MY2004

Set-up, Service

and Shop Manual

SNOW HAWK 600HO

FOREWORD

Congratulations, and thank you for buying an A.D.

Boivin design inc. Snow Hawk™ vehicle. We

appreciate the confidence in our product that you

have demonstrated by making this purchase

Several years of design, tests and improvements

were necessary to produce this vehicle which

combines performance, driving pleasure and safety.

Proper maintenance on a regularly-scheduled basis is

essential in order to obtain the performance you have

the right to expect from your machine. In this manual,

you will find all the information needed for adjustments

to and the maintenance of this vehicle.

We sincerely hope that you will have many years of

enjoyment with your Snow Hawk™.

.

AD Boivin design Inc.

All the information, illustrations, photographs and

specifications found in this manual are based on the

latest available data at the time of publication. Due to

improvements or other changes, it is possible that

you will note a few differences. AD Boivin design Inc.

reserves the right to make changes at any time.

WARNING /CAUTION / NOTICE

●

NOTICE:

The information in the NOTICES is designed to

explain maintenance procedures and to ensure the

best possible use of the vehicle.

IMPORTANT REMARKS

Using this vehicle can be a very pleasurable

experience and we wish you all the enjoyment that it

can bring you. However, if certain rules are not

respected, this sport can become a source of

environmental problems and of interpersonal

conflicts.

Adopting a responsible attitude and behaving in a

responsible manner at all times will help avoid such

problems and conflicts.

PROTECT THE FUTURE OF YOUR SPORT. BE

RESPONSIBLE AND RESPECT LOCAL LAWS AT

ALL TIMES. DEMONSTRATE AN AWARENESS

OF THE IMPORTANCE OF THE ENVIRONMENT

AND RESPECT THE RIGHTS OF OTHERS.

WARRANTY

1. All the parts of this vehicle are covered by the

warranty for a period of one winter season

against any problem related to its assembly

or construction.

Please read this manual and follow the instructions

carefully. Pay particular attention to the boxes

entitled WARNING and CAUTION as well as to the

paragraphs preceded by the word NOTICE.

◆ WARNING

This symbol is designed to call attention to

particular instructions and procedures, which,

if not followed to the letter, could cause injury

and even fatal accidents.

▼ CAUTION

This symbol is designed to call attention to

particular instructions and procedures, which,

if not followed to the letter, could cause

damage to or even destruction of the vehicle.

2. The labour costs of repairs covered by the

warranty are the responsibility of the vehicle

owner.

3. The company reserves the right to require

that the dealer carrying out the repairs send

back any parts declared or suspected to be

defective.

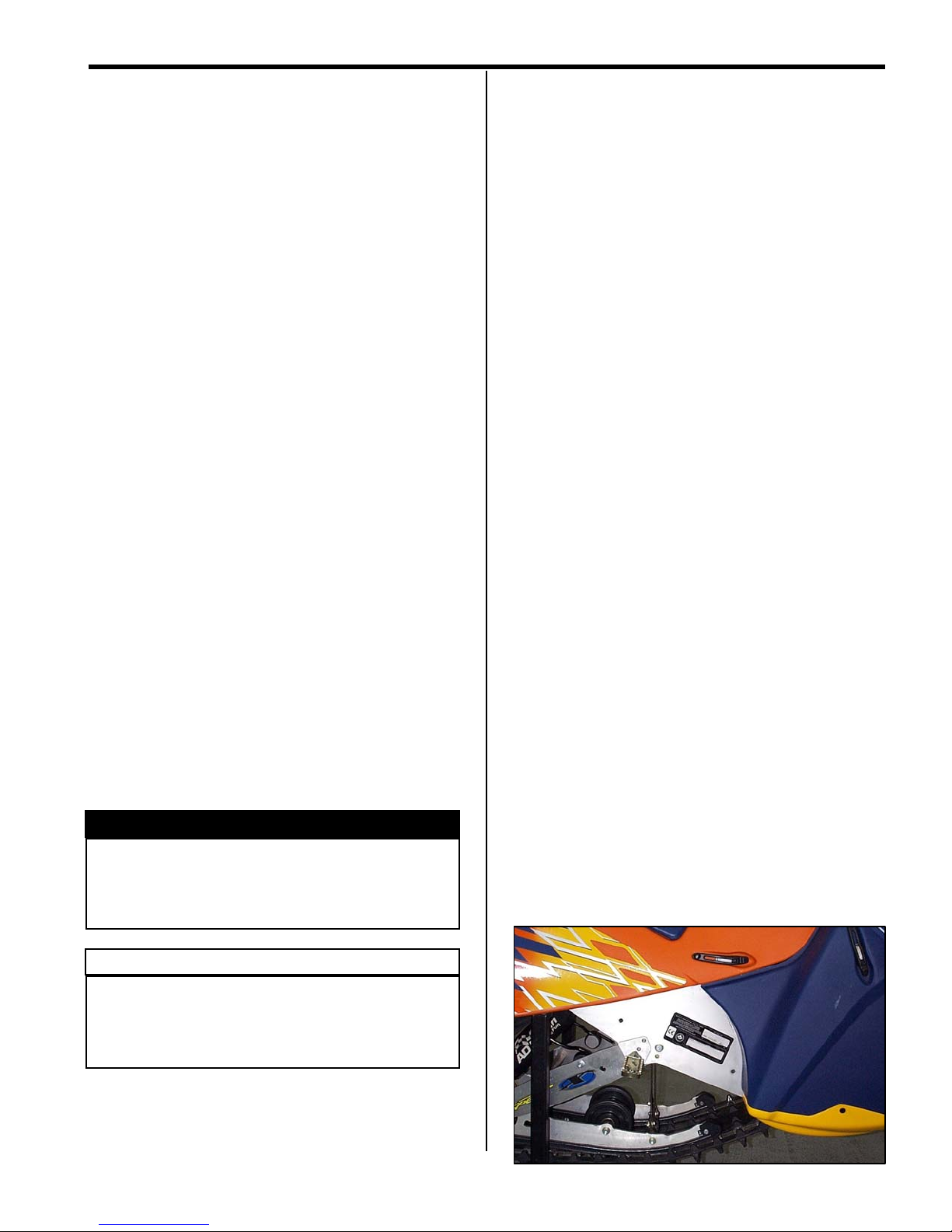

LOCATION OF THE V.I.N.

IMPORTANT MAINTENANCE WARNINGS:

◆ WARNING

Never have the motor running inside a building.

The exhaust fumes contain carbon monoxide, a

colourless, odourless gas which can cause

death or severe injuries.

Allow the motor to run only in a well-ventilated

area.

◆ WARNING

When hot, a motor, an exhaust system or a

drive system can cause burns.

Wait until they have cooled before carrying out

maintenance.

◆ WARNING

The gas tank can catch fire if it is not handled

correctly. Gas vapours can burst into flames

easily.

◆ WARNING

Carrying out maintenance of this vehicle while

the motor is running can be dangerous.

Injuries could result from contact with moving

parts.

Make sure you turn off the motor before

working on the vehicle.

◆ WARNING

Working on this vehicle without wearing the

appropriate clothing can be dangerous.

Injuries could result if you are not adequately

protected.

Always wear the necessary equipment when

working on the vehicle: shoes, goggles, gloves

and/or mask if necessary.

Important information concerning maintenance

o Replace any joints, brake shoes, pins and clips

by new ones.

Do not smoke while carrying out vehicle

maintenance.

Do not carry out maintenance anywhere near

exposed flames or sparks.

◆ WARNING

Brake fluid can be dangerous for people and

animals. These fluids are harmful or fatal if

swallowed and must not come into contact with

the skin or eyes.

o Use special tools when so indicated.

o Use original parts as well as recommended

products.

o After reassembling the vehicle, inspect the parts

and verify the torque on the nuts and bolts.

Replacement parts

Use only A D Boivin parts or their equivalent. A D

Boivin’s original high-quality parts are designed and

manufactured especially for your vehicle.

●

NOTICE:

Using replacement parts that are not equivalent or

are of inferior quality could mean your vehicle will not

be able to perform as it should and could damage

your machine.

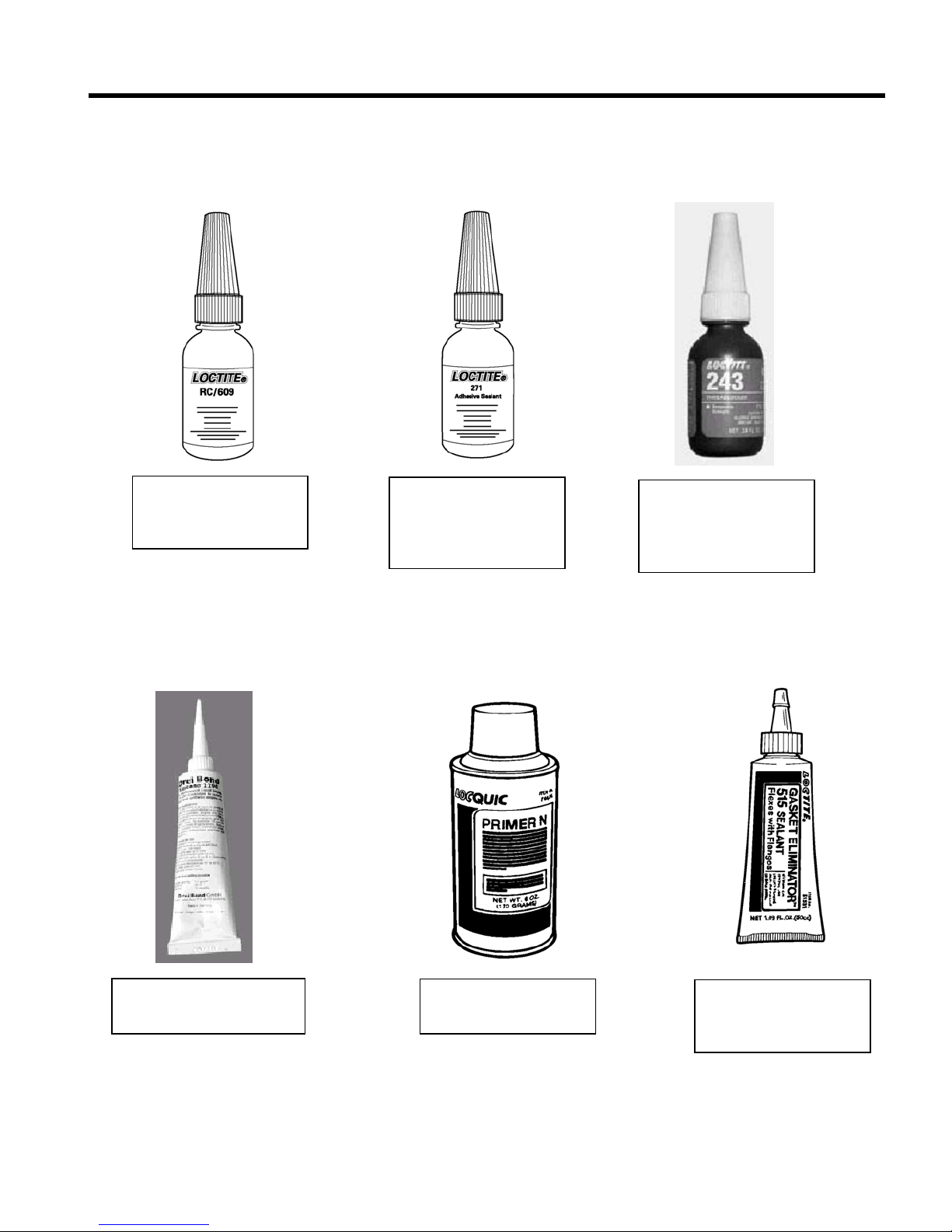

MANDATORY SERVICE PRODUCTS

Loctite RC/609, 10 ml

Retaining compound

P/N 413 703 100

Loctite 271, 10 ml

High strength

threadlocker

P/N 293 800 005

Loctite 243, 10 ml

Medium-strength

threadlocker

P/N 293 800 015

Sealing compound, 30 ml

P/N 420 297 905

Loctite Primer, 128g

P/N 413 708 100

Loctite 515, 50 ml

Paste gasket

P/N 413 702 700

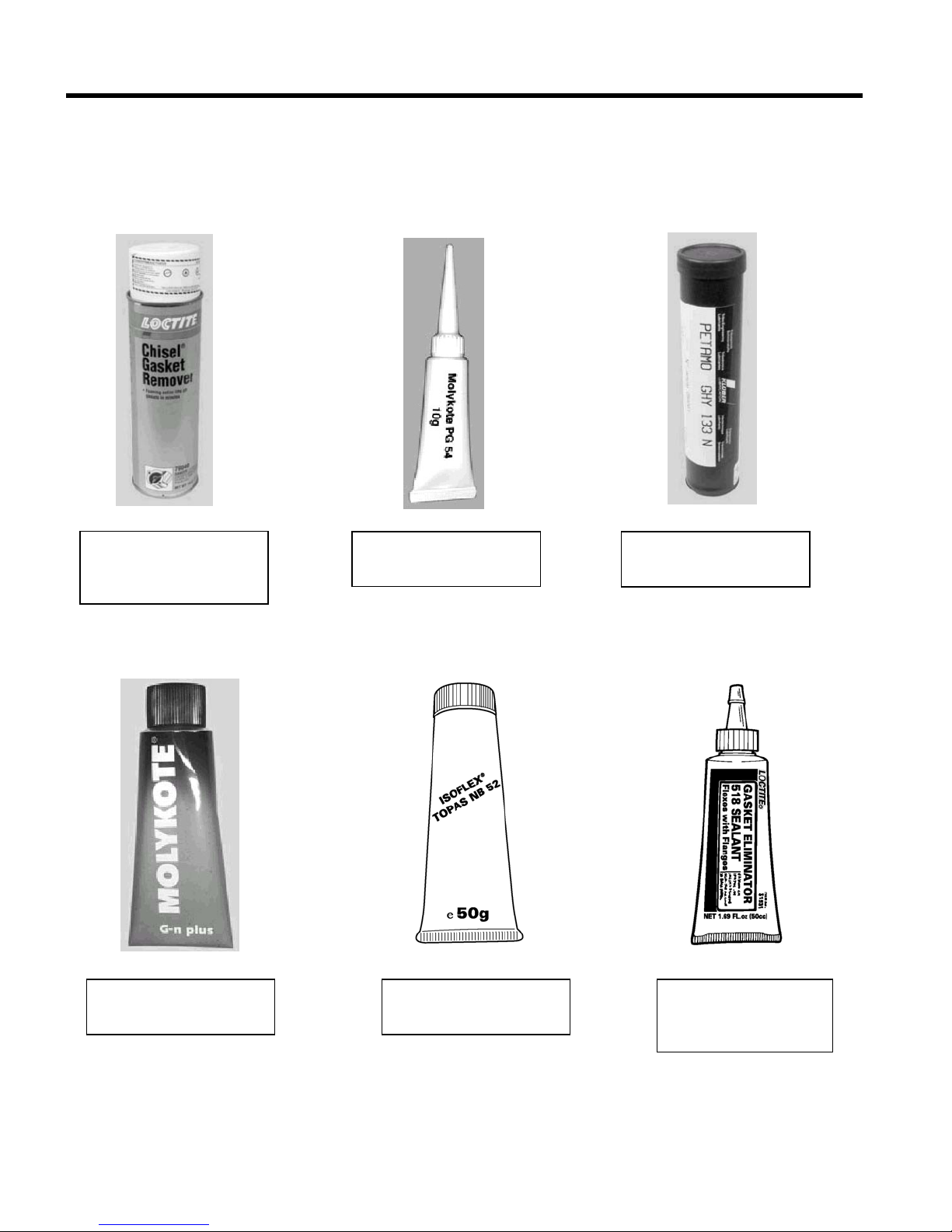

MANDATORY SERVICE PRODUCTS (continued)

Loctite chisel, 510g

Gasket/paint remover

P/N 420 899 763

Molykote G-n plus. 50g

P/N 711 297 433

Molykote PG 54, 10g

P/N 420 899 763

Isoflex Grease, 50g

P/N 293 550 021

Petamo Grease

P/N 420 899 271

Loctite 518, 50 ml

Gasket Paste

P/N 293 800 038

RECOMMENDED SERVICE PRODUCTS

Bombardier injection oil

3 x 4 litres P/N 413 803 000

Pre-mix oil

12 x 500ml P/N 413 803 100

Premixed coolant 50/50

16 x 1 litre P/N 293 600 038

Synthetic injection oil

Bombardier Formula XP-S II

3 x 4 litres P/N 293 600 046

Synthetic injection oil

Bombardier Formula XP-S II

12 x 1 litre P/N 293 600 045

Fuel stabilizer

12 x 8 oz P/N 413 408 600

RECOMMENDED SERVICE PRODUCTS (continued)

Storage oil 12 x 350 g

Canada P/N 413 711 600

USA P/N 413 711 900

Synthetic Grease 400 g

P/N 413 711 500

LMZ Grease No 1, 400 g

P/N 413 707 500

Molykote 111, 50 g

P/N 413 707 000

Bombardier lube

12 x 14 oz P/N 293 600 016

Silicone dielectric grease, 3 oz

P/N 293 550 004

RECOMMENDED SERVICE PRODUCTS (continued)

Anti-seize compound, 236 ml

P/N 293 800 070

Pulley flange cleaner, 320 g

P/N 413 711 809

Brake fluid SRF ( DOT 4 )

P/N 293 600 063

Heavy Duty Cleaner

400 g P/N 293 110 001

4 litres P/N 293 110 002

Brake fluid GTLMA (DOT 4)

P/N 293 600 062

Shock oil 32 oz

P/N 293 600 035

RECOMMENDED SERVICE PRODUCTS (continued)

Loctite 592, 50 ml

Pipe sealant

P/N 293 800 018

Loctite 648, 5 ml

High temperature and strength

retaining compound

P/N 413 711 400

Plastic and vinyl cleaner

P/N 413 711 200

Loctite Ultra Copper, 80 ml

High temperature RTV sealant

P/N 293 800 090

Loctite 5150, 300ml

P/N 293 800 066

TABLE OF CONTENTS

GENERAL INSTRUCTIONS

PERIODIC MAINTENANCE

FUEL SYSTEM

ENGINE REMOVAL

REWIND STARTER

COOLING SYSTEM

ENGINE (CYLINDERS / HEAD / BASE)

PRIMARY TRANSMISSION SYSTEM

SECONDARY TRANSMISSION SYSTEM

1

2

3

4

5

6

7

8

9

HYDRAULIC BRAKE SYSTEM

FRONT FORK AND TWIN-AXIS SKI

REAR SUSPENSION, SHOCKS AND TRACK

CHASSIS AND STEERING

ELECTRICAL SYSTEM

DIMENSIONS AND TOLERANCES

WIRE, CABLE AND HOSE ROUTING

10

11

12

13

14

15

16

FIRST CONTACT

The SNOW HAWK™ is a completely new type of vehicle.

