Page 1

www.s-a-m.com

Installation & Quick Start Manual

Sirius 840 Router

A 576 x 576 non-expandable frame, with up to

140 multiviewer outputs in a 27U chassis

Page 2

Sirius 840 Installation Manual www.s-a-m.com

Issue 2 Rev 3 Page 2 © 2016 SAM

Page 3

Sirius 840 Installation Manual www.s-a-m.com Contents

Issue 2 Rev 3 Page 3 © 2016 SAM

Contents

1. About this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Contact Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Copyright and Disclaimer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2. Warnings and Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Explanation of Safety Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2 Safety Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.3 Lithium Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.4 Fiber Output Modules Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.5 Cable Management. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.6 Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.7 Earth Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

2.7.1 Important Protective Earth Information . . . . . . . . . . . . . . . . . . . . . . . . . .11

2.7.2 Important Functional Earth Information . . . . . . . . . . . . . . . . . . . . . . . . . .11

2.8 Safety Standards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3. Prerequisites. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1 Size Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1.1 Sirius 840 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1.2 Power Supply Shelf . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.2 Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.2.1 Packed Shipping Crate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.2.2 Sirius 840 Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.2.3 Power Supply Shelf . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.3 Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.4 Electrical Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.4.1 Important Protective Earth Information . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.4.2 Cable Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.4.3 Mains Power Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.4.4 DC Power Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.4.5 Power Supply Redundancy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4. Unpacking the Sirius 840. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.1 Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.1 Installing into a 19" Rack. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.1.1 Opening the Door. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.1.2 Securing the Sirius 840 in a 19” Rack . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.2 Mounting the Power Supply Shelf into a 19" Rack . . . . . . . . . . . . . . . . . . . . . . . 24

6. Rear Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.1 Rear of Sirius 840 Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.2 Alarm Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.3 Control Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7. Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

7.1 Earthing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

7.2 Cable Management. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

7.3 Mains Power Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

7.4 Ethernet Cabling (Optional). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

7.4.1 Changing IP Addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

7.5 External Panel Cabling (Optional). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

7.5.1 RS485 Control Pin-outs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

7.5.2 Example Connecting a 6026776 2U Control Panel to the Router . . . . . 33

8. Power Supplies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Page 4

Sirius 840 Installation Manual www.s-a-m.com Contents

Issue 2 Rev 3 Page 4 © 2016 SAM

8.1 Power Supply Shelf. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

8.2 Power Distribution. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

8.3 Power and Alarm Connections to the Sirius 840 Frame . . . . . . . . . . . . . . . . . . . 37

8.3.1 48 V DC Power Out Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

8.3.2 Single Power Shelf Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

8.3.3 Dual Power Shelf Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

8.3.4 Alternative Dual Power Shelf Connections . . . . . . . . . . . . . . . . . . . . . . 40

9. Powering the Sirius 840. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

9.1 Powering Up the Sirius 840. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

9.1.1 Power Sequencing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

9.1.2 Power Up and Initialization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

9.1.3 Starting the Door PC Manually. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

9.2 Powering Down the Sirius 840 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

10. Testing the Sirius 840 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

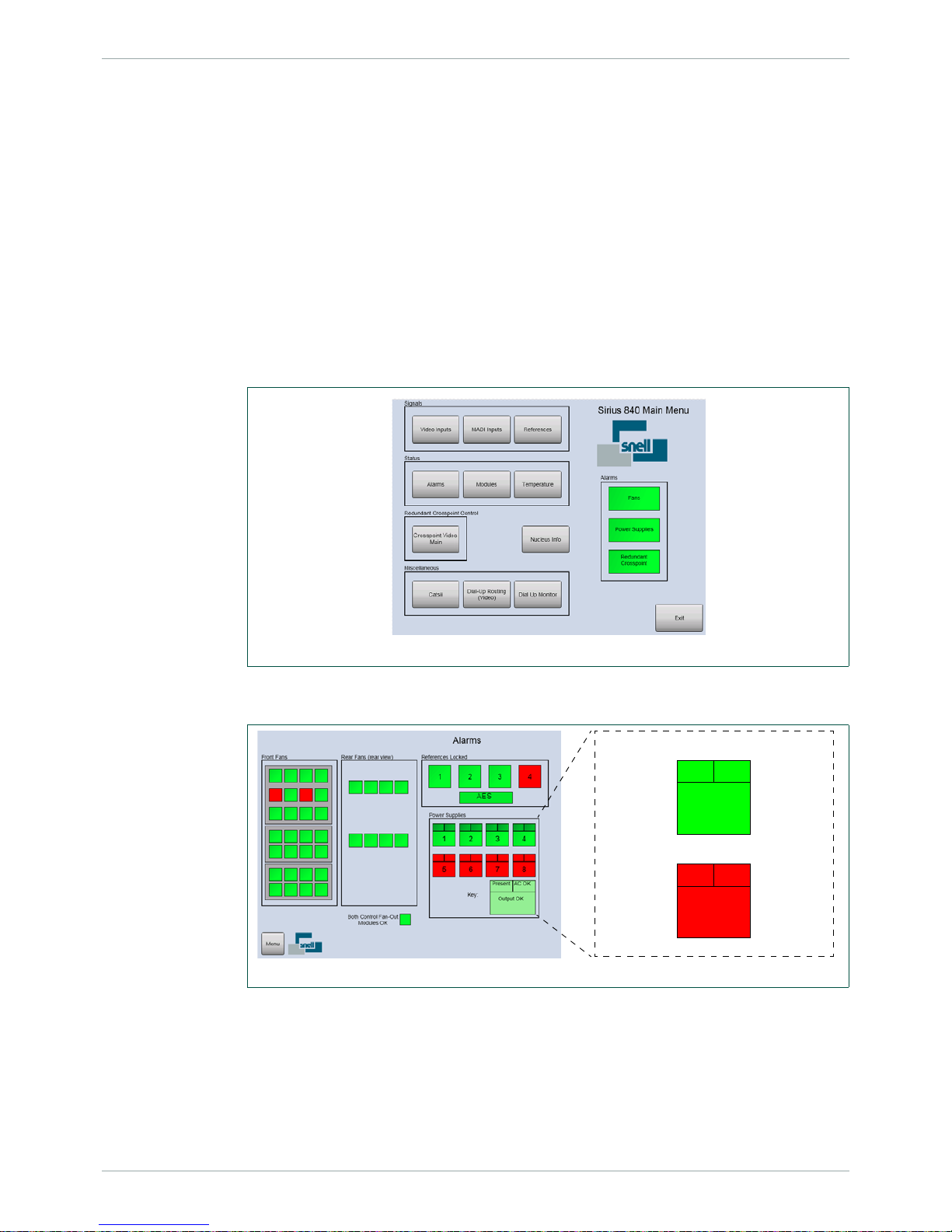

10.1 Alarms Displayed on the Router Door PC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

10.2 Setting a Route Using the Router Door PC. . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

10.3 Signal Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

10.3.1 Video Signal Catsii Colors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

10.3.2 MADI Audio Catsii Colors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

10.4 External Control Input and Output Port Mapping . . . . . . . . . . . . . . . . . . . . . . . 49

10.5 Default Serial Port Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

10.6 External Control Panels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

10.6.1 Powering Up the Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

11. Workbench . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

11.1 Installing Workbench . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

11.2 Associating Workbench with the Workbench Database . . . . . . . . . . . . . . . . . . 58

11.2.1 Create a New Blank Workbench Database . . . . . . . . . . . . . . . . . . . . . 59

11.2.2 Connect to an Existing Workbench Database . . . . . . . . . . . . . . . . . . . 59

11.2.3 Move the Existing Workbench Database from the Router Door PC. . . 60

11.3 Starting Workbench . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

11.4 Adding Router Control Module(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

11.5 Controller Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

11.5.1 Configuration Using the Workbench Configuration Screens . . . . . . . . 67

11.5.2 Configuration Using the Generic Configuration Editor . . . . . . . . . . . . . 69

11.5.3 Configuration Using the Generic Online Configuration Editor . . . . . . . 70

11.5.4 Pushing the Configuration to the Controller(s) . . . . . . . . . . . . . . . . . . . 71

Page 5

Sirius 840 Installation Manual www.s-a-m.com About this Manual

Issue 2 Rev 3 Page 5 © 2016 SAM

1. About this Manual

This manual describes the installation of the Sirius 840 Router.

Refer to the Sirius 800 User Manual and the Workbench Manual for details on configuring

hardware and software.

Refer to the Workbench manual for details on configuring hardware and software panels.

If you have any questions regarding the installation and setup of your pro duct, please refer to

the Customer Service contact details (see section 1.1).

