Snapper ZTR 800X Series, 5901236, 5900658, 5900654, 5900656 Dealer Setup & Adjustment Instructions Manual

...Page 1

Not for

Reproduction

800X Series Zero-Turn Rider - 61” & 72” Mower Deck

Dealer Setup

& Adjustment Instructions

800X Series Zero-Turn Rider • 61” & 72” Mower Deck

This Dealer Setup Instruction covers the following products:

Model No. Description Model No. Description

5900654 S800XB31 5901236 F800XB31

5900658 S800XKAV28

ZTR

5900656 S800X/61 5901237 F800X/61

5900875 S800X/72 5901238 F800X/72

Mower

Deck

ATTENTION SETUP PERSONNEL:

The safety warnings provided in this guide and

in the operator’s manual included with the unit

contain important information that must be

obeyed when assembling, setting-up, operating,

servicing, transporting, or storing the unit.

These warnings are highlighted by the safety alert triangle

symbol shown above, which signifies that an important

safety message is being provided.

You must read, understand, and follow these warnings and

instructions, and use safe shop and work practices at all

times while working on or around this unit and all other

outdoor power equipment.

Sections and items denoted by the Setup symbol

provide the information necessary to fully

assemble, test, and prepare the units described

above for delivery to your customers.

A Quick Setup List is provided on page 2 of this booklet

to help you identify and check that the items have been

performed.

Additional information concerning functional

tests, general adjustment procedures, and the

location of normal lubrication points are included

in these instructions.

Although all required lubrication and normal adjustments on

factory-assembled components are done at the factory, this

additional information is provided to assist you in ensuring

that each unit is delivered to the customer in proper working

order.

TABLE OF CONTENTS:

SETUP PROCEDURES

Quick Setup List..................................................2

Uncrating ..........................................................3

Connect the Battery..............................................3

Tractor Assembly ................................................4

Ground Speed Control Lever Assembly ...........................4

Seat Assembly ..................................................................4

Roll Bar Assembly ...............................................5

Check Fluid levels ...............................................7

Check Engine Oil Level .....................................................7

Check Hydraulic Oil Level .................................................7

Check Tire Pressure .............................................7

Mower Assembly.................................................8

Check Torque - Mower Blades .........................................8

Check Deck Drive Belt ..........................................9

Check the Mower Belt Idler Tensioning Spring

Length (72” Models Only) ................................................9

Adjust the Mower Belt Idler Tensioning Spring

Length (72” Models Only) ................................................9

Install the Mower Deck .......................................10

Adjust Deck Lift Rod Timing .................................12

Check & Level the Mower Deck .............................13

Deck Lift Spring ................................................ 14

Lubrication ...................................................... 15

Adding Fuel ..................................................... 17

Starting The Engine ........................................... 17

Perform Safety Checks ........................................ 18

Functional Tests .............................................................18

Safety Interlock System .................................................18

ADJUSTMENT PROCEDURES

Seat Adjustment ............................................... 19

Ground Speed Control Lever Adjustment ..................20

Speed Balancing Adjustment ................................20

Neutral Adjustment ............................................ 21

Return-To-Neutral Adjustment ............................... 22

Parking Brake Adjustment .................................... 23

5101742

1

Rev. J

1

Page 2

Not for

Reproduction

800X Series Zero-Turn Rider - 61” & 72” Mower Deck

Setup Procedures

Quick Setup List

Page Setup Procedure Steps to Perform

3 Uncrating

3 Connect Battery Cables

4 Tractor Assembly

5 Roll Bar Assembly

7 Check Fluid Levels

8 Check Mower Assembly

10 Install the Mower Deck

15 Lubrication &

Fuel Preparation

18 SAFETY CHECK

Register Product

Remove Crate & Banding.

Loosen Hydraulic Release Valves.

Release Parking Brake and Roll Tractor forward off skid.

Tighten Hydraulic Release Valves

Connect Battery Cables.

Assemble the Ground Speed Control Levers.

Assemble the Seat.

Assemble the Retainer Pins.

Assemble the Top Loop.

Install the Roll Bar.

Check Engine Oil Level.

Check Hydraulic Oil Level.

Check Tire Pressure.

Check Blade Bolt Torque.

Check Deck Drive Belt.

Install the Mower Deck.

Positioning the Mower Deck for Operation.

Check Deck Lift Rod Timing Adjustment.

Check & Level the Mower Deck.

Lubricate all grease & oil points.

Add fuel.

Start the Engine.

Check for loose hardware.

Check all operator controls.

Perform safety interlock system check.

To register the product: log onto www.thepowerportal.

com, select the appropriate brand, click “My Resources,”

select the “Product Registration and Rebate” icon and

then the “New Product Registration / Rebate” tab. Fill

out and submit the online product registration form.