Technically speaking, it is a cross between a snowmobile and a

motorcycle. However, its behaviour depends on the conditions in

which it is used. Sometimes, it will react more like a bike while

at other times, it will react more like a snowmobile or a jetski.

Describing exactly how the SNOW HAWK™ behaves is difficult.

This is why we recommend that you take the time to become

acquainted with your machine in an area free of any obstacle.

This first contact should take place at low speed, with a series of

basic manoeuvres that will allow you to learn about the reactions

of the vehicle.

A good exercise is to follow a "figure 8" trajectory because this

will allow you to experiment with right- and left-hand turns

followed by accelerating and braking.

Turning can be done by steering right or left, keeping in mind the

speed of the vehicle, the snow conditions and how quickly you

want to change direction.

GENERAL INSTRUCTIONS 1 - 1

◆ WARNING

Some people enter a turn by stretching out a leg on the

inside of the turn and letting the foot slide over the

ground (a technique used in motocross). We advise

against this practice which could cause severe injuries if

your foot should sink into the snow. We rather suggest

keeping both feet on the footpegs as much as possible.

An upright position, with the knees clutching the gas tank and

the elbows pointing away from the vehicle, will give a sense of

security and provide greater freedom of movement while

accelerating or slowing down.

◆ WARNING

The greatest danger in using this vehicle is the perception

you may have of how competent you are. Overestimating

how competent you are can result in hazardous situations

both for yourself and for other trail users.

Do not forget to take all the time that is necessary for you to

practice and feel comfortable at low speeds before attempting

high-speed manoeuvres. You will then be able to fully

appreciate the joy of driving.

GENERAL INSTRUCTIONS 1 - 2

LOCATION OF MECHANISMS AND CONTROLS (503 SHOWN, 600HO IDENTICAL)

8

6

1

1. Throttle control

2. Brake lever

4

5

3

2

9

7

3. Parking brake lever

4. Engine-cutoff (tether)

5. Gas tank cap

6. Dimmer switch

7. Choke control

8. Emergency-stop button

9. Temperature Light

14

10

15

10. Hood latches (4)

11. Rear module latches (4)

12. Bellypan latches (6)

11

13. Kick stand

14. Headlight

13

15. Stop and tail light

12

18

16

17

16. Recoil starter handle

17. Hood latches (4)

18. Rear module latches (4)

19. Bellypan latches (6)

19

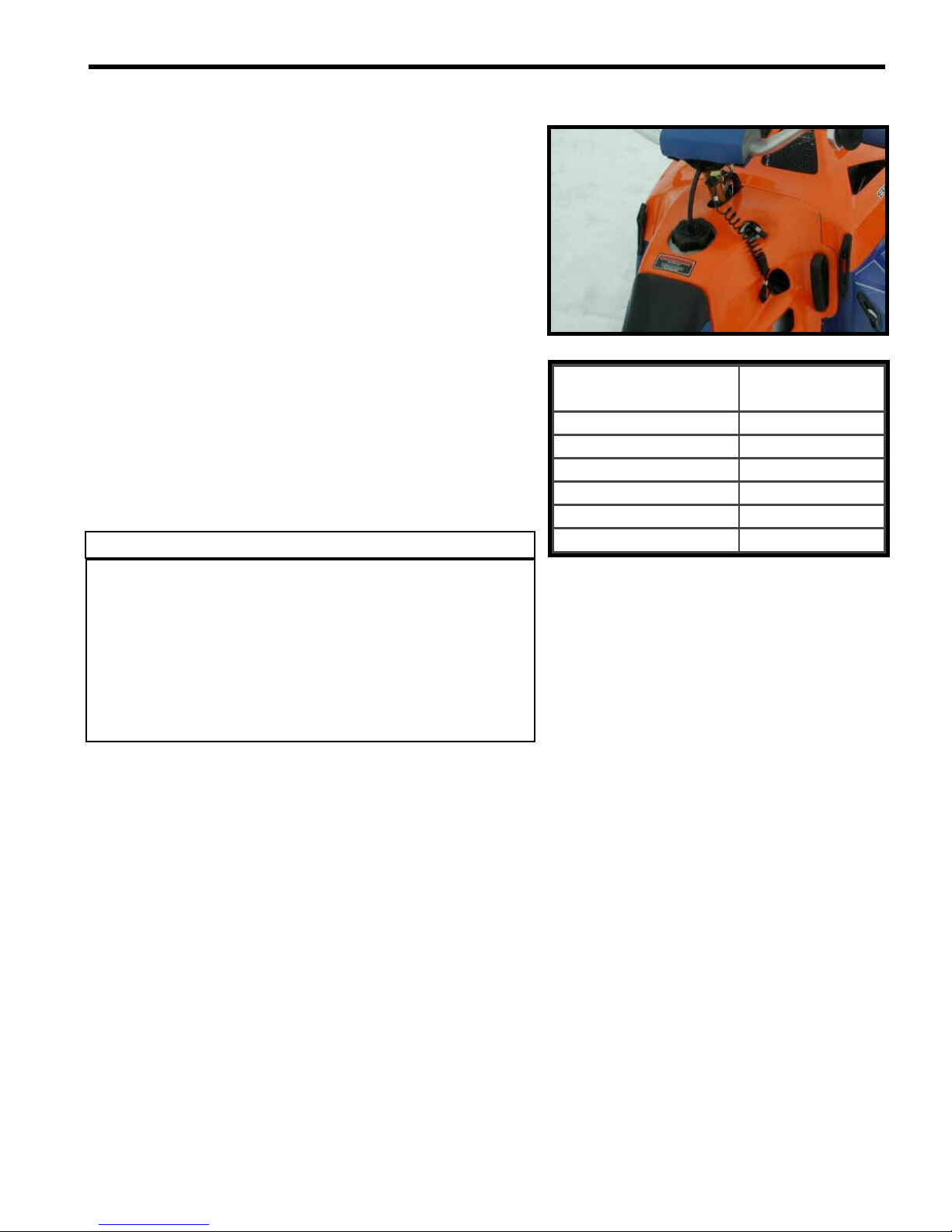

FUEL

(

)

(

)

0

This vehicle is powered by a two-stroke engine that uses a premixed gasoline and oil mixture.

Gasoline: Regular unleaded gas with a minimum octane

rating of 89 (R+M)/2

GENERAL INSTRUCTIONS 1 - 3

Motor oil: Bombardier / ROTAX Formula XPS Synthetic

Pre-mix oil (P/N 293600045)

Mixture ratio: 40 : 1 (32 : 1 for break in and CAN safely be

used thereafter if desired)

Fuel tank capacity: 30 L (9.5 gallons)

▼ CAUTION

A mixture in which the proportion of oil is too low will

cause piston failure. On the other hand, a mixture in

which the proportion of oil is too high will cause

excessive carbon deposits that will result in fouled spark

plugs and will affect performance.

Always mix in a proportion of 40 parts of gasoline for

each part of oil.

●

NOTICE:

o The use of isop[ropyl alcohol (commonly known as “gas-

line antifreeze) is recommended in a ratio of 150 mL per

fuel tank in very cold temperatures.

Gasoline

L

Oil

ml

5125

10 250

15 375

20 500

25 625

30 75

o Avoid mixing oils of different brands.

GENERAL INSTRUCTIONS 1 - 4

OPERATING INSTRUCTIONS

Pre-driving inspection

◆ WARNING

A pre-driving inspection is of the utmost importance

before using the vehicle. Do not start the machine until

you are sure all mechanisms and controls are functioning

properly. Failing to proceed in the prescribed manner may

result in severe injuries or even death.

o Make sure the track and the idler wheels are not frozen and

that they move freely.

o Depress the brake lever and make sure the brake is fully

engaged before the end of the lever touches the handlebar.

The lever must return to its original position as soon as it is

released.

o Turn the twist throttle control a few times to make sure it

functions properly. The control must return automatically to

the idle position as soon as it is released.

o Make sure the engine cutoff switch, the stop light, the

headlight (high and low beams) and the tail light are in good

working order.

Starting the engine

o Put the cap of the engine cutoff (tether) switch in place. The

other end of the cord must be securely attached to the

driver.

o If the engine is cold, use the choke control.

0. Normal position (not activated)

1. Intermediate choke position

2. Full choke position

o Start the engine by firmly pulling the handle of the rewind

starter.

◆ WARNING

Do not touch the throttle control while starting the engine.

Stopping the engine

o While the engine is idling, remove the engine cutoff cap

(tether) or press the emergency-stop button.

BREAK-IN PERIOD

Engine

▼ CAUTION

A cautious break-in period of 10 to 15 hours is essential

before using the vehicle at full power. Failure to provide a

sufficient break-in period could result in severe engine

damage.

▼ CAUTION

The timing of all Snow Hawk 600HO’s is retarded by 3o for

a period of 1-hour during the first stages of the break-in

period. You may notice a slight increase in performance

and a reduction in fuel consumption after this time.

GENERAL INSTRUCTIONS 1 - 5

During the break-in period, the throttle control should not be

turned more than ¾ of its range. However, occasional periods

of brief, brisk acceleration and frequent speed variations

contribute to a good break-in. On the other hand, periods of

long, high acceleration, sustained high speed and engine

overheating are harmful during the break-in period.

◆ WARNING

This vehicle is equipped with a liquid cooling system.

ALWAYS ride with the rear deflector pad installed and in

conditions where there is enough snow to properly cool

the engine. If the red temperature light on the steering

column should ever illuminate, stop immediately and let

the vehicle cool down, and then find some snow. NEVER

continue to operate the vehicle with the temperature light

illuminated as severe engine damage will occur.

▼ CAUTION

A fuel : oil mixture of 32 : 1 MUST be used during the

engine break-in period.

◆ WARNING

During the first hour of the break-in period the fluid levels

in the coolant reservoir and the small water pump oil

reservoir will go down slightly. This is perfectly normal.

Be sure to top-up these fluids with proper coolant (P/N

293600038) and proper oil (P/N 293600045).

GENERAL INSTRUCTIONS 1 - 6

Drive Belt

A new drive belt must be submitted to a 5-hour break-in period.

Avoid high-speed driving and brisk accelerations during this

period.

Inspection – 10 hours

A general inspection is recommended after the first 10 hours of

use. This inspection must be carried out by an authorized

SNOW HAWK ™ dealer.

●

NOTICE:

o Most of the wear in this vehicle occurs during the break-in

period.

o Bolts and nuts can easily become loose in a new machine.

Make sure you check them regularly during this period.

REMOVAL OF THE BODY PANELS (HOOD, REAR

MODULE AND BELLYPAN)

In order to work on the vehicle more easily and to access the

anchor ties, we suggest that you remove the rear module from

the vehicle. To do so, you must first remove the hood. Proceed

as follows:

o Disconnect the front headlight.

o Unhook the 4 rubber latches (2 / side).

o Remove the hood.

o Remove the fuel tank cap.

o Set the choke to the full position.

o Unplug the tail light connector located under the light

itself, underneath the rear fender.

o Release the rear module from its four rubber latches,

slip the rewind starter handle through the space

provided and remove the rear module.

Roll the two O-rings down and pull the two white plastic

collars down over the fork legs. To ensure that they will not

interfere, let them hang loose at the base of the fork leg.

o Remove the circular fork disc

o De-latch the two rubber latches on the sides of the belly

pan (towards the rear of the vehicle)

o De-latch the four rubber latches on the bottom of the

belly pan.

o Descend the belly pan to floor level; most maintenance

can be performed with the belly pan in this position.

However, if it is required to completely remove the belly

pan, remove the single bolt attaching the ski to the fork.

At this point, a second person can lift the front of the

vehicle slightly and the belly pan can be slid out from

underneath.

GENERAL INSTRUCTIONS 1 - 7

PERIODIC MAINTENANCE 2 - 1

V

V

V

V

V

V

V

V

V

V

V

V

V

V-V

V

V

V

V

(

)

V

V

V

y

V

V-V

y

V-V

V

y

V

V

y

)

V

V

V

V

V

V

V-V

V

V-V

V

V

V

V

V

g

V

V

V

V-V

V-V

V

V

V-V

V

g

V

V

V

g g

V

V

V

V

V

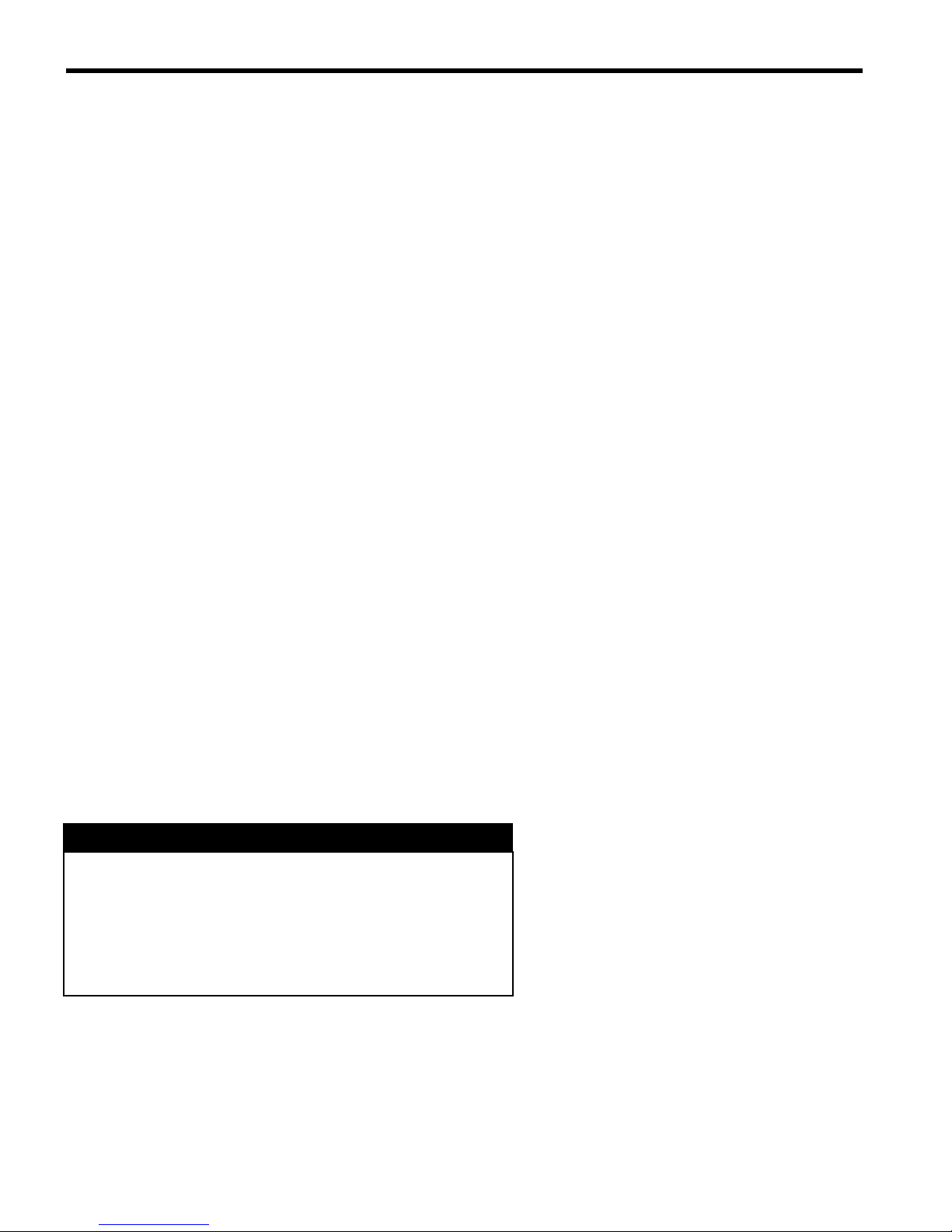

●

NOTICE:

Regular inspection and maintenance of the Snow Hawk is of utmost importance. Follow the guidelines in the table

below for optimum vehicle performance. Suggested intervals must be reduced if the vehicle is subjected to severe

usage conditions.

65 Hrs

(yearly)

- A

- F

- R

- C

- R

- A

- A

-

F

- A - R

- A

- A

Item

2.1 Carburetion

2.2 Motor

2.3 Primary transmission

system

2.4 Secondary

transmission system

2.5 Brake system

2.6 Front suspension and

ski

2.7 Rear suspension and

track

2.8 Chassis

2.9 Electrical system

Interval (Hrs)

Fuel lines and connections

Carburetor adjustment

Throttle cable

Air Intake Filter

Carburetor support bracket

Starter cord

Cylinder head bolts

Engine support bolts

Exhaust system

Coolant level

Oil level

Cooling System (hose connections)

Primar

Primar

Primar

Secondary clutch pre-tension

Secondar

Cog sprockets

Torque Limiter

Taper Locks

Brake fluid

Brake pads

Brake microswitch

Front Fork

Fork rubber cushion and bolt

Fork air bleeder screw

Twin axis ski bushin

Ski and runners

Suspension

Shocks

Track

Handlebar bolts

Steering components

Assembly bolts / nuts

Spark plu

Spark plu

Fuse

Headlight projection/aim

Lighting system, stop lamp and

emergency stop switch

water pump oil reservoir

drive belt

and secondary clutch

clutch bolt

drive belt (cog belt

s / nuts

s

ap

Break-in

( ~ 10 Hrs. )

- A - -

---V

- A -

- A V--V

V - A - - V - A

V--V

V--V

F-FF

- A

- A VV - R

V - A - V - A V - A

V--V - C

- A - R -

- A - -

---

VV-V

5 Hrs

--

--

--V - C

--

--

--

--

--

--

--V - A

--F

- A

V - R as needed

--

--

15 Hrs

- R

- A

- A

- A - R

●

NOTICE:

V = Verify, A = Adjust, C = Clean, R = Replace one or several part(s), F = Replace fluid

PERIODIC MAINTENANCE 2 - 2

2.1. CARBURETION

Fuel lines and connections

Check all hoses and connections in order to find and fix leaks

and/or to help prevent them.

