Page 1

DEALER SET-UP INSTRUCTIONS for EUROPEAN SNAPPER

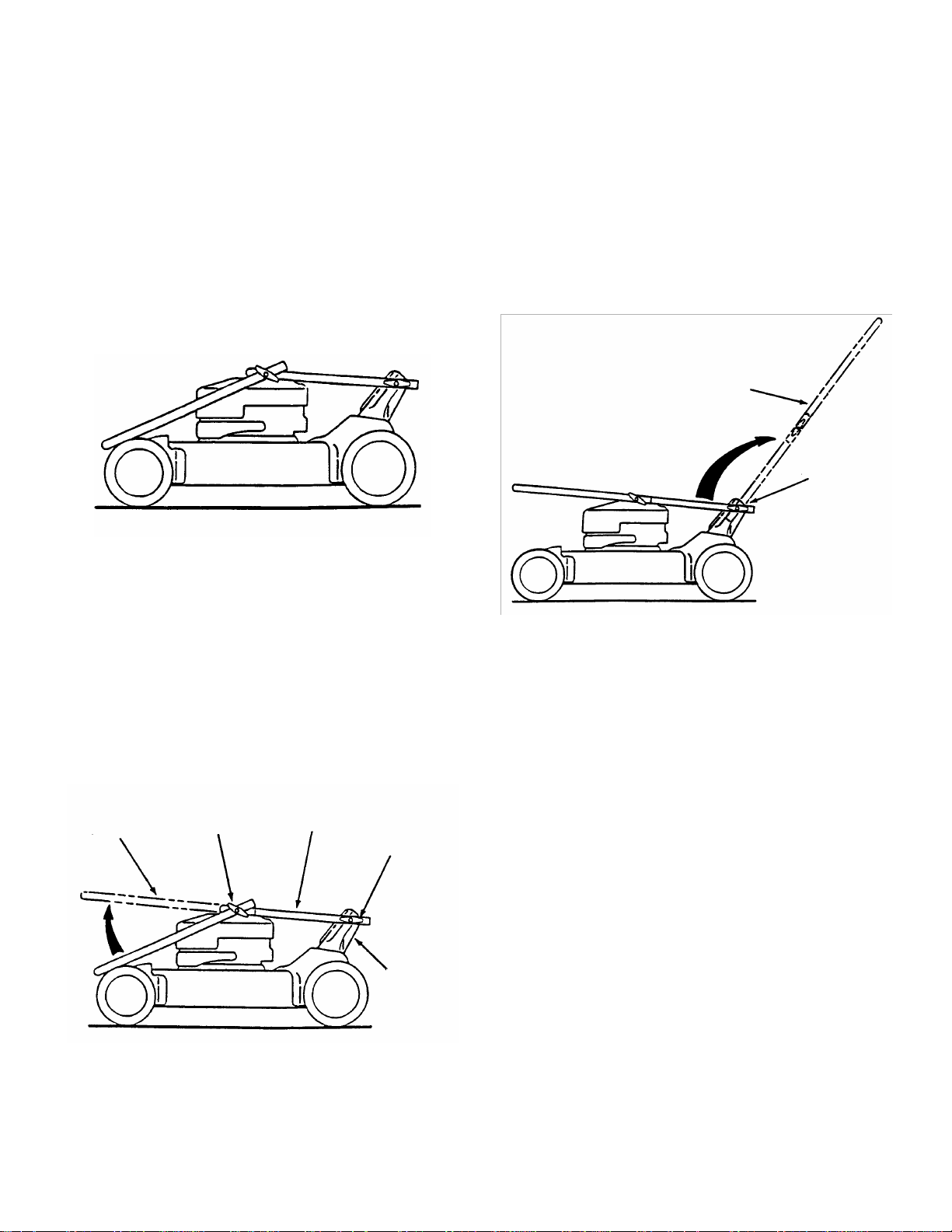

MOWER SHOWN AS REMOVED FROM SHIPPING

MODEL SHOWN)

UPPER

UPPER

LOWER

LOWER

LOWER

UPPER HANDLE &

LOWER

21” STEEL DECK “M” MODEL WALK BEHIND MOWERS

This SNAPPER Walk Behind Mower uses a handle engine control bail s ystem to kill th e engine for the SAFETY of

the operator. These mowers are designed for quick set-up. T he checklist on Page 4 should be filled out by the

dealer as the items are checked off and/or performed and the Consumer/Operator Product Regist rati on card filled

out and sent to the Customer Serv ice department at SNAPPER when completed . CAUTION: Cutting blades are

extremely sharp. We ar heavy leather gloves when handling or working with blades. Be careful to avoid cutting

yourself on sharp edges of blade.

