TBS100OPS 20/10/06 www.snellwilcox.com Version 2 Issue 5 0.1

TBS100, TBS100D,

TBS100TX, TBS100DTX

Synchronizer/Time Base Correctors

Operator’s

Manual

© October 2006

www.snellwilcox.com

Snell & Wilcox Ltd., Southleigh Park House, Eastleigh Road, Havant, Hants, PO9 2PE, United Kingdom.

For General Enquiry’s contact: Tel: +44 (0) 2392 489000 Fax: +44 (0)23 9245 1411

For Technical assistance contact: Tel: +44 (0) 2392 489058 Fax: +44 (0) 2392 489057

Web: http://www.snellwilcox.com/support Ftp: ftp://ftp.snellwilcox.com/support

TBS100/100D SECTION 0

TBS100OPS 20/10/06 www.snellwilcox.com Version 2 Issue 5 0.2

Explanation of Safety Symbols

This symbol refers the user to important information contained in

the accompanying literature. Refer to manual.

This symbol indicates that hazardous voltages are present inside.

No user serviceable parts inside.

This unit should only be serviced by trained personnel.

Servicing instructions where given, are for use by

qualified service personnel only.

To reduce risk of electric shock do not perform any

servicing other than that contained in the operating

instructions unless you are qualified to do so.

Refer all servicing to qualified personnel.

To reduce the risk of electric shock, do not expose this appliance

to rain or moisture.

Always ensure that the unit is properly earthed and power connections

correctly made.

This equipment must be supplied from a power system providing a

PROTECTIVE EARTH connection and having a neutral connection

which can be reliably identified.

The power outlet supplying power to the unit should be close to the

unit and easily accessible

Power connection in countries other than the USA

The equipment is normally shipped with a power cable with a standard IEC

moulded free socket on one end and a standard IEC moulded plug on the other.

If you are required to remove the moulded mains supply plug, dispose of the

plug immediately in a safe manner.

The colour code for the lead is as follows:

GREEN/YELLOW lead connected to E

(Protective Earth Conductor)

BLUE lead connected to N (Neutral Conductor)

BROWN lead connected to L (Live Conductor)

Caution If the unit has two mains supply inputs ensure that both power

cords are plugged into mains outlets operating from the same phase.

L N

E

N L

E

GB

!

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT REMOVE COVERS

NO USER SERVICEABLE PARTS

REFER SERVICING TO QUALIFIED

PERSONNEL ONLY

!

!

Safety Warnings

Légende :

Ce symbole indique qu'il faut prêter attention et se référer

au manuel.

Ce symbole indique qu'il peut y avoir des tensions électriques

à l'intérieur de l'appareil. Ne pas intervenir sans l'agrément

du service qualifié.

Pour réduire le risque de choc électrique, ne pas exposer l'appareil

dans un milieu humide.

Toujours s'assurer que l'unité est correctement alimentée,

en particuliers à la liaison à la terre.

La source électrique de cet équipement doit posséder une connexion

à la terre , ainsi qu'une liaison « neutre » identifiable.

La prise électrique qui alimente l'appareil doit être proche

de celle-ci et accessible.

Câble secteur de pays autres que les Etats-Unis

L'équipement est livré avec un câble secteur au standard IEC, moulé

mâle/femelle.

Si vous souhaitez changr la prise mâle de votre cordon, voici les

codes couleurs des fils :

Le fil VERT/JAUNE est connecté à T (Terre)

Le fil BLEU est connecté à N (Neutre)

Le fil MARRON est connecté à P (Phase)

Attention si l'appareil a 2 alimentations, s'assurer que les cordons

soient branchés sur la même phase.

Précaution d'emploi :

F

Les procédures de maintenance ne concernent

que le service agréé. Afin de réduire le risque de

choc électrique, il est recommandé de se limiter

aux procédures d'utilisation, à moins d'en être qualifié.

Pour toute maintenance, contacter le service compétent.

!

ATTENTION

RISQUEDE CHOC ELECTRIQUE

NE PAS RETIRERLE COUVERCLE

NE PAS INTERVENIRSANS

L'AGREMENTDU SERVICE

QUALIFIE

P N

T

N P

T

Connecteur Prise

!

!

Erklärung der Sicherheitssymbole

Dieses Symbol weist den Benutzer auf wichtige Informationen

hin, die in der begleitenden Dokumentation enthalten sind.

Dieses Symbol zeigt an, dass gefährliche Spannung vorhanden ist.

Es befinden sich keine vom Benutzer zu wartenden Teile im Geräteinneren.

Dieses Gerät sollte nur von geschultem Personal gewartet werden

Um das Risiko eines Elektroschocks zu reduzieren, setzen Sie das

Gerät weder Regen noch Feuchtigkeit aus.

Stellen Sie immer sicher, dass das Gerät ordnungsgemäß geerdet

und verkabelt ist.

Dieses Equipment muss an eine Netzsteckdose mit Schutzleiter

angeschlossen werden und einen zuverlässig identifizierbaren Nullleiter haben.

Die Netzsteckdose sollte nahe beim Gerät und einfach zugänglich sein.

Netzanschluss in anderen Ländern als der USA

Das Equipment wird im Normalfall mit einem Netzkabel mit Standard IEC

Anschlussbuchse und einem Standard IEC Anschlussstecker geliefert.

Sollten Sie den angeschweißten Stecker auswechseln müssen, entsorgen

Sie diesen bitte umgehend. Die farbliche Belegung des Netzkabels ist wie folgt:

GRÜN GELB E = Schutzleiter

BLAU N = Nulleiter

BRAUN L = P = Phase

Achtung: Wenn das Gerät zwei Anschlussbuchsen hat, stellen

Sie bitte sicher, dass beide Netzkabel mit der selben Phase in die

Netzsteckdose gesteckt werden.

Sicherheits-Warnhinweise

D

!

!

Die angeführten Service-/Reparatur-Anweisungen sind

ausschließlich von qualifiziertem Service-Personal

auszuführen. Um das Risiko eines lektroschocks zu

reduzieren, führen Sie ausschließlich die im

Benutzerhandbuch eschriebenen Anweisungen aus,

es sei denn, Sie haben die entsprechende Qualifikation.

Wenden Sie sich in allen Service-Fragen an qualifiziertes Personal.

!

ACHTUNG

GefahrvonElektroschocks.

Abdeckungennichtentfernen

Keine vomBenutzer zu wartendeTeile

WendenSie sich ausschließlich

an qualifiziertes Personal

L =

Phase

N =

Nulleiter

N =

Nulleiter

L =

Phase

E =

Schutzleiter

E =

Schutzleiter

Explicación de los Símbolos de Seguridad

Éste símbolo refiere al usuario información importante contenida

en la literatura incluida. Referirse al manual.

Éste símbolo indica que voltajes peligrosos están presentes en el interior.

No hay elementos accesibles al usuario dentro.

Esta unidad sólo debería ser tratada por personal cualificado.

Las instrucciones de servicio cuando sean dadas, son

sólo para uso de personal cualificado. Para reducir el

riesgo de choque eléctrico no llevar a cabo ninguna

operación de servicio aparte de las contenidas en las

instrucciones de operación, a menos que se esté

cualificado para realizarlas.

Referir todo el trabajo de servicio a personal cualificado.

Para reducir el riesgo de choque eléctrico, no exponer este equipo

a la lluvia o humedad.

Siempre asegurarse de que la unidad está propiamente conectada a

tierra y que las conexiones de alimentación están hechas correctamente.

Este equipo debe ser alimentado desde un sistema de alimentación

con conexión a TIERRA y teniendo una conexión neutra fácilmente

identificable.

La toma de alimentación para la unidad debe ser cercana y fácilmente

accesible.

Conexión de alimentación en otros países que no sean USA

El equipo es normalmente entregado con un cable de alimentación con un

enchufe hembra estándar IEC en un extremo y con una clavija estándar

IEC en el otro. Si se requiere eliminar la clavija para sustituirla por otra,

disponer dicha clavija de una forma segura.

El código de color a emplear es como sigue:

Advertencia Si la unidad tuviera dos tomas de alimentación, asegurarse

de que ambos cables de alimentación están conectados a la misma fase.

ESP

!

!

Advertencias de Seguridad

L N

E

N L

E

Clavija

Aerea Macho

Enchufe

Aereo Hembra

VERDE/ AMARILLO conectado a E

(Conductor de protección a Tierra

-Earth en el original-)

AZUL conectado a N (Conductor Neutro -Neutral en el original-)

MARRÓN conectado a L (Conductor Fase -Live en el original-)

RIESGO DE CHOQUE ELECTRICO

NO QUITAR LAS PROTECCIONNES

ELEMENTOS NO ACCESIBLES AL

USUARIO.

SERVICIO SOLAMENTE A PERSONAL

CUALIFICADO

TBS100/100D SECTION 0

TBS100OPS 20/10/06 www.snellwilcox.com Version 2 Issue 5 0.3

Simboli di sicurezza:

Questo simbolo indica l'informazione importante contenuta nei

manuali appartenenti all'apparecchiatura. Consultare il manuale.

Questo simbolo indica che all'interno dell'apparato sono presenti

tensioni pericolose. Non cercare di smontare l'unità.

Per qualsiasi tipo di intervento rivolgersi al personale qualificato.

Le istruzioni relative alla manutenzione sono ad uso

esclusivo del personale qualificato. E' proibito all'utente

eseguire qualsiasi operazione non esplicitamente

consentita nelle istruzioni. Per qualsiasi informazione

rivolgersi al personale qualificato.

