SnowEx B2330521, B2330520, B2330519 User Manual

AccuSpray De-Icing Systems

This Manual Must Be Read Before Operating The Equipment

See Back Page for Details!

Warm Up to

with a

Winter Band!

FREE

FREE

VSS-1000

VSS-2000

VSS-3000

Rev. 02

FOR MODELS

Madison Heights, Michigan 48071

800-725-8377

© Trynex International 2010 L1506

Table of Contents

Rev. 02

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

General Information & Registration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

VSS 1000 Parts Information & Assemby/Installation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-20

VSS 1000 Electrical System Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

VSS 1000 Blank Pages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22-24

VSS 1000 Calibration Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

VSS 2000 & 3000 Parts Information & Assembly Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26-36

VSS 2000 & 3000 Electrical System Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37-38

VSS 2000 & 3000 Mounting Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

VSS 2000 & 3000 Calibration Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

De-Icing Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41-42

Blank Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Sprayer Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Trouble Shooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46-47

1 — 2

Have a question or need assistance?

SnowEx Customer Service

(800) 725-8377

or (586) 756-6555

Monday through Friday 8:00 AM to 4:30 PM EST

Fax: (586) 427-0552

E-Mail: customercare@trynexfactory.com

Website: www.snowexproducts.com

© Trynex International 2010 L1506

Introduction

Rev. 02

Thank you for your purchase of the new SnowEx Accu-Spray Liquid De-Icing System. Welcome to the SnowEx

family of products.

You have purchased an innovative liquid system that lets you apply ice control solutions directly to the spreading

material or directly to the pavement with a choice of three patterns. The choice is yours!

As with all SnowEx products, read your Owner’s Manual carefully. Maintained properly, your system will give you

trouble-free service. SnowEx products are the best built de-icing products in North America.

Sincerely,

The SnowEx Team

© Trynex International 2010 L1506

1 — 3

General Information

Rev. 02

CONGRATULATIONS!

The sprayer you have purchased is an example of snow and ice control technology at its nest! Your sprayer’s self-contained

design is a trademark of all Snowex products. Here’s why...

SIMPLICITY: Fast installation, easy operation and high quality parts means minimal maintenance for your SnowEx sprayer system.

RELIABILITY:

coupled to a unique spray boom system.

VERSATILITY:

WARRANTY:

The benets you are about to recognize are that of time, money and eort.

We welcome you to the world of Snowex Performance.

High impact linear low density polyethelyne tank, custom engineered powder coated frame, 12 volt high output pumps

Multi-use capabilities allows spraying of a variety of materials for snow and ice control.

Two years from date of installation.

Registration

Record the following information in this manual for quick reference.

Sprayer Model Number _____________________________________________________________________________________

Sprayer Serial Number ________________________________

Date of Purchase ___________________________________________________________________________________________

Dealer Where Purchased _____________________________________________________________________________________

When ordering parts, the above information is necessary. This will help to insure

that you receive the correct parts.

At the right is a diagram of the ID tag. This tag on the spreader is located

on the frame.

Please ll out the warranty card with all the necessary information to validate it. This will also give us a record so that

any safety or service information can be communicated to you.

1 — 4

SER. NO.______________________

TRYNEX INTERNATIONAL

Madison Heights, MI 48071 (800) 725-8377

L1506 © Trynex International 2010

Safety

Rev. 02

Before attempting any procedure in this book, these safety instructions must be read and understood by all workers who

have any part in the preparation or use of this equipment.

For your safety, warning and information decals have been placed on this product to remind the operator of safety

precautions. If anything happens to mark or destroy the decals, please request new ones from Snowex.

Unit must be strapped down and locked into position before operating vehicle.

Never exceed the Gross Vehicle Weight Rating of vehicle. Failure to do so may limit a vehicles

handling characteristics.

Never attempt to take a unit o a truck with material in it.

Never exceed 45 m.p.h. when loaded spreader is attached to vehicle. Braking distances may be

increased and handling characteristics may be impaired at speeds above 45 m.p.h.

Never allow children to operate or climb on equipment.

Always check areas to be spread to be sure no hazardous conditions or substances are in the area.

Always inspect unit for defects: broken, worn or bent parts, weakened areas on sprayer mounts.

Always shut o vehicle and power source before attempting to attach or detach or service spray

system. Be sure vehicle/power source is properly braked or chocked.

Always keep hands, feet, and clothing away from power-driven parts.

responsibility to communicate information on safe usage and proper maintenance of all

equipment.

Always make sure personnel are clear of areas of danger when using equipment. Maintain 60'

distance from all bystanders when operating the spray system.

Inspect the unit periodically for defects. Parts that are broken, missing, or worn out must be

replaced immediately. The unit, or any part of it cannot be altered without prior written

permission from the manufacturer.

Remember

it is the owner’s

© Trynex International 2010 L1506

1 — 5

Safety

Rev. 02

(continued)

Always inspect pins and latches whenever attaching or detaching sprayer system and before

traveling.

Never leave material in spray tank for long periods of time.

