Page 1

Rotary Broom

SS-4000

Owner's Manual

Original Instructions

April 15, 2017

Lit. No. 83751, Rev. 00

CAUTION

Read this document before operating or

servicing the rotary broom.

This document is for SnowEx® SS-4000 rotary brooms with

serial numbers beginning with 170301 and higher.

This document supersedes all editions with an earlier date.

Page 2

TABLE OF CONTENTS

PREFACE ..................................................................................................................................................................3

Owner's Information ............................................................................................................................................3

SAFETY INFORMATION ..........................................................................................................................................4

OPERATING INSTRUCTIONS .................................................................................................................................7

Component Vocabulary ......................................................................................................................................7

General Safety ....................................................................................................................................................8

Operating in Winter .............................................................................................................................................8

Operator Controls ...............................................................................................................................................9

Starting/Stopping Motor ....................................................................................................................................11

Adjusting Handlebar Height ..............................................................................................................................13

Transport ...........................................................................................................................................................13

Adjusting Ejection Direction ..............................................................................................................................14

Adjusting Brush Pressure .................................................................................................................................15

Plow Blade ........................................................................................................................................................16

Debris Collector Box (Optional Accessory) ......................................................................................................17

MAINTENANCE ...................................................................................................................................................... 18

Oil and Gas ....................................................................................................................................................... 18

Tire Pressure ....................................................................................................................................................19

Adjusting Control Cables .................................................................................................................................. 20

Replacing/Changing Brushes ........................................................................................................................... 21

Maintenance Plan .............................................................................................................................................22

Cleaning ............................................................................................................................................................22

TROUBLESHOOTING ............................................................................................................................................23

Lit. No. 83751, Rev. 00 2 April 15, 2017

Page 3

PREFACE

This manual has been prepared to acquaint you with

the safety information, operation and maintenance

of your new rotary broom. Please read this manual

carefully and follow all recommendations. This will

help ensure profi table and trouble-free operation of

your rotary broom. Keep this manual accessible. It is a

handy reference in case minor service is required.

Register your rotary broom online at www.snowexproducts.com

When service is necessary, bring your rotary broom

to your distributor. They know your rotary broom best

and are interested in your complete satisfaction.

OWNER'S INFORMATION

Owner's Name: _______________________________________________________________________

Date Purchased: ______________________________________________________________________

Outlet Name: ______________________________________________ Phone: ___________________

Outlet Address: _______________________________________________________________________

Engine Model: _______________________________________ Weight: ____________________ lb/kg

Rotary Broom Serial #: ________________________________ Engine Serial #: _________________

NOTE: Some photos in this manual show the rotary broom with the optional Multi-Purpose Brush Kit (PN 72258).

Lit. No. 83751, Rev. 00 3 April 15, 2017

Page 4

SAFETY

D

A

N

G

E

R

Z

O

N

E

SAFETY DEFINITIONS

WARNING

Indicates a potentially hazardous situation

that, if not avoided, could result in death or

serious personal injury.

CAUTION

Indicates a potentially hazardous situation

that, if not avoided, may result in minor or

moderate injury. It may also be used to alert

against unsafe practices.

NOTE: Indicates a situation or action that can lead

to damage to your rotary broom or other property.

Other useful information can also be described.

LABELS

Please become familiar with the labels on the rotary

broom.

NOTE: If labels are missing or cannot be read, see

your sales outlet.