Per prevenire il pericolo di scosse elettriche è necessario non esporre

mai l'apparecchiatura alla pioggia o a qualsiasi tipo di umidità.

Assicurarsi sempre, che l'unità sia propriamente messa a terra e che

le connessioni elettriche siano eseguite correttamente.

Questo dispositivo deve essere collegato ad un impianto elettrico

dotato di un sistema di messa a terra efficace.

La presa di corrente deve essere vicina all'apparecchio

e facilmente accessibile.

Connessione elettrica nei paesi diversi dagli Stati Uniti

L'apparecchiatura normalmente è spedita con cavo pressofuso con la presa

e spina standard IEC. Nel caso della rimozione della spina elettrica,

gettarla via immediatamente osservando tutte le precauzioni del caso.

La leggenda dei cavi è la seguente:

VERDE/GIALLO cavo connesso

ad "E" (terra)

BLU cavo connesso ad "N" (neutro)

MARRONE cavo connesso ad "L" ( fase)

Attenzione! Nel caso in cui l'apparecchio abbia due prese di corrente,

assicurarsi che i cavi non siano collegati a fasi diverse della rete elettrica.

I

!

!

Attenzione:

!

ATTENZIONE

L N

E

N L

E

Presa volante Spina volante

RISCHIO DI SHOCK ELETTRICO

NON CERCARE DI SMONTARE

L'UNITA PER QUALSIASI TIPO DI

INTERVENTO RIVOLGERSI AL

PERSONALE QUALIFICATO

Förklaring av Säkerhetssymboler

Denna symbol hänvisar användaren till viktig information som

återfinns i litteraturen som medföljer. Se manualen.

Denna symbol indikerar att livsfarlig spänning finns på insidan.

Det finns inga servicevänliga delar inne i apparaten.

Denna apparat få endast repareras av utbildad personal.

Serviceinstruktioner som anges avser endast kvalificerad

och utbildad servicepersonal. För att minska risken för

elektrisk stöt, utför ingen annan service än den som

återfinns i medföljande driftinstruktionerna, om du ej är

behörig. Överlåt all service till kvalificerad personal.

För att reducera risken för elektrisk stöt, utsätt inte apparaten för

regn eller fukt.

Se alltid till att apparaten är ordentligt jordad samt att strömtillförseln

är korrekt utförd.

Denna apparat måste bli försörjd från ett strömsystem som är försedd

med jordadanslutning samt ha en neutral anslutning som lätt identifierbar.

Vägguttaget som strömförsörjer apparaten bör finnas i närheten samt

vara lätttillgänglig.

Strömkontakter i länder utanför USA

Apparaten utrustas normalt med en strömkabel med standard IEC gjuten

honkontakt på ena änden samt en standard IEC gjuten hankontakt på den

andra änden. Om man måste avlägsna den gjutna hankontkaten, avyttra

denna kontakt omedelbart på ett säkert sätt. Färgkoden för ledningen är följande:

GRÖN/GUL ledning ansluten till E

(Skyddsjordad ledare)

BLÅ ledning ansluten till N (Neutral ledare)

BRUN ledning ansluten till L (Fas ledare)

Varning! Om enheten har två huvudsakliga elförsörjningar, säkerställ att

båda strömkablarna som är inkopplade i enheten arbetar från samma fas.

S

!

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT REMOVE COVERS

NO USER SERVICEABLE PARTS

REFER SERVICING TO QUALIFIED

PERSONNEL ONLY

!

!

Säkerhetsvarningar

L N

E

N L

E

Stickkontakt-Hane Stickkontakt-Hona

Forklaring på sikkerhedssymboler

Dette symbol gør brugeren opmærksom på vigtig information

i den medfølgende manual.

Dette symbol indikerer farlig spænding inden i apparatet. Ingen bruger

servicerbare dele i apparatet på brugerniveau.

Dette apparat må kun serviceres af faglærte personer..

Serviceinstruktioner er kun til brug for faglærte

servicefolk. For at reducere risikoen for elektrisk

stød må bruger kun udføre anvisninger i

betjeningsmanualen.

Al service skal udføres af faglærte personer.

For at reducere risikoen for elektrisk stød må apparatet ikke

udsættes for regn eller fugt.

Sørg altid for at apparatet er korrekt tilsluttet og jordet.

Dette apparat skal forbindes til en nettilslutning, der yder

BESKYTTENDE JORD og 0 forbindelse skal være tydeligt markeret.

Stikkontakten, som forsyner apparatet, skal være tæt på apparatet

og let tilgængelig

.

Nettilslutning i andre lande end USA

Udstyret leveres normalt med et strømkabel med et standard IEC støbt løst

hunstik i den ene ende og et standard IEC støbt hanstik i den anden ende.

Hvis et af de støbte stik på strømkablet er defekt, skal det straks kasseres på

forsvarlig vis. Farvekoden for lederen er som følger:

GRØN/GUL leder forbundet til J (Jord)

BLÅ leder forbundet til 0

BRUN leder forbundet til F(Fase)

Forsigtig Hvis enheden har to lysnetindgange, skal der sørges for at

begge ledninger tilsluttes lystnetudgange fra den samme fase.

DK

!

!

!

Sikkerhedsadvarsler

!

FORSIGTIG

RISIKO FORELEKTRISKSTØD

DÆKPLADERMÅ IKKEFJERNES

INGEN BRUGERSERVICERBARE

DELESERVICEMÅ KUN UDFØRES

AFFAGLÆRTEPERSONER

F 0

J

0 F

J

Han-stik Hun-stik

Turvamerkkien selitys

Tämä merkki tarkoittaa, että laitteen mukana toimitettu kirjallinen

materiaali sisältää tärkeitä tietoja. Lue käyttöohje.

Tämä merkki ilmoittaa, että laitteen sisällä on vaarallisen voimakas jännite.

Sisäpuolella ei ole mitään osia, joita käyttäjä voisi itse huoltaa.

Huollon saa suorittaa vain alan ammattilainen.

Huolto-ohjeet on tarkoitettu ainoastaan alan

ammattilaisille. Älä suorita laitteelle muita

toimenpiteitä, kuin mitä käyttöohjeissa on

neuvottu, ellet ole asiantuntija. Voit saada sähköiskun.

Jätä kaikki huoltotoimet ammattilaiselle.

Sähköiskujen välttämiseksi suojaa laite sateelta ja kosteudelta.

Varmistu, että laite on asianmukaisesti maadoitettu ja että

sähkökytkennät on tehty oikein.

Laitteelle tehoa syöttävässä järjestelmässä tulee olla

SUOJAMAALIITÄNTÄ ja nollaliitännän on oltava luotettavasti

tunnistettavissa.

Sähköpistorasian tulee olla laitteen lähellä ja helposti tavoitettavissa.

Sähkökytkentä

Laitteen vakiovarusteena on sähköjohto, jonka toisessa päässä on muottiin

valettu, IEC-standardin mukainen liitäntärasia ja toisessa päässä muottiin

valettu, IEC-standardin mukainen pistoliitin. Jos pistoliitin tarvitsee poistaa,

se tulee hävittää heti turvallisella tavalla. Johtimet kytketään seuraavasti:

KELTA-VIHREÄ suojamaajohdin E-napaan

SININEN nollajohdin N-napaan

RUSKEA vaihejohdin L-napaan

Huom! Jos laitteessa on kaksi verkkojännitteen tuloliitäntää, niiden johdot

on liitettävä verkkopistorasioihin, joissa on sama vaiheistus.

FI

!

!

Turvaohjeita

!

SÄHKÖISKUN VAARA ÄLÄ AVAA

LAITTEEN KANSIA EISISÄLLÄ

KÄYTTÄJÄLLEHUOLLETTAVIA

OSIA HUOLTO AINOASTAAN

AMMATTILAISEN SUORITTAMANA

VAROITUS

L N

E

N L

E

Pistoliitin Liitäntärasia

TBS100/100D SECTION 0

TBS100OPS 20/10/06 www.snellwilcox.com Version 2 Issue 5 0.4

Símbolos de Segurança

O símbolo triangular adverte para a necessidade de consultar o

manual antes de utilizar o equipamento ou efectuar qualquer ajuste.

Este símbolo indica a presença de voltagens perigosas no interior

do equipamento. As peças ou partes existentes no interior do equipamento

não necessitam de intervenção, manutenção ou manuseamento por parte

do utilizador. Reparações ou outras intervenções devem ser efectuadas

apenas por técnicos devidamente habilitados.

As instruções de manutenção fornecidas são para

utilização de técnicos qualificados. Para reduzir o

risco de choque eléctrico, não devem ser realizadas

intervenções no equipamento não especificadas no

manual de instalações a menos que seja efectuadas

por técnicos habilitados.

Para reduzir o risco de choque eléctrico, não expor este equipamento

à chuva ou humidade.

Assegurar que a unidade está sempre devidamente ligada à terra e

que as ligações à alimentação estão correctas.

O sistema de alimentação do equipamento deve, por razões de

segurança, possuir ligação a terra de protecção e ligação ao

NEUTRO devidamente identificada.

A tomada de energia à qual a unidade está ligada deve situar-se na

sua proximidade e facilmente acessível.