PUSH MODELS

STEP 1: Remove mower from shipping carton. Mower

shown as removed from shipping carton with handles

folded in Figure 1.

STEP 3: Raise upper an d lower handle until i t seats into

position in the lower handle brackets. Securely tighten

lower handle T-Knobs on both sides. See Figure 3.

LOWER HANDLE

SHOWN IN POSITION

HANDLE

T-KNOB

CARTON WITH HANDLES FOLDED (PUSH

FIGURE 1

STEP 2: Remove and dis c ard c ardboard from between all

handles. Raise upper handle until it is in line and seats

into lower handle. Securel y tighten upper handle T -Knobs

on both sides. See Figure 2.

HANDLE

HANDLE

T-KNOB

HANDLE

HANDLE

T-KNOB

HANDLE

BRACKET

FIGURE 2

FIGURE 3

IMPORTANT: DO NOT tip machine with carburetor or

spark plug down. Oil fr om crankcase will saturate the air

filter and cause the engi ne to be hard to start or not start

at all. If contaminatio n does oc c ur , the air filter will have to

be replaced.

IMPORTANT: DO NOT tip machine with carburetor or

spark plug down. Oil fr om crankcase will saturate the air

filter and cause the engi ne to be hard to start or not start

at all. If contaminatio n does oc c ur , the air filter will have to

be replaced.

STEP 4: Tip mower back against the upper handle to gain

access to cutting blade. Remove foam shipping block

from cutting blade. T his must be removed before star ting

the engine.

INSTRUCTION No. 7-3133 (REV 1, 2/12/01)

