Snell Acoustics 730770830870 User Manual

Owner’s Manual

AMC

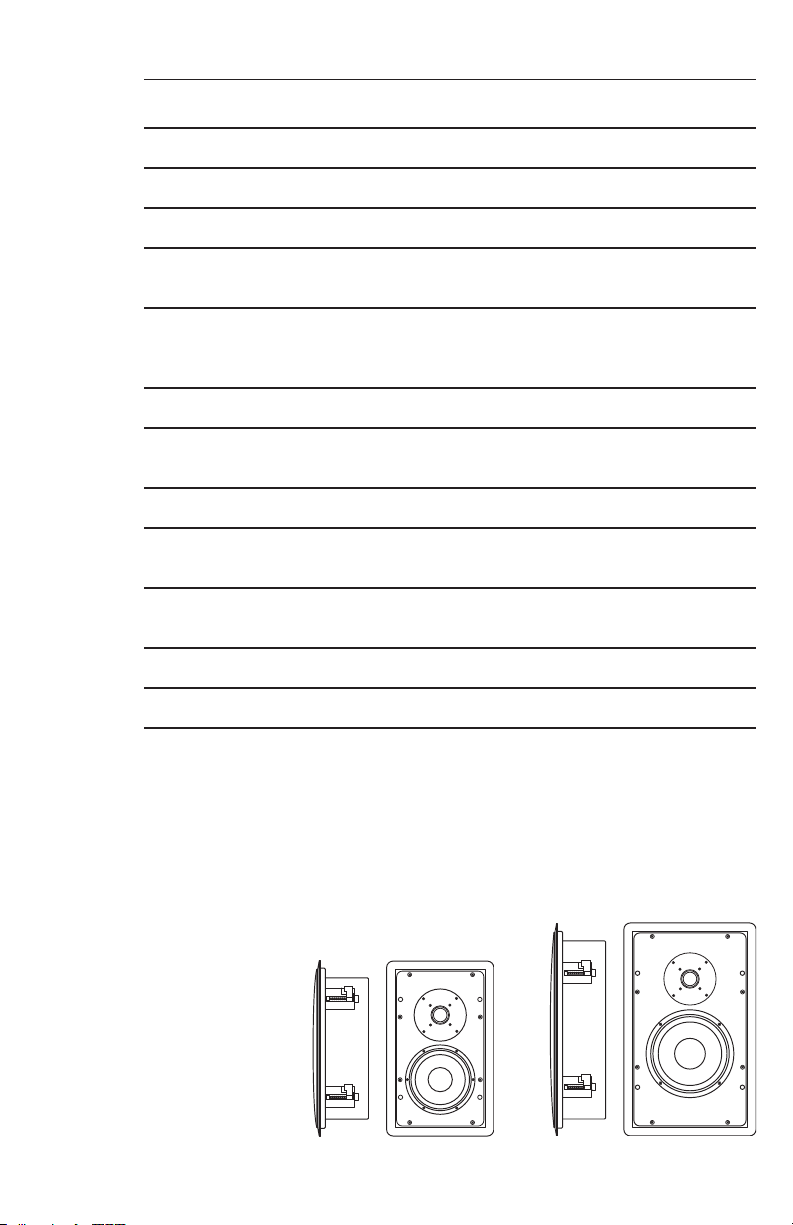

730

770

830

870

SPECIFICATIONS

AMC730

AMC770

Frequency Response (±3dB)

Recommended Amplifier

Nominal Impedance

Sensitivity (2.83v at 1m)

Tweeter

78 Hz–20 kHz

50–125W

8 ohms

87dB SPL

1” SEAS silk dome, ferrofluid

cooling

Bass Driver

51/4-inch (132mm) treated

paper cone with butyl rubber

surround, 5mm excursion

Crossover Point

Composite Baffle

Grille

Dimensions

(HxWxD)

Rough Opening Cutout

(HxW)

Finish*

2.5 khz

Specialty adhesive between two

1

/4” layers of HD fiberboard

Perforated metal, 53% open

14 x 91/2 x 33/4 inches

(356 x 241 x 95mm)

127/8 x 83/8 inches

(327 x 212mm)

White trim, suitable for painting

66 Hz–20 kHz

50–150W

8 ohms

87dB SPL

1” SEAS silk dome, ferrofluid

cooling

61/2-inch (165mm) copolymer

with butyl rubber surround

5mm excursion

2.5 khz

Specialty adhesive between

two 1/4” layers of HD fiberboard

Perforated metal, 53% open

17 x 101/2 x 33/4 inches

(432 x 267 x 95mm)

157/8 x 93/8 inches

(403 x 238mm)

