www.s-a-m.com

User Manual

IQMIX25/26

3G/HD/SD-SDI Multi-channel 10/25GbE IP Transceiver

IQMIX40/41

3G/HD/SD-SDI Multi-channel 10/40GbE IP Transceiver

IQMIX25/26/40/41 Information and Notices

Issue 1 Rev 4 Page 2 © 2017 SAM

Information and Notices

Copyright and Disclaimer

Copyright protection claimed includes all forms and matters of copyrightable materia l and

information now allowed by statutory or judicial law or hereinafter granted, including without

limitation, material generated from the software programs which are displayed on the screen

such as icons, screen display looks etc.

Information in this manual and software are subject to change without notice and does not

represent a commitment on the part of SAM. The software described in this manual is

furnished under a license agreement and can not be reproduced or copied in any manner

without prior agreement with SAM or their authorized agents.

Reproduction or disassembly of embedded computer programs or algorithms prohibited.

No part of this publication can be transmitted or reproduced in any form or by any means,

electronic or mechanical, including photocopy, recording or any information storage and

retrieval system, without permission being granted, in writing, by the publishers or their

authorized agents.

SAM operates a policy of continuous improvement and development. SAM reserves th e ri ght

to make changes and improvements to any of the products described in this document

without prior notice.

Contact Details

Customer Support

For details of our Regional Customer Support Offices please visit the SAM website and

navigate to Support/24/7 Support Contact Details.

www.s-a-m.com/support/247-support/

Customers with a support contract should call their personalize d number, which can b e found

in their contract, and be ready to provide their contract number and details.

IQMIX25/26/40/41 Safety Information

Issue 1 Rev 4 Page 3 © 2017 SAM

Safety Information

Explanation of Safety Symbols

This symbol refers the user to important information contained in

the accompanying literature. Refer to manual.

This symbol indicates that hazardous voltages are present inside.

No user serviceable parts inside.

This unit should only be serviced by trained personnel.

Servicing instructions where given, are for use by

qualified service personnel only.

To reduce risk of electric shock do not perform any

servicing other than that contained in the operating

instructions unless you are qualified to do so.

Refer all servicing to qualified personnel.

· To reduce the risk of electric shock, do not expose this appliance

to rain or moisture.

· Always ensure that the unit is properly earthed and power connections

correctly made.

· This equipment must be supplied from a power system providing a

PROTECTIVE EARTH connection and having a neutral connection

which can be reliably identified.

· The power outlet supplying power to the unit should be close to the

unit and easily accessible

Power connection in countries other than the USA

The equipment is normally shipped with a power cable with a standard IEC

moulded free socket on one end and a standard IEC moulded plug on the other.

If you are required to remove the moulded mains supply plug, dispose of the

plug immediately in a safe manner.

The colour code for the lead is as follows:

GREEN/YELLOW lead connected to E

(Protective Earth Conductor)

BLUE lead connected to N (Neutral Conductor)

BROWN lead connected to L (Live Conductor)

Caution If the unit has two mains supply inputs ensure that both power

cords are plugged into mains outlets operating from the same phase.

LNENL

E

GB

!

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT REMOVE COVERS

NO USER SERVICEABLE PARTS

REFER SERVICING TO QUALIFIED

PERSONNEL ONLY

!

!

Safety Warnings

Erklärung der Sicherheitssymbole

Dieses Symbol weist den Benutzer auf wichtige Informationen

hin, die in der begleitenden Dokumentation enthalten sind.

Dieses Symbol zeigt an, dass gefährliche Spannung vorhanden ist.

Es befinden sich keine vom Benutzer zu wartenden Teile im Geräteinneren.

Dieses Gerät sollte nur von geschultem Personal gewartet werden

· Um das Risiko eines Elektroschocks zu reduzieren, setzen Sie das

Gerät weder Regen noch Feuchtigkeit aus.

· Stellen Sie immer sicher, dass das Gerät ordnungsgemäß geerdet

und verkabelt ist.

· Dieses Equipment muss an eine Netzsteckdose mit Schutzleiter

angeschlossen werden und einen zuverlässig id entifizierbaren Nullleiter haben.

· Die Netzsteckdose sollte nahe beim Gerät und einfach zugänglich sein.

Netzanschluss in anderen Ländern als der USA

Das Equipment wird im Normalfall mit einem Netzkabel mit Standard IEC

Anschlussbuchse und einem Standard IEC Anschlussstecker geliefert.

Sollten Sie den angeschweißten Stecker auswechseln müssen, entsorgen

Sie diesen bitte umgehend. Die farbliche Belegung des Netzkabels ist wie folgt:

GRÜN GELB E = Schutzleiter

BLAU N = Nulleiter

BRAUN L = P = Phase

Achtung: Wenn das Gerät zwei Anschlussbuchsen hat, stellen

Sie bitte sicher, dass beide Netzkabel mit der selben Phase in die

Netzsteckdose gesteckt werden.

Sicherheits-Warnhinweise

D

!

!

Die angeführten Service-/Reparatur-Anweisungen sind

ausschließlich von qualifiziertem Service-Personal

auszuführen. Um das Risiko eines lektroschocks zu

reduzieren, führen Sie ausschließlich die im

Benutzerhandbuch eschriebenen Anweisungen aus,

es sei denn, Sie haben die entsprechende Qualifikation.

Wenden Sie sich in allen Service-Fragen an qualifiziertes Personal.

!

ACHTUNG

Gefahr von Elektrosc hocks.

Abde ckunge n nicht entfernen

Keine vom Benutzer zu wa rtende Teile

Wenden Sie sich ausschließlich

an qualifi zi ertesPersonal

L=

PhaseN=NulleiterN=NulleiterL=Phase

E=

Schutzleiter

E=

Schutzleiter

Légende :

Ce symbole indique qu'il faut prêter attention et se référer

au manuel.

Ce symbole indique qu'il peut y avoir des tensions électriques

à l'intérieur de l'appareil. Ne pas intervenir sans l'agrément

du service qualifié.

· Pour réduire le risque de choc électrique, ne pas exposer l'appareil

dans un milieu humide.

· Toujours s'assurer que l'unité est correctement alimentée,

en particuliers à la liaison à la terre.

· La source électrique de cet équipement doit posséder une connexion

à la terre , ainsi qu'une liaison « neutre » identifiable.

· La prise électrique qui alimente l'appareil doit être proche

de celle-ci et accessible.

Câble secteur de pays autres que les Etats-Unis

L'équipement est livré avec un câble secteur au standard IEC, moulé

mâle/femelle.

Si vous souhaitez changr la prise mâle de votre cordon, voici les

codes couleurs des fils :

Le fil VERT/JAUNE est connecté à T (Terre)

Le fil BLEU est connecté à N (Neutre)

Le fil MARRON est connecté à P (Phase)

Attention si l'appareil a 2 alimentations, s'assurer que les cordons

soient branchés sur la même phase.

Précaution d'emploi :

F

Les procédures de maintenance ne concernent

que le service agréé. Afin de réduire le risque de

choc électrique, il est recommandé de se limiter

aux procédures d'utilisation, à moins d'en être qualifié.

Pour toute maintenance, contacter le service compétent.

!

ATTENTION

RISQUEDE CHOC ELECTRIQUE

NE PAS RETIRER LE COUVERC LE

NE PAS INTERVENI R SANS

L'AGREMENTDU SERVICE

QUALIFIE

PNTNP

T

Connecteur Prise

!

!

Explicación de los Símbolos de Seguridad

Éste símbolo refiere al usuario información importante contenida

en la literatura incluida. Referirse al manual.

Éste símbolo indica que voltajes peligrosos están presentes en el interior.

No hay elementos accesibles al usuario dentro.

Esta unidad sólo debería ser tratada por personal cualificado.

Las instrucciones de servicio cuando sean dadas, son

sólo para uso de personal cualificado. Para reducir el

riesgo de choque eléctrico no llevar a cabo ninguna

operación de servicio aparte de las contenidas en las

instrucciones de operación, a menos que se esté

cualificado para realizarlas.

Referir todo el trabajo de servicio a personal cualificado.

· Para reducir el riesgo de choque eléctrico, no exponer este equipo

a la lluvia o humedad.

· Siempre asegurarse de que la unidad está propiamente conectada a

tierra y que las conexiones de alimentación están hechas correctamente.

· Este equipo debe ser alimentado desde un sistema de alimentación

con conexión a TIERRA y teniendo una conexión neutra fácilmente

identificable.

·

La toma de alimentación para la unidad debe ser cercana y fácilmente

accesible.

Conexión de alimentación en otros p aíses que no sean USA

El equipo es normalmente entregado con un cable de alimentación con un

enchufe hembra estándar IEC en un extremo y con una clavija estándar

IEC en el otro. Si se requiere eliminar la clavija para sustituirla por otra,

disponer dicha clavija de una forma segura.

El código de color a emplear es como sigue:

Advertencia Si la unidad tuviera dos tomas de alimentación, asegurarse

de que ambos cables de alimentación están conectados a la misma fase.

ESP

!

!

