This Manual Must Be Read Before Operating The Equipment

Owner / Operator’s Manual

FOR MODELS

SP-7550 Serial # L1-144130 and higher

Madison Heights, Michigan 48071

800-725-8377

www.snowexproducts.com

© Trynex International 2011 (REV 001)

Customer Copy

1

Table of Contents

General Information ...................................................................................................................................................................................... 3

Introduction ................................................................................................................................................................................................. 4

Safety .......................................................................................................................................................................................................... 5

Warning Decal Positions..............................................................................................................................................................................6-7

Operating the Spreader ...............................................................................................................................................................................8-9

Drive Enclosure Installation Instructions ..................................................................................................................................................... 10

Spreader Maintenance ............................................................................................................................................................................... 11

General Wiring Instructions ........................................................................................................................................................................ 12

Control and Harness Diagram ............................................................................................................................................................... 13-17

Mounting Instructions .............................................................................................................................................................................18-19

Troubleshooting .................................................................................................................................................................................... 20-21

Warranty .................................................................................................................................................................................................... 22

Spreader Views

Model # SP-7550 ......................................................................................................................................................................... 23

Frame Assembly Parts Breakdown

Model # SP-7550 .................................................................................................................................................................... 24-25

Auger Drive Assembly Parts Breakdown

Model # SP-7550 .................................................................................................................................................................... 26-27

Hopper Assembly Parts Breakdown

Model # SP-7550 .................................................................................................................................................................... 28-29

Drive Assembly Parts Breakdown

Model # SP-7550 .................................................................................................................................................................... 30-31

Notes .............................................................................................................................................................................................. 32-33

Have a question or need assistance?

SnowEx Customer Care

(800) 725-8377

or (248) 586-3500

Monday through Friday 8:00 AM to 4:30 PM EST

Fax: (248) 691-8378

E-Mail: customercare@trynexfactory.com

Website: www.snowexproducts.com

2

© Trynex International 2011 (REV 001)

General Information

CONGRATULATIONS!

The spreader you have purchased is an example of snow and ice control technology at its nest! Your spreader’s self-contained design is a

trademark of all SnowEx products. Here’s why…

SIMPLICITY: Fewer moving parts manufactured of higher quality means minimal maintenance for your SnowEx spreader.

RELIABILITY: High impact linear low density polyethelyne hopper. State-of-the-art electronic dual variable speed control, custom engineered

powder coated frame, maximum torque 12-volt motor coupled to a custom engineered transmission; found only on SnowEx products.

VERSATILITY: Multi-use capabilities allows spreading of a variety of materials for snow and ice control.

WARRANTY: Best in the industry, hands down! 2 years standard and now 5 year extended (optional).

The benets you are about to recognize are that of time, money and effort.

We welcome you to the world of SnowEx Performance.

Registration

Record the following information in this manual for quick reference.

Spreader Model Number

Spreader Serial Number Controller Serial Number

Date of Purchase

Dealer Where Purchased

When ordering Parts, the above information is necessary. This will help to see that you

receive the correct parts.

At the right is a diagram of the ID tag. This tag on the spreader is located on the frame.

Madison Heights, MI 48071

Please ll out the warranty card with all the necessary information to validate it.

This will also give us a record so that any safety or service information can be

communicated to you.

U.S.A.

1-800-725-8377

www.trynexfactory.com

Model No.

SP-7550

L1-000000

Serial No.

© Trynex International 2011 (REV 001)

3

Introduction

This manual has been designed for your help. It will assist you and instruct you on the proper set-up, installation and use of this spreader.

Refer to the table of contents for an outline of this manual.

We require that you read and understand the contents of this manual completely (especially all safety information) before attempting any

procedure contained herein.

THIS SIGN SHOULD ALERT YOU:

The Society of Automotive Engineers has adopted this SAFETY ALERT SYMBOL to pinpoint characteristics

that, if NOT carefully followed, can create a safety hazard. When you see this symbol in this manual or on the

machine itself, BE ALERT! Your personal safety and the safety of others is involved.

Dened below are the SAFETY ALERT messages and how they will appear in this manual:

(RED)

Information that, if not carefully followed,

can cause death!

(ORANGE)

Information that, if not carefully followed,

can cause serious personal injury or death!

(YELLOW)

Information that, if not carefully followed,

can cause minor injury or damage to equipment

4

© Trynex International 2011 (REV 001)

Safety

Before attempting any procedure in this book, these safety instructions must be read and understood by all workers who have any part in the

preparation or use of this equipment.

For your safety warning and information decals have been placed on this product to remind the operator of safety precautions . If anything

happens to mark or destroy the decals, please request new ones from SnowEx.

Never exceed the Gross Vehicle Weight Rating of vehicle. Failure to do so may limit a vehicles handling

characteristics.

Never attempt to take a unit off a truck with material in it.

Always keep hands, feet, and clothing away from power driven parts.

Unit must be pinned and locked into position before operating vehicle.

Always shut off vehicle and power source before attempting to attach or detach or service unit Be sure

vehicle/power source is properly braked or chocked.

Remember, most accidents are preventable and caused by human error. Exercising of care and precautions

must be observed to prevent the possibility of injury to operator or others!

Never operate equipment when under the inuence of alcohol, drugs, or medications that might alter your

judgment and/or reaction time.

Before working with the spreader, secure all loose tting clothing and unrestrained hair.

Always wear safety glasses with side shields when servicing spreader. Failure to do this could result in

serious injury to the eyes.

Never allow children to operate or climb on equipment.

Always check areas to be spread to be sure no hazardous conditions or substances are in the area.

