SnowEx SP-9800X User Manual

Owner / Operator’s Manual

This Manual Must Be Read Before Operating The Equipment

Madison Heights, Michigan 48071

800-725-8377

www.snowexproducts.com

© TrynEx International 2012

(REV B) F50735

SP-9800X

Serial # W2-100000 and higher

CUSTOMER COPY

Table of Contents

General Information ...................................................................................................................................................................................... 3

Introduction ................................................................................................................................................................................................. 4

Safety .......................................................................................................................................................................................................... 5

Warning Decal Positions..............................................................................................................................................................................6-7

Operating the Spreader .............................................................................................................................................................................8-11

Spreader Maintenance ............................................................................................................................................................................... 12

Wiring Instructions ..................................................................................................................................................................................... 13

Control and Harness Diagram ............................................................................................................................................................... 14-19

Mounting Instructions ............................................................................................................................................................................ 20-21

Troubleshooting .................................................................................................................................................................................... 22-23

Warranty .................................................................................................................................................................................................... 24

Spreader Views

Model # SP-9800X ....................................................................................................................................................................... 25

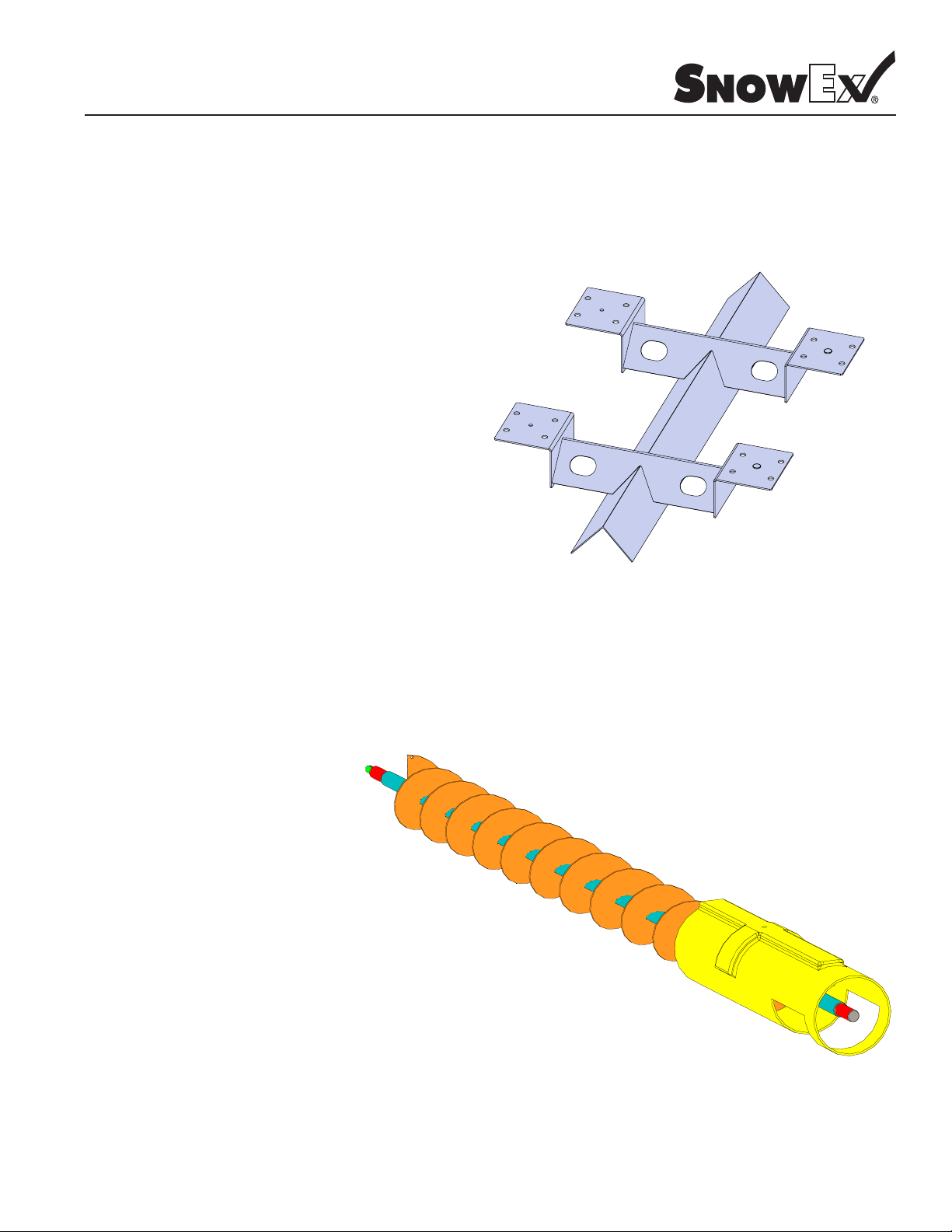

Frame Assembly Parts Breakdown

Model # SP-9800X .................................................................................................................................................................. 26-27