Ligação da alimentação noutros países que não os EUA

O equipamento é, normalmente, enviado com cabo de alimentação com ficha

IEC fêmea standard num extremo e uma ficha IEC macho standard no extremo

oposto. Se for necessário substituir ou alterar alguma destas fichas, deverá

remove-la e elimina-la imediatamente de maneira segura.

O código de cor para os condutores é o seguinte:

Condutor VERDE/AMARELO ligado a E (Terra)

Condutor AZUL ligado a N (Neutro)

Condutor CASTANHO ligado a L (Vivo).

Atenção: Se a unidade tem duas fontes de alimentação assegurar que os

dois cabos de alimentação estão ligados a tomadas pertencentes à mesma fase.

P

!

!

Avisos de Segurança

L N

E

N L

E

Ficha Livre TomadaLivre

Products employing Lithium batteries

Power cable supplied for the USA

The equipment is shipped with a power cord with a standard IEC molded free socket on one end and a

standard 3-pin plug on the other. If you are required to remove the molded mains supply plug, dispose of the

plug immediately in a safe manner. The color code for the cord is as follows:

GREEN lead connected to E (Protective Earth

Conductor)

BLACK lead connected to L (Live Conductor)

WHITE lead connected to N (Neutral Conductor)

For products with more than one power supply inlet

Caution:

To reduce the risk of electric shock plug each power supply cord into separate branch circuits

employing separate service grounds.

G

CAUTION

This equipment contains a lithium battery.

There is a danger of explosion if this is replaced incorrectly.

Replace only with the same or equivalent type.

Dispose of used batteries according to the instructions of the manufacturer.

Batteries shall only be replaced by trained service technicians.

TBS100/100D SECTION 0

TBS100OPS 20/10/06 www.snellwilcox.com Version 2 Issue 5 0.5

Rack Mounting the Enclosure

When rack-mounting the product, one of the following methods of installation must be used: -

• Place the unit on a suitably specified, and installed rack shelf and secure the product to the rack via the

front rack ears or,

• Fit the unit using the rear rack mount kit available from Snell & Wilcox by quoting the order code FGACK

RACK-MNT-KIT.

This product must not be rack mounted using only the front rack ears.

TBS100/100D SECTION 0

TBS100OPS 20/10/06 www.snellwilcox.com Version 2 Issue 5 0.6

Safety Standard

This unit conforms to the following standards:

BS EN60950:1992 Specification for safety of information

technology equipment, including electrical business equipment

cULus Listed Professional Video Equipment File No. E193966

EMC Standards

This unit conforms to the following standards:

BS EN 55103-1 : 1997

Electromagnetic Compatibility, Product family standard for audio, video, audio-visual and entertainment lighting

control apparatus for professional use. Part 1. Emission

BS EN 55103-2 : 1997

Electromagnetic Compatibility, Product family standard for audio, video, audio-visual and entertainment lighting

control apparatus for professional use. Part 2. Immunity

Federal Communications Commission Rules Part 15, Class A :1998

EMC Environment

The product(s) described in this manual conform to the EMC requirements for, and are intended for use in,

either

The commercial and light industrial environment (including, for example, theatres) E2

or

The controlled EMC environment (for example purpose-built broadcasting or recording studios), and the rural

outdoor environment (far away from railways, transmitters, overhead power lines, etc.) E4

The applicable environment is stated in the Technical Profile section of the product operation manual under

“EMC Performance Information/Environment.”

EMC Performance Information

Please refer to the Technical Profile/Specifications section of the product operation manual.

EMC Performance of Cables and Connectors

Snell & Wilcox products are designed to meet or exceed the requirements of the appropriate European EMC

standards. In order to achieve this performance in real installations it is essential to use cables and connectors

with good EMC characteristics.

All signal connections (including remote control connections) shall be made with screened cables terminated in

connectors having a metal shell. The cable screen shall have a large-area contact with the metal shell.

COAXIAL CABLES

Coaxial cables connections (particularly serial digital video connections) shall be made with high-quality

double-screened coaxial cables such as Belden 8281 or BBC type PSF1/2M.

D-TYPE CONNECTORS

D-type connectors shall have metal shells making good RF contact with the cable screen. Connectors having

"dimples" which improve the contact between the plug and socket shells, are recommended.

No: 60AA

Professional Video

Equipment

TBS100/100D SECTION 0

TBS100OPS 20/10/06 www.snellwilcox.com Version 2 Issue 5 0.7

About this Manual

This manual covers the following products:

• TBS100 Synchronizer/Time Base Corrector

• TBS100D Synchronizer/Time Base Corrector

• TBS100TX Synchronizer/Time Base Corrector

• TBS100DTX Synchronizer/Time Base Corrector

Packing List

The unit is supplied in a dedicated packing carton provided by the manufacturer and should not be accepted if

delivered in inferior or unauthorised materials. Carefully unpack the carton and check for any shipping damage

or shortages.

Any shortages or damage should be reported to the supplier immediately.

Enclosures:

• 1U Mainframe fitted with TBS100 card(s)

• Power cable

• Operator's Manual

Software Version Amendments

Notes about Versions Fitted

Firmware. This TBS100 is shipped with Version 5.1.5 of the firmware.

This TBS100D is shipped with Version 6.0.6 of the firmware.

Manufacturers Notice

Copyright protection claimed includes all forms and matters of copyrightable material and information now

allowed by statutory or judicial law or hereinafter granted, including without limitation, material generated from

the software programs which are displayed on the screen such as icons, screen display looks etc.

Reproduction or disassembly of embedded computer programs or algorithms prohibited.

Copyrighted names: Microsoft Windows™

Information in this manual and software are subject to change without notice and does not represent a

commitment on the part of Snell & Wilcox Ltd. The software described in this manual is furnished under a

licence agreement and may not be reproduced or copied in any manner without prior agreement with Snell &

Wilcox Ltd. or their authorised agents.

TBS100/100D SECTION 0

TBS100OPS 20/10/06 www.snellwilcox.com Version 2 Issue 5 0.8

Table of Contents

SECTION

1 Introduction

Description.......................................................................................................................... 1.1

Features .............................................................................................................................1.2

2 Specifications ................................................................................................................... 2.1

3 Installation

Power Connections .................................................................................................. 3.1

Input Connections .................................................................................................... 3.2

Output Connections ................................................................................................. 3.3

Communication Connections .................................................................................. 3.3

Opening and Closing the Front Panel..................................................................... 3.4

Matching the Front Panel to a Gateway Address .................................................. 3.4

4 Operation

Operating the TBS100 using the Front Panel Buttons and the Menu System................... 1

Using the Dedicated Push Buttons ......................................................................... 4.4

Input.................................................................................................................. 4.4

Input select........................................................................................................ 4.4

Timing ............................................................................................................... 4.6

Freeze............................................................................................................... 4.6

Pattern .............................................................................................................. 4.6

Noise reduce..................................................................................................... 4.7

Y gain (luminance gain) .................................................................................... 4.8

C gain (chrominance gain)................................................................................ 4.8

Black ................................................................................................................. 4.8

Hue ................................................................................................................... 4.8

Memory 1, 2, 3.................................................................................................. 4.9

Genlock........................................................................................................... 4.10

Enhance.......................................................................................................... 4.11

Setup............................................................................................................... 4.12

Browse............................................................................................................ 4.16

Status.............................................................................................................. 4.17

TBS100/100D SECTION 0

TBS100OPS 20/10/06 www.snellwilcox.com Version 2 Issue 5 0.9

4 Operation (continued)

RollCall PC Control Panel Screens for the TBS100/100D/100TX/100DTX...................... 4.19

Control ............................................................................................................ 4.19

Input Select..................................................................................................... 4.19

Standards........................................................................................................ 4.20

Proc Amp ........................................................................................................ 4.21

Features.......................................................................................................... 4.22

Enhancer......................................................................................................... 4.23

Noise Reduction.............................................................................................. 4.24

Encoder........................................................................................................... 4.25

Genlock........................................................................................................... 4.26

Memories ........................................................................................................ 4.28

RollTrack 1-4, RollTrack 5-8 ........................................................................... 4.29

GPI.................................................................................................................. 4.30

Logging And Preset ........................................................................................ 4.32

Status.............................................................................................................. 4.33

Help................................................................................................................. 4.34

Operation via Card Edge Controls..................................................................................... 4.35

5 Appendix 1 RollCall Commands

TBS100D Commands................................................................................................ 5.1

TBS100 Commands .................................................................................................. 5.5

TBS100/100D SECTION 0

TBS100OPS 20/10/06 www.snellwilcox.com Version 2 Issue 5 0.10

Product Support Procedure

If you experience any technical or operational difficulties with a Snell & Wilcox product please do not hesitate

to contact us or utilize our online form to request assistance.

There is a lot of information you can give us that will enable us to diagnose your problem swiftly. Please read

the following guidelines, as these suggestions will help us to help you.

Basic Information

For Units ..................... Please provide the exact product Model, unit Serial Number and Software

Version information.

For Cards or Modules . Please provide the Sub-Assembly Number, card Serial Number and the

Software Version information.

Basic Application

Inputs .......................... Please provide full details of the Input Signals being used including any

references etc. and where they are being generated.

Outputs ....................... Please provide full details of the Output Signals required and how they are

being monitored.

System ........................ Please provide a brief description of the system in which your S&W equipment

is currently being used.

Basic Tests

Preset Unit .................. Please use the Preset Unit function to return the settings back to the factory

default.

