SnowEx 261381 User Manual

Owner / Operator’s Manual

This Manual Must Be Read Before Operating The Equipment

Madison Heights, Michigan 48071

800-725-8377

www.snowexproducts.com

© TrynEx International 2013

(REV B) F50753

SP-65

Serial # PA-201033 and higher

CUSTOMER COPY

Table of Contents

General Information ..................................................................................................................................................................................... 3

Introduction ................................................................................................................................................................................................. 4

Safety .......................................................................................................................................................................................................... 5

Operation ..................................................................................................................................................................................................... 6

Assembly Instructions ........................................................................................................................................................................... 7 - 10

Troubleshooting ......................................................................................................................................................................................... 11

Warranty .................................................................................................................................................................................................... 12

Key to Parts ............................................................................................................................................................................................... 13

Hopper Assembly Parts Breakdown

Model # SP-65 ..................................................................................................................................................................... 14 - 15

Axle Assembly Parts Breakdown

Model # SP-65 ..................................................................................................................................................................... 16 - 17

Handle Assembly Parts Breakdown

Model # SP-65 ..................................................................................................................................................................... 18 - 19

Notes .................................................................................................................................................................................................. 20 - 23

Have a question or need assistance?

SnowEx Customer Care

1-800-SALTERS

or (248) 586-3500

Monday through Friday 8:00 AM to 4:30 PM EST

Fax: (248) 691-8378

E-mail: customercare@trynexfactory.com

Website: www.snowexproducts.com

© TrynEx International 2013 (REV B) F507532

General Information

PA-201033

CONGRATULATIONS!

The SnowEx product you have purchased is an example of snow and ice management product at its nest! Your SnowEx product’s self

contained design is a trademark of all SnowEx products. Here’s why...

SIMPLICITY: Fewer moving parts manufactured of higher quality means minimal maintenance for your SnowEx product.

RELIABILITY: High impact linear low density polyethylene hopper, custom engineered powder coated frame.

VERSATILITY: Multi-use capability allows spreading of a variety of materials.

WARRANTY: Two years parts and labor from date of installation.

The benets you are about to recognize are that of time, money and effort.

We welcome you to the world of SnowEx Performance.

Registration

Record the following information in this manual for quick reference.

Model Number

Serial Number

Date of Purchase

Dealer Where Purchased

When ordering parts, the above information is necessary. This will help to ensure

that you receive the correct parts.

At the right is a diagram of the ID tag. This tag is located on the frame.

Please ll out the warranty card with all the necessary information to validate it. This will

also give us a record so that any safety or service information can be communicated to

you.

© TrynEx International 2013 (REV B) F50753 3

Introduction

This manual has been designed for your help. It will assist you and instruct you on the proper set-up, installation and use of this product.

Refer to the table of contents for an outline of this manual.

We require that you read and understand the contents of this manual completely (especially all safety information) before attempting any

procedure contained in this manual. Extra copies of Owner / Operator Manuals can be purchased at your SnowEx Dealer.

THIS SIGN SHOULD ALERT YOU:

The Society of Automotive Engineers has adopted this Safety Alert Symbol to pinpoint characteristics that,

if not carefully followed, can create a safety hazard. When you see this symbol in this manual or on the

machine itself, be alert! Your personal safety and the safety of others is involved.

Dened below are the Safety Alert Messages and how they will appear in this manual:

(RED)

Information that, if not carefully followed,

can cause death!

(ORANGE)

Information that, if not carefully followed,

can cause serious personal injury or death!

(YELLOW)

Information that, if not carefully followed,

can cause minor injury or damage to equipment

© TrynEx International 2013 (REV B) F507534

Safety

Before attempting any procedure in this book, these safety instructions must be read and understood by all workers who have any part in the

preparation or use of this equipment.

For your safety warning and information decals have been placed on this product to remind the operator of safety precautions . If anything

happens to mark or destroy the decals, please request new ones from SnowEx.

Remember, most accidents are preventable and caused by human error. Exercising of care and precautions

must be observed to prevent the possibility of injury to operator or others!

Never operate equipment when under the inuence of alcohol, drugs, or medications that might alter your

judgment and/or reaction time.

Before working with the spreader, secure all loose tting clothing and unrestrained hair.

Always wear safety glasses with side shields when servicing spreader. Failure to do this could result in serious

injury to the eyes.

Never attempt to lift a unit with material in it.

Never allow children to operate or climb on equipment.

Always check areas to be spread to be sure no hazardous conditions or substances are in the area.

Always inspect unit for defects: broken, worn or bent parts, weakened areas on spreader.

Remember it is the owner’s responsibility to communicate information on safe usage and proper maintenance

of all equipment.

Always make sure personnel are clear of areas of danger when using equipment.

Never weld or grind on equipment without having a re extinguisher available.

Inspect the unit periodically for defects. Parts that are broken, missing or worn out must be replaced

immediately. The unit or any part of it can not be altered without prior written permission from the

manufacturer.

