SnowEx Liqui Maxx 170802 Owner's Manual And Installation Instructions

November 15, 2018

Lit. No. 76616, Rev. 02

Liqui Maxx™ Sprayer Systems

Owner's Manual and Installation Instructions

Original Instructions

CAUTION

Read this document before operating

or servicing the equipment.

This manual and instructions are for Liqui Maxx Sprayer Systems

with serial numbers beginning with 170802 and higher.

This document supersedes all editions with an earlier date.

TABLE OF CONTENTS

PREFACE ....................................................................4

Warranty Registration ........................................... 4

Owner's Information Form ....................................4

SAFETY ...................................................................... 5

Safety Defi nitions .................................................. 5

Warning/Caution Labels ....................................... 5

Serial Number Label ............................................. 6

Safety Precautions ................................................ 6

Fuses ....................................................................7

Personal Safety..................................................... 7

Fire and Explosion ................................................ 8

Cell Phones ...........................................................8

Ventilation .............................................................8

Battery Safety ....................................................... 8

Torque Chart ......................................................... 8

LOADING .................................................................... 9

Certifi cation ........................................................... 9

Specifi cations ........................................................ 9

INSTALLATION INSTRUCTIONS ............................ 10

Installation and Removal ..................................... 10

Control Box Mounting ......................................... 12

Wiring Diagram ................................................... 13

Installation ........................................................... 14

Mounting the Display Console & Switches ... 14

Speed Sensor Installation ............................ 15

Standard Control Installation .............................. 15

Wiring Diagram ............................................. 15

Battery Connections ..................................... 15

FILLING .................................................................... 16

First Time Filling .................................................. 16

Routine Filling ..................................................... 16

Gasoline ....................................................... 16

Adding Brine ................................................. 16

Oil ................................................................. 16

OPERATING & CALIBRATION INSTRUCTIONS ... 18

Control Operation ............................................... 18

Deluxe Control .............................................. 18

Standard Control .......................................... 19

Deluxe Console Functions .................................. 20

Rotary Switch Position Functions ................. 20

Calibration Positions ..................................... 20

Soft Key Functions .......................................20

Calibration ........................................................... 21

Entering Calibration Values .......................... 21

"Special" Calibration ........................................... 24

Entering Calibration Values .......................... 24

Console Switches & Buttons...............................28

Section Switches .......................................... 28

Resetting System Counters .......................... 29

Standard Sprayer Control ................................... 30

Sprayer Console ........................................... 30

Spray Boom Operation .......................................30

Wing Spray Nozzle Selection ....................... 30

Downward Spray Nozzle Selection .............. 31

Nozzle Alignment ......................................... 31

Default Control Settings ...................................... 31

Deluxe Control .............................................. 31

Application Rates ................................................ 32

Manual Mode ................................................ 32

Calculations ........................................................ 33

Equations ...................................................... 33

Conversions.................................................. 33

Example Calculation .....................................34

MAINTENANCE ........................................................35

Periodic Maintenance .........................................35

Cleaning .............................................................. 35

End of Season and Storage ................................ 35

Nozzle Maintenance ...........................................35

Pump Maintenance ............................................. 35

TROUBLESHOOTING .............................................. 36

TROUBLESHOOTING – DELUXE CONTROL ........37

Wiring Diagram – Electric Start System ............. 38

Wiring Diagram – Hydraulic System ................... 39

Lit. No. 76616, Rev. 02 3 November 15, 2018

PREFACE

This manual has been prepared to acquaint you with

the safety information, operation, and maintenance of

your new machine. Improper installation and operation

could cause personal injury and/or equipment and

property damage. Read and understand the Owner's

Manual before installing, operating, or making

adjustments. Keep this manual accessible.

®

When service is necessary, call SnowEx

Service at 1-800-SALTERS (725-8377).

NOTE: This unit is designed to be used with

salt brine; the use of additives may impact

performance.

NOTE: Do not modify or alter the machine.

Altering the unit in any way will void the warranty.

The Liqui Maxx™ Sprayer System is designed to apply

brine to pre-treat, anti-ice, and post-treat parking lots

and roadways. Each Liqui Maxx unit consists of a

holding tank, pumping system and control, and a spray

boom.

Technical

Standard Control

The standard version of the control has the ability

to turn the sprayers ON and OFF and increase or

decrease the pressure of the system from the cabin.

Deluxe Control

The deluxe version of the control unit has many

features that include: push-button controls, application

rate adjustment and selection, automatic and manual

control modes, visual and audio alarms, and a BLAST

function for spot applications.

A separate GPS unit is offered that incorporates the

vehicle speed to automatically adjust the fl ow rate

and maintain the desired application rate. The deluxe

control is also compatible with some vehicle speed

sensors that can replace the GPS unit. Consult your

vehicle owner's manual for more information.

WARRANTY REGISTRATION

Warranty registration is available online at

www.snowexproducts.com. Under "Support" select

"Warranty Registration" and submit the form online.