Always inspect unit for defects: broken, worn or bent parts, weakened areas on spreader.

Remember it is the owner’s responsibility to communicate information on safe usage and proper

maintenance of all equipment.

Always make sure personnel are clear of areas of danger when using equipment.

Never weld or grind on equipment without having a re extinguisher available.

Inspect the unit periodically for defects. Parts that are broken, missing or worn out must be replaced

immediately. The unit or any part of it can not be altered without prior written permission from the

manufacturer.

Always inspect pins and latches whenever attaching or detaching spreader, and before operation of spreader.

Never exceed 45 m.p.h. when loaded spreader is attached to vehicle. Braking distances may be increased

and handling characteristics may be impaired at speeds above 45 m.p.h.

Never use wet materials or materials with foreign debris with any of these spreaders. These units are

designed to handle dry, clean, free owing material.

Never leave material in hopper for long periods of time. Be aware that all ice melters are hygroscopic and will

attract atmospheric moisture and harden up.

© Trynex International 2011 (REV 001)

5

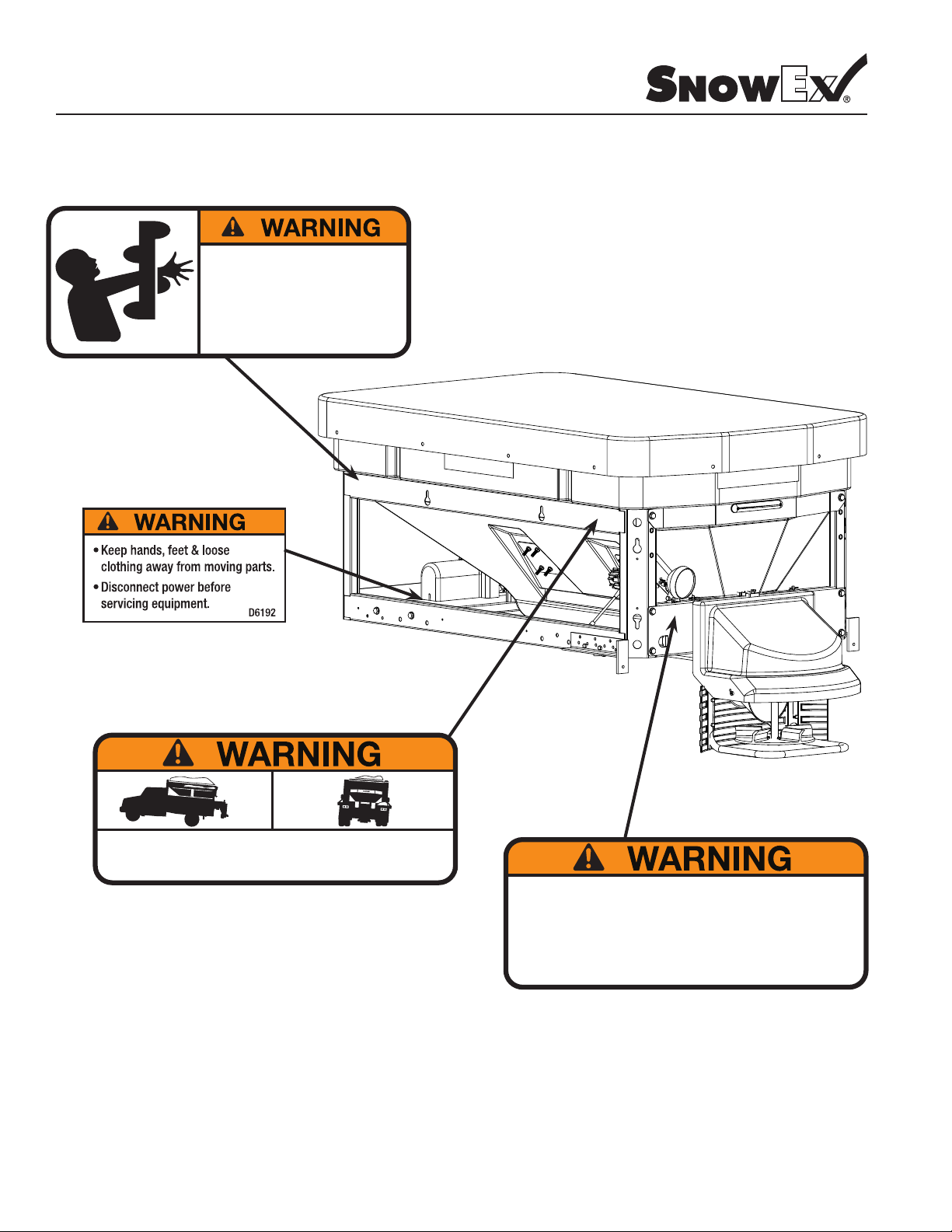

Warning Decal Positions

Model # SP-7550

ROTATING AUGER CAN CAUSE

SERIOUS INJURY OR DEATH

• Keep arms, hands, and loose clothing

away from auger.

• Shut off control and unplug spreader

before servicing.

D6335

• DO NOT EXCEED GVWR OF VEHICLE

• DO NOT OVERLOAD SPREADER

• LOAD SPREADER EVENLY

6

D6546

• Read Owner’s Manual for Installation Instructions.

• Secure spreader to truck with ratchet straps.

• Anchor spreader securely to truck body with bolt kit provided to prevent

slipping or sliding.

• Routinely check straps and handware to make sure they are secure.

