Page 1

IMPORTANT SAFETY INSTRUCTIONS

WARNING: This powerful cutting machine is capable of amputating hands and feet and can throw objects that

can cause injury and damage! Failure to comply with the following SAFETY instructions could result in serious

injury or death to the operator or other persons. The owner of the machine must understand these instructions

and must allow only persons who understand these instructions to operate machine. Each person operating the

machine must be of sound mind and body and must not be under the influence of any substance, which might

impair vision, dexterity or judgment. If you have any questions pertaining to your machine which your dealer

cannot answer to your satisfaction, call or write the Customer Service Department at SNAPPER, McDonough,

Georgia 30253. Phone: (1-800-935-2967).

PROTECTION FOR CHILDREN

Tragic accidents can occur if the operator is not alert

to the presence of children. Children are often

attracted to the machine and the mowing activity.

Never assume that children will remain where you last

saw them.

1. KEEP children out of the mowing area and under

the watchful care of a responsible adult.

2. DO NOT allow children in yard when machine is

operated (even with the blade OFF).

3. DO NOT allow children or others to ride on

machine or on attachments (even with the blades

OFF). They may fall and be seriously injured.

4. DO NOT allow pre-teenage children to operate

machine.

5. ALLOW only responsible adults & teenagers with

mature judgment under close adult supervision to

operate machine.

6. DO NOT operate blades in reverse. STOP BLADES.

LOOK and SEE behind and down for children, pets

and hazards before and while backing.

7. USE EXTRA CARE when approaching blind

corners, shrubs, trees, or other objects that may

obscure vision.

PROTECTION AGAINST TIPOVERS

Slopes are a major factor related to loss-of-control

and tip-over accidents, which can result in severe

injury or death. All slopes require extra CAUTION. If

you cannot back up the slope or if you feel uneasy on

the slope, DO NOT mow it. Use extra care with grass

catchers or other attachments; these affect the

handling and the stability of the machine.

1. DO NOT operate machine on slopes exceeding 15

degrees (27% grade).

2. Exercise EXTREME CAUTION on slopes above 10

degrees (18% grade). Turn blades OFF when

traveling uphill. Use a slow speed and avoid

sudden or sharp turns.

3. DO NOT operate machine back and forth across

face of slopes. Operate up and down. Practice on

slopes with blades off.

4. AVOID uphill starts. If machine stops going uphill

or tires lose traction, turn blades OFF and back

slowly down the slope.

PROTECTION AGAINST TIPOVERS

(Continued From Previous Column)

5. STAY ALERT for holes and other hidden hazards.

Tall grass can hide obstacles. Keep away from

ditches, washouts, culverts, fences and

protruding objects.

6. KEEP A SAFE DISTANCE (at least 3 feet) away

from edge of ditches and other drop offs. The

machine could turn over if an edge caves in.

7. Always begin forward motion slowly and with

caution.

8. Use weights or a weighted load carrier in accordance

with instructions supplied with a grass catcher. DO

NOT operate machine on slopes exceeding 10

degrees (18% grade) when equipped with grass

catcher.

9. DO NOT put your foot on the ground to try to

stabilize the machine.

10. DO NOT operate machine on wet grass. Reduced

traction could cause sliding.

11. DO NOT operate machine under any condition

where traction, steering or stability is doubtful.

PREPARATION

1. Read, understand, and follow instructions and

warnings in this manual and on the machine,

engine and attachments. Know the controls and

the proper use of the machine before starting.

2. Only mature, responsible persons shall operate

the machine and only after proper instruction.

3. Data indicates that operators age 60 and above,

are involved in a large percentage of mower-

related injuries. These operators should evaluate

their ability to operate the mower safely enough to

protect themselves and others from serious injury.

4. Handle fuel with extra care. Fuels are flammable

and vapors are explosive. Use only an approved

fuel container. DO NOT remove fuel cap or add

fuel with engine running. Add fuel outdoors only

with engine stopped and cool. Clean spilled fuel

from machine. DO NOT smoke.

5. Practice operation of machine with BLADES OFF

to learn controls and develop skills.

6. Check the area to be mowed and remove all

objects such as toys, wire, rocks, limbs and other

objects that could cause injury if thrown by blade

or interfere with mowing.

