears, use the checkboxes to

enable/disable symbologies. Tap ok.

Note:Enabling all possible symbologies will make the decode

process slightly longer.

22

Page 23

SocketScan Trigger

If you find it inconvenient or impossible to assign or use a

hardware button to trigger the reader, you can install this virtual

trigger button that “floats” on top of the active application.

1. Make sure to do all of the following before using SocketScan

Trigger:

• Install SocketScan Trigger from the installation CD. The

software must be installed separately from SocketScan.

• Start SocketScan. Tap Start | Programs | SocketScan.

• Insert the CF RFID Reader Card into your device.

• Open the application that you want to receive data.

2. Start SocketScan Trigger. Tap Start | Programs | SocketScan

Trigger.

3. The floating trigger button will appear on your screen on top

of the active application.

Drag from the title bar to move the trigger button to a

convenient place on the screen.

Tap the trigger button to activate the RFID reader/bar code

scanner.

CHAPTER 2: SETUP FOR WINDOWS MOBILE 23

Page 24

4. A SocketScan Trigger icon will also appear in the menu bar of

the Today screen. Tap on this icon to reveal a pop-up menu

with the following options:

• Tap Scan Now to activate the scanner as if you had

tapped the trigger button.

• Tap Remove Floating Trigger to remove the trigger

button from the screen but keep the icon handy on the

task bar. To restore the trigger button, tap on the menu

bar icon. In the pop-up menu, tap Launch Floating

Trigger.

• Tap About to view SocketScan Trigger version

information.

• Tap Close SocketScan Trigger to close the application

completely. From this state, the SocketScan trigger can

only be launched from the Programs page.

24

Page 25

DUAL DEVICE SUPPORT

SocketScan for Windows Mobile versions 7.2.4.0 and later

support the simultaneous use of two Socket data collection

devices with the same computer.

Note: SocketScan can capture data from only one cordless

scanner at a time.

Simply connect or plug in each device you plan to use as you

normally would.

The functionality of each device is the same, and no extra

configuration is required.

You can configure each device separately. In the SocketScan

menu, tap on the appropriate device to configure its settings.

CHAPTER 2: SETUP FOR WINDOWS MOBILE 25

Page 26

3 | RFID Demo

This chapter explains how to use the Socket

Mobile RFID Demo application with the CF RFID

Reader-Scan Card to perform the following:

• Read an RFID Tag.

• Enable Loop Mode.

• Select Tag Type.

• Advanced – Write to Tag.

Before you begin using the Socket Mobile RFID Demo

application, make sure you have done the following:

• Installed the RFID Demo application onto your device,

following the same software installation procedure described

in Chapter 2.

• Inserted the CF RFID Reader Card into your device.

• When you use this application, you should only trigger the

RFID Reader Card by tapping on the Select Tags or Read Tag

button on the RFID Demo screen.