Advertencias de Seguridad

LNENL

E

Clavija

Aerea Macho

Enchufe

Aereo Hembra

VERDE/ AMARILLO conectado a E

(Conductor de protección a Tierra

-Earth en el original-)

AZUL conectado a N (Conductor Neutro -Neutral en el original-)

MARRÓN conectado a L (Conductor Fase -Live en el original-)

RIESGO DE CHOQUE ELECTRICO

NO QUITAR LAS PROTECCIONNES

ELEMENTOS NO ACCESIBLES AL

USUARIO.

SERVICIO SOLAMENTE A PERSONAL

CUALIFICADO

IQMIX25/26/40/41 Safety Information

Issue 1 Rev 4 Page 4 © 2017 SAM

Simboli di sicurezza:

Questo simbolo indica l'informazione importante contenuta nei

manuali appartenenti all'apparecchiatura. Consultare il manuale.

Questo simbolo indica che all'interno dell'apparato sono presenti

tensioni pericolose. Non cercare di smontare l'unità.

Per qualsiasi tipo di intervento rivolgersi al personale qualificato.

Le istruzioni relative alla manutenzione sono ad uso

esclusivo del personale qualificato. E' proibito all'utente

eseguire qualsiasi operazione non esplicitamente

consentita nelle istruzioni. Per qualsiasi informazione

rivolgersi al personale qualificato.

· Per prevenire il pericolo di scosse elettriche è necessario non esporre

mai l'apparecchiatura alla pioggia o a qualsiasi tipo di umidità.

· Assicurarsi sempre, che l'unità sia propriamente messa a terra e che

le connessioni elettriche siano eseguite correttamente.

· Questo dispositivo deve essere collegato ad un impianto elettrico

dotato di un sistema di messa a terra efficace.

· La presa di corrente deve essere vicina all'apparecchio

e facilmente accessibile.

Connessione elettrica nei paesi diversi dagli Stati Uniti

L'apparecchiatura normalmente è spedita con cavo pressofuso con la presa

e spina standard IEC. Nel caso della rimozione della spina elettrica,

gettarla via immediatamente osservando tutte le precauzioni del caso.

La leggenda dei cavi è la seguente:

VERDE/GIALLO cavo connesso

ad "E" (terra)

BLU cavo connesso ad "N" (neutro)

MARRONE cavo connesso ad "L" ( fase)

Attenzione! Nel caso in cui l'apparecchio abbia due prese di corrente,

assicurarsi che i cavi non siano collegati a fasi diverse della rete elettrica.

I

!

!

Attenzione:

!

ATTENZIONE

LNENL

E

Presa volante Spina volante

RISCHIO DI SHOCK ELETTRICO

NON CERCARE DI SMONTARE

L'UNITA PER QUALSIASI TIPO DI

INTERVENTO RIVOLGERSI AL

PERSONALE QUALIFICATO

Forklaring på sikkerhedssymboler

Dette symbol gør brugeren opmærksom på vigtig information

i den medfølgende manual.

Dette symbol indikerer farlig spænding inden i apparatet. Ingen bruger

servicerbare dele i apparatet på brugerniveau.

Dette apparat må kun serviceres af faglærte personer..

Serviceinstruktioner er kun til brug for faglærte

servicefolk. For at reducere risikoen for elektrisk

stød må bruger kun udføre anvisninger i

betjeningsmanualen.

Al service skal udføres af faglærte personer.

· For at reducere risikoen for elektrisk stød må apparatet ikke

udsættes for regn eller fugt.

· Sørg altid for at apparatet er korrekt tilsluttet og jordet.

· Dette apparat skal forbindes til en nettilslutning, der yder

BESKYTTENDE JORD og 0 forbindelse skal være tydeligt markeret.

· Stikkontakten, som forsyner apparatet, skal være tæt på apparatet

og let tilgængelig

.

Nettilslutning i andre lande end USA

Udstyret leveres normalt med et strømkabel med et standard IEC støbt løst

hunstik i den ene ende og et standard IEC støbt hanstik i den anden ende.

Hvis et af de støbte stik på strømkablet er defekt, skal det straks kasseres på

forsvarlig vis. Farvekoden for lederen er som følger:

GRØN/GUL leder forbundet til J (Jord)

BLÅ leder forbundet til 0

BRUN leder forbundet til F(Fase)

Forsigtig Hvis enheden har to lysnetindgange, skal der sørges for at

begge ledninger tilsluttes lystnetudgange fra den samme fase.

DK

!

!

!

Sikkerhedsadvarsler

!

FORSIGTIG

RISIKO FOR ELEKTRISK STØD

DÆKPLADERMÅ IKKEFJERNES

INGEN BRUGER SERVICERBARE

DELE SERVI CE M Å KUN UDFØRES

AF FAGLÆRTE PERSONER

F0J0F

J

Han-stik Hun-stik

Förklaring av Säkerhetssymboler

Denna symbol hänvisar användaren till viktig information som

återfinns i litteraturen som medföljer. Se manualen.

Denna symbol indikerar att livsfarlig spänning finns på insidan.

Det finns inga servicevänliga delar inne i apparaten.

Denna apparat få endast repareras av utbildad personal.

Serviceinstruktioner som anges avser endast kvalificerad

och utbildad servicepersonal. För att minska risken för

elektrisk stöt, utför ingen annan service än den som

återfinns i medföljande drifti nstrukti onerna, om du e j ä r

behörig. Överlåt all service till kvalificerad personal.

· För att reducera risken för elektrisk stöt, utsätt inte apparaten för

regn eller fukt.

· Se alltid till att apparaten är ordentligt jordad samt att strömtillförseln

är korrekt utförd.

· Denna apparat måste bli försörjd från ett strömsystem som är försedd

med jordadanslutning samt ha en neutral anslutning som lätt identifierbar.

· Vägguttaget som strömförsörjer apparaten bör finnas i närheten samt

vara lätttillgänglig.

Strömkontakter i länder utanför USA

Apparaten utrustas normalt med en strömkabel med standard IEC gjuten

honkontakt på ena änden samt en standard IEC gjuten hankontakt på den

andra änden. Om man måste avlägsna den gjutna hankontkaten, avyttra

denna kontakt omedelbart på ett säkert sätt. Färgkoden för ledningen är följande:

GRÖN/GUL ledning ansluten till E

(Skyddsjordad ledare)

BLÅ ledning ansluten till N (Neutral ledare)

BRUN ledning ansluten till L (Fas ledare)

Varning! Om enheten har två huvudsakliga elförsörjningar, säk erställ att

båda strömkablarna som är inkopplade i enheten arbetar från samma fas.

S

!

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT REMOVE COVERS

NO USER SERVICEABLE PARTS

REFER SERVICING TO QUALIFIED

PERSONNEL ONLY

!

!

Säkerhetsvarningar

LNENL

E

Stickkontakt-Hane Stickkontakt-Hona

Turvamerkkien selitys

Tämä merkki tarkoittaa, että laitteen mukana toimitettu kirjallinen

materiaali sisältää tärkeitä tietoja. Lue käyttöohje.

Tämä merkki ilmoittaa, että laitteen sisällä on vaarallisen voimakas jännite.

Sisäpuolella ei ole mitään osia, joita käyttäjä voisi itse huoltaa.

Huollon saa suorittaa vain alan ammattilainen.

Huolto-ohjeet on tarkoitettu ainoastaan alan

ammattilaisille. Älä suorita laitteelle muita

toimenpiteitä, kuin mitä käyttöohjeissa on

neuvottu, ellet ole asiantuntija. Voit saada sähköiskun.

Jätä kaikki huoltotoimet ammattilaiselle.

· Sähköiskujen välttämiseksi suojaa laite sateelta ja kosteudelta.

· Varmistu, että laite on asianmukaisesti maadoitettu ja että

sähkökytkennät on tehty oikein.

· Laitteelle tehoa syöttävässä järjestelmässä tulee olla

SUOJAMAALIITÄNTÄ ja nollaliitännän on oltava luotettavasti

tunnistettavissa.

· Sähköpistorasian tulee olla laitteen lähellä ja helposti tavoitettavissa.

Sähkökytkentä

Laitteen vakiovarusteena on sähköjohto, jonka toisessa päässä on muottiin

valettu, IEC-standardin mukainen liitäntärasia ja toisessa päässä muottiin

valettu, IEC-standardin mukainen pistoliitin. Jos pistoliitin tarvitsee poistaa,

se tulee hävittää heti turvallisella tavalla. Johtimet kytketään seuraavasti:

KELTA-VIHREÄ suojamaajohdin E-napaan

SININEN nollajohdin N-napaan

RUSKEA vaihejohdin L-napaan

Huom! Jos laitteessa on kaksi verkkojännitteen tuloliitäntää, niiden johdot

on liitettävä verkkopistorasioihin, joissa on sama vaiheistus.

FI

!

!

Turvaohjeita

!

SÄHKÖISKUN VAARA ÄLÄ AVAA

LAITTEEN KANSI A EI SISÄLLÄ

KÄYTTÄJÄLLE H UOLLETTAVI A

OSIAHUOLTOAINOASTAAN

AMMATTILAISEN SU ORITTAM ANA

VAROITUS

LNENL

E

Pistoliitin Liitäntärasia

IQMIX25/26/40/41 Safety Information

Issue 1 Rev 4 Page 5 © 2017 SAM

Laser Safety

This product operates with Class 1 laser products.