OWNER'S INFORMATION

Owner's Name: ______________________________________________________________________

Date Purchased: _____________________________________________________________________

Outlet Name: ______________________________________________ Phone: _________________

Outlet Address: ______________________________________________________________________

Vehicle Model: _______________________________________________ Year: _______________

Equipment Model: ____________________________________ Serial #: ______________________

Length: ________________________ Weight: __________________ lb/kg: _________________

Lit. No. 76616, Rev. 02 4 November 15, 2018

SAFETY

SAFETY DEFINITIONS

WARNING

Indicates a potentially hazardous situation

that, if not avoided, could result in death or

serious personal injury.

CAUTION

Indicates a potentially hazardous situation

that, if not avoided, may result in minor or

moderate injury. It may also be used to alert

against unsafe practices.

NOTE: Indicates a situation or action that can lead

to damage to your sprayer and vehicle or other

property. Other useful information can also be

described.

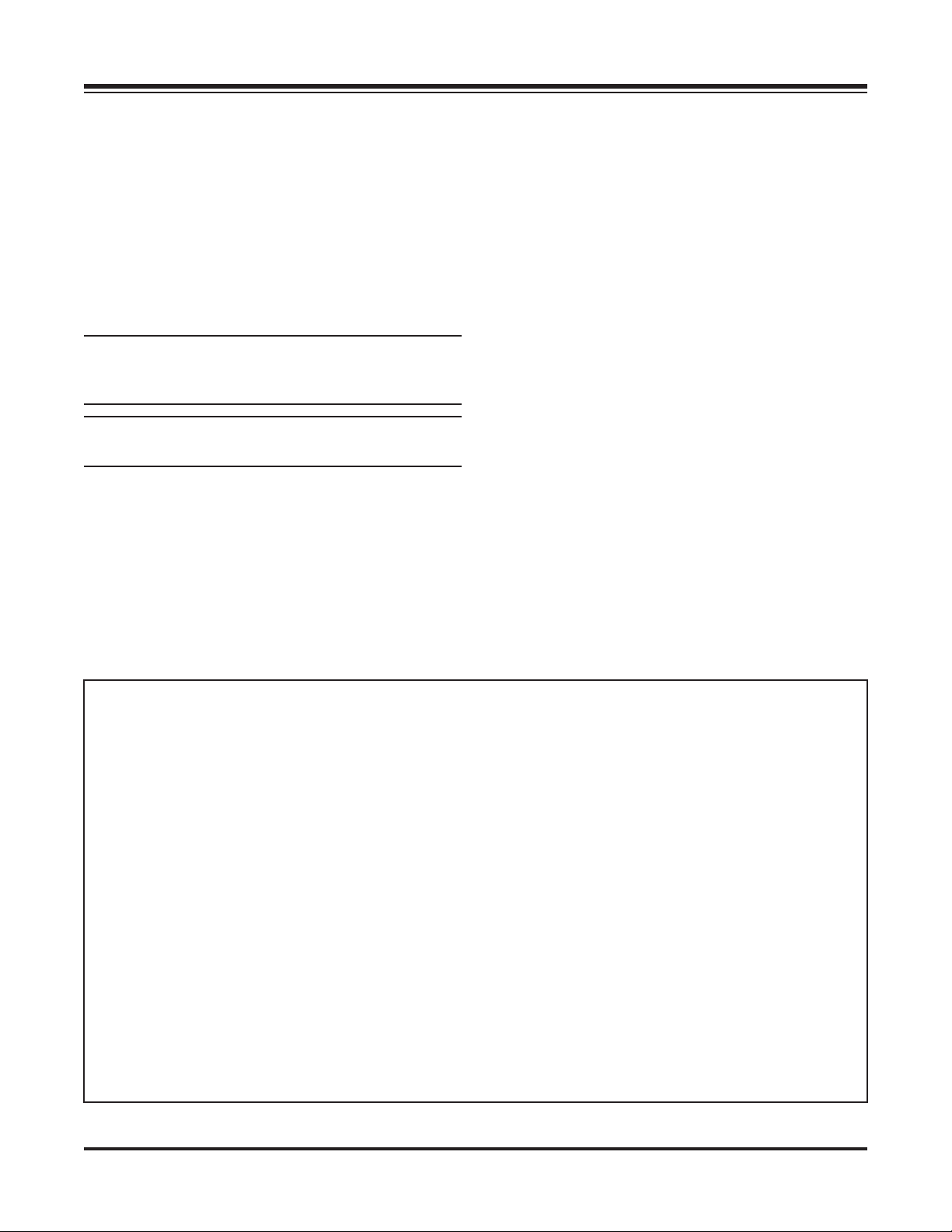

WARNING/CAUTION LABELS

Become familiar with and inform users about the

warning and caution labels on the machine.

If labels are missing or cannot be read, call

1-800-SALTERS (725-8377).

