SnowEx SP-2400 User Manual

www.snowexproducts.com

© Trynex International 2009 (REV 004)

SP-2400

8 — 1

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

General Information and Registration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Spreader Assembly and Exploded Views . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wiring Instructions For Spreader & Work Light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical System Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Spreader Mounting System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Work Light Assembly & Spreader Operating Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Spreader Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Determine Vehicle Payload Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-7

8-17

18

19-22

23-24

25-28

29-31

32

33

34-35

Have a question or need assistance?

SnowEx Customer Service

(800) 725-8377

or (586) 756-6555

Monday through Friday 8:00 AM to 4:30 PM EST

Fax: (586) 427-0552

E-Mail: customercare@trynexfactory.com

Website: www.snowexproducts.com

8 — 2

© Trynex International 2009 L1186

Introduction

This manual has been designed for your help. It will assist you and instruct you on the proper set-up, installation and

use of this spreader. Refer to the table of contents for an outline of this manual.

We require that you read and understand the contents of this manual completely (especially all safety information)

before attempting any procedure contained herein.

THIS SIGN SHOULD ALERT YOU:

The Society of Automotive Engineers has adopted this SAFETY ALERT SYMBOL to pinpoint characteristics

that, if NOT carefully followed, can create a safety hazard. When you see this symbol in this manual or on

the machine itself, BE ALERT! Your personal safety and the safety of others is involved.

Dened below are the SAFETY ALERT messages and how they will appear in this manual:

(RED)

Information that, if not carefully followed,

can cause death!

.

(ORANGE)

Information that, if not carefully followed,

can cause serious personal injury or death!

(YELLOW)

Information that, if not carefully followed,

can cause minor injury or damage to equipment.

© Trynex International 2009 L1186 8 — 3

General Information

CONGRATULATIONS!

The spreader you have purchased is an example of snow and ice control technology at its nest! Your spreader’s innovative,

self-contained design is a trademark of all Trynex products. Here’s why...

SIMPLICITY: Fewer moving parts manufactured of higher quality means minimal maintenance for your SnowEx spreader.

RELIABILITY: High impact linear low density polyethelyne hopper, state-of-the-art electronic dual variable speed control,

custom engineered powder coated frame, maximum torque 12 volt motor coupled to a custom engineered transmission

found only on SnowEx products.

VERSATILITY: Multi-use capabilities allows spreading of a variety of materials for snow and ice control.

WARRANTY: Best in the industry, hands down! 2 Years Standard and now a 5 Year Extended (optional).

The benets you are about to recognize are that of time, money and eort.

W

e welcome you to the world of Trynex Performance.

Registration

Record the following information in this manual for quick reference.

Spreader Model Number _____________________________________________________________________________________

Spreader Serial Number ________________________________ Controller Serial Number _______________________________

Date of Purchase ___________________________________________________________________________________________

Dealer Where Purchased _____________________________________________________________________________________

When ordering parts, the above information is necessary. This will help to insure

that you receive the correct parts.

At the right is a diagram of the ID tag. This tag on the spreader is located

on the frame.

Please ll out the warranty card with all the necessary information to validate it. This will also give us a record so that

any safety or service information may be communicated to you.

8 — 4

L1186 © Trynex International 2009

Safety

Before attempting any procedure in this book, these safety instructions must be read and understood by all workers who

have any part in the preparation or use of this equipment.

For your safety warning and information decals have been placed on this product to remind the operator of safety

precautions . If anything happens to mark or destroy the decals, please request new ones from Trynex, International.

Unit must be strapped down and locked into position before operating vehicle.

Never exceed the Gross Vehicle Weight Rating of vehicle. Failure to do so may limit a vehicles

handling characteristics.

Never attempt to take a unit o a truck with material in it.

Never exceed 45 m.p.h. when loaded spreader is attached to vehicle. Braking distances may

be increased and handling characteristics may be impaired at speeds above 45 m.p.h.