Code Defi nition

YY 2-Digit Year

MM 2-Digit Month

DD 2-Digit Day

LL 2-Digit Location Code

#### 4-Digit Sequential Number

SS4000 Part Number

Serial Number Label

2017

170301041234SS4000

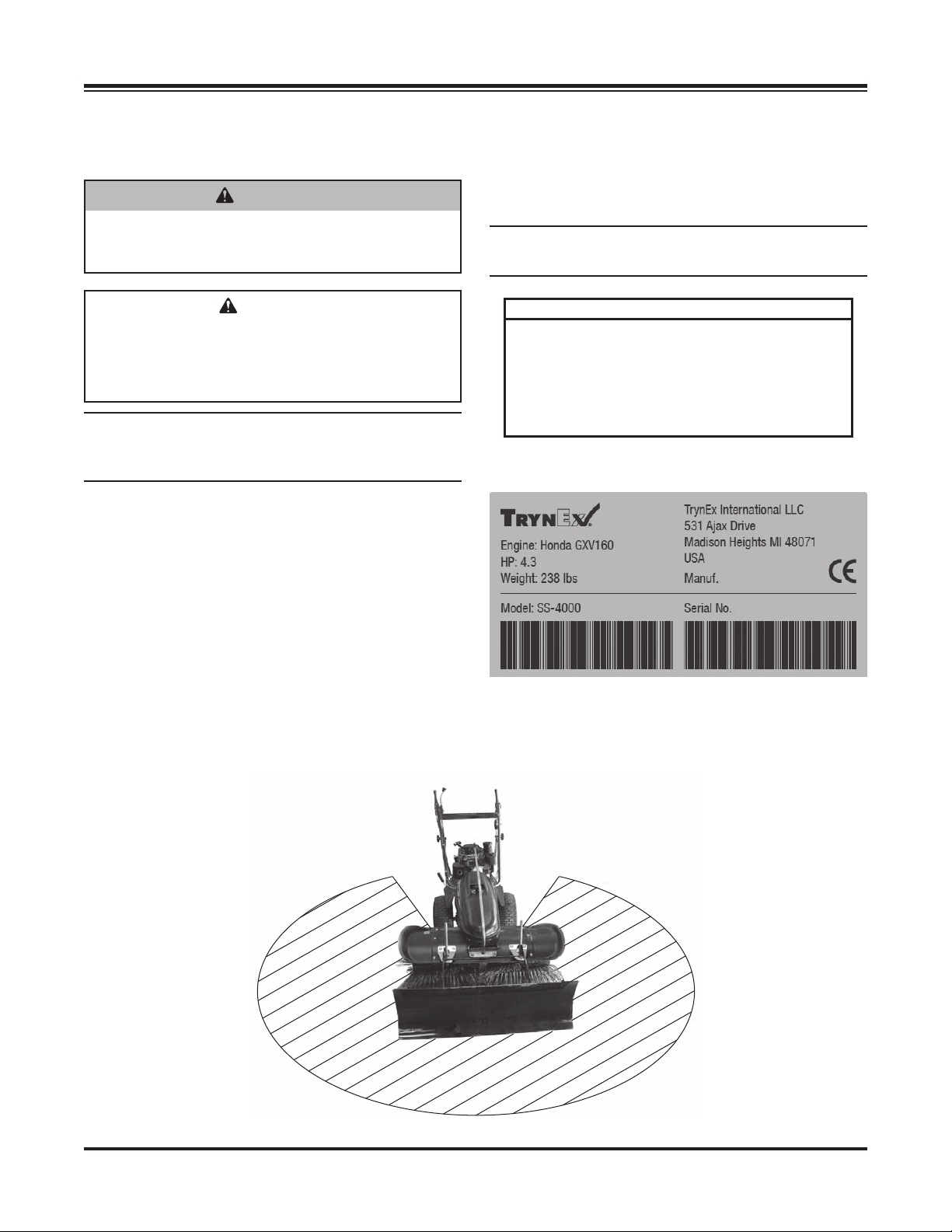

DANGER ZONE

Keep all bystanders away from the machine at least 30 feet (10 meters), as depicted in the diagram below.

Lit. No. 83751, Rev. 00 4 April 15, 2017

Page 5

SAFETY

SAFETY PRECAUTIONS

Improper assembly and operation could cause

personal injury and/or equipment and property

damage. Read and understand labels and this

Owner's Manual before assembling, operating, or

making adjustments.

The machine is intended exclusively for use for

brushing operations in property maintenance and

snow clearance. Examples of intended use are: snow

clearing; sidewalk, driveway and parking lot cleaning

(with multi-purpose brushes); spring debris clean-up;

dethatching; clearing debris from artifi cial turf; and leaf

clean-up (with multi-purpose brushes).

WARNING

• Always make sure personnel are clear of

areas of danger when using equipment.

• Before working with the rotary broom,

secure all loose-fi tting clothing and

unrestrained hair.

• Do not climb onto or ride on rotary broom.