Model TSA-300 Only

Both Sides

Lit. No. 76616, Rev. 02 5 November 15, 2018

SAFETY

SERIAL NUMBER LABEL

SAFETY PRECAUTIONS

Improper installation and operation could cause

personal injury and/or equipment and property

damage. Read and understand labels and the

Owner's Manual before installing, operating, or making

adjustments.

WARNING

• Before working with the equipment, secure all

loose-fi tting clothing and unrestrained hair.

• Before operating the sprayer system, verify

that all safety guards are in place.

• Always shut vehicle OFF before attempting

to attach, detach, or service sprayer system.

• Never attempt to take a unit off a truck with

liquid in it.

• Do not climb into or ride on the machine.

WARNING

Overloading could result in an

accident or damage. Do not exceed

GVWR or GAWR ratings as found

on the driver-side vehicle door

cornerpost. See Filling section to determine

maximum volumes of spraying material.

Code Defi nition

YY 2-Digit Year

MM 2-Digit Month

DD 2-Digit Day

LL 2-Digit Location Code

XXXX 4-Digit Sequential Number

ZZZZZZ Model #

WARNING

Securely bolt and strap unit into place on the

vehicle bed using the optional UMK-200 bolt

kit and ratchet straps or similar. Unit must

be strapped down and bolted into position

before operating or transporting.

WARNING

Vehicle handling and characteristics will

change with the unit installed. Avoid any

sudden steering maneuvers, starts, or stops

that could create sloshing and instability.

WARNING

Always make sure that personnel are clear

of areas of danger when using equipment.

Maintain 60' distance from all bystanders

when operating the sprayer system.

Lit. No. 76616, Rev. 02 6 November 15, 2018

SAFETY

WARNING

Do not install the control for this product in

the deployment path of an air bag. Refer to

vehicle manufacturer's manual for air bag

deployment area(s).

WARNING

Inspect the unit periodically for defects. Parts

that are broken, missing, or worn out must be

replaced immediately. Do not alter any part of

the unit without prior written permission from

the manufacturer.

WARNING

Vehicles <10,000 lb GVWR: Obstructing the

visibility from the vehicle's rear camera could

result in serious injury or damage. An auxiliary

camera system shall be installed if the

vehicle's rear camera is removed or blocked.

CAUTION

Brine is typically a clear to cloudy white

liquid with no odor. It may be irritating to the

eyes, skin, and respiratory system. For more

safety information on brine and other de-icing

materials, refer to the manufacturer's Safety

Data Sheet (SDS).

CAUTION

During the sprayer system installation

we recommend the addition of an OSHA

compliant Backup Alarm. This alarm is

required for OSHA governed employers.

CAUTION

Disconnect electric and/or hydraulic power

and tag out, if required, before servicing or

performing maintenance.

CAUTION

Do not leave material in the unit for long

periods of time.

NOTE: Lubricate grease fi ttings after each use.

Use a good quality multipurpose grease.

FUSES

The electrical system contains several

automotive-style fuses. If a problem should occur and

fuse replacement is necessary, the replacement fuse

must be of the same type and amperage rating as

the original. Installing a fuse with a higher rating can

damage the system and could start a fi re.

PERSONAL SAFETY

• Remove ignition key and put the vehicle in PARK

or in gear to prevent others from starting the

vehicle during installation or service.

• Wear only snug-fi tting clothing while working on

your vehicle or sprayer system.

• Do not wear jewelry or a necktie, and secure long

hair.

• Wear safety goggles to protect your eyes from

brine, battery acid, gasoline, dirt, and dust.

CAUTION

• Do not operate a sprayer system in need of

maintenance.

• Before operating the sprayer system,

reassemble any parts or hardware removed

for cleaning or adjusting.

• Before operating the sprayer system,

remove materials such as cleaning rags,

brushes, and hand tools from the unit.

• Before operating the sprayer system, read

the engine owner's manual, if so equipped.

• While operating the unit, use auxiliary warning

lights, except when prohibited by law.

• Tighten all fasteners according to the

Torque Chart. Refer to Torque Chart for the

recommended torque values.

Lit. No. 76616, Rev. 02 7 November 15, 2018

• Do not eat, drink, smoke, rub your eyes, or touch

bare skin while spraying.

• Never point spray gun at people or animals.

• Avoid touching hot surfaces such as the engine,

radiator, hoses, and exhaust pipes.

• Always have a fi re extinguisher rated BC handy,

for fl ammable liquids and electrical fi res.

SAFETY

FIRE AND EXPLOSION

WARNING

Gasoline is highly fl ammable and gasoline

vapor is explosive. Never smoke while

working on vehicle. Keep all open fl ames

away from gasoline tank and lines. Wipe up

any spilled gasoline immediately.

Be careful when using gasoline. Do not use gasoline

to clean parts. Store only in approved containers away

from sources of heat or fl ame.

CELL PHONES

A driver's fi rst responsibility is the safe operation of

the vehicle. The most important thing you can do

to prevent a crash is to avoid distractions and pay

attention to the road. Wait until it is safe to operate

Mobile Communication Equipment such as cell phones,

text messaging devices, pagers, or two-way radios.