Never allow children to operate or climb on equipment.

Always check areas to be spread to be sure no hazardous conditions or substances are in the area.

ways inspect unit for defects: broken, worn or bent parts, weakened areas on spreader or mount.

Al

Always shut o vehicle and power source before attempting to attach or detach or service

spreader unit. Be sure vehicle/power source is properly braked or chocked.

Always keep hands, feet, and clothing away from power-driven parts. Remember it is the

owner’s responsibility to communicate information on safe usage and proper maintenance of

all equipment.

Always make sure personnel are clear of areas of danger when using equipment. Maintain 60'

distance from all bystanders when operating the spreader.

Inspect the unit periodically for defects. Parts that are broken, missing, or worn out must be

replaced immediately. The unit, or any part of it cannot be altered without prior written

permission from the manufacturer.

© Trynex International 2009 L1186

Never use V-Maxx 2400 with foreign debris in the spreader. These units are designed to handle

clean, free-owing material.

8 — 5

Safety

(continued)

Always inspect pins and latches whenever attaching or detaching spreader, and before

traveling.

Never leave material in hopper for long periods of time. Be aware that all ice melters are

hygroscopic and will attract atmospheric moisture and harden up.

Remember, most accidents are preventable and caused by human error.

and precautions must be observed to prevent the possibility of injury to operator or

others!

Never operate equipment when under the inuence of alcohol, drugs, or medication that

might alter your judgment and/or reaction time.

Before working with the spreader, secure all loose tting clothing and unrestrained hair.

Always wear safety glasses with side shields when servicing spreader. Failure to do this

could result in serious injury to the eyes.