Carburetor adjustment

For carburetor adjustment, refer to Chapter 3 - Fuel system

section.

Throttle cable

The throttle cable can be adjusted by setting the adjustment

mechanism on the throttle end of the throttle cable.

Air intake filter

The air intake filter must be cleaned at least once a year, or

more often under severe usage conditions. Clean the filter in a

solution containing a non-flammable cleaning solvant (such as

hot soapy water). Once dry, apply some light engine to the filters

to prevent the infiltration of water and dust.

2.2. ENGINE

Recoil starter cord

Pull gently on the handle to unwind the full length of the cable.

Inspect the cable visually to detect any wear or other damage

that could eventually cause the cord to break.

Cylinder head bolts

Refer to the appropriate procedure in Chapter 7 – Engine

(Cylinders/Head/Base).

Engine support bolts

To carry out this operation, refer to the appropriate procedure in

Chapter 7 – Engine (Cylinders/Head/Base).

Exhaust system

Using a torque wrench, check the torque of the retaining bolts of

the exhaust manifold. Apply a torque of 10 N-m (1 kg-m, 7.4 lbf-

ft).

Then, proceed to a visual inspection of the system to detect any

leak or abnormality in the gasket material.

PERIODIC MAINTENANCE 2 - 3

Cooling system

Inspect the coolant level in the coolant reservoir located on the

MAG side of the vehicle. If the coolant level is below the “Cold”

coolant mark when the vehicle is not warm or has not been

ridden within 30mins or more, add coolant until this line. Check

all of the hoses / hose connections and ensure that there are no

fluid leaks in the system.

Cold

Level

PERIODIC MAINTENANCE 2 - 4

2.3. PRIMARY TRANSMISSION

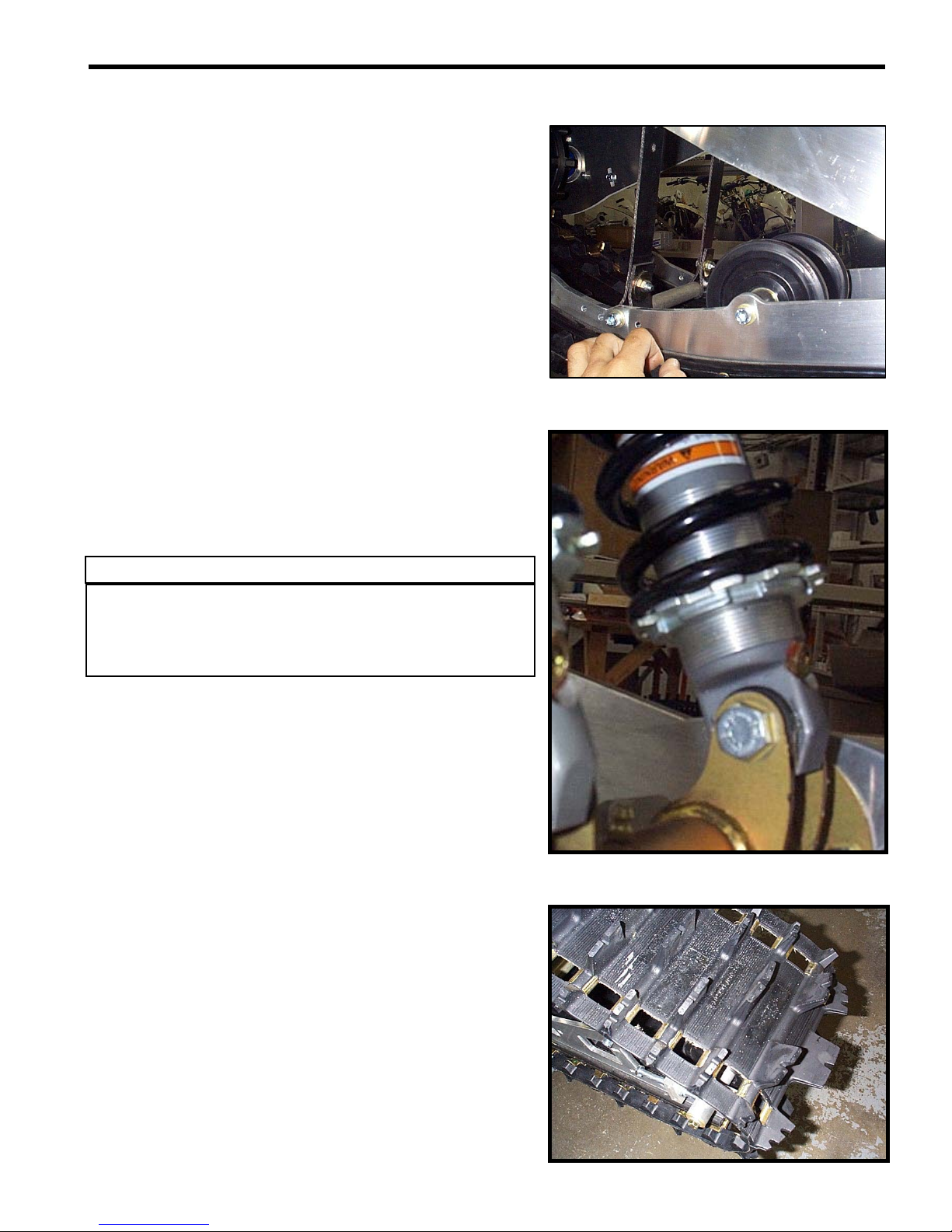

Primary and secondary clutches

Remove the belt and verify that the sliding half-pulleys of the two

clutches is in good working condition.

To take the belt off, first use the special tool provided to open

the secondary clutch (P/N 529 008 700). Then, slip the belt over

the pulley from rear to front as illustrated. To reinstall the belt,

proceed in the reverse order.

Primary clutch bolt

Check the torque on the primary clutch retaining bolt.

Recommended torque: 90 - 100 N-m (9–10 kg-m, 70 lbf-ft).

For more information, refer to Chapter 8 - Primary

Transmission System.

Pre-tension of the secondary clutch spring

For more information, refer to Chapter 8 - Primary

Transmission System.

Primary transmission belt

Examine the belt. Make sure it is not cracked, frayed or worn in

an abnormal way (uneven wear, wear on one side only, missing

cogs, or cracked material). Abnormal wear of the belt is often

due to mis-alignment of the pulleys, excessive throttle when the

track is frozen, quick acceleration without a preliminary warmup, a scratched or rusted pulley, oil on the belt, or a twisted

replacement belt. If need be, ask an authorized SNOW

HAWK™ dealer for advice.

Measure the width of the belt. Replace if it is less than 31.6 mm

(1.245 in) wide.

For more information, refer to Chapter 8 - Primary

Transmission System.

2.4. SECONDARY TRANSMISSION

Secondary transmission cog belt

Examine the cog belt. Make sure it is not cracked, frayed or

worn in an abnormal way. If in doubt as to the condition of the

belt, replace it with a new one.

Verify the tension of the secondary transmission belt according

to the instructions found in Chapter 9 - Secondary

Transmission System.

PERIODIC MAINTENANCE 2 - 5

Cog Sprockets

Check the appearance of the cog sprockets. Make sure all the

sprockets are there and are free of any accumulated dirt. Clean

if necessary.

Taper-locks

Refer to Chapter 9 - Secondary Transmission System.

2.5. BRAKE SYSTEM

Brake fluid

Check to see if the brake fluid level is above the "mimimum"

mark (see illustration). If not, add fluid.

▼ CAUTION

MIN

Use only DOT 4 brake fluid from a sealed container. Do

not use any other type of brake fluid.

PERIODIC MAINTENANCE 2 - 6

Brake pads

Verify the thickness of the brake pad linings as illustrated. Brake

pads must both be replaced if either one of them shows a

clearance of less than 1 mm (1/32 in.).

●

NOTICE:

For the replacement of brake fluid, refer to Chapter 10 –

Hydraulic Brake System.

2.6. FRONT SUSPENSION AND SKI

Front fork

The air pressure inside the fork legs must be as close as

possible to atmospheric pressure. Therefore, it is advisable to

remove the bleeder screws after every ride to re-establish the

pressure. It should be done more frequently when temperature

variations are greater and more frequent (such as when the

vehicle is stored in a heated garage).

A visual inspection of the fork legs can reveal oil leaks that might

indicate broken main seals. If excessive oil is presest on the

lower fork leg, a seal replacement may be required.

It is recommended to replace the fork oil after the break-in

period and, from then on, after every 15 hours of use. For

details, refer to Chapter 11 – Front Fork and Twin-Axis Ski.

▼ CAUTION

It is advisable to change the fork fluid when preparing the

vehicle for storage. The presence of condensation in the

suspension fluid could cause corrosion during the

storage period.

Twin-Axis Ski and Runners

Verify the torque of all the bolts holding the ski, as well as all the

studs and nuts retaining the runners. Also inspect the

appearance of the runners to detect any wear, distortion, or

broken studs.

2.7. REAR SUSPENSION AND TRACK

Suspension

Verify that all suspension bolts and nuts are well tightened,

especially the four that retain the suspension to the chassis (use

Loctite 243 here) Verify that none of the parts are damaged or

missing.

Verify that the suspension wheel bearings are in good working

order. Check the condition of the suspension limiter straps.

Check the condition of the hyfax.

For more information, refer to Chapter 12 - Rear suspension

and Track.

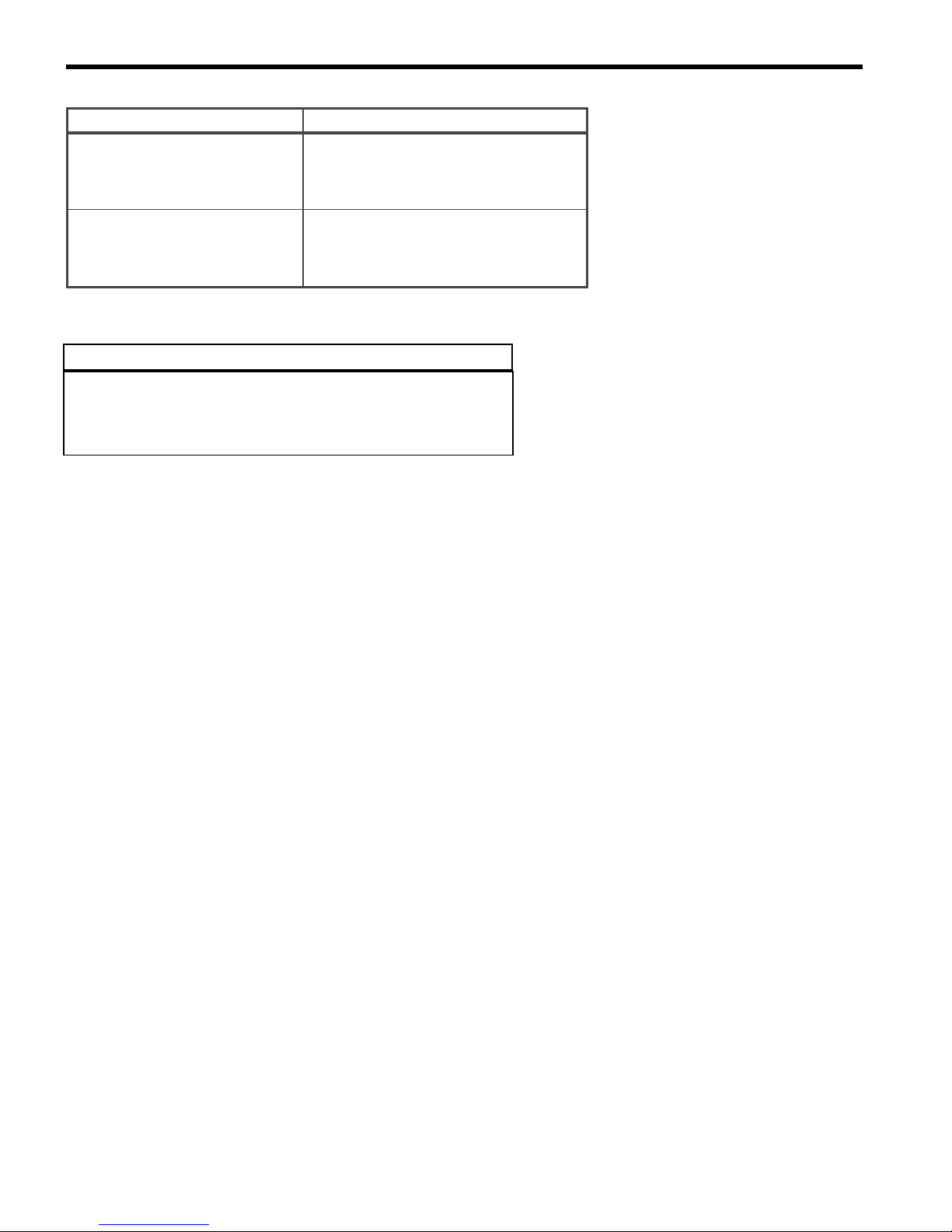

Shock absorbers

Check around the shock guards for the presence of oil leaks.

PERIODIC MAINTENANCE 2 - 7

Shock oil must be replaced once a year. Refer to Chapter 12 Rear suspension and Track.

▼ CAUTION

It is advisable to change the shock fluid when preparing

the vehicle for storage. The presence of condensation in

the suspension fluid could cause corrosion during the

storage period.

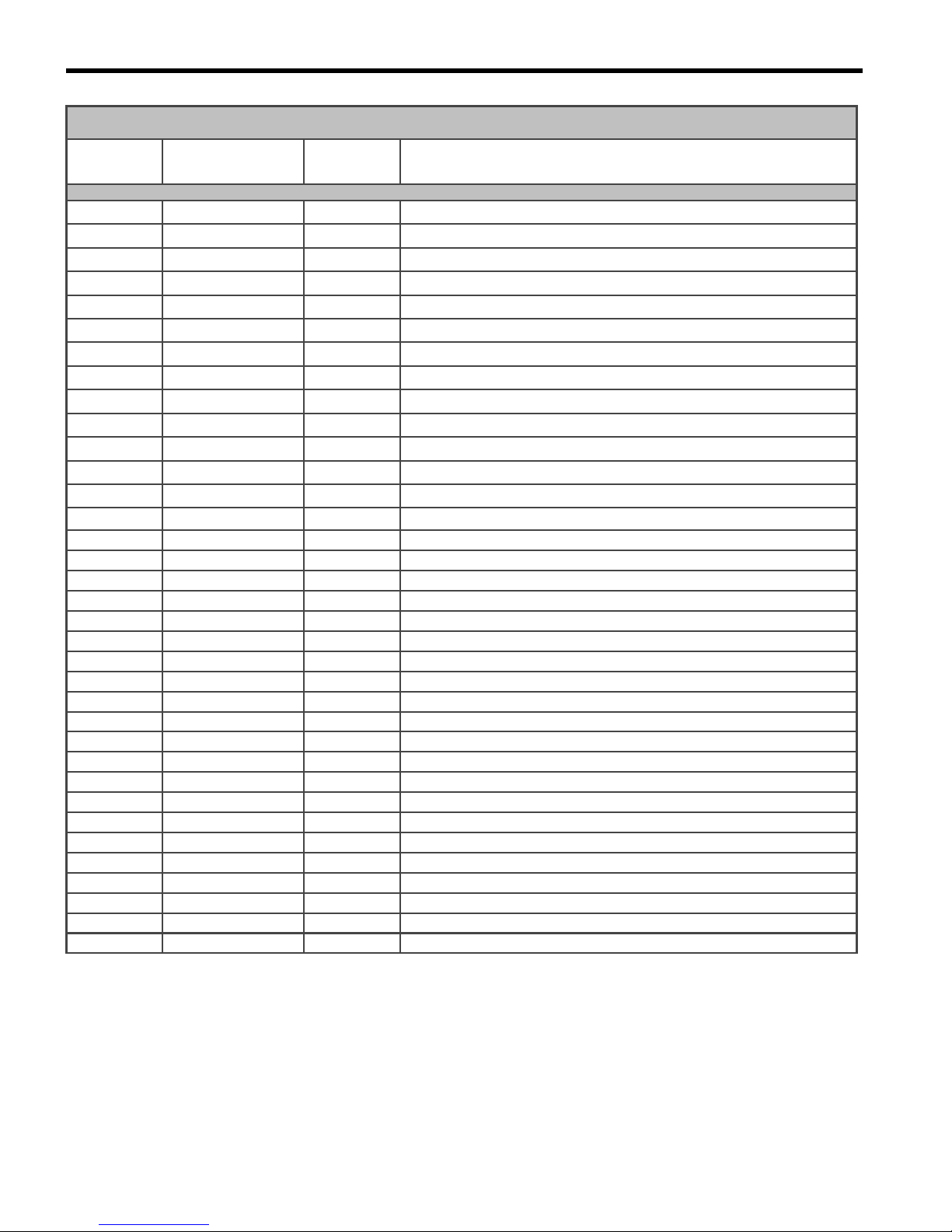

Track

Check the condition, alignment and tension of the track.

With the engine turned off and the rear end of the machine

raised from the ground, rotate the track manually and inspect it

to make sure it is in good working condition. It must not be

cracked and all the lugs must be intact.

●

NOTICE:

For track alignment and tension, refer to Chapter 12 - Rear

Suspension, Shocks and Track.

PERIODIC MAINTENANCE 2 - 8

2.8. CHASSIS AND STEERING

Handlebar mounting bolts

Verify and adjust the torque to 36.5 N-m (3.7 kg-m, 27 lbf-ft),

following a criss-cross order.