Page 2

2

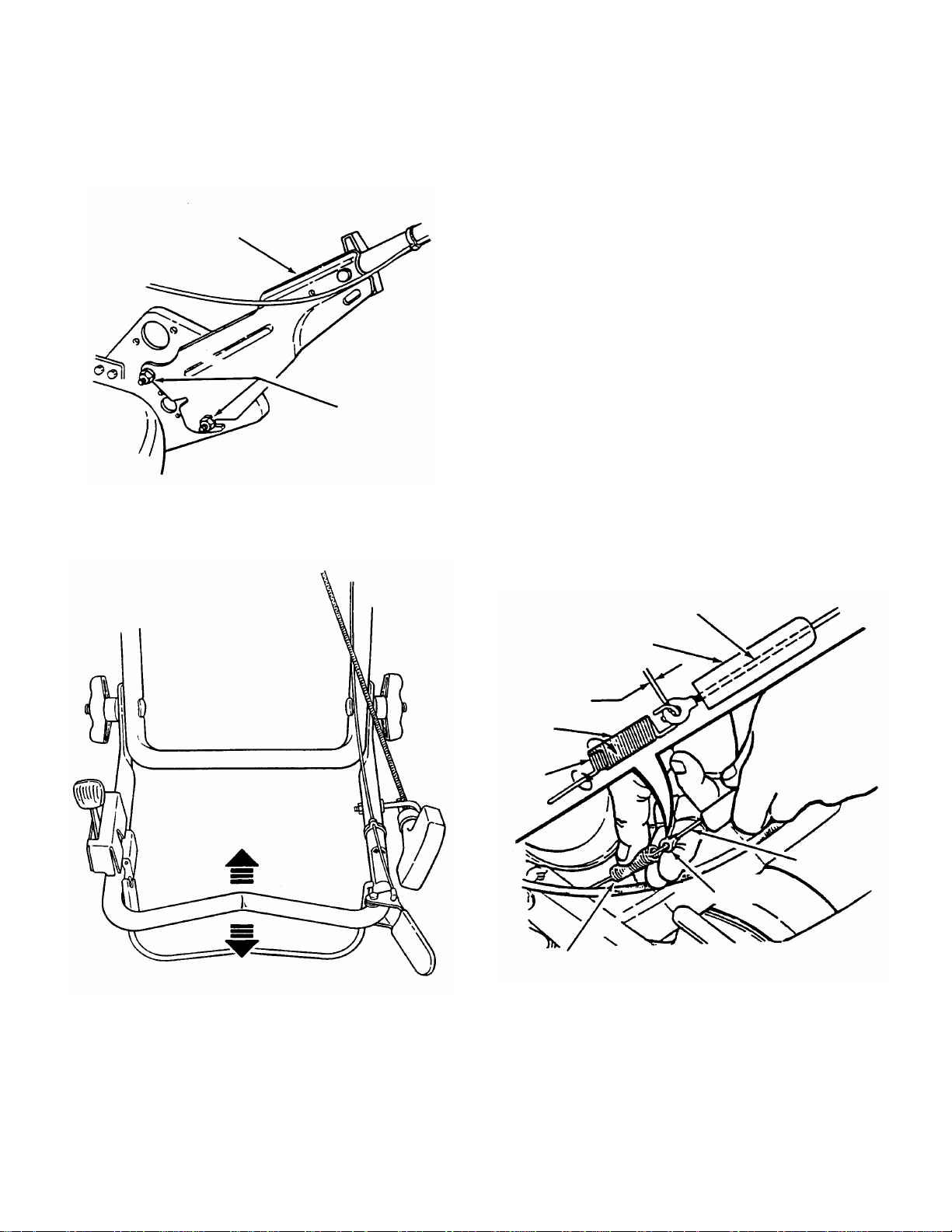

STEP 5: Handle hei ght is adjus table f or dif ferent hei ght of

LOWER HANDLE

LOOSEN

MOVE UPPER HANDLE

1/16”

-

1/8”

CLEARANCE

OUTER

INNER

SPRING

CLUTCH

operators. Loosen the two nuts on the inside of each of

the lower handles. S ee Figure 4. Move the hand le up or

down to the desired height. See Figure 5. Retighten all

nuts securely after adjus tment. Pull blade control agains t

upper handle, pull rope start handle and loop into rope

guide. See Figure 5.

BRACKET

TWO NUTS

FIGURE 4

STEP 6: Set-up is now complete for push models

without self-propelled drive system. For self-propelled

models continue to the “Self-Propelle d Models” Sectio n.

Proceed to the pre-s ale ch ecklist page of this i nstruction

to prepare the mower for use.

SELF-PROPELLED MODELS

NOTE: The set-up procedure for self-propelled models is

basically the same as the Push Models. Follow the exact

procedure as described in Steps 1 thru 6 from the Push

Models section.

STEP 7: Check the cleara nce between the clutch cable

and clutch spring. NOTE: Clearanc e betwee n spring and

cable is very im portant. Excessive clearance will c ause

drive system NOT to oper ate when wheel drive control

handle is depressed. No clearance at all will cause

mower to continue to propel itself when wheel drive

control handle is released to stop mower movement.

Slide vinyl spring cover (located at the end of clutch

cable) up clutch cable to gain access to the end of spring

and cable loop. With wheel drive control handle

released, clearanc e bet ween spri ng hook and cab le loop

should be 1/16” to 1/8”. If cleara nce is m ore or less than

specified, unhook spring from clutch cable eye, then

adjust by rotating outer spring clockwise or counter

clockwise to achieve the proper clearance. Rehook

spring to clutch cable eye. Slide vinyl cover over the

spring when correct clearance is reached. See Figure 6.

CLUTCH CABLE

VINYL SPRING COVER

SPRING

UP OR DOWN FOR

PROPER HEIGHT

CABLE

CABLE EYE

SPRINGS

FIGURE 5

FIGURE 6

Page 3

3

STEP 8: Driven d isc to driv e disc adjustment is set up at

MOVE GROUND SPEED

SIXTH SPEED

FIRST SPEED

DRIVEN DISC

DRIVEN

TRANSFER

CONNECTOR HEX

1/8” MEASUREMENT

SLIDE DRIVEN

TRANSFER

CONNECTOR

OUTSIDE

DRIVE

the factory. In case driven disc may need adjustment,

proceed as follows:

A. Place s peed control rod in the num ber six speed

position. See Figure 7.