2

ferrismowers.com | snapperpro.com

Page 3

Not for

Reproduction

800X Series Zero-Turn Rider - 61” & 72” Mower Deck

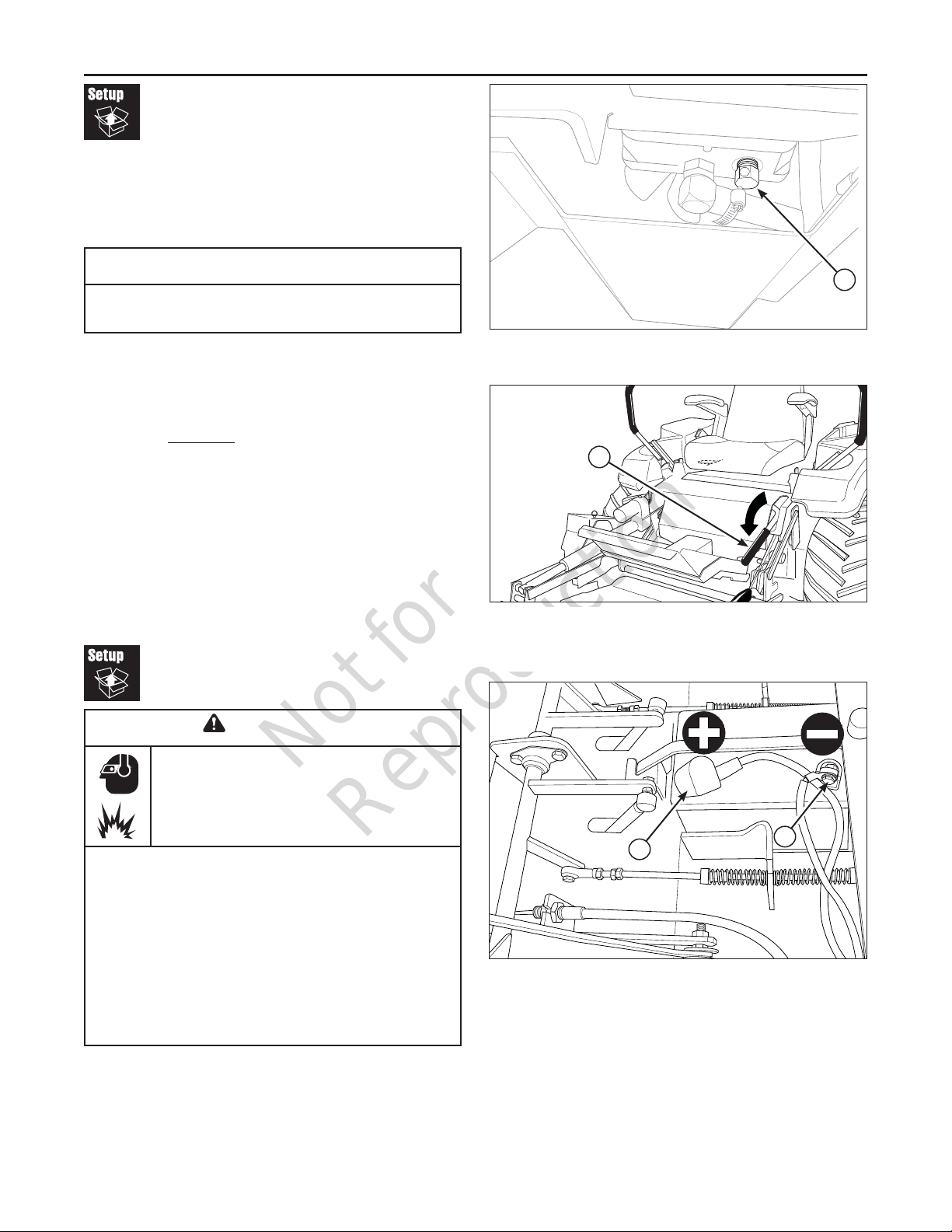

Uncrating

1. Using a reciprocating utility saw or equivalent, cut the

crate away from the bottom skid. Remove the crate.

Remove the shrink-wrap plastic.

2. Cut the nylon banding that secures the unit to the crate.

NOTICE

When cutting the crate from the bottom skid, use caution

around the tires and the mower rollers.

3. Locate the hydraulic release valves (A, Figure 1) on the

bottom side of the hydraulic pumps.

4. Open the hydraulic release valves. To open the release

valves, turn the release valve counter-clockwise two (2)

full turns MAXIMUM See Figure 1 for valve location.

5. Push down on the parking brake lever (A, Figure 2) to

release the parking brake.

6. Be sure there are no nails or sharp objects on the bottom

skid to puncture the machine’s tires. Roll the machine

forward off the bottom skid.

7. After moving the tractor, re-engage the pumps (drive

position) by turning the release valves clockwise and

tighten to 80-120 in/lbs (9-13.5 Nm). See Figure 1 for

valve location.

Connect Battery Cables

A

Figure 1. Hydraulic System By-Pass

A. Hydraulic Release Valve (right-hand pump shown)

A

Figure 2. Disengaging the Parking Brake

(lever shown in disengaged position)

A. Parking Brake Lever

WARNING

Battery acid can cause severe burns. Wear

protective gear when handling the battery.

Open flames and sparks can cause the

battery to explode.

BATTERY SAFETY RULES:

• Battery acid causes severe burns. Avoid contact with

skin.

• Wear eye protection when handling the battery.

• To avoid an explosion, keep flames and sparks away

from battery, especially while charging.

• When installing the battery cables, CONNECT THE

POSITIVE (+) CABLE FIRST and negative (-) cable last.

If not done in this order, the positive terminal can be

shorted to the frame by a tool.

1. Connect the red positive battery cable (B, Figure 3) to

the positive battery post.

2. Connect the black negative battery cable (A) to the

negative battery post.

A

B

Figure 3. Battery Compartment

A. Positive Battery Cable

B. Negative Battery Cable

3

Page 4

Not for

Reproduction

800X Series Zero-Turn Rider - 61” & 72” Mower Deck

Tractor Assembly

Ground Speed Control Lever Assembly

1. Remove the ground speed control lever and mounting

hardware from the handle bar box.

NOTE: There is a LEFT-HAND and a RIGHT-HAND ground

speed control lever . When assembled to the control lever

mount, the control lever base should be pointing towards the

rear of the machine as shown in Figure 4.

2. Install the ground speed control levers (A, Figure 4)

onto the control lever mount (C) using the 5/16-18 x 1”

bolts, 5/16” lock washers and 5/16” flat washers (B).

Prior to tightening the bolts, align the levers with each

other (see Ground Speed Control Lever Adjustment).

Seat Assembly

1. Unpack the seat.

2. Install the seat onto the seat mount plate and secure with

the 5/16-18” nylock flange nuts (A, Figure 5).

A

B

C

Figure 4. Ground Speed Control Lever Installation

A. Ground Speed Control Lever

B. 5/16-18 x 1” Bolt(s), 5/16” Lock Washer(s) & 5/16”

Flat Washer(s)