D6548

© Trynex International 2011 (REV 001)

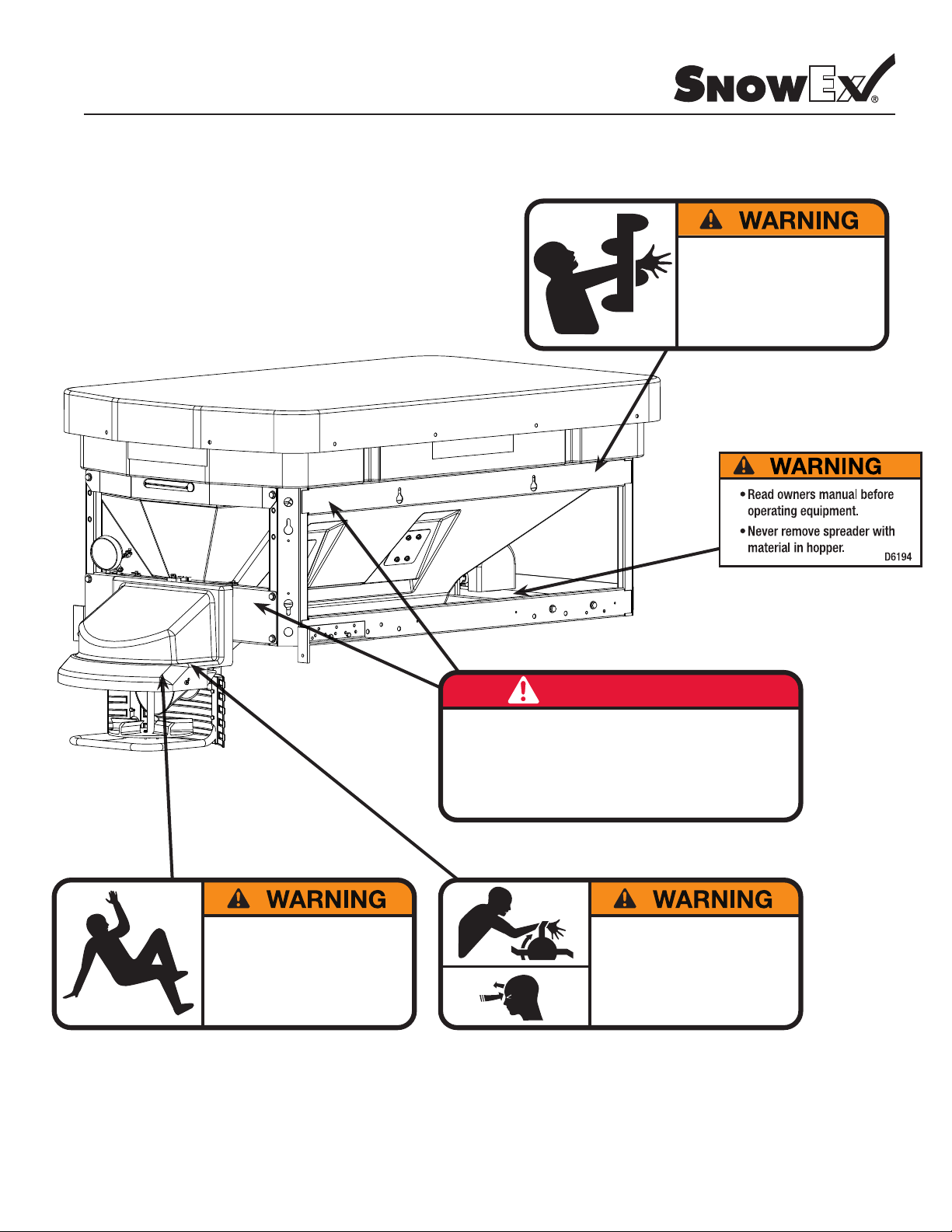

Warning Decal Positions

Model # SP-7550

ROTATING AUGER CAN CAUSE

SERIOUS INJURY OR DEATH

• Keep arms, hands, and loose clothing

away from auger.

• Shut off control and unplug spreader

before servicing.

D6335

NO STEP

• Slippery Surface When Wet.

• May Cause Severe Injury

D6545

DANGER

• DO NOT REMOVE SPREADER WITH MATERIAL IN HOPPER

• FASTEN SPREADER DOWN WITH APPROVED RATCHET STRAPS

AND BOLT KIT

• REAR FRAME LOCATOR BARS MUST BE IN PLACE BEFORE

OPERATING VEHICLE

ROTATING PARTS AND FLYING OBJECTS

CAN CAUSE INJURY OR DEATH

• Keep hands, arms, feet and loose clothing away

• Shut off power ans stop engine before servicing

• Read owners manual before operating.

• Keep bystanders at least 60 ft away.

D6547

D6544

© Trynex International 2011 (REV 001)

7

Operating the Spreader

Model # SP-7550

SPREADER LOADING

WARNING – Do not overload vehicle. Use chart below to calculate weight of material. Weights of material are an average for dry

materials.

Material Weight Per Cubic Ft.

Rock Salt 80-90 lbs.

Sand/Salt Mix 95-120 lbs.

• Warning – Never leave material in hopper for long periods of time as salt is hygroscopic and will attract atmospheric moisture and harden up.

When spreading sand mix, a 1:1 ratio for Sand/Salt mix is recommended to prevent the material from freezing.

SPREADER OPERATION

• The Dual Variable Speed Controller has dual nger-tip dials for maximum performance, digital system status with warning protection and built-

in Vibrator Switch.

• To start, press power switch on controller and spreader will accelerate to speed set on spinner and auger dials.

• To stop, press power on controller to off position.

• Speed of Auger and Spinner may be adjusted separately to get desired ow and spread distance

• The Vibrator Switch is needed for dense material or to increase the ow to the Auger. This eliminates bridging of material in hopper.