26

Page 27

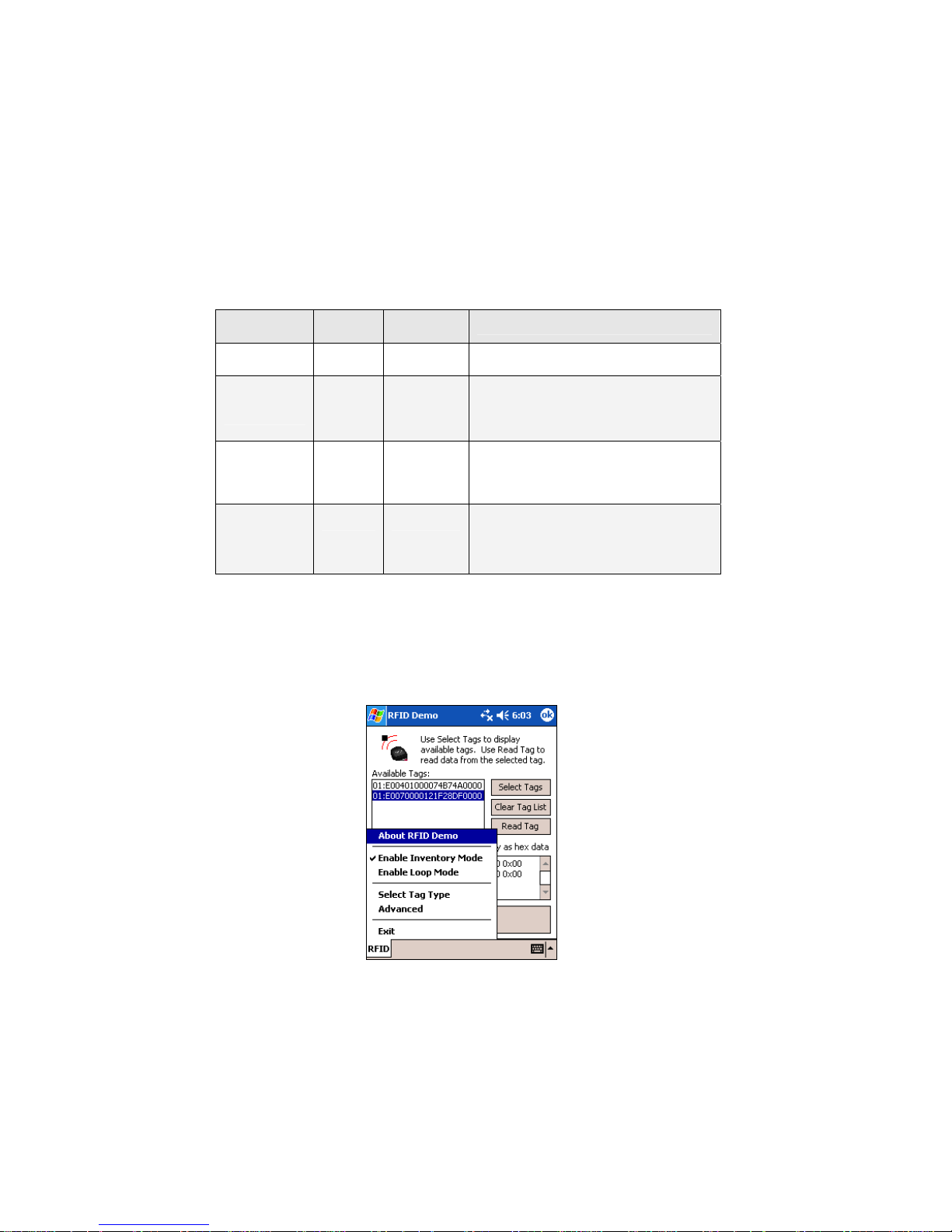

Read an RFID Tag

1. Start RFID Demo. Tap Start | Programs | RFID Demo.

2. The main screen of RFID Demo will appear with blank fields.

3. Hold the device in the correct position to read an RFID tag, as

described in Chapter 2. Hold the device so the CF RFID Reader

Card is parallel

inches above the tag.

to and directly above the tag, at most 2.0

Parallel,

3.0 inches (7.6 cm)

maximum

4. Tap Select Tags.

CHAPTER 3: RFID DEMO 27

Page 28

5. Tag ID(s) should appear in the Available Tags field.

Additionally, the bottom of the screen will report the number

of RFID tags found in range.

6. In the Available Tags field, tap to highlight the RFID tag you

wish to read, then tap Read Tag.

7. After the CF RFID Reader Card reads the tag, Tag Data will

appear. If desired, check Display as hex data to view the

data in hexadecimal format.

28

Page 29

Enable Inventory and Loop Modes

The CF RFID Reader Card has four reading modes, based on

different combinations of inventory mode and loop mode. The

chart below shows the results of enabling or disabling the modes.

Tag Select

Mode

One tag Disabled Disabled Selects the first tag in RF field

Loop

Mode

Inventory

Mode

Description

One tag

continuously

All tags

present

All tags

continuously

Enabled Disabled

Disabled Enabled

Enabled Enabled

Selects the first tag continuously (the

same tag ID will be returned as long

as the tag remains in the RF field.

Inventory mode: returns the tag IDs

of all tags in the RF field and then

reports when there are no more tags.

Returns the tag IDs of all tags in the

RF field. It does not repeat a tag ID

unless the tag goes out and then reenters the RF field.

Note: Not all tag types are readable in Inventory Mode.

1. In the main screen of RFID Demo, tap RFID at the bottom of

the screen. In the pop-up menu, select adjust the Inventory

Mode and/or Loop Mode settings as desired.

2. After selecting the desired settings, tap Select Tags. The CF

RFID Reader Card will search for tags in range, according to

your settings.

CHAPTER 3: RFID DEMO 29

Page 30

Select Tag Type

1. In the main screen of Socket Mobile RFID Demo, tap RFID at

the bottom of the screen. In the pop-up menu, tap Select

Tag Type.

2. In the Select Tag Type dialog box, use the drop-down menu to

select the tag type. Tap ok.

Note:

• Tag selection response time is longer with Auto Detect than

for specific tag types. If Auto Detect is not selected, only the

type of tags selected can be read or written to.

• Auto Detect will search for tag types 01 to 04. Pico Tag (06)

must be selected in order to read tag ID.

30

Page 31

ADVANCED: Write to Tag

1. In the main screen of Socket Mobile RFID Demo, tap RFID at

the bottom of the screen. In the pop-up menu, tap

Advanced.

2. Use the next screen to read and write data in specific blocks of

an RFID tag. Enter the number of the starting block and

number of blocks you would like to read.

3. Hold the Pocket PC in the correct position to read RFID tags —

parallel to the tag and directly above it, at most 2.0 inches

above. Tap Read Tag.

CHAPTER 3: RFID DEMO 31

Page 32

4. RFID Demo will report any data saved to the RFID tag, as well

as the type of tag and number of bytes per block. The bottom

of the screen will report the read status and tag ID.

5. To write data to the tag, enter text into the bottom field. The

type and amount of text that can be written varies depending

on your tag type. After entering text, hold the Pocket PC in

the correct reading/writing position and tap Write Tag.

Note:

• The number of characters in the Write Tag field must

match the number of bytes per block multiplied by the

number of blocks, or an error will occur.

• See Appendix B to find out the type and amount of text

that can be written to your tag.

• The most common cause of write failures is either an

incorrect “start block” or number of blocks.

32

Page 33

6. After writing data to the tag, the bottom of the screen will

report the write status.

7. To verify that the data was written successfully to the tag,

hold the device in the correct reading/writing position, and

tap Read Tag.