C. Control Lever Mount

A

4

A

Figure 5. Install the Seat & Connect the Harness

A. 5/16-18” Nylock Flange Nuts

ferrismowers.com | snapperpro.com

Page 5

Not for

Reproduction

800X Series Zero-Turn Rider - 61” & 72” Mower Deck

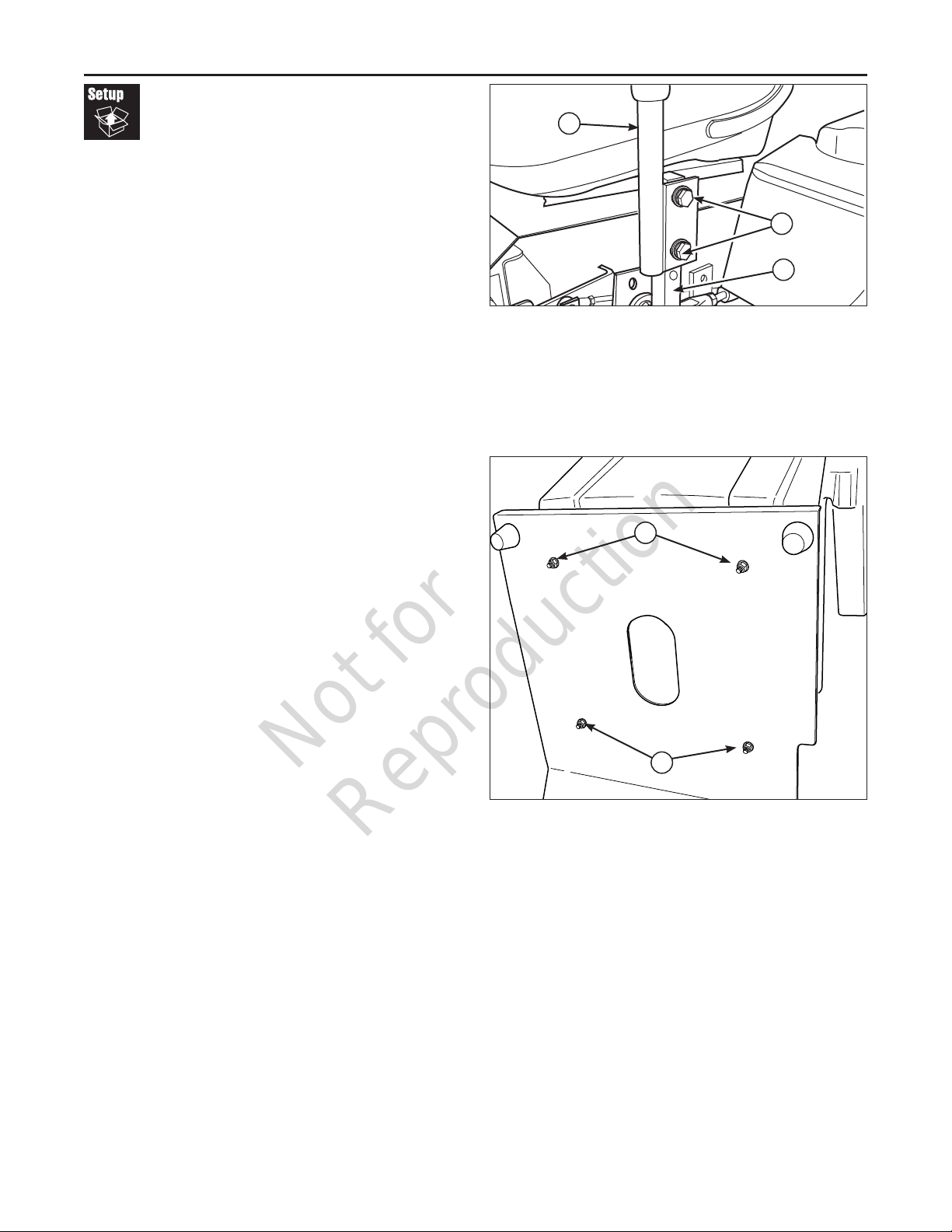

Roll Bar Assembly

Assemble Retainer Pins

1. Unpack the roll bar and hardware from the box.

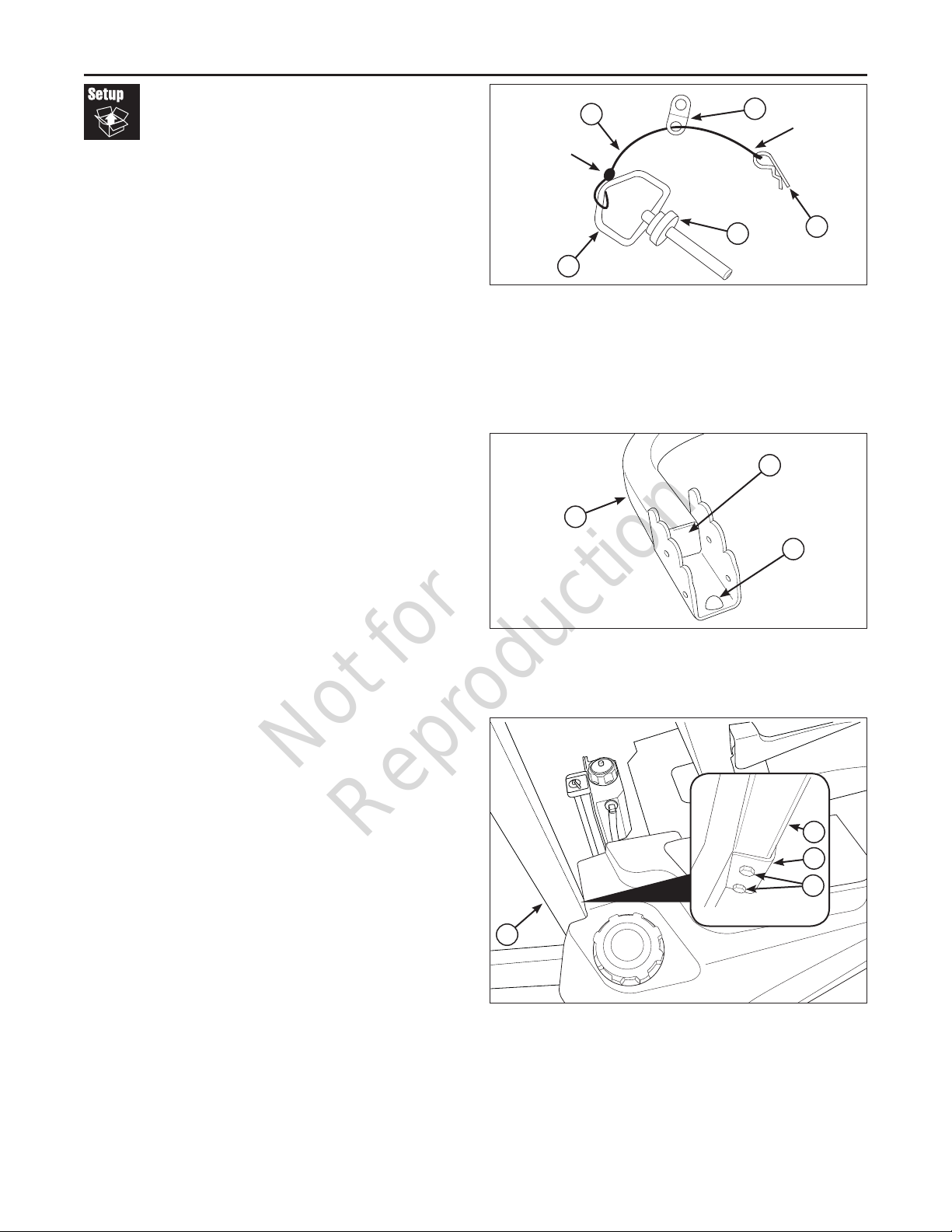

2. Assemble the foam ring (A, Figure 6) onto the retainer

pin (B).

3. Loop the snap end of the lanyard (C) through the retainer

pin handle and snap together.

4. Install the lanyard anchor (D) onto the lanyard.

5. Install the clevis pin (E) onto the loop end of the lanyard

as shown in Figure 6.

Assemble the Top Loop

1. Install the plastic cap (B, Figure 7) into the end of the

top loop tube (A). Repeat for other end of tube.

2. Make sure the rubber stop (C) is properly seated against

the inside of the pivot mount. See Figure 7.