• A Material Bafe has been installed in your spreader to stop ne material from free owing. If using dense or damp material, or if more ow is

desired, remove Material Bafe. However, it is recommended that the Material Bafe remain in place if using bulk salt.

• It is important that the Inverted Vee not be removed except when servicing.

• If there are any problems while operating the spreader, refer to Troubleshooting Guide.

SPREADING TIPS

• Spread ice melters with the storm to prevent unmanageable levels of ice.

• Never exceed 10 m.p.h. when spreading.

• For a wider pass, increase spinner speed.

• For a heavier pass, drive slower or increase auger speed.

• Never operate spreader near pedestrians.

• Calculate spread pattern when near vegetation.

WARNING PROTECTION

• If audible beeping occurs, read display to identify problem. If display reads “OL” (overload) or “OH” (overheat), shut controller down and

carefully clear jammed auger. If display reads “E1“ this means there is a dead short in system. Do not use until problem is corrected. If display

reads “E0” this means that the motor is not getting any power. Check all connections. If display reads “LB” the vehicle battery is extremely

low (possibly caused by a poor or corroded connection) and could damage the system.

• If there are any problems while operating the spreader, refer to Troubleshooting Guide.

8

© Trynex International 2011 (REV 001)

Operating the Spreader (continued)

Model # SP-7550

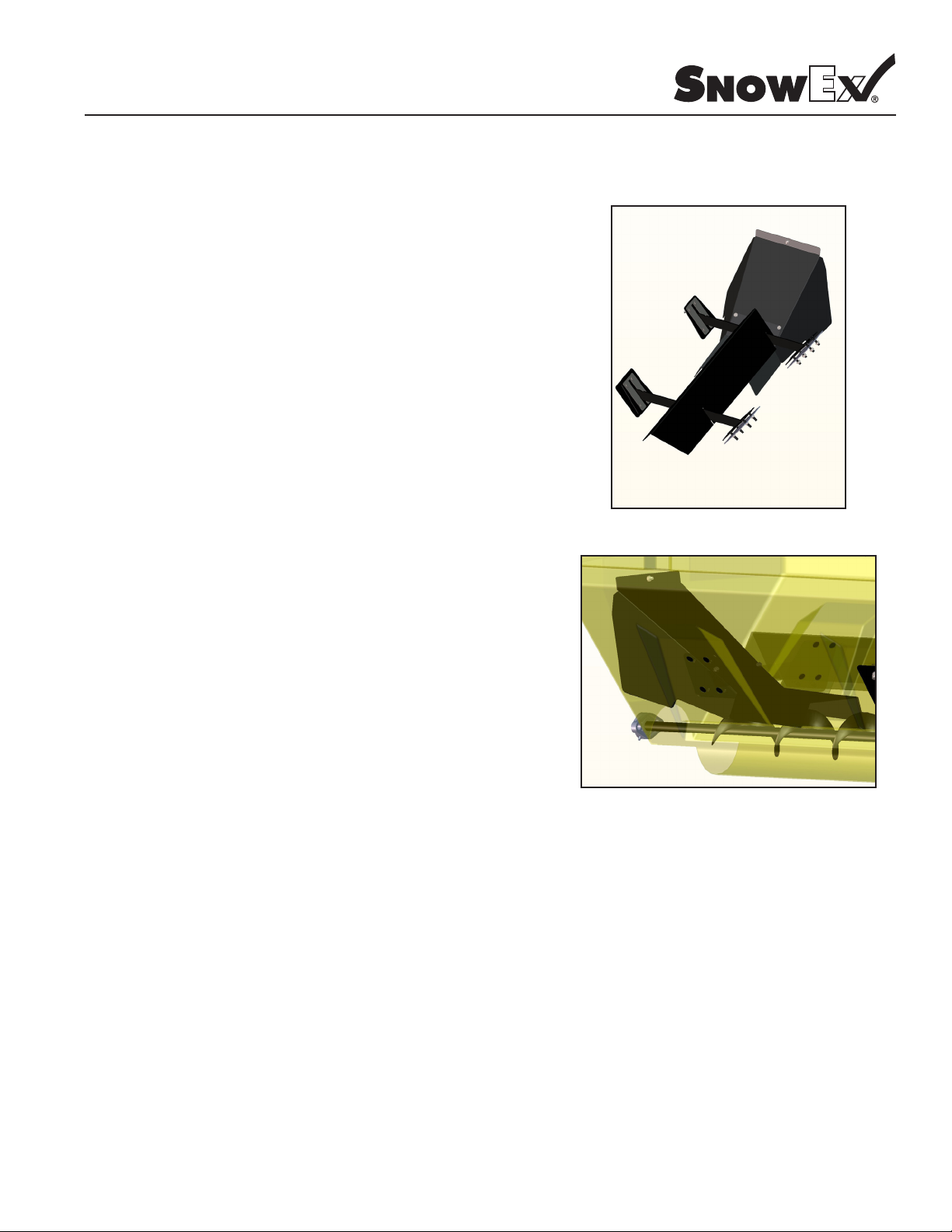

DISCHARGE BAFFLE and INVERTED-V INSTRUCTIONS

• The 7550 uses an Inverted-v design over the auger area. This

inverted-v (D5510) is used to reduce load to the auger drive train. It

must not be removed unless servicing the unit.

• WARNING: Always disconnect power source before attempting to

remove material bafe.

• The 7550 uses a discharge bafe (D5517) to reduce material

leakage. It must not be removed unless servicing the unit.