Ventilation

Although the unit is constructed to meet normal environmental requirements, ensure that

there is a free flow of air at the front, rear, and sides of the unit to dissipate the heat produced

during operation. Installations should be designed to allow for this.

Safety Standards

This equipment conforms to the following standards:

EN60950-1 2006

Safety of Information T echnology Equi pment Including

Electrical Business Equipment.

UL1419 (3rd Edition) - UL File E193966

Standard for Safety – Professional Video and Audio equipment.

Símbolos de Segurança

O símbolo triangular adverte para a necessidade de consultar o

manual antes de utilizar o equipamento ou efectuar qualquer ajuste.

Este símbolo indica a presença de voltagens perigosas no interior

do equipamento. As peças ou partes existentes no interior do equipamento

não necessitam de intervenção, manutenção ou manuseamento por parte

do utilizador. Reparações ou outras intervenções devem ser efectuadas

apenas por técnicos devidamente habilitados.

As instruções de manutenção fornecidas são para

utilização de técnicos qualificados. Para reduzir o

risco de choque eléctrico, não devem ser realizadas

intervenções no equipamento não especificadas no

manual de instalações a menos que seja efectuadas

por técnicos habilitados.

· Para reduzir o risco de choque eléctrico, não expor este equipamento

à chuva ou humidade.

· Assegurar que a unidade está sempre devidamente ligada à terra e

que as ligações à alimentação estão correctas.

· O sistema de alimentação do equipamento deve, por razões de

segurança, possuir ligação a terra de protecção e ligação ao

NEUTRO devidamente identificada.

· A tomada de energia à qual a unidade está ligada deve situar-se na

sua proximidade e facilmente acessível.

Ligação da alimentação noutros países que não os EUA

O equipamento é, normalmente, enviado com cabo de alimentação com ficha

IEC fêmea standard num extremo e uma ficha IEC macho standard no extremo

oposto. Se for necessário substituir ou alterar alguma destas fichas, deverá

remove-la e elimina-la imediatamente de maneira segura.

O código de cor para os condutores é o seguinte:

Condutor VERDE/AMARELO ligado a E (Terra)

Condutor AZUL ligado a N (Neutro)

Condutor CASTANHO ligado a L (Vivo).

Atenção: Se a unidade tem duas fontes de alimentação assegurar que os

dois cabos de alimentação estão ligados a tomadas pertencentes à mesma fase .

P

!

!

Avisos de Segurança

LNENL

E

Ficha Livre TomadaLivre

!

CAUTION

RISK OF ELEC TRIC SHOC K

DO NOT REMOVE COVERS

NO USER SERVIC EABLE PARTS

REFER SERVICING TO QUALIFIED

PERSONNEL O N LY

Caution: Use of controls or adjustments or performance of procedures other than those

specified herein may result in hazardous radiation exposure.

Do not obstruct the ventilation holes on the right-side of the unit. Dam age to the equipment

may result.

IQMIX25/26/40/41 Safety Information

Issue 1 Rev 4 Page 6 © 2017 SAM

EMC Standards

This equipment conforms to the following standards:

EN 55032:2012 (Class A)

Electromagnetic Compatibility of Multimedia Equipment - Emission Requirements.

EN 61000-3-2:2014 (Class A)

Limits for Harmonic Current Emissions.

EN 61000-3-3:2013

Limitation of V oltage Cha nges, Voltage Fluctuations and Flicker in Pu blic Low-Voltage Supply

Systems.

FCC/CFR 47:Part 15, Class A

Federal Communications Commission Rules Part 15, Subpart B, Class A.

EMC Environment

The product(s) described in this manual conform to the EMC requirements for, and are

intended for use in, the controlled EMC environment (for example, purpose-b uilt broadcasting

or recording studios), and the rural outdoor enviro nment (far away from railways, transmitter s,

overhead power lines, etc.) E4.

EMC Performance of Cables and Connectors

SAM products are designed to meet or exceed the req uirement s of the appro priate Europe an

EMC standards. In order to achieve this performance in real installations it is essential to use

cables and connectors with good EMC characteristics.

All signal connections (including remote control connections) shall be made with screened

cables terminated in connectors having a metal shell. The cable screen shall have a

large-area contact with the metal shell.

Coaxial Cables

Coaxial cables connections (particularly serial digital video connections) shall be made with

high-quality double-screened coaxial cables such as Belden 1694 or BBC type PSF1/2M.

D-type Connectors

D-type connectors shall have metal shells making good RF contact with the cable screen.

Connectors having indents which improve contact between the p lug and socket shells are

recommended.

Warning: This eq uip m en t is com p liant with Class A of CISPR

32. In a residential environment this equipment may cause r adio

interference.

IQMIX25/26/40/41 Contents

Issue 1 Rev 4 Page 7 © 2017 SAM

Contents

Information and Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.2 Block Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.2.1 IQMIX25/26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.2.2 IQMIX40/41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.3 Order Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.4 Rear Panel View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

1.5 Feature Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.5.1 IQMIX25 3G/HD/SD-SDI Multi-channel IP Transceiver . . . . . . . . . . . . . . . 16

1.5.2 IQMIX40 3G/HD/SD-SDI Multi-channel IP Transceiver . . . . . . . . . . . . . . . 16

1.6 Enclosures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1.6.1 B-style Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1.6.2 IQFAN00 Cooling Fan Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1.6.3 Fitting the Fan Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2 Technical Specification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3 Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.1 SDI BNC Input/Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.2 10/25G Ethernet SFP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.3 40G Ethernet QSFP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.4 DensiShield. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4 Card Edge LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5 RollCall Control Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.1 Terminology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.2 Navigating Pages in the RollCall Template . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.2.1 Template Pages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.2.2 Setting Values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.3 Information Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.3.1 Selecting the Information to Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.4 Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.5 Time Sync Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.5.1 Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.5.2 Histogram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.6 Link Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.7 TPG (Test Pattern Generator). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.8 FEC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.9 Ethernet Pages 1 and 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.9.1 The Ethernet Pane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.9.2 The All Traffic/CPU Traffic Panes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.10 Ethernet 1 and 2 RTP Sender. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.11 Ethernet 1 and 2 RTP Receiver. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.12 Spigot Pages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5.12.1 Input Spigots . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5.12.2 Output Spigots. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5.13 Logging - Misc. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.14 Logging - SFP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.15 Logging - FPGA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

5.16 Logging - Spigot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.17 RollTrack. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

5.17.1 Disable All . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

5.17.2 RollTrack Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

IQMIX25/26/40/41 Contents

Issue 1 Rev 4 Page 8 © 2017 SAM

5.17.3 RollTrack Source. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

5.17.4 RollTrack Address. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

5.17.5 RollTrack Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

5.17.6 RollTrack Sending. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

5.17.7 RollTrack Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

5.18 Loopback Router. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.19 Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