VENTILATION

WARNING

Vehicle exhaust contains lethal fumes.

Breathing these fumes, even in low

concentrations, can cause death. Never

operate a vehicle in an enclosed area without

venting exhaust to the outside.

BATTERY SAFETY

CAUTION

Batteries normally produce explosive gases

which can cause personal injury. Therefore,

do not allow fl ames, sparks, or lit tobacco

to come near the battery. When charging or

working near a battery, always cover your

face and protect your eyes, and also provide

ventilation.

• Batteries contain sulfuric acid, which burns

skin, eyes, and clothing.

• Disconnect the battery before removing or

replacing any electrical components.

TORQUE CHART

CAUTION

Read instructions before assembling.

Fasteners should be fi nger tight until

instructed to tighten according to the Torque

Chart. Use standard methods and practices

when installing equipment, including proper

personal protective safety equipment.

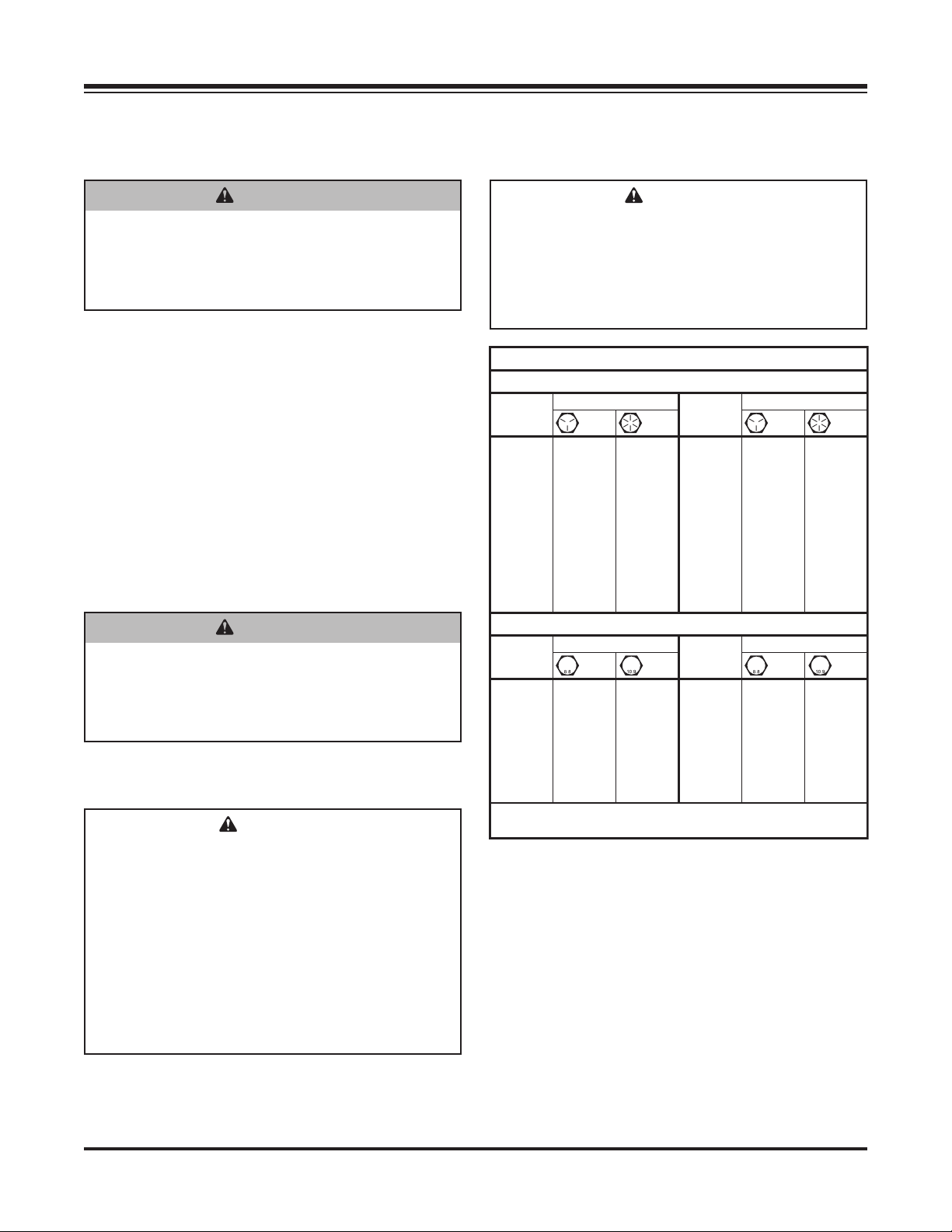

Recommended Fastener Torque Chart

Inch Fasteners Grade 5 and Grade 8

Size Size

1/4-20 109 154

1/4-28 121 171

5/16-18 150 212

5/16-24 170 240

3/8-16 269 376

3/8-24

7/16 -14

7/16 -20

1/2-13

1/2-20

Tor qu e (ft-l b)