1.1 Contact Details

For details of our Regional Customer Support Offices please visit the SAM web site and

navigate to Support/Customer Support Contacts.

www.s-a-m.com/support/247-support/

Customers with a support contract should call their personalize d number, which can be found

in their contract, and be ready to provide their contract number and details.

1.2 Copyright and Disclaimer

Copyright protection claimed includes all forms and matters of copyrightable materia l and

information now allowed by statutory or judicial law or hereinafter granted, including without

limitation, material generated from the software programs which are displayed on the screen

such as icons, screen display looks etc.

Information in this manual and software are subject to change without notice and does not

represent a commitment on the part of SAM Limited. The sof tware described in this manual is

furnished under a license agreement and can not be reproduced or copied in any manner

without prior agreement with SAM Limited or their authorized agents.

Reproduction or disassembly of embedded computer programs or algorithms prohibited.

No part of this publication can be transmitted or reproduced in any form or by any means,

electronic or mechanical, including photocopy, recording or any information storage and

retrieval system, without permission being granted, in writing, by the publishers or their

authorized agents.

SAM operates a policy of continuous improvement and development. SAM reserves th e ri ght

to make changes and improvements to any of the products described in this document

without prior notice.

Page 6

Sirius 840 Installation Manual www.s-a-m.com About this Manual

Issue 2 Rev 3 Page 6 © 2016 SAM

Page 7

Sirius 840 Installation Manual www.s-a-m.com Warnings and Precautions

Issue 2 Rev 3 Page 7 © 2016 SAM

2. Warnings and Precautions

Erklärung der Sicherheitssymbole

Dieses Symbol weist den Benutzer auf wichtige Informationen

hin, die in der begleitenden Dokumentation enthalten sind.

Dieses Symbol zeigt an, dass gefährliche Spannung vorhandenist.

Es befinden sich keine vom Benutzer zu wartenden Teile im Geräteinneren.

Dieses Gerät solltenur von geschultem Personal gewartet werden

· U m da s Ri siko eines El ektros cho ck s zu reduz ieren, setzen Sie das

Gerät w ed er R eg en noch Feuc htigke it aus.

· S tellen Sie imm er sicher, dass das G erä t or dnu ng sge m ä ß g eer det

und ve rka belt ist.

· D ieses Eq uipm e nt m us s an e ine Netzsteck do se m it Sch utz leiter

angeschlossen werden und ei nen zuverlässig identifizierbaren Nullleiter haben.

· D ie Netzsteck dos e s ollte n ahe beim Gerät und ei nfach zug äng lich se in.

Sicherheits-Warnhinweise

D

!

Die angeführten Service-/Reparatur-Anweisungen sind

ausschließlich von qualifiziertem Service-Personal

auszuführen. Um das Risiko eines lektroschockszu

reduzie re n , fü hren S ie auss ch ließ lich die im

Benutzerhandbuch eschriebenen A nweisungen aus,

es sei denn, Sie haben die entsprechende Q ualifikation.

Wenden Sie sich in allen Service-Fragen an qualifiziertesPersonal.

!

ACHTUNG

Ge fa hr vo n E le ktro sc hoc ks .

Abde ck ungen nicht entferne n

Keine vom Benutze r z u w artend e T eile

Wenden Sie sich ausschließlich

an q ua lifiziertes Personal

Explicación de los Símbolos de Seguridad

Éste símbolo refiere al usuario información importante contenida

en la literatura incluida. Referirse al manual.

Éste símbolo indica que voltajes peligrosos están presentes en el interior.

No hay elementos accesibles al usuario dentro.

Esta unidad sólo debería ser tratada por personal cualificado.

Las instrucciones de servicio cuando sean dadas, son

sólo para uso de personal cualificado. Para reducir el

riesgo de choque eléctrico no llevar a cabo ning una

operación de servicio aparte de las contenidas en las

instrucciones de operación, a menos que se esté

cualificado para realiz arla s.

Referir todo el trabajo de servicio a personal cualificado.

·

Para reducir el riesgo de choque eléctrico, no exponer este equipo

a la lluvia o humedad.

·

Siempre asegurarse de que la unidad está propiamente conectada a

tierra y que las conexiones de alimentación están hechas correctamente .

·

Este equipo debe ser alimentado desde un sistema de alimentación

con conexión a TIERRA y teniendo una conexión neutra fácilmente

identificable.

·

La toma de alimentación para la unidad debe ser cercana y fácilmente

accesible.

ESP

!

Advertencias de Seguridad

RIESGO DE CHOQUE ELECTRICO

NO QUITAR LAS PROTECCIONNES

ELEMENTOS NO ACCESIBLES AL

USUARIO.

SERVICIO SOLAMENTE A PERSONAL

CUALIFICADO

Simboli di sicurezza:

Questo simbolo indica l'informazione importante contenuta nei

manuali appartenenti all'apparecchiatura. Consultare il manuale.

Questo simbolo indica che all'interno dell'apparato sono presenti

tensioni pericolose. Non cercare di smontare l'unità.

Per qualsiasi tipo di intervento rivolgersi al personale qualificato.

Le istruzioni relative alla manutenzione sono ad uso

esclusivo del personale qualificato. E' proibito all'utente

eseguire qualsiasi operazione non esplicitamente

consentita nelle istruzioni. Per qualsiasi informazione

rivolgersi al personale qualificato.

·

Per prevenire il pericolo di scosse elettriche è necessario non esporre

mai l'apparecchiatura alla pioggia o a qualsiasi tipo di umidità.

·

Assicurarsi sempre, che l'unità sia propriamente messa a terra e che

le connessioni elettriche siano eseguite correttamente.

·

Questo dispositivo deve essere collegato ad un impianto elettrico

dotato di un sistema di messa a terra efficace.

·

La presa di corrente deve essere vicina all'apparecchio

e facilmente accessibile.

I

!

Attenzione:

!

ATTEN ZIONE

RISCHIO DI SHOCK ELETTRICO

NON CERCARE DI SMONTARE

L'UNITA PER QUALSIASI TIPO DI

INTERVENTO RIVOLGERSI AL

PERSONALE QUALIFICATO

Forklaring på sikkerhedssymboler

Dette symbol gør brugeren opmærksom på vigtig information

i den medfølgende manual.

Dette symbol indikerer farlig spænding inden i apparatet. Ingen bruger

servicerbare dele i apparatet på brugerniveau.

Dette apparat må kun serviceres af faglærte personer..

Serviceinstruktioner er kun til brug for faglærte

servicefolk. For at reducere risikoen for elektrisk

stød må bruger kun udføre anvisninger i

betjeningsmanualen.

Al service skal udføres af faglærte personer.

·

For at reducere risikoen for elektrisk stød må apparatet ikke

udsættes for regn eller fugt.

·

Sørg altid for at apparatet er korrekt tilsluttet og jord et.

·

Dette apparat skal forbindes til en nettilslutning, der yder

BESKYTTENDE JORD og 0 forbindelse skal være tydeligt markeret.

·

Stikkontakten, som forsyner apparatet, skal være tæt på apparatet

og let tilgængelig

.

D

K

!

!

Sikkerhedsadvarsler

!

FORSIGTIG

RISIKO FOR ELEKTRI SK STØD

DÆKPLADERMÅIKKEFJERNES

INGEN BRUGERSERVICERBARE

DELESERVICE MÅ KUN UDFØRES

AF FAGLÆRTE PERSON ER

Page 8

Sirius 840 Installation Manual www.s-a-m.com Warnings and Precautions

Issue 2 Rev 3 Page 8 © 2016 SAM

Förklaring av Säkerhetssymboler

Denna symbol hänvisar användaren till viktig information som

återfinns i litteraturen som medföljer. Se manualen.

Denna symbol indikerar att livsfarlig spänning finns på insidan.

Det finns inga servicevänliga delar inne i apparaten.

Denna apparat få endast repareras av utbildad personal.

Serviceinstruktioner som anges avser endast kvalificerad

och utbildad servicepersonal. För att minska risken för

elektrisk stöt, utför ingen annan service än den som

återfinns i medföljande driftinstruktionerna, om du ej är

behörig. Överlåt all service till kvalificerad personal.

·

För att reducera risken för elektrisk stöt, utsätt inte apparaten för

regn eller fukt.

·

Se alltid till att apparaten är ordentligt jordad samt att strömtillförseln

är korrekt utförd.

·

Denna apparat måste bli försörjd från ett strömsystem som är försedd

med jordadanslutning samt ha en neutral anslutning som lätt identifierbar.