8. To close the advanced screen, tap ok.

CHAPTER 3: RFID DEMO 33

Page 34

Appendix A

Product Specifications

Physical Characteristics

CompactFlash Card Size: 1.4 x 1.68 x 0.20 inches (36 x 42.7 x 5.0 mm)

Reader/Scanner Head Size: 1.8 x 1.9 x 0.83 inches (45 x 49 x 21 mm)

Weight:

6E: 1.1 oz. (31 g)

6M/6P: 1.3 oz (37 g)

Environmental:

Operating Temperature: -10 to +50°C (-4 to +122°F)

Storage Temperature: -40 to +70°C (-40 to +158°F)

Humidity: 5-95% RH non-condensing

Ambient Light for Bar Code Scanning (6M/6P only): Sunlight: 10,000 ft candles (107,640 lux)

Artificial light: 450 ft candles (4,844 lux)

Electrical Specifications:

Power Consumption (3.3 V):

6E: Standby: 11mA (36 mW),

Reading/Writing RFID: 52 mA (171 mW)

6M/6P: Standby: 11 mA (36 mW) typical

Scanning bar codes: 72 mA (238 mW) typical

Reading/Writing RFID: 52 mA (171 mW)

Also operates at 5 V

Laser Power

6M: 0.7 mW (±0.1 mW)

6P: 1.7 mW (±0.2 mW)

Compatibility: Windows COM port

Operating System Support:

Windows Mobile 2003, 2003SE, 5.0 for Pocket PC

Windows Mobile 6.0/6.1 Classic

Certification: FCC: Part 15, Class B, CE: EN55024:1998, C-TICK: s.182

RFID Characteristics:

Frequency: 13.56 MHz (HF)

Maximum Read Range: approx 3.0 inches for ISO15693 tags, depending on tag antenna size

34

Page 35

HF RFID Tags Supported

ISO15693: ICode SL1/SL2, LRI512, my-d, Tag-It HF-I

Proprietary: ICode 1, PicoTag, Tag-It HF

ISO14443A, ISO14443B (Tag ID only): Mifare, Mifare Ultralight

Bar Code Scanner Characteristics (6M/6P only):

Bar Code Symbologies Automatically Detected (Default): Code 128, Code 39, Interleaved 2

of 5, UPC/EAN

Additional Bar Code Symbologies Supported (Must Be Enabled): Chinese 2 of 5, Codabar,

Code 11, Code 93, Discrete 2 of 5, MSI, RSS-14/Limited/Expanded

Scan Repetition Rate: 100 scans/sec (bidirectional)

Optical Resolution: 0.004 in. minimum/bar code element width (X Dimension)

Print Contrast: Minimum 25% absolute dark/light reflectance (MRD) measured at 650 MRD

Scan Angle: Wide (default): 47° ±3°, Narrow: 35° ±3°

Decode Zone:

6M: 1.5-20 inches (3.8 to 51 cm)

6P: 1.5 to 45+ inches (3.8 to 144+ cm)

APPENDIX A: PRODUCT SPECIFICATIONS 35

Page 36

Appendix B

HF RFID Standards and Tag Descriptions

ISO15693

The ISO/IEC 15693 standard was developed for “Contactless Vicinity Cards”. Adopted in

1998, ISO15693 has significantly enabled global acceptance of 13.56MHz RFID technology.

Based on contributions by Texas Instruments and Philips, ISO/IEC 15693 is largely a superset

of the features and specifications of the Tag-it HF and I·Code1 products, respectively.

• ISO15693-1: Defines the physical characteristics of a credit card transponder.

• ISO15693-2: Specifies the 13.56MHz air interface and modulation methods that

accommodate regulatory bodies worldwide.

• ISO15693-3: Specifies the command protocol and anti-collision method for data

exchange between tags and readers.

The ISO15693 “standard” permits tags to be manufactured that support optional and

custom commands, and that have custom memory structures, sizes and architectures. The

SkyeRead family of RFID readers fully supports all four (4) IC manufacturers that offer

ISO/IEC 15693 compatible tags.

Tag-It HF-I ISO15693 (Texas Instruments)

The complete Tag-It HF-I specification can be found in the Texas Instruments publication

titled “Tag-It HF-I Transponder Inlays Reference Guide”.

Figure 1 - Memory Structure of the Tag-It HF-I

2K bits (256 bytes) of user memory is available for read/write.

Block #

0 (0x00)

1 (0x01)

2 (0x02)

.

.

.

62 (0x3E)

63 (0x3F)

A 64-bit ID (factory programmed) uniquely identifies each Tag-It HF-I chip.

36

TID 0xE0 0x07 Unique Tag ID - 48 bits (6 bytes)

(4 bytes per block)

.

.

.

32 bits

.

.

.

The user can permanently

.

.

.

lock any block.

.

.

Once a block is locked it

.

can not be unlocked.

Page 37

I·Code SLI ISO15693 (Philips)

The complete I·Code SLI specification can be found in the Philips publication titled “I·Code

SLI Smart Label IC SL2 ICS20 Functional Specification”.

Figure 1 - Memory Structure of the I·Code SLI (version SL2 ICS20)

896 bits (112 bytes) of user memory is available for read/write.

Block #

(4 bytes per block)

0 (0x00)

1 (0x01)

2 (0x02)

.

.

.

26 (0x1A)

27 (0x1B)

.

.

.

32 bits

.

.

.

The user can permanently

.

.

.

lock any block.

.

.

Once a block is locked it can

.

not be unlocked.

A 64-bit ID (factory programmed) uniquely identifies each I·Code SLI chip (SL2 ICS20).

TID 0xE0 0x04 0x01 Unique Tag ID 40 bits (5 bytes)

my-d SRF55VxxP ISO15693 (Infineon)

The complete my-d SRF55VxxP specification can be obtained from Infineon.

Figure 2 - Memory Structure of the my-d SRF55V02P

29 blocks of 8 bytes = 232 bytes (1856 bits) of user memory is available for read/write.

Block #

3 (0x03)

4 (0x04)

(8 bytes per block)

64 bits

The user can

permanently lock

5 (0x05)

.

.

.

30 (0x1E)

31 (0x1F)

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

any block

.