• BAFFLE EXTENSION INSTRUCTIONS

• The Bafe Extension (D-5503) is intended to be used with very dry

products that free-ow with little effort. The bafe is designed to

keep these types of materials from leaking out.

• If you plan on using damp/wet materials, you should remove this

bafe by removing the self-drilling screws.

D5517

D5510

D5503

• If you are using a sand/salt mixture, remove bafe extension.

© Trynex International 2011 (REV 001)

9

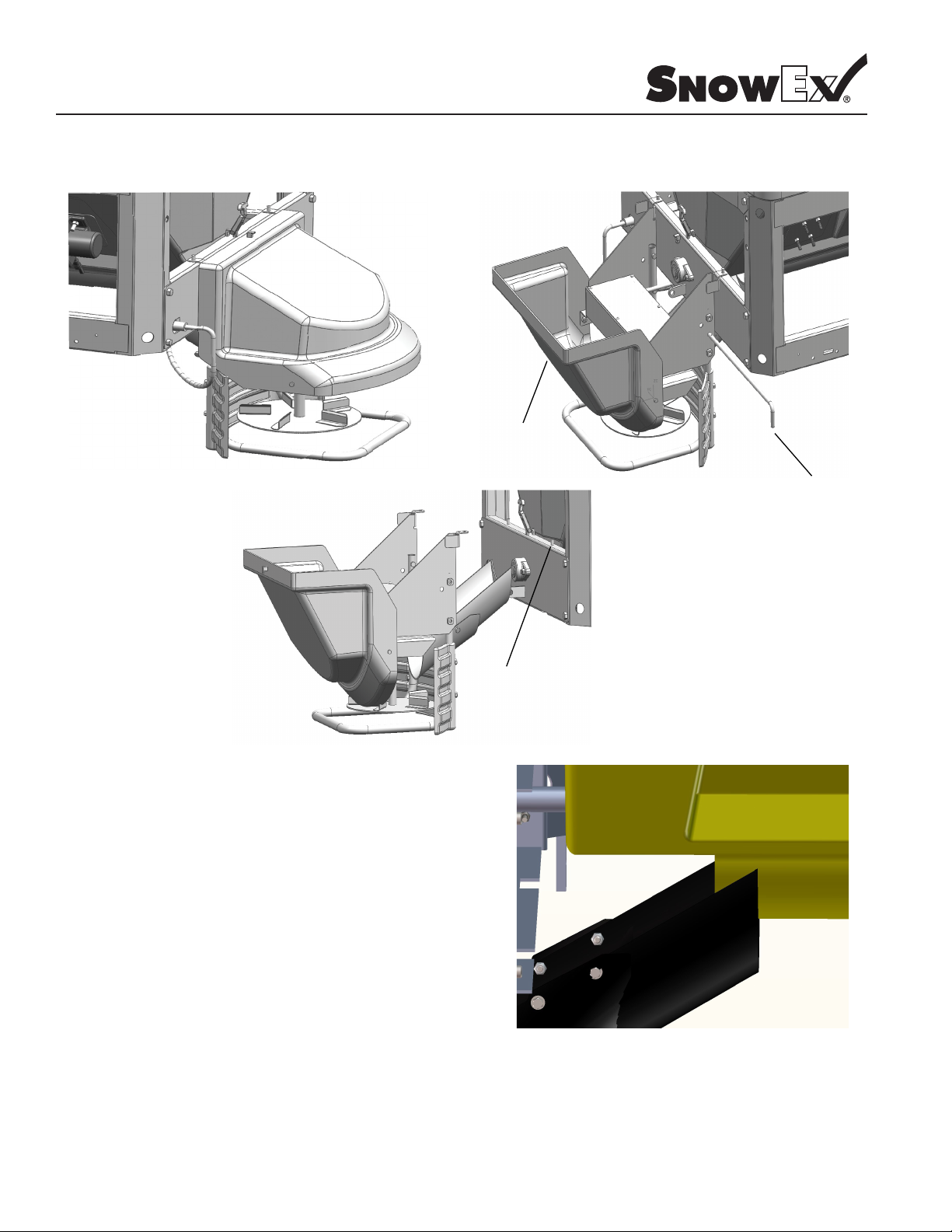

Drive Enclosure Installation Instructions

Model # SP-7550

Step1: Lift latch up

Step 2: Swing hood

open

Step 3: Pull main pin

Important

When installing drive unit on spreader make sure the material

chute clips under the trough of the hopper.

Step 4: Lift drive assembly off pins

10

© Trynex International 2011 (REV 001)

Spreader Maintenance

Model # SP-7550

• WARNING – When servicing is necessary, perform it in a protected area Do not use power tools in rain or snow because of danger of electrical

shock or injury. Keep area well lighted. Use proper tools. Keep the area of service clean to help avoid accidents.

• WARNING: Never remove spreader with material in hopper.

• WARNING: Disconnect electricity to spreader before servicing.

• CAUTION: – When replacing parts use only original manufacturer”s parts. Failure to do so will void warranty.

• CAUTION: – The controller is a solid state electronic unit and is not serviceable. Any attempt to service will void warranty.

• CAUTION: - There are no serviceable parts in the motor/transmission assembly. Any attempt to service will void warranty.

• CAUTION: - Spinner motor is not designed for continuous duty. Allow motor to cool between long cycle times.

• CAUTION: – When pressure washing motor enclosure area, stay at least 36’’ away from motor enclosures.

• ATTENTION: Store control in cool dry place during the off season.

• Use dielectric grease on all electrical connections to prevent corrosion at the beginning and end of the season and each time power plugs are

disconnected.