·

Vägguttaget som strömförsörjer apparaten bör finnas i närheten samt

vara lätttillgänglig.

S

!

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT REMOVE COVERS

NO USER SERVICEABLE PARTS

REFER SERVICING TO QUALIFIED

PERSONNEL ONLY

!

Säkerhetsvarningar

Turvamerkkien selitys

Tämä merkki tarkoittaa, että laitteen mukana toimitettu kirjallinen

materiaali sisältää tärkeitä tietoja. Lue käyttöohje.

Tämä merkki ilmoittaa, että laitteen sisällä on vaarallisen voimakas jännite.

Sisäpuolella ei ole mitään osia, joita käyttäjä voisi itse huoltaa.

Huollon saa suorittaa vain alan ammattilainen.

Huolto-ohjeet on tarkoitettu ainoastaan alan

ammattilaisille. Äl ä suorita laitteelle muita

toimenpiteitä, kuin mitä käyttöohjeissa on

neuvottu, ellet ole asiantuntija. Voit saada sähköiskun.

Jätä kaikki huoltotoimet ammattilaiselle.

·

Sähköiskujen välttämiseksi suojaa laite sateelta ja kosteudelta.

·

Varmistu, että laite on asianmukaisesti maadoitettu ja että

sähkökytkennät on tehty oikein.

·

Laitteelle tehoa syöttävässä järjestelmässä tulee olla

SUOJAMAALIITÄNTÄ ja nollaliitännän on oltava luotettavasti

tunnistettavissa.

·

Sähköpistorasian tulee olla laitteen lähellä ja helposti tavoitettavissa.

F

I

!

Turvaohjeita

!

SÄHKÖISKU N VAARA ÄLÄ AVAA

LAITTEEN KANSIA EI SISÄLLÄ

KÄYTTÄJÄLLEH UOLLETTAVIA

OSIAHUOLTO AINOASTAAN

AMMATTILAISEN SUORITTAM ANA

VAROITUS

Símbolos de Segurança

O símbolo triangular adverte para a necessidade de con sult ar o

manual antes de utilizar o equipamento ou efectuar qualquer ajuste.

Este símbolo indica a presença de voltagens perigosas no interior

do equipamento. As peças ou partes existentes no interior do equipamento

não necessitam de intervenção, manutenção ou manuseamento por parte

do utilizador. Reparações ou outras intervenções devem ser efectuadas

apenas por técnicos devidamente habilitados.

As instruções de manutenção fornecidas são para

utilização de técnicos qualificados. Para reduzir o

risco de choque eléctrico, não devem ser realizadas

intervenções no equipamento não especificadas no

manual de instalações a menos que seja efectuadas

por técnicos habilitados.

·

Para reduzir o risco de choque eléctrico, não expor este equipamento

à chuva ou humidade.

·

Assegurar que a unidade está sempre devidamente ligada à terra e

que as ligações à alimentação estão correctas.

·

O sistema de alimentação do equipamento deve, por razões de

segurança, possuir ligação a terra de protecção e ligação ao

NEUTRO devidamente identificada.

·

A tomada de energia à qual a unidade está ligada deve situar-se na

sua proximidade e facilmente acessível.

P

!

Avisos de Segurança

Page 9

Sirius 840 Installation Manual www.s-a-m.com Warnings and Precautions

Issue 2 Rev 3 Page 9 © 2016 SAM

2.1 Explanation of Safety Symbols

2.2 Safety Warnings

Servicing instructions, where given, are for use by qualified personnel only. To reduce the risk

of electric shock, do not perform any actions on this equipment other than contained in the

operating instructions, unless you are qualified to do so. Refer all servicing to qualified

personnel.

Always ensure that the unit is properly earthed and power connections correctly made.

This equipment must be supplied from a power system providing a PROTECTIVE EARTH

connection and having a neutral connection which can be reliably identified.

The power circuit breakers or switches supplying power to the unit should be close to the unit

and easily accessible.

2.3 Lithium Batteries

The Sirius 840 door PC and router contro l module(s) each cont ain a Lithium ba ttery to provide

non-volatile memory.

This symbol refers the user to important information contained in the accompanying

literature.

This symbol indicates that hazardous voltages are present inside. No user serviceable

parts inside. the Sirius 840 should only be serviced by trained personnel.

To reduce the risk of electric shock, do not expose this appliance to rain or moisture.

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT REMOVE COVERS

NO USER SERVICABLE PARTS

REFER SERVICING TO QUALIFIED

PERSONNEL ONLY

This equipment contains a lithium battery

There is a danger of explosion if this is replaced incorrectly

Replace only with the same type from the same manufacturer.

Dispose of used batteries in accordance with local

and national laws/regulations.

Batteries shall only be replaced by trained service technicians

CAUTION

Page 10

Sirius 840 Installation Manual www.s-a-m.com Warnings and Precautions

Issue 2 Rev 3 Page 10 © 2016 SAM

2.4 Fiber Output Modules Warning

2.5 Cable Management

It is important that the cabling to and from the router is correctly labelled and routed. This will

simplify the work required if the installation needs to be changed or added to at a futur e date.

2.6 Power Supplies

The power supply shelves are separate 2RU modules. Power supply shelves are rack

mountable and can be placed above, below or remote from the Sirius frame.

The power supply alarm cable(s) and 48 V DC cables are supplied by SAM and can be

ordered as either 2.5 metre cables or 8 metre cables.

LASER SAFETY

The average optical output power does not exceed 0 dBm (1mW) under normal

operating conditions. Unused optical outputs should be covered to prevent direct

exposure to the laser beam.

Even though the power of these lasers is low, the beam should be treated with caution

and common sense because it is intense and concentrated. Laser radiation can cause

irreversible and permanent damage of eyesight. Please read the following guidelines

carefully:

• Make sure that a fiber is connected to the board's fiber outputs before power is

applied. If a fiber cable (e.g. patchcord) is already connected to an output, make

sure that the cable's other end is connected, too, before powering up the board.

• Do not look in the end of a fiber to see if light is coming out. The laser

wavelengths being used are totally invisible to the human eye and can cause

permanent damage. Always use optical instrumentation, such as an optical

power meter, to verify light output.

• Cables connected to the router must be fitted with adequ ate vertical and ho rizont al

strain relief to avoid twisting of the rear panels causing damage to the router

connectors and loss of electrical/signal connection to the router.

• Cables connected to the router should be ro ut ed so the y do not cove r an y of th e

frame fan exhausts as this can restrict airflow through the router.

• Ensure that the power supply shelves are correctly earthed see section 2.7 for

details.

• The Power Supply Units are sealed and do not contain any serviceable items

• Power supply shelves are heavy so it is advised that two people are needed to

support the weight of the power supply shelves during installation.

• To prevent damage, power supply shelves should not be mounted using just the

front ears, and should have support at the rear of the shelves.

Page 11

Sirius 840 Installation Manual www.s-a-m.com Warnings and Precautions

Issue 2 Rev 3 Page 11 © 2016 SAM

2.7 Earth Cables

2.7.1 Important Protective Earth Information

Due to the high leakage current, ensure that all of the power supply shelves are grounded to

the protective earth. Earth studs are provided on the rear of each power supply shelf for this

purpose. These studs have M6 size nuts, and are suitable to take an eyelet crimp.

2.7.2 Important Functional Earth Information

Up to two earth cables (636027) are supplied with the Sirius 840 depending on how many

power supply shelves are fitted. One should be fitte d fr om eac h powe r sup p l y she lf to th e

Sirius 840 router frame, this is called a Functional Earth.

Fig 1. Power Supply Shelf Rear Panel

Functional

Earth Point, see

section 2.7.2

PowerCon AC Input

Connectors x 4

48Vdc power

connectors

Protective Earth

Point, see

section 2.7.1

25 Way D Type

Alarms Connector

Note:

• The Protective earth is indicated on the power supply shelf by this symbol:

(located on the right side of the power supply shelf, see Fig 1.).

• Protective Earthing is a conductor in the building installation wirin g, or in the po wer

supply cord, connecting a main protective earthing terminal to an ear th poin t in the

building installation.

PROTECTIVE EARTH

• The building installation must provide a means for connection to the protective

earth and the equipment must be connected to that means.

• A service person must check that the socket outlets that the equipment is to be

powered from provide a connection to the protective e arth. If not the service person

must arrange for the installation of the protective earth wire in the building.

Warning

High leakage current; the Protective Earth connection is essential before connecting the

supply.

Note:

• The Functional Earth on the power supply shelf is indicated by this symbol:

(located on the left side of the power supply shelf, see Fig 1.).