Once a block is

.

locked it can not

be unlocked.

.

A 64-bit ID (factory programmed) uniquely identifies each my-d SRF55V02P chip.

TID 0x60 0x05 0x02 Unique Tag ID - 40 bits (5 bytes)

APPENDIX B: HF RFID STANDARDS AND TAG DESCRIPTIONS 37

Page 38

Figure 4 - Memory Structure of the my-d SRF55V10P

125 blocks of 8 bytes = 1000 bytes (8000 bits) of user memory is available for read/write.

.

.

.

64 bits

.

.

.

The user can

permanently lock

any block

.

.

.

.

.

.

.

.

.

.

Once a block is

.

locked it can not

be unlocked.

.

Block #

3 (0x03)

4 (0x04)

5 (0x05)

.

.

.

126 (0x7E)

127 (0x7F)

(8 bytes per block)

.

.

.

.

.

.

A 64-bit ID (factory programmed) uniquely identifies each my-d SRF55V10P chip.

TID

0x60 0x05 0x00 Unique Tag ID - 40 bits (5 bytes)

LRI512 ISO15693 (ST Microelectronics)

The full LRI512 specification was included in “LRI512 Memory TAG IC 512 bit High

Endurance EEPROM 13.56MHz, ISO 15693 Standard Compliant with E.A.S.” by ST

Microelectronics.

Figure 5 - Memory Structure of the STM LRI512

512 bits (64 bytes) of user memory is available for read/write.

Block #

(4 bytes per block)

3 (0x03)

4 (0x04)

5 (0x05)

.

.

.

14 (0x0E)

15 (0x0F)

.

.

.

32 bits

.

.

.

The user can permanently lock any

.

.

.

.

block.

.

.

Once a block is locked it can not

be unlocked.

A 64-bit ID (factory programmed) uniquely identifies each STM LRI512 chip.

TID 0xE0 0x02 Unique Tag ID 48 bits (6 bytes)

38

Page 39

Tag-it HF

The first 13.56MHz RFID IC that Texas Instruments developed was the Tag-it HF. Still in high

volume production, Tag-it HF is widely used in applications globally and has an existing

installed base of millions of tags. The Tag-it HF uses a protocol air interface that is

proprietary to Texas Instruments.

By contrast, the Tag-it HF-I was released by Texas Instruments in 2001 is compatible with

ISO/IEC 15693 parts -2 and -3. The host application developer should be aware of the

distinction between the Tag-it HF and the Tag-it HF-I.

Figure 6 - Memory Structure of the Tag-it HF

256 bits (32 bytes) of user memory is available for read/write.

Block #

(4 bytes per block)

0 (0x00)

1 (0x01)

2 (0x02)

.

.

.

6 (0x06)

7 (0x07)

.

.

.

A 32-bit ID (factory programmed) uniquely identifies each Tag-it HF chip.

TID Unique Tag ID 32 bits (4 bytes)

The complete Tag-it HF specification can be obtained from Texas Instruments.

32 bits

.

.

.

The user can permanently lock any

.

.

.

.

block.

.

.

Once a block is locked it can not be

unlocked.

APPENDIX B: HF RFID STANDARDS AND TAG DESCRIPTIONS 39

Page 40

I·Code1

The first long range 13.56MHz RFID IC that Philips released was the I·Code1 (SL1). Still in

high volume production, I·Code1 (SL1) is still widely used in applications globally and has an

existing installed base of millions of tags. The I·Code1 (SL1) uses a protocol and air interface

that is proprietary to Philips.

By contrast, the I·Code SLI (SL2), released by Philips in 2002, is fully compatible with ISO/IEC

15693 parts -2 and -3. The host application developer should be explicitly aware of the

distinction between the I·Code1 (SL1) and the I·Code SLI (SL2).

Figure 7 - Memory Structure of the I·Code1 (version SL1 ICS30 01)

512 bits (64 bytes) of user memory is available for read/write.

Block #

(4 bytes per block)

3 (0x03)

4 (0x04)

5 (0x05)

.

.

.

14 (0x0E)

15 (0x0F)

.

.

.

A 64-bit ID (factory programmed) uniquely identifies each I·Code1 chip.

TID Unique Tag ID 64 bits (8 bytes)

32 bits

.

.

.

The user can permanently lock

.

.

.

.

any block.

.

.

Once a block is locked it cannot

be unlocked.

40

Page 41

PicoTag

Inside Contactless (formerly Inside Technologies) makes a contactless RFID product series

called the PicoTag. There are two different sizes of PicoTag memories, 2K and 16K. There

are two different modes of operation, plain and secure.

Figure 8 - Memory Structure of the PicoTag 2K

29 blocks of 8 bytes = 232 bytes (1856 bits) of user memory is available for read/write.

.

.

.

64 bits

.

.

.

The user can

permanently

lock any block

.

.

.

.

.

.

.

.

.

.

Once a block is

.

locked it can not

be unlocked.

.

Block #

3 (0x03)

4 (0x04)

5 (0x05)

.

.

.

30 (0x1E)

(8 bytes per block)

.

.

.

.

.

.

31 (0x1F)

A 64-bit ID (factory programmed) uniquely identifies each PicoTag chip.

TID Unique Tag ID 64 bits (8 bytes)

Note: Only the tag ID can be read by the CF RFID Reader-Scan Card.

APPENDIX B: HF RFID STANDARDS AND TAG DESCRIPTIONS 41

Page 42

ISO14443

ISO/IEC 14443 is a 4-part RFID standard for short-range “Contactless Proximity Cards”.

Adopted in 1999 and 2000, ISO14443 has become the worldwide standard for cashless

payment and contactless stored value applications.