• Wash unit after each use to prevent material build-up and corrosion.

• Paint or oil all bare metal surfaces at the end of the season.

• Apply small amount of light oil to latches as needed.

• If motor cover is removed for any reason, use silicone sealant to ensure weather proong of enclosure.

• After rst use, tighten all nuts and bolts on spreader and mount.

• Grease bearings after every 20 hour’s use.

• CAUTION – Vibrator is not designed for continuous duty. Allow motor to cool between long cycle times.

• CAUTION – Do not modify vehicle or spreader wiring harness. Doing so will void product warranty.

© Trynex International 2011 (REV 001)

11

General Wiring Instructions

Model # SP-7550

Step 1: Take harness assembly and route from the rear of the vehicle to the front. Route harness along frame and attach to frame hole and

frame supports. It is not recommended to attach to fuel or brake lines for obvious reasons. Do not route close to exhaust system or

engine, even though Snowex uses high temperature wiring. It still could melt under extreme heat and short the spreader electrical

system, as well as the vehicle electrical system.

Step 2: Mount rear plug on bumper using supplied bolts, locate towards the center of the bumper to reduce the amount of debris the tires

will throw to the rear. Important: Apply a small amount of dielectric grease to the plug. Also try to mount so plug faces upward to

help keep plugs tightly sealed.

Step 3: Secure harness from the rear to the front using heavy duty ty-wraps or frame clips along the frame and lighter duty ty-wraps

everywhere else.

Step 4: Layout harness portion that connects to the battery along the re wall and fender well. Do not connect power leads to battery yet.

Drill a 3/4” hole in the re wall, or use existing access hole, for the control portion of the harness and route connector and harness

through hole. Be sure to check the area on the other side of the re wall to make sure you are not drilling into the vehicle harness

or a control module. Generally you can drill on either side of the steering wheel for a good location.

Step 4A: The power harness from control box to battery will need to be routed from the inside of the cab to the battery – this results from

the large high amperage connector. Route leads with lugs to battery — do not connect power at this time.

Step 5: Connect harness to the back of the controller and mount to a suitable location. NOTE: You may want to contact customer before

mounting controller as some prefer not to have holes drilled into the dashboard. Ty-wrap loose controller harness and move to the

engine compartment. Do not mount close to any heater vents.

Step 6: Connect power leads to the battery: Red + Positive, Black – Negative, always connect to the primary battery if using a dual battery

system. Secure loose loom to any other large or medium vehicle harness with medium duty ty-wraps, this will secure wiring

harness.

Step 7: Push the ON/OFF button on the controller to check for power ; when that has been conrmed turn power OFF. The electrical portion

of the installation is complete.

12

© Trynex International 2011 (REV 001)

Control and Harness Diagram

Model # SP-7550

5

7

9

IMPORTANT: In the off season remove control

2

and put in a cool dry place. The interior summer

temperatures could damage circuit board and

6

1

void warranty.

See CHMSL page 15

4

IMPORTANT: Do Not modify harness length. Any modications

will void warranty.

Special Notes:

1) All external connections must have dielectric grease.

2) Read lead labels before attaching to power source or ground.

3) No other devices may be spliced into wiring harness.

4) Any repairs to wiring harness must be done with heat shrink butt

connectors.

12

10

11

3

8

Key Part No. Description Qty

1 D5524 Spreader Harness | 87-1/4” 1

2 D5525 Spreader Control | SP-7550 1

3 D6118 Dust Cover | Standard 1

4 D6170 Connector Adapter | 6” Anderson 1

5 D6237 Power Switch | 5 Terminal 1

6 D6322 Vehicle Harness | 311” 1

7 D6341 Control Power Cable | 156” Pro 1

8 D6343 Dust Cover | Pro 2

9 D6354 Vibrator Switch | 3 Terminal Red 1

10 D6784 Utility Work Light 1

11 D6785 Spreader Auxiliary Harness | 56” 1

12 D6786 Vehicle Auxiliary Harness | 310” 1

© Trynex International 2011 (REV 001)

13

Harness Diagram

Model # SP-7550

D6322 Vehicle Harness

End View

White

10 GA

Spinner+

Black

10 GA

Spinner -

Blue

12 GA

Vibrator -

Red

Red

10 GA

Auger+

Green

10 GA

Auger -

Black

Orange

10 GA

Vibrator -

Spinner+

10 GA White

Auger+

10 GA Red

Vibrator+

12 GA Orange

Mold Cap

Spinner10 GA Black

Auger10 GA Green

Vibrator12 GA Blue

D6341 Control Power Cable

3/8” Terminal w/Heat Shrink

Black

Red

124” Tubing

Hot

Circuit

Front View

Red to

Positive +

Grd

Circuit

Black to

Negative -

14

© Trynex International 2011 (REV 001)

Harness Diagram

Model # SP-7550

D5524 Spreader Harness

VIBRATOR

PLUG

58"

5"

AUGER

SPINNER PLUG

LOAD

VIEW

RED

B

A

BLACK

BLACK

RED

D5525 Controller

87 1/4"

47"

Vibrator

Black Negative (-)

Vibrator

Red Positive (+)

VIBRATOR + RED

AUGER + RED

SPINNER + RED

BLACK - VIBRATOR

BLACK - AUGER

BLACK - SPINNER

LOAD VIEW

Black

Negative (-)

Red

Positive (+)

© Trynex International 2011 (REV 001)

Spinner

Black Negative (-)

Auger

Black Negative (-)

Auger

Red Positive (+)

Spinner

Red Positive (+)

IMPORTANT: In the off season remove control

and put in a cool dry place. The interior summer

temperatures could damage circuit board and

void warranty.