Steering mechanism

Verify the condition of the tie rod ends and check for excessive

play in the pivots of the steering system. For alignment, refer to

Chapter 13 – Chassis and Steering.

PERIODIC MAINTENANCE 2 - 9

Assembly

The chassis of the SNOW HAWK is different in that most of the

assembly is done by bolting components rather than welding

them. Therefore, bolts must be checked and tightened as need

be. When doing this, refer to the Torque Table at the end of this

section.

2.9. ELECTRICAL SYSTEM

Spark plug

Check the general condition of the plug, the colour of its

electrodes, carbon deposits, plug gap and possible damage to

the gasket

A NGK BR9ECS spark plug is recommended.

Check the spark plug gap. The suggested gap is 0.45 mm

(0.018").

When tightening the spark plug, the torque must be between 25

and 30 N-m (18 and 21.5 lbf-ft; 2.5 and 3.0 kg-m).

Lean

(light grey)

Normal

(brownish)

Rich

(black)

PERIODIC MAINTENANCE 2 - 10

Porcelain Colour Probable Cause

- Plug Temperature rating is too high

Light Grey (Overheated)

Blackish (Fouled)

- Plug gap too wide

- Air/Fuel mixture too lean

- Stale gasoline

- Plug temperature rating too low

- Plug gap is too small

- Air/Fuel mixture too rich

- Oil/Fuel mixture too rich

▼ CAUTION

The engine may be seriously damaged if the temperature

rating of the spark plug is inadequate.

Refer to the NGK codification on the next page.

Symbols used on the NGK spark plugs

PERIODIC MAINTENANCE 2 - 11

PERIODIC MAINTENANCE 2 - 12

(6)

g

)

g

)

g

y

y

g

g

(4)

Spark plug gap

The suggested gap is 0.45 mm (0.018"). For more information,

refer to Chapter 14 – Electrical System.

Wiring Harness

Electrical wires and connections should be inspected visually to

quickly locate broken wires or faulty connections. For more

information, refer to Chapter 14 – Electrical System.

Headlamp, stop lamp and engine cut-off switch

Before each ride or excursion, it is recommended to verify that

the headlamp, the stop/tail lamp and the engine cut-off switch

are in good working order.

TORQUE TABLE

ITEM N-m kg-m lbf-ft lbf-in

Torque Limiter bolts

Rear Suspension mountin

Rear Suspension lower swin

Recoil starter housin

Primar

Secondar

Taper-Lock installation setscrews

Spark plu

Handlebar mountin

Triple clamp bolts

Fork pivot bolts

Ski runner nuts

Lower clamp nuts

Ski saddle/fork adaptor nut

clutch bolt

clutch bolt

s

bolts

bolts (4

arm bolts (2

bolt

6.20.624.6 55

51 5.1 38 450

90 9 66 792

70.75 62

90 9 66 792

31.7 3.17 23 276

14 1.4 10.4 125

25 2.5 18 216

36.5 3.65 27 324

6.8 0.68 5 60

45 4.5 33 396

19 1.9 14 168

23 2.3 17 204

85 8.5 63 756

For any other bolt or screw that is not mentioned in the list, please refer to the following table.

BOLT

DIAMETER

(MM)

6 101 784151.511132

8 25 2.5 18 216 36 3.6 27 324

10 49 4.9 36 432 72 7.2 53 636

12 85 8.5 63 756 125 12.5 92 1104

N-m kg-m lbf-ft lbf-in N-m kg-m lbf-ft lbf-in

GRADE " 8.8 "

GRADE " 10.9 "

FUEL SYSTEM

FUEL SYSTEM 3 - 1

16

15

12

14

11

11

13

10

9

8

9

8

5

17

35

35

22

24

6

26

19

29

28

3

7

1

27

2

4

21

19

20

34

19

18

23

22

24 25

30

32

33

31

32

FUEL SYSTEM 3 - 2

1 ADB-SH1 1 Fuel tank 31L

2 322111-BKL 1 Gas tank cap

3 907301 1 7/32" gas tank (overflow)

4 SH15 1 Rubber Strap 15"

5ADB-01401Air box

6 508,000,240 1 Intake horn

7 508,000,199 1 Foam

8 508,000,132 2 Intake adaptor

9 508,000,346 2 Gear clamp

10 415,128,729 1 TM40 Carburetors (racked together, as a pair)

11 512,059,835 2 Gear clamp

12 07-0401 1 Throttle cable

13 512,059,110 1 Choke cable

14 512,059,094 1 Plastic nut

15 394,103,300 1 Lock washer (interior tooth)

16 01-0054 1 Twist throttle

17 24-1101 1 Grips (pair)

18 403,901,811 1 Fuel pump

19 414,420,700 3 Spring clamp (green)

20 14-349 1 Tubing

21 415 080 200-1 1 Hose (pump - carburetor)

22 414,415,200 2 Spring clamp (red)

23 415,079,800 1 Impulse hose

24 513,032,979 2 Spring clamp (dark green)

25 513,033,022 1 Hose

26 420,874,370 1 Male connector

27 07-241 1 Fuel filter

28 570,135,100 1 Grommet

29 415 080 200-4 1 Hose (connector - tank)

30 SH 092 1 Short spacer

31 SH 091 1 Long spacer

32 170-103 2 " T " Nut

33 SN328-016 1 Hexagon flange head cap screw ¼-20 x 1 ¼

Fuel System

Part DescriptionsRef. P/N Qty

34 SN328-014 1 Hexagon flange head cap screw ¼-20 x ¾

35 8461k133-1 2 Adhesive rubber pad 1/8" thick x 2" wide

CARBURET0RS (TM 40)

FUEL SYSTEM 3 - 3

FUEL SYSTEM 3 - 4

Carburetors (TM 40)

1 403,138,740 1 TM40 Carburetors (racked together, as a pair)

2 404,162,017 1 Funnel (PTO)

3 404,161,955 2 Screw

4 404,161,945 2 O-ring

5 404,106,200 2 Main jet 380

6 404,161,944 2 Pilot jet 17.5

7 404,162,016 2 Needle 9DHI12-58-3

8 404,162,020 2 Piston Valve 2.0

9 404,137,600 2 Packing

10 404,152,200 2 E-ring

11 404,161,940 2 Gasket

12 404,161,939 2 Cover

13 404,162,006 1 Throttle shaft

14 -XXX- 1 Screw

15 -XXX- 1 Adjustment spring

16 404,161,935 2 O-ring

17 404,161,961 2 O-ring

18 404,161,933 4 Screw

19 404,161,932 2 Float

20 404,161,960 2 Float Body

21 707,200,027 1 E-ring

22 404,162,007 4 Plate

23 404,162,008 2 Holder

24 404,161,928 2 Screw

25 404,162,009 2 Lever

26 404,161,926 2 Ring

27 404,161,925 1 Ring

28 404,161,924 2 Ring

29 404,161,923 4 Screw

30 404,138,300 2 E-ring

31 404,162,010 2 Spring

32 404,162,011 1 Spring

33 404,161,920 2 Screw

34 404,161,919 2 Plate

35 404,162,012 1 Funnel (MAG)

36 404,161,918 1 Spring (PTO)

37 404,161,917 1 Screw (PTO)

38 404,162,022 1 Bracket (PTO)

39 404,162,014 1 Spring

40 404,162,015 1 Throttle shaft

41 404,137,500 1 Adjustment screw

42 404,161,913 1 Spring

Part DescriptionsRef. P/N Qty

FUEL SYSTEM 3 - 5

Ref. P/N Qty Part Descriptions

43 404,161,912 1 Screw

44 404,136,100 1 Screw

Carburetors (TM 40)

45 404,161,911 2 Screw

46 404,161,910 3 Screw

47 404,161,909 2 Lever

48 404,140,000 2 Cap

49 404,136,900 2 Holder guide

50 404,161,908 2 Spring

51 404,161,907 2 Plunger ass'y

52 404,161,906 2 Screw

53 404,161,905 1 Nipple

54 404,162,001 2 Hose

55 404,161,903 2 Screw

56 404,162,000 1 Bracket

57 404,161,901 1 Starter lever

58 404,161,899 2 Cap

59 404,161,898 2 Adjuster

60 404,161,897 2 Spring

61 404,161,896 2 Washer

62 404,161,895 2 Packing

63 404,153,400 2 Nipple

64 404,154,900 2 Cap

65 404,161,894 3 Packing

66 404,103,500 1 Spring

67 404,161,981 1 Shaft ass'y

68 404,161,956 1 Hose

69 404,161,957 2 Clip

70 404,138,800 8 Screw

71 -XXX- 1 Spring

72 270,500,118 2 Packing

73 270,500,095 2 Closure cap

FUEL SYSTEM 3 - 6

REMOVAL

Loosen clamps # 9 retaining air box # 5 to carburetor assembly

and remove air box.

Disconnect the carburetor support block that is located at the

middle-bottom of the carburetor assembly. Pull rearwards on the

upper portion of the block to disconnect it completely.

Loosen clamps # 11 retaining dual carburetor assembly to

carburetor sockets.

Disconnect throttle and choke cables.

▼ CAUTION

Always loosen the LOWER nut when removing the throttle

or choke cable as to avoid disturbing the settings of

either.

Remove dual carburetor assembly, pinch and disconnect fuel

line. Take care to recuperate fuel.

Clamp

Carburetor

support

◆ WARNING

Fuel is flammable and explosive under certain conditions.

Always wipe off any fuel or oil spillage from the vehicle.

Ensure work area is ventilated. Do not smoke or allow

open flames or sparks in the vicinity.

CLEANING AND INSPECTION

The entire carburetor should be cleaned with an all-purpose

cleaner and dried with compressed air before disassembly.

▼ CAUTION

Heavy duty carburetor cleaner may be harmful to the float

material and to the rubber parts, O-ring, seats, etc.

Therefore, it is recommended to remove those parts prior

to cleaning.

Fuel line

Lower nut

Lower nut

▼ CAUTION

Carburetor body and jets should be cleaned with

carburetor cleaner following manufacturer’s instructions.

When jets are very dirty or coated with varnish and gum,

replace them.

◆ WARNING

Solvents with a low flash point such as gasoline,

naphtha, benzol, etc., should not be used as they are

flammable and explosive.

Inspect the condition of the tip of the fuel inlet valve. If the tip is

worn, replace both the valve and its seat.

FUEL SYSTEM 3 - 7

●

NOTICE:

Install only a snowmobile carburetor inlet valve as it is designed

to function with a fuel pump.

Check to see if the throttle slide is worn and replace it if

required.

Check for fuel that may have soaked into float # 8; replace as

necessary.

Check float for cracks or other damage affecting free movement;

replace as necessary.

Inspect throttle and choke cables and housings for any damage.

Replace as necessary.

FUEL SYSTEM 3 - 8

DISASSEMBLY AND RE-ASSEMBLY

●

NOTICE:

To ease the carburetor disassembly and assembly procedure, it

is recommended to use carburetor tool kit (P/N 404 112 000)

# 20 FLOAT BOWL

Unscrew drain screw # 3 and screw # 52. Remove float bowl.

# 19 FLOAT AND NEEDLE VALVE ASS’Y

Unfasten both screws # 18 then, pull out float and needle valve

assembly # 19.

Upon re-assembly, apply Loctite 243 on screw threads.

# 5 MAIN JET

The main jet installed in the carburetor has been selected for a

temperature of - 20°C (0°F) at sea level. Different jetting can be

installed to suit temperature and/or altitude changes. A service

bulletin will give information about calibration according to

altitude and temperature.

Main jet # 5 may be removed without removing float bowl # 20

by first removing drain screw # 3.

# 6 PILOT JET

Use narrow screwdriver from carburetor tool kit (P/N 404 112

000) to unfasten pilot jet # 6.

◆ WARNING

It is critical to the free operation of the throttle slide that

the 2 connecting plates as assembled in one carburetor

be of the exact same length. Always replace the

connecting plates by a pair of new ones that were

matched at the factory for length and discard the old

ones. Simultaneously replace all the plates of the

carburetors of a same rack.

●

NOTICE:

Do not disassemble throttle slide needlessly.

▼ CAUTION

After throttle slide reassembly, proceed with a leak test.

See below for procedure.

# 7 NEEDLE

FUEL SYSTEM 3 - 9

Remove carburetor cover

Loosen needle retainer screw # 33.

# 12.

Fully open throttle and hold in this position for the following step.

Move aside needle retainer # 34.

1. Needle retainer moved aside.

Turn dual carburetor assembly upside down to free needle # 7.

Take care not to loose plastic washer # 9 under needle circlip #

10.

# 2 INTAKE SPICKET

Unscrew throttle slide cover screws # 70.

Open throttle 3/4 wide and hold it there.

Lift throttle slide covers bottom first until they are free from

carburetor bodies. Then, slide them out.

1. Lift bottom first

2. Slide out

After inserting throttle slide cover in place and be-fore installing

screws, ensure O-ring gasket is properly seated in its groove

especially in the area around vent nipple. See illustration at

right.

1. Needle retainer

2. Ensure O-ring gasket is properly seated in nipple area.

FUEL SYSTEM 3 - 10

CARBURETOR ADJUSTMENTS

Adjustments should be performed following this sequence:

- Pilot screw adjustment

- Carburetor synchronization and throttle slide height

(preliminary idle speed adjustment)

- Throttle cable adjustment

- Choke cable adjustment

- Final idle speed adjustment (engine running).

PILOT SCREW ADJUSTMENT

Completely close the pilot screw (until a slight seating resistance

is felt) then back off as specified.

Turning screw clockwise leans mixture and conversely, turning it

counter-clockwise enriches mixture.

Refer to “DIMENSIONS AND TOLERANCES” for the exact

specifications.

1- Idle speed screw

2- Pilot screw (one on each carburetor)

Mikuni TM 40

Pilot jet 17.5 17.5

Air s crew 1.5 turns 1.5 turns

Sli de cutaw ay 2.0 2.0

Needle 9DHI12-58-3 9DHI12-58-3

Main jet 380 380

Fuel le vel N/A N/A

---

Setting

MAG PTO

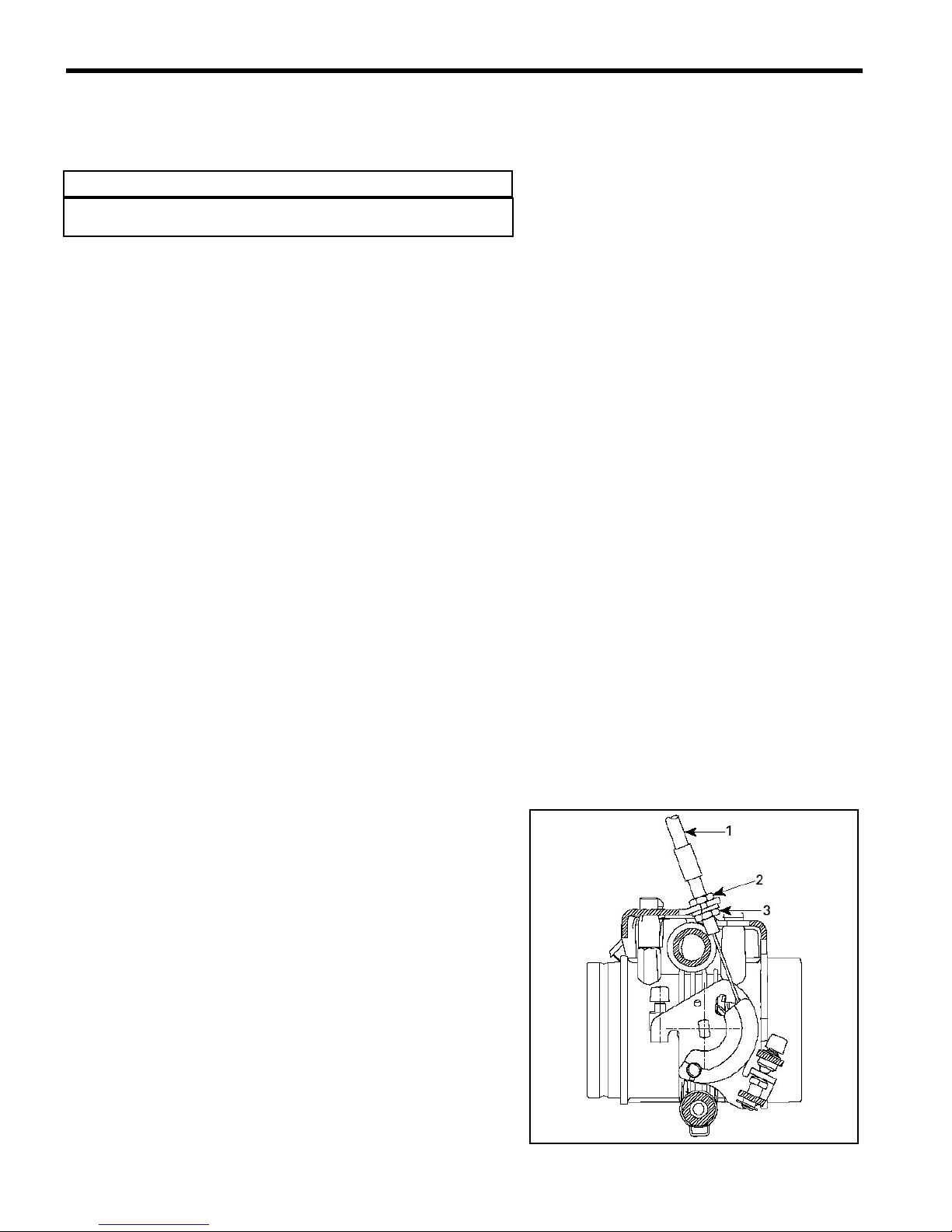

CARBURETOR SYNCHRONIZATION AND THROTTLE SLIDE

HEIGHT (PRELIMINARY IDLE SPEED ADJUSTMENT)

FUEL SYSTEM 3 - 11

First proceed on PTO carburetor.

Use a drill bit to measure the throttle slide height (see table at

right) on outlet side of carburetor (engine side).

1- Adjust PTO carburetor first

2- Drill bit used as a gauge to measure throttle height

3- Idle speed screw

Adjust by turning idle speed screw # 41.