• ISO14443-1 defines the physical characteristics of an RFID card.

• ISO14443-2 specifies two types (A and B) of 13.56MHz air interface and modulation

methods used for communication between tags and readers.

• ISO14443-3 specifies the anti-collision method for selecting one tag among many.

• ISO14443-4 defines the high-level protocol and method for data exchange between tags

and readers.

14443-A Mifare Standard 4K (Philips)

The Mifare chip from Philips is used in millions of secure contactless applications since it was

introduced in 1995.

Figure 9 - Memory Structure of the Mifare Standard 4K (MF1 IC S70)

BLOCK SECTOR

0 Serial Number

1

2

3

4

5

6

7

.

.

.

60

61

62

63

The complete Mifare specification can be obtained from the Philips publication “Mifare

Standard 4 kByte Card IC MF1 IC S70” dated October 2002.

Note: Only the tag serial number can be read by the CF RFID Reader Card.

0

1

.

.

.

15

15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

Check

Byte

Key A Lock Bits Key B

Key A Lock Bits Key B

Key A Lock Bits Key B

BYTE

Manufacturer Data

Data

Data

Data

Data

Data

.

.

.

Data

Data

Data

42

Page 43

Mifare Ultralight (Philips)

The complete Mifare Ultralight specification can be obtained from the Philips publication

“Mifare Ultralight Contactless Single-trip Ticket IC MF0 IC U1 Functional Specification”

dated March 2003.

Figure 10 - Memory Structure of the Mifare Ultralight (MF0 IC U1)

Byte

Block

00 01 02 03

0 SN0 SN1 SN2 BCC0

1 SN3 SN4 SN5 SN6

2 BCC1 Internal Lock 0 Lock 1

3 OTP 0 OTP 1 OTP 2 OTP 3

4 Data 0 Data 1 Data 2 Data 3

.

.

.

.

.

.

15 Data 44 Data 45 Data 46 Data 47

System Area

User Area

Note: Only the tag serial number can be read by the CF RFID Reader Card.

APPENDIX B: HF RFID STANDARDS AND TAG DESCRIPTIONS 43

Page 44

LTO CM 14443-A (LTO) The LTO-CM is compliant with ISO14443-A air

interface.

Figure 12 - Memory Structure of the LTO CM

128 blocks of 32 bytes = 4096 bytes (32768 bits) of user memory is available for read/write.

Note: Only the tag serial number can be read by the CF RFID Reader-Scan Card.

44

Page 45

Appendix C

Bar Code Label Specifications

All bar code symbols/labels should satisfy the appropriate AIM Uniform Symbology

Specification.

Background Substrate:

The bar code symbol should be printed on material (media) that is reflective and has a matte

(not glossy) finish. A background diffuse reflectance of at least 70% to 80% is desirable for

optimum contrast. Retro-reflective media should be used to obtain decode distances greater

than 36 inches.

Ink Color and Type:

The inked bars should not exceed 25% reflectance at the wavelength that is being used for

reading, whether printed with black ink or colored ink. The reflectance value should not

vary more than 5% within the same character.

Voids and Specks:

The code should be printed clearly, free of voids, specks, blemishes and lines that could

“fool” the scanner. Specks or blemishes in the white spaces, or false or missing bar sections

could be interpreted by the reading equipment as part of the code. Generally, the width of

such flaws is more serious than the height. Code symbols/ labels should be rejected if these

defects are present.

Definition:

The bars in the bar code symbol should be well defined. Their edges should not be rough or

fuzzy, so that the bars and spaces have the proper widths intended for the bar code

symbology used.

Contrast:

Background reflectance (that of the substrate on which the codes are printed) should always

provide a good contrast relative to the ink reflectance (that of the code bars). The difference

between the two should be at least 37.5% at the wavelength used for reading.

Tolerance:

The ratio of the widths of bars and spaces in a bar code symbol must conform to the

appropriate AIM bar code specifications and can cause problems if not correct throughout

the bar code. Problems can occur when bar edges are smeared or rough, or when they

exhibit voids.

APPENDIX B: BAR CODE LABEL SPECIFICATIONS | 45

Page 46

Appendix D

Class 1 vs. Class 2 Laser Scanners

Socket Mobile offers the popular CF RFID Reader-Scan Card with either a Class 1 or Class 2

laser engine. This document describes the differences between the Class 1 and Class 2

devices and the appropriate applications for each.

The primary difference is the power output of the laser. The Class 1 laser has a nominal

power output of 0.5 milliwatts, while the output of the Class 2 laser is 1.2 milliwatts. This

difference impacts the scanning performance of the device in three ways:

Distance

For scanning distances of up to 10 inches, there is very little difference in the ability of

either the Class 1 or the Class 2 laser to scan a given bar code. Beyond 10 inches, the Class 2

laser will scan a standard, high quality bar code about 20% - 25% farther than the Class 1

laser.

Scanning a standard bar code of any size at a distance greater than 25 inches becomes

difficult with the Class 1 laser, while the Class 2 laser will easily scan very large bar codes at

60 inches and beyond. There are a many variables involved in determining the distance at

which a bar code can be scanned, including:

The size of the bar code

‘mils’) is referred to as the “X dimension” or “size” of a bar code. Standard retail UPC or

EAN bar codes are 10 mils (0.010 inches). Larger bar codes, such as warehouse location bar

codes, can be 200 mils or larger. The larger a bar code, the greater the distance from which

it can be scanned.

Please refer to the Decode Zone charts in Appendix F for more detailed information on the

relationship between the size of a bar code and the distance at which it can be scanned.