C

Snap End

B

Figure 6. Assemble the Retainer Pins

A. Foam Ring

B. Retainer Pin

C. Lanyard

D. Lanyard Anchor

E. Clevis Pin

A

D

A

Loop End

E

B

C

Install the Roll Bar

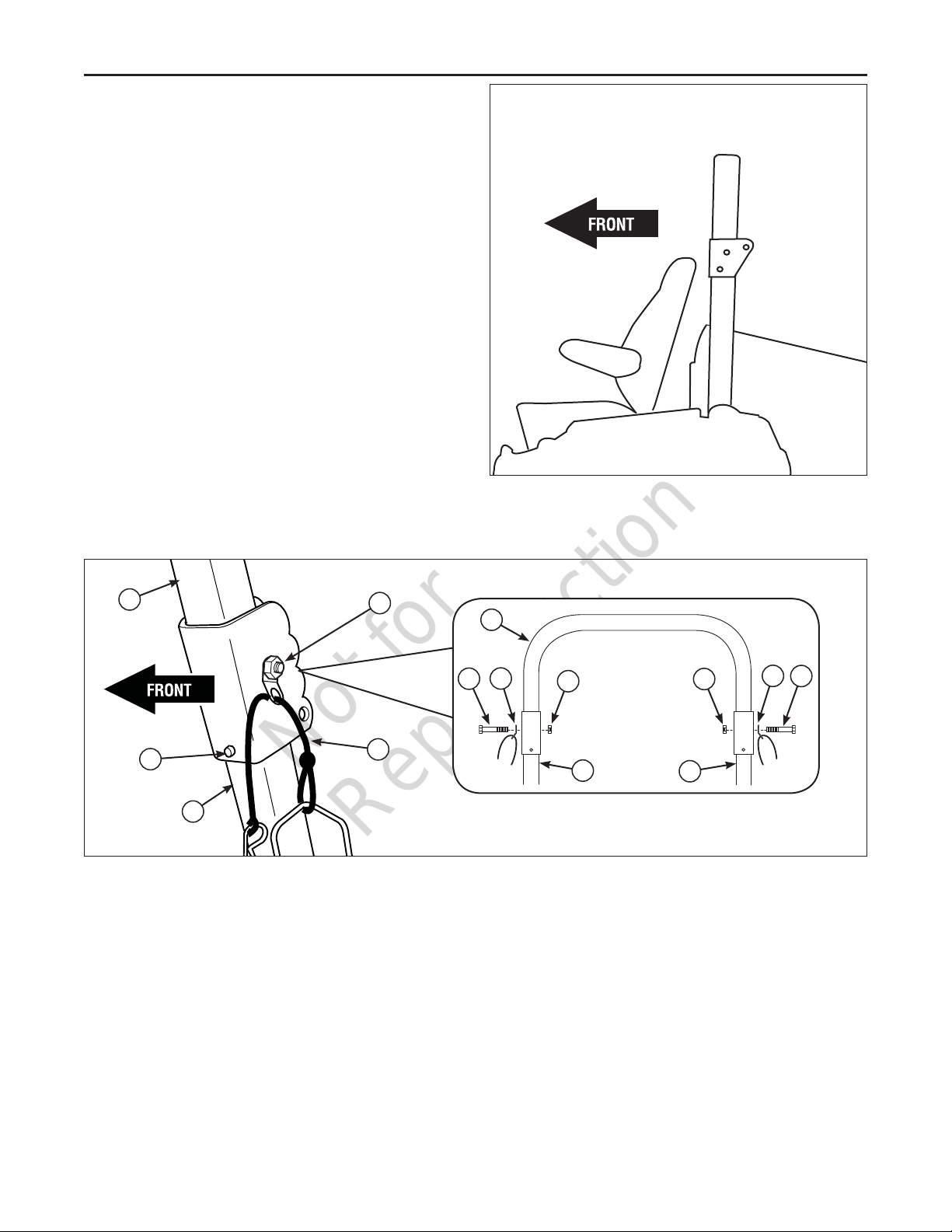

1. Make sure the roll bar sockets (A, Figure 8) are clear of

any obstructions, wires, foreign objects, etc.

2. Install the roll bar upright tubes (B) into the sockets.

Loosely Install the 1/2-13 X 3-1/4” hex head bolts and

1/2-13 hex side lock nuts (C).

3. Repeat steps 1 and 2 for the other side of the machine.

Figure 7. Assemble the Top Loop

A. Top Loop Tube

B. Plastic Cap

C. Rubber Stop

B

A

C

Rear View

B

Figure 8. Install the Upright Tubes

A. Roll Bar Sockets

B. Upright Tube

C. 1/2” x 3-1/4” Bolt, 1/2” Flat Washer & 1/2” Nylock Flange

Nut (not shown)

5

Page 6

Not for

Reproduction

800X Series Zero-Turn Rider - 61” & 72” Mower Deck

4. Install the top loop (A, Figure 10) onto the upright tubes

(B). From the outside, install the 1/2” x 3-1/4” bolt (C)

through the retainer pin assembly (D), then through

the top loop and upright tube and shown in FIgure 10.

Loosely install the 1/2” side lock nut (E). Repeat for

other side.

5. Tighten the hardware securing the upright tubes to the

frame (see Figure 8). Torque the hardware to 75 ft. lbs.

(102 Nm).

6. Tighten the 1/2” x 3-1/4” bolts and hex side lock nuts

(C & E) securing the top loop (A) to the upright tubes

(B). Do not over-tighten. The top loop should pivot

snugly with the retainer pins removed.

7. Raise the top loop (A) until the rubber stops (F) contact

the upright tubes.

8. Push or pull the top of the roll bar forward against the

rubber stops and install the retainer pins and hair pin

clips to secure the roll bar in the raised position.

Figure 9. Upright Tube Orientation

A

F

B

Figure 10. Install Top Loop

A. Top Loop

B. Upright Tube

C. 1/2” x 3-1/4” Bolt GD.5

D. Retainer Pin Assembly

E. 1/2” Side Lock Nut

F. Rubber Stop

C

A

D

D

C

D

E

B

E

B

C

6

ferrismowers.com | snapperpro.com

Page 7

Not for

Reproduction

800X Series Zero-Turn Rider - 61” & 72” Mower Deck

Check Fluid Levels

Check Engine Oil Level

1. Raise the hood to gain access to the engine oil dipstick.

2. Use the engine oil dipstick (A, Figure 11) to check the

engine oil level. If necessary add engine oil through the

crankcase oil fill (B). Check the engine manufacturer’s

owner’s manual for oil recommendations.

Check Hydraulic Oil Level

1. Raise the hood to gain access to the hydraulic oil

reservoir.

2. Before removing the reservoir cap, make sure the area

around the reservoir cap and the fill neck of the reservoir

is free of dust, dirt, or other debris.

3. Unscrew the reservoir cap (B, Figure 12).

4. Look down the filler neck of the hydraulic oil reservoir

(A) and observe the oil level. When cold, the oil level

should be approximately 4” (10 cm) below the top of the

filler neck.

5. If necessary, add either Mobil 1™, 15W-50 synthetic oil

or Castrol Syntec™ 5W-50 oil. DO NOT use conventional

oils.

6. Reinstall the reservoir cap.

B

A

Figure 11. Check Engine Oil Level (Unit Shown With Hood

Raised)

A. Engine Oil Dipstick

B. Crankcase Oil Fill

B

A

Check Tire Pressures

Tire pressure should be checked periodically, and

maintained at the levels shown in the chart. Note that these

pressures may differ slightly from the “Max Inflation”

stamped on the side-wall of the tires. The pressures shown

provide proper traction, improve cut quality, and extend tire

life.

Tire

Deck Caster Tires 25 psi (1,03 bar)

Drive Tires 10 psi (0,69 bar)

Tractor Caster Tires

Pressure

25 psi (1,03 bar)