• Functional Earthing is the earthing of a point on the equipment or system, which is

necessary for purposes other than safety.

Warning

The Functional Earth cable from the power supply shelf to the Sirius frame must be fitted.

Page 12

Sirius 840 Installation Manual www.s-a-m.com Warnings and Precautions

Issue 2 Rev 3 Page 12 © 2016 SAM

2.8 Safety Standards

This equipment complies with the following standards:

EN60950-1 2006

Safety of information Technology Equipment Including Electrical Business Equipment.

UL1419 (3rd Edition) - UL File E193966

Standard for Safety - Professional Video and Audio equipment

EMC Standards

This unit conforms to the following standards:

EN55103-1:1996 (Environment E4)

Electromagnetic Compatibility, Product family standard for audio, video, audio-visual and

entertainment lighting control apparatus for professional use. Part 1. Emission

EN55103-2:1996 (Environment E2)

Electromagnetic Compatibility, Product family standard for audio, video, audio-visual and

entertainment lighting control apparatus for professional use. Part 2. Immunity

Federal Communications Commission Rules, 47 CFR: Part 15, Subpart B (Class A)

EMC Performance of Cables and Connectors

SAM products are designed to meet or exceed the req uirement s of the appro priate Europe an

EMC standards. In order to achieve this performance in real installations it is essential to use

cables and connectors with good EMC characteristics.

All signal connections (including remote control connections) shall be made with screened

cables terminated in connectors having a metal shell. The cable screen shall have a

large-area contact with the metal shell.

COAXIAL CABLES

Coaxial cables connections (particularly serial digital video connections) shall be made with

high-quality double-screened coaxial cables such as Belden 1694A or Belden 1505A.

D-TYPE CONNECTORS

D-type connectors shall have metal shells making good RF contact with the cable screen.

Connectors having “dimples” which improve the contact between the plug and socket shells,

are recommended.

Page 13

Sirius 840 Installation Manual www.s-a-m.com Prerequisites

Issue 2 Rev 3 Page 13 © 2016 SAM

3. Prerequisites

This chapter describes the electrical and space requirements for the Sirius system.

3.1 Size Requirements

Make sure that sufficient space is available for the Sirius 840. For ventilation purposes, there

must be an additional 50 mm (2 inch) gap on the left and right sides.

The full height of the Sirius 840 is 1198 mm (47.17 inches). Allow an additional 200 mm

(8 inches) behind the unit for power, control and signal cables.

3.1.1 Sirius 840 Dimensions

Fig 2. Sirius 840 Frame Dimensions

Dimensions are for a full size system (without the power supply shelves)

Dimensions are in millimeters (inches).

Page 14

Sirius 840 Installation Manual www.s-a-m.com Prerequisites

Issue 2 Rev 3 Page 14 © 2016 SAM

3.1.2 Power Supply Shelf

The power supply shelf is a separate 2U assembly; Power Supply Shelves are rack

mountable and can be placed above, below or remote from the Sirius Frame.

You must allow at least 250 mm (10 Inches) at the rear of the shelf for cables and con nectors.

Fig 3. Power Supply Shelf Dimensions

All dimensions are in

millimeters (inches).

Page 15

Sirius 840 Installation Manual www.s-a-m.com Prerequisites

Issue 2 Rev 3 Page 15 © 2016 SAM

3.2 Weights

3.2.1 Packed Shipping Crate

Shipping Crate: between 300 kg (660 lbs) and 325 kg (716 lbs) when full (depending on

modules fitted).

3.2.2 Sirius 840 Frame

Sirius 840: between 150 kg (330 lbs) and 175 kg (386 lbs) typical full frame (without

packaging and depending on modules fitted).

3.2.3 Power Supply Shelf

Power Supply Shelf: 24 kg (53 lbs) typical (without packaging).

The crate containing the Sirius 840 is extremely heavy. A fully populated 27RU size system

with two power supply shelves and cabling weighs between 300 kg (660 lbs) and 325 kg

(716 lbs). When lifting use the correct local Health and Safety lifting guidelines.

The Sirius 840 is extremely heavy. A fully populated 27RU size system weighs between

150 kg (330 lbs) and 175 kg (386 lbs). When lifting use the co rrect local Health and Safety

lifting guidelines.

The power supply shelf weighs 24 kg (53lb). When lifting use the correct local Health and

Safety lifting guidelines.

Page 16

Sirius 840 Installation Manual www.s-a-m.com Prerequisites

Issue 2 Rev 3 Page 16 © 2016 SAM

3.3 Ventilation

A fully populated Sirius 840 is ventilated by groups of fan modules mounted in the front and

rear of the router . The ven ts in the front, sides and rear m ust not be obstructed and sho uld be

periodically cleaned and kept free from the build-up of dust. All the fan modules are monitored

for failure.

Air is pulled in through the ventilation slots in the front door and circulated through the router,

passing over the modules, and then expelled by the rear fans, air is also expelled o ut at points

on each side of the frame, where the crosspoint modules are situated.

The power supply shelves have their own integral cooling system.

• Ensure the flow of air through the vents is not restricted

• Do not obstruct the air vents situated on both sides of the frame, and allow a

minimum of 50 mm (2 inches) clearance to allow air flow. The air that is exhausted

from the sides must be able to flow past the rear of the router frame without being

obstructed. This also applies to the Power Supply Shelves.

• The fan assemblies should be placed back into the closed position as soon as

possible after opening, as this ensures correct ventilation of the frame. Failure to

do this will result in failure.

• In practice the maximum time that a fan assembly can be left open will depend on a

number of factors such as; ambient temperature, frame loading, crosspoint

routings, etc. To ensure correct operation under all conditions the fan assemblies

should be left open for no more than 4 minutes at a time.

Fig 4. Vent ila tio n

Page 17

Sirius 840 Installation Manual www.s-a-m.com Prerequisites

Issue 2 Rev 3 Page 17 © 2016 SAM

3.4 Electrical Requirements

3.4.1 Important Protective Earth Information

See section 2.7.1 for full details of the Protective Earthing requirements.

3.4.2 Cable Management

See Section 2.5 for details on cable management.

3.4.3 Mains Power Cables

The maximum current drawn by each power supply unit is dependant on the local mains

voltage, the configuration of the router and the number of power supply shelves installed.

Each AC feed must have an Isolating Switch or Circuit Breaker rated at 16 A type B to

IEC 60898-1. The isolating switch/circuit breaker must be Type B (t rips at 3 to 5 times full load

current) so that it is capable of handling a maximum inrush current of 50 A. Installation must

be in accordance with Local and National electrical codes.

Any mains cables used must be rated above the rating of the circuit breaker.

See section 7.3 for details on wiring the PowerCon connectors supplied with the Sirius 840

router.

3.4.4 DC Power Cables

The 48 V DC cables are supplied by SAM and can be ordered as either 2.5 metre cables or

8 metre cables.

PROTECTIVE EARTH

1. The building installation must provide a means for connection to the protective

earth. The equipment must be connected to that means.

2. A service person must check that the socket outlets that the equipment is to be

powered from provide a connection to the protective e arth. If not the service person

must arrange for the installation of the protective earth wire in the building.

• Installation must be in accordance with Local and National electrical codes. This

product is pluggable type B (IEC 60309).

• Each AC feed must be capable of supplying a minimum of 16 A at the supply

voltage in use (110 V AC or 220 V AC).

Important:

Sirius 840 has up to eight “PowerCon” AC power connectors for the power supply shelves

(four per power supply shelf). It is the responsibility of the customer to connect these to the

mains supply.

Note:

Ensure all DC power cables are fitted before powering up the Sirius 840.

Note:

All of the 48V DC cables from the power supply shelves to the Sirius 840 router must be

the same length to ensure that the voltage drop along each cable is the same at high

currents.

Page 18

Sirius 840 Installation Manual www.s-a-m.com Prerequisites

Issue 2 Rev 3 Page 18 © 2016 SAM

3.4.5 Power Supply Redundancy

To ensure full dual redundancy, half of the power supplies should be powered from a separate

power source to the other power supplies. Under normal operating conditions with dual power

sources, each power supply unit runs at less than 50% loading.

The number of power supply shelves should be selected based on the mains supply

operating voltage and router configuration, see Table 1. for information.

To reduce the risk of electric shock, plug each power supply shelf into separate branch

circuits employing separate service grounds.