Throttle slide height

Model

--

(drill bit size)

± 0.1 mm (±0.004'')

1.6 mm ( 0,063'')Snow hawk 600 HO 2004

For MAG carburetor, proceed using the synchronization screw.

Use the same drill bit used for the PTO carburetor to measure

throttle slide height. Turn synchronization screw to adjust.

1- PTO carburetor adjusted first

2- Drill bit used as a gauge to measure throttle height.

3- Synchronization screw

●

NOTICE:

Make sure that throttle cable does not hold the throttle slide.

Loosen cable adjuster accordingly

Final idle speed adjustment (engine running at idle speed)

should be within 1/2 turn of idle speed screw from preliminary

adjustment.

FUEL SYSTEM 3 - 12

INSTALLATION

▼ CAUTION

Never allow throttle slide(s) to snap shut.

To re-install the carburetor, carry out the removal operations in

the reverse order.

Be sure that the carburetor assembly is properly inserted into

the engine intake sockets before tightening the two hose

clamps. (A small amount of white grease can help here) After

this, be sure to reconnect the black plastic carburetor support

block to the lower shaft at the middle-bottom of the carburetor

assembly.

THROTTLE CABLE ADJUSTMENT

Adjust throttle cable as per following procedure:

Loosen throttle cable housing adjusting and locking nuts.

Connect throttle cable barrel to carburetor cam lever # 40.

While holding throttle lever to wide open throttle position, pull on

the throttle cable until mechanism touches the stopper. In this

position, turn cable housing adjusting nut and tighten lock nut.

Also ensure that, when throttle is released to idle position, the

idle adjusting screw end touches its stopper.

1- Throttle cable

2- Adjusting nut

3- Locking nut

CHOKE CABLE ADJUSTMENT

Adjust choke cable as per following procedure:

Loosen choke cable housing adjusting and locking nuts.

Connect choke cable on starter lever # 57.

While choke lever is fully open, pull choke cable until starter

lever reaches the stopper. Tighten cable housing adjusting and

locking nuts in this position.

As a confirmation, the gap between the stopper and the bracket

should be within 0 and 0.5 mm (0 and 1/64 in).

FUEL SYSTEM 3 - 13

A - Within 0 and 0.5 mm (0 and 1/64 in)

Idle Speed Final Adjustment

Start engine and allow it to warm then adjust idle speed to

specifications by turning idle speed screw clockwise to increase

engine speed or counterclockwise to decrease it.

Refer to Chapter 15 – Dimensions and Tolerances for the

specifications.

●

NOTICE:

Do not attempt to set the idle speed by using the pilot screw.

Severe engine dam-age can occur.

FUEL SYSTEM 3 - 14

FUEL PUMP

REMOVAL

Install a hose pincer (P/N 295 000 076) on fuel supply line close

to pump inlet.

Disconnect fuel outlet line(s).

Disconnect impulse line.

Remove screws securing fuel pump to chassis.

PUMP VERIFICATION

Check fuel pump valves operation as follows:

Connect clean plastic tubing to the inlet nipple and alternately

apply pressure and vacuum with pump of leak test kit. The inlet

valve should re-lease with pressure and hold under vacuum.

Repeat the same procedure at the outlet nipple. This time the

outlet valve should hold with pres-sure and also under vacuum.

Check impulse diaphragm and gasket as follows:

Connect clean plastic tubing to the impulse nipple and plug vent

hole on top cover with a finger. Either applies pressure or

vacuum using the pump (P/N 529 021 800) from the Engine leak

tester kit. The diaphragm/gasket must not leak.

1- Pump

2- Plug vent hole

CLEANING AND INSPECTION

Check fuel pump valves operation as follows:

The entire pump should be cleaned with general-purpose

solvent before disassembly.

Fuel pump components should be cleaned in general purpose

solvent and dried with compressed air.

◆ WARNING

Solvent with a low flash point such as gasoline, naphtha,

benzol, etc., should not be used as each is flammable and

explosive.

FUEL SYSTEM 3 - 15

Inspect diaphragm. The pumping area should be free of holes,

tears or imperfections. Replace as needed.

INSTALLATION

Inverse removal procedure.

◆ WARNING

Perform a pressure test to ensure there is no leak in the

fuel system.

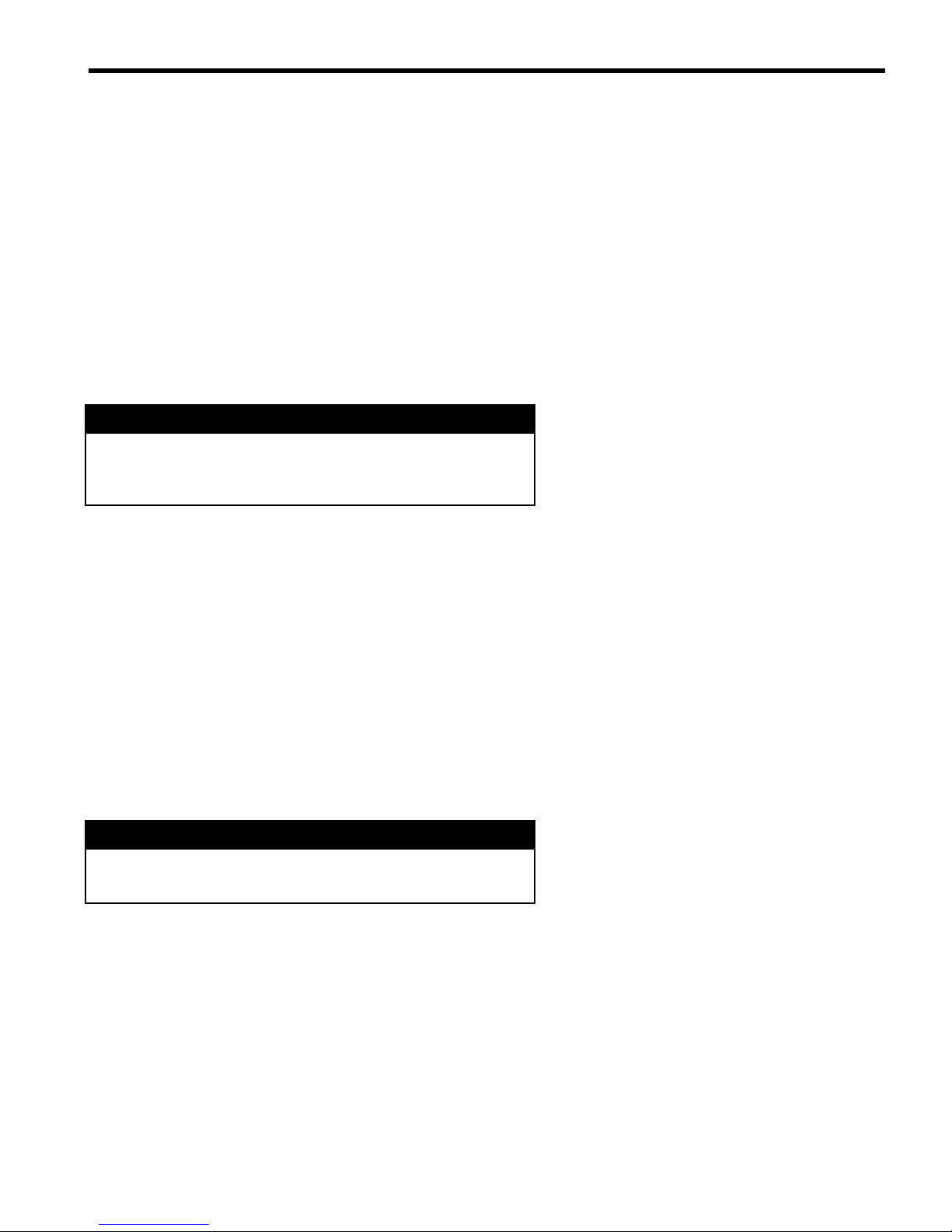

ENGINE REMOVAL 4-1

ENGINE REMOVAL

Unfasten or remove the following parts of the vehicle:

Remove the hood, bellypan and rear module from the vehicle.

Removing the bellypan will require that you remove the ski as

well.

Exhaust Pipe

o Remove the hose clamp retaining the exhaust pipe as

well as the two forward brackets (P/N’s SH032L and

SH032R).

o Remove the four springs that hold the exhaust pipe tight

against the Y-manifold.

o Remove the two exhaust springs that hold the exhaust

pipe tight with the exhaust canister.

o Now free, pull the exhaust pipe forward to remove the

pipe completely from the vehicle.

o Plug the outlet of the Y-manifold with a clean cloth.

Front Fork

ENGINE REMOVAL 4-2

o Unfasten the tie rod end which connects the steering

column to the upper triple clamp.

o Unfasten the two fork pivot bolts that retain the fork to

the vehicle. The upper bolt is shown at right, the other

is directly below it.

●

NOTICE:

Use a crate or box to support to support the vehicle just

under the drive sprockets when removing the fork.

Recoil Starter

o Using a flat-head screwdriver, push the knot out of the

recess in the starter handle. Since it is often easier, cut

the cord just before the knot while holding the cord

securely such that it does not slip and go into the recoil

housing. Make a new knot in the cord once the starter

handle has been removed to prevent this from

happening.

Fork Pivot Bolt

ENGINE REMOVAL 4-3

o Make a knot as shown at right.

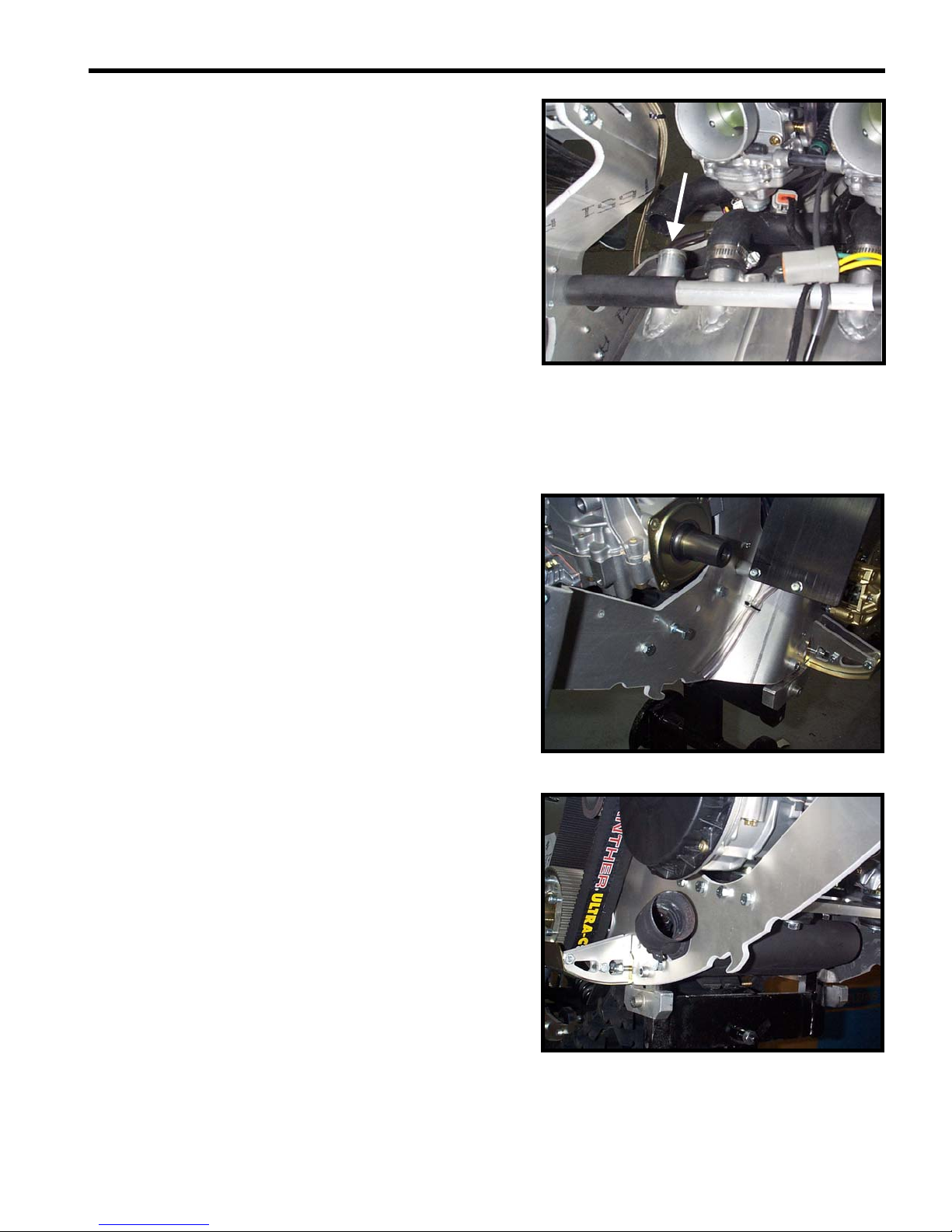

Secondary Clutch

o Open the secondary clutch using the the spacer tool

(P/N 529 008 700). For more details, see Chapter 8 –

Primary Transmission System.

o Remove the bolt retaining the secondary clutch to the

jackshaft and then slide the secondary off the jackshaft

at the same time removing the drive belt.

o Using the primary clutch holder tool (P/N 529 027 600),

remove the primary clutch bolt.

o Using the primary clutch puller (P/N 529 022 400)

remove the primay clutch from the engine.

Fuel Tank

o Remove the rubber latch retaining the fuel tank and

place it as shown on the right to have free access to the

airbox and carburetors.

Airbox

o Loosen the too hose clamps that fasten the air box to

the rear of the carburetors and remove the airbox

completely.

Carburetors

o Unfasten the black plastic clip that supports the bottom

of the carburetors. Push the top of it forward to snap it

out of place. Rotate it sufficiently to allow clearance.

ENGINE REMOVAL 4-4

o Loosen the two hose clamps that fasten the carburetors

to the engine intake boots and then remove the

carburetors completely, as a pair.

Engine Connector

o Cut the tie-wrap and disconnect the two-place housing

that connects the Crank Position Sensor (CPS) to the

wiring harness (blue and white/yellow wires). This

connector is located just above the jackshaft, near the

ignition coil and the water pump oil reservoir.

o The engine-side of the Crank Position Sensor (CPS)

wire then passes down the height of the chassis –

towards the magneto – and is attached to the tube that

goes from the water pump oil reservoir to the water

pump itself via a tie-wrap. Cut this tie-wrap as well.

ENGINE REMOVAL 4-5

o Cut the tie-wraps that secure the wires from the engine

to the voltage regulator. Then disconnect the four-place

housing (yellow, yellow and yellow wires) and the twoplace housing (green and black wires) that is next to the

four-place housing.

o Unplug the two wires from the two temperature sensors

located at the rear of the head of the engine.

Impulse Hose

o Disconnect the impulse hose from the crankcase of the

engine.

Water Pump Oil Resrevoir

ENGINE REMOVAL 4-6

o Using a drill and a 3/16 in. bit, drill out the two rivets that

secure the water pump oil reservoir to the MAG side

chassis.

o Cut the tie-wrap that secures the choke cable to the oil

reservoir hose.

Cooling System

o Loosen the hose clamp that holds the forward cooling

hose to the water pump housing inlet at the front of the

engine. With a bucket below this point, let the coolant

drain from the system completely.

o Loosen the hose clamp on the reservoir end of the short

hose that runs from the head to the reservoir and

disconnect the hose from the reservoir, as shown at

right.

ENGINE REMOVAL 4-7

o Loosen the hose clamp farthest towards the PTO side

on the PTO side heat exchanger and disconnect the

hose there. This hose runs from the head of the engine

to the inlet of the tunnel-mounted heat exchangers and

should remain connected to the engine when removing.

o Now that all of the peripheral equipment has been

disconnected, unscrew and remove the 4 bolts (per

side) that secure the engine plate to each side of the

chassis.

o PTO side bolts (x 4)

o MAG side bolts (x 4)

o Now the engine can be completely removed from the

vehicle.

Re-Installating Engine

To re-install the engine, follow the instructions above in the

reverse order. However, pay close attention to the following

details :

o Ensure that the 4 (per side) engine plate bolts are well

torqued to 37 N-m (27lbf-ft, 325 lbf-in). Loctite 243 is

recommended here.

o Ensure the correct alignment of the clutches and the

preload/deflection of the drive belt.

o Ensure that each cable, wire and hose is properly

connected and its original routing is used. (See Chapter

17 – Wire, Cable and Hose Routing for more details.)

o Ensure that each coolant line is re-installed using the

original routing and that each hose clamp is well

tightened.

o Re-fill the coolant reservoir to the Cold Level line before

attempting to start the vehicle. It is recommended to

elevate the front of the vehicle about 12 in. off the

ground when adding coolant to the system to ensure

that all of the air bubbles will escape. See Chapter 6 –

Cooling System for more details.

ENGINE REMOVAL 4-8

REWIND STARTER

REWIND STARTER 5 - 1

REWIND STARTER 5 - 2

REWIND STARTER

1 420810865 1 Connecting flange

2 420241236 4 Socket head screw M6 x 16

3-12 420889764 1 Rewind starter

3 420811404 1 Starter housing

4 420939115 1 Rewind spring

5 420852286 1 Rope sheave

6 412500200 1 Starter rope (2200mm)

7 420852297 1 Pawl

8 420852305 1 Pawl lock

9 420847925 1 Stage sleeve

10 420250400 1 O-ring

11 420852520 1 Lock ring

12 420845560 1 Locking element

13 - 1 Positioning pin

14 420941256 4 Hex collar screw M6 x 20

15 420899763 @ Molykote PG 54, 10g

16 293530011 @ Sealant, Sikaflex black # 221

17 572084400 1 Starter grip

Part descriptionsRef. P/N Qty

INSPECTION

●

NOTICE:

Due to dust accumulation, rewind starter must be periodically

cleaned, inspected and re-lubricated.