Exercising of care

© Trynex International 2009 L11868 — 6

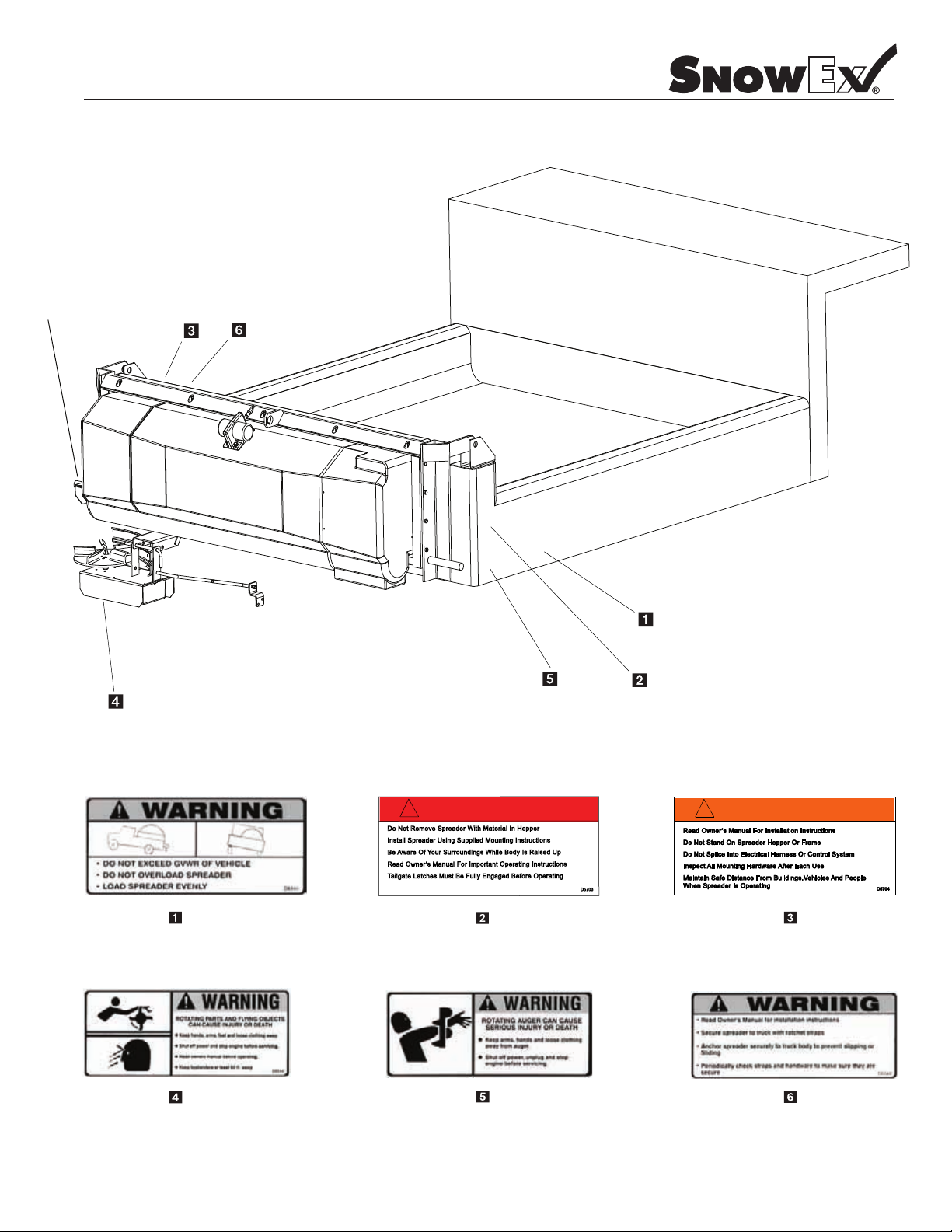

Safety and Warning Labels

DANGER

!

.

.

.

D5703

.

.

.

.

Do Not R emove Spre ader With Material I n Hopper

Install Spreader U sing Suppl ied Mounti ng Instruct ions

Be Aware O f Your Surroun dings Whil e Body Is R aised Up

Read Own er’s Manu al For Imp ortant Oper ating Inst ructions

.

Tailgate Lat ches Must Be Fully E ngaged Bef ore Operati ng

Model # SP-2400

SERIAL NUMBER

ON INSIDE OF COVER

D 6546

BOTH SIDES

D 5703

BOTH SIDES

BOTH SIDES

.

.

!

!

WARNING

WARNING

.

.

.

.

.

.

Read Own er’s Manu al For Ins tallation I nstruction s

Read Own er’s Manu al For Ins tallation I nstruction s

Do Not S tand On Sp reader Hop per Or Fra me

Do Not S tand On Sp reader Hop per Or Fra me

.

.

.

.

Do Not S plice Into Electrica l Harness Or Control System

Do Not S plice Into Electrica l Harness Or Control System

.

.

Inspect Al l Mounting Hardware Af ter Each U se

Inspect Al l Mounting Hardware Af ter Each U se

Maintain Safe Dist ance From Buildings, Vehicles And Pe ople

Maintain Safe Dist ance From Buildings, Vehicles And Pe ople

.

.