Figure 12. Checking Hydraulic Oil Level

A. Hydraulic Oil Reservoir

B. Reservoir Cap

Figure 13. Checking Tire Pressure

7

Page 8

Not for

Reproduction

800X Series Zero-Turn Rider - 61” & 72” Mower Deck

Check Mower Assembly

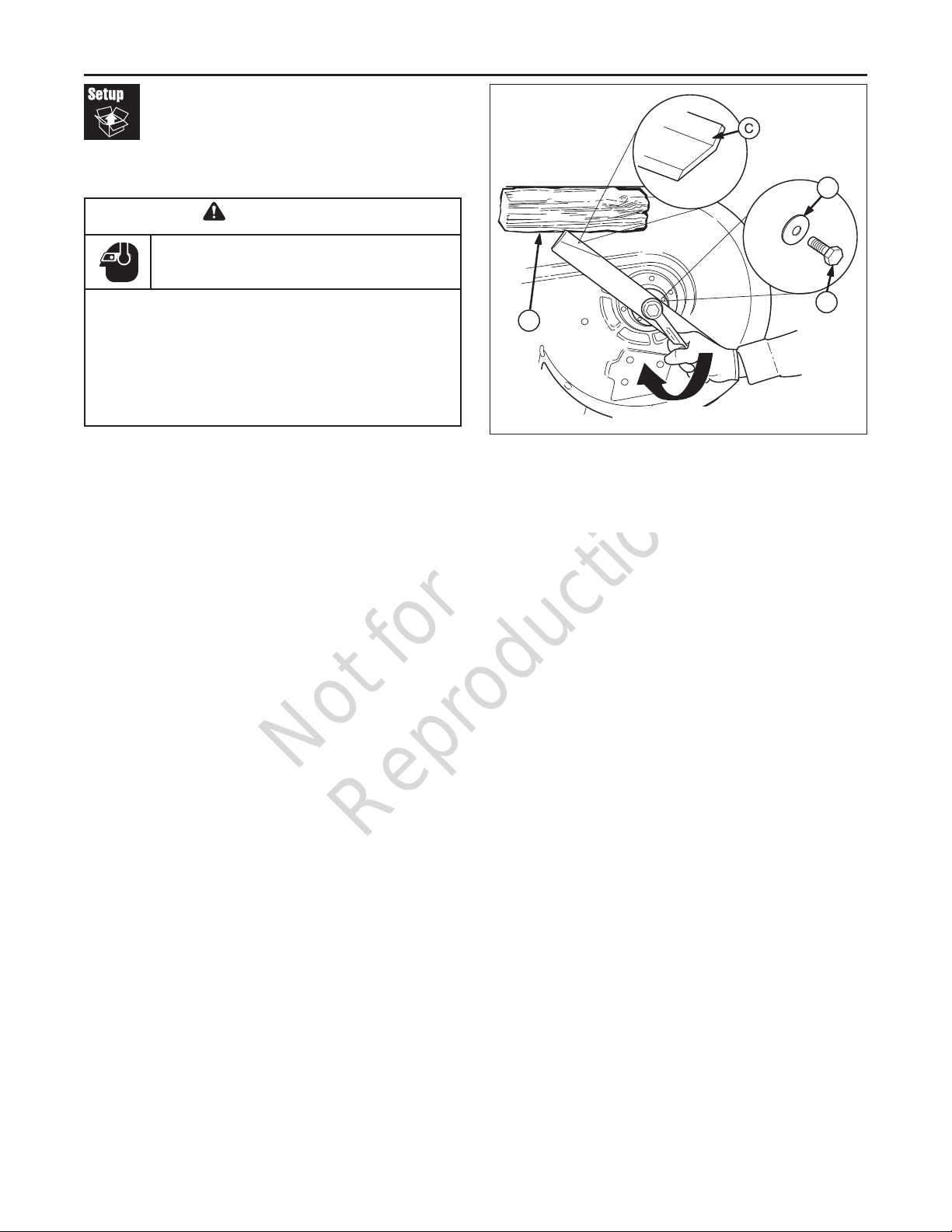

Check Torque - Mower Blades

WARNING

Avoid injury! Mower blades are sharp.

• Mower blades are sharp. For your personnal safety, do

NOT handle mower blades with bare hands.

• Careless or improper handling of blades may result in

serious injury.

• Blade mounting bolts must each be installed with a flat

washer then securely tightened. Torque blade mounting

bolts to 120 ft.lbs (163 Nm).

1. Check that blades are installed with the tabs pointing up

towards the deck as shown in Figure 14. Torque bolts

to 120 ft.lbs. (63 Nm).

B

A

D

TIGHTEN

Figure 14. Tightening the Mower Blade for Installation

A. Mower Blade Mounting Bolt

B. Flat Washer

C. Mower Blade Air Lift (Points Up)

D. 4 X 4 Wooden Block

8

ferrismowers.com | snapperpro.com

Page 9

Not for

Reproduction

800X Series Zero-Turn Rider - 61” & 72” Mower Deck

Check Deck Drive Belt

NOTICE

To avoid damaging belts, do NOT pry belts over pulleys.

1. Make sure the V-side of the belt runs in the pulley

grooves (Figure 15).

WARNING

Spring loaded components can kick back

causing injuries.

Use extreme caution when rotating the idler arm with the

breaker bar, due to the increased tension in the spring

as the idler arm is being rotated. Injury may result if the

breaker bar is prematurely released while the spring is

under tension.

2. If belt is not properly seated remove the mower deck

guards.

3. Use a 1/2” breaker bar, and place the square end in

the square hole located in the end of the idler arm (A,

Figures 15). Carefully rotate the breaker bar counterclockwise, which will relieve the tension on the belt

exerted from the idler arm and spring.

4. Re-seat belt and carefully release the tension on the

breaker bar.

Check the Mower Belt Idler Tensioning Spring

Length (72” Models Only)

1. Remove the mower deck guards.

2. Set the mower deck to the 3-1/2” (8.9 cm) cutting

height.

3. Measure the coil length (A, Figure 16) of the mower belt

idler tensioning spring (B). The measurement should

equal 7-1/4” ± 1/8” (18.42 cm ± .32 cm). If not, perform

the Adjust the Mower Belt Idler Tensioning Spring

Length.

A

D

C

B

Figure 15. Mower PTO Belt

A. Idler Arm

B. Stationary Idler Pulley

C. Deck Drive Belt

D. Spindle Pulley

E. Gearbox Pulley

A

D

E

Figure 16. Mower Belt Idler Tensioning Spring (72” Models)

A. Coil Length

B. Idler Tensioning Spring

C. Jam Nut

D. Eye Bolt

E. Adjustment Nut

D

E

D

B

B

C

Adjust the Mower Belt Idler Tensioning Spring

Length (72” Models Only)

1. Loosen the jam nut (C, Figure 16) on the eye bolt (D).

2. Turn the adjustment nut (E) until the measurement

equals 7-1/4” ± 1/8” (18.42 cm ± .32 cm).

3. Re-tighten the jam nut.

4. Re-install the mower deck guards.

5. Run the mower under no-load condition for about five

(5) minutes to break in the new belt.

9

Page 10

Not for

Reproduction

800X Series Zero-Turn Rider - 61” & 72” Mower Deck

Install the Mower Deck

CA B D E

Installing the Mower Deck

1. Remove the mower deck from the crate and place on a

hard, level surface.

2. Install the 1/4” SQ. X 1-1/4” key in the key slot of the

gear box shaft.

3. Orient the telescoping drive shaft so that end with

the drive shaft collar is away from the gear box shaft.

Install the telescoping driveshaft to the gear box

shaft. The gear box shaft should be 1/16” from being

flush with the back end of the universal joint of the

telescoping drive shaft.

4. Secure the telescoping drive shaft using the 3/8-16

X 1-3/4” bolt and 3/8-16 hex nylon lock nut that is

included with the unit. Also, tighten the 3/8-16 X 3/8 set

screw

5. Remove the pins with lanyards (B, Figure 17) from the

rear holes of the attachment latches (D).

6. Raise the deck attachment lever (E) by pulling the lever

up and back.

7. Slowly drive the tractor into the mower deck so that

the attachment lift arms (A) contact the front frame

assembly on the mower deck.

8. Engage the parking brake and turn the ignition key to the

OFF position.

9. Push the deck attachment lever (E) forward and down.

Make sure the attachment latches latch into place.

10. Connect the actuator (A, Figure 18) to the tractor using

the pin w/ lanyard (B).

11. Raise the seat plate and connect the actuator wire

harness (A, Figure 19) to the main wiring harness of

the tractor by pressing the connector ends together and

then rotating the connector dial (B) to lock the harness

together.

12. Locate the drive shaft (A, Figure 20) under the machine

and connect it by pulling the drive shaft collar (B)

towards the universal joint and then sliding the drive

shaft onto the spline shaft. Release the drive shaft collar

so that the drive shaft locks into place.

13. Turn the ignition key (C, Figure 21) to the RUN position

and retract the actuator completely by pushing the

deck lift switch actuator (B) backwards (towards the

operator’s position). When the actuator is completely

retracted turn the ignition key to the OFF position.

14. Connect the two (2) spring links (C, Figure 17) to the

tractor at the tractor connection point (F) using a 1/2

SAE washer and a .0915 X 1-7/8 hair pin.