Grade

5

8.4

9.7

17.4

19.2

30.8

35.0

49.4

55.2

75.3

85.0

106.4

120. 0

Grade

11. 9

13.7

24.6

27.3

43.6

49.4

69.8

77.9

8

9/16-12

9/16-18

5/8-11

5/8-18

3/4-10

3/4-16

7/8 -9

7/8 -14 474 66 9

1-12 704 995

Metric Fasteners Class 8.8 and 10.9

Size Size

M6 x 1.00

M8 x 1.25

M10 x 1.50

M12 x 1.75

M14 x 2.00

M16 x 2.00

M18 x 2.50 318222

Tor qu e (ft-l b)

Class

8.8

7.7

19.5

38.5

67

107

167

These torque values apply to fasteners

except those noted in the instructions.

Class

26.9

53.3

93

148

231

10.9

M20 x 2.5011.1

M22 x 2.50

M24 x 3.00

M27 x 3.00

M30 x 3.50

M33 x 3.50

M36 x 4.00

Tor qu e (ft-l b)

Grade

5

297 420

429 60 6

644 9091-8

Tor qu e (ft-l b)

Class

8.8

325

428

562

796

1117

1468

1952

Grade

8

Class

10.9

450

613

778

113 9

1545

2101

2701

Lit. No. 76616, Rev. 02 8 November 15, 2018

LOADING

This Owner's Manual covers vehicles that have been

recommended for carrying the sprayer system. Please

see your local dealer for proper vehicle applications.

CERTIFICATION

WARNING

New untitled vehicle installation of a sprayer

system requires National Highway Traffi c

Safety Administration altered vehicle

certifi cation labeling. Installer to verify that

full sprayer does not exceed GVWR or GAWR

rating label and complies with FMVSS.

WARNING

Overloading could result in an accident or

damage. Do not exceed GVWR or GAWR as

found on the driver-side cornerpost of vehicle.

CAUTION

Read and adhere to manufacturer's

ice-control material package

labeling, including Material Safety

Data Sheet requirements.