Remember, most accidents are preventable and caused by human error.

precautions must be observed to prevent the possibility of injury to operator or others!

Never operate equipment when under the inuence of alcohol, drugs, or medication that might

alter your judgment and/or reaction time.

Before working with the sprayer system, secure all loose tting clothing and unrestrained hair.

Always wear safety glasses with side shields when servicing sprayer system. Failure to do this

could result in serious injury to the eyes.

Exercising of care and

1 — 6

L1506 © Trynex International 2010

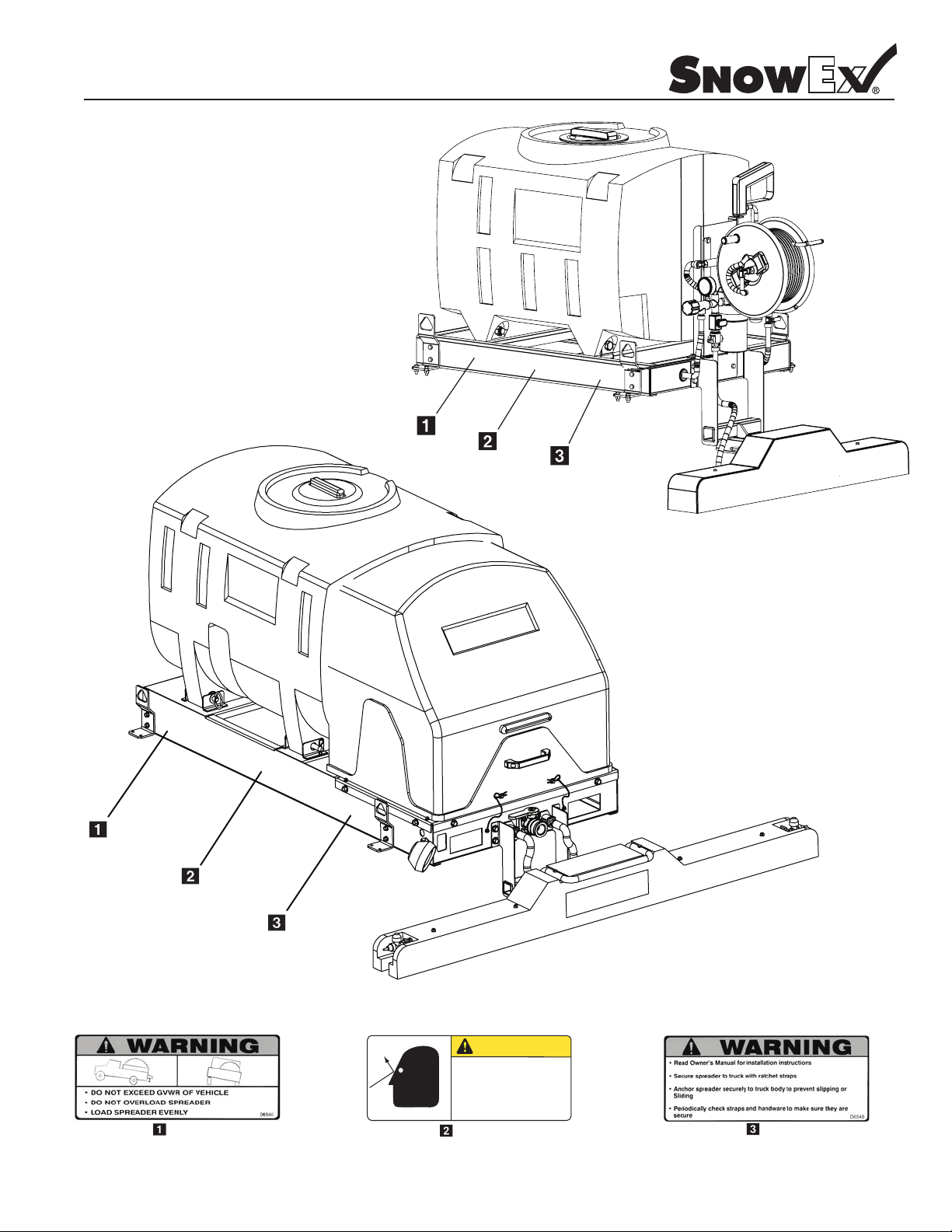

Safety and Warning Labels

Rev. 02

VSS 1000

D 6546

© Trynex International 2010 L1506

CAUTION

.

WEAR SAFETY GOGGLES WHEN

OPERATING EQUIPMENT.

.

WEAR SAFETY GOGGLES WHEN

FILLING EQUIPMENT.

.

DO NOT EAT, DRINK, SMOKE, RUB YOUR

EYES OR TOUCH BARE SKIN WHILE

HANDLING CHEMICALS OR SPRAYING.

.

NEVER POINT SPRAY GUN AT PEOPLE

OR ANIMALS.