RollCall ........................ Is your unit currently connected to a RollCall capable PC? This software is

obtainable for free and provides a very user friendly GUI for virtually all S&W

equipment - perfect for complex products, large systems or those with passive

front panels.

Card Edge Info. ........... What is the status of the card edge LEDs or display? These can often provide

information such as power status and input detection conditions.

Internal TPG ............... Many S&W products have an internal test pattern/tone generator. Please

activate this to assist you with your problem analysis.

In addition to the above, please do not forget to provide us with all of the necessary contact information:

• Names

• Telephone & Fax numbers

• e-mail addresses

• Business address

A form has been provided for this information and will be found on the next page or an on-line form is available

on the Snell & Wilcox website at:

http://www.snellwilcox.com/support/request

TBS100/100D SECTION 0

TBS100OPS 20/10/06 www.snellwilcox.com Version 2 Issue 5 0.11

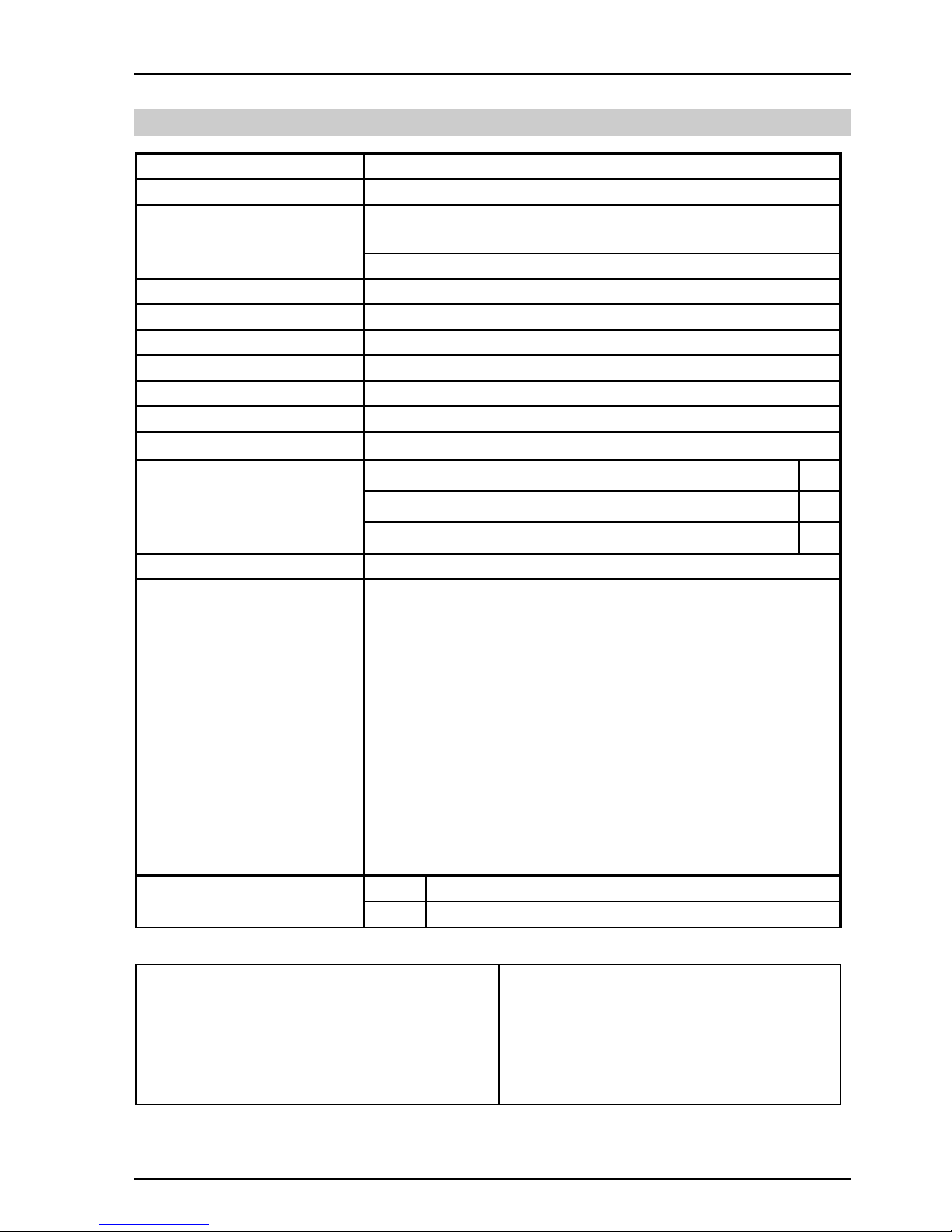

Product Support Request Form

Name: *

Company:

Address Details: *

Post/ZIP Code:

Country: *

Telephone: *

Fax:

Email: *

Local S&W Center: *

Product Name: *

Switchers (i.e. Magic DaVE, Switchpack, Kahuna)

File & Data Transfer Products (i.e. RollCall, Memphis & iCR)

Product Type: *

Video Products (i.e. Modular, Kudos Plus and Alchemist)

Unit Serial Number: *

Fault/Spare Part Information: *

(please advise us how many

units show this fault and the

system layout showing all other

manufacturers' products)

e-mail

* Preferred Method of Contact:

Phone

• Item is required.

Please mail to:

Snell & Wilcox Ltd.,

Southleigh Park House,

Eastleigh Road,

Havant,

Hants,

PO9 2PE.

United Kingdom.

Service Contact Information:

Tel: +44 (0) 2392 489058

Fax: +44 (0) 2392 489057

http://www.snellwilcox.com/support

ftp://ftp.snellwilcox.com/support

TBS100/100D SECTION 0

TBS100OPS 20/10/06 www.snellwilcox.com Version 2 Issue 5 0.12

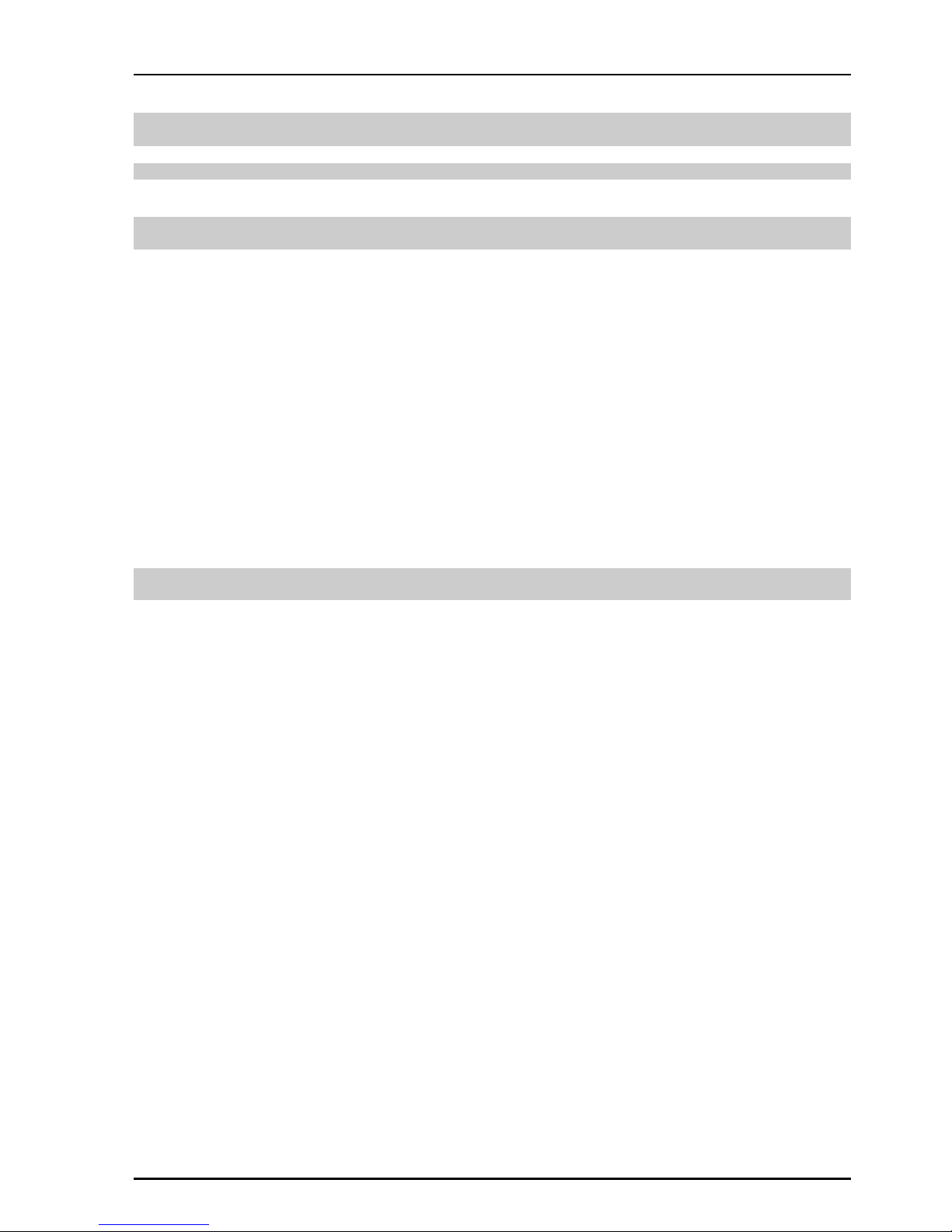

Manual Revision Record

Date Version No. Issue No. Change Comments

230801 1 1 First Issue

151001 1 2 Page 3.3 Buttons Proc Amp to Y

Gain, Size to Black

New section 00 to V1.2 and 03

to V1.2issued

060302 1 3 Changes for new front panel Complete new manual issued

00 to V1.3, 01 to V1.2, 02 to

V1.2, 03 to V1.3, 04 to V1.3

290103 1 4 Luma response to 5 MHz ±3 dB New section 00 to V1.4 and 02

to V1.3 issued

110203 1 5 Linearity specification New section 00 to V1.5 and 02

to V1.4 issued

130203 1 6 TX version added New section 00 to V1.6 and 01

to V1.3 issued

170303 1 7 Techspec Y Response 5 MHz

+0.2 dB, -0.5 dB

New section 00 to V1.7 and 02

to V1.5 issued

130603 2 1 Multilingual safety data and

mounting warning added to

section 00, 03, TX added section

01, opening the front panel data

added to section 03 and card

edge data added to section 04

Complete new manual issued

030703 2 2 UL Listed mark added section 00 Complete new manual issued

190504 2 3 Default output/Genlock additions

and PSP added

Complete new manual issued

160904 2 4 RollCall Log fields added. New

section 5 with RollCall commands

added.