Never use wet materials or materials with foreign debris with any of these spreaders. These units are designed

to handle dry, clean, free owing material.

Never leave material in hopper for long periods of time. Be aware that all salt is hygroscopic and will attract

atmospheric moisture and harden up.

© TrynEx International 2013 (REV B) F50753 5

Spreader Operation

Model # SP-65

SPREADER LOADING

Capacity: 1.5 Cubic Foot Hopper

Do not overload spreader. Weights of material are an average for dry materials.

Material Weight Per Cubic Ft.

Rock Salt 80-90 lbs.

Sand/Salt Mix 95-120 lbs.

Never remove spreader from vehicle with material in it as this could cause damage to the frame assembly.

Never leave materials in hopper for long periods of time, salt is hygroscopic and will attract atmospheric

moisture and harden up.

SPREADING TIPS

For a heavier pass:

Walk Slower

Increase Gate Opening

For a lighter pass:

Walk Faster

Restrict Gate Opening

For a wider pass:

Walk Faster

Spread ice melters with the storm to prevent unmanageable levels of ice.

Calculate spread pattern when near vegetation and vehicles

Gate Stop can be used to set how much salt is put down at your normal walking speed.

© TrynEx International 2013 (REV B) F507536

Assembly Instructions

Model # SP-65

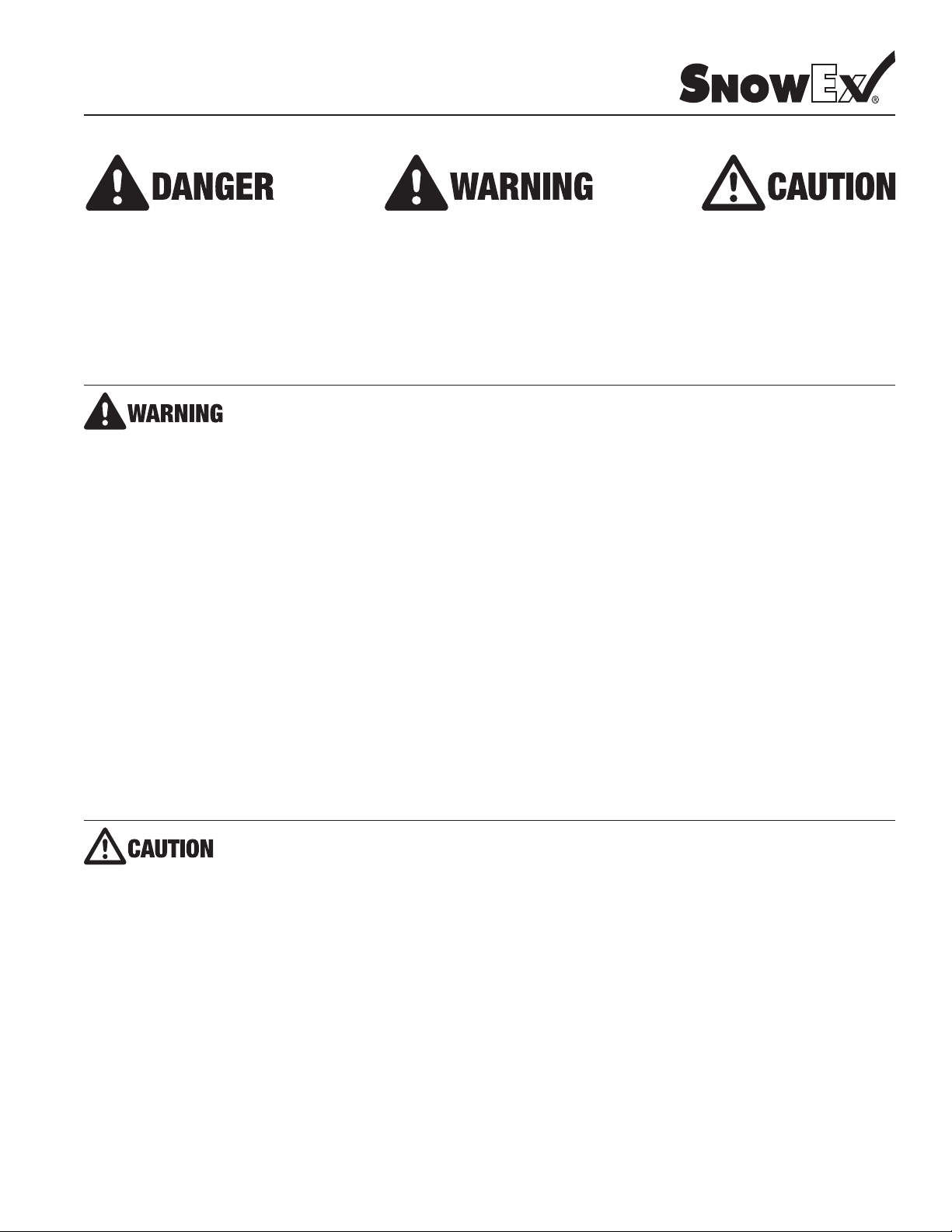

STEP 1

Open Box. Remove the Axle/Spinner Assembly. Slide the Shaft Collars

from the hardware kit onto the axle - one on each side of the Gearbox

One Hole in Axle – Left.