15

Harness Diagram

Model # SP-7550

D6785 Spreader Auxiliary Harness

28"

12"

BLUNT (2)

BURY LEADS

IN CONDUIT

BLACK-BLUNT

BLACK TO

MOLDED 2-WAY

BLACK TO PACKARD

LOAD VIEW

RED-BLUNT

RED TO

MOLDED 2-WAY

RED TO PACKARD

D6786 Vehicle Auxiliary Harness

27'

A-RED B-BLACK

B

A

28"

2-WAY CHMSL

3"

MOLD CAP

14"

BK

RD

BURY 12" WIRE IN CONDUIT

16

14"

310"

34"

12"

TAPE

27' BK

12" BK

4' BK

27' RD

4' RD

12" RD

© Trynex International 2011 (REV 001)

Harness Diagram

Model # SP-7550

D6514 Center High Mount Stop Lamp

Connect to Spreader Harness D6785

© Trynex International 2011 (REV 001)

17

Mounting System Diagrams

Model # SP-7550

Through Floor/Bed Mounting Bolts

1

2

3

Figure 2 : Frame Mounting Bolts

Key Part No. Description Qty

1 D4116 Bolt | 1/2”-13 X 1-1/2” 4

2 D4119 Washer | 1/2” Flat 4

3 D4120 Nut | 1/2”-13 Nylox 4

4 D4121 Bolt | 3/8”-16 X 1” 4

5 D4124 Nut | 3/8”-16 Nylox 4

6 D6536 Adjustable Stop Bracket | Right 1

7 D6537 Adjustable Stop Bracket | Left 1

8 D6856 V-Maxx Ratchet Straps 4

Rear Stop LT & RT

5 6 7

4

Figure 1 :

Side Strap On Each Side

8

Cross Front Straps

18

© Trynex International 2011 (REV 001)

Mounting Instructions

Model # SP-7550

Step 1: Remove tailgate from pickup bed.

Step 2: Load spreader on to truck bed and mount spinner assembly.

Step 3: Slide spreader forward until deector/chute assembly makes contact with vehicle. Then, slide spreader back approx. 1” to allow for

proper clearance.

Step 4: Install stop bars using supplied hole patterns (see Fig.2). To achieve the best position, you may need to drill additional holes in bracket in

order to properly position spreader.

Step 5: Now that the spreader is positioned front to back, you will now center it left to right. Looking at the inside front and corner of the lower

frame area, you will notice (4) holes in the bottom of the frame. Using a paint pen or similar marking device, mark hole locations.

Step 6: Before drilling holes, look beneath the approximate area where each hole will be located. Make sure there are no vehicle components

that will be in the path of the drill before doing this step. If there are interferences, you can relocate holes as needed making sure there

are at least two forward and two rearward of the front to back centerline.

Step 7: Install and tighten all (4) bolts.

Step 8: Install ratchet straps (see 7550 Mounting System: Strapping Techniques). It is very important for everyone’s safety this strapping method

be used as the standard mounting procedure. (Do not use ratchet straps exclusively.)

Step 9: Connect the spreader power cord to vehicle main power plug mounted at rear of vehicle (see Electrical Installation).

© Trynex International 2011 (REV 001)

19

Troubleshooting

Model # SP-7550

Spreader

Does Not Run

Controller Turns On

Beeps Shuts Off

Displays Error Code

OL Code

EO Code

Denition

Amp Draw

Too High

Denition

Open Circuit Between

Motor And Controller

Jammed Material

Bad Motor

Check With Test Kit

Bad Transmission

Check With Test Kit

Corrosion

Bad Controller

Check With Test Kit

Spreader Unplugged

Motor Power Cord

Disconnected

Inside Drive Assembly

Break In

Wiring Harness

Check With Test Kit

Clear Jam

Test 4 to 20 Amp Draw

No Load Good

20+ Amp Draw

No Load Bad

Test Turn Shaft

By Hand

Should Turn Freely

Replace All

Corroded

Connections

Plug In Spreader

Open Access Cover

And Plug Together

Replace Harness

Don´t Forget

Use Doelectric

Grease

On/Off Switch

Lights No Display

Nothing Happens

No Display

On/Off Will Not Light Up

LB Code

E1 Code

All Other Codes

Check Input Power

Check Power Source

To Controller

Denition

Bad Electrical

Connection

Low Battery

Less Than 12 Volt

Output

Denition

Dead Short

In Motor Circuit

Check Harness

For Spliced In

Accessory

Bad Controller

Check With Test Kit

Bad Controller

Check With Test KIt

Corrosion

Loose Connection

Load Test Battery

Replace Affected

Components

Bad Controller

Check With Test Kit

Replace All Corroded

Connections

Tighten Or Replace

Replace

Snowex Diagnostic Test Kit (STK-090) Is Available To Accurately Diagnose Any Issues With Snowex Spreaders.

Call Your Dealer For Details.

20

© Trynex International 2011 (REV 001)

Troubleshooting Material Flow

Model # SP-7550

Material Free Flows

Material Does Not Flow

Slow Material Flow

Check Bafe Length

Check Bafe Position

Material Obstruction

Auger Runs Backwards

Turn On Vibrator

Turn On Vibrator

Increase Auger Speed

Material Issue

18” Correct

Should Touch Hopper

On 3 Sides

Remove Obstruction

Run 12 Volt To Auger

Circuit On Spreader

Power Cord

Material Issue

Material Issue

Material Issue

Auger Runs Proper

Direction

Auger Runs

Backwards

Replace Vehicle

Harness

Check Connections

At Auger Motor For

Reverse Polarity

Polarity Correct

ReplaceSpreader

Harness

Snowex Diagnostic Test Kit (STK-090) Is Available To Accurately Diagnose Any Issues With Snowex Spreaders.