T 20317

VSS 2000 & 3000

T-20317

D 6548

1 — 7

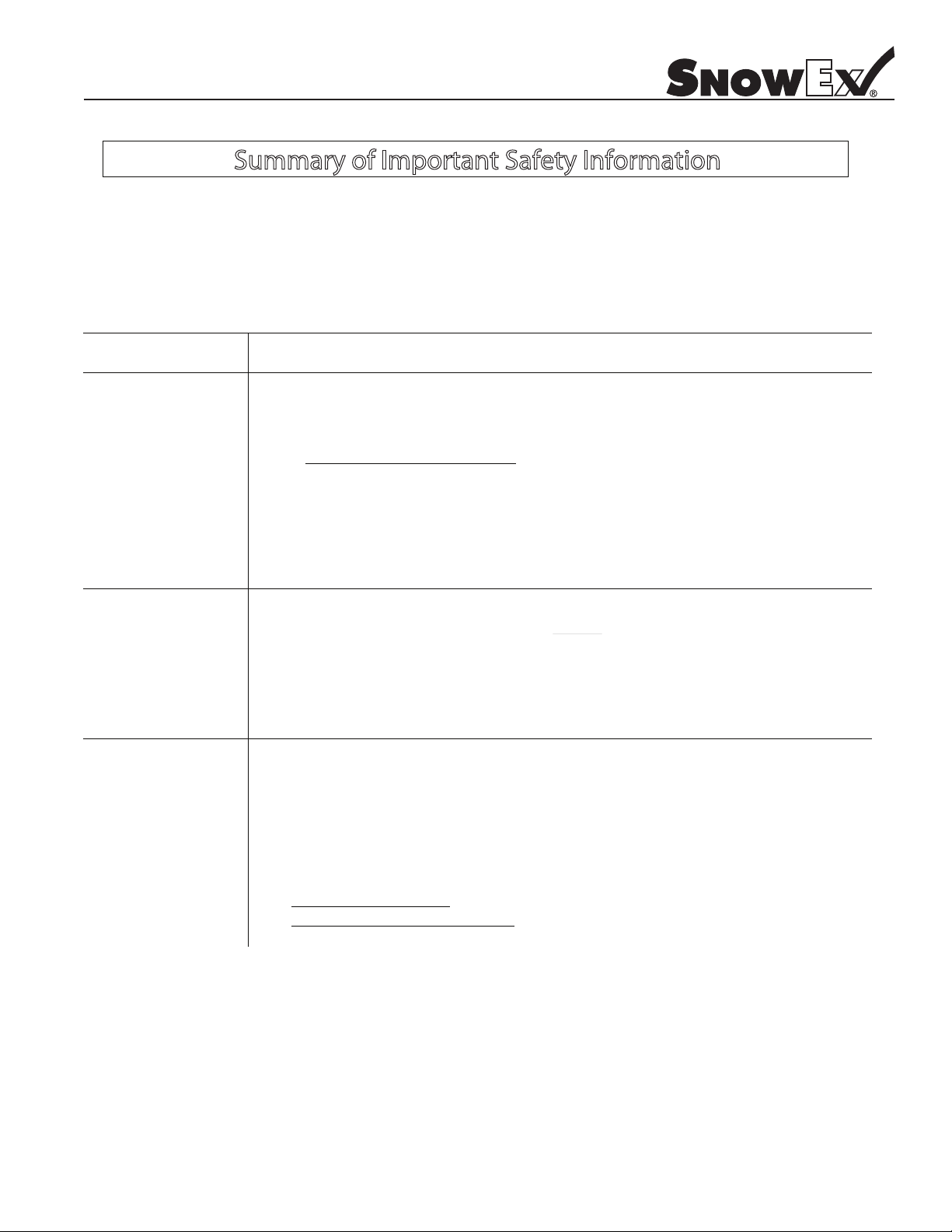

Operational Safety Information

Rev. 02

Summa y of Important Safe y nformat on

Chemical accident procedures

Immediate response is necessary in

spills. See instructions below:

Sprayer leak

Bodily chemical

contact

Poisoning by

ingestion or

inhalation

Chemical spills

If the sprayer develops a leak, immediately stop spraying

and follow directions below, as applicable.

Personal contamination can occur when chemicals splash, sp

onto a person.

1. Immediately follow First Aid instructions on chemical label.

2. Seek medical advice if instructed on the label or the victim experiences symptoms of

harmful eects. Bring the chemical label for reference.

In case of poisoning from ingestion or inhalation

If the victim has collapsed or is not breathing, call 911

1. If you are the victim, immediately seek assistance from nearby personnel, because you

may become incapacitated.

2. Immediately follow rst aid instructions on chemical label.

3. Call a poison control center for further advice. In the U.S., call 1-800-222-1222. Have

the chemical label available for reference.

Chemical spills must quickly be contained and properly cleaned up.

Refer to the chemical label for any specic clean-up instructions.

the event of sprayer leaks, bodily chemical contact, poisoning, or

. Turn o power to the sprayer

ill, or spray directly

General procedures can include:

a) Eyes – immediately ush with water.

b) Skin – wash all contaminated skin surfaces with soap and water.

c) Clothing – remove contaminated clot

clothing per chemical label instructions.

hing. Dispose of heavily contaminated

:

. Otherwise:

1 — 8

General procedures include:

1. Controlling

2. Containing

3. Cleaning up

4. Seeking additional advice from:

the spill by stopping the source of the spill.

the spill so that it does not spread and get into water sources.

the spill immediately.