When Spr eader Is O perating

When Spr eader Is O perating

D 5704

D5704

D5704

D 6544

© Trynex International 2008 L1186

D 6335

D 6548

8 — 7

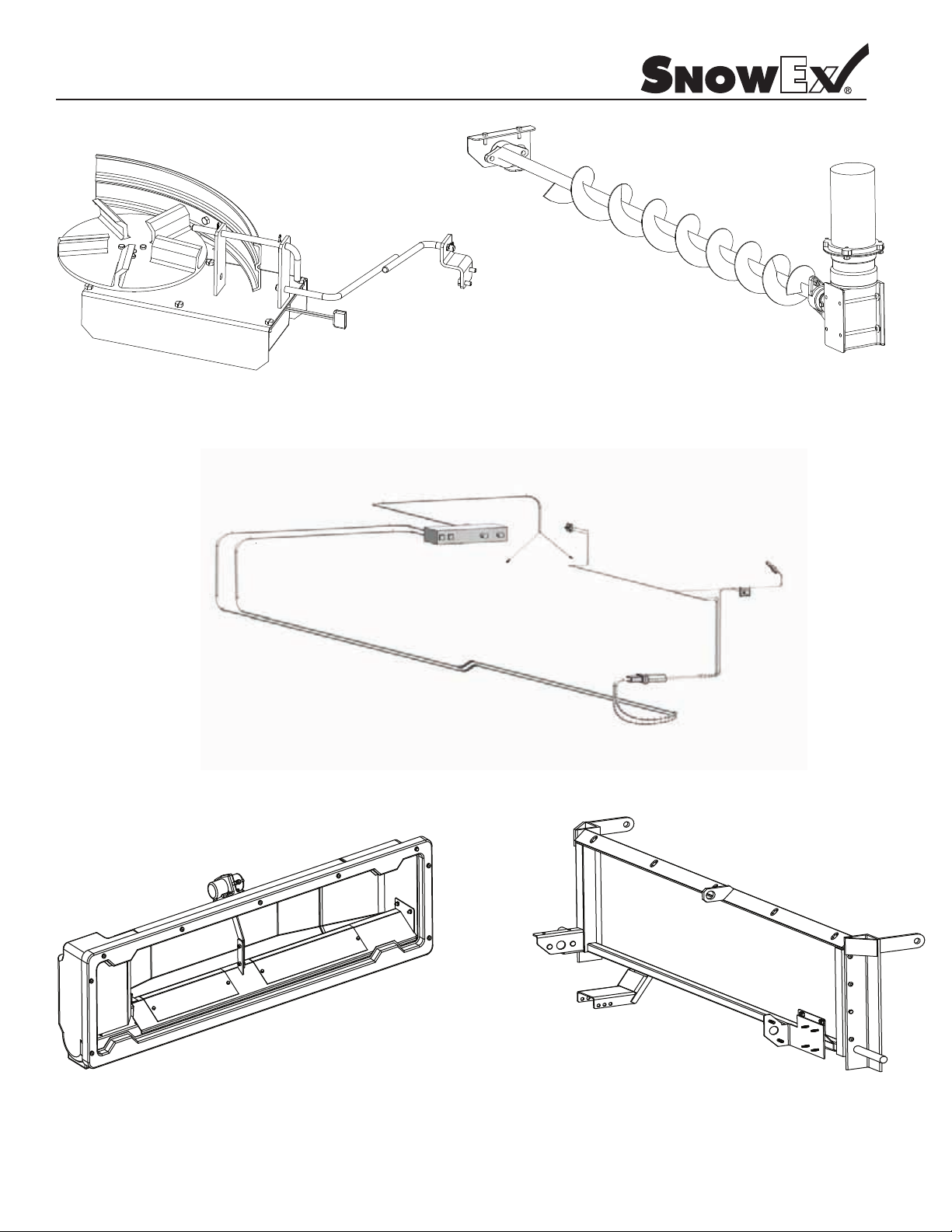

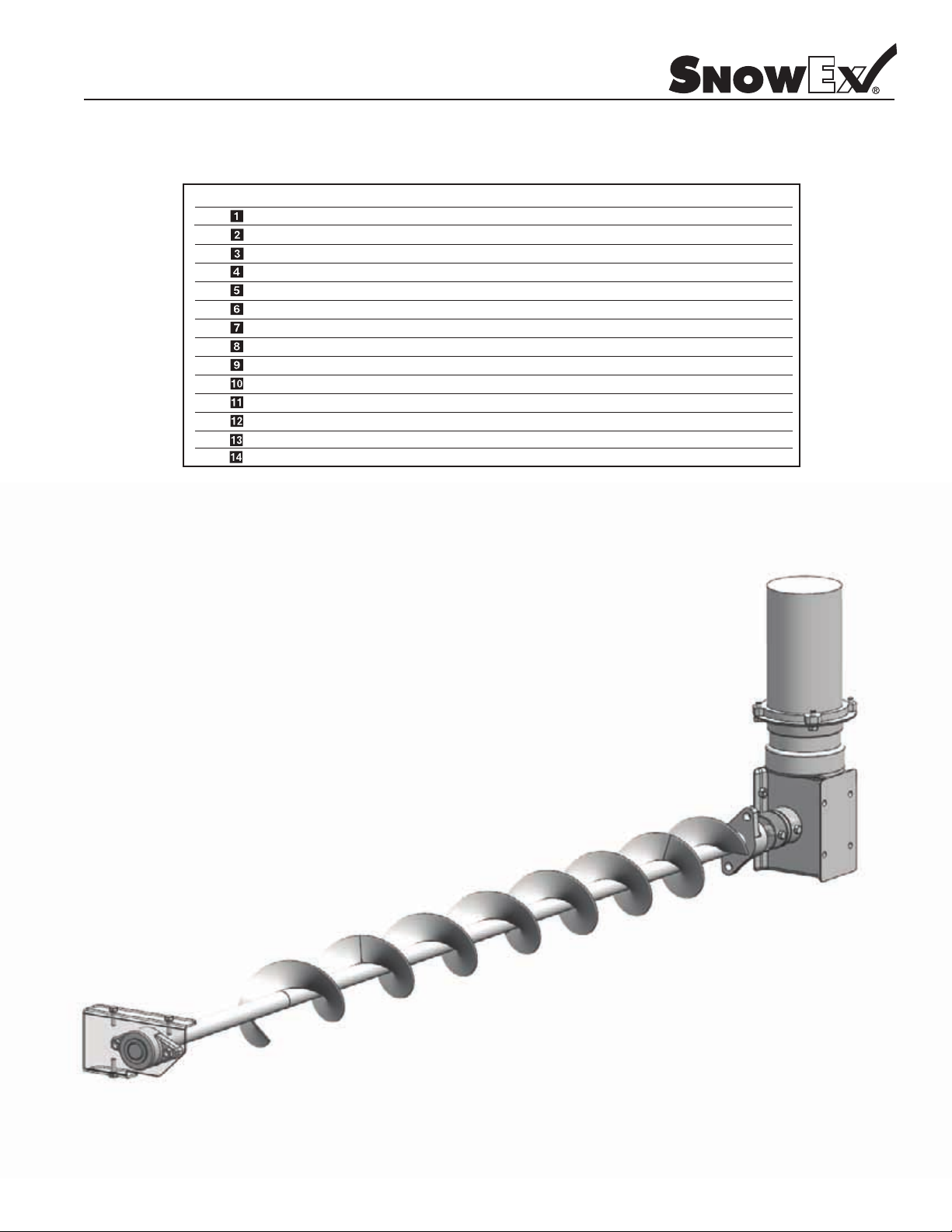

Component Assembly Views

Model # SP-2400

Spinner Drive

Assembly

Auger Drive

Assembly