Call Your Dealer For Details.

© Trynex International 2011 (REV 001)

21

Warranty

Warranty

Limited Warranty

Snowex products are warranted for a period of two years from the date of purchase against

defects in material or workmanship under normal use and service, subject to limitations detailed

below. Warranty period of two years begins on the date of purchase by the original retail user.

The WARRANTY REGISTRATION CARD must be returned to the manufacturer for this warranty

to become eective. This warranty applies to the original retail purchaser only. This warranty does

not cover damages caused by improper installation, misuse, lack of proper maintenance, alterations

or repairs made by anyone other than authorized Snowex dealers or Snowex personnel. Due to the

corrosive properties of the materials dispensed by spreaders, Trynex does not warrant against

damage caused by corrosion. Warranty claims by the user must be made to the dealer from where

the product was purchased, unless otherwise authorized by Snowex. Snowex reserves the right to

determine if any part is defective and to repair or replace such parts as it elects. This warranty does

not cover shipping costs of defective

parts to or from the dealer.

LIMITATION OF LIABILITY

Neither Snowex, nor any company aliated with it, makes any warranties, representations for

promise as to the performance or quality other than what is herein contained. The liability of Snowex

to the purchaser for damages arising out of the manufacture, sale, delivery, use or resale of this

spreader shall be limited to and shall not exceed the costs of repair or replacement of defective

parts. Snowex shall not be liable for loss of use, inconvenience or any other incidental, indirect or

consequential damages, so the above limitations on incidental or consequential damages may not

apply to you.

NO DEALER HAS AUTHORITY TO MAKE ANY REPRESENTATION OR PROMISE ON BEHALF OF

SNOWEX, OR TO ALTER OR MODIFY THE TERMS OR LIMITATIONS OF THIS

WARRANTY IN ANY WAY.

22

© Trynex International 2011 (REV 001)

Spreader Views

Model # SP-7550

23

© Trynex International 2011 (REV 001)

Frame Assembly Parts Breakdown

8

9

8

4

1

8

2

5

6

3

7

Model # SP-7550

24

© Trynex International 2011 (REV 001)

Frame Assembly Parts Breakdown

ID #

Part #

Qty

1

D5504

1

2

D5505

2

3

D5506

1

4

D5507

2

ID #

Part #

Qty

5

D6158

2

6

D6468

2

7

D6514

1

8

D6528

14

ID #

Part #

Qty

9

D6529

2

Model # SP-7550

© Trynex International 2011 (REV 001)

25

Auger Drive Assembly Parts Breakdown

20

13

12

5

18

15

11

16

6

22

23

3

10

17

21

9

7

8

17

19414

1

2

Model # SP-7550

26

© Trynex International 2011 (REV 001)

Auger Drive Assembly Parts Breakdown

ID #

Part #

Qty

1

D4121

4

2

D4122

2

3

D5383

2

4

D5513

1

5

D5514

1

6

D5520

1

7

D5522

1

8

D5532

2

ID #

Part #

Qty

9

D5533

1

10

D5535

4

11

D6105

1

12

D6158

2

13

D6159

2

14

D6452

2

15

D6528

4

16

D6553

2

ID #

Part #

Qty

17

D6584

6

18

D6784

1

19

D6826

1

20

D6873

3

21

D7164

2

22

T20315

1

23

T30742

1

Model # SP-7550

© Trynex International 2011 (REV 001)

27

Hopper Assembly Parts Breakdown

14

6

15

4

15

11

2

3

5

13

1

7

8

3

13

9

12

10

Model # SP-7550

28

© Trynex International 2011 (REV 001)

Hopper Assembly Parts Breakdown

ID #

Part #

Qty

1

D5500

1

2

D5503

1

3

D5508

4

4

D5510

1

5

D5511

1

6

D5512

1

ID #

Part #

Qty

7

D5517

1

8

D6138

1

9

D6165

1

10

D6166

1

11

D6509

4

12

D6515

1

ID #

Part #

Qty

13

D6584

16

14

D6815

2

15

D6874

10

Model # SP-7550

© Trynex International 2011 (REV 001)

29

Drive Assembly Parts Breakdown

16

3

10

23

27

9

19

22

12

18

20

26721

4

14

6

10

25

24

5

11

8

1

2

15

17

28

13

Model # SP-7550

30

© Trynex International 2011 (REV 001)

Drive Assembly Parts Breakdown

ID #

Part #

Qty

1

D4135

1

2

D4289

7

3

D5502

1

4

D5518

1

5

D5536

2

6

D6107

1

7

D6131

4

8

D6132

4

9

D6133

1

10

D6138

6

ID #

Part #

Qty

11

D6162

1

12

D6172

2

13

D6198

1

14

D6232

1

15

D6467

6

16

D6524

8

17

D6553

1

18

D6563

1

19

D6781

1

20

D6819

1

ID #

Part #

Qty

21

D6820

1

22

D6823

1

23

D6824

1

24

D6827

1

25

D6832

1

26

D6833

1

27

D6854

3

28

F50438

2

Model # SP-7550

© Trynex International 2011 (REV 001)

31

Notes

32

© Trynex International 2011 (REV 001)

Notes

© Trynex International 2011 (REV 001)

33

Notes

34

© Trynex International 2011 (REV 001)

Notes

© Trynex International 2011 (REV 001)

35

Loading...

Loading...