- Chemical manufacturer. See chemical label for contact information.

- State pesticide regulatory agency. In the U.S., call the National Pesticide Info. Ctr.

at 800-858-7378 for assistance in contacting your state’s agency.

© Trynex International 2010 L1506

Operational Safety Information

Rev. 02

Summary of Important Safety Information

LISTED BELOW is a summary of safety information of particular importance.

See individual sections of this owner’s manual for more details.

DURING ASSEMBLY

C CK and ES completed assembly as directed in this manual. Serious injury could result from chemical

leaks if sprayer is improperly assembled.

DO NOT MODIFY SPRAYER DESIGN

DURING OPERATION

D and O O each chemical label’s instructions and warnings.

O inhaling, ingesting, or coming into contact with any chemicals.

KO applicable licensing and regulatory requirements for the chemical you plan to use.

KO

emergency procedures before handling chemicals. Carefully review “Chemical Accident

Procedures” listed below and later in this manual. Also see First Aid instructions on the chemical label.

protective clothing

cleaning the sprayer. Wear additional protective gear, such as facemask or apron, as recommended on the

chemical label.

X CS X A CAU O around children and pets. Pesticides are especially toxic to them. Keep

sprayer and spray materials away from them at all times.

M O O chemicals in an enclosed, unventilated area.

O

O ammable or corrosive chemicals in the sprayer.

O

US

the sprayer before switching chemicals in orderto prevent dangerous chemical interactions.

pesticides in a correctly labeled container and in a secure location

SO

O O the health of operators frequently exposed to pesticides, as recommended by the chemical

label or local/federal regulations.

, eye protection, and chemical resistant gloves when lling, using and

.

B OR S AY NG

N and A sprayer before each use

U O S for SAFELY FUELING the engine. Gasoline is ammable and can explode.

Always use caution when handling gasoline.

O sprayer until ready to spray

DO

AD O A SN O CV Q if you will be spraying overhead.

You will be exposed to much more chemical fallout in these applications. Wear chemical resistant head and neck

protection, full face mask or half face mask with sealed goggles, and consider using a respirator.

O A when wind speed exceeds 4 MPH in order to minimize spray drift.

DO

sprayer and spray materials away from children/pets. Pesticides can be especially toxic to children

K

and animals.

O O anyone younger than 16 to operate sprayer since pesticides are especially toxic to

DO

© Trynex International 2010 L1506

as directed in this manual.

in order to avoid unintentional spray release.

children.

1 — 9

Operational Safety Information

Rev. 02

Summary of Important Safety Information

During Spraying

•

O V pesticide. Apply at rate recommended by chemical manufacturer. Excess

pesticide can be dangerous to humans/animals, damage desirable plants, and contaminate soil and water

sources.

• O E , D K, OK , U OU , or OU OU K while

handling chemicals and spraying.

• O S G at people or animals.

• O NO S near open ames or sources of heat.

• A S U M when using it to spray at higher pressures in order to

prevent gun from whipping. Keep good footing and balance at all times.

• X CS X A CAU O when spraying near areas accessible to children and pets

• up spills immediately

per instructions on the chemical label.

.

• U O vehicle and set brake or block wheels, U sprayer, and E V system

pressure before leaving sprayer unattended.

• Troubleshooting section of this manual before attempting any repairs. Wear personal protective

equipment and follow safety instructions.

After Spraying

C sprayer immediately after use according to the directions provided in this manual.

C

O A yourself after you are done spraying and have cleaned the sprayer. Wash all exposed

areas of the body with soap and water, and remove and launder clothing.

S

POE O or O remaining chemicals in secure storage with correctly marked container.

Transporting Safety

A safety instructions in your vehicle manual with regard to carrying heavy cargo loads.

D

O O O drivers younger than 16

KE SU CU E C to vehicle.

X CS CU N in vehicle handling when driving with lled sprayer to avoid loss of control or

rollover.

Keep speed to a minimum so you can maintain control. Reduce speed prior to turns.

o

Allow for more distance to stop.

Avoid any sudden steering maneuvers, starts, or stops that could create liquid sloshing in the sprayer

and instability.

O

DO and RC R C O on sloped or uneven terrain. Pick the most level

route possible across elds--drive up and down slopes when necessary, rather than across. Use a vehicle

equipped with a roll over protection system (

that visibility may be reduced when making turns or backing up.

NO DE or cargo on the sprayer.

D

both sprayer and vehicle, and K

to drive the vehicle with the lled sprayer attached.

O if you will be working on non-level terrain.

before leaving unattended.