F

Figure 17. Attachment Lift Arms

A. Attachment Lift Arms

B. Pin with Lanyard

C. Spring Links

D. Attachment Latches

E. Deck Attachment Lever

F. Tractor Connection Point

B

A

Figure 18. Actuator

A. Actuator

B. Pin with Lanyard

A

B

Figure 19. Actuator Wire Harness

A. Actuator Wire Harness

B. Connector Dial

10

ferrismowers.com | snapperpro.com

Page 11

Not for

Reproduction

800X Series Zero-Turn Rider - 61” & 72” Mower Deck

Positioning the Mower Deck for Operation

1. Turn the ignition key to the ON position and extend the

actuator fully by pushing the deck lift switch actuator (B,

Figure 21) forward (away from the operator’s position).

2. Install the pins with lanyards (B, Figure 17) into the

attachment lift arms (A) as shown in Figure 16.

3. Reposition the cutting height adjustment pin (A, Figure

21) to the desired cutting height.

4. Retract the actuator until contact is made with the

cutting height adjustment pin. Continue to retract the

actuator until the operating position indicator lamp (C)

stops flashing and shuts off.

NOTE: The actuator MUST be positioned correctly before

attempting to move the ground speed control levers out of

their NEUTRAL positions. If the actuator is not positioned

as described in the above step the mower’s safety

interlock system will cause the engine to shut off.

Figure 20. Drive Shaft

A. Drive Shaft Universal Joint

B. Drive Shaft Coupler

D

B

A

A

B

Figure 21. Mowing Height Adjustment

A. Cutting Height Adjustment Pin

B. Actuator Deck Height Toggle Switch

C. Ignition Switch Key

D. Operating Position Indicator Lamp

C

11

Page 12

Not for

Reproduction

800X Series Zero-Turn Rider - 61” & 72” Mower Deck

Check the Deck Lift Rod

Timing Adjustment

1. Park the machine on a flat, level surface. Disengage the

PTO, engage the parking brake, turn off the engine, and

remove the ignition key. Drive tires must be inflated to

10 psi (0,69 bar); tractor caster tires to 25 psi (1,72 bar);

mower deck caster tires to 25 psi (1,72 bar).

2. To check the deck lift rod timing, set the cutting height

adjustment to 3-1/4” (8,26 cm). Both the front and rear

rod pivots should be straight up and down. See Figure

22.

3. If the front and back rod pivots are straight up and down,

no further adjustment is required. If the front and back

rod pivots are NOT straight up and down, adjustment is

required, continue with Step 4.

4. Block up the mower deck up until all hanger chains are

slack. Refer to Figure 23.

5. See Figure 24. To adjust the lift rod, loosen the jam nut

(B, Figure 24) on the front clevis (C) and then remove

the 1/2” clevis pin fastening the clevis to the lift pivot

arm.

• Turn the clevis CLOCKWISE to cause the rod pivot to

pivot backwards;

• Turn the clevis COUNTER-CLOCKWISE to cause the

rod pivot to pivot forwards.

Reinstall the clevis on the lift pivot arm and secure with

the 1/2” clevis pin previously removed. Tighten the jam

nut against the clevis.

6. Remove the blocks from under the mower deck.

7. Extend the actuator until the pressure is removed from

the cutting height adjustment pin. Position the cutting

height adjustment pin in the desired cutting height

location and retract the actuator until contact is made

with the cutting height adjustment pin. Continue to

retract the actuator until the back end of the deck lift

shaft bolt (D, Figure 21) is 1/2” (1,27 cm) from the end

of the slot in the actuator link bar (E).

NOTE: The actuator must be positioned correctly before

attempting to activate the PTO clutch. If the actuator is not

positioned as described in the above step the mower’s safety

interlock system will cause the engine to shut off.

Figure 22. Checking the Deck Lift Rod Timing

Figure 23. 2 x 4 Locations

A

Figure 24. Deck Lift Rod Timing Adjustment

A. Rod Pivots

B. Jam Nut

C. Clevis

These edges of the

rod pivots should be

straight up and down.

C

B

A

12

ferrismowers.com | snapperpro.com

Page 13

Not for

Reproduction

800X Series Zero-Turn Rider - 61” & 72” Mower Deck

Check the Level of the Mower

Deck

NOTE: Before adjusting the deck level, the deck lift rod

timing must be checked and/or adjusted.

Coarse Adjustment Procedure

When adjusting the deck level, the coarse adjustment

procedure should be used to make the majority of the

adjustment and the fine adjustment procedure should be

used to complete the adjustment.

1. Park the machine on a flat, level surface. Disengage

the PTO, stop the engine and engage the parking brake.

Drive tires must be inflated to 10 psi (0,69 bar); tractor

caster tires to 25 psi (1,72 bar); mower deck caster tires

to 25 psi (1,72 bar).

2. Extend the actuator until the pressure is removed from

the cutting height adjustment pin. Place the cutting

height adjustment pin in the 4” position and retract the

actuator until contact is made with the cutting height

adjustment pin.

3. Place 2 x 4 blocks under each corner of the mower deck

with the 3-1/2” sides being vertical. See Figure 25.

4. Loosen the nuts (A, Figure 26) and allow the front of the

deck to rest on the 2 x 4’s. Slide the chains down in the

slots until the chains are tight and tighten the nuts. See

Figure 26.

5. Loosen the nuts (A) and allow the rear of the deck to rest

on the 2 x 4’s. Slide the chains down in the slots until

the chains are tight and tighten the nuts. See Figure 26.

6. Remove all 2 x 4 blocks from under the mower deck.

Figure 25. 2 x 4 Locations

A

Figure 26. Hanger Chain Adjustment

A. Adjustment Point

A

A

CAUTION

Avoid injury! Mower blades are sharp.

Always wear gloves when handling mower blades or

working near blades.

7. Position the outside mower blades so that they face

front-to-back (Figure 27).

8. Measure from the front tip of the blade from the cutting

edge to the ground. Measure from the rear tip of the

blade from the cutting edge to the ground. Repeat this

process for the other side of the machine.

• The front measurement should be 4” (10,2 cm);

• The back measurement should be 4” (10,2 cm).

If the above measurements are achieved not further

adjustment is necessary. If the above measurements are

NOT achieved proceed with Fine Adjustment Procedure.

A

Figure 27. Checking The Blade Height Adjustment

A

13

Page 14

Not for

Reproduction

800X Series Zero-Turn Rider - 61” & 72” Mower Deck

Fine Adjustment Procedure

1. Loosen the jam nut (A, Figure 28) and turn the fine

adjustment bolt (B) to adjust the deck height until the

front measurement equals 4” (10,2 cm) and the back

measurement equals 4” (10,2 cm)

• Turn the bolt CLOCKWISE to raise the deck.

• Turn the bolt COUNTER-CLOCKWISE to lower the

deck.

2. Position the outside mower blades so that they face

front-to-back.

3. Re-measure from the front tip of the blade from the

cutting edge to the ground. Measure from the rear tip of

the blade from the cutting edge to the ground. Repeat

the process for the other side of the machine.

3. Once the front measurement equals 4” (10,2 cm) and the

back measurement equals 4” (10,2 cm), re-tighten the

jam nut.

Figure 28. Fine Adjustment of the Deck Cutting Height

A. Jam Nut

B. Fine Adjustment Bolt

B

A

Deck Lift Spring

The deck lift springs (A, Figure 29) are factory set to

provide optimal lifting performance.