PERSONAL SAFETY

• Wear only snug-fi tting clothing while working on

your rotary broom.

• Do not wear jewelry or a necktie, and secure long

hair.

• Wear safety goggles to protect your eyes from dirt,

dust and fl ying debris.

• Be aware of and avoid pinch points when

assembling and operating. Pinch points can exist

around levers and when putting two parts together

(during assembly).

CAUTION

• Do not operate a rotary broom in need of

maintenance.

• Before operating the rotary broom,

reassemble any parts or hardware removed

for cleaning or adjusting.

• Before operating the rotary broom, remove

materials such as cleaning rags, brushes,

and hand tools from the rotary broom.

• Tighten all fasteners according to the

Torque Chart. Refer to Torque Chart for the

recommended torque values.

NOTE: Lubricate grease fi ttings after each use.

Use a good quality multipurpose grease.

Lit. No. 83751, Rev. 00 5 April 15, 2017

Page 6

SAFETY

FIRE AND EXPLOSION

WARNING

Gasoline is highly fl ammable and gasoline

vapor is explosive. Never smoke while

working on vehicle. Keep all open fl ames

away from gasoline tank and lines. Wipe up

any spilled gasoline immediately.

VENTILATION

WARNING

Engine exhaust contains lethal fumes.

Breathing these fumes, even in low

concentrations, can cause death. Never

operate an engine in an enclosed area without

venting exhaust to the outside.

NOISE

Noise emission values comply with EC guideline

98/37/EWG or 2006/42/EG.

The measurement was carried out with the machine at

standstill with driven brushes on an asphalted road.

• The sound pressure level at the ear: L

• The sound power level: LW = 102 dB.

• Measuring devices used comply with DIN 45634.

p user

= 87 dB.

VIBRATION

Hand-arm vibration values comply with VDI 2057,

Sheet 2.

The measurement was carried out on asphalted road.

• Vibrations were measured in three axes on the

handlebars: X, Y and Z axes, see DIN 45675,

Part 8. The value for 60 seconds duration was

determined.

• Measurement results: 60s effective value = 9.9 m/s

• Measuring device used complies with DIN 45675.

• Machine in operating condition:

◦ Warmed up, retracted machine under full load.

◦ Brush height adjustment: standard

◦ Fuel tank: approx. 50% full

◦ Brush axle: middle position

2

Lit. No. 83751, Rev. 00 6 April 15, 2017

Page 7

OPERATING INSTRUCTIONS

COMPONENT VOCABULARY

Receiver

Bar

Brush Height

Adjustment

Brush Angle

Adjustment

Handlebar

Plow

Blade

Brushes

Brush

Engagement

Drive

Wheels

Support

Wheels

Brush Speed

Adjustment

Throttle

Control

Forward

Reverse

Gear

Selection

Lever

Lit. No. 83751, Rev. 00 7 April 15, 2017

Page 8

GENERAL SAFETY/OPERATING IN WINTER

GENERAL SAFETY

Do not operate the machine in an unsafe manner.

Make yourself familiar with the surroundings

before starting work in a new location. The working

surroundings include any obstacles in the work area

or on roads, the ground load-bearing capacity and any

necessary workplace safety precautions in live traffi c.

Take precautions to ensure that the machine is only

operated in a safe and functional condition. Only

operate the machine if all protective and safety

devices are present and working.

Check the machine for externally visible damage

and faults before operation. If malfunctions occur

stop the machine and secure it immediately. Repair

malfunctions immediately. Only start the machine from

the operator's position. Ensure that no one can be

endangered by starting the machine before switching

it on or operating it.

Check that braking, steering, and brushing are fully

functional before operation.

OPERATING IN WINTER

Check regularly that the air fi lter is dry. If the air

fi lter has become wet, let it dry overnight. There is a

possibility of the engine not starting due to a clogged

air fi lter.

Spray the throttle cable with silicone spray at both

ends, and the throttle linkage before operating to

prevent the cable or throttle mechanism from freezing

up.

Before putting the machine away, sweep it clear of

snow.

Avoid freezing the machine. Store the machine in a

frost-free room.

Silicone spray attracts dust and binds it to the

machine. It is only a suitable lubricant in wintry and

snowy conditions.