Auger Drive Assembly Parts Breakdown

Model # SP-9800X .................................................................................................................................................................. 28-29

Hopper Assembly Parts Breakdown

Model # SP-9800X .................................................................................................................................................................. 30-31

Auger Extension Assembly Parts Breakdown

Model # SP-9800X.......................................... ........................................................................................................................ 32-33

Drive Assembly Parts Breakdown

Model # SP-9800X .................................................................................................................................................................. 34-35

Notes .............................................................................................................................................................................................. 36-37

Have a question or need assistance?

SnowEx Customer Care

(800) 725-8377

or (248) 586-3500

Monday through Friday 8:00 AM to 4:30 PM EST

Fax: (248) 691-8378

E-mail: customercare@trynexfactory.com

Website: www.snowexproducts.com

© TrynEx International 2012 (REV B) F50735 2

General Information

CONGRATULATIONS!

The spreader you have purchased is an example of snow and ice control technology at its nest! Your spreader’s self-contained design is a

trademark of all SnowEx products. Here’s why…

SIMPLICITY: Fewer moving parts manufactured of higher quality means minimal maintenance for your SnowEx spreader.

RELIABILITY: High impact linear low density polyethylene hopper. State-of-the-art electronic dual variable speed control, custom engineered

powder coated frame, maximum torque 12-volt motor coupled to a custom engineered transmission; found only on SnowEx products.

VERSATILITY: Multi-use capabilities allows spreading of a variety of materials for snow and ice control.

WARRANTY: Best in the industry, hands down! 2 years standard and now 5 year extended (optional).

The benets you are about to recognize are that of time, money and effort.

We welcome you to the world of SnowEx Performance.

Registration

Record the following information in this manual for quick reference.

Spreader Model Number

Spreader Serial Number

Handheld Control Pendant Serial Number Control Board Serial Number

Date of Purchase

Dealer Where Purchased

When ordering Parts, the above information is necessary. This will help to see that you

receive the correct parts.

At the right is a diagram of the ID tag. This tag on the spreader is located on the

frame.

Please ll out the warranty card with all the necessary information to validate it.

This will also give us a record so that any safety or service information can be

communicated to you.

SP-9800X

W2-100000

3© TrynEx International 2012 (REV B) F50735

Introduction

This manual has been designed for your help. It will assist you and instruct you on the proper set-up, installation and use of this spreader.

Refer to the table of contents for an outline of this manual.

We require that you read and understand the contents of this manual completely (especially all safety information) before attempting any

procedure contained herein.

THIS SIGN SHOULD ALERT YOU:

The Society of Automotive Engineers has adopted this SAFETY ALERT SYMBOL to pinpoint characteristics

that, if NOT carefully followed, can create a safety hazard. When you see this symbol in this manual or on the

machine itself, BE ALERT! Your personal safety and the safety of others is involved.

Dened below are the SAFETY ALERT messages and how they will appear in this manual:

(RED)

Information that, if not carefully followed,

can cause death!

(ORANGE)

Information that, if not carefully followed,

can cause serious personal injury or death!

(YELLOW)

Information that, if not carefully followed,

can cause minor injury or damage to equipment

© TrynEx International 2012 (REV B) F50735 4

Safety

Before attempting any procedure in this book, these safety instructions must be read and understood by all workers who have any part in the

preparation or use of this equipment.

For your safety warning and information decals have been placed on this product to remind the operator of safety precautions . If anything

happens to mark or destroy the decals, please request new ones from SnowEx.

Never exceed the Gross Vehicle Weight Rating of vehicle. Failure to do so may limit a vehicles handling

characteristics.

Never attempt to take a unit off a truck with material in it.

Always keep hands, feet, and clothing away from power driven parts.

Unit must be pinned and locked into position before operating vehicle.

Always shut off vehicle and power source before attempting to attach or detach or service unit Be sure

vehicle/power source is properly braked or chocked.

Remember, most accidents are preventable and caused by human error. Exercising of care and precautions

must be observed to prevent the possibility of injury to operator or others!

Never operate equipment when under the inuence of alcohol, drugs, or medications that might alter your

judgment and/or reaction time.

Before working with the spreader, secure all loose tting clothing and unrestrained hair.

Always wear safety glasses with side shields when servicing spreader. Failure to do this could result in

serious injury to the eyes.

Never allow children to operate or climb on equipment.