◆ CAUTION

It is of the utmost importance that the rewind starter spring be

lubricated periodically using Molykote PG 54 (P/N 420 899

763). Otherwise, rewind starter component life will be

shortened and/or rewind starter will not operate properly under

very cold temperatures.

o Check if rope # 6 is fraying, replace if so.

o When pulling starter grip, mechanism must engage

within 30 cm (1 ft) of rope pulled. If not, disassemble

rewind starter, clean and check for damaged plastic

parts. Replace as required, lubricate, reassemble and

recheck. Always replace O-ring # 10 every time rewind

starter is disassemble.

REWIND STARTER 5 - 3

o When releasing starter grip, it must return to its stopper

and stay against it. If not, check for proper spring

preload or damages. Readjust or replace as required.

O When pulling starter grip 10 times in a row, it must

return freely. If not, check for damaged parts or lack of

lubrication. Replace parts or lubricate accordingly.

REMOVAL

o Using a small screwdriver, extract rope knot from starter

grip # 17. Cut rope close to knot. Tie a knot near starter.

o Remove screw # 14 securing rewind starter to engine

then remove rewind starter.

REWIND STARTER 5 - 4

ROPE REPLACEMENT

o Pull out rope. Hold rewind starter in a vise. Slide rope

and untie the knot. Pull out the rope completely.

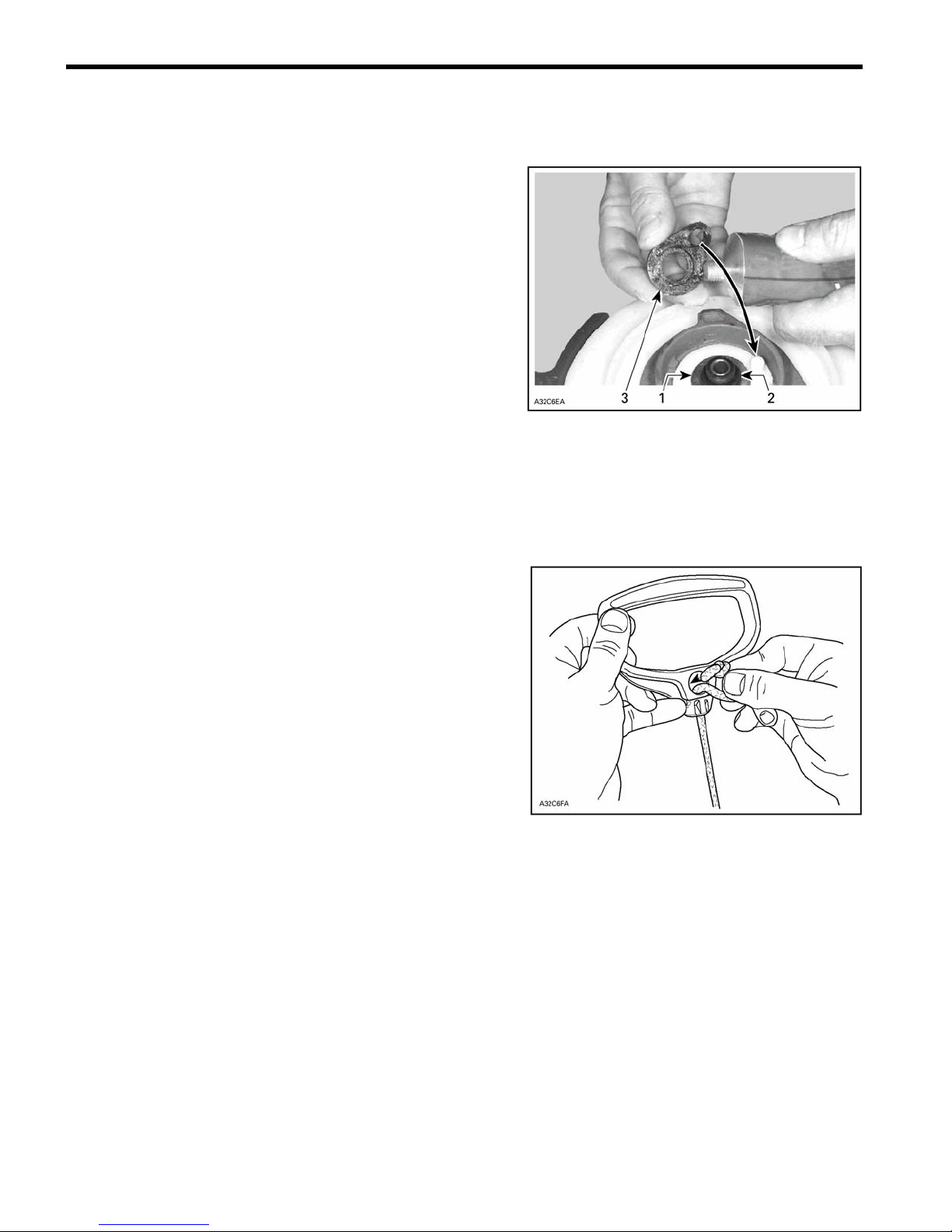

1) Knot to be untied.

●

NOTICE:

When rope is completely pulled out, spring preload is 4 ½ turns.

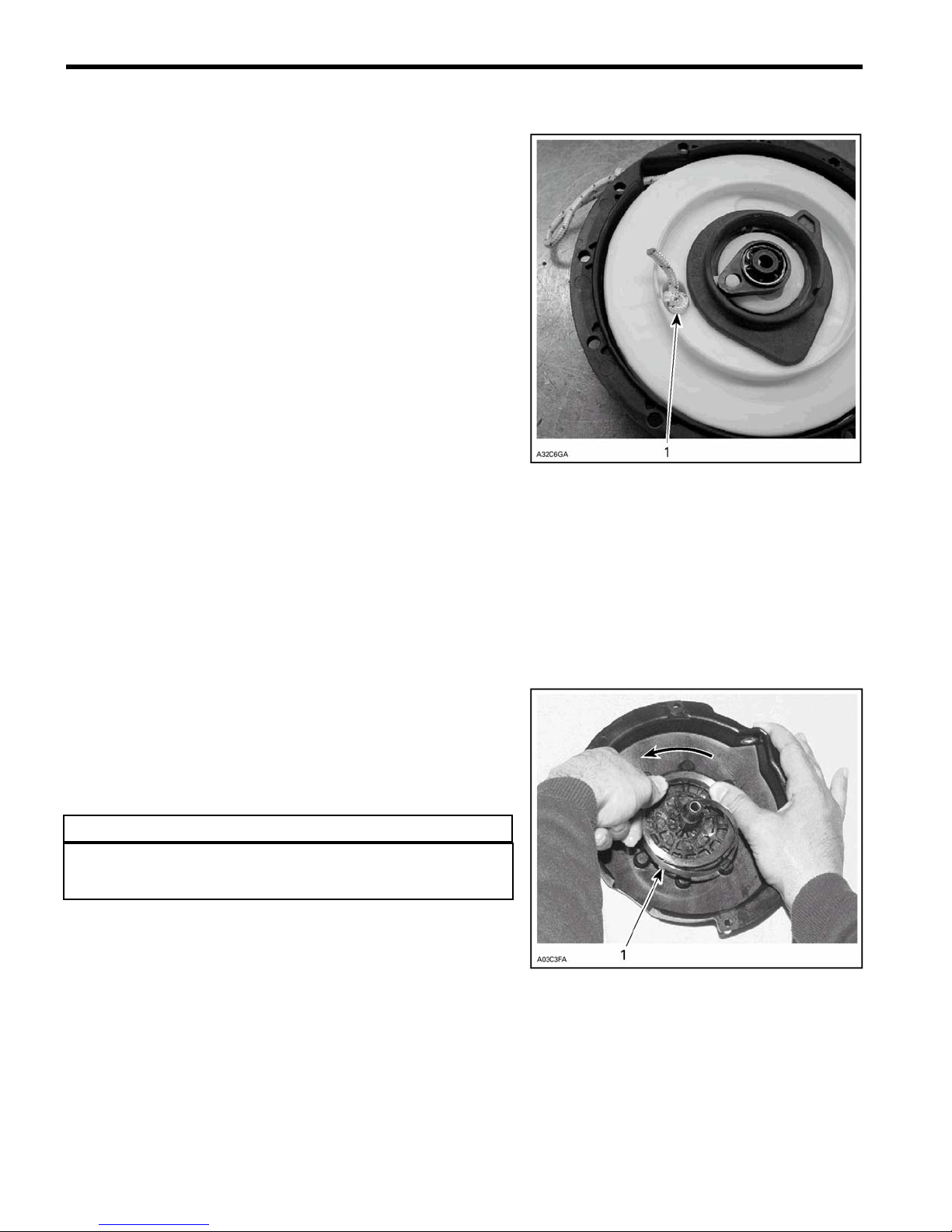

DISASSEMBLY

o Undo knot previously tied at removal. Let sheave get

free to release spring preload.

o Cut locking element # 12 and discard. Remove lock ring

# 11, O-ring # 10, stepped sleeve # 9, Pawl lock # 8 and

Pawl # 7.

o Remove sheave # 5 from starter housing # 3. Hold the

spring with a screwdriver.

o Pull out knot and then pull out rope # 6.

ASSEMBLY

At assembly, position spring # 4 outer end into spring guide

notch then wind the spring counter clockwise into guide.

▼ WARNING

Since the spring is tightly wound inside the guide it may fly out

when rewind is handled. Always handle with care.

1) Outer end into guide notch

◆ CAUTION

It is of the utmost importance that the rewind starter spring be

lubricated periodically using Molykote PG 54 (P/N 420 899

763). Otherwise, rewind starter component life will be

shortened and/or rewind starter will not operate properly under

very cold temperatures.

o Lubricate spring assembly and 1cm (1/2 in) wide on

bottom of housing with Molykote PG 54.

1) Molykote PG 54

◆ CAUTION

REWIND STARTER 5 - 5

The use of standard multi-purpose grease could result in

rewing starter malfunction.

o To install rope # 6, insert rope into sheave # 5 orifice

and lock it by making a knot, leaving behind a free

portion of about 25 mm in length. Fuse rope end with a

lit match and insert it into sheave.

o Free portion inserted into the sheave.

o Lubricate housing post with silicone compound grease.

Install sheave.

To adjust cord tension:

o Wind rope on the sheave and place the rope sheave

into the starter housing making sure that the sheave hub

notch engages in the rewind spring hook.

o Rotate the sheave counter-clockwise until rope end is

accessible through rope exit hole. This will give ½ turn

of preload.

o Pull the rope out of the starter housing and temporarily

make a knot to hold it.

REWIND STARTER 5 - 6

o Lubricate pawl # 7 with Molykote PG 54 (P/N 420 899

763) then install over rope sheave.

o Lubricate pawl lock # 8 with Molykote PG 54. Install

over pawl.

o Instal stepped sleeve # 9 with its sleeve first. Lubricate a

new O-ring # 10 and lock ring # 11 whit Molykote PG

54. Install over pawl lock.

1) Stepped sleeve

2) O-ring

3) Lock ring

o Install the locking element nut # 12.

INSTALLATION

o Fuse rope end with a lit match.

o Thread starter rope # 6 over guide pulleys and through

eye bolt.

o Reinstall rewind starter assembly on engine.

o Pass rope through starter grip # 17 and tie a knot in the

rope end. Insert rope end down and pull the starter grip

over the knot.

COOLING SYSTEM

COOLING SYSTEM 6 - 1

7

12

2

1

12

12

11

10

12

3

12

9

12

4

6

12

5

12

12

8

COOLING SYSTEM 6 - 2

Cooling System

1 509000281 1 Coolant reservoir

2 509000187 1 Closure cap

3 SH-108SA 1 MAG side heat exchanger

4 SH-109SA 1 PTO side heat exchanger

5 SH-093 1 Coolant tube #4

6 SH-094 1 Coolant tube #3

7 SH-095 1 Coolant tube #1

8 SH-096 1 Coolant tube #5

9 SH-097 1 Coolant tube #2

10 - 1 Overflow tube

11 414554800 1 Spring clamp (black)

12 408800400 10 Hose clamp (geared)

- 278001016 1 Temperature sensor (Bosch, Blue, MAG side)

- 512047000 1 Temperature sensor (Indebras, Black, PTO side)

- 420922517 1

- 420931272 1 Thermostat sealing ring

Thermostat (42

Part descriptionsRef. P/N Qty

o

)

◆ WARNING

This vehicle is equipped with a liquid cooling system.

ALWAYS ride with the rear deflector pad installed and in

conditions where there is enough snow to properly cool

the engine. If the red temperature light on the steering

column should ever illuminate, stop immediately and let

the vehicle cool down, and then find some snow. NEVER

continue to operate the vehicle with the temperature light

illuminated as severe engine damage will occur.

COOLING SYSTEM LEAK TEST

o Install special radiator cap (P/N 529021400) included in

engine leak tester kit (P/N 861749100) on coolant tank.

o Install hose pincher (P/N 295000076) on the overflow

hose. Using pump also included in the kit and

pressurize the entire system through the coolant

reservoir to 100 kPa (15 PSI).

o Check all hoses and cylinder/base for coolant leaks.

Spray all connections with a soapy water solution and

look for air bubbles.

INSPECTION

Check the general condition of hoses and clamp tightness.

DRAINING THE SYSTEM

To drain the cooling system:

o Siphon the coolant mixture from the coolant tank.

o Disconnect the hose at the water pump inlet housing to

drain coolant from engine.

o When the coolant level is low enough, lift the rear

of the vehicle to drain the heat exchangers.

COOLING SYSTEM 6 - 3

◆ WARNING

Never drain or refill the cooling system when the engine

is hot.

DISASSEMBLY AND ASSEMBLY

Temperature sensors:

o Apply Loctite 592 (P/N 413 702 300) thread sealant to

temperature sensor threads to avoid leakage.

COOLING SYSTEM 6 - 4

Pressure Cap (No. 2):

o Check if the cap pressurizes the system. If not,

install a new 90 kPa (13 PSI) cap (do not exceed this

pressure).

Thermostat:

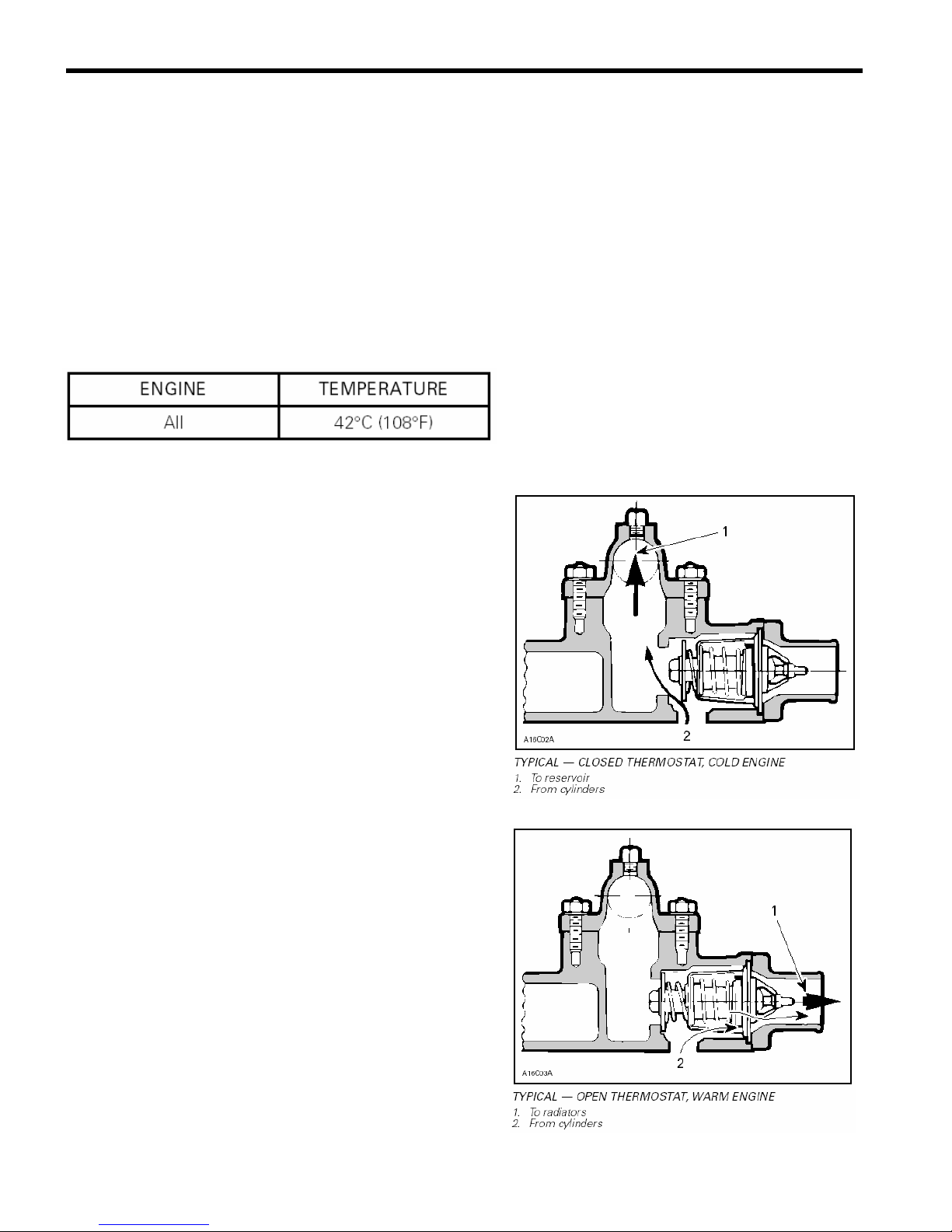

To check the thermostat, put it in a basin of water and gradually

heat it. The thermostat should start to open when water

temperature nears 42°C (108°F). It will be almost fully open at

50°C (122°F).

The thermostat is a double action type:

(1) Its function is to give faster warm up of the engine by

controlling a circuit; water pump — engine — coolant

tank. This is done by bypassing the heat exchanger

radiator circuit and using what it called a short circuit

during warm up, i.e. before the coolant temperature

reaches 42°C (108°F).

(2) When the liquid is warmed enough, the thermostat

progressively opens the circuit; water pump

— engine — heat exchangers — coolant tank to keep

the liquid at the desired temperature. (See the

diagram of the exploded view on page 6-1).