Do not spray silicone spray on hot engine. It could

cause a fi re. Follow the instructions on the spray can.

Before operating the machine, always check that

accessories are fi tted correctly. Always observe

applicable traffi c regulations before operating on

public roads, paths or parks, and ensure that the

machine is in a condition suitable for use in traffi c.

Always ensure that suitable lighting is available

before working in poor light or darkness. Always

keep a suffi cient distance between the machine and

drop-offs, holes, or slopes.

Do not permit any method of working which will affect

the stability of the machine.

Never traverse across slopes; always travel up and

down, not across.

Adjust the speed to suit the conditions on inclines.

Change gear before the incline, not on it. Always

secure the machine against rolling away and

unauthorized operation before leaving it unattended.

Lit. No. 83751, Rev. 00 8 April 15, 2017

Page 9

OPERATING INSTRUCTIONS

OPERATOR CONTROLS DRIVING AND SWEEPING

WARNING

The handlebar can get stuck inside long

sleeves. This could prevent the drive from

disengaging and result in injury. Set the bar

lower if wearing long sleeves or tightly button

the sleeves.

WARNING

Avoid injury and damage; Make completely

sure that there are no persons or objects

within the danger zone.

CAUTION

If the brushes are switched ON and the rotary

broom is not in gear, the machine can roll

backwards. The handlebar must be securely

engaged at the required height.

HANDLEBAR CONTROLS

Sweeping and driving can be engaged independent

of each other. Having the brush engaged without the

transmission engaged will cause the machine to roll

backward. The brush can be engaged and disengaged

as necessary while driving.

The brush speed can be adjusted to your preference.

Pushing the lever forward will increase the speed;

pulling back will decrease the brush speed. If the

brush starts to leave debris behind, increase the

rotation speed (see Adjusting Brush Speed) and select

a lower gear (see Selecting a Gear).

The rotary broom is also equipped with a reverse gear.

Come to a complete stop before engaging the reverse

gear. Ensure the area behind is clear before backing

up. Do not operate brush in reverse.

Forward

Brush

Engagement

Brush Speed

Throttle

Control

Reverse

Lit. No. 83751, Rev. 00 9 April 15, 2017

Page 10

OPERATING INSTRUCTIONS

SELECTING A GEAR

Come to a complete stop before changing gears.

The rotary broom is equipped with a 3-speed

transmission:

• 1st gear is the slowest setting and is engaged by

pulling the shift lever all the way back.

• 3rd gear is the fastest setting and is engaged by

pushing the lever all the way forward.

• 2nd gear is in the middle.

You will feel the lever lock into a detent and hear a "click".

Freewheel

Gear Lever Location

FREEWHEEL

There is a freewheel mechanism on each wheel. The

freewheel makes turning the machine easier. One or

both wheels can be locked for working on inclines and

when clearing snow.

The freewheel is disabled by putting the linchpin

through both wheel and axle, locking the two together.

When removing snow with the plow, locking the wheel

on the windrow-side will reduce the lateral force on the

handlebars.

Locked

Locked

Freewheel

Plowing

Lit. No. 83751, Rev. 00 10 April 15, 2017

Page 11

OPERATING INSTRUCTIONS

ADJUSTING BRUSH SPEED

The speed of the brushes can be increased using the

lever on the right handlebar. The brush speed must

only be adjusted when the brush is switched on.

When sweeping dust, use a low brush speed.

When sweeping leaves or similar material, use a high

brush speed.

When sweeping snow, use a high brush speed.

When using the debris collector box, use a medium

brush speed.

Remember that an increased brush speed will

throw debris farther, therefore increasing the

danger zone.

STARTING/STOPPING MOTOR

WARNING

Engine exhaust contains lethal fumes.

Breathing these fumes, even in low

concentrations, can cause death. Never

operate an engine in an enclosed area without

venting exhaust to the outside.

CAUTION

Ensure that the transmission and brush are

switched OFF before starting. The handlebar

must be secure at the required height.

NOTE: Before starting the motor, ensure there is

suffi cient oil. The motor is not fi lled with oil when

the machine is delivered.

Starting the Motor

Move throttle control to the choke position. Adjust choke.