Although it is fastened with an adjustable anchor, this is

NOT an adjustment point.

Do NOT attempt to adjust the length of the deck lift spring

or lifting performance will be compromised.

A

Figure 29. Deck Lift Spring Location

A. Deck Lift Spring

14

ferrismowers.com | snapperpro.com

Page 15

Not for

Reproduction

800X Series Zero-Turn Rider - 61” & 72” Mower Deck

Lubrication

Lubricate the unit at the location shown in Figures 30

through 36 as well as the following lubrication points:

Grease:

• front caster wheel axles & yokes

• drive shaft pillow blocks

• deck lift pivot blocks

• mower deck spindles & idler arm

• rear pivoting axle

• hydraulic pump drive and PTO clutch idler arms

Use grease fitting when present. Disassemble parts to apply

grease to moving parts when grease fittings are not installed.

Not all greases are compatible. Red grease (p/n 5022285)

is recommended, automotive-type high temperature, lithium

grease may be used when this is not available.

Oil:

• control handle pivots

• seat plate pivots

• deck lift pivots

• discharge chute pivots

• attachment lift arm pivots

Generally, all moving metal parts should be oiled when

contact is made with other parts. Keep oil and grease off of

belts and pulleys. Remember to wipe fittings and surfaces

clean both before and after lubrication.

Lubricating the Casters:

NOTE: Casters should be lubricated annually.

1. Remove the 1/4-28 bolt (A, Figure 31) screwed into the

caster and install a 1/4-28 grease fitting.

2. Grease the front caster.

3. Remove the 1/4-28 grease fitting and reinstall the 1/4-28

bolt.

4. Repeat the process for the other side of the machine.

Figure 30. Drive Shaft and Pivoting Axle

A

Figure 31. Front Caster & Wheel

A. 1/4-28 Bolt

15

Page 16

Not for

Reproduction

800X Series Zero-Turn Rider - 61” & 72” Mower Deck

Figure 32. Control Handle Pivots & Seat Plate Pivot

A B

Figure 33. Idler Arms

A. PTO Clutch Drive Belt Idler Arm

B. Hydraulic Pump Drive Belt Idler Arm

Figure 35. Attachment Lift Arms & Actuator

Figure 36. Deck Lift Rods

Figure 34. Mower Deck Lubrication Points

16

ferrismowers.com | snapperpro.com

Page 17

Not for

Reproduction

800X Series Zero-Turn Rider - 61” & 72” Mower Deck

Adding Fuel

To add fuel:

1. Remove the fuel cap (A, Figure 37).

2. Fill the tank to the bottom of the filler neck. This will

allow for fuel expansion.

NOTE: Do not overfill. Refer to your engine manual for

specific fuel recommendations.

3. Install and hand tighten the fuel cap.

Starting The Engine

1. While sitting in the operator’s seat, engage the parking

brake and make sure the PTO switch is disengaged

and the ground speed control levers are locked in the

NEUTRAL position. Make sure the fuel valve (B, Figure

37) is in the “ON” position.

2. Set the engine throttle control to FAST throttle position.

Then fully close the choke by pulling the knob OUT fully.

3. Insert the key into the ignition switch and turn it to

START.

4. After the engine starts, gradually open the choke (push

knob down fully). Reduce to half throttle speed and

allow the engine to warm up.

Warm up the engine by running it for at least a minute

before engaging the PTO switch or driving the rider.

5. After warming the engine, ALWAYS operate the unit at

FULL THROTTLE when mowing.

Safety Interlock and Mower Deck Positioning

Instructions

This unit is equipped with an safety interlock system to

help keep the operator safe while running the unit. Please

read and understand the SAFETY INTERLOCK SYSTEM and

FEATURES AND CONTROLS sections before attempting to

drive or operate the mower. In order for the unit to operate

properly, the controls must be in the correct positions and

used in the correct sequence.

Driving the Mower:

The mower deck MUST either be positioned in the Operating

position or the Service position before you move the ground

speed control levers out of the neutral position. If not, the

safety interlock system will cause the engine to shut off.

The safety interlock system will prevent you from driving

the mower UNTIL the mower deck is positioned in either the

Operating or Service position.

Operating the Mower:

The mower deck MUST be positioned in the Operating

position BEFORE engaging the PTO clutch. If not, the PTO

will NOT engage and remain off UNTIL the mower deck is

properly positioned in the operating position, the PTO switch

is DISENGAGED and then RE-ENGAGED.

If you raise the mower deck from the operating position with

the PTO clutch ENGAGED the PTO will shut off and remain

off UNTIL the mower deck is properly positioned in the

operating position, the PTO switch is DISENGAGED and then

RE-ENGAGED.

B

Figure 37. Adding Fuel

A. Fuel Cap

B. Fuel Valve

A

17

Page 18

Not for

Reproduction

800X Series Zero-Turn Rider - 61” & 72” Mower Deck

Perform Safety Checks

Functional Tests

WARNING

• Disengage the PTO, stop the engine, set the parking

brake, and wait for moving parts to stop before leaving

operator’s position for any reason.

• If the machine does not pass the test, do NOT operate

the machine. Under no circumstance should you attempt

to defeat the purpose of the safety system.

1. Check the unit for loose bolts, screws, nuts, etc.

2. Start the engine and check all controls for proper

operation: ground speed control levers, parking brake,

throttle cable, electric PTO clutch, etc.

3. Stop the engine and check for fluid leaks: oil, fuel, gear

and hydraulic oil.

4. If any control fails to operate properly during testing or

seems to be out of adjustment, check and readjust it

according to the following Adjustments section.

WARNING

If the unit does not pass a safety test, do NOT operate

it. See your authorized dealer. Under no circumstance

should you attempt to defeat the purpose of the safety

interlock system.

Safety Interlock System

This unit is equipped with safety interlock switches. These

safety systems are present for your safety, do not attempt

to bypass safety switches, and never tamper with safety

devices. Check their operation regularly.

Operational SAFETY Checks

Test 1 — Engine should NOT crank if:

• PTO switch is engaged, OR

• Parking brake is not engaged, OR

• Ground speed control levers are not in the NEUTRAL

position, OR

Test 2 — Engine SHOULD crank if:

• PTO switch is NOT engaged, AND

• Parking brake is engaged, AND

• Ground speed control levers are locked in the NEUTRAL

position, AND

Test 3 — Engine should SHUT OFF if:

• Operator rises off the seat with the PTO engaged, OR

• Operator rises off the seat with the parking brake

disengaged.

• Operator moves the ground speed control levers out of

their NEUTRAL positions before disengaging the parking

brake.

• Operator moves the ground speed control levers out of

the NEUTRAL position be positioning the mower deck in

the operating position.

Test 4 — PTO SHOULD shut off if:

• Operator raises the deck from the operating position

with the PTO engaged.

Test 5 — PTO should NOT engage if:

• Operator engages the PTO before the mower deck is in

the operating position.

Test 6 — Blade Brake Check

Mower blades and mower drive belt should come to a

complete stop within seven (7) seconds after electric PTO

switch is turned off (or operator raises from the seat). If

mower drive belt does not stop within seven (7) seconds,

see your dealer.

18

NOTE: Once the engine has stopped, the PTO switch must

be turned off, parking brake must be engaged, the ground

speed control levers must be locked in the NEUTRAL

position, after the operator returns to the seat to start the

engine.

ferrismowers.com | snapperpro.com

Page 19

Not for

Reproduction

800X Series Zero-Turn Rider - 61” & 72” Mower Deck

Adjustment Procedures

Seat Adjustment

Models Equipped with Standard Seat

The seat can be adjusted forward and back.