5.19.1 Restart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

5.19.2 Defaults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

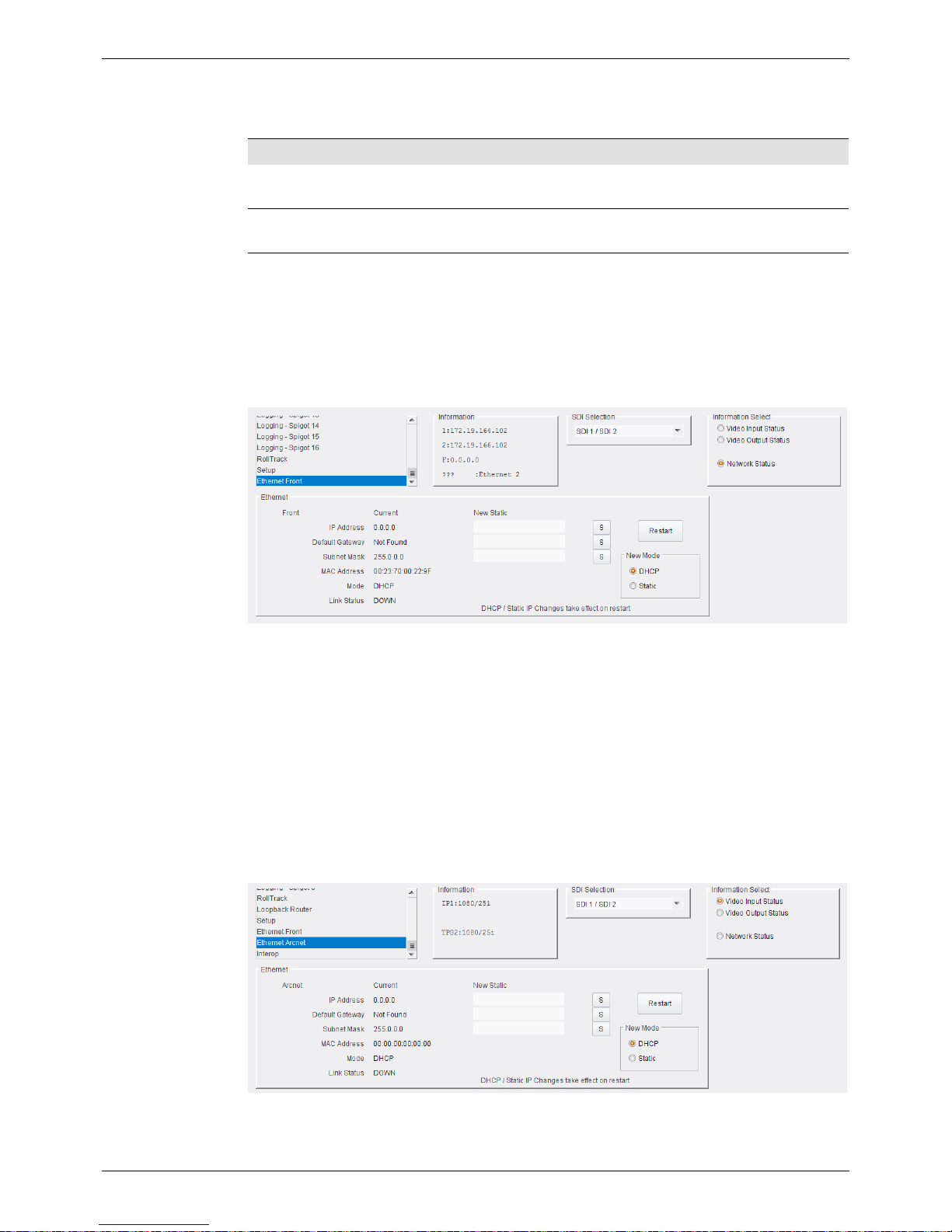

5.20 Ethernet Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

5.20.1 The Ethernet Pane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

5.21 Ethernet Arcnet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

5.22 Interop Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

5.23 SFP Configuration Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

IQMIX25/26/40/41 Introduction

Issue 1 Rev 4 Page 9 © 2017 SAM

1 Introduction

1.1 Description

The IQMIX series is a range of multi-channel video over IP transceiver modu les developed for

use within low latency, high bandwidth Ethernet IP networks, capable of encoding/decoding

multiple SDI signals. They provide both compressed and uncompressed modes of operation.

Using SMPTE 2042 (VC2) lightweight compression allows for high quality signal carriage

whilst optimizing bandwidth requirements, while sendin g signals uncompressed provides best

quality transport although at the expense of bandwidth.

Encapsulation of signals in a SMPTE 2022-6 transport stream can also be handled to prov ide

compatibility with other video over IP solutions.

RFC417 provides for uncompressed video transport, and supports RFC3190 for Audio and

the yet-to-be ratified Edwards standard for data.

At a physical level, HD-BNC and DensiShield connectors are catered for. DensiShield

connectors allow the cards to be partnered with SAM's IP expansion cards for the Sirius S800

router, allowing easy integration of video over IP networking with existing SDI base band

operations.

1.2 Block Diagrams

1.2.1 IQMIX25/26

IQMIX25/26/40/41 Introduction

Issue 1 Rev 4 Page 10 © 2017 SAM

1.2.2 IQMIX40/41

1.3 Order Codes

The following product order codes are covered by this manual:

Note:

Modules with "B" order codes (for example, IQFDA3100-1B3) can be fitted only into B-type

enclosures. Modules with "A" order codes (for example, IQFDA3100-1A3) can be fitted into

either A- or B-type enclosures.

IQMIX4000-2B3 16 channel SDI to IP transceiver with 40GbE interface. Up to 16 SDI

inputs or outputs, 2 x 40GbE ports.

IQMIX4001-3B3 16 channel SDI to IP transceiver with 40GbE interface. Up to 16 SDI

inputs or outputs, 2 x 40GbE ports. Includes IQFAN rear panel for

additional cooling in IQH3B frame.

IQMIX4010-2B3 16 channel SDI to IP transceiver with 10GbE interface. Up to 16 SDI

inputs or outputs, 2 x 10GbE ports.

IQMIX4011-3B3 16 channel SDI to IP transceiver with 10GbE interface. Up to 16 SDI

inputs or outputs, 2 x 10GbE ports. Includes IQFAN rear panel for

additional cooling in IQH3B frame.

IQMIX4100-2B3 16 channel SDI to IP transceiver using DensiShield connectors with

40GbE interface. Up to 8 SDI inputs and 8 SDI outputs, 2 x 40GbE ports.

IQMIX25/26/40/41 Introduction

Issue 1 Rev 4 Page 11 © 2017 SAM

1.4 Rear Panel View

The following rear panel types are available:

IQMIX4101-3B3 16 channel SDI to IP transceiver using DensiShield connectors with

40GbE interface. Up to 8 SDI inputs and 8 SDI outputs, 2 x 40GbE ports.

Includes IQFAN rear panel for additional cooling in IQH3B frame.

IQMIX4110-2B3 16 channel SDI to IP transceiver using DensiShield connectors with

10GbE interface. Up to 8 SDI inputs and 8 SDI outputs, 2 x 10GbE ports.

IQMIX4111-3B3 16 channel SDI to IP transceiver using DensiShield connectors with

10GbE interface. Up to 8 SDI inputs and 8 SDI outputs, 2 x 10GbE ports.

Includes IQFAN rear panel for additional cooling in IQH3B frame.

IQMIX2500-2B3 16 channel SDI to IP transceiver with 25GbE interface. Up to 16 SDI

inputs or outputs, 2 x 25GbE ports.

IQMIX2501-3B3 16 channel SDI to IP transceiver with 25GbE interface. Up to 16 SDI

inputs or outputs, 2 x 25GbE ports. Includes IQFAN rear panel for

additional cooling in IQH3B frame.

IQMIX2600-2B3 16 channel SDI to IP transceiver using DensiShield connectors with

25GbE interface. Up to 8 SDI inputs and 8 SDI outputs, 2 x 25GbE ports.

IQMIX2601-3B3 16 channel SDI to IP transceiver using DensiShield connectors with

25GbE interface. Up to 8 SDI inputs and 8 SDI outputs, 2 x 25GbE ports.

Includes IQFAN rear panel for additional cooling in IQH3B frame.

Figure 1 IQMIX4000-2B3

Figure 2 IQMIX4001-3B3

IQMIX25/26/40/41 Introduction

Issue 1 Rev 4 Page 12 © 2017 SAM

:

Figure 3 IQMIX4010-2B3

Figure 4 IQMIX4011-3B3

Figure 5 IQMIX4100-2B3

IQMIX25/26/40/41 Introduction

Issue 1 Rev 4 Page 13 © 2017 SAM

Figure 6 IQMIX4101-3B3

Figure 7 IQMIX4110-2B3

Figure 8 IQMIX4111-3B3

IQMIX25/26/40/41 Introduction

Issue 1 Rev 4 Page 14 © 2017 SAM

Figure 9 IQMIX2500-2B3

Figure 10 IQMIX2501-3B3

Figure 11 IQMIX2600-2B3

IQMIX25/26/40/41 Introduction

Issue 1 Rev 4 Page 15 © 2017 SAM

Figure 12 IQMIX2601-3B3

IQMIX25/26/40/41 Introduction

Issue 1 Rev 4 Page 16 © 2017 SAM

1.5 Feature Summary

1.5.1 IQMIX25 3G/HD/SD-SDI Multi-channel IP Transceiver

• Handles up to 16 SDI signals over dual 10GbE or25GbE IP links (dependent on SDI

signal format and compressed/uncompressed transport mode).

• Supports configuration of Ethernet links for maximum signal transport using both

SFPs, or for dual link mode to provide link redundancy as per SMPTE 2022-7.

• Multiple transport types available for each SDI input, including:

• Compressed IP transport using SMPTE-2042 (VC2) low latency high quality

encoding profile.

• Uncompressed video transport using either RFC 4175 RTP or SMPTE-2022-6

encapsulation.

• PCM audio using RFC 3190 & AES67

• SMPTE-291M metadata support via IETF standard RTP Payload for Ancillary

Data.

• Timing and synchronization provided by IEEE-1588v2 (PTP), compliant with

SMPTE-2059-2, or via the IQH3B frame analog reference bus.

• Supports unicast as well as IGMPv3 source-specific multicast, allowing point to point

operation or transmission in multicast groups.

• Standards supported:

• 3G-SDI to SMPTE 424M/425M level A compatible.

• HD-SDI to SMPTE292M/274M/296M.

• SD-SDI to SMPTE259M-C.

• 10G Ethernet to IEEE 802.3.

• Rollcall control and monitoring compatible, with standard logging and reporting

features.

1.5.2 IQMIX40 3G/HD/SD-SDI Multi-channel IP Transceiver

• Handles up to 16 SDI signals over dual 10GbE or dual 40GbE IP links (dependent on

Ethernet rate, SDI signal format and compressed/uncompressed transport mode).

• Supports configuration of Ethernet links for maximum signal transport using both

SFPs, or for dual link mode to provide link redundancy as per SMPTE 2022-7.

• Multiple transport types available for each SDI input, including:

• Compressed IP transport using SMPTE-2042 (VC2) low latency high quality

encoding profile.