Lit. No. 83751, Rev. 00 11 April 15, 2017

Page 12

OPERATING INSTRUCTIONS

Make sure fuel valve is ON.

Pull starter coil. Stand behind the handlebars. Do not

press any levers.

Shutting Down the Motor

Close throttle.

Close fuel valve.

Lit. No. 83751, Rev. 00 12 April 15, 2017

Page 13

OPERATING INSTRUCTIONS

ADJUSTING HANDLEBAR HEIGHT

There are seven settings for adjusting the handlebar

height.

Loosen the knob on both sides and choose the

desired position

TRANSPORT

Use a ratchet strap around front and around rear axle

when transporting.

Always use two straps on the rear axle; one on each

side.

You can fold the handlebar forward to save space

when storing.

Lit. No. 83751, Rev. 00 13 April 15, 2017

Page 14

OPERATING INSTRUCTIONS

ADJUSTING EJECTION DIRECTION

There are fi ve different settings available for the

ejection direction.

Shown below: Forward ejection direction. The swept

material will heap up in front of the brushes. You

should give preference to angled brush settings.

Shown below: Material will be ejected to the left.

If you use a plow, an angled direction must be used.

Shown below: Ejection to the left.

To adjust brush angle: Lift the lever; Turn the brush in

the desired direction; Release the lever and ensure

the lever is latched in place.

With an angled setting, the material will be swept to

one side.

Shown below: Material will be ejected to the right.

A sideways setting is recommended if using the

optional debris collector. This will allow sweeping

against a wall or curb. (Debris collector box is an

optional accessory).

Lit. No. 83751, Rev. 00 14 April 15, 2017

Page 15

OPERATING INSTRUCTIONS

ADJUSTING BRUSH PRESSURE

The brush height can be adjusted in fi ne increments

by adjusting the height of the support wheel.

Support Wheel

The adjustment knob is located above the support

wheel.

Turn clockwise (+): Raise brush

Turn counter-clockwise (–): Lower brush

IMPORTANT: If the brushes are heavily worn, or

if you are brushing cobblestones or brick pavers,

lower the brush one more turn.

Lower the brush by turning the knob in the direction

of the "minus" arrow until it just touches the fl oor. Turn

the knob three more turns and the brush height is just

right for sweeping.

NOTE: If the brush pressure is too heavy, the

cleaning effect is decreased because the brush

fi bers are bent too much. If you do not intend to

use the rotary broom for a long period of time,

release the pressure on the brush by raising the

brush.

Lit. No. 83751, Rev. 00 15 April 15, 2017

Page 16

OPERATING INSTRUCTIONS

PLOW BLADE

To install the plow blade, lift the plow and hold it at an angle; slide it over the receiver bar and lower it into position.

12

3

An angled setting must be used when plowing snow.

The plow can be removed when clearing small

amounts of snow – 1" or less (2.5 cm).

For snow over 1" (2.5 cm), use the plow blade.

The rotary broom can clear a maximum of

5-1/2" (14 cm) of snow in one pass. If snow is heavy,

the capacity will be less.

See "Freewheel" section to adjust freewheel correctly

for plowing snow.

Lit. No. 83751, Rev. 00 16 April 15, 2017

Page 17

OPERATING INSTRUCTIONS

DEBRIS COLLECTOR BOX (PN 72279)

(Optional Accessory)

Rotary Broom with Debris Collector Box

Mount as shown below, paying attention to the

alignment with brush hood.

To dump the debris, simply pull the handle from the

operating position so the debris can fall out.

To dump the debris into a separate

container, remove the debris collector box

from the sweeper and use the handle to tow it to

your other container.

Lit. No. 83751, Rev. 00 17 April 15, 2017

Page 18

OIL AND GAS

Gas

MAINTENANCE

Full Leve l

Oil

Capacities:

Oil: 20 oz (0.6 L)

Gasoline: 1.5 qt (3 L)

Use 86 octane or higher unleaded gasoline.

1. Remove oil cap; wipe dipstick clean.

2. Replace dipstick in the oil fi ller neck; do not screw

down.

3. Remove dipstick; check oil level. The oil should be

up to the upper marking.