Router Configuration

Mains Supply

(V AC)

Number of Power Supply

Shelves and Units

Required for Redundancy

Typical router configuration of less than

36 video AHP modules

(5919/5949/5915/5925) fitted in the router

220 - 240 VAC

Nominal

1 Shelf

4 Power Supply Units

If 36 or more video AHP modules

(5919/5949/5915/5925) are fitted in the router

220 - 240 VAC

Nominal

2 Shelves

8 Power Supply Units

All router configurations 100 - 120 VAC

Nominal

2 Shelves

8 Power Supply Units

Table 1. Sirius 840 Power Supply Redundancy

Important:

• If the router is expanded from its initial configuration check Table 1. to see if extra

power supply shelves are required.

• It is the responsibility of the Sirius 840 installer to ensure any AC power

requirements are met.

Page 19

Sirius 840 Installation Manual www.s-a-m.com Unpacking the Sirius 840

Issue 2 Rev 3 Page 19 © 2016 SAM

4. Unpacking the Sirius 840

4.1 Unpacking

The Sirius 840, power supply shelf/shelves and cables are supplied in a single wooden crate.

The crate is delivered in the horizontal position with the crate lid facing upwards. The top end

of the crate has two rings that can be used for handling the crate, see Fig 5.

1. With the crate in its horizontal position re move all of the bolts a nd lift off the lid, see Fig

5. Keep the bolts they will be needed again.

2. Please check that the following items are included in the crate with the Sirius 840. If

any items are missing please contact your SAM representative immediately:

• This Installation & Quick Start Manual (also found on the Product CD)

• Sirius 840 router frame (6088) containing all configured modules

• Power Supply Shelf: one or two Power Supply Shelves, each containing four

Power Supply Units depending on customer specification

• One or two Alarm cables 2.5 metres (98 inches) or 8 metres (315 inches) in

length - depending on customer specifications (one cable supplied with each

power supply shelf)

• Four or eight PowerCon connectors for the power supply shelves depending on

customer specifications (four connectors supplied with each power supply shelf)

• Two or four DC Power cables 2.5 metres (98 inches) or 8 me tres (315 inches) in

length - depending on customer specification (two cables supplied with each

power supply shelf)

• One or two Earth Cables depending on customer specification. Functional Earth

for connecting to the Sirius frame (one cable supplied with each power supply

shelf)

• The crate containing the Sirius 840 is extremely heavy. A fully populated 27RU size

system with two power supply shelves and cabling weighs between 300 kg

(660 lbs) and 325 kg (716 lbs). When lifting the crate use the correct local Health

and Safety lifting guidelines.

• Each Power Supply Shelf weighs 24 kg (53lb). When lifting use the correct local

Health and Safety lifting guidelines.

• This is only a guide to unpacking the Sirius 840, and procedures may need to

change depending on the location of the Sirius 840.

Fig 5. Unpacking

Handling rings on

top end of crate

Remove all of the

bolts and lift off

the lid

Page 20

Sirius 840 Installation Manual www.s-a-m.com Unpacking the Sirius 840

Issue 2 Rev 3 Page 20 © 2016 SAM

• Software DVD: Workbench

• Software CD: PC Touch-screen Drivers

3. Carefully remove everything except the router from the crate and put them to one side

for later use.

4. Fix the lid back on the crate using the bolts that you previously removed.

5. Carefully raise the crate from the top end so that is in the upright position, see Fig 6.

Use a forklift and a strap attached to the handling rings on the top of the crate, if

possible, (see Fig 5.) to raise the crate into an upright position.

6. Once the crate is in the upright position remove the bolts from the lid and lift the lid off

of the crate.

7. Remove the packing material on top of the Sirius 840.

8. The Sirius 840 frame is bolted to a “dolly” with wheels. The front wheels have toe

brakes to stop the dolly from rolling out of the crate unexpectedly.

9. Hold the frame to stop it from falling forwards.

10. Unlock the brake on each of the front dolly wheels and carefully withdraw the frame

from the crate. It is best to use a forklift to lift the dolly and Sirius 840 frame out of the

crate.

1 1. When the frame and dolly are out of the crate, move the Sirius 840 frame to the bay

where it is going to be installed.

12. Once the Sirius 840 is in position apply the toe brak es on the dolly . See sectio n 5.1 for

instructions on rack mounting the Sirius 840.

Fig 6. Raise the Crate to the Upright Position

Lift from under the dolly rather than the und erside of the Sirius 840 frame. Failure to do this

could cause the metalwork on the underside of the Sirius 840 frame to bend.

Raise the crate carefully

onto its bottom end

Remove all of the bolts

to lift off the lid

Page 21

Sirius 840 Installation Manual www.s-a-m.com Installation

Issue 2 Rev 3 Page 21 © 2016 SAM

5. Installation

5.1 Installing into a 19" Rack

The Sirius 840 has rack mount ears, for mounting into a 19" rack. Place the frame on a

suitably specified and installed rack shelf for extra stability.

1. Move the Sirius 840 so that the frame rear lines up with the fron t of th e rack it w ill be

mounted in and apply the toe brakes on the dolly.

2. Undo the three 17mm bolts on one side of th e dolly to release the wooden up right and

repeat for the other side.

3. The Sirius 840 frame will be left standing on the dolly and is ready to be slid into the

19” rack.

4. Once the Sirius 840 has been slid into the rack put the dolly, the wooden uprights and

the bolts in the packing crate in case they are needed in the future.

5. The Sirius 840 has a single large door, that provides access to the rack mount

mounting points. The door must be opened as far as p ossible on its hinges to expose

the rack mount ears (see section 5.1.1).

Sirius 840 is extremely heavy between 150 kg (330 lbs) and 175 kg (386 lbs) for a full

frame (without packaging and depending on modules fitted). When lifting the Sirius 840

into a 19" rack use the correct local Health and Safety lifting guidelines.

Fig 7. Remove the Dolly Uprights

3 x 17 mm bolts both

sides of the dolly

Page 22

Sirius 840 Installation Manual www.s-a-m.com Installation

Issue 2 Rev 3 Page 22 © 2016 SAM

5.1.1 Opening the Door

The door is hinged on the left hand side so that you can access the inside of the frame without

removing the door.

To remove a latch guard and open the door:

1. Un-screw the captive screw on the left side of the guard, see Fig 8.

2. Take hold of the guard by the captive screw and carefully swing open the guard to the

right until the guard is at 90° to the door, the guard can then be pulled outwards and

away from the door. When re-fitting the guards, take care when inserting the two

prongs on the guard back into the location holes in the door.

3. Turn the two door latches counter clockwise to release the door catches.

4. Take hold of the both door handles, carefully pull the left handle outwards slightly and

then move the door to the left, to free the door fro m the catches in the ri ght side of the

frame.

5. Open the door to the left.

Note:

The two door latches have guards fitted which prevent them from turning. Remove the

guards before attempting to open the door.

Fig 8. Removing a Latch Guard

Fig 9. Open the Door

Page 23

Sirius 840 Installation Manual www.s-a-m.com Installation

Issue 2 Rev 3 Page 23 © 2016 SAM

5.1.2 Securing the Sirius 840 in a 19” Rack

1. The rack mounting ears will be exposed once the Sirius 840 door is fully open,

see Fig 10.

2. To secure the frame to the rack, use the correct rack mount screws or bolts. For

stability and rigidity, secure the frame at all the rack mounting-points.

If you experience any difficulties installing the Sirius frame, please contact SAM Customer

Support (see section 1.1 for contact details).

Fig 10. Installing into a 19" Rack

Air for ventilation is drawn through the front door and exhausted through the rear of the

frame, and out of each side, this must be considered when mounting the unit into the rack.

See section 3.3 for more details on ventilation.

To secure the

frame to the rack,

use the correct

rack mount screws

or bolts.

Page 24

Sirius 840 Installation Manual www.s-a-m.com Installation

Issue 2 Rev 3 Page 24 © 2016 SAM

5.2 Mounting the Power Supply Shelf into a 19" Rack

The Power Supply Shelf can be placed above, below or remote from the Sirius Frame. The

power supply shelf requires a 2RU space within a rack system.

1. Place the unit on a suitably specified and installed rack shelf.

2. Use the correct rack mount screws or bolts to secure the power supply shelf to the

rack.

• The Power Supply Shelf weighs 24 kg (53lb). When lifting use the correct local

Health and Safety lifting guidelines.

• Do not obstruct the air vents situated on both sides of the power supply shelf, and

allow a minimum of 50 mm (2 inches) clearance to allow air flow. The air that is

exhausted from the sides must be able to flow past the rear of the rack without

being obstructed.