These 2 functions have the advantage of preventing

a massive entry of cold water into the engine.

COOLING SYSTEM REFILLING PROCEDURE

▼ CAUTION

To prevent the formation of corrosion or freezing, always

re-fill the system with the recommended premixed

coolant.

REFILLING PROCEDURE

●

NOTICE:

Use the 50/50 premixed coolant rated for -37°C (- 35°F) (P/N 293

600 038).

o Do not reinstall pressure cap.

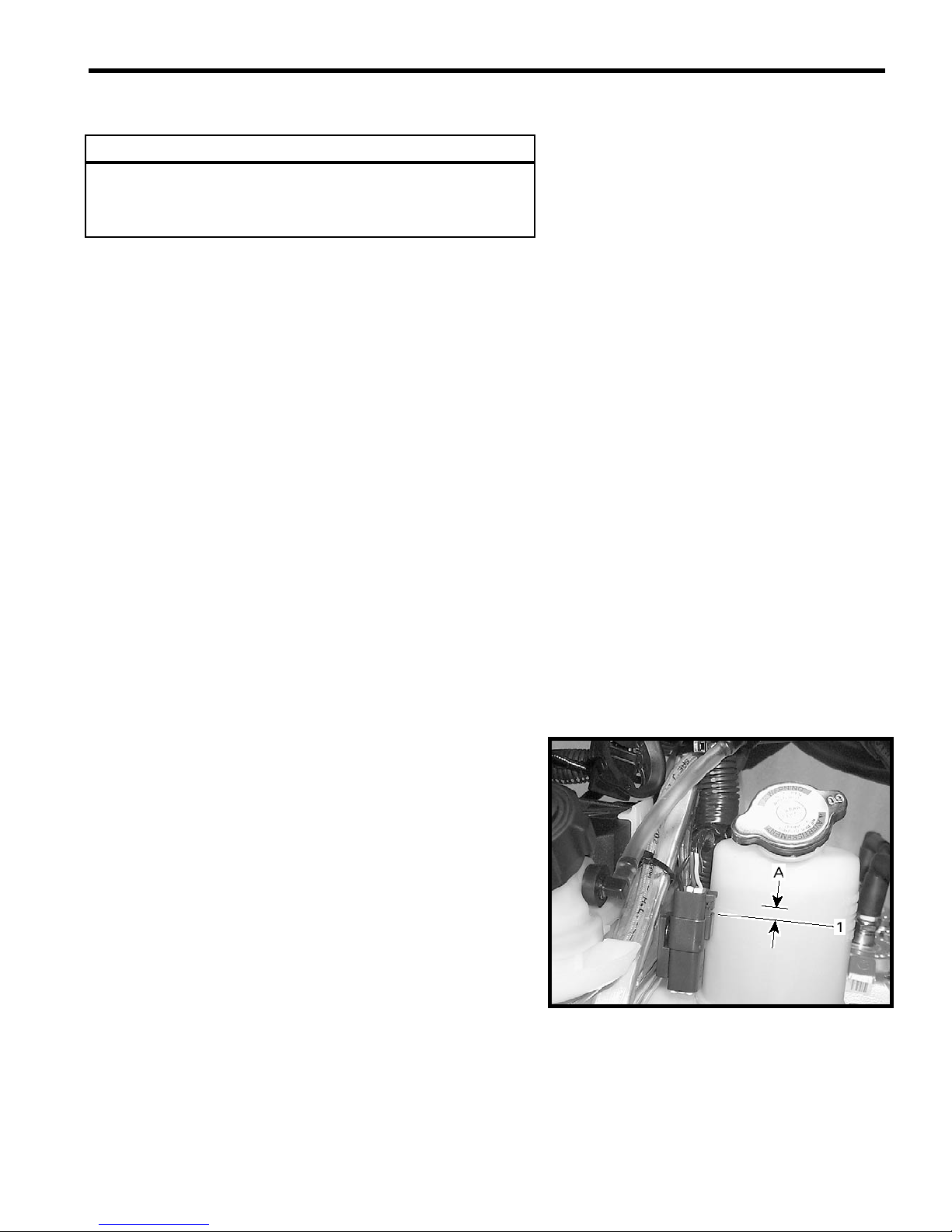

o With engine cold, refill coolant tank up to COLD LEVEL

line.

o Start engine. Refill up to line while engine is idling until

rear heat exchangers are warm to the touch (about 4 to 5

minutes).

o Always monitor coolant level while filling tank to avoid

emptying.

o Install pressure cap.

o Lift rear of vehicle and support it safely.

o Blip the throttle 3 - 4 times to bring engine speed to 7000

RPM.

o Apply the brake to stop the track.

o Lower vehicle back on ground and add coolant up to 15

mm (1/2 in) above the COLD LEVEL line, as shown at

right.

o Lift front of vehicle approximately 60 cm (24 in) and

support it safely. Let the vehicle idle for two minutes like

this

o Put the vehicle back on the ground and add coolant up to

15 mm (1/2 in) above the COLD LEVEL line.

o When the engine has completely cooled down, recheck

coolant level in coolant tank and refill up to the line if

needed.

o Check for coolant mixture freezing point. The

specification is - 37°C (- 35°F). Adjust as necessary.

COOLING SYSTEM 6 - 5

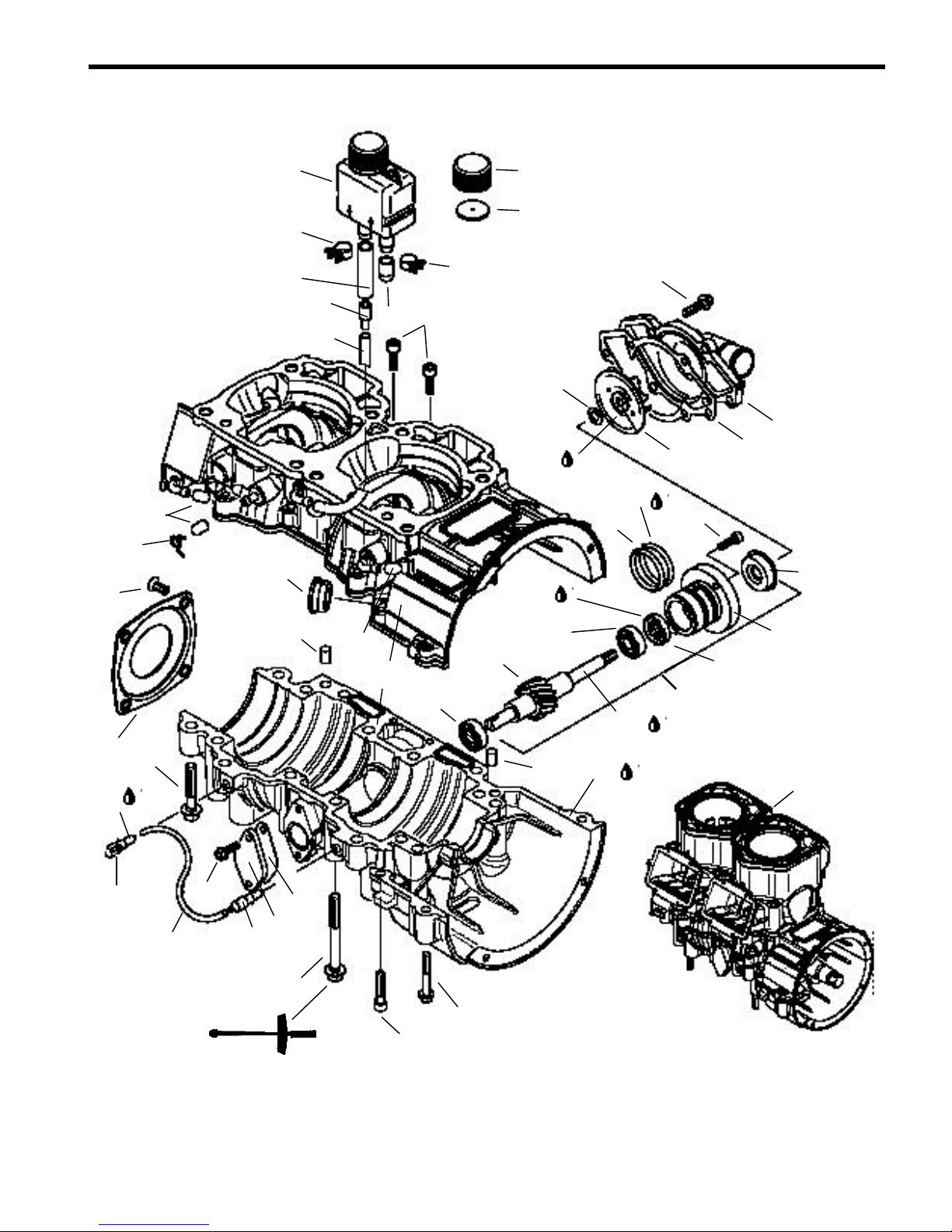

ENGINE / BOTTOM END

ENGINE (CYLINDERS / HEAD / BASE) 7 - 1

49

31

10

45

42

41

9

40

39

44

7

43

47

46

22

36

33

19

26

35

23

21

25

24

18

48

34

13

3

30

6

29

13

29 N-m ( 21.5 lbf-ft

3.0 kg-m, 258 lbf-in)

8

2

28

11

1-12

5

12

4

20

17

8

37

15

16

14-20

38

32

ENGINE (CYLINDERS / HEAD / BASE) 7 - 2

8

Engine / Bottom End

Ref. P/N Qty Part Descriptions

1-12 420889083 1 Crankcase ass‘y

2 420640836 10 Hex. collar screw M8 x 75

3 420640431 6 Hex. collar screw M8 x 45

4 420640311 2 Hex. collar screw M6 x 45

5 205063044 1 Socket head screw M6 x 30

6 420941925 2 Screw M5 x 16

7 420840401 2 Socket head screw M6 x 22

8 290632010 2 Dowel pin

9 420860965 1 Cable Grommet

10 420960770 2 Cap

11 420960777 1 Cap

12 420232100 1 Ball Bearing

13 420956510 2 Check Valve

14-20 420837421 1 Water Pump Assy

15 - 1 Step Collar

16 420230195 1 Oil Seal

17 420232100 1 Ball Bearing

18 420650370 1 Oil Seal

19 420950890 2 O-Ring

20 - 1 Water Pump Shaft

21 420840511 2 Socket Head Screw M5 x 16

22 420227945 1 Washer

23 420222505 1 Water impeller

24 420931810 1 Gasket

25 420922630 1 Water pump housing

26 420240031 6 Hex screw M6 x 25

27 420230400 1 O-ring

28 420931565 1 Gasket

29 420810825 1 Block-off plate

30 414413800 - Oil Line

31 420938190 1 Clamp

32 420059340 - Short Block Assy 593HO

33 293800060 10mL Loctite 243

34 413711400 10mL Loctite 648

35 413707000 - Molykote 111

36 420899271 400g Petamo Grease, GHY133N

37 420297906 30mL Sealing compound

3

413802900 12 x 1L Injection Oil

ENGINE (CYLINDERS / HEAD / BASE) 7 - 3

Engine / Bottom End

Ref. P/N Qty Part Descriptions

39 420974535 - Oil Line

40 420874370 1 Reducer fitting

41 420956239 - Oil Line

42 420951260 1 Clamp

43 420951240 1 Clamp

44 420960279 1 Cap

45-47 420956240 1 Oil Reservoir Assy

46 420850350 1 Rubber Gasket

47 420956250 1 Oil Cap

48 420812420 1 Oil Seal Cover

49 420941430 4 Countersunk screw M6 x 20

ENGINE (CYLINDERS / HEAD / BASE) 7 - 4

ENGINE / CRANKSHAFT AND PISTONS

ENGINE (CYLINDERS / HEAD / BASE) 7 - 5

Engine / Crankshaft and Pistons

Ref. P/N Qty Part Descriptions

1 - 9 420889090 1 Crankshaft Assy

2 420832635 1 Brg. 6207

3 420832575 1 Brg. 6207

4 420931792 1 Oil Seal

5 420832606 1 Brg.

6 420926190 1 Washer

7 420832600 1 Brg.

8 420931285 1 Oil Seal

9 420246015 1 Woodruff key

10 420945759 1 Lock Washer 22mm

11 420842230 1 Hex Nut M22

12 420832425 2 Needle Brg.

13-14 420889181 2 Piston Assy (71.89mm)

14 420815290 2 Semi-trapez ring

15 420916410 2 Gudgeon pin

16 420845106 4 Piston Circlip

17 420832575 1 Brg. 6207

18 420931455 2 Oil Seal

19 420834355 1 Central Gear (15 teeth)

20 420819709 1 Crankshaft (PTO section)

21 420819739 1 Crankshaft (MAG section)

22 420889093 1 Rod Repair Kit (MAG)

- 420889094 1 Rod Repair Kit (PTO)

23 293800060 10mL Loctite 243

24 293800070 8oz Loctite 767, anti-seize lubricant

25 413711400 10mL Loctite 648

26 420899271 400g Petamo Grease, GHY133N

27 293550021 50g Isoflex Grease

28 413802900 12 x 1L Injection Oil

ENGINE (CYLINDERS / HEAD / BASE) 7 - 6

ENGINE / TOP END

ENGINE (CYLINDERS / HEAD / BASE) 7 - 7

5

5

Ref. P/N Qty Part Descriptions

Engine / Top End

1 420931895 1 Base Gasket 0.8 mm

420931894 - Base Gasket 0.7 mm

420931892 - Base Gasket 0.6 mm

420931893 - Base Gasket 0.5 mm

2 420613710 2 Nicasil Cylinder

3 420854650 2 Exhaust Valve Guillotine

4 420430110 2 O-ring

5 420931542 2 Gasket

6 420854455 2 Valve Housing

7 205062544 4 Socket head screw M6 x 25

8 420260729 2 Bellows

9 420838253 2 Spring Clamp

10 420854449 2 Exhaust Valve

11 290239048 2 Hose Spring

12 420239944 2 Spring

13 290911558 2 Valve Cover

14 420430220 2 O-ring

15 420241221 2 Adjuster Screw

16 420241270 4 Screw M5 X 25

17 420640524 4 Hex collar screw M10 x 80

18 420640534 4 Hex collar screw M10 x 120

19 420931590 2 Rubber Ring Seal

20 293300026 2 O-ring

21 420613700 1 Cylinder Head (Silver)

22 290950320 1 O-ring

23 420430782 2 O-ring

24 420923460 1 Cylinder Head Cover (Silver)

25 420841306 10 Hex collar screw M8 x 65

26 420941621 2 Hex collar screw M8 x 56.5

o

27 420922517 1

Thermostat (42

C)

28 420931272 1 Sealing Ring

29 420922025 1 Outlet Socket

30 420941250 3 Screw M6 x 20

31 420850338 1 Gasket

32 420922062 1 Curved Neck Outlet

33 420240480 1 Plug Screw 1/8-27 NPT

34 420941451 1 Hex collar screw M8 x 40

35-38 420867879 2 Intake Socket Assy

36 420924680 4 Reed Petal

37 420924695 4 Reed Petal Stop

38 42094121

12 Screw M3 x

ENGINE (CYLINDERS / HEAD / BASE) 7 - 8

Engine / Top End

Ref. P/N Qty Part Descriptions

39 420941925 12 Screw M5 x 16

40 420850552 2 Gasket

41 420673070 1 Exhaust Manifold

42 420889920 1 Engine Gasket Set

43 420889925 1 Cyliinder Gasket Set

44 420297906 30mL Sealing Compound

45 293800038 50mL Loctite 518

TOP END

●

NOTICE:

The engine must be removed from the chassis to carry out the

following operations. See Chapter 4 – Engine Removal for

details.

TROUBLESHOOTING

Before completely disassembling the engine, check airtightness.

Refer to the section named LEAK TEST AND ENGINE

DIMENSION MEASUREMENT at the end of this chapter.

CLEANING

o Discard all gaskets and O-rings.

o Clean all metal components in a non-ferrous metal

cleaner.

o Scrape off carbon formation from cylinder exhaust

port cylinder head and piston dome using a wooden

spatula.

●

NOTICE:

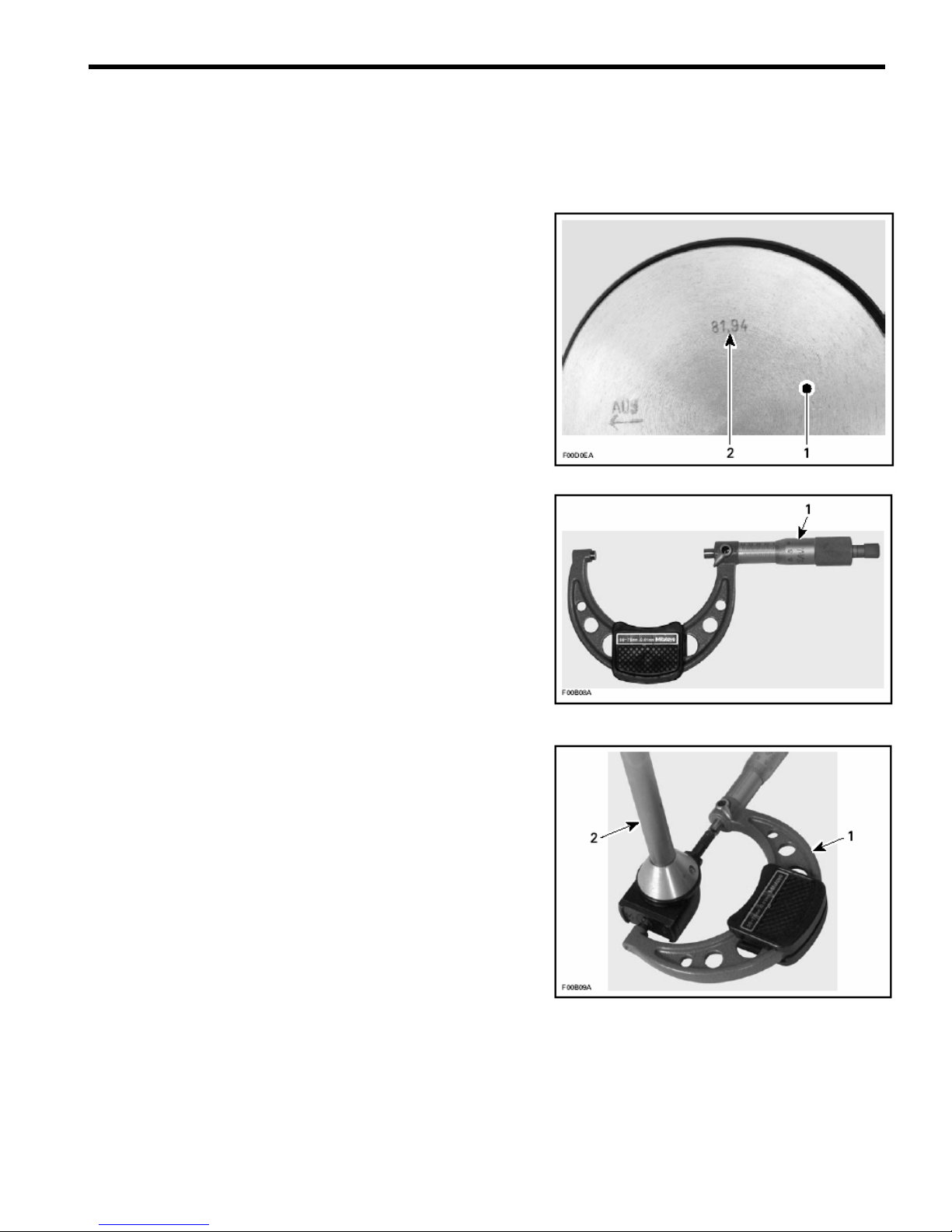

The letters “AUS” (over an arrow on the piston dome) must be

visible after cleaning.

o Clean the piston ring groove with a groove cleaner

tool or with a piece of broken ring.