• Uncompressed video transport using either RFC 4175 RTP or SMPTE-2022-6

encapsulation.

• PCM audio using RFC 3190 & AES67.

• SMPTE-291M metadata support via IETF standard RTP Payload for Ancillary

Data.

• Timing and synchronization provided by IEEE-1588v2 (PTP), compliant with

SMPTE-2059-2, or via the IQH3B frame analog reference bus.

• Supports unicast as well as IGMPv3 source-specific multicast, allowing point to point

operation or transmission in multicast groups.

• Standards supported:

• UHD-SDI (4x3G-SDI)

• 3G-SDI to SMPTE 424M/425M level A/B compatible.

IQMIX25/26/40/41 Introduction

Issue 1 Rev 4 Page 17 © 2017 SAM

• HD-SDI to SMPTE292M/274M/296M.

• SD-SDI to SMPTE259M-C.

• 10G Ethernet to IEEE 802.3.

• Rollcall control and monitoring compatible, with standard logging and reporting

features.

1.6 Enclosures

The IQMIX fits the enclosure shown. Ensu re that the supplied cooling fan module is also fitted

as described in section 1.6.2.

1.6.1 B-style Enclosure

Enclosure order codes: IQH3B-S-0, IQH3B-S-P

Note:

The IQH3B enclosure provides two internal analog reference inputs. These inputs are

applicable to modules with “B” order codes only.

IQMIX25/26/40/41 Introduction

Issue 1 Rev 4 Page 18 © 2017 SAM

1.6.2 IQFAN00 Cooling Fan Module

IQMIX25/26/40/41 cards are supplied with IQFAN00 cooling modules. Ensure these are fitted

according to the instructions below.

IQFAN00 Cooling Module

1.6.3 Fitting the Fan Module

A fan module must be fitted immediately to the left of each IQMIX card, as viewed from the

rear.

1. Choose an empty slot position for the module, immediately to the left of the IQMIX as

viewed from the rear.

2. Remove the screws securing the blanking plate covering the chosen slot position.

Remove and store the blanking plate in a safe place for future use.

3. Ensuring correct orientation, fit the fan module rear conn ecting panel to the rear of the

enclosure in the vacant aperture, and secure with the fixing screws provided.

4. Reattach the power supply and start up the enclosure. The fan should start

immediately.

Front

View

Rear

View

Do not run IQMIX cards without the fan modules. This can cause severe damage to

the equipment.

Before performing this operation, ensure that the power supply is switched OFF and the

mains power connection at the rear of the unit is removed.

IQMIX25/26/40/41 Technical Specification

Issue 1 Rev 4 Page 19 © 2017 SAM

2 Technical Specification

Inputs/Outputs

Signal Inputs

Inputs Up to 16 (0/4/8/12/16)

Connector/Format BNC/75R

Conforms to 3G-SDI to SMPTE 424M/425M level A compatible

HD-SDI to SMPTE292M/274M/296M

SD-SDI to SMPTE259M-C

Input cable length Belden 1694A @ 3 Gbit/s - TBC

Belden 1694A @ 1.5 Gbit/s - TBC

Belden 1694A @ 270 Mbit/s - TBC

Signal Outputs

Outputs Up to 16 (16/12/8/4/0)

Connector/Format BNC/75R

Conforms to 3G-SDI to SMPTE 424M/425M level A/B compatible

HD-SDI to SMPTE292M/274M/296M

SD-SDI to SMPTE259M-C

DensiShield

Inputs 2:0/1:1/0:2 (DensiShield connectors In:Out)

16:0/0:16/8:8 (SDI In:Out)

Connector/Format DensiShield pair

Conforms to 3G-SDI to SMPTE 424M/425M level A/B compatible

HD-SDI to SMPTE292M/274M/296M

SD-SDI to SMPTE259M-C

Ethernet

Connector/Format 10GbE = SFP+

25GbE = SFP+

40GbE = QSFP

Conforms to RFC4175

RFC3190

SMPTE-291M /IETF RTP Payload for Ancillary Data

VC-2

AES'67

IEEE-1588v2/SMPTE-2059-2

Video Standards 1125 (1080)/50p (A), 1125 (1080)/59p (A),

750 (720)/50p, 750 (720)/59p,

1125 (1080)/25i, 1125 (1080)/29i,

625 (576)/25i, 525 (480)/29i

RollCall Features

Status Input and Output status

User memories None

Communication

RollCall/RollCall+ Via gateway or directly via rear SFP

IQMIX25/26/40/41 Technical Specification

Issue 1 Rev 4 Page 20 © 2017 SAM

Indicators Front Panel and Card Edge

Power OK (Green)

CPU OK (Green flashing)

1-12 Input standard

detection LEDs

UHD (White)

3G (Green)

HD (Green)

SD (Yellow)

None (Red)

Logging Input Status

Input Alarms

Output Alarms

Output Status

Misc

RollTrack controls On/off, Index, Source, Address, Command, Status, Sending

Setup Versions, reset defaults, restart

Specifications

Electrical Transport Stream

Connector/Format HD-BNC

Standard SAM screw terminal

Start-up Time

Power Consumption

Module Power

Consumption

IQMIX25/26 34.5 PR Max (B frame only)

IQMIX40/41 37.5 PR Max (B frame only)

IQMIX25/26/40/41 Connections

Issue 1 Rev 4 Page 21 © 2017 SAM

3 Connections

This section describes the physical input and output connections provided by the IQMIX

modules.

3.1 SDI BNC Input/Outputs

3.2 10/25G Ethernet SFP

3.3 40G Ethernet QSFP

3.4 DensiShield

16 x 3G/HD/SD-SDI interfaces provided

with HD-BNC.

SFP+ supporting 10/25G Ethernet.

QSFP+ supporting 40G Ethernet.

One in/out DensiShield interface.

IQMIX25/26/40/41 Card Edge LEDs

Issue 1 Rev 4 Page 22 © 2017 SAM

4 Card Edge LEDs

The LEDs on the edge of the module indicate its operating status.

Front Panel

Description

STATUS PB=IDENT

STATUS

Green = PTP-LOCK OK

Off = PTP-LOCK Fail

BOARD CPU

BOARD

Green flashing= PTP-SYNC OK

Off = PTP-SYNC Fail

PTP REF

REF

Green flashing = Watchdog timer OK

8 16

1 - 8 = Input port status.

Green = OK

Red = Fail

Yellow = TPG

9 - 16 = Output port status

Green = OK

Red = Fail

Yellow = TPG

7 15

6 14

5 13

4 12

3 11

2 10

1 9

SFP 2 QSFP 2

SFP 1 - 2 = Status/lane.

Green = OK (10G SFP), Blue = OK

(25G SFP). If flashing, link is down.

QSFP 1 - 2 = Status/lane.

Cyan = OK (40G QSFP). If flashing,

link is down.

SFP 1 QSFP 1

PB=RESET

IQMIX25/26/40/41 RollCall Control Panel

Issue 1 Rev 4 Page 23 © 2017 SAM

5 RollCall Control Panel

This section contains information on using the IQMIX modules with RollCall.

For help with general use of the RollCall application, open the user manual by clicking the

button on the main RollCall toolbar.

5.1 Terminology

5.2 Navigating Pages in the RollCall Template

The RollCall template has a number of pages, each of which can be selected from the

drop-down list at the top left of the display area. Right-clicking anywhere on the pages will

also open a page view list, allowing quick access to any of the pages.

5.2.1 Template Pages

The following pages are available:

• Configuration - see section 5.4.

• Time Sync Configuration - see section 5. 5.

• Link Control - see section 5.6.

• TPG (Test Pattern Generator) - see section 5.7.

•FEC - see section 5.8.

• Ethernet Pages 1 and 2 - see section 5.9.

• Ethernet 1 and 2 RTP Sender - see section 5.10.

• Ethernet 1 and 2 RTP Receiver - see section 5.11.

• Spigot 1-x - see section 5.12.

Term Description

Essence A general term used to describe an SDI

component; Video, Audio and Data are all

essences.

Spigot Generic term for a Source or Destination.

Flow Sequence of RTP packets of a single

essence.

Source Originator of one or more flows, i.e. a set of

one or more sender spigots.

Destination Receiver of one or more flows, i.e. a set of

one or more receiver spigots.

Figure 13 Template Pages

Pages

List

IQMIX25/26/40/41 RollCall Control Panel

Issue 1 Rev 4 Page 24 © 2017 SAM

• Logging Misc - see section 5.13.

• Logging SFP - see section 5.14.

• Logging FPGA- see section 5.15.

• Logging Spigot 1-x - see section 5.16.

•Rolltrack - see section 5.17.

• Loopback Router - see section 5.18

• Setup - see section 5.19.

• Ethernet Front - see section 5.20

• Ethernet Arcnet - see section 5.21

• Interop - see section 5.22

• SFP Configuration - see section 5.23

5.2.2 Setting Values

Many of the settings within the templates have values, either alpha or numeric.

When setting a value in a field, the value, whether text or a number, must be set by pressing

the E

NTER key, or clicking the Save Value button.