Always check areas to be spread to be sure no hazardous conditions or substances are in the area.

Always inspect unit for defects: broken, worn or bent parts, weakened areas on spreader.

Remember it is the owner’s responsibility to communicate information on safe usage and proper

maintenance of all equipment.

Always make sure personnel are clear of areas of danger when using equipment.

Never weld or grind on equipment without having a re extinguisher available.

Inspect the unit periodically for defects. Parts that are broken, missing or worn out must be replaced

immediately. The unit or any part of it can not be altered without prior written permission from the

manufacturer.

Always inspect pins and latches whenever attaching or detaching spreader, and before operation of spreader.

Never exceed 45 m.p.h. when loaded spreader is attached to vehicle. Braking distances may be increased

and handling characteristics may be impaired at speeds above 45 m.p.h.

Never use wet materials or materials with foreign debris with any of these spreaders. These units are

designed to handle dry, clean, free owing material.

Never leave material in hopper for long periods of time. Be aware that all ice melters are hygroscopic and will

attract atmospheric moisture and harden up.

5© TrynEx International 2012 (REV B) F50735

Warning Decal Positions

Model # SP-9800X

D6335 D6546

ROTATING AUGER CAN CAUSE

SERIOUS INJURY OR DEATH

• Keep arms, hands, and loose clothing

away from auger.

• Shut off control and unplug spreader before

servicing.

D6335

• DO NOT EXCEED GVWR OF VEHICLE

• DO NOT OVERLOAD SPREADER

• LOAD SPREADER EVENLY

D6546

D6192

• Read Owner’s Manual for Installation Instructions.

• Secure spreader to truck with ratchet straps.

• Anchor spreader securely to truck body with bolt kit provided to prevent

slipping or sliding.

• Routinely check straps and hardware to make sure they are secure.

D6548

F50645

ROTATING PARTS CAN CAUSE

SERIOUS INJURY OR DEATH

• ALWAYS DISCONNECT POWER

WHEN NOT IN USE

WHEN NOT IN USE

• ALWAYS DISCONNECT POWER

SERIOUS INJURY OR DEATH

ROTATING PARTS CAN CAUSE

D6547D6548

DANGER

• DO NOT REMOVE SPREADER WITH MATERIAL IN HOPPER

• FASTEN SPREADER DOWN WITH APPROVED RATCHET STRAPS

AND BOLT KIT

• REAR FRAME LOCATOR BARS MUST BE IN PLACE BEFORE

OPERATING VEHICLE

D6547

© TrynEx International 2012 (REV B) F50735 6

Warning Decal Positions

Model # SP-9800X

D6547 D6335

DANGER

• DO NOT REMOVE SPREADER WITH MATERIAL IN HOPPER

• FASTEN SPREADER DOWN WITH APPROVED RATCHET STRAPS

AND BOLT KIT

• REAR FRAME LOCATOR BARS MUST BE IN PLACE BEFORE

OPERATING VEHICLE

ROTATING PARTS CAN CAUSE

SERIOUS INJURY OR DEATH

• ALWAYS DISCONNECT POWER

WHEN NOT IN USE

D6547

WHEN NOT IN USE

• ALWAYS DISCONNECT POWER

SERIOUS INJURY OR DEATH

ROTATING PARTS CAN CAUSE

ROTATING AUGER CAN CAUSE

SERIOUS INJURY OR DEATH

• Keep arms, hands, and loose clothing

away from auger.

• Shut off control and unplug spreader before

servicing.

D6335

D6194F50645

7© TrynEx International 2012 (REV B) F50735

Operating the Spreader

Model # SP-9800X

Spreader Operation

1. Push On/Off button.

2. Press the Start/Stop button. Auger and Spinner will begin to turn, spreading material.

3. Use dials in center of Control Pendant to adjust Material Distribution Shaft speed. This will change the spread rate at constant vehicle speed.

4. Press Start/Stop to stop spreading.

5. Turn off Spreader by pushing the On/Off button.

Spreader Loading

WARNING: Do not overload vehicle.

Use chart below to calculate weight of material. Weights of material are an average for dry materials.

Material Weight Per Cubic Ft.

Rock Salt 80-90 lbs.

Sand/Salt Mix 95-120 lbs.

WARNING: Never leave material in hopper for long periods of time as salt is hygroscopic and will attract atmospheric moisture and harden up.

When spreading sand mix, a 1:1 ratio for Sand/Salt mix is recommended to prevent the material from freezing.

Spreading Tips

For a heavier pass:

Decrease vehicle speed

Increase Auger speed

For a lighter pass:

Increase vehicle speed

Decrease Auger speed

For a wider pass:

Increase spinner speed

Spread ice melters with the storm to prevent unmanageable levels of ice.