The label media

type of paper but can also be a plastic or even metallic material. Because the reading

mechanism in a bar code scanner is based on contrast, the whiter and more reflecting a

media is, the farther away it can be scanned. Retro-reflective media (like a stop sign) is used

for scanning very large bar code labels at distances of 20 feet and more.

The bar code symbology

such as UPC, EAN, Code 39, Code 128, Code 93 and more. Some symbologies are easier to

decode than others and can, therefore, be scanned at greater distances.

— The media is the material a bar code is printed on. This is usually some

— The width of the narrowest bar in thousandths of an inch (or

— There are many different bar code symbologies (or ‘languages’),

46 | APPENDIX D: CLASS 1 VS. CLASS 2 LASER SCANNERS

Page 47

Packaging or covering materials

The Class 2 laser can more effectively scan through difficult packaging materials such as

Mylar (used for electronic components) or thick plastic or glass such as automobile

windshields.

Ambient Light

The Class 2 laser can more effectively scan in high ambient light conditions such as high

intensity lighting or even daylight (indirect sunlight). Scanning bar codes in direct sunlight

is extremely difficult because sunlight contains enough energy in the red spectrum used by

the laser to ‘blind’ the scanner’s decode system.

The second difference between the Class 1 and Class 2 lasers in the CF RFID Reader-Scan

Card is the wavelength frequency

of the laser beam. The Class 1 laser has a 670 nanometer

(nm) beam common in most laser bar code scanners, while the Class 2 features a 650 nm

beam. There is no difference in the scanning capability of the two frequencies, but the 650

nm beam is more visible to the human eye, making it appear brighter than the Class 1 laser.

The user must see the oscillating laser beam in order to aim it effectively at the bar code to

be scanned. The Class 2, 650 nm laser is easier to see and aim than the Class 1 laser,

especially when scanning at greater distances, through difficult materials or in high ambient

light.

A third difference between the Class 1 and Class 2 lasers is the current demand during

scanning. At 3.3 Volt power (standard for CompactFlash card slots) the Class 1 laser draws

about 67 milliamps (mA) and the Class 2 laser draws about 75 mA. Both lasers draw about 3

– 4 mA when idle. Therefore, for a given level of scanning activity, using the Class 1 laser

should result in a slightly longer battery life.

A final consideration in the selection of either a Class 1 or Class 2 laser is safety. Staring

directly into any laser beam for an extended period of time will cause damage to the eyes

of humans and animals. The normal use of a bar code scanner is inherently very safe

because (a) the laser is typically aimed away from the person using the scanner, and (b) the

beam oscillates 39 times per second over a 53° arc, making it impossible to stare into the

beam. Additionally, using the lower powered Class 1 laser makes it even less likely that eye

damage will occur. There are certain organizations in Europe, in fact, that require a Class 1

laser in bar code scanners to meet more stringent safety standards. The Socket Mobile CF

RFID Reader-Scan Scan Card with Class 1 laser meets these European safety standards.

Please refer to the Regulatory Compliance section at the end of this User’s Guide for more

detailed safety information.

Conclusion

The Class 1 laser is suitable for most applications with expected scanning distances of less

than 20 inches and normal ambient light conditions. The Class 1 laser may be required by

certain European organizations to meet more stringent safety standards. When an

APPENDIX D: CLASS 1 VS. CLASS 2 LASER SCANNERS | 47

Page 48

application is likely to require more demanding scanning capabilities, the Class 2 laser

provides the assurance of maximum scanning performance.

Note: People who use portable computers to gather and manage data at the point of

activity are typically very quick to learn how to use a laser bar code scanner and realize the

resulting gains in productivity. They are easily discouraged, however, if time and effort are

required to obtain a successful scan – thus the decline in popularity of the much less

expensive bar code contact wands seen at most retail checkout counters during the 1980’s.

The higher cost of the Class 2 version of the CF RFID Reader-Scan Card is easily justified if

the application requires higher scanning performance.

48 | APPENDIX D: CLASS 1 VS. CLASS 2 LASER SCANNERS

Page 49

Appendix E

Enabling or Disabling Symbologies

All Socket Mobile bar code scanning products are preset to automatically detect and decode

(autodiscriminate) the most common bar code symbologies. Refer to the table on the next

page to determine which symbologies and parameters are enabled by default. If you would

like to change your symbology settings, you can use either of two methods, depending on

which device you are using and which settings you want to change.

Note: If more symbologies are enabled, the scanner must work harder to search through all

possible combinations. This may make the decoding process slightly longer.

OPTION 1: Symbology Selector

If you are using a Windows Mobile-based device, you can quickly enable and disable any of

the seventeen most popular symbologies by using the SocketScan Symbology Selector. Refer

to Chapter 2 for instructions.

Note: The length of some symbologies will change after Symbology Selector is used. Refer to

the table on the next page.

OPTION 2: Scan Programming Bar Codes

If you want to modify an option not included in Symbology Selector, you can scan

programming bar codes to configure your CF RFID Reader-Scan Card. There are a variety of

programming bar codes available that let you enable/disable symbologies as well as

configure special features (e.g., specify bar code lengths, transmit check digits, recognize

supplementals, etc.).

To obtain the programming bar codes, download the Programming Guide online from

www.socketmobile.com/support/downloads

WARNING!

When scanning programming bar codes with the CF RFID Reader-Scan

Card 6M/6P, do not scan any bar codes that set communication

protocols, or the card will be disabled and must be returned to Socket

Mobile for reprogramming.

.