Clicking an associated Preset Value button returns the value to the factory default

setting.

5.3 Information Display

The Information display pane appears at the top of each p age , and shows basic information

on the input, standard and status of the module. The information to be displayed is defined on

the SDI Selection and Information Select panes to the right of the Information display.

5.3.1 Selecting the Information to Display

• Select the inputs to display data for from the SDI Selection drop-down list.

•Select Video Input Status, Video Output Status or Network Status from the

Information Select pane as required.

The selected information will be displayed on the Information display pane.

Figure 14 Information and Selection Panes

IQMIX25/26/40/41 RollCall Control Panel

Issue 1 Rev 4 Page 25 © 2017 SAM

5.4 Configuration

The Configuration page allows basic module parameters to be set.

The following facilities are available from this page:

Figure 15 Configuration Page

Option Operation

SDI IO Displays how input and output spigots are currently

configured. See Card Firmware/Software Version, below, for

information on how to change this.

Where Am I Causes the front-edge LEDs to flash, allowing the module to

be easily identified.

Genlock Select Genlock type:

• Network - click to select PTP.

• Chassis Reference A/B - click to select an

on-chassis reference.

• Freerun - click to allow free running.

GUID Displays the absolute unique identifier associated with the

module.

IQMIX25/26/40/41 RollCall Control Panel

Issue 1 Rev 4 Page 26 © 2017 SAM

Domain RollCall+ uses domains to partition a network; only nodes

on the same domain can communicate with one another. A

domain is uniquely identified with a number and a friendly

name/alias.

Set an ID as required, then press Take to confirm the

change.

Interface Configuration Displays the IP address for each of the Ethernet inter faces.

Card Firmware/Software

Version

Each software version contains multiple firmware images.

These allow different spigot input/output and flow standard

combinations to be selected.

Select the required software from the Software Version

pane, then select the firmware which provides the required

combination of inputs, outputs and flow standards from the

list displayed on the Firmware pane. Note: Restore and

Restart buttons are displayed only when an item not

currently installed is selected.

Click Take to restart the module and implement any

changes made.

Option Operation

IQMIX25/26/40/41 RollCall Control Panel

Issue 1 Rev 4 Page 27 © 2017 SAM

5.5 Time Sync Configuration

The Time Sync Configuration page allows selection of the source to be used for

synchronizing flows, and configuration of any properties associated with the relevant source.

The following facilities are available from this page:

Figure 16 Time Sync Configuration Page

Option Operation

Time Sync Mode Click a radio button to select the required mode. Note that

the PTP options require a grandmaster clock to be present

in the system.

NTP Configuration To add an NTP server, enter the server’s IP address in to

the New field.

PTP Network Interface Click check boxes to select the required network interfaces.

If an interface fails, the next interface on the list will be

switched to automatically.

PTP Configuration Select values from the PTP Domain and PTP Delay

Request Frequency drop-down lists, as required. Type the

appropriate IP number into the PTP Multicast address field.

Show Status Check the Show Status checkbox to display status

information. See section 5.5.1 .

Save Settings Displayed only if settings on this page are changed. Clicking

Restore will discard the changes, while clicking Restart will

implement the changes and reboot the module.

IQMIX25/26/40/41 RollCall Control Panel

Issue 1 Rev 4 Page 28 © 2017 SAM

5.5.1 Status

Displays important system status information on a single convenient panel.

5.5.2 Histogram

Located to the right of the Status panel, the Histogram provides a graphical representation of

the distribution of differences between the card's clock and the PTP grand master clock. Every

time the clock difference is recalculated, the relevant bar is incremented. A correctly

functioning system will show a distinct peak around the 0ns level.

Figure 17 Time Sync Status

Figure 18 Time Sync Status Information - Histogram

IQMIX25/26/40/41 RollCall Control Panel

Issue 1 Rev 4 Page 29 © 2017 SAM

5.6 Link Control

The Link Control page allows quad-link 4K inputs to be synchronized by the IQMIX module.

To have the IQMIX synchronize quad-link inputs, e nable the check box next to the set of

inputs to synchronize.

To use 4K SMPTE352 Insertion, enable the adjacent check box.

Figure 19 Link Control Page

IQMIX25/26/40/41 RollCall Control Panel

Issue 1 Rev 4 Page 30 © 2017 SAM

5.7 TPG (Test Pattern Generator)

The TPG page allows test patterns to be applied on a spigot-by-spigot basis.

The following options are available for each spigot:

If a test pattern is applied, either a pattern or a tone, the spigot cannot be used for streaming

any other essence.

The caption generator allows a caption to be overlaid on the video essence.

Figure 20 TPG Page

Option Operation

TPG Select the test pattern to apply to the spigot from the

drop-down list.

Audio Freq Select the audio frequency to apply to the spigot from the

drop-down list.

Caption Type a caption (max 19 characters) to optionally be

displayed with the test pattern.

Audio dB Select the dB level to apply to the spigot from the drop-down

list.

Show Caption Enable the checkbox to display the caption with the test

pattern.

Audio Mute Enable the checkbox to mute the audio tone.

IQMIX25/26/40/41 RollCall Control Panel

Issue 1 Rev 4 Page 31 © 2017 SAM

5.8 FEC

The FEC page allows FEC Clause 74 to be selected and FEC logging to be activated, if

required. FEC stats are also available.

The following facilities are available from this page:

Note:

This page is available for IQMIX25 modules only.

Figure 21 FEC Page

Option Operation

FEC Clause 74 Allows low-latency FEC Clause 74 error correction to be

used. Options are:

•On

•Off

Status Displays lock status for each SFP.

FEC Stats Displays the number of corrected and uncorrected errors

received via the SFPs. Click Enable Stats to activate, and

Clear Count to zero the counters.

FEC Logging Information on several parameters can be made available to

a logging device connected to the RollCall network. Enable

check boxes to activate log fields as required.

Available log fields are shown in the table below.

IQMIX25/26/40/41 RollCall Control Panel

Issue 1 Rev 4 Page 32 © 2017 SAM

Where N is the SFP number

Log Field Description

FEC_N_CORRECTED_

ERRORS=

Number of corrected errors for FEC N.

FEC_N_UNCORRECTED_

ERRORS=

Number of uncorrected errors for FEC N.

IQMIX25/26/40/41 RollCall Control Panel

Issue 1 Rev 4 Page 33 © 2017 SAM

5.9 Ethernet Pages 1 and 2

The Ethernet pages show details and status for each network interface. The IQMIX defaults

to use of DHCP, but this can be overridden and a static IP address defined if required.

5.9.1 The Ethernet Pane

The Ethernet pane displays details of the currently selected network interface, and allows a

static IP address to be defined. Enter information as required, then click S to save. New

settings are applied when Restart is clicked.

Where am I? Checkbox

When enabled, the Where Am I function causes the SFP/QSFP LEDs for the relevant

Ethernet connector to flash.

5.9.2 The All Traffic/CPU Traffic Panes

Click the Enable Stats check box to display information on traffic through the module.

Note:

Ethernet pages 1 & 2 refer to the rear-p anel Ethernet connectors only. See section 5.20 for

information on managing the on-module Ethernet connector.

Figure 22 Ethernet 1 Page

IQMIX25/26/40/41 RollCall Control Panel

Issue 1 Rev 4 Page 34 © 2017 SAM

5.10 Ethernet 1 and 2 RTP Sender

The RTP Sender page displays the amount of data transmitted, on a spigot-by-spigot basis.

Units are megabits per second.

Click Enable Stats to display values.

Figure 23 Ethernet 1 & 2 RTP Sender Page

IQMIX25/26/40/41 RollCall Control Panel

Issue 1 Rev 4 Page 35 © 2017 SAM

5.11 Ethernet 1 and 2 RTP Receiver

The RTP Receiver page displays the amount of da t a received, plus de t ails of p acket loss, on

a spigot-by-spigot basis. Units are megabits per second.

Click Enable Stats to display the values.

Figure 24 Ethernet 1 & 2 RTP Receiver Pag e

IQMIX25/26/40/41 RollCall Control Panel

Issue 1 Rev 4 Page 36 © 2017 SAM

5.12 Spigot Pages

A separate page is provided for each of the active spigots. These pages are dynamically

configured by the product, based on the capabilities of the software version/firmware

selected.

5.12.1 Input Spigots

Input spigots are defined by selecting the appropriate firmware version on the Configuration

page. See section 5.4 for more information.

5.12.1.1 Spigot Pane

The Spigot pane provides basic monitoring for the selected Spigot. Click Take to apply any

changes made.

The Spigot pane details:

• Spigot direction;

• Associated BNC connector;

• Current status;

• The last Take performed on the spigot.

Disable Extended Headers

Extended header operation can be disabled for TR-03/TR-04 compatibility. Enable the

Disable Extended Headers checkbox, then click Take to disable the extended headers.

Note:

The pages shown here may differ from those seen on your par ticular system, depending on

the model and configuration of your IQMIX module.