4. If oil level is low, fi ll up to the upper marking on the

dipstick with the recommended oil (see Honda

Owner's Manual).

5. See marking on the dipstick for fi ll level.

®

Lit. No. 83751, Rev. 00 18 April 15, 2017

Page 19

MAINTENANCE

TIRE PRESSURE

IMPORTANT: If the tire pressure is too low,

the inner tube will rub against the wheel and

be damaged. Over-infl ation can cause the tire

to burst. Check the tire pressure for both the

support and drive wheels regularly.

Unscrew the valve cap and use a tire infl ation device

to check or infl ate the tire as necessary. Always

replace the valve cap when you have fi nished infl ating.

SUPPORT WHEEL

30 psi (2 bar)

On rough surfaces:

22 psi (1.5 bar)

DRIVE WHEEL

22 psi (1.5 bar)

Lit. No. 83751, Rev. 00 19 April 15, 2017

Page 20

MAINTENANCE

ADJUSTING CONTROL CABLES

IMPORTANT: It may be necessary to reset the

cables after machine has been operating for a few

hours.

Loosen the top nut with a 10 mm wrench.

Reverse Lever:

There should be about 3-1/8" (80 mm) of space

between the handlebar and lever when there starts to

be a resistance to the lever.

3-1/8"

Turn the throttle cable the desired direction using an

8 mm wrench.

Tighten the nut. Check the adjustment by pressing the

lever down.

Brush Drive and Forward Levers:

There should be about 5-1/2" (140 mm) of space

between the handlebar and lever when there starts to

be a resistance to the lever.

5-1/2"

Lit. No. 83751, Rev. 00 20 April 15, 2017

Page 21

MAINTENANCE

REPLACING/CHANGING THE BRUSHES

IMPORTANT: Check the brushes after every

20 hours use. The brushes must be replaced if

you are no longer satisfi ed with the brushing

result, or if the brush diameter is below

8-5/8" (22 mm).

Loosen the nut on the axle. Use two 19 mm wrenches.

Remove the left brush.

Parts after disassembly.

Right

Brush

Left

Brush

Remove the axle with the right brush.

If replacing the multi-purpose brushes, or changing

to them: The black row of bristles must touch the ground

before the white row when the brush rotates.

Locknut

Washer

If replacing the snow brushes (standard), or changing

them: The rows must curve upward from the left.

NOTE: Multi-purpose bristle shown for clarity.

Cap

Axle

Nut

Refer to the Installations Instructions for installing the

new brushes.

Lit. No. 83751, Rev. 00 21 April 15, 2017

Page 22

MAINTENANCE

MAINTENANCE PLAN/

CLEANING

Check screws and nuts C

Check motor oil level, refi ll if

necessary

First motor oil change S

All further motor oil changes S S

Check air fi lter C

Clean air fi lter element, earlier if

necessary

Replace air fi lter element, earlier if

necessary

Replace fuel hoses

Clean cool air screen M

Clean baffl e plate, cooling ribs,

earlier if necessary

Clean spark plugs, adjust gap S

Replace spark plugs S

Before

every

use

C

After the following operating hours:

5102550100

MM

M

After 3

month

min.

S

At least

annually

(2 years)

After

every

cleaning

S

Clean exhaust M

Lubricate all moving parts MM

Check hand lever play setting C

Check brush wear, earlier if

necessary

Stretch chain drive C S

S = Maintenance by Specialist C = Check by Operator M = Maintenance by Operator

C

NOTE: Store the machine properly. Contact the local dealer for suitable storage practices in your

geographic locations.

CLEANING

To keep your rotary broom in good condition, clean it regularly.

Remove loose dirt or dust with a car wash brush. Wash plastic surfaces with water and soap. Use normal car

cleaning soap. Rinse off all cleaners thoroughly with clean water.

To give plastic parts a gloss fi nish, use a plastics care product.

Observe the instructions on the cleaning solution package.

Use glycerine as a corrosion protection for heavily soiled parts.

Do not use pressure washers. The high pressure may force water into bearings, seals, and the motor, causing damage.