Never exceed 10 miles per hour when spreading.

Calculate spread pattern when near vegetation and other vehicles.

Never operate spreader near pedestrians.

© TrynEx International 2012 (REV B) F50735 8

Operating the Spreader

Model # SP-9800X

Warning Protection

If audible beeping occurs, read display to identify problem. If display reads “OL” (overload) or “OH” (overheat), shut the controller down and

carefully clear jammed auger. If display reads “E1” this means there is a dead short in the system. Do not use until problem is corrected. If the

display reads “E0” this means the motor is not getting any power. Check all connections. If the display reads “LB” the vehicle battery is extremely

low (possibly caused by a poor or corroded connection) and could damage the system.

If there are any problems while operating the spreader, refer to Troubleshooting Guide.

Auto Reverse

If your controller displays “OL” this could indicate a jammed auger.

To engage the Auto-Reverse “AR” Function:

Step 1: Shut the Main Power Switch OFF for 3 seconds.

Step 2: Turn the Main Power Switch ON. When the machine starts back up, the “AR” sequence will automatically start and the auger will

reverse for several rotations to clear the jam.

After a pause of several moments, the auger will automatically return to correct rotation. If the jam is still not cleared, the controller will again

display “OL.”

You may repeat Steps 1 and 2 for a second and third time.

If after the third try the controller displays “OL,” you must extract the material that is causing the problem.

Follow all warning directions when clearing jams.

9© TrynEx International 2012 (REV B) F50735

Operating the Spreader

Model # SP-9800X

ADJUSTABLE SPINNER INSTRUCTIONS

Your spreader is equipped with an adjustable spinner to assist you in more precise material application. The Spinner plate gives the operator

control of whether the material spreads to the right, left or is centered. All of the ns should be in the same position; this will keep the spread

pattern consistent and have even ground coverage. Before operating the spreader, spread some material in a clear area where you can easily

observe the spread pattern and how it changes. Adjust according to the instructions below to get the pattern you desire.

When the ns are in their center adjustment position, the spread pattern will be mostly centered. However, collisions and other damage to

the equipment may change this. Check the n position and resulting

spread pattern often enough to prevent the equipment performance

from being adversely affected.

When looking down at the spinner, moving the ns clockwise will

adjust the spread pattern toward the left side of the spreader.

When looking down at the spinner, moving the ns counter-clockwise

will adjust the spread pattern toward the right side of the spreader.

© TrynEx International 2012 (REV B) F50735 10

Operating Spreader

Model # SP-9800X

INVERTED-V INSTRUCTIONS

• The Super-Maxx 9800 uses an inverted-v design over the auger

area. This inverted-v (F50375) is used to reduce load to the auger

drive train. It must not be removed unless servicing the unit.

• WARNING: Always disconnect power source before attempting to

remove material bafe.

F50375

AUGER DISCHARGE TUBE INSTRUCTIONS

• The Super-Maxx Spreaders use an auger discharge tube to reduce

material leakage. It must not be removed unless servicing the unit.

• WARNING: Always disconnect power source before attempting to

remove auger discharge tube.

Auger Discharge Tube

11© TrynEx International 2012 (REV B) F50735

Spreader Maintenance

Model # SP-9800X

General Maintenance

Use dielectric grease on all electrical connections to prevent corrosion at the beginning and end of the season and each time power plugs are

disconnected.

Wash unit after each use to prevent material build-up and corrosion.

Paint or oil all bare metal surfaces at the end of the season.

Apply small amount of light oil to latches as needed.

After rst use, tighten all nuts and bolts on spreader and mount.

Grease bearings after every 20 hour’s use.

Store control in cool dry place during the off season.

Warning

When servicing is necessary, perform it in a protected area Do not use power tools in rain or snow because of danger of electrical shock or injury.

Keep area well lighted. Use proper tools. Keep the area of service clean to help avoid accidents.

Never remove spreader with material in hopper.

Disconnect electricity to spreader before servicing.

Caution

Vibrator is not designed for continuous duty. Allow motor to cool between long cycle times.

Do not modify vehicle or spreader wiring harness. Doing so will void product warranty.

When replacing parts use only original manufacturer’s parts. Failure to do so will void warranty.

The controller is a solid state electronic unit and is not serviceable. Any attempt to service will void warranty.

There are no serviceable parts in the motor/transmission assembly. Any attempt to service will void warranty.

Spinner motor is not designed for continuous duty. Allow motor to cool between long cycle times.

When pressure washing motor enclosure area, stay at least 36’’ away from motor enclosures.

© TrynEx International 2012 (REV B) F50735 12

Loading...

Loading...