Figure 25 Typical Input Spigot Page

Figure 26 Input Spigot Pane

IQMIX25/26/40/41 RollCall Control Panel

Issue 1 Rev 4 Page 37 © 2017 SAM

Audio Channels

Allows the number of audio channels in use to be restricted. Select from the list the highest

connector number to be used.

Streaming

Select the Ethernet connectors to use for this spigot. This will also determine the bandwidth to

be used. Options are:

• Dual - use both Ethernet connectors, and so all available bandwidth.

• Single - use either Ethernet connector, and so half of the available bandwidth.

•A or B - use one particular Ethernet connector, and so half of the available bandwidth.

• None - do not use an Ethernet connector for this spigot.

Format

Select the format to be used on this spigot. This will ensure that the appropriate level of

bandwidth is allocated.

5.12.1.2 Flow Pane

The Flow pane allows multicast IP and port details to be defined for the selected spigot. Stats

for the spigot can also be enabled from here.

Each spigot can support a variety of flows:

• SMPTE 2022-6

• RFC4175

•VC-2

• RFC3190

•Data

Setting Multicast Details

To set multicast details:

• Enter IP and port details as required.

•Select SMPTE 2022 from the Flow Type drop-down menu, if required.

• Click Packetizer Stats to view network statistics for an outgoing flow, if required.

• Click S to save the details.

In order to provide redundancy, Primary and Secondary flows are available.

Figure 27 Input Spigot Pane

IQMIX25/26/40/41 RollCall Control Panel

Issue 1 Rev 4 Page 38 © 2017 SAM

5.12.2 Output Spigots

Output spigots are defined by selecting the appropriate firmware version on the

Configuration page. See section 5.4 for more information.

5.12.2.1 Spigot Pane

The Spigot pane provides basic monitoring for the selected Spigot. Click Take to apply any

changes made.

The Spigot pane details:

• Spigot direction;

• Associated BNC connector;

• Current status;

• The last Take performed on the spigot.

Audio Delay

Move the slider to set an Audio Delay as required. Click P to return to the preset default

value.

Make/Break Mode

Specifies how changes to an output’s destination will be made. Make before Break causes

the new destination to buffer dat a before conne ction to the previous d estination is broken; this

results in a smoother transition, but requires more bandwidth. Break before Make simply

swaps the output’s destination without buffering.

Select the required mode from the drop-down list.

Figure 28 Typical Output Spigot Page

Figure 29 Output Spigot Pane

IQMIX25/26/40/41 RollCall Control Panel

Issue 1 Rev 4 Page 39 © 2017 SAM

Streaming

Select the Ethernet connectors to use for this spigot. This will also determine the bandwidth to

be used. Options are:

• Dual - use both Ethernet connectors, and so all available bandwidth.

• Single - use either Ethernet connector, and so half of the available bandwidth.

•A or B - use one particular Ethernet connector, and so half of the available bandwidth.

• None - do not use an Ethernet connector for this spigot.

Format

Select the format to be used on this spigot. This will ensure that the appropriate level of

bandwidth is allocated.

5.12.2.2 Flow Pane

The Flow pane provides status information for video, audio and metadata. It also allows the

video output standard, loopback and multicast IP/port details to be defined for the selected

spigot.

Loopback

The IQMIX can be put into loopback mode for diagnostic purposes. Select the Loopback

radio button and click Take.

Setting Multicast Details

To set multicast details:

• Select the required video output standard from the drop-down list.

• Enter multicast IP and port details as required.

• Make a selection from the Flow Type drop-down menu, if required.

• Click S to save the details, or P to return to the preset default value.

In order to provide redundancy, Primary and Secondary flows are available.

Figure 30 Output Spigot Flow Pane

IQMIX25/26/40/41 RollCall Control Panel

Issue 1 Rev 4 Page 40 © 2017 SAM

5.13 Logging - Misc

Information on several parameters can be made available to a logging device connected to

the RollCall network. Each logging page comprises three columns:

• Log Enable - Select the check boxes that co rrespond to the p aramete rs for which log

information should be collected.

• Log Field - Displays the name of the logging field.

• Log Value - Displays the current log value.

Figure 31 Logging Misc Page

IQMIX25/26/40/41 RollCall Control Panel

Issue 1 Rev 4 Page 41 © 2017 SAM

The following options are available. Enable check boxes to activate log fields as required.

Log Field Description

SN= Reports the module serial number, which consists of an S

followed by eight digits.

Note: this cannot be deselected.

OS_VERSION= Reports the operating system name and version.

BUILD_NUMBER= Reports the build number.

HARDWARE_VERSION= Reports the hardware version number.

HARDWARE_MOD= Reports the hardware modification number.

FIRMWARE_VERSION= Reports the firmware version number.

POWER_USAGE= Reports the power usage in Watts (A-type rack)/PR Units

(B-type rack).

UPTIME= Reports the time since the last restart in the format

ddd:hh:mm:ss.

ROL_STATES= Reports the RollCall status. Valid values are:

• OK

• FAIL:n wh er e n is the RollTrack index or indices

which are failing

• Disabled

REAR_ID= Reports the code number of the rear fitted.

REAR_STATUS= Reports the status of the rear where it can be determined.

SLOT_WIDTH= Reports the slot width. IQMIX modules are available in

single and triple width.

SLOT_START= Reports the slot in the rack where IQMIX is located.

TEMP_N_NAME= Temperature measurement name.

TEMP_N_CELSIUS= Reports the temperature status of the FPGA.

REFERENCE_N_SOURCE= Reports time reference source.

REFERENCE_N_STATE= Valid values are:

• OK: Locked

• OK: Input

• WARN: Freerun

• WARN: CrossLock

TIMESYNC_N_MODE= Valid values are:

• Free running: Card is using its own clock with no

reference to any other source.

• PTP Multicast: Card is synchronizing to a PTP

grandmaster clock using multicast network

messages.

• PTP Unicast: As PTP Multicast but using the

delay request. Reply messages are unicast to

minimize network traffic.

•NTP: Module clock is synchronized to an NTP

clock. Generally less precise than PTP.

IQMIX25/26/40/41 RollCall Control Panel

Issue 1 Rev 4 Page 42 © 2017 SAM

TIMESYNC_N_NETWORK= Network port currently being used for synchronization for

IQMIX modules, dependant on the choice of interfaces

made on the Time Configuration p age. If PTP and multiple

interfaces are enabled, the PTP synchronization will

switch ports if it doesn't see regular sync messages on

the port.

TIMESYNC_N_CLOCK_ID= Identification number of PTP clock being used for

synchronization. This is not necessarily the grandmaster

clock identity, as there can be intermediate clocks

between the grandmaster and the card, depending on

network configuration.

TIMESYNC_N_CLOCK_STATE= Valid values are:

• Free running: Card is not being synchronized.

•No Lock: PTP being used but clocks haven't

synchronized within +/- 1mS.

• Locked: PTP being used and clocks are within

the accepted range.

•NTP: Module using NTP to synchronize.

TIMESYNC_N_AVG_DELAY= The current network delay time between the card and the

clock sending the synchronization messages. This should

be relatively constant and is dependant on network

configuration.

TIMESYNC_N_STDV_DELAY= The current standard deviation in the network delay time

between the card and the clock sending the

synchronization messages. Should be a low number as

the network delay is expected to be constant.

TIMESYNC_N_AVG_ERROR= The current difference between the cards time and the

grandmaster time. Should be close to zero once card has

synchronized.

TIMESYNC_N_STDV_ERROR= The standard deviation in the average error.

TIMESYNC_N_

GRANDMASTER=

Identity of network clock acting as PTP grandmaster. This

is the source of the PTP synchronization messages used

by all PTP slave clocks on the network. If there are

multiple grandmasters, they should negotiate between

themselves to identify the most accurate and then silence

the others.

TIMESYNC_N_LAST_LOCK= Time when the module last changed from not locked to

locked. Ideally this will be a few seconds after the module

has powered up. This allows the user to confirm which

clock the module has synchronized to.

TIMESYNC_N_

SYNCHRONISATION=

Reports the number of times the card has synchronized

since it was powered up. Ideally this will be a low number,

as cards are expected to synchronize and stay

synchronized. Large numbers indicate possible problems

with the network or grandmaster clock.

LAN_PORT_N_NAME= Ethernet port name as defined by the OS.

Log Field Description

IQMIX25/26/40/41 RollCall Control Panel

Issue 1 Rev 4 Page 43 © 2017 SAM

Where N is the input number

LAN_PORT_N_SPEED= Ethernet connection speed. Valid values are:

• 10 Mbit/s Full Duplex

• 10 Mbit/s Half Duplex

• 100 Mbit/s Full Duplex

• 100 Mbit/s Half Duplex

• 1 Gbit/s Full Duplex

• No Link

LAN_PORT_N_IPADDRESS= Ethernet port IP address.

LAN_PORT_N_MACADDRESS= Ethernet port MAC address.