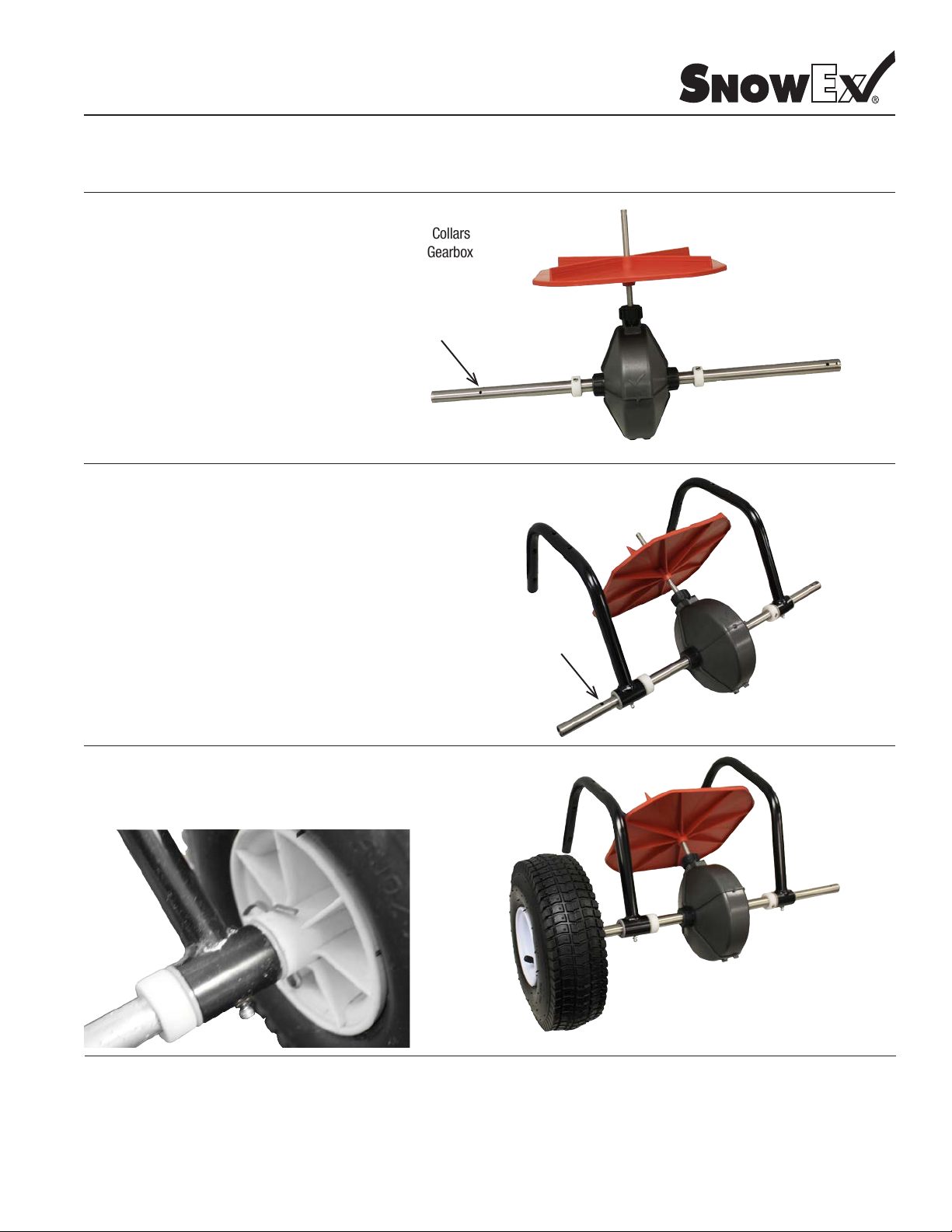

STEP 2

Slide the Hopper Frame Assemblies over the Axle – one on each side

of the Gearbox.

One Hole in Axle – Left.

STEP 3

Install Drive Wheel. Slide the 2” Cotter Pin through both the wheel and

axle.

© TrynEx International 2013 (REV B) F50753 7

Assembly Instructions

Model # SP-65

STEP 4

Install the other Wheel. Slide the 1.5” Cotter Pin through the Axle,

outside the Wheel.

STEP 5

Install Frame Stand. Attach to the Hopper Supports.

STEP 6

Install Hopper. Put Bolts with Washers through all four holes in Hopper

and Frame. Thread on the Nuts.

STEP 7

Put Agitator Pin through Spinner Shaft inside hopper.

STEP 8

Bolt Cable to both handles. It should be positioned so the cable points

toward the base of the handle and will be to the operator’s left. Handtighten only.

© TrynEx International 2013 (REV B) F507538

Loading...

Loading...