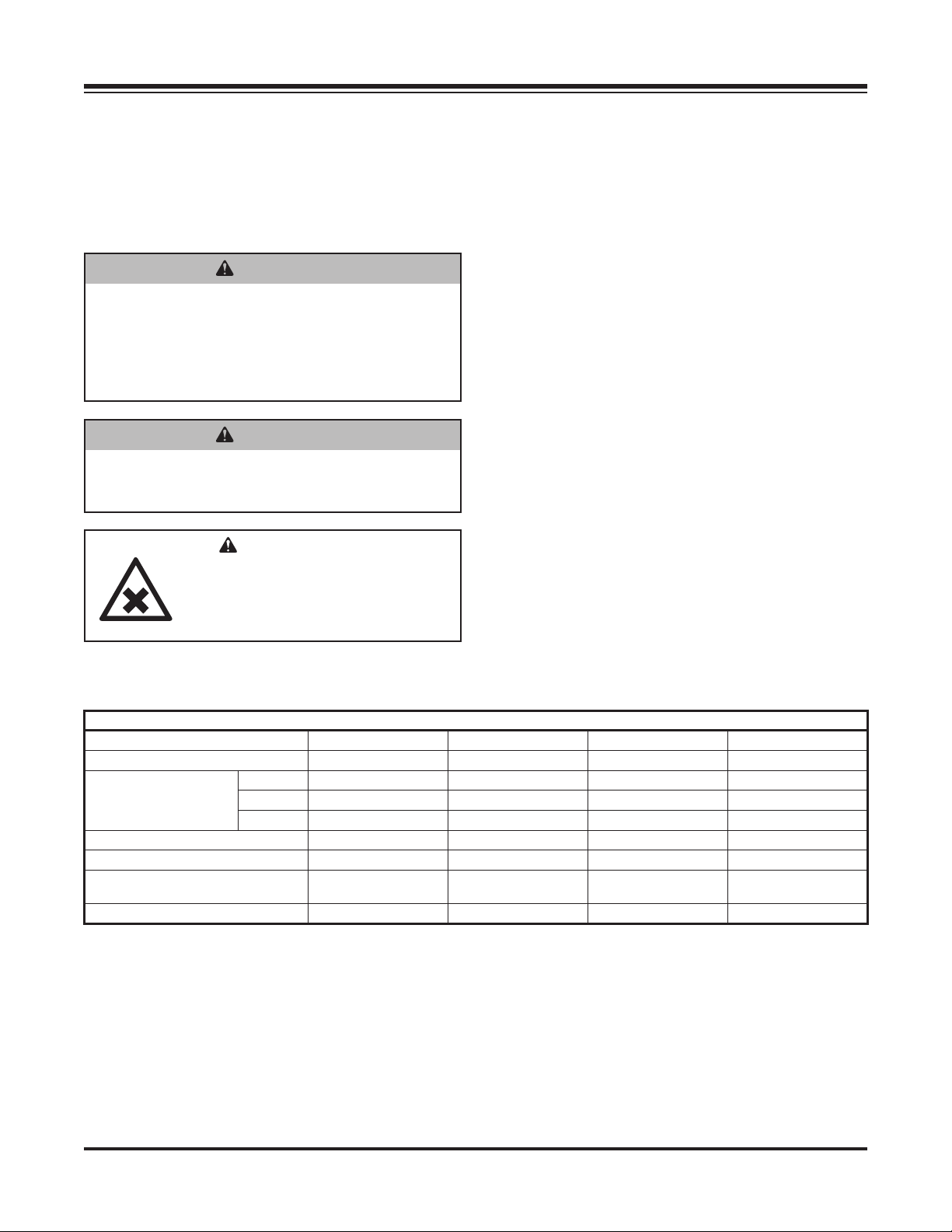

SPECIFICATIONS

Liqui Maxx™ Sprayer System

Tank Model TSA-300 TSA-500 TSA-750 TSA-1250

Capacity (gal) 300 500 750 1250

Tank and Pump

Dimensions (in)

Empty Unit Weight (lb) 500 600 700 1000

Full Unit Weight (lb) 3500 5600 8200 13500

Suggested Gross Vehicle

Weight Rating (GVWR) (lb)

Vehicle Class Class 2B Class 4 Class 5 Class 6

Length 101 112 118 119

Width 53 59 75 85

Height 24 48 55 73

8,500–10,000 14,000–16,000 16,000–19,500 19,500–26,000

Lit. No. 76616, Rev. 02 9 November 15, 2018

INSTALLATION INSTRUCTIONS

WARNING

Overloading could result in an

accident or damage. Do not exceed

GVWR or GAWR ratings as found

on the driver-side vehicle door

cornerpost. See Specifi cations to determine

maximum volumes of spraying material.

WARNING

New untitled vehicle installation of a sprayer

system requires National Highway Traffi c

Safety Administration altered vehicle

certifi cation labeling. Installer to verify that

full sprayer does not exceed GVWR or GAWR

rating label and complies with FMVSS.

WARNING

Always shut vehicle OFF before attempting to

attach, detach, or service sprayer system.

WARNING

Never attempt to take a unit off a truck with

liquid in it.