Page 2

IMPORTANT SAFETY INSTRUCTIONS

PREPARATION

(Continued From Previous Page)

7. Keep people and pets out of mowing

Immediately STOP blades, STOP engine, and

STOP machine if anyone enters the area.

8. Check shields, deflectors, switches, blade

controls and other safety devices frequently for

proper operation and location.

9. Make sure all safety decals are clearly legible.

Replace if damaged.

10. Protect yourself when mowing and wear safety

glasses, long pants and substantial footwear.

11. Know how to STOP blades and engine quickly

in preparation for emergencies.

12. Use extra care when loading or unloading the

machine into a trailer or truck.

13. Check grass catcher components frequently for

signs of wear or deterioration and replace as

needed to prevent injury from thrown objects

going through weak or worn spots.

area.

OPERATION

1. Mount and dismount machine from left side.

2. Start engine from operator's seat, if possible.

Make sure blades are OFF and parking brake is

set.

3. DO NOT leave machine with engine running.

STOP engine, STOP blades, SET brake, and

Remove key before leaving operators position

of any reason.

4. DO NOT operate machine unless properly

seated with feet on feet rests or pedal(s).

5. STOP BLADES and ENGINE and make sure

blades have stopped before removing grass

catcher or unclogging mower to prevent loss of

fingers or hand.

6. Blades must be OFF except when cutting grass.

Set blades in highest position when mowing

over rough ground.

7. Keep hands and feet away from rotating blades

underneath deck. DO NOT place foot on ground

while BLADES are ON or machine is in motion.

8. DO NOT operate machine without entire grass

catcher or guards in place. DO NOT point

discharge at people, passing cars, windows or

doors.

9. Slow down before turning.

10. Watch out for traffic when near or crossing

roadways.

11. STOP engine immediately after striking an

obstruction. Inspect machine and repair

damage before resuming operation.

12. Operate machine only in daylight or with good

artificial light.

13. Move joystick (if equipped) SLOWLY to

maintain control during speed and directional

changes.

OPERATION

(Continued From Previous Column)

14. Exercise CAUTION when pulling loads. Limit

loads to those you can safely control and attach

loads to hitch plate as specified with SNAPPER

attachment instructions.

15. DO NOT operate engine in enclosed areas.

Engine exhaust gases contain carbon

monoxide, a deadly poison.

MAINTENANCE

1. DO NOT store machine or fuel container inside

where fumes may reach an open flame, spark or

pilot light such as in a water heater, furnace,

clothes dryer or other gas appliance. Allow

engine to cool before storing machine in an

enclosure. Store fuel container out of the reach

of children in a well ventilated, unoccupied

building.

2. Keep engine free of grass, leaves or excess

grease to reduce fire hazard and engine

overheating.

3. When draining fuel tank, drain fuel into an

approved container outdoors and away from

open flame.

4. Check brakes frequently; adjust, repair or

replace as needed.

5. Keep all bolts, nuts and screws properly tight.

Check that all cotter pins are in proper position.

6. Always provide adequate ventilation when

running engine. Exhaust gases contain carbon

monoxide, an odorless and deadly poison.

7. Disconnect negative (black) cable from battery

before performing maintenance or service.

Cranking engine could cause injury.

8. DO NOT work under machine without safety

blocks.

9. Service engine and make adjustments only

when engine is stopped. Remove spark plug

wire(s) from spark plug(s) and secure wire(s)

away from spark plug(s).

10. DO NOT change engine governor speed

settings or overspeed engine.

11. Lubricate machine at intervals specified in

manual to prevent controls from binding.

12. Mower blades are sharp and can cut. Wrap the

blades or wear heavy leather gloves and use

CAUTION when handling them.

13. DO NOT test for spark by grounding spark plug

next to spark plug hole; spark plug could ignite

gas exiting engine.

14. Have machine serviced by an authorized

SNAPPER dealer at least once a year and have

the dealer install any new safety devices.

15. Use only genuine SNAPPER replacement parts

to assure that original standards are

maintained.

16. If battery is removed, DO NOT operate engine

without insulating Positive + battery cable

terminal with electrical tape, or sparking from

battery cables can result.