POSITION

CONTROL TO SIX SPEED

POSITION

SIXTH

POSITION

C. Slide driven disc assembly over until 1/8” from

outside edge of drive disc. Maintaining the 1/8”

measurement, remove any looseness from the linkage.

This can be done by holding the transfer rod and

applying pressure to the left (as viewed from operators

position), then retighten the connector hex nut

securel y. See Figure 9. Move shift ro d to the number

one speed pos i ti o n, t h en ba c k to the number s ix s p ee d

position. Recheck the 1/8” measurement described

previously. Reinstall driven disc spring to driven disc

assembly.

TO OUTSIDE EDGE

DISC ASSEMBLY

TOWARD

OUTSIDE EDGE

OF DRIVE DISC

DISC

FIRST

FIGURE 7

B. Remove driven disc spring from driven disc

assembly as shown. Lo osen c onnector hex- nut. See

Figure 8.

ASSEMBLY

DRIVE DISC

DISC

SPRING

ROD

NUT

CONNECTOR

FIGURE 8

CONNECTOR

ROD

HEX NUT

FIGURE 9

STEP 9: Make sure all nuts and bolts are tight. Set-up is

now complete for self-propelled models Proceed to t he

pre-sale checklist page of this instruction to prepare

mower for use.

EDGE

Page 4

4

DEALER PRE SALE CHECKLIST for SNAPPER

21” STEEL DECK “M” MODEL WALK BEHIND MOWERS

The following must b e accomplished prior to sale. Refer to the previo us pages in this instruction fo r detailed

set-up instructions. Revi ew this checklist with purchaser. Ch eck (

checklist.

SET-UP CHECKLIST

_____ FOAM SHIPPING BLOCK removed from cutting blade.

_____ UPPER HANDLE & LOWER HANDLE secured in place and hardware tightened securely.

_____ SIDE CHUTE, RECYCLING COVER or GRASS BAG installed on mower.

_____ BLADE retaining bolt(s) checked and tighten securely.

LUBRICATION

_____ ENGINE OIL added to bring level up to full mark on 4-cycle engines (Refer to Engine Manual).

_____ DIFFERENTIAL grease checked and added if needed.

OPERATIONAL TEST

_____ ENGINE started, engine control settings checked and adjusted as needed.

_____ WHEEL DRIVE checked for proper operation and adjusted as needed (Self-Propelled Models).

_____ DRIVE DISC adjustment checked and made (Self-Propelled Models).

_____ GROUND SPEED control checked (Self-Propelled Models).

CPSC (Consumer Product Safety Commission) COMPLIANCE TEST

_____ BLADE CONTROL stops engine when released.

DEALER’S RECORDS & FINAL CHECK

_____ PERSONALLY HANDED Operator’s Manual & Mower Safety Booklet to purchaser.

_____ INSTRUCTED purchaser to read and follow instructions in Operator’s Manual.

_____ DEMONSTRATED proper starting procedure and operation of mower to purchaser.

_____ INSTRUCTED purchaser how to service air cleaner, maintain oil level (4-cycle).

_____ ASSISTED purchaser in completing Product Registration Card.

CONSUMER/OPERATOR PRODUCT REGISTRATION CARD

Purchase Date ___________________ Model _______________________ Serial No.________________________

Retailers Name ___________________________________ Signature _____________________________________

Address _____________________________________ City ____________________ State _______ Zip _______

MOWER WILL BE USED COMMERCIALLY? _______ YES _____ NO

Purchaser’s Name _________________________________ Signature ____________________________________

Address ____________________________________ City _____________________ State _______ Zip _______

IMPORTANT: This form is to be retained by the Dealer for future reference regarding Warranty, proof of

purchase, traceability for product recall or service, etc. Complete the Product Registration Card and Mail to

Customer Service Department at SNAPPER, P.O. BOX 1379, McDonough, Georgia, 30253.

✓) items actually performed and signed on

INSTRUCTION No. 7-3133 (REV 1, 2/12/01)

Loading...

Loading...