APPENDIX E: ENABLING/DISABLING SYMBOLOGIES | 49

Page 50

Table 1. Default Symbologies and Settings of the CF RFID Reader-Scan Card

Length with

Symbology Default Length

UPC-A Enabled N/A N/A

UPC-E Enabled N/A N/A

UPC-E1 Disabled N/A N/A

EAN-8 Enabled N/A N/A

EAN-13 Enabled N/A N/A

• Supplementals Disabled N/A N/A

• Transmit Check Digit Enabled N/A N/A

Bookland EAN Disabled N/A N/A

Code 128 - All Enabled Any Any

Code 39 Enabled 2 to 55 2 to 55

Trioptic Code 39 Disabled 2 to 55 2 to 55

Code 39 Full ASCII Disabled 2 to 55 2 to 55

• Transmit Check Digit Disabled N/A

Code 93 Disabled 4 to 55 2 to 55

Interleaved 2 of 5* Enabled 14 Only 2 to 55

• Transmit Check Digit Disabled N/A

Discrete 2 of 5* Disabled 12 Only 2 to 55

Codabar Disabled 5 to 55 2 to 55

MSI Plessey* Disabled 6 to 55 2 to 55

• Transmit Check Digit Disabled N/A

Symbology

Selector

N/A

N/A

N/A

*WARNING: Setting the length to “Any” may lead to inaccurate decodes in these symbologies

50 | APPENDIX E: ENABLING OR DISABLING SYMBOLOGIES

Page 51

Appendix F

Laser Decode Zone

The decode zones for the Class 1 and Class 2 lasers in the CF RFID Reader-Scan Card are

shown below. The minimum element width (“X Dimension” or bar code “size”) is the width

in thousandths of an inch (mils) of the narrowest element (bar or space) in the symbol. The

figures shown are the typical scanning distances (depths of field) for selected bar code sizes.

The maximum usable length of a bar code symbol (Width of Field) at any given range is also

shown below.

Class 1 Laser Decode Zone

APPENDIX F: DECODE ZONE | 51

Page 52

Class 2 Laser Decode Zone

52 | APPENDIX F: DECODE ZONE

Page 53

Appendix G

Troubleshooting

For help on SocketScan on a Windows Mobile-based device, tap Start | Help.

SYMPTOM:

I get the “No Card Detected” icon in the task tray and can’t trigger the

RFID reader or scan any bar codes.

POSSIBLE REASON SOLUTION

Your device does not recognize the card. Make sure the card is inserted properly.

Push it in all the way. If necessary, remove

and reinsert.

SYMPTOM:

When I try to read an RFID tag, no data appears on my screen.

POSSIBLE REASON SOLUTION

You are holding the RFID Reader Card in

the wrong position.

The RFID tag antenna is broken or

incorrectly formatted.

The tag type may be disabled. Use RFID Demo to determine the tag type.

SYMPTOM:

When I press the trigger button, nothing happens.

POSSIBLE REASON SOLUTION

You programmed the trigger button

incorrectly.

Hold the device so the RFID Reader Card is

parallel to and directly above the RFID tag,

at most 2.5 inches above the tag.

Try reading another RFID tag that is

correctly formatted.

If needed, reconfigure the RFID Reader

Card for the correct tag type.

Test the button by assigning a different

program to it and make sure it works

properly.

APPENDIX C: TROUBLESHOOTING | 53

Page 54

Appendix H

Technical Support

If you have trouble installing or using the CF RFID Reader Card, Socket has

different support options to help you.

Online Knowledge Base: Search for articles, Frequently Asked Questions

or Hot Topics any time, day or night. www.socketmobile.com/support

Click on FAQs.

Online Requests: Register your product and submit a question to our

Technical Support Team. www.socketmobile.com/support/support/login.asp

By Phone: Contact our Tier 1 Technical Support by calling either:

• USA & Canada Toll-Free: 800-279-1390

• Direct: +1- 510-933-3020

Please refrain from disassembling the card. Disassembly of this device will void the

product warranty.

54 | APPENDIX D: TECHNICAL SUPPORT

Page 55

Socket Mobile, Inc. warrants this product against defects in material and workmanship, under

normal use and service, for one (1) year from the date of purchase.

EXCLUDES: Consumables such as batteries, removable cables, cases, straps, chargers,

and CF-to-PC Card adapters (90 day coverage only)

Limited Warranty

Incompatibility is not a defect covered by the Socket Mobile warranty. During the warranty

period, Socket Mobile will, at its option, repair or replace the defective product at no charge

when furnished with proof of retail purchase, provided that you deliver the product to Socket

Mobile or to an authorized Socket Mobile Service Center.

The returned product must be accompanied by a return material authorization (RMA) number

issued by Socket Mobile or by an authorized Socket Mobile Service Center. If you ship the

product, you must use the original container or equivalent and you must pay the shipping

charges to Socket. Socket Mobile will pay surface shipping charges back to any location in the

contiguous United States. This warranty applies only to the original retail purchaser and is not

transferable.

Socket Mobile may, at its option, replace or repair the product with new or reconditioned parts

and the returned product becomes the property of Socket Mobile. Socket Mobile warrants the

repaired or replaced products to be free from defects in material or workmanship for ninety (90)

days after the return shipping date, or for the remainder of the original warranty period,

whichever is greater.

This warranty does not cover the replacement of products damaged by abuse, accident, misuse or

misapplication, nor as a result of service or modification other than by Socket Mobile.