Fig 11. Mounting the Power Supply Shelf into a 19" Rack

Page 25

Sirius 840 Installation Manual www.s-a-m.com Rear Connectors

Issue 2 Rev 3 Page 25 © 2016 SAM

6. Rear Connectors

This section shows the rear connectors on the Sirius 840 router.

6.1 Rear of Sirius 840 Frame

Fig 12. shows a fully populated Sirius 840 frame with BNC Inputs and Outputs.

See Section 2.5 for details on cable management.

Cables connected to the router must be fitted with adequate vertical and horizontal strain

relief to avoid twisting of the rear panels causing d amage to the r outer connectors and loss

of electrical/signal connection to the router.

Fig 12. Sirius 840 frame with BNC Inputs and Outputs

Multiviewer

48 V DC Power Connectors

Inputs, see the User

Manual for details

Control Panel

see Fig 14.

Outputs, see the User

Manual for details

Pre-Processing

Input/Output, see the

User Manual for details

Alarm Panel,

see Fig 13.

Fans

Fans

Not Used

Page 26

Sirius 840 Installation Manual www.s-a-m.com Rear Connectors

Issue 2 Rev 3 Page 26 © 2016 SAM

6.2 Alarm Rear Panel

Fig 13.shows the Alarm Rear Panel.

Fig 13. Alarm Rear Panel Connections

Connector Function

4 x RJ45 Connectors Not Used

Alarms 25-Way D-Type socket - Alarm Outputs: Alarm outputs switch in

the event of the following failures: Fan, Controller, PSU. For

details on the output that switches for each failure see the

Sirius 800 User Manual.

For example the outputs can be used for warning lights in a panel

or monitoring by an external control system.

PSU Status B

PSU Status A

25 Way D-Type socket x 2 - PSU Alarm Inputs. Collects alarm

signals from the PSU(s), using the supplied cable(s)

Frame ID Rotary Switch - Frame identification switch

Set to position 3

Door Ethernet RJ45 Ethernet - Used to connect the door PC to an external

network

Door Fuse &

Spare Fuse

5 A Anti-Surge, Ceramic fuse (5 mm x 20 mm)

Table 2. 1288 Alarm Rear Panel Connections

4 x RJ45 Connectors

Not Used

Alarms

PSU Status B

PSU Status A

Door Ethernet

Door Fuse

Spare Fuse

Frame ID - Rotary

Switch Set to Position 3

Page 27

Sirius 840 Installation Manual www.s-a-m.com Rear Connectors

Issue 2 Rev 3 Page 27 © 2016 SAM

6.3 Control Rear Panel

Fig 14.shows the Control Rear Panel.

Fig 14. Sirius 840 Control Rear Panel

Connector Function

Unbal BNC - AES reference, 75 termination

BAL + LTC 9 Pin D-Type socket - AES reference 110 balanced termination

and LTC input termination

Note: Physically only one AES reference (balanced or unbalanced) should be connected.

Connecting both will stop the audio router module(s) functioning correctly.

Ethernet A, B RJ45 x 2 - Ethernet for controller A and B.

If two Nucleus controllers are fitted both the Ethernet A and

Ethernet B ports must be connected to the network.

Video Ref BNC x 8 - Video reference (4 pairs, each with passive loop

through) B+B, and Tri-level

Note: No internal termination.

RS485 1 (COM 3)

to 4 (COM 6)

9 Pin D-Type socket x 4 - Serial Control, these correspond to

ports; COM 3 to COM 6 in Workbench

Ethernet Not Used

EXP Not Used

Monitor Out 1 - 4 BNC x 4 - Supports 3G, SD, HD video and AES audio output

monitoring (see the Sirius 800 User manual for configuration

requirements)

Table 3. Control Rear Panel

Unbal

BAL + LTC

Ethernet

Video Ref

Ethernet

Not Used

EXP

Not Used

Monitor Outputs

AES Ref

A

B

1

2

3

4

1 (COM 3)

2 (COM 4)

3 (COM 5)

4 (COM 6)

4

3

2

1

RS485 Serial

Ports

Page 28

Sirius 840 Installation Manual www.s-a-m.com Rear Connectors

Issue 2 Rev 3 Page 28 © 2016 SAM

Page 29

Sirius 840 Installation Manual www.s-a-m.com Cabling

Issue 2 Rev 3 Page 29 © 2016 SAM

7. Cabling

7.1 Earthing

For full details on the earthing requirements please see section 2.7.

7.2 Cable Management

See Section 2.5 for details on cable management.

7.3 Mains Power Cables

For full details on the mains cable requirements please see section 3.4.3.

PowerCon Wiring:

• Cable outside diameter: 17 mm (general range: 8.0 to 20.0 mm)

• Cable Connector: Screw-type terminals for stranded wires up to 6.0 mm

2

(AWG 10)

Cables connected to the router must be fitted with adequate vertical and horizontal strain

relief to avoid twisting of the rear panels causing d amage to the r outer connectors and loss

of electrical/signal connection to the router.

1. The following PowerCon connector wiring instructions MUST be followed.

2. The AC supply feed MUST be isolated before connecting or disconnecting the

“PowerCon” connectors. This is required because the “PowerCon” connectors are

not suitable for isolating current.

3. The mains conductor colors for Live, Neutral and Earth in Fig 15. are only

examples and may not match the colors used in your geographical location.

Fig 15. Cable Connector Assembly instructions

Page 30

Sirius 840 Installation Manual www.s-a-m.com Cabling

Issue 2 Rev 3 Page 30 © 2016 SAM

Fig 16. Cable Connector Assembly instructions (continued)

Page 31

Sirius 840 Installation Manual www.s-a-m.com Cabling

Issue 2 Rev 3 Page 31 © 2016 SAM

7.4 Ethernet Cabling (Optional)

The router can be connected to a local network so that it can be monitored and configured

from one or more remote Workbench comput er s. Ethernet cables are used to connect the

Door PC and the router controllers to the network.

Connect the Nucleus router control module(s) and router Door PC to a network switch on the

same network as the computer(s) that Workbench is being installed on. For Workbench

installation details see section 11..

If the router control module(s) are shipped loaded with the sample/default database the

default controller and Door PC IP addresses are as listed below.

If the IP addresses don’t suit the host network the network switch and the computer running

Workbench should form an isolated network until the IP addresses are changed to suit the

host network. If the IP Addresses need to be changed see section 7.4.1.

Sirius 840 Default IP Addresses:

- Controller A - 172.31.9.205

- Controller B - 172.31.9.206

- Door PC - 172.31.9.207

Note:

• If the router is shipped with a custom database the IP addresses may be different

from those listed below. See section 7.4.1 for information on how to check or edit

the IP addresses.

• By default the Nucleus2 2463 router control module will automatically negotiate its

communication speed with the network switch. If the network switch is set to force

a specific speed the controller must be set to match the network switch setting, see

the Sirius 800 User manual for details on changing this setting 10Base-T or

100Base-T only (1000Base-T is not supported).

Fig 17. Ethernet Connections

Ethernet Hub

Door Ethernet

Port

Ethernet A/B Ports

Page 32

Sirius 840 Installation Manual www.s-a-m.com Cabling

Issue 2 Rev 3 Page 32 © 2016 SAM

7.4.1 Changing IP Addresses

• If the controller IP addresses need to be changed, see the Sirius 800 User manu al for

details.

• The Door PC IP address is changed via Windows XP on the Door PC using Windows

remote desktop or by connecting a USB mouse and Keyboard locally. See the Door

PC Maintenance section of the Sirius 800 Maintenance & Upgrade manual for login

and connection details.

7.5 External Panel Cabling (Optional)

SAM external panels can be connected to the router by using RS485 cables and the

Multidrop Communications protocol (SW-P-06).

The Sirius 840 is supplied with a default database. The default database configures the

RS485 3 (COM 5) connector on the rear of the router to use the Multidrop Communications

protocol (SW-P-06). RS485 3 (COM 5) supports a variety of BPX and XY control panels (see

Table 9. on page 50 for details).

Fig 18. shows the RS485 connector pin-outs for Multi-drop cables. See section 7.5.2 for

details on connecting an external panel to the router and section 10.6 for operating the

panels.