New issue released

201006 2 5 Logo and support data updated New issue released

TBS100/100D SECTION 1

TBS100OPS 20/10/06 www.snellwilcox.com Version 2 Issue 5 1.1

Description

The TBS100 provides multi-standard Y-C and

composite timebase correction and

synchronization. The composite input automatically

detects PAL, NTSC, NTSC-J, PAL-M, PAL-N, N4.4

and SECAM, and is sampled and decoded using

an adaptive line comb filter to ensure optimum

decoding performance. The signal correction

features include luminance and chrominance gain,

black level, NTSC hue, linear horizontal enhancer,

Y-C horizontal timing and picture position. The

TBS100D includes a vertical enhancer. Rugged

sync and clock recovery ensures reliable operation

with unstable and noisy inputs. In addition a

powerful frame recursive noise reducer

automatically eliminates much background noise.

A motion detector switches off the noise reduction

in moving picture areas.

The broadcast quality output encoder is fully

genlockable to a composite reference and

supports PAL, NTSC, NTSC-J, PAL-M, PAL-N and

SECAM. The TBS100 will also operate as a

transcoder between any of the available standards

of the same line rate. Serial digital component

outputs are available simultaneously on the

TBS100D.

Other features include freeze, pattern generation,

power-off composite bypass and GPI control/audio

delay flag output. Full RollCall remote control is

available including RollTrack for audio delay

tracking.

The TBS100/100D is designed to integrate up to

four IQ modules alongside its dedicated function.

This enables users to customize their unit

according to system needs.

The TX versions have a blank front panel with

RollCall only control.

FRONT PANEL VIEWS

REAR PANEL VIEWS

TBS100/TBS100TX

Fuse

ROLLCALL

2

OUTPUTS

INPUTS

2

Y

C

1

A

CVBS

GPI/O

Y/B

CVBS

C

REFERENCE

100-240V~

60/50 Hz

1.8A

T

T2A H

250V

TBS100D/TBS100DTX

Fuse

ROLLCALL

2

OUTPUTS

INPUTS

2

Y

C

1

2

1

A

CVBS

SERIAL OUT

GPI/O

Y/B

CVBS

C

REFERENCE

100-240V~

60/50 Hz

1.8A

T

T2A H 250V

TBS100/100D SECTION 1

TBS100OPS 20/10/06 www.snellwilcox.com Version 2 Issue 5 1.2

Features

•

4:2:2 frame synchroniser / timebase corrector

• Input standards - PAL, NTSC, NTSC-J, PAL-N, PAL-M, N4.4.3 and SECAM

• Output standards - PAL, NTSC, NTSC-J, PAL-N, PAL-M and SECAM

• Auto standards detection

• Y-C and Composite input / output

• Handles VHS tape-playback feature modes

• Optional SDI output – SMPTE 259M –1997 (TBS100D)

• Adaptive line comb decoder

• Motion adaptive recursive noise reducer with automatic noise floor measurement

• PAL Hanover bar suppression

• Linear horizontal enhancer

• Vertical enhancer (TBS100D)

• Broadcast quality encoder

• Genlockable SPG with phasing adjustments

• Test signal generator (100/75% colour bars, multi-burst, black)

• VITS insertion on composite / YC outputs

• PAL Line 23 and NTSC Line 21 process, pass or blank

• Selectable Automatic Gain Control.

• Selectable ACC referenced to colour burst

• Adjustment of luma gain, black level, chroma gain, NTSC Hue and horizontal timing

• Frame freeze, black or input pass through on loss of input

• Power-down bypass (composite A in to composite 1 output)

• Vertical information passed or blanked on either composite/YC or SDI outputs (TBS100D)

• Delay Flag (GPI/O port) output and RollTrack™ for audio tracking

• Programmable GPI/O port

• 3 programmable memories

• Full RollCall remote control (including RollTrack for audio delay)

• Spare slot for S&W IQ modules (e.g. Stereo Audio Delay)

TBS100/100D SECTION 2

TBS100OPS 20/10/06 www.snellwilcox.com Version 2 Issue 5 2.1

Technical Profile

Features

Signal Inputs

Composite 2 x via BNC connectors

Separated Y/C S-VHS/Hi-8 via 2 x via BNC

connectors

Reference 1 via Loop-through BNC

connectors

Signal Outputs

Composite

2 x program outputs via BNC

connectors

Separated Y/C

1 x program output via 2 x BNC

connectors

Serial Component

(TBS100D version only)

2 x outputs via BNC connectors

Control Interface

GPI I/O 1x via BNC connector Closing

contact

RollCall Via BNC connector

(Single Source)

Remote S & W RollCall RS485 or RS422

at 38 kb via 9-pin D-type

connector (Optional)

Front Panel

Controls

Luminance Gain ±3 dB in 0.1 dB steps

Chrominance Gain ±3 dB in 0.1 dB steps

Black Level ±100 mV in 1.6 mV steps

NTSC Hue 360° in 1° steps

Luminance Noise

Reduce

Off, Low, Medium, High

Chrominance Noise

Reduce

Off, Low, Medium, High

Enhance (TBS100)

H Enhance: Off, De-enhance,

Low, Medium, High

Enhance (TBS100D)

H Enhance: Off, Low, Medium,

High

H Enhance Frequency: 2.25 MHz

and 3.375 MHz

V Enhance: Off, Low, Medium,

High

Y-C Timing ±1036 ns in 148 ns steps

Picture Position ±1036 ns in 148 ns steps

Genlock Off/On, ScH Lock, HV Lock

Frame Freeze Off/On

Memory Recall Select 1, 2 or 3

Pattern Select Black, Multi-burst, 100% bars,

75% bars

Preset Controls

Input Standard Select

Standards in Auto detect: NTSC,

PAL, PAL-M, NTSC-J, PAL-N,

SECAM, NTSC4.43

Output Standard 625 PAL, PAL-M, PAL-N,

Output Standard 525 NTSC, PAL-M, NTSC-J,

AGC On/Off

(Auto Gain Range +3 dB to -6 dB)

ACC On/Off

Genlock H-Phase ±113 µs

Genlock Subcarrier

Phase

±180°

Memory Store / Recall / Clear

Insert VITS On / Off

Pass vertical data

(encoder)

On / Off

Pass vertical data

(SDI output)

On / Off (TBS100D only)

PAL Line 23 Process As video / Pass / Blank

NTSC Line 21 Process As video / Pass / Blank

SECAM Notch filter On / Off

SECAM Bottles On / Off

SECAM Carrier On / Off

SECAM Chroma PreFilter

On / Off

Noise Reduction Split

screen

Off / Top Bottom split, Left Right

split

Default Output Input, Pattern, Freeze, Stable Input

Logging (via RollCall) Reference, Input State, Input

Standard

GPI action Memory 1, 2, 3 Pattern, Freeze

GPI Output

Off, [On - Delay Flag, Input Loss,

polarity high/low]

RollTrack Setup Enable Unit 1…8

Preset Memories

Returns all memory settings to

factory defaults

Preset Unit Returns unit to factory defaults

Indicators

Input Loss Input Select LED Illuminates

Input Error Input Error LED flashes

Reference Loss Genlock Select LED Illuminates

TBS100/100D SECTION 2

TBS100OPS 20/10/06 www.snellwilcox.com Version 2 Issue 5 2.2

Specifications

Input

Return Loss Better than -35 dB to 5 MHz

Composite Level 1 V pk-pk typ. Into 75 ohms

Y Level 1 V pk-pk into 75 Ohms

C Level Color Burst at standard level into

75 Ohms

Reference Level Composite or Black Burst at

standard level via loop-thru

connection. (>10k)

Performance

Sampling 4:2:2 (13.5 MHz)

Y Frequency Response 5 MHz +0.2 dB, -0.5 dB

C Frequency Response Better than 1.5 MHz -3 dB

2T Pulse Shape Krating

Better than 1%

Signal to Noise Ratio

Better than 60 dB (Weighted,

Ramp)

Subcarrier Rejection

Better than 46 dB (PAL and

NTSC) 75% Red

Return Loss: Inputs better than 35 dB to 5.0 MHz

Return Loss: Outputs better than 35 dB to 5.0 MHz

Return Loss SDI

Outputs

better than 15 dB at 270 MHz

Power

Mains Supply 115/230V 60/50 Hz 1.2 A

Power

Consumption

140 W max

Mechanical

Temperature Range 0° to 40° C operating

Cooling Axial fan

Case Type 1RU Rack Mounting

Dimensions Overall 483 x 440 x 45 mm.