Page 3

Section 2 - OPERATING INSTRUCTIONS

WARNING

DO NOT leave machine with the engine running.

Stop engine. Stop blade. Shift to neutral. Engage

parking brake. Remove key.

2.4

STOPPING - ENGINE, WHEEL DRIVE, BLADE

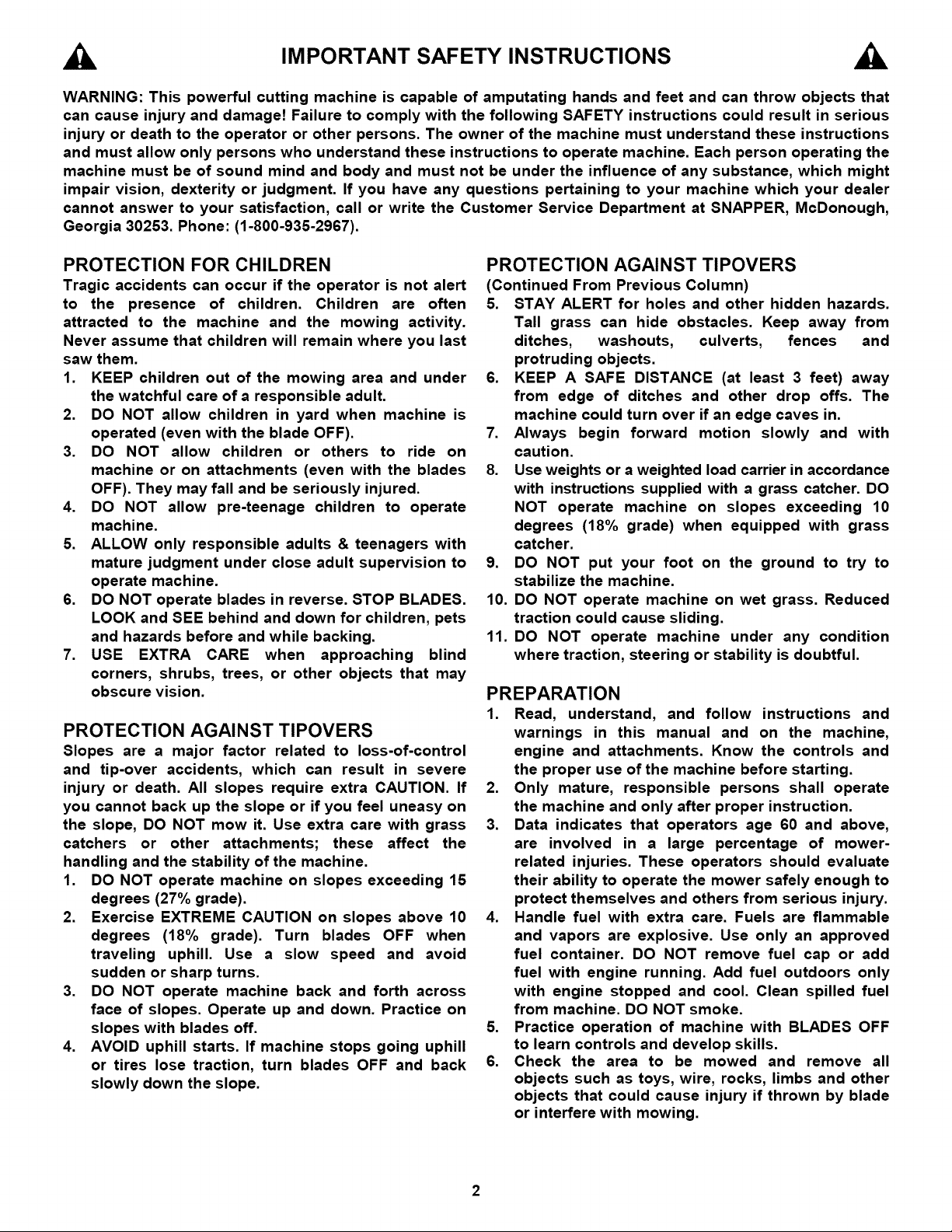

2.4.1. ENGINE

1. Stop engine by turning key to the "OFF" position.

See Figure 2.13.

PARK BRAKE

LATCH SHOWN

ENGAGED