1— 10

© Trynex International 2010 L1506

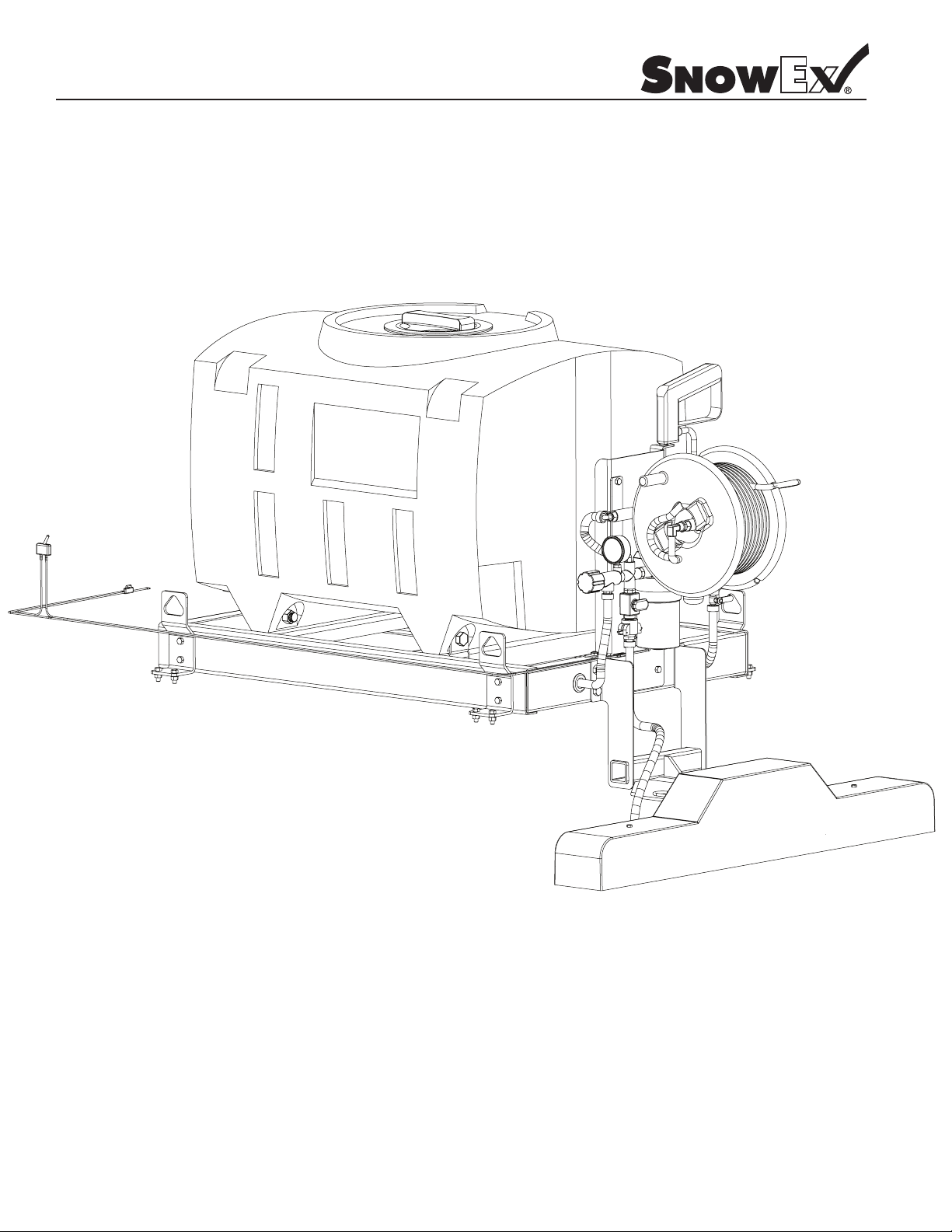

Main Assembly View

Rev. 02

Model # VSS-1000

© Trynex International 2010 L1506

1 — 11

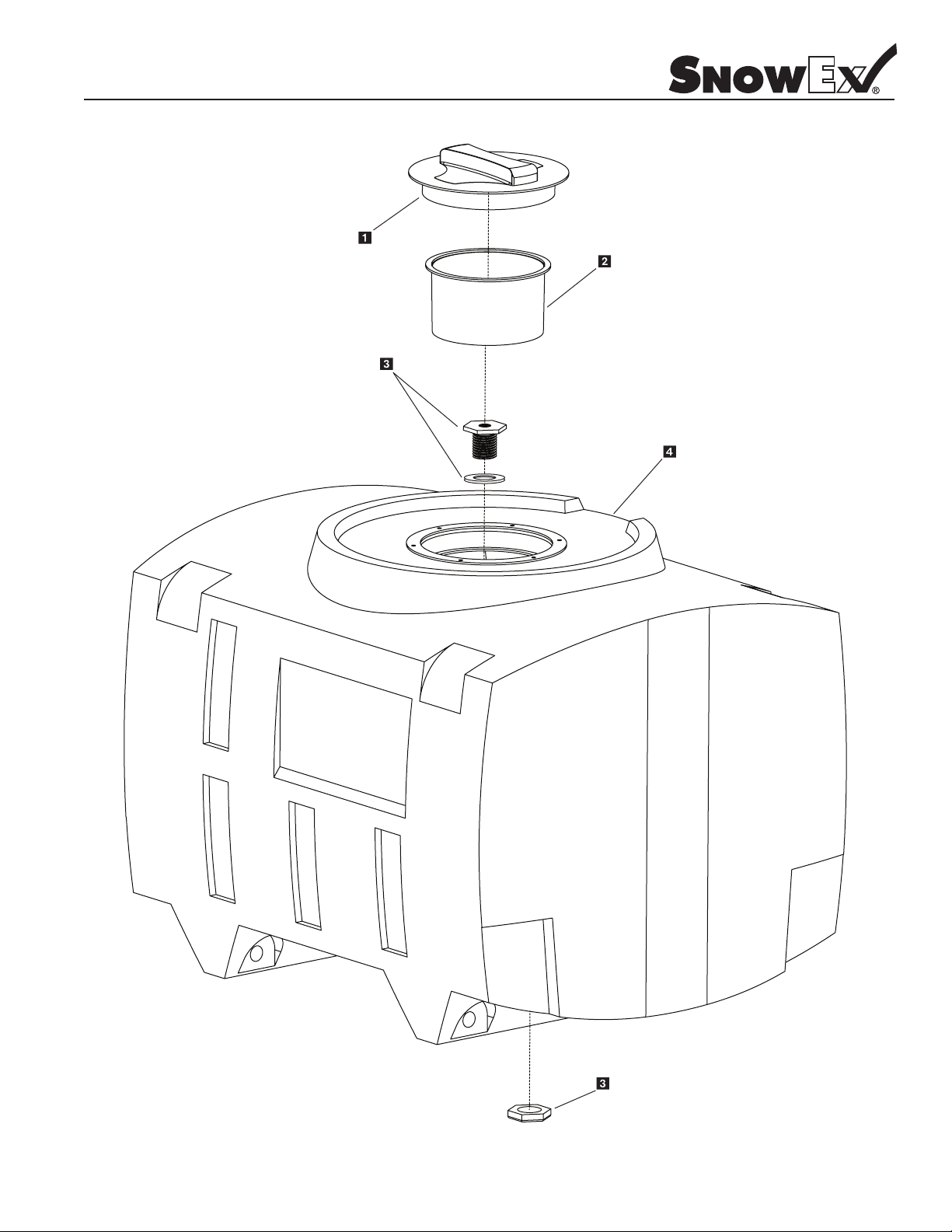

Tank Assembly Parts Breakdown

Rev. 02