(w x d x h).

Depth from mounting face (including

unmated connectors) 415 mm.

Weight 9.75 kg

EMC Environment This unit is intended for use in the

commercial and light industrial

environment E2.

TBS100/100D SECTION 3

TBS100OPS 20/10/06 www.snellwilcox.com Version 2 Issue 5 3.1

Installation

Unpacking the TBS100/TBS100D

The unit is packed in a single carton. The contents

of the flight case are as follows:

• 1U Mainframe fitted with TBS100 card

• Power cable

• Operator's Manual

Unpack the carton carefully and check for any

shortages or shipping damage. Immediately report

any shortages or damage to Snell and Wilcox

Limited.

POWER CONNECTIONS

Power Supply

Mains power is supplied to the unit via a filtered IEC

connector.

The mains power fuse rating is 2 A (T) HBC and the

rated current for the unit is 1.2 A.

The power supply ON/OFF switch is located on the

front of the power supply inside the front panel.

CAUTION: THE VENTILATION HOLES AT THE

SIDES OF THE UNIT AND THE FAN EXIT AREA

MUST NOT BE OBSCURED.

Supply Voltage

The power supplies are auto switching for input

voltages in the ranges of 100 V to 250 V nominal.

No voltage adjustment procedure is required.

CAUTION: THIS UNIT MUST NOT BE

OPERATED WITHOUT

AN EARTH CONNECTION.

Fuse

100-240V~

60/50 Hz

1.8A

T

T2A H 250V

Rack Mounting the 1U Enclosure

The product must not be rack mounted using only the front rack mounting ears. When installing the product in

a rack one of the following methods must be used: -

• Place the unit on a suitably specified, and installed rack shelf and secure the product to the rack via the

front rack ears

• Alternatively fit the unit using additional rear rack mounts

A suitable mounting kit is available for purchase from Snell & Wilcox by quoting the order code:

FGACK RACK-MNT-KIT

Note: The rear mounting brackets must be attached using the two M3 threaded inserts on both sides of the

product; the maximum length of screw that can be used is M3 x 6mm. Ensure that the product is secured to

the rack in all four corners.

TBS100/100D SECTION 3

TBS100OPS 20/10/06 www.snellwilcox.com Version 2 Issue 5 3.2

INPUT CONNECTIONS

Composite A and B

These are the 2 Composite video inputs to the

decoder module via BNC connectors. Nominal input

level is 1 V p-p terminated in 75 Ohms.

Separated Y C

A Y-C (S-VHS, Hi-8 etc.) input signal may be

connected to the unit via 2 BNC connectors marked

Y and C.

Y input level is a nominal 1V p-p into 75 Ohms.

C input is nominal colour burst level into 75 Ohms.

Reference Input

When suitable signals are connected to this input,

the video output of the unit will be fully synchronised

to the reference signal source when the genlock

function is selected. If no signal is present the unit

will automatically revert to internal free-running

operation.

BNC loop-through connectors are provided and the

signal may be black burst or composite video at

standard level.

GPI I/O

This BNC connector provides GPI input and output

control for the module.

Input Functions Selects pattern as output.

Recalls memory.

Selects freeze function.

Output Functions Provides a flag representing the

video delay through the unit.

Indicates a loss of input signal

and the Input line standard.

INPUT

S

A

Y/B

CVBS

INPUT

S

A

Y/B

C

2

GPI/O

TBS100/100D SECTION 3

TBS100OPS 20/10/06 www.snellwilcox.com Version 2 Issue 5 3.3

OUTPUT CONNECTIONS

Composite Outputs 1 & 2

Two isolated composite outputs are available from

these BNC connectors.

Output level is standard 1V p-p into 75 Ohms.

SDI 1 & 2 (TBS100D only)

These are the 2 SDI outputs of the unit via BNC

connectors.

Y-C Separated Output

A Y-C (S-VHS/Hi-8) output signal is available via

these 2 BNC connectors marked Y and C.

Y output level is a nominal 1 V p-p into 75 Ohms

C output is a nominal colour burst level into 75

Ohms

COMMUNICATION CONNECTORS

Remote

This 9 pin `D' connector on the rear panel allows

the unit to be connected to the RollCall 485 network

communications system. This connector may also

be used as a RS422 port. For more information see

RollCall section.

RollCall

This single BNC connector allows the unit to be

connected to the RollCall network communications

system.

2

1

CVBS

2

1

SERIAL OUT

OUTPUTS

Y

C

2

ROLLCALL

TBS100/100D SECTION 3

TBS100OPS 20/10/06 www.snellwilcox.com Version 2 Issue 5 3.4

OPENING AND CLOSING THE FRONT PANEL

To Open

Release the front panel by pulling the front panel

forward and downwards using the release handles

on either side of the front panel.

To Close

Replace the front panel by pushing the front panel

rearwards and upwards using the release handles

on either side of the front panel. Ensure that the

panel is fully seated in the case.

TBS100/100D SECTION 3

TBS100OPS 20/10/06 www.snellwilcox.com Version 2 Issue 5 3.5

INSTALLING/REMOVING A MODULE

Internal View of Mainframe.

Rear of Mainframe

Fuse

ROLLCALL

2

OUTPUTS

INPUTS

2

Y

C

1

2

1

A

CVBS

SERIAL OUT

GPI/O

Y/B

CVBS

C

REFERENCE

100-240V~

60/50 Hz

1.8A

T

T2A H 250V

Warning

Before installing a new module into the enclosure

the Configuration Rules given below must be

followed.

The rear of the enclosure must have a full

complement of rear panels. Any vacant slots must

have a blank rear panel fitted

Configuration Rules

These rules limit the total power dissipation of

modules that can be installed in the box. Use the

module power ratings to calculate the total power

dissipated in the enclosure.

Module Power Rating

The power rating for each module is given in its

associated operation manual.

Available Power

The Enclosure has 70 W of available power. The

power ratings of each module should be added

together and the total should not exceed 70 W.

The table opposite may be used for this

calculation.

Warning

The sum of the module power ratings (calculated

using the method above) in the enclosure must not

exceed 70 W.

REFER TO USER MANUAL

BEFORE INSTALLING MODULES

!!

Power Rating Table

Slot Position Module Name Power Rating

1

2

14.5 W

3

4

5

6

Total Power (Watts)

(70 W Maximum)

TBS100/100D SECTION 3

TBS100OPS 20/10/06 www.snellwilcox.com Version 2 Issue 5 3.6

Installing a New Module

Warning Ensure that the power supply is

switched OFF and the mains power connection at

the rear of the unit is removed before these

operations are attempted.

1. Before installing a new module consult the

“Installing/Removing a Module” section to

ensure there is adequate power available for

the module to be added.

2. Release the front panel by pulling the front

panel forward and downwards using the

release handles on either side of the front

panel.

3. Choose an empty slot position for the module.

4. Loosen the screw securing the appropriate

module retaining plate.

5. Slide the module retaining plate upwards or

downwards as appropriate to uncover the card

entry slots.

6. At the rear of the enclosure remove the screws

securing the blanking plate associated with the

chosen slot position.

7. Store the blanking plate in a safe place for

future use.

8. Ensuring correct orientation fit the rear

connecting panel (supplied with the new

module) to the rear of the enclosure in the

vacant aperture and secure with the fixing

screws provided.

9. At the front of the enclosure, (ensuring correct

orientation) carefully slide in the new module

until it fully mates with the rear connector

panel.

10. Slide the module retaining plate upwards or

downwards as appropriate to cover the card

entry slots.

11. Tighten the screw securing the module

retaining plate.

12. Replace the front panel ensuring that the panel

is fully seated in the case.

13. Update the Power Rating table on previous

page.

Removing a Module

1. Remove the front panel as previously

described

2. Loosen the screw securing the appropriate

module retaining plate.

3. Slide the module retaining plate upwards or

downwards as appropriate to uncover the card

entry slots.

4. Carefully slide out the desired module

If a different type of module is to be installed in this

position proceed as in Installing a New Module

item 1 and items 4 to 14.

If the slot is to left vacant, proceed as follows:

1. Tighten the screw securing the module

retaining plate.

2. Replace the front panel ensuring that the panel

is fully seated in the case.

3. At the rear of the enclosure fit the blanking

plate in the associated position using two

screws.

4. Update the Power Rating table on previous

page.

TBS100/100D SECTION 3

TBS100OPS 20/10/06 www.snellwilcox.com Version 2 Issue 5 3.7

Matching the Front Panel to a Gateway Address

If the TBS100/D is to be used on a RollCall network with other equipment, it may be necessary to change the

unit address to that of a vacant network slot in order to avoid confusion between units.

If an address is already in use by the network the RollCall receive and transmit LEDs will flash alternately at a

1-second rate. In this event, the following steps must be taken to set a new unit address:

1. Select an unused network address for the unit.

2. Set the address using the two switches on the gateway card, which is located behind the front panel.

Note that this address will only be read at unit power up.

Position 0 on the left-hand switch will disable the RollCall function on the unit.

Addresses 00 to 0F are pre-arranged.

All other positions on these switches may be used to set the unit address in hex.