7.5.1 RS485 Control Pin-outs

Multi-drop RS485 Pin to Pin Connections

Pins

Router RS485

Connector

External Panel

RS485

Connector

1 Chassis Chassis

2 Rx- Tx3 Tx+ Rx+

40V 0V

5N/C N/C

60V 0V

7 Rx+ Tx+

8 Tx- Rx9 Chassis Chassis

Fig 18. RS485 Connector Pin-outs

1

9

Page 33

Sirius 840 Installation Manual www.s-a-m.com Cabling

Issue 2 Rev 3 Page 33 © 2016 SAM

7.5.2 Example Connecting a 6026776 2U Control Panel to the Router

This example assumes the following:

• The default router database is loaded

• A 6026776 (mimicking a 6276) control panel is available

• Only one control panel is connected to the router

• The control panel will be connected to RS485 3 (COM 5) of the router usin g an RS485

cable in accordance with the default database (see Fig 18. on page 32 for cable

connections)

• The control panel will be set to address 1 so that any source and any destination can

be dialed up in accordance with the default database (see Table 9.)

Other control panel types can be connected to the same router using either RS485 Multidrop

or Ethernet connections. For details see the control panel user manuals.

For details of control panel rear see Fig 19.

1. Configure the control panel to be connected to a Nucleus controller:

DIP Switch 6 = Down

2. Select the communications type to RS485:

DIP Switch 10 = Up

3. Connect the multidrop pin to pin RS485 cable to either one of the RS485 connectors

on the rear of the control panel and to RS485 3 (COM 5) of the router.

As this is the only control panel on the RS485 connection terminate the link:

DIP Switches 1 & 2 = Down

4. Set the control panel address to 1:

Rotary Hex Switch 1 = 1 (Must match database configuration)

5. Rotary Hex Switch 2 sets the brightness of the control panel keys:

Rotary Hex Switch 2 = 0 (minimum brightness)

Rotary Hex Switch 2 = 7 (maximum brightness)

Fig 19. 6026776 2U Control Panel Rear

1) Control Panel Mode

DIP Switch 6 = Down (Nucleus)

2) Communications Config

DIP Switch 10 = Up (RS485)

3) Termination configuration if this is the final panel on an RS485 chain

DIP Switches 1 & 2 = Down (Terminated)

4) Control Panel Address (see Table 9.)

For this example set to Address 1

Rotary Hex Switch 1 = 1

Note: Must match database configuration.

5) IEC Power

Socket

Page 34

Sirius 840 Installation Manual www.s-a-m.com Cabling

Issue 2 Rev 3 Page 34 © 2016 SAM

7.5.2.1 6276 Control Panel Rear Panel

If you are connecting the router to an older 6276 control panel the procedure is similar to the

6026776. The 6276 rear panel is different to the 6026776 control panel (for the correct

connections and configuration see Fig 20.)

For information on operating the 6276 control panel see section 10.6.1.1.

Fig 20. 6276 2U Contro l Panel Rear

1) Control Panel Mode

DIP Switch 6 = Down (Nucleus)

2) Communications Config

DIP Switch 7 = Down (Multidrop)

4) Control Panel Address (see Table 9.)

For this example set to Address 1

DIP Switch 8 = Up

Rotary Hex Switch = 1

Note: Must match database configuration.

5) IEC Power

Socket

3) Connect RS485 to IN

Page 35

Sirius 840 Installation Manual www.s-a-m.com Power Supplies

Issue 2 Rev 3 Page 35 © 2016 SAM

8. Power Supplies

8.1 Power Supply Shelf

A Sirius 800 Power Supply Shelf is a separate 2RU assembly which contains up to four

sealed power supply units (PSU’s), see Fig 21. The Power Sup ply Shelf is ra ck-mountable

and can be placed above, below or remote from the Sirius frame. The PSU’s are

self-contained and do not contain any serviceable components.

Each PSU requires an individual AC power input connection, i.e. up to four power cables per

2RU shelf.

The current drawn by each PSU is dependent on the:

• Local mains supply voltage.

• Configuration of the router.

• Number of PSU’s installed.

Each individual PSU has auto-sensing inputs.

Each individual PSU is rated:

• 100-240 V AC, 50-60 Hz, 25-15 A.

• Routers powered from 100-120 V AC nominal mains supply

will draw 25 A maximum per PSU.

• Routers powered from 220-240 V AC nominal

will draw 15 A maximum per PSU.

Caution

• Ensure that the power supply shelves are correctly earthed see section 2.7 for

details.

• The power supply units contain dangerous high voltages and are NOT

user-serviceable.

• The DC leads connecting the power supply shelf to the router are capable of

supplying very high electric current. Do not short circuit.

• The power supply shelf has a protective metal mesh cover over the front of the

individual power supply units, this should only be removed by a qualified engineer.

See the Sirius 800 Maintenance & Upgrade manual for details on replacin g power

supply units.

• There is one spare DC connector on each power supply shelf and up to four on the

Sirius 840 router frame. Do not remove the covers of the unused connectors.

Fig 21. Front View of the Power Supply Shelf

Power Supply

Shelf with

protective Cover

Individual Power

Supply Units (with

protective mesh

cover removed)

Page 36

Sirius 840 Installation Manual www.s-a-m.com Power Supplies

Issue 2 Rev 3 Page 36 © 2016 SAM

In all router configurations, a non-redundan t Sirius 80 0 router uses o ne or more power supply

shelves fitted with multiple PSU’s. A failure of any one of these PSU’s is considered a failure

of the power feed to the router.

For example:

A Sirius 840 for 220-240 V AC mains supply operation is supplied with:

• One shelf containing four PSU’s for power feed A.

• Plus one shelf fitted with four PSU’s for power feed B.

A failure of any PSU connected to power feed A is considered a failure of power feed A.

In this case, operation of the router on power feed A with three PSU’s is not guaranteed.

PSU’s in a power supply shelf will actively power-share, equalizing the load on each PSU.

If one or more PSU’s in shelf A fail, each remaining PSU can draw up to 25 A from the AC

supply.

At higher AC supply voltages (220-240 V AC), in the event of one PSU failure, the current

drawn by the remaining PSU’s may exceed the 15 A rated operating current. This is outside

normal operating conditions for this AC supply voltage.

Depending on the installation, circuit breakers on the remaining PSU’s may trip. In this case,

power shelf B is required for redundant operation.

Installing the PSU’s with 25 A rated breakers and cabling means that in the event of one PSU

failing, other PSU’s will not draw current beyond the breaker rating and will continue to

operate. This can offer an additional level of PSU resilience beyond normal 1+1 redundancy.

Installation should take these factors into account. Installation should be done in accordance

with local and national electrical codes. This product is pluggable type B (IEC 60309).

The power supply shelf outputs 48 V DC and the power supply units current-share on the

output. Each power supply shelf has three 48 V DC connectors at the rear but only two are

used (see Fig 22.). The power supply shelf can generate alarm signals to indicate presence

and output status.

• Do not obstruct the air vents situated on both sides of the power supply shelf, and

allow a minimum of 50 mm (2 inches) clearance to allow air flow. The air that is

exhausted from the sides must be able to flow past the rear of the power supply

shelf without being obstructed.

• The power supply unit is heavy weighing 24 Kg (53 lbs). When lifting use the

correct local Health and Safety lifting guidelines.

Fig 22. Power Supply Shelf Rear Panel

Functional

Earth Point, see

section 2.7.2

PowerCon AC Input

Connectors x 4

48 V DC power

connectors

Protective Earth

Point, see

section 2.7.1

25-Way D Type

Alarms Connector

Page 37

Sirius 840 Installation Manual www.s-a-m.com Power Supplies

Issue 2 Rev 3 Page 37 © 2016 SAM

8.2 Power Distribution

The power supply shelves provide 48 V DC for distribution to the entire frame. All router

modules (inside the frame) have on-board DC to DC converters to locally supply the required

voltages. A single Green LED on the front edge of each module indicates that all is working

correctly. This arrangement provides simple power distribution, as well as effective power

de-coupling between modules.

8.3 Power and Alarm Connections to the Sirius 840 Frame

The Sirius 840 is powered by up to two 2RU power supply Shelves depending on the router

configuration and mains voltage (see section 3.4.5). The power supply shelves each have

four PowerCon AC input connectors (see Fig 22.).

Each power supply shelf has three 48 V DC power connectors, only two connectors from

each power supply shelf are used to power the Sirius 840. The cover on the unused 48 V DC

socket must be left on the power shelf.

Up to two power supply alarm cables (636028) are sup plied with the Sir ius 840 d ependin g on

the number of power supply shelves fitted. Connect each power supply shelf to the router

alarm rear panel using the 25-Way connector. The alarm signals send a warning to the Door

PC, and via external GPIs or an external Workbench system if there is a power supply failure.

The power supply alarm cables are supplied by SAM and can be ordered as either 2.5 metre

cables or 8 metre cables.

Important:

The Fan Control modules provide power to all fan modules. At least one Fan Control

module must be present or the fans will stop, which can cause the Sirius 840 to quickly

overheat. To prevent the fans from stopping, there are two Fan Control modules.