Model # VSS-1000

1 — 12

© Trynex International 2010 L1506

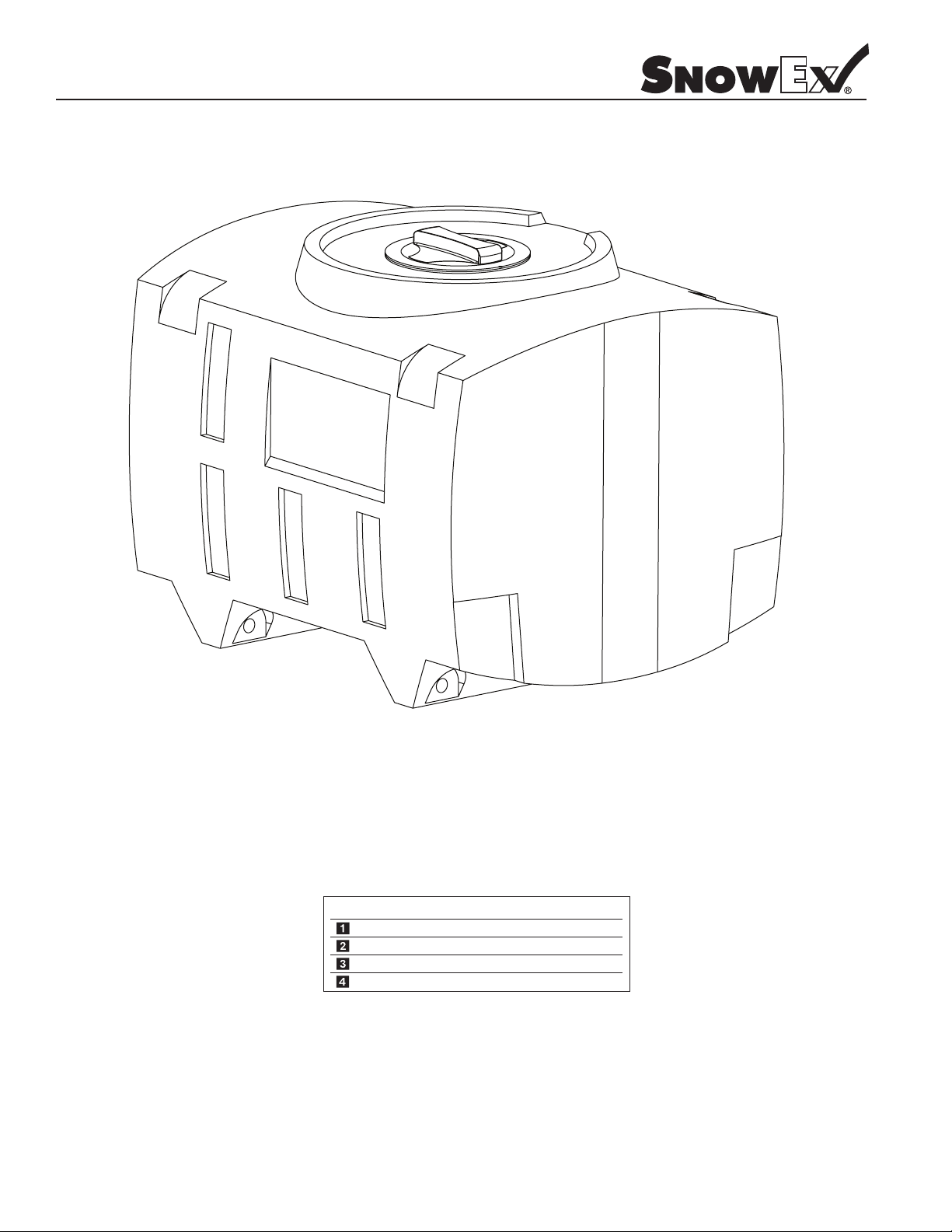

Tank Parts Breakdown

Rev. 02

Model # VSS-1000

© Trynex International 2010 L1506

Key

Part No.

T 20323

T 20324

D 6917

D 5600

Description Qty.