DISASSEMBLY

RAVE System

ENGINE (CYLINDERS / HEAD / BASE) 7 - 9

●

NOTICE:

RAVE stands for Rotax Adjustable Variable Exhaust.

o Remove spring clip or screws no. 16, cover no. 13

and spring no. 12.

o Remove spring no. 11.

o Unscrew valve piston no. 10.

o Remove bellows no. 8 and spring no. 9.

o Remove cylindrical screws. Remove valve housing

no. 13.

o Pull out exhaust valve no. 3. (see right)

2, Cylinder

Remove spark plugs, coolant outlet no. 32. Unscrew

cylinder head cover no. 24 then cylinder

head no. 21.

13, Piston

Place a clean cloth or rubber pad (P/N 529 023 400)

over crankcase. Then with a pointed tool inserted

in piston notch, remove both circlips no. 16 from

piston no. 13.

ENGINE (CYLINDERS / HEAD / BASE) 7 - 10

All engines are equipped with cageless piston pin

Bearings, as shown at right.

Once the head and cylinder(s) has been removed, Use piston pin

puller (P/N 529 035 503) along with 20 mm sleeve kit (P/N 529

035 542). Use also a locating sleeve.

●

NOTICE:

The locating sleeve is the same that contains new cageless

bearing.

Insert piston pin puller (P/N 529 035 503) making

sure it sits squarely against piston as shown at right.

Install sleeve (1) then shouldered sleeve (2) over puller

rod as shown at right.

Screw in (LH threads) extracting nut.

Pull out piston pin no. 15 by unscrewing puller until shouldered

sleeve end is flush with thrust washer of piston pin bearing.

Remove puller. Pull out shouldered sleeve carefully.

Remove piston from connecting rod.

Install locating sleeve. Then push the needle bearings, thrust

washers and sleeve into the upper connecting rod journal

ENGINE (CYLINDERS / HEAD / BASE) 7 - 11

ENGINE (CYLINDERS / HEAD / BASE) 7 - 12

INSPECTION

●

NOTICE:

For details, Refer to LEAK TEST AND ENGINE DIMENSIONS

MEASUREMENT AT THE END OF THIS CHAPTER.

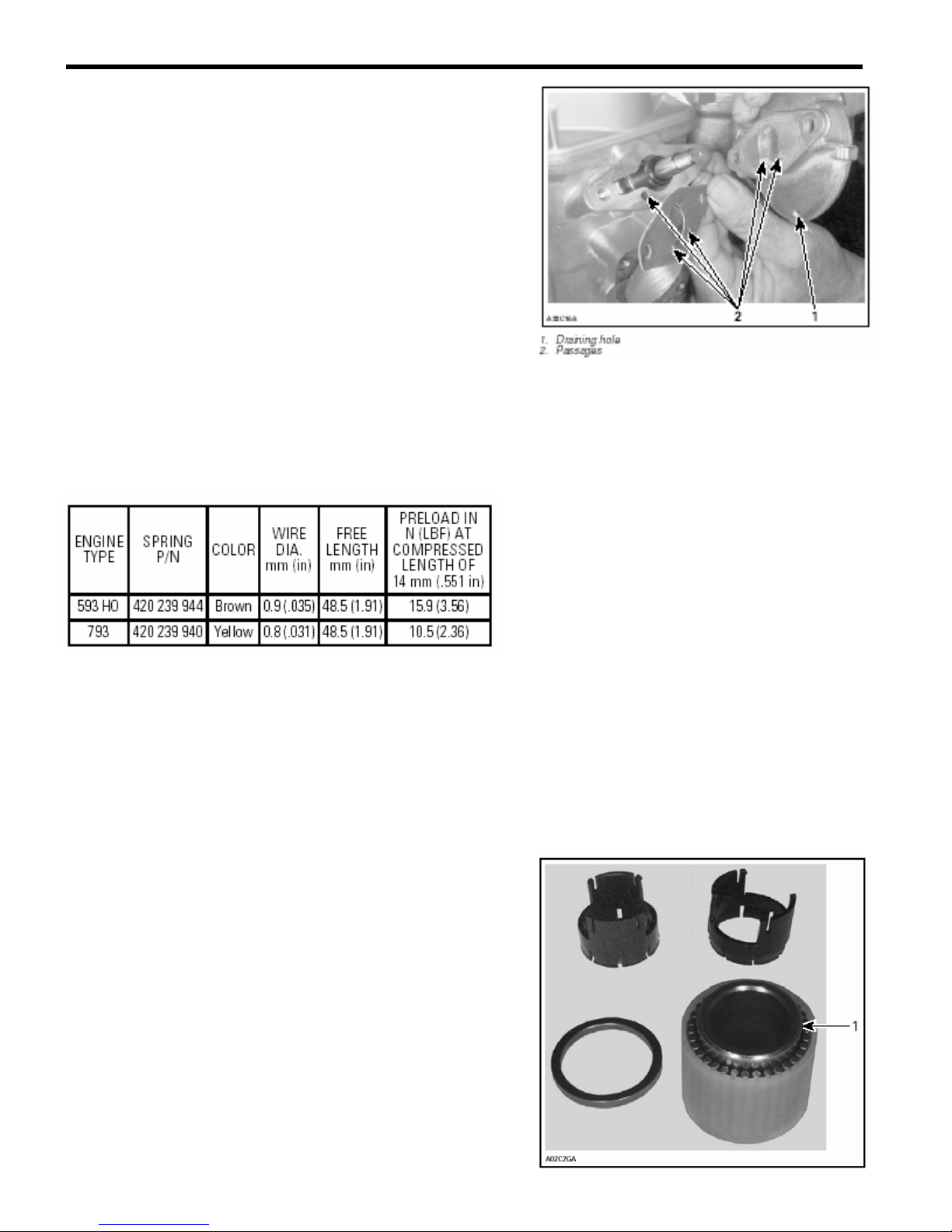

RAVE System

Check valve rod housing and cylinder for clogged

passages.

●

NOTICE:

Oil dripping from draining hole (No. 1) indicates a loose spring or

damaged bellows.

8, Bellows

Check for cracked, dried or perforated bellows.

12, Spring

ASSEMBLY

RAVE System

Install RAVE valve (noting which is the top side when it was

removed) Tighten red cap no. 15 screw to bottom.

2,13, Cylinder and Piston

Before inserting piston in cylinder, lubricate the

cylinder with new injection oil or equivalent.

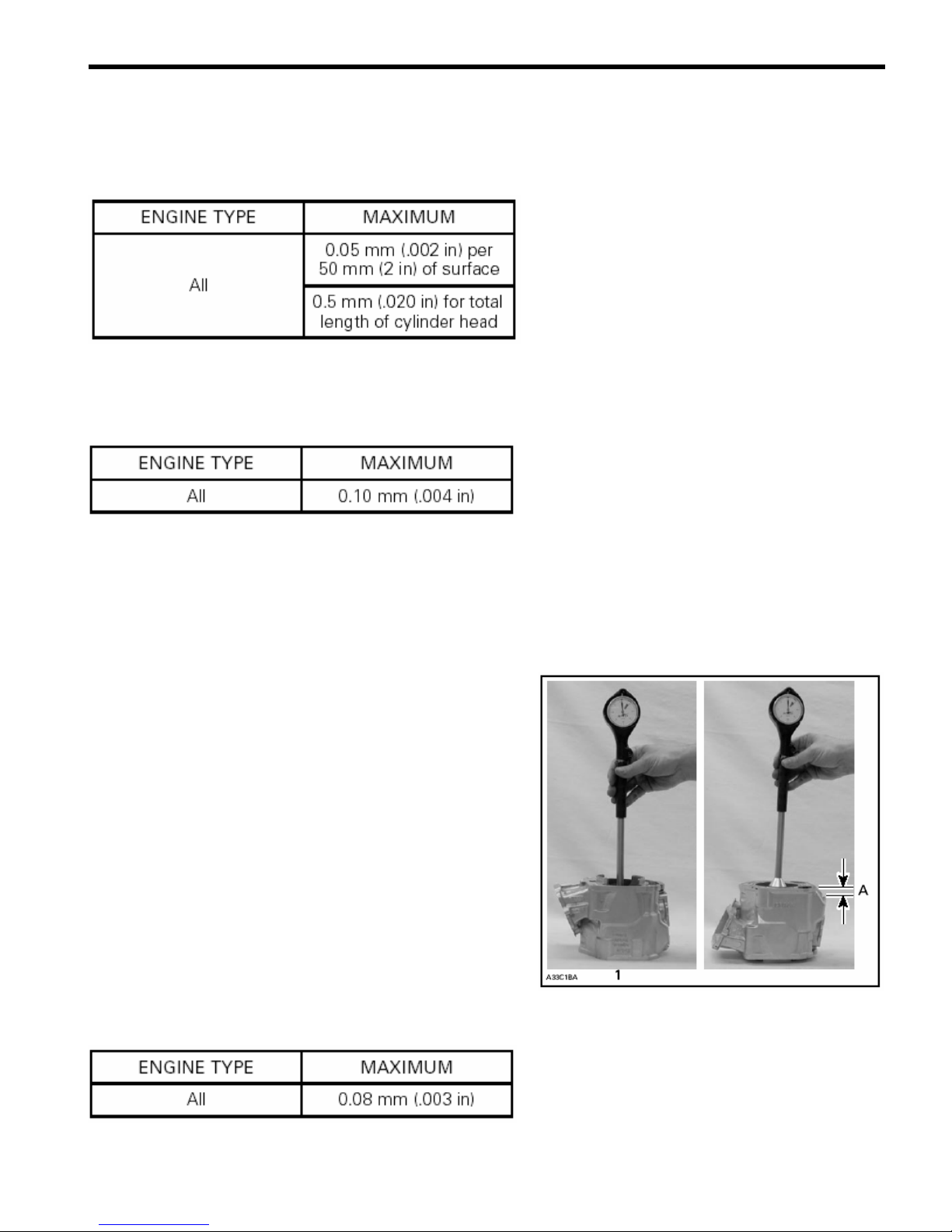

24,21,2, Cylinder Head Cover, Cylinder Head and Cylinder

Make sure parts sealing surfaces are flat. Refer to LEAK TEST

AND ENGINE DIMENSION MEASUREMENT at the end of this

chapter and look for CYLINDER HEAD WARPAGE.

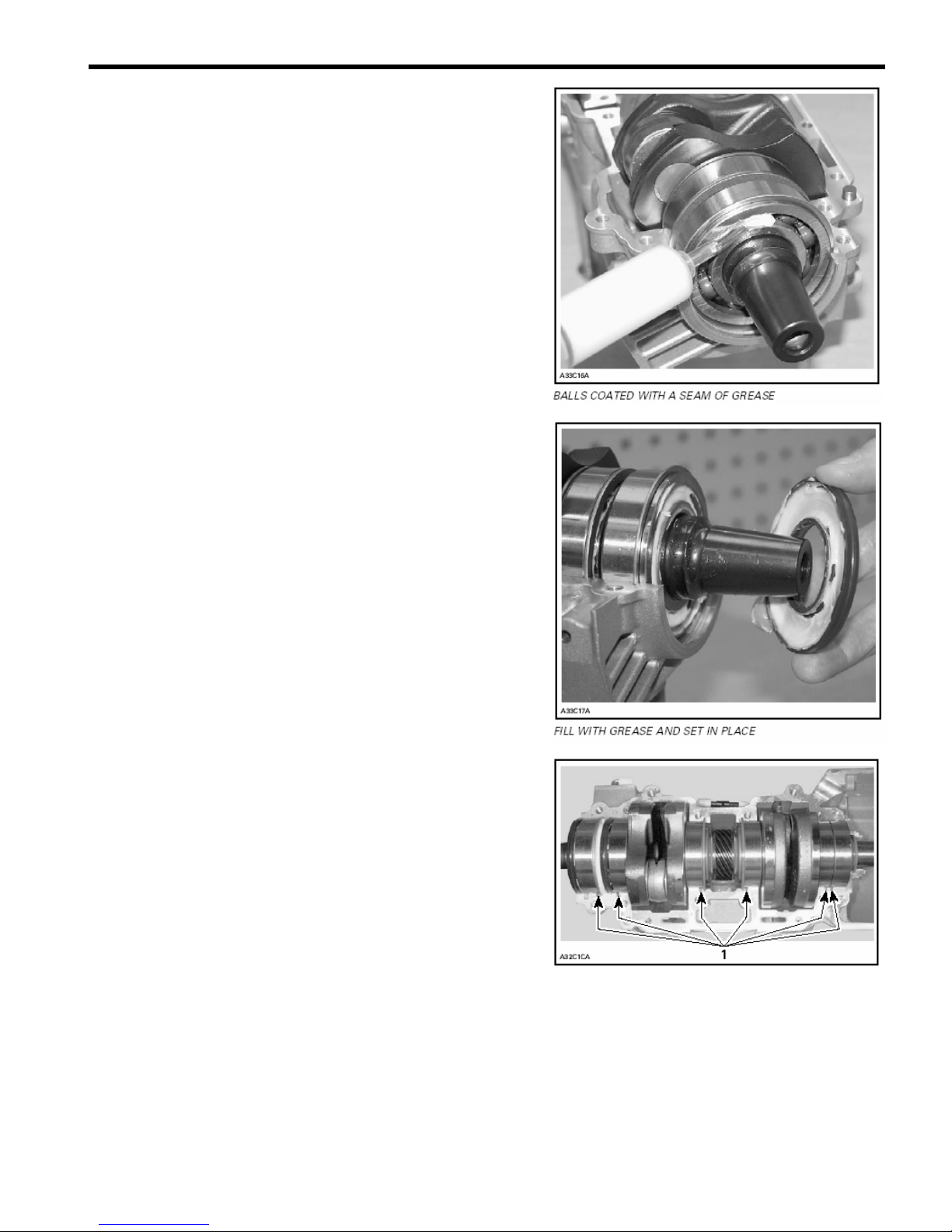

When installing a new cageless bearing, replace half plastic

cages with sleeve.

●

NOTICE:

All 593 HO engine cageless bearings have 28 needles.

o Oil needle bearing with injection oil.

o Grease thrust washers and install them on each end of

needles. The grease will help to hold them in place.

o Insert cageless bearing into connecting rod.

o Heat piston with a 100 W lamp or a heat gun before

piston installation to make the insertion of the pin much

easier.

▼ CAUTION

Piston temperature must not exceed 46°C (115°F). Never

use direct flame to heat the piston and never freeze the

pin.

At assembly, place the pistons over the connecting rods with the

letters “AUS” (over an arrow on the piston dome) facing towards

the exhaust port.

1. Exhaust

Install shouldered sleeve.

Install piston pin puller and turn handle until piston pin is correctly

positioned in piston.

ENGINE (CYLINDERS / HEAD / BASE) 7 - 13

ENGINE (CYLINDERS / HEAD / BASE) 7 - 14

All Models

▼ CAUTION

Always install new circlips. To minimize the effect of

acceleration forces on circlip, install each circlip so the

circlip break is at 6 o’clock as illustrated. Use appropriate

piston circlip installer.

Use circlip installer (P/N 529 035 686) to install new mono-hook

circlips no. 16. Insert circlip into support so that, when installed

in piston groove, the tab faces upward.

With round end of pusher, position circlip perpendicularly to the

support axis.

With the other end of the pusher, push circlip into the

support groove.

Using a plastic hammer, tap the pusher to put the circlip in place.

Make sure to install new circlips with the tab toward the top as

per the following photos.

▼ CAUTION

Always install new mono-hook circlips. If circlip

installation fails at the first attempt, always retry with a

new one because, on a second attempt, the circlip will

lose its normal retaining capabilities.

▼ CAUTION

Circlips must not move freely after installation; if so,

replace them. Clean cylinders and crankcase mating

surfaces with Loctite Chisel (P/N 413708500). Coat

crankcase mating surface with Loctite 518 (P/N

293800038). Choose the right gasket thickness according

to combustion chamber volume. Refer to LEAK TEST

AND ENGINE DIMENSION MEASUREMENT. Install it on

the crankcase. Coat gasket with Loctite 518.

ENGINE (CYLINDERS / HEAD / BASE) 7 - 15

▼ CAUTION

Always install a gasket of the proper thickness. Failure to

do so may cause detonation and severe engine damage.

Before inserting piston in cylinder, lubricate the cylinder