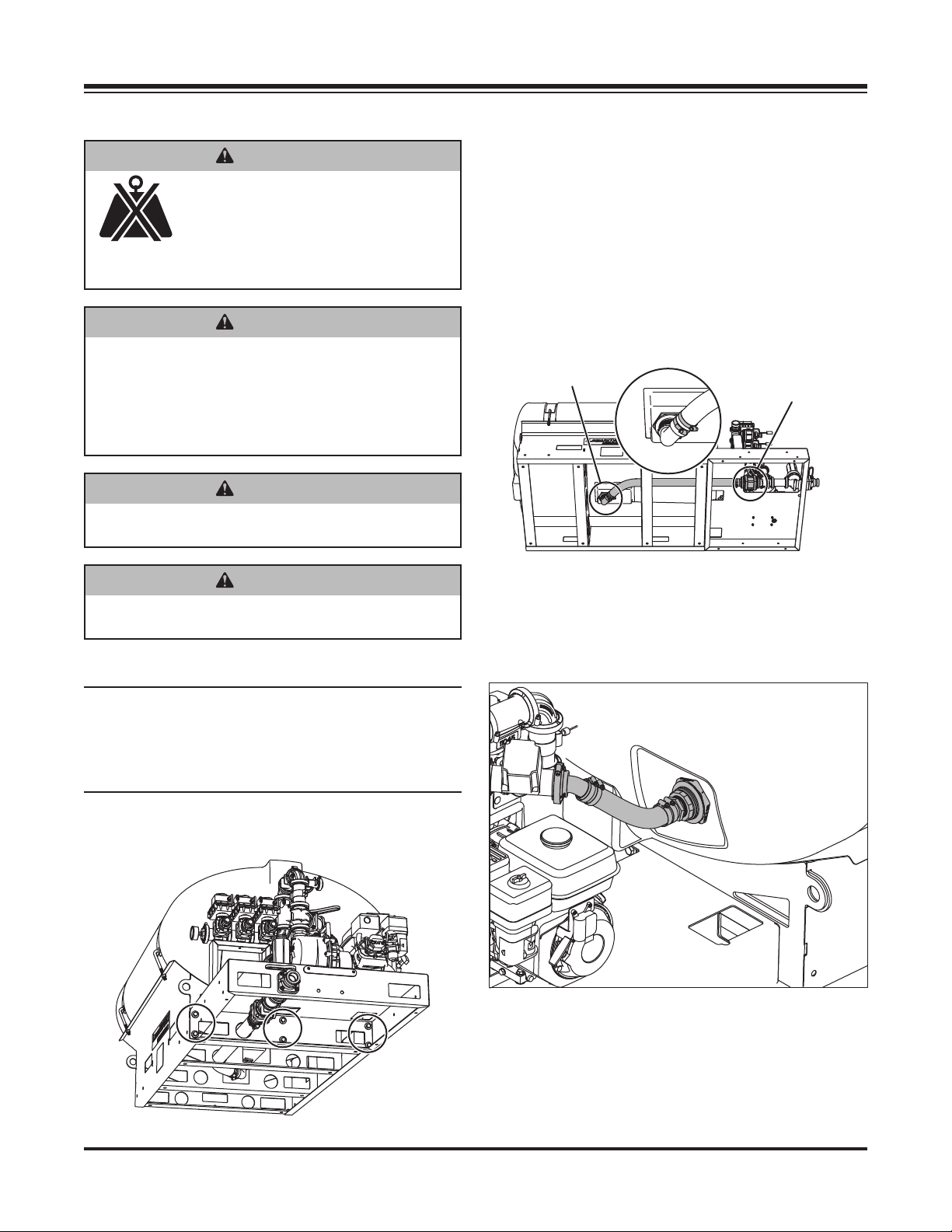

INSTALLATION AND REMOVAL

2. Connect the hose underneath the unit:

Securely fasten the 90° elbow connection to the

tank bulkhead fi tting underneath the unit. Make

sure that the bulkhead fi tting is securely fastened

to the tank to prevent leaks. Run the 2" hose from

the elbow to the shut-off valve below the pump.

Clock the 90° elbow so that the hose remains free

of kinks; cut it to length. Clamp the hose using

two (2) clamps on each end to prevent leaks. In

low temperatures, warming the hose may ease

installation. Dip the hose in hot water or carefully

use a heat gun for 20– 40 seconds.

90° Elbow

Shut-Off Valve

3. Connect the servo valve to the 1-1/2" bulkhead

fi tting on the pump side of the brine tank with

supplied 1-1/2" fl exible hose. Insert 1-1/2" hose

barb into bulkhead fi tting with pipe dope. Tighten

securely. Cut hose to length and attach with four

provided hose clamps.

NOTE: To prevent leaks, use a thread-sealing

compound on all threaded connections. Do

not use Tefl on® tape, as fragments will clog the

spray nozzles. Clamped connections may require

periodic retightening.

1. Bolt the pump and tank platforms together

(six places).

Tefl on® is a registered trademark of E. I. du Pont de Nemours and Company.

4. Lift the main tank and pump assembly using the

fork lift pockets. Use caution when inserting forks.

Improper insertion may puncture or damage the

brine tank and tubing routed underneath the unit.

Center the tank and pumping system from driver's

side to passenger's side on top of the truck bed

and lower into position.

Lit. No. 76616, Rev. 02 10 November 15, 2018

INSTALLATION INSTRUCTIONS

5. Install any optional kits and equipment. To install the

BRM-175 Adjustable Boom Receiver Mount, unfasten

the rear brake light, install the kit, and re-install the

light on the top rear face of the BRM bracket.

6. Securely bolt and strap unit into place on the

vehicle bed using the optional UMK-200 Universal

Mounting Kit or similar brackets and ratchet straps.

Hardware attaching the sprayer system directly to

the vehicle is the responsibility of the end user.

NOTE: Pay special attention when drilling or

clamping dissimilar metals to aluminum bodies.

Galvanic corrosion can occur if not handled

properly. Contact vehicle manufacturer for

recommended attachment practices.