SOCKET MOBILE IS NOT RESPONSIBLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES

RESULTING FROM BREACH OF ANY EXPRESS OR IMPLIED WARRANTY, INCLUDING DAMAGE TO

PROPERTY AND, TO THE EXTENT PERMITTED BY LAW, DAMAGES FOR PERSONAL INJURY. THIS

WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES INCLUDING IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

Some states do not allow limitation of implied warranties, or the exclusion or limitation of

incidental or consequential damages, so that the above limitations or exclusions may not apply

to you. This warranty gives you specific legal rights and you may also have other rights which

vary from state to state.

This product may contain fully tested, recycled parts, warranted as if new.

For warranty information, please visit: www.socketmobile.com/support

55

Page 56

Limited Software Warranty

LIMITED WARRANTY. SOCKET MOBILE warrants that the original disk or CD ROM is free from

defects for 90 days from the date of delivery of the SOFTWARE.

CUSTOMER REMEDIES. The entire liability of SOCKET MOBILE and your exclusive remedy shall be,

at the option of SOCKET MOBILE, either (a) return of the price paid or (b) replacement of the

SOFTWARE which does not meet the SOCKET MOBILE Limited Warranty and which is returned to

SOCKET MOBILE with a copy of your receipt. Any replacement SOFTWARE will be warranted for

the remainder of the original warranty period or 30 days, whichever is longer. THESE REMEDIES

ARE NOT AVAILABLE OUTSIDE OF THE UNITED STATES OF AMERICA.

NO OTHER WARRANTIES. SOCKET MOBILE disclaims all other warranties, either express or

implied, including but not limited to implied warranties of merchantability and fitness for a

particular purpose, with respect to the SOFTWARE and the accompanying written materials. This

limited warranty gives you specific legal rights. You may have others which vary from state to

state.

NO LIABILITY FOR CONSEQUENTIAL DAMAGES. In no event shall SOCKET MOBILE or its suppliers

be liable for any damages whatsoever (including, without limitation, damages for loss of

business profits, business interruption, loss of business information, or other pecuniary loss)

arising out of the use of or inability to use the SOFTWARE, even if SOCKET MOBILE has been

advised of the possibility of such damages. Because some states do not allow the exclusion or

limitation of liability for consequential or incidental damages, the above limitation may not

apply to you.

EXPORT LAW ASSURANCES. You may not use or otherwise export or re-export the SOFTWARE

except as authorized by United States law and laws of the jurisdiction in which the SOFTWARE

was obtained. In particular, but without limitation, none of the SOFTWARE may be used or

otherwise exported or re-exported (a) into (or to a national or resident of) a United States

embargoed country or (b) to anyone on the U.S. Treasury Department’s list of Specially

Designated Nationals or the U.S. Department of Commerce’s Table of Denial Orders. By using the

SOFTWARE, you represent and warrant that you are not located in, under control of, or a

national or resident of any such country or on any such list.

GOVERNMENT END USERS. If the SOFTWARE is supplied to the U. S. Government, the SOFTWARE

is classified as “restricted computer software” as defined in clause 52.227-19 of the FAR. The U. S.

Government ‘s rights to the SOFTWARE are as provided in clause 52.227-19 of the FAR.

CONTROLLING LAW AND SEVERABILITY. This License shall be governed by the laws of the United

States and the State of California. If for any reason a court of competent jurisdiction finds any

provision, or portion thereof, to be unenforceable, the remainder of this License shall continue in

full force and effect.

56

Page 57

Regulatory Compliance

This equipment has been tested and found to comply with the limits for a Class B

digital device, pursuant to Part 15 of the FCC rules. This equipment is also CE

EN55024:1998 and C-TICK compliant. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a

commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential

area may cause harmful interference in which case the user will be required to correct

the interference at his or her own expense.

If this equipment does cause harmful interference to radio or television reception,

which can be determined by turning the equipment off and on, the user may try to

correct the interference by doing any of the following:

• Reorient or relocate the receiving antenna of the radio or television.

• Increase the distance separating the equipment and the receiver.

• Connect the equipment to an outlet on a different branch circuit than that of the

receiver.

• Consult the dealer or an experienced radio/TV technician for help.

The user may find the following booklet helpful: How to Identify and Resolve Radio-TV

Interference Problems. This booklet is available from the U.S. Government Printing

Office, Washington, D.C. 20402

LASER DEVICES: Socket bar code scanning product(s) described in this User Guide

contain a Symbol SE955 laser scan engine.

For the Class 1 version of this engine, the following applies:

• Complies with 21CFR1040.10 and 1040.11 except for deviations pursuant to Laser

Notice No. 50, dated July 26, 2001. “

• Class 1 Laser devices are not considered to be hazardous when used for their

intended purpose. The following statement is required to comply with US and

international regulations:

Caution: Use of controls, adjustments or performance of procedures other

than those specified herein may result in hazardous laser light exposure.”

57

Page 58

A label such as the one below should appear on the end product.

Example of Class 1 Laser Warning Label

For the Class 2 version of this engine, the following applies:

• Complies with 21CFR1040.10 and 1040.11 except for deviations pursuant to Laser

Notice No. 50, dated July 26, 2001.”

Caution: Use of controls, adjustments or performance of procedures other

than those specified herein may result in hazardous laser light exposure.

• Class 2 laser scanners use a low power, visible light diode. As with any very bright

light source, such as the sun, the user should avoid staring directly into the light

beam. Momentary exposure to a Class 2 laser is not known to be harmful.”

A label such as the one below should appear on the end product.

Example of Class 2 Laser Warning Label

PRODUCT DISPOSAL: Your device should not be placed in municipal waste. Please check

local regulations for disposal of electronic products.

58

Page 59

10/2008 Printed in U.S.A.

Loading...

Loading...