LAN_PORT_N_STATE= Ethernet connection state. Valid values are:

•Active

• Inactive

LAN_PORT_N_TRAFFIC_IN= Traffic in. Valid values are:

• NNN.n Kbps, Mbps, Gbps

LAN_PORT_N_TRAFFIC_OUT= Traffic out. Valid values are:

• NNN.n Kbps, Mbps, Gbps

Log Field Description

IQMIX25/26/40/41 RollCall Control Panel

Issue 1 Rev 4 Page 44 © 2017 SAM

5.14 Logging - SFP

Information on several parameters can be made available to a logging device connected to

the RollCall network. Each logging page comprises three columns:

• Log Enable - Select the check boxes that corr espond to the p arameters for which log

information should be collected.

• Log Field - Displays the name of the logging field.

• Log Value - Displays the current log value.

The following options are available. Enable check boxes to activate log fields as required.

Figure 32 Logging - SFP Page

Log Field Description

SFP_N_FITTED=

SFP_N_STATUS= Displays presence of (Q)SFP. Valid values are:

•OK

•Missing

SFP_N_TYPE= Displays (Q)SFP identifier from device.

SFP_N_VENDOR= Displays (Q)SFP manufacturer from device.

SFP_N_VENDOR_PN= Displays (Q)SFP model number from device.

SFP_N_SERIAL_NR= Displays the module serial number, which consist s of an S

followed by eight digits.

SFP_N_REVISION= Displays manufacturer revision number.

IQMIX25/26/40/41 RollCall Control Panel

Issue 1 Rev 4 Page 45 © 2017 SAM

Where N is the input/(Q)SFP number and X is the lane

SFP_N_CONNECTOR= Displays connector type.

TEMP_N_NAME= Displays temperature sensor name.

TEMP_N_CELSIUS= Displays current temperature sensor reading.

TEMP_N_STATE= Displays temperature sensor state. Valid values are:

• WARN: Disabled - Temperature sensor disabled.

• WARN: Low - Low, but in tolerance.

• WARN: High - High, but in tolerance.

•OK

• FAIL: Low - Low and out of tolerance.

• FAIL: High - High and out of tolerance.

VOLTAGE_N_NAME= Displays voltage sensor name.

VOLTAGE_N_VALUE= Displays current voltage reading.

VOLTAGE_N_STATE= Displays temperature sensor state. Valid values are:

•OK

• WARN: Low - Low, but in tolerance.

• WARN: High - High, but in tolerance.

SFP_N_WAVELENGTH= Displays transmit wavelength in nm.

SFP_N_X_LASER_BIAS= Displays bias level in mA.

SFP_N_X_TX_POWER= Displays transmit power level in dBm.

SFP_N_X_TX_POWER_

STATE=

Displays transmit power level. Valid values are:

•OK

• WARN: Low - Low, but in tolerance.

• WARN: High - High, but in tolerance.

• FAIL: Low - Low and out of tolerance.

• FAIL: High - High and out of tolerance.

SFP_N_X_RX_POWER= Reports receive power level in dBm.

SFP_N_X_RX_POWER_

STATE=

Reports receive power level. Va lid values are:

•OK

• WARN: Low - Low, but in tolerance.

• WARN: High - High, but in tolerance.

• FAIL: Low - Low and out of tolerance.

• FAIL: High - High and out of tolerance.

Log Field Description

IQMIX25/26/40/41 RollCall Control Panel

Issue 1 Rev 4 Page 46 © 2017 SAM

5.15 Logging - FPGA

Information on several parameters can be made available to a logging device connected to

the RollCall network. Each logging page comprises three columns:

• Log Enable - Select the check boxes that corr espond to the p arameters for which log

information should be collected.

• Log Field - Displays the name of the logging field.

• Log Value - Displays the current log value.

The following options are available. Enable check boxes to activate log fields as required.

Where N is the input number

Figure 33 Logging - FPGA Page

Log Field Description

TEMP_N_NAME= Reports temperature sensor name.

TEMP_N_CELSIUS= Reports current temperature sensor reading.

VOLTAGE_N_NAME= Voltage sensor name.

VOLTAGE_N_VALUE= Reports current voltage reading.

IQMIX25/26/40/41 RollCall Control Panel

Issue 1 Rev 4 Page 47 © 2017 SAM

5.16 Logging - Spigot

The Logging - Spigot pages are used to select the fields to be enabled for each available

spigot. Depending on whether the spigot is an input or an output, the appropriate log fields

are shown.

An additional field is provided for the user to optionally specify a name for the input/output.

Figure 34 Input Spigot Logging Page

Figure 35 Output Spigot Logging Page

IQMIX25/26/40/41 RollCall Control Panel

Issue 1 Rev 4 Page 48 © 2017 SAM

The following options are available. Enable check boxes to activate log fields as required.

Where N is the input/output number

Log Field Description

INPUT_N_IDENT= System-defined identifier for the input, based on the rear

ID.

INPUT_N_NAME= Name of the input, as defined by the user on the Setup

page. See section 5.19 .

INPUT_N_STATE= Valid values are:

• OK: input signal good.

• FAIL: input signal not detected.

INPUT_N_TYPE= HD/SD/3G SDI

INPUT_N_STANDARD= PAL/NTSC/625 Mono/525 Mono

OUTPUT_N_IDENT= Name of the output as shown on the rear panel.

OUTPUT_N_NAME= Name of the output as defined by the user.

OUTPUT_N_STATE= Valid values are:

•OK - output signal good.

•FAIL - output signal not detected.

• WARN:Freeze

• WARN: Pattern

• WARN:Black

OUTPUT_N_TYPE= Valid values are:

•SD SDI

•HD SDI

• HD/SD/3G SDI

OUTPUT_N_STANDARD= Reports the output standard in the format:

<Lines>(<Active>)/<Rate><i/p/sf>

Where:

•Lines = Total lines

• Active = Active lines

•Rate = Frame rate

•I = interlaced

•P = Progressive

•SF = Segmented Frame

For example: 1080/50p or 1125(1080)/25i

IQMIX25/26/40/41 RollCall Control Panel

Issue 1 Rev 4 Page 49 © 2017 SAM

5.17 RollTrack

The RollTrack page allows information to be sent, via the RollCall network, to other

compatible units connected on the same network.

The Source window lists the RollTrack sources:

5.17.1 Disable All

When checked, all RollTrack items are disabled.

5.17.2 RollTrack Index

This slider allows up to 16 distinct RollTrack outputs to be set up. Dragging the slider selects

the RollTrack Index number, displayed below the slider. Clicking P selects the default preset

value.

5.17.3 RollTrack Source

The source of information that triggers transmission of data is selected with this control.

Dragging the slider selects the RollTrack source, displayed below the slider. Clicking P

selects the default preset value. When no sour ce is selected, Unused is displayed.

Where N is the input number

Figure 36 Source Pane

RollTrack Source Description

Unused No RollTracks sent.

Input N OK Input N is good.

Input N LOST Input N is bad.

IQMIX25/26/40/41 RollCall Control Panel

Issue 1 Rev 4 Page 50 © 2017 SAM

5.17.4 RollTrack Address

This item enables the address of the selected destination unit to be set.

The address may be changed by typing the new dest ination into the text field, then clicking S

to save the selection. Clicking P returns to the default preset destination.

The RollTrack address consists of four sets of numbers, for example, 0000:10:01*99:

• The first set, 0000, is the network segment code number.

• The second set, 10, is the number identifying the (enclosure/mainframe) unit.

• The third set, 01, is the slot number in the unit

• The fourth set, 99, is a user-definable number that is a unique identifier for the

destination unit in a multi-unit system. This ensures that only the correct unit will

respond to the command. If left at 00, an incorrectly fitted unit may respond

inappropriately.

5.17.5 RollTrack Command

This item enables a command to be sent to the selected destination unit.

The command may be changed by typing a code in to the text field, and then selecting S to

save the selection. Clicking P returns to the default preset command.

A RollTrack command consists of two sets of numbers, for example: 84:156:

• The first number, 84, is the actual RollTrack command.

• The second number, 156, is the value sent with the RollTrack command.

5.17.6 RollTrack Sending

A message is displayed here when the unit is actively sending a RollTrack command.

Possible messages are:

5.17.7 RollTrack Status

A message is displayed here to indicate the status of the currently selected RollTrack index.

Possible RollTrack Status messages are:

Message Description

No The message is not being sent.

Yes The message is being se nt.

RollTrack Source Description

OK RollTrack message was sent and received successfully.

Unknown RollTrack message has been sent but transmission has not

yet completed.

Timeout RollTrack message has been sent but acknowledgement

not received. This could be because the destination unit is

not at the location specified.

Bad RollTrack message has not been correctly ackn owledged at

the destination unit. This could be because the destination

unit is not of the type specified.

Disabled RollTrack sending is disabled.

IQMIX25/26/40/41 RollCall Control Panel

Issue 1 Rev 4 Page 51 © 2017 SAM

5.18 Loopback Router

The Loopback Router page provides a basic SDI router as a redundan t backup in case of

Ethernet failure.

If an Ethernet failure is encountered:

1. Use the matrix radio buttons to specify which inputs should be routed to which

outputs.

2. Select the Video Flow to Use - SMPTE-2022, RFC4175 or VC2.

3. When set as required, click the Enable Router Control check box to activate routing.

Figure 37 Loopback Router Page

IQMIX25/26/40/41 RollCall Control Panel