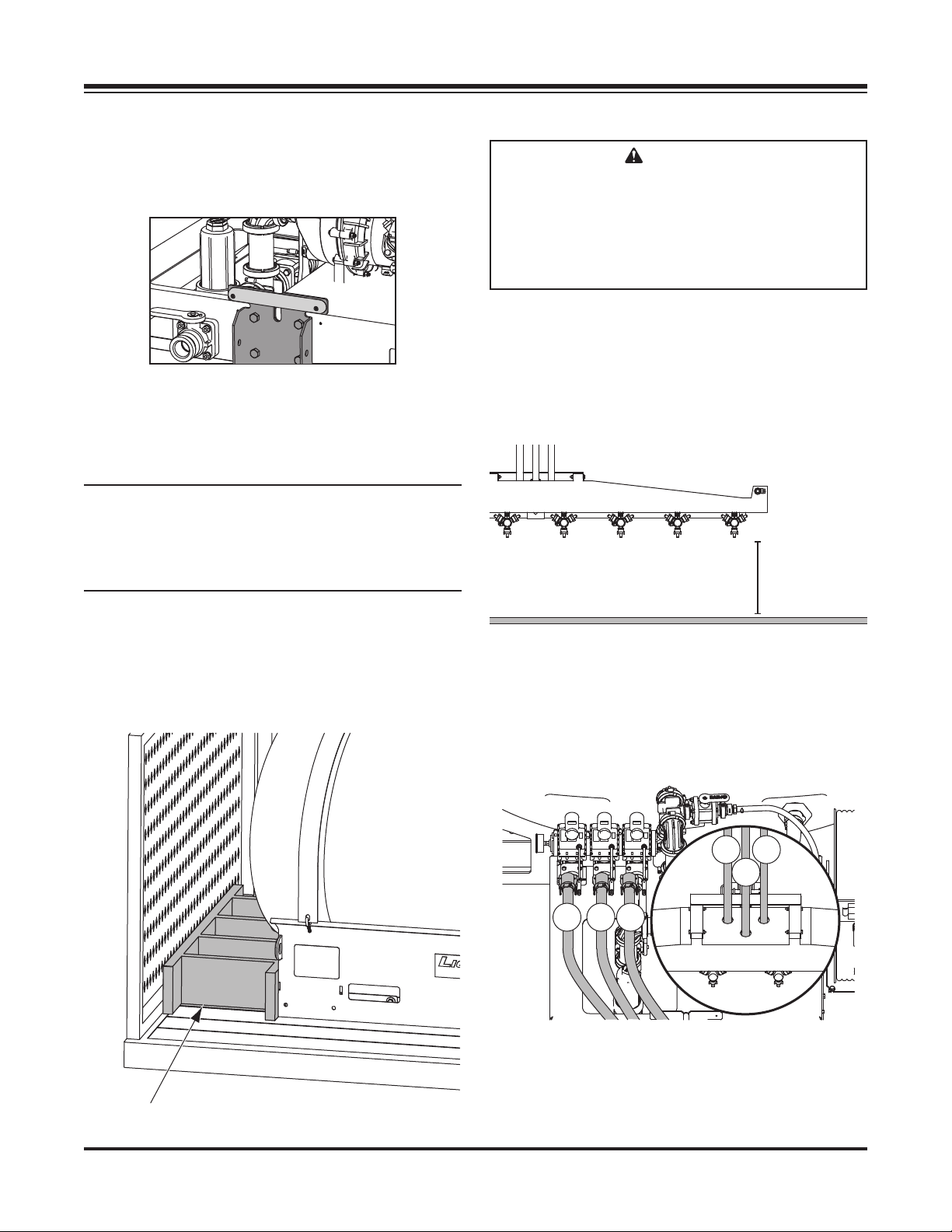

CAUTION

Ensure that nozzles have minimum 18 inches

ground clearance. Low boom heights can

cause accidental breakage from curbs,

uneven surfaces, and other obstacles.

Adjustment may require optional BRM-175

Adjustable Boom Mount.

8. Install the boom so that the nozzles measure

18"–22" from ground to nozzle tip. This is to

prevent damage and ensure optimal performance.

Consider using the optional BRM-175 Adjustable

Boom Receiver Mount if the tips of the nozzles lie

outside this zone when using your stock receiver

hitch.

18"–22"

7. Measure the distance between the front of the

truck bed and the tank base. Make a spacer to fi ll

area between the tank base and the front of the

truck bed. Failure to install this spacer could result

in damage to the sprayer and/or vehicle.

9. Connect the boom to the pump. Clamp the quick

disconnect attachments on the boom hoses to the

manifold valves on the pumping unit. Route the

hoses to the installed boom with adequate slack

and cut the hoses to fi t. Clamp the hose tightly to

the boom to prevent leaks.

1

3

2

1

2 3

Wood Spacer

Lit. No. 76616, Rev. 02 11 November 15, 2018

INSTALLATION INSTRUCTIONS

CONTROL BOX MOUNTING

NOTE: Use dielectric grease to prevent corrosion

on all connections.

Before beginning the installation, remove all battery

cables from the vehicle battery terminals.

1. Route the vehicle harness (PN 72141) along the

vehicle frame. Do not route it close to the exhaust

system or engine, where extreme heat could melt

the wiring insulation and short out the sprayer and

vehicle electrical systems. Attach the harness to

frame holes and frame supports. Do not attach

to fuel or brake lines. Use heavy-duty cable ties

or frame clamps to fasten the harness along the

frame.

CAUTION

Before drilling holes, check to see that no

vehicle wiring or other components could be

damaged.

2. Route the control harness (PN 72143) using

an existing access hole through the fi re wall

into the vehicle cab. If adding an access hole is

necessary, check the area on the other side of

the fi re wall to make sure that you will not drill

into vehicle wiring or other components. Attach

securely with cable ties.

WARNING

Do not install the control for this product in

the deployment path of an air bag. Refer to

vehicle manufacturer's manual for air bag

deployment area(s).

CAUTION

Do not mount the control close to any heater

vents or in areas prohibited by the vehicle

manufacturer for crashworthiness. See

the vehicle's body builder's book, owner's

manual, or service manual for details.

CAUTION

Do not alter, modify, or install component in

shaded areas shown below. Failure to comply

may interfere with air bag deployment or

cause injury to operator in an accident.

3. Connect the harness to the back of the control

(PN 72145) and mount the control in a suitable

location within easy reach of the vehicle operator

without restricting access to the vehicle controls

and instruments.

4. Connect the harness to the battery. Refer to the

wiring diagrams for battery connections.

Lit. No. 76616, Rev. 02 12 November 15, 2018

Loading...

Loading...