Electrical System

Assembly

8 — 8

Hopper

Assembly

Frame

Assembly

L1186 © Trynex International 2009

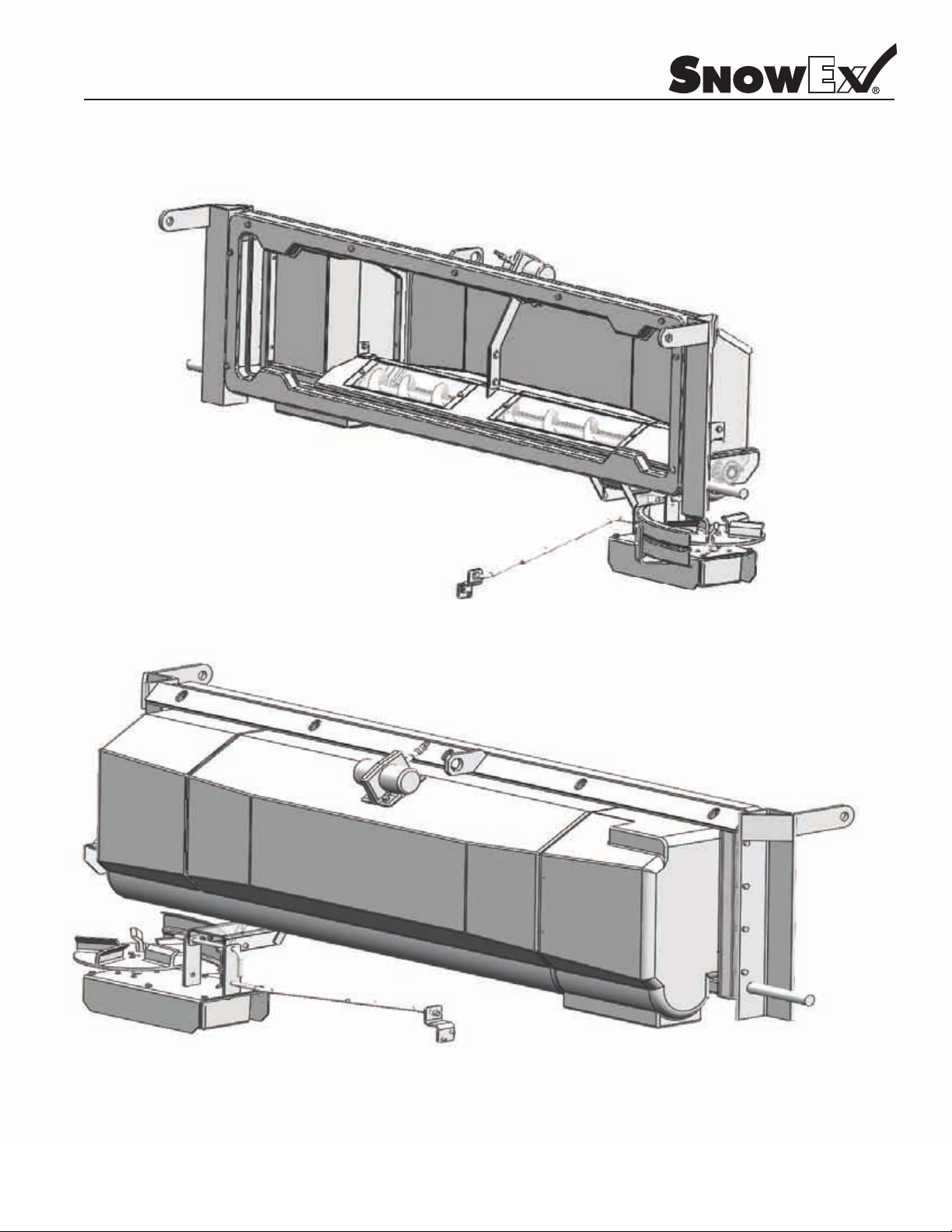

Front and Rear Views

Model # SP-2400

© Trynex International 2009 L1186

8 — 9

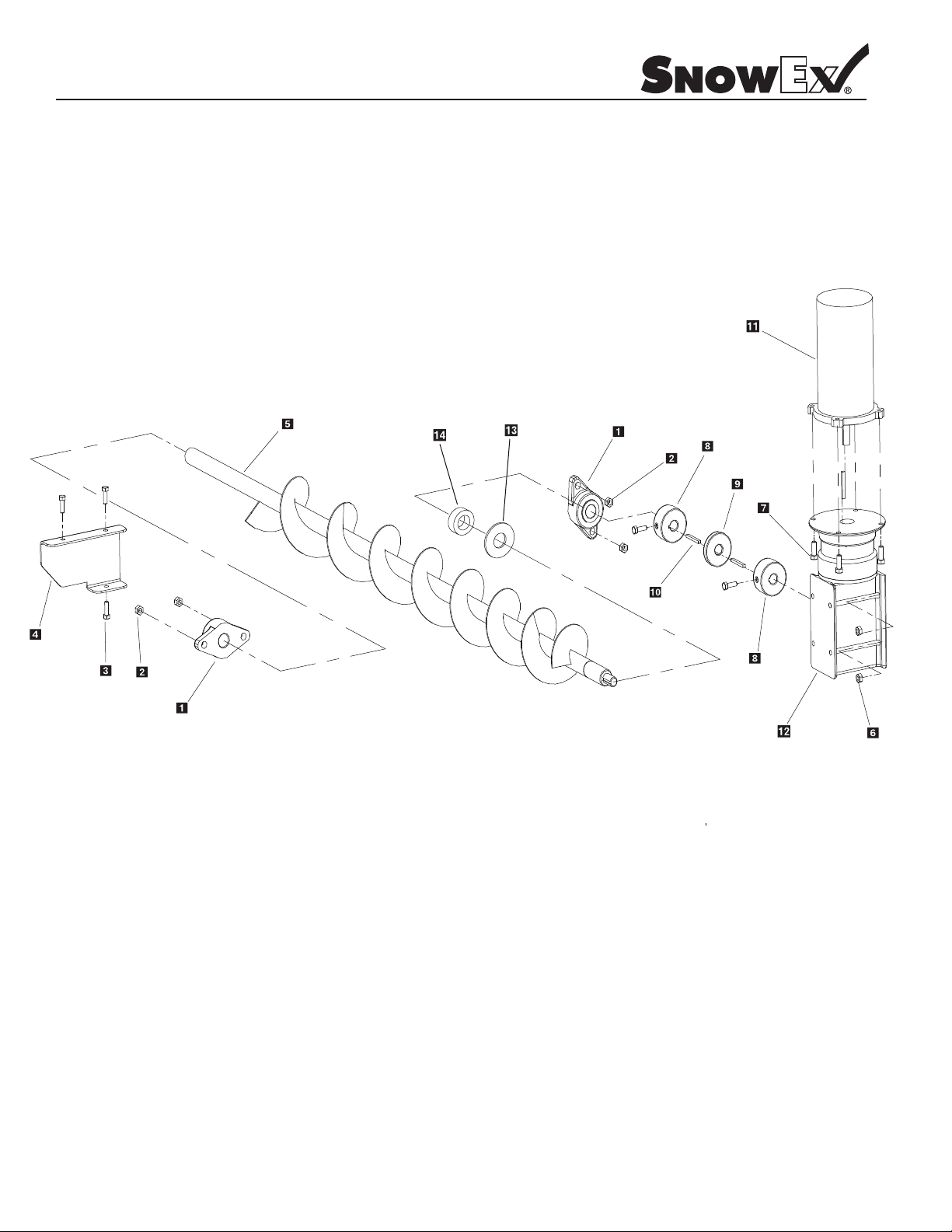

Auger Drive Assembly Parts Breakdown

Model # SP-2400

8 — 10

L1186 © Trynex International 2009

Auger Drive Assembly Parts Breakdown

Model # SP-2400

D5527 1” Bearing

D6584 3/8” Flange Nut

D6453 5/16” x 1” Serrated 18-8 SS

D5702 Bearing Cover

D5709 6” Variable Pitch Auger

D5706 5/16” Serrated Flange Nut

D6452 3/8” Serrated HHCS

D6842 Love Joy Coupling

D6843 Urethane Spyder

D6873 3/16” Key Stock

D6825 12 Volt Auger Motor

D6894 Auger Transmission

D6789 Auger Shaft Hopper Washer

D6792 Auger Shaft Hopper Collar

.ytQ noitpircseD .oN traP yeK

2

4

3

1

1

4

4

2

1

3

1

1

1

1

© Trynex International 2009 L1186

Auger Drive

Assembly

8 — 11

Loading...

Loading...