• The power supply shelves MUST be isolated from the AC supply by means of the

external distribution switch/circuit breaker before connecting or di sconnecting the

48 V DC power cables. This is required because the “PowerCon” connectors are

not suitable for isolating current.

• This equipment has more than one power source, to reduce risk of electric shock

isolate all power supplies before servicing.

• High leakage current, Protective Earth connection essential befor e connecting

supply (see section 2.7.1).

Page 38

Sirius 840 Installation Manual www.s-a-m.com Power Supplies

Issue 2 Rev 3 Page 38 © 2016 SAM

8.3.1 48 V DC Power Out Cables

See sections 8.3.2, 8.3.3 or 8.3.4 (depending on the numbe r of power supply shelves used)

for the 48 V DC connection details. The 48 V DC cables are supplied by SAM and can be

ordered as either 2.5 metre cables or 8 metre cables.

8.3.2 Single Power Shelf Connections

This connection method is suitable for a single power shelf fitted with four power supply units.

Two separate mains supplies should be used to maintain redundancy in the event of one

supply failing.

Important:

• All of the 48 V DC cables from the power supply shelves to the Sirius 840 router

must be the same length to ensure that the voltage drop along each cable is the

same at high currents.

• The power supply shelves MUST be isolated from the AC supply by means of the

external distribution switch/circuit breaker before connecting or di sconnecting the

48 V DC power cables.

Fig 23. Power and Alarm Connections

There is one spare 48 V DC connector on the powe r supply shelf and four on the Sirius 840

router frame. Do not remove the covers of the unused connectors.

Note:

• The three 48 V DC power connectors on the power supply shelf are common. Any

two of the three sockets on th e power sup ply shelf can be use d to po wer th e rou ter.

• The six 48 V DC power sockets on the router frame are common. Any two of the

six sockets on the rear of the router frame can be used to power the router.

48 VDC Terminals

Functional Earth Stud

48 V DC Power Connectors

25-Way D-Type

Alarm Connection

Functional

Earth

PSU Alarm

Connector

Protective Earth

AC Power

Cables with

PowerCon

Connectors

Mains

Supply A

Mains

Supply B

Page 39

Sirius 840 Installation Manual www.s-a-m.com Power Supplies

Issue 2 Rev 3 Page 39 © 2016 SAM

8.3.3 Dual Power Shelf Connections

This connection method is suitable for systems with two power shelves and allows an

individual power supply shelf to be isolated if required (se e the Siriu s 800 Ma in te na nc e &

Upgrade Manual for details).

Two separate mains supplies should be used to maintain redundancy in the event of one

supply failing.

Fig 24. Power and Alarm Connections

There is one spare 48 V DC connector on each power supply shelf and two on the Sirius

840 router frame. Do not remove the covers of the unused connectors.

Note:

• The three 48 V DC power connectors on each power supply shelf are common.

Any two of the three sockets on each power supply shelf can be used to power the

router.

• The six 48 V DC power sockets on the router frame are common. Any four of the

six sockets on the rear of the router frame (two from each power supply shelf) can

be used to power the router.

48 V DC Connectors

Functional Earth Stud

48 V DC Power Connectors

25-Way D-Type

Alarm Connection

Functional

Earth

PSU Alarm

Connectors

Protective Earth

AC Power

Cables with

PowerCon

Connectors

Mains

Supply B

Mains

Supply A

Page 40

Sirius 840 Installation Manual www.s-a-m.com Power Supplies

Issue 2 Rev 3 Page 40 © 2016 SAM

8.3.4 Alternative Dual Power Shelf Connections

This connection method is suitable for systems with two power shelves and is often used

when a system is expanded from one power supply shelf to two power supply shelves.

Two separate mains supplies should be used to maintain redundancy in the event of one

supply failing.

Note:

An individual power supply shelf cannot be isolated wh en connected in this co nfiguration. If

you need to be able to isolate an individual power supply shelf the mains supplies should

be connected as described in section 8.3.3.

Fig 25. Power and Alarm Connections

There is one spare 48 V DC connector on each power supply shelf and two on the Sirius

840 router frame. Do not remove the covers of the unused connectors.

Note:

• The three 48 V DC power connectors on each power supply shelf are common.

Any two of the three sockets on each power supply shelf can be used to power the

router.

• The six 48 V DC power sockets on the router frame are common. Any four of the

six sockets on the rear of the router frame (two from each power supply shelf) can

be used to power the router.

48 V DC Connectors

Functional Earth Stud

48 V DC Power Connectors

25-Way D-Type

Alarm Connection

Functional

Earth

PSU Alarm

Connectors

Protective Earth

AC Power

Cables with

PowerCon

Connectors

Mains

Supply A

Mains

Supply B

Mains

Supply A

Mains

Supply B

Page 41

Sirius 840 Installation Manual www.s-a-m.com Powering the Sirius 840

Issue 2 Rev 3 Page 41 © 2016 SAM

9. Powering the Sirius 840

If you have installed the Sirius 840 as described in the preceding sections, you can apply

power to the Sirius 840.

9.1 Powering Up the Sirius 840

When power is connected to the Sirius 840, the controllers and fans switch on immediately.

The main signal modules within the Sirius 840 start to po wer up one second af ter the 48 V DC

supply has been switched on.

9.1.1 Power Sequencing

To reduce the inrush current when the whole unit is powered up the modules in the router

power up over a period of six seconds starting with the controllers and fans, and ending with

the audio crosspoints.

9.1.2 Power Up and Initialization

Once the controller has booted (see Fig 25. for LED states when the controller is running), it is

ready to setup. Router Configuration is carried out using Workbench. If the system has

already been configured, it returns to the state it was in (all signal routing and monitor

settings) when it was last powered.

Important:

To avoid overloading the individual external power supply units, make sure that you power

them all up as quickly as possible and at least half of the power supply units within one

second of each other.

Note:

When hot-plugging in a module to the Sirius 840, there is a delay before the module

powers up.

Fig 26. Nucleus2 2463 Controller LED State when Running

Note:

For full details of the Controller LED colors see the Sirius 800 User manual.

Flashing Green = Controller Active, Flashing Blue = Controller Idle - 1

Steady Green - Power OK

Steady Green = Master Controller, Flashing Blue = Slave Controller - 2

Flashing Green or Orange - 3

Pulsing Orange = Controller Mismatch - 4

Off or Flashing - 5

Not used - Off - 6

Not used - Off - 7

Nucleus2 2463 Controller

Page 42

Sirius 840 Installation Manual www.s-a-m.com Powering the Sirius 840

Issue 2 Rev 3 Page 42 © 2016 SAM

9.1.2.1 Configuration Errors

The router controller generates an error if one or more of the configu red modules in the router

fails to power up. Errors are displayed on the Door screen and the router controller LEDs

(see Table 4. for LED color and Fig 26. for LED location).

If the Door screen and router controller indicate that the configuration is not as expected

(i.e. modules added or missing) then this can be resolved using Work bench. For details of

how to add modules to the router see the Sirius 800 Maintenance & Upgrade manual.

9.1.3 Starting the Door PC Manually

The Door PC starts automatically when the Sirius 84 0 is powered up. If the Door PC has b een

shut down and needs starting manually the following procedure should be used.

1. With the Sirius 840 running open the frame door.

2. Inside the back of the door is the power switch for the Door PC (see Fig 27.).

3. Switch the Door PC on by pressing and releasing the Door PC power switch (it will not

latch in place). Wait until the computer is fully booted up before proceeding further.

Router Controller LED LED Color

Nucleus2 2463 4 Pulsing Orange

Table 4. Controller Mismatch Notification

Fig 27. Door PC

Door PC Power

Switch

LED Power

Indicator

Page 43

Sirius 840 Installation Manual www.s-a-m.com Powering the Sirius 840

Issue 2 Rev 3 Page 43 © 2016 SAM

9.2 Powering Down the Sirius 840

Before powering down the Sirius 840 router switch the Door PC off using one of the following

methods:

Method 1

1. Navigate to the Door PC main menu and touch the Exit button on the screen.

2. A new screen will be displayed with a Shutdown button.

3. Touch the Shutdown button and the Door PC will shutdown.

4. Wait until Windows closes and the screen goes black, then power down the Sirius

840. Make sure that all the external power supply shelves are switched off as quickly

as possible.

Method 2

1. Alternatively open the door and press and release the Door PC power switch

(see Fig 27.). The power switch does not latch in place.

2. This causes Live Runner to close and Windows to shut down.