White trim, suitable for painting

Weight

* Custom paint and grilles are available for an extra charge

2

6 lbs (2.7kg) / each

AMC730

9 lbs (4kg) / each

AMC770

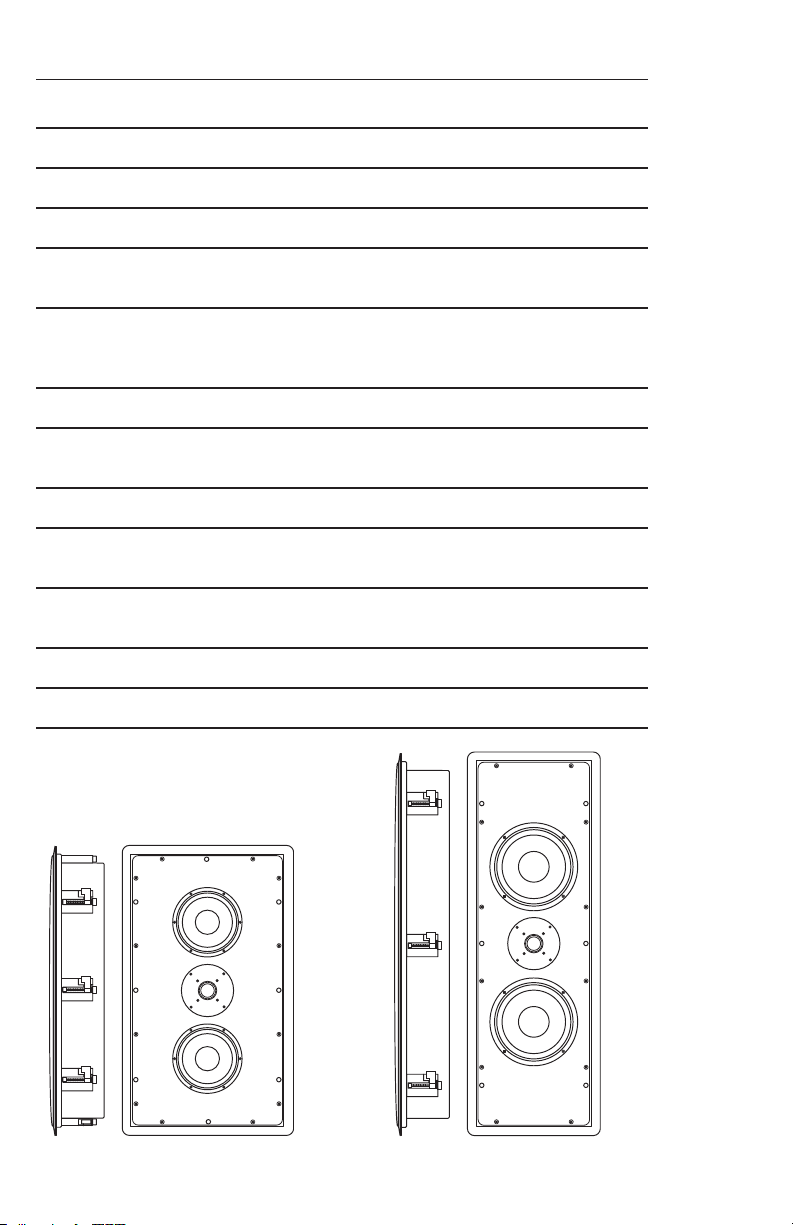

AMC830

AMC870

70 Hz-20 kHz

50–250W

4 ohms

89dB SPL

1” SEAS silk dome, ferrofluid

cooling

2 - 51/4-inch (132mm) treated

paper cone with butyl rubber

surround, 5mm excursion

2kHz

Specialty adhesive between two

1

/4” layers of HD fiberboard

Perforated metal, 53% open

231/4 x 131/4 x 33/4 inches

(590 x 336 x 95mm)

22 x 12 inches

(559 x 305mm)

White trim, suitable for painting

62 Hz-20 kHz

50–250W

4 ohms

90dB SPL

1” SEAS silk dome, ferrofluid

cooling

2- 61/2-inch (165mm) copolymer

with butyl rubber surround,

5mm excursion

2kHz

Specialty adhesive between two

1

/4” layers of HD fiberboard

Perforated metal, 53% open

301/2 x 101/2 x 33/4 inches

(775 x 267 x 95mm)

293/8 x 93/8 inches

(746 x 238mm)

White trim, suitable for painting

19 lbs (8.6kg) / each

AMC830

19 lbs (8.6kg) / each

AMC870

3

INTRODUCTION: WHAT IS A HIGH END IN-WALL?

The new Snell AMC series units bring a novel approach to the design and construction of

in-wall loudspeakers, expanding the boundaries of in-wall performance.

Our primary goal was to develop loudspeakers that delivered performance that was as close as

possible to that of our highly regarded freestanding loudspeakers, like the K7 and LCR7. To do

this several issues had to be addressed.

The bass performance of conventional loudspeakers mounted in wall cavities is very unpredictable. Cavity volume can be large, which should be good for bass performance. However, with

one very short dimension (approximately 4”) and one very long dimension (up to 8’), the wall

cavity takes on the characteristics of a closed-end organ pipe. This creates a strong resonance

that tends to null out the bass. Lining this cavity with fiberglass will reduce the “Q” of the

notch but not restore the bass. What is needed is a defined volume of a more regular size. This

is best done with fully enclosed in-wall speakers.

The Snell AMC loudspeaker enclosure is a thin, but strong, aluminum tub. It is both damped

and braced. This largely contains the back radiated sound of the woofer within the enclosure.

An added benefit of containing the woofer output is a reduced chance that resonances will be

excited in the house walls. Furthermore, sound “bleed through” to adjacent rooms is reduced.

To minimize resonances in the Snell enclosure, the speaker baffle uses a technique first

pioneered on our .5 and XA series loudspeakers. The baffle is a three part composite with MDF

(fiberboard) outer layers around a thin, but highly effective, damping layer. This controls the

panel resonances of the baffle that can obscure midrange clarity. As we have found with our

freestanding loudspeakers, a better loudspeaker cabinet means a better sounding loudspeaker.

In addition to these unique solutions, all traditional Snell attributes are retained. Highly coherent in-phase crossover networks ensure a seamless blend from driver to driver. Drivers are

designed for smooth, wide range response and low distortion. Long sessions of listening and

adjusting give each system that special, characteristic Snell sound. Finally, that Snell sound is

guaranteed in every production pair by Snell’s proprietary 0.5dB production tuning techniques.

4

Loading...

Loading...