Tank Lid

Basket Strainer

Bulkhead Assembly

100 Gallon Poly Tank

1

1

1

1

1 — 13

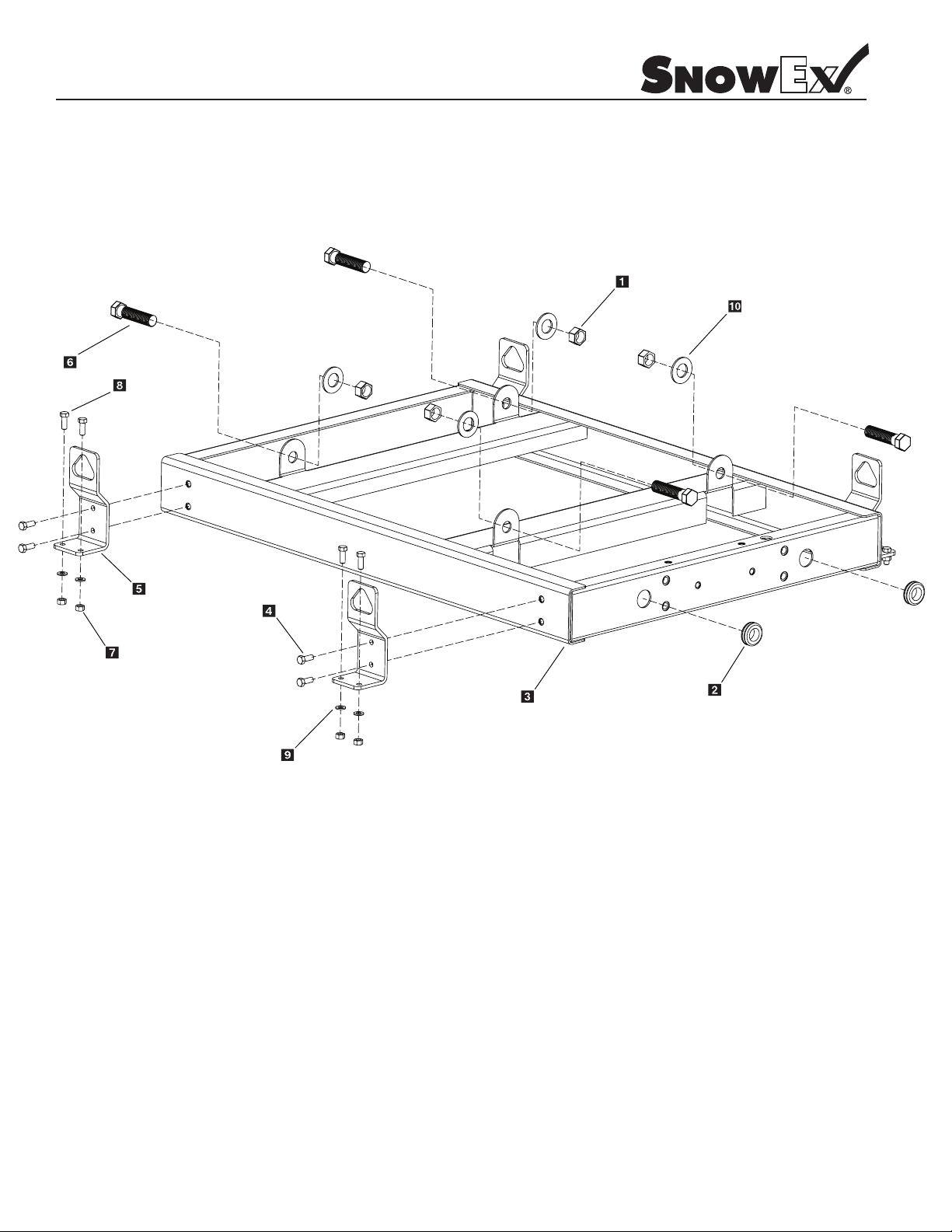

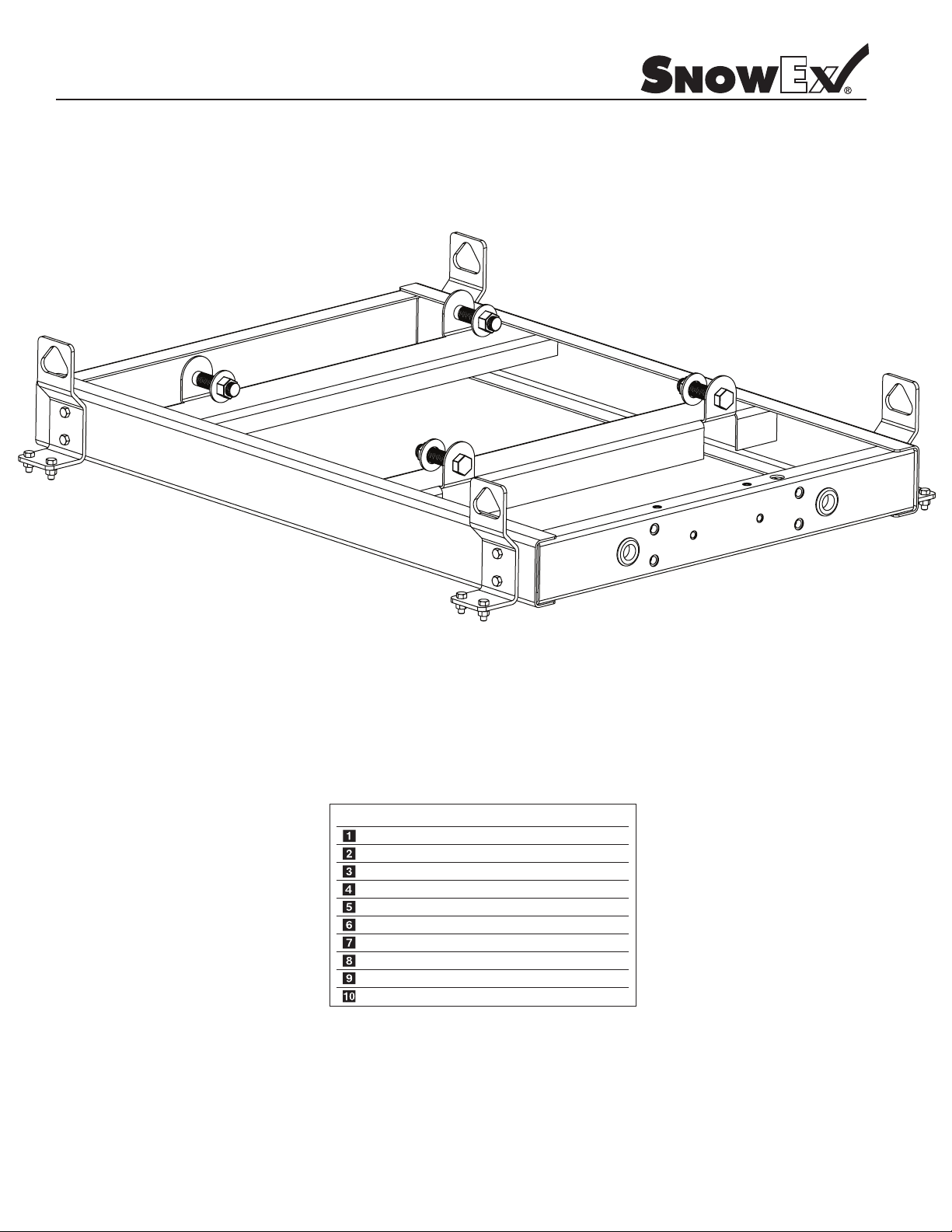

Frame Assembly Parts Breakdown

Rev. 02

Model # VSS-1000

1— 14

© Trynex International 2010 L1506

Frame Parts Breakdown

Rev. 02

Model # VSS-1000

© Trynex International 2010 L1506

Key

Part No.

D 4129

D 5602

D 5601

D 6452

D 5244

D 5614

D 4124

D 4122

D 4125

D 4409

Description Qty.

3/4-10 Nylox Nut

Hose Grommett

100 Gallon Base Weldment

3/8-16 x 1 Serrated Flange

Lift / Mounting Bracket

3/4-10 x 3-1/2 Hex Head

3/8-16 Nylox Nut

3/8-16 x 1-1/2 Hex Head

3/8 Flat Washer

3/4 Flat SAE Washer

4

2

1

8

4

4

8

8

8

4

1 — 15

Loading...

Loading...