3. Restart the front panel by holding down the Y Gain and Black Level buttons together.

4. Select Yes to the front panel question “Restart panel! Are you sure?”

5. Hold down the Y Gain button to enter the setup mode.

6. When the message “Setup mode” is displayed, release the Y Gain button.

7. Momentarily press the Y Gain button.

8. Select Auto-Connect.

9. Ensure that the top two lines read

Auto-Connec\\\\snellwilcox.local\\root\\Marketing\\Prodmgmt\\Data00

?

by selecting

▶

if necessary.

10. On the third line, change the middle two numbers

0000 (00) 01

to match the network address selected in step 2 above.

11. Restart the unit.

TBS100/100D SECTION 4

TBS100OPS 20/10/06 www.snellwilcox.com Version 2 Issue 5 4.1

Operation

THE ACTIVE CONTROL PANEL (TBS100/TBS100D)

Operating the TBS100 using the Front Panel Buttons and the Menu System

USING THE FRONT PANEL PUSH BUTTONS

These buttons have two modes of operation

depending on the length of time they are pressed,

A momentary push will select or deselect the

named function.

Holding down a button will reveal the menu

associated with the chosen function.

Making a Direct Function Selection

A momentary push of the COMPOSITE

A

button will select Composite Input A (CVBS A).

Making a Direct Adjustment Selection

A momentary push of the

Y GAIN button will

reveal the Luminance Gain adjustment screen.

Turning a Function ON or OFF

A momentary push of the

Pattern button will

turn the pattern ON or OFF.

Accessing the Menus

Holding down a button will reveal the menu

associated with the chosen function.

For example, holding down the

Pattern button

will reveal the Pattern selection menu.

Note that some buttons do not have an ON/OFF

function e.g. SETUP; in this case a momentary

push will reveal the associated menu.

USING THE MENU SYSTEM

(See TBS100 Menu System' drawing on page 4.3)

The system may be considered structured as a set

of menus and sub-menus that are displayed in the

LCD window.

A new menu is selected by pressing the appropriate

dedicated function button.

If necessary a sub-menu may be then be selected

by pressing the push button adjacent to the

arrowhead in the text line of the menu name.

This sub-menu will then be displayed in the window

and will have the option of selecting another

sub-menu in the same manner, or allow the

adjustment of a particular parameter. Parameters

enabled will appear as highlighted reverse text

(white text on a black background)

The spin-wheel

allows

parameters and

menus to be

displayed in the

LCD window

Display Control

Buttons

This LCD window

displays the

parameters and submenus that may be

selected by the push

buttons and by the

spin-wheel

Dedicated Push

Buttons

TBS100/100D SECTION 4

TBS100OPS 20/10/06 www.snellwilcox.com Version 2 Issue 5 4.2

CONTROL PANEL - GENERAL INFORMATION

Pressing the Home button will display the home

status screen in the display window from any

position in the menu hierarchy.

The Previous button allows a return to the last

menu item that was changed. Up to 20 changed

menu items may be retraced using this function.

The Return button will allow access to the

previously selected menu or back to the home

screen as appropriate.

When the Scroll LED is illuminated this indicates

that a menu contains more than four text lines and

the spinwheel may be used to scroll through the

menu.

When the Adjust LED is illuminated this indicates

that parameter values and alpha-numerics may be

changed.

If a menu title is followed by three dots

e.g. Input Standards...

this indicates that a further sub-menu is available

for selection.

Display Window

The display window displays all Selection Menus

sub-menus and unit status information.

The selection is made by pressing the button

adjacent to the required item and will become

highlighted (reversed text) when active.

The example opposite shows the Auto Gain Control

function selected.

An example of the display showing the unit status is

shown opposite.

Note that the display window will automatically

revert to the home page (as would be seen if the

Home button was pressed) if a front panel control

has not been operated for a period of 1 minute.

For details of other abbreviations used in this

display please see pages 4.39 and 4.40.

Auto Gain Control

Auto Chroma Control

PAL Chroma Averager

PAL Line 23

01:TBS100D

In:CVBS A Ref : OK

Enhance: off YNr: off

Timin

g

: of

f

CNr: Low

TBS100/100D SECTION 4

TBS100OPS 20/10/06 www.snellwilcox.com Version 2 Issue 5 4.3

TBS100 MAIN MENU

Input...

ProcAmp...

Features...

Memories...

Output...

Freeze...

Status...

Setup...

TBS100/100D

Menu System

Note that highlighted items

indicate

Preset Unit conditions

Genloc k

Genlock Enable

SCH Lock

HV Lock

PAL H P has e

PAL SC Phase

PAL N H P ha se

PALN SC Phase

SECAM H Phase

NTSC H Phase

NTSC SC Phase

PALM H Phase

PALM SC Phase

H_Phase

0 ns

Preset

H_Phase

SC_Phase

0.0 Deg

Preset

SC_Phase

Setup

Encoder...

Genlock...

Pattern...

GPI...

RollTrack...

Logging...

Preset_Unit

RollTrack

Unit 1

Unit 3

Unit 5

Unit 7

Show RollTrack Err

Unit 2

Unit 4

Unit 6

Unit 8

Unit 1 to 8

Unit 1 to 8

0000:00:00 00 00

Clear

Preset

**

OK

Status

Status Display...

GPI Delay

Software Version

Serial Number

Build Number

Restart

Serial_Number

Serial Number

xxxxxxx

OK

Build Number

Build Number

xxxxxxx

OK

GPI Delay

GPI Delay

18 ms

OK

Software Version

Software Version

x.x.x

OK

GPI Open...

GPI Close...

GPI Input Setup

Output

625 Standards...

525 Standards...

Default Output...

Serial Output...(TBS100D)

Input

Input Select...

Input Standards...

Decoder...

Proc Amp

Luminance Gain

Black Level

Chroma Gain

NTSC Hue

Timing...

NTSC Hue

0.0deg

Preset

NTSC Hue

Preset

Luminance Gain

0.0 dB

Luminance Gain

Chroma Gain

0.0 dB

Preset

Chroma Gain

Black Level

0 mV

Preset

Black Level

625

AutoDetect

Enhance (TBS100D)

Enhancer Enable

H Enhance...

V Enhance...

625

AutoDetect

Split Screen

Split Screen Off

Left Right

Top Bottom

YC Timing

0ns

Preset

YC Timing

Picture Position

0ns

Preset

Picture Position

625

AutoDetect

Timing

Timing Enable

Picture Position

YC Timing

625

AutoDetect

Noise Reduce

Noise Reduce Enable

Y Level...

C level...

Split Screen...

Features

Noise Reduce...

Enhance...

625

AutoDetect

PAL Line 23

Process As Video

Pass Line 23

Blank Line 23

625

AutoDetect

NTSC Line 21/283

Process As Video

Pass Line 21/283

Blank Line 21/283

625

AutoDetect

SECAM Options

Notch Disable

Bottles Enable

Carrier Disable

Chroma Filt Disable

Memory 1, 2, 3

Memory 1, 2, 3

Recall

Clear

Save

Memories

Memory 1...

Memor

y

2...

Memor

y

3...

Preset Memories

Input Standards

PAL

PALN

NTSC

PALM

N4.43

SECAM

Mono 625

NTSCJ

Mono 525

Logging

Log Input State

Log Input Standard

Log Reference State

Input Select

Composite A

Composite B

YC

625

AutoDetect

525 Standards

NTSC

PAL M

NTSCJ

625

AutoDetect

625 Standards

PAL

PAL N

SECAM

Status Display

Default Display

Status Display

RollTr ack Error

Decoder

Auto Gain Control

Auto Chroma Control

PAL Line 23...

NTSC Line 21/283...

PAL Chroma Averager

625

AutoDetect

Encoder

VITS Insert

Pass Vertical Data

SECAM Options...

Pass Vertical Data

625

AutoDetect

V

Enhance (TBS100D)

V Enhancer Off

V Enhancer Low

V Enhancer Medium

V Enhancer High

V

Enhancer Low

625

AutoDetect

C Level

C Off

C Low

C Medium

C High

C Low

Pattern

Pattern Enable

Black

75% Colour Bars

100% Colour Bars

MultiBurst

Black

GPI Open/Close

Off

Pattern On

Pattern Off

Freeze On

Freeze Off

Memory 1

Memory 2

Memory 3

Off

GPI Output Setup

Delay Fla

gHig

h On Input Loss

Low On Input Loss

Input Line Std 625

Input Line Std 525

Input Line Std 625

GPI

GPI Input Enable

GPI Input Setup...

GPI Output Enable

GPI Output Setup...

GPI Input Enable

625

AutoDetect

Default Output

Input

Freeze

Stable Input

Pattern

Input

Serial Output (TBS100D)

Pass V e rti cal Data

Pass Vertical Data

625

AutoDetect

Y Level

Y Off

Y Low

Y Medium

Y High

Y Low

625

AutoDetect

H Enhance (TBS100D)

H Enhancer Off

H Enhancer Low

H Enhancre Medium

H Enhancer High

Frequenc

y

2.25 MHz

Frequency 3.375 MHz

H Enhancer Low

Frequency 2.25 MHz

625

AutoDetect

Enhance (TBS100)

Enhancer Enable

De-Enhance

Enhancer Low

Enhancer Medium

Enhancer High

Enhancer Low

TBS100/100D SECTION 4

TBS100OPS 20/10/06 www.snellwilcox.com Version 2 Issue 5 4.4

Using the Dedicated Push Buttons

INPUT

These buttons allow the input signal connected to

the rear panel to be selected for processing.