S/N: 2014648787 & Below: Move the seat adjustment lever

(A, Figure 38) forward, position the seat as desired, and

release the lever to lock the seat in position.

S/N: 2014648788 & Above: Move the seat adjustment lever

(A, Figure 38) to the left, position the seat as desired, and

release the lever to lock the seat in postion.

Models Equipped with Suspension Seats

In addition to the forward and backward seat adjustment,

models equipped with a suspension seat can be adjusted for

lumbar support, suspension and back angle.

Forward and Backward Adjustment:

Twist the forward / backward seat adjustment lever (A,

Figure 39) counter-clockwise, position the seat as desired,

and release the lever to lock the seat into position.

Lumbar Adjustment:

Turn the lumbar adjustment knob (B) until the desired

amount of lumbar is achieved.

Back Angle Adjustment:

Turn the back angle adjustment knob (C) until the desired

amount of back angle is achieved.

Suspension Adjustment:

Turn the suspension adjustment knob (D) until the display

scale has a reading that matches the weight of the operator.

A

B

Figure 38. Seat Adjustment - Standard Seat

A. Seat Adjustment Lever - S/N: 2014648787 & Below

B. Seat Adjustment Lever - S/N: 2014648788 & Above

C

B

A

D

Figure 39. Seat Adjustment - Suspension Seat

A. Forward / Backward Seat Adjustment Lever

B. Lumbar Adjustment Knob

C. Back Angle Adjustment Knob

D. Suspension Adjustment Knob

19

Page 20

Not for

Reproduction

800X Series Zero-Turn Rider - 61” & 72” Mower Deck

Ground Speed Control Lever

Adjustment

The ground speed control levers can be adjusted in three

ways. The alignment of the control levers, the placement of

the levers (how close the ends are to one another) and the

height of the levers can be adjusted.

To Adjust the Handle Alignment

Loosen the ground speed control lever mount bolts (D,

Figure 40) and pivot the lever(s) (C) to align with each other.

To Adjust the Handle Placement

Loosen the jam nuts and adjust the placement bolt (B) in or

out to properly adjust the lever end spacing.

To Adjust the Handle Height

Remove the mounting hardware (D) and reposition the

handle either up or down from its original position. You will

need to readjust the handle alignment as described above.

Speed Balancing Adjustment

If the rider veers to the right or left when the ground speed

control levers are in the maximum forward position, the top

speed of each of these levers can be balanced by adjusting

the top speed adjustment bolt(s) (A, Figure 40). Only adjust

the speed of the wheel that is traveling faster.

A

B

C

D

Figure 40. Top Speed Adjustment

A. Top Speed Adjustment Bolt

B. Handle Placement Hardware

C. Alignment Hardware

D. Ground Speed Control Lever Mount Bolts

E. Control Lever Base

A

E

To Reduce the Speed of the Faster Wheel

1. Loosen the securing nut.

2. Turn the top speed adjustment bolt COUNTERCLOCKWISE to reduce the speed.

3. Retighten the securing nut when adjustment is complete.

WARNING

Do NOT adjust the tractor for a faster overall speed

forward or reverse than it was designed for.

20

ferrismowers.com | snapperpro.com

Page 21

Not for

Reproduction

800X Series Zero-Turn Rider - 61” & 72” Mower Deck

Neutral Adjustment

If the tractor “creeps” while the ground speed control levers

are locked in NEUTRAL, then it may be necessary to adjust

the linkage rod.

1. Park the machine on a hard, level surface such as a

concrete floor. Disengage the PTO, engage the parking

brake, and turn off the engine.

CAUTION

This adjustment should not be performed while the

machine is running.

2. The locking nuts (A, Figure 41) are to be used together

to turn the rod. Loosen the jam nut that locks against

the ball joint (B) and turn the linkage rod (C) to adjust:

• If the machine creeps forward, turn the rod

CLOCKWISE (while standing at the rear of the machine

facing forward).

• If the machine creeps backward, turn the rod

COUNTER-CLOCKWISE (while standing at the rear of

the machine, facing forward).

3. Lock the jam nut (D) against the ball joint (B) when

neutral is achieved.

4. Start the engine.

5. Disengage the parking brake and lock the ground speed

control levers in the neutral position.

6. If the machine still “creeps,” repeat the Neutral

Adjustment procedure. It may take several attempts to

achieve neutral, depending on how much the machine

creeps.

A

C

Figure 41. Neutral Adjustment

A. Locking Nuts

B. Ball Joint

C. Linkage Rod

B

21

Page 22

Not for

Reproduction

800X Series Zero-Turn Rider - 61” & 72” Mower Deck

Return-to-Neutral Adjustment

Checking the Adjustment:

To determine if it is necessary to adjust the neutral return,

perform the following steps.

1. Disengage the PTO, engage the parking brake and turn

off the engine.

2. Move the ground speed control levers into the operating

position, pull the levers rearward and release.

3. Move the ground speed control levers out towards the

neutral position. If the levers do not align with the

notches in the neutral lock plate, it is necessary to adjust

the neutral return rod.

Adjustment:

1. Loosen the set collar (B, Figure 42) locked against the

return spring (A).

2. Lock the ground speed control levers in neutral.

3. Tighten the set collar snug against the return spring

4. Pull the ground speed control levers rearward and

release to check that the lever stops aligned with the

notch in the neutral lock plate.

NOTE: It is important to note that after every adjustment of

the neutral return spring, the lever must be returned to the

locked position to properly check the neutral position.

Figure 42. Return-to-Neutral Adjustment

A. Return Spring

B. Set Collar

AB

BA

22

ferrismowers.com | snapperpro.com

Page 23

Not for

Reproduction

800X Series Zero-Turn Rider - 61” & 72” Mower Deck

Parking Brake Adjustment

1. Disengage the PTO, engage the parking brake, stop the

engine and remove the ignition key.

2. Remove the kick plate (A, Figure 43)

3. Locate the brake spring (A, Figure 44).

4. With the parking brake engaged, measure the

compressed spring length. The spring should be 2-1/4”

(5,72 cm) when compressed.

5. If the spring does not measure 2-1/4” (5,72 cm), release

the parking brake and turn the adjustment nut (B) to

compress or relax the spring.

6. Engage the parking brake and re-measure the spring.

7. Once the measurement of 2-1/4” (5,72 cm) is achieved,

re-install the kick plate.

NOTICE

A

Figure 43. Remove the Kick Plate

A. Kick Plate

Do NOT adjust the spring to be shorter than 2-1/4” (5,72

cm) when compressed. This may damage the brake

mechanism.

(5,72 cm)

B

A

Figure 44. Parking Brake Adjustment

A. Brake Spring

B. Adjustment Nut

2-1/4”

23

Page 24

Not for

Reproduction

800X Series Zero-Turn Rider - 61” & 72” Mower Deck

Copyright © Briggs & Stratton Corporation

Milwaukee, WI, USA. All rights reserved.

SNAPPER PRO is a trademark of Briggs & Stratton

Corporation, Milwaukee, WI, USA.

FERRIS is a trademark of Briggs & Stratton Corporation,

Milwaukee, WI, USA.

Briggs & Stratton Corporation

5375 North Main Street

Munnsville, NY 13409

(800) 933-6175

24

ferrismowers.com | snapperpro.com

Loading...

Loading...