Lit. No. 83751, Rev. 00 22 April 15, 2017

Page 23

TROUBLESHOOTING

FAULT POSSIBLE CAUSE FAULT REMEDY

Motor will not start Fuel tank empty Fill fuel tank

Throttle lever not set to choke when motor is cold Set throttle lever to choke

Spark plug leads not connected Connect spark plug leads

Fuel line blocked Send fuel line to workshop for cleaning

Motor receiving wrong air due to loose carburetor Tighten fi xing screws

Fuel valve closed on Honda

Motor will not start;

gasoline smell

Motor running badly;

misfi res

Motor misfi res at high

speed

Motor overheating Oil level too low Refi ll motor oil

Motor often stops during

turnover

Motor has lost power Air fi lter soiled Clean air fi lter

Motor will not stop Motor stop lever not correctly adjusted See Honda owner's manual/Send to dealer

Perpetual squeaking when

brushes switched on

Brushes do not turn, or

stop moving under load

Machine will not move

forward

Machine leaves unbrushed

central strip

Bad brushing results Brushes wrongly mounted Mount brushes correctly; observe working direction

Bad brushing results with

debris collector box

Motor is receiving too much fuel Set throttle lever to full speed, not to choke

Air fi lter dirty Clean air fi lter

Motor running with choke activated Move throttle lever out of choke position

Spark plug leads loose Allow motor to cool and connect spark plug leads fi rmly

Air fi lter soiled Clean air fi lter

Air bleed hole in fuel tank fi ller cap blocked Replace fuel lines

Fuel line blocked Run fuel system cleaner through tank of gas

Carburetor not correctly adjusted Adjust carburetor/Send to dealer

Motor overheating See fault "Motor Overheating"

Spark plug gap not correct Adjust spark plug gap/Send to dealer

Carburetor not correctly adjusted Adjust carburetor/Send to dealer

Air cooling system restricted Send to dealer/adjust air cooler grille & cooling ribs

Air fi lter dirty Clean air fi lter

Carburetor not correctly adjusted Adjust carburetor/Send to dealer

Throttle lever not set to choke when motor is cold Set throttle lever to choke

Spark plug gap not correct Send carburetor to workshop for adjustment

Air fi lter dirty Clean air fi lter

Compression too low Send to workshop for adjustment

Switch lever not completely pressed down Press switch lever completely down

Control cable not correctly adjusted Readjust brush control cable

Switch lever not completely pressed down Press switch lever completely down

Control cable not correctly adjusted Readjust brush control cable

Toothed belts defective Send to dealer

Movement control cable not correctly adjusted Re-adjust control cable

Tension on toothed belt between motor and gearbox

too low

Ejection direction for ward with worn brushes Turn the ejection direction to the side

Brushes worn Replace brushes

Brush pressure too high Readjust support wheel; Reduce brush pressure

Brushes not genuine SnowEx

Brushes not suitable for application Install SnowEx multi-purpose brushes (PN 72258)

Debris collector box not fi tted correctly, sealing lip

above brush cover

®

motor Open fuel valve on Honda motor

Send to dealer

®

parts Use only SnowEx brushes

Mount swept material container correctly.

Lit. No. 83751, Rev. 00 23 April 15, 2017

Page 24

Tr ynEx Int e r nation a l

531 Ajax Drive

Madison Heights, MI 48071-2429

www.snowexproducts.com

A DIVISION OF DOUGLAS DYNAMICS, LLC

This product conforms to EU Machinery Directive 2006/42/EC.

Copyright © 2017 Douglas Dynamics, LLC. All rights reserved. This material may not be reproduced or copied, in whole or in part, in any

printed, mechanical, electronic, fi lm or other distribution and storage media, without the written consent of TrynEx International. Authorization

to photocopy items for internal or personal use by TrynEx International outlets or rotary broom owner is granted.

TrynEx International reserves the right under its product improvement policy to change construction or design details and furnish equipment

when so altered without reference to illustrations or specifi cations used. TrynEx International may require or recommend optional equipment

for rotary brooms. TrynEx International offers a limited warranty for all rotary brooms and accessories. See separately printed page for this

important information. The following are registered (

®

) trademarks of Douglas Dynamics, LLC: SnowEx®, TrynEx®.

Printed in U.S.A.

Lit. No. 83751, Rev. 00 April 15, 2017

Loading...

Loading...