Selections available are: Composite A

Composite B

Y/C

A prolonged push of any of these buttons will reveal

the Input Menu.

Note that these buttons are mutually exclusive and

only one of the inputs may be selected.

◀

◀ ◀

◀ Input…

This function allows the input parameters to be set.

Input

Input S elect...

Input S tandards . ..

Decoder...

◀

◀ ◀

◀ Input Select

This allows any of the three sources of video input

signal to be selected for processing.

Input Select

Composite A

Composite B

YC

◀

◀ ◀

◀ Input Standards

The decoder employs an auto standard detection

system. It will auto detect any of the standards that

are checked in the list of standards.

Input Standards

PAL

PAL N

NTSC

PAL M

N4.43

SECAM

Mono 625

NTSCJ

Mono 525

In the example above it will auto detect all

standards except NTSCJ, Mono 625 and Mono

525. Any number (one or more) of standards may

be selected. For example, in a given situation where

it is known that only PAL and NTSC input signals

are expected, only the PAL and NTSC standards

should be checked.

The decoder will then only auto detect between PAL

and NTSC standards. Other standards will not be

decoded and will produce an unstable lock.

To force the unit to decode only one standard,

check that standard and uncheck all others.

Note that at least one standard must be selected; if

an attempt is made to uncheck all items the last

standard selected will remain checked and become

the only standard to be decoded.

For NTSC signals either NTSC or NTSCJ may be

checked, but it is not possible to check both NTSC

and NTSCJ.

The output line standard will be the same as the

detected input standard. i.e. the output signal will be

at a line rate of 625 if the detected input signal has

a line rate of 625; similarly the output signal will be

at a line rate of 525 if the detected input signal has

a line rate of 525.

NTSCJ When this function is enabled the decoder

will correctly process a NTSCJ signal (an NTSC

signal without pedestal)

TBS100/100D SECTION 4

TBS100OPS 20/10/06 www.snellwilcox.com Version 2 Issue 5 4.5

◀

◀ ◀

◀ Decoder

This function allows settings to be made to the

decoder section.

Decoder

Auto Gain Control

Auto Chroma Control

PAL Line 23...

NTSC Line 21/283...

PAL Chroma Averager

◀

◀ ◀

◀ Auto Gain Control

When this item is enabled the luminance gain will

vary relative to the input peak white amplitude.

This will maintain the output signal at a normalised

level even though the input signal level may be

above or below standard level. The control will be

effective over an input level range of +3 dB to -6 dB.

◀

◀ ◀

◀ Auto Chroma Control

When this item is enabled the chrominance gain will

vary relative to the input burst amplitude. This will

maintain correct colour saturation regardless of

changes in subcarrier amplitude.

◀

◀ ◀

◀ PAL Chroma Averager

When selected this will provide PAL Hanover bar

suppression.

◀

◀ ◀

◀ PAL Line 23

This item allows various options to be applied to

line 23 of the input signal.

625

AutoDetect

PAL Line 2 3

Process As Video

Pass Line 23

Blank Line 23

◀

◀ ◀

◀ Process As Video

When enabled line 23 of the PAL input signal will be

processed as active picture and the ProcAmp

controls will effect Line 23.

◀

◀ ◀

◀ Pass Line 23

When selected (text reversed) the first half line of

line 23 is passed unprocessed, the second half line

is blanked and the ProcAmp controls will not effect

Line 23.

◀

◀ ◀

◀ Blank Line 23

When enabled line 23 of the PAL input signal will be

blanked.

◀

◀ ◀

◀ NTSC Line 21/283

This item allows various options to be applied to

line 21/283 of the input signal.

625

AutoDetect

NTSC Line 21/283

Process As Video

Pass Line 21/283

Blank Line 21/283

◀

◀ ◀

◀ Process As Video

When enabled line 21/283 of the input signal will be

processed and the ProcAmp controls will effect Line

21/283.

◀

◀ ◀

◀ Pass Line 21/283

When selected (text reversed) lines 21/283 are

passed unprocessed and the ProcAmp controls will

not effect Line 21/283.

◀

◀ ◀

◀ Blank Line 21/283

When enabled line 21/283 of the input signal will be

blanked.

Note that the first half of line 283 on the composite

(NTSC) output is always blanked.

TBS100/100D SECTION 4

TBS100OPS 20/10/06 www.snellwilcox.com Version 2 Issue 5 4.6

TIMING

A momentary push of this button will toggle the

Timing function ON or OFF.

A prolonged push of this button will reveal a menu

that allows various timing adjustments to be

selected.

625

AutoDetect

Timing

Timing Enable

Picture Position

YC Timing

◀

◀ ◀

◀ Timing Enable

When this item is selected (text highlighted) the

timing values will be enabled.

◀

◀ ◀

◀ Picture Position

Selecting this item will reveal a display showing the

timing of the picture position relative to the normal

value, in nanoseconds. Rotating the spin-wheel will

adjust this value.

Picture Position

0ns

Preset

Picture Position

Range is from ±1036 ns in 148 ns steps.

Selecting Preset returns the setting to the preset

value of 0.

◀

◀ ◀

◀ YC Timing

Selecting this item will reveal a display showing the

timing of the chrominance signal relative to the

luminance signal, (i.e. Y to Cb/Cr timing) in

nanoseconds. Rotating the spin-wheel will adjust

this value.

YC Timing

0ns

Preset

YC Timing

Range is from ±1036 ns in 148 ns steps.

Selecting Preset returns the setting to the preset

value of 0.

FREEZE

The Freeze button allows the output picture to be

frozen and the Green LED will be illuminated to

indicate the function is activated.

This function toggles between a normal picture and

a frozen picture.

PATTERN

A momentary push of this button will toggle the

Pattern function ON or OFF i.e. the output will be

either the selected pattern or the processed picture.

A prolonged push of this button will reveal a menu

that allows various patterns to be selected and used

as the output signal.

Pattern

Pattern Enable

Black

75% Colour Bars

100% Colour Bars

MultiBurst

Black

◀

◀ ◀

◀ Pattern Enable

When this item is selected (text highlighted) the

selected pattern will become the output signal when

the pattern function is enabled.

TBS100/100D SECTION 4

TBS100OPS 20/10/06 www.snellwilcox.com Version 2 Issue 5 4.7

NOISE REDUCE

This item allows Recursive noise reduction with

automatic threshold to be applied to the Luminance

and Chrominance channels.

A momentary push of this button will toggle the

Noise Reducer function ON or OFF.

The amount of noise reduction applied will be the

value set in the Y and C Level menus.

A prolonged push of this button will reveal a menu

that allows various levels of noise reduction to be

applied using the Y (luminance) and C

(chrominance) level controls.

625

AutoDetect

Noise Reduce

Noise Reduce Enable

Y Level

C level

Split Screen...

◀

◀ ◀

◀ Noise Reduce Enable

When this item is selected (text highlighted) the Y

noise reduction function will be enabled. This

function will toggle the Noise Reduce function On or

Off.

◀

◀ ◀

◀ Y level

When this item is selected a menu will be revealed

that allows the amount of Y noise reduction applied

may be chosen.

625

AutoDetect

Y Level

Y Off

Y Low

Y Medium

Y High

Y Low

◀

◀ ◀

◀ C level

When this item is selected a menu will be revealed

that allows the amount of C noise reduction applied

may be chosen.

625

AutoDetect

C Level

C Off

C Low

C Medium

C High

C Low

Note that the Preset Unit function in the Setup

menu turns the Noise Reduce function OFF and

returns the Y and C Noise Reduce Level values to

Low.

◀

◀ ◀

◀ Split Screen

To enable the effects of noise reduction to be easily

seen this function allows the screen to be split into 2

halves either left/right or top/bottom. One half will

show the picture with noise reduction and the other

half without noise reduction.

625

AutoDetect

Split Screen

Split Screen Off

Left-Right

Top-Bottom

◀

◀ ◀

◀ Split Screen Off

When this item is selected (text highlighted) this will

disable the split screen function.

◀

◀ ◀

◀ Left-Right

When enabled the screen will be split into two equal

sections separated by a vertical white line.

The processed picture will occupy the left hand

section of the screen and the unprocessed picture

will occupy the right hand side section.

◀

◀ ◀

◀ Top-Bottom

When enabled the screen will be split into two equal

sections separated by a horizontal white line.

The processed picture will occupy the top section of

the screen and the unprocessed picture will occupy

the bottom section.

TBS100/100D SECTION 4

TBS100OPS 20/10/06 www.snellwilcox.com Version 2 Issue 5 4.8

Y GAIN (Luminance Gain)

Pressing this button will reveal a numerical readout

display for the gain of the luminance signal.

By rotating the spinwheel the gain may be adjusted

by ±3 dB in steps of 0.1 dB.

Luminance Gain

0.0 dB

Luminance Gain

Selecting Preset returns the setting to the calibrated

value of 0.

C GAIN (Chrominance Gain)

Pressing this button will reveal a numerical readout

display for the gain of the chrominance signal.

By rotating the spinwheel the gain may be adjusted

by ±3 dB in steps of 0.1 dB.

Chroma Gain

0.0 dB

Preset

Chroma Gain

Selecting Preset returns the setting to the calibrated

value of 0.

BLACK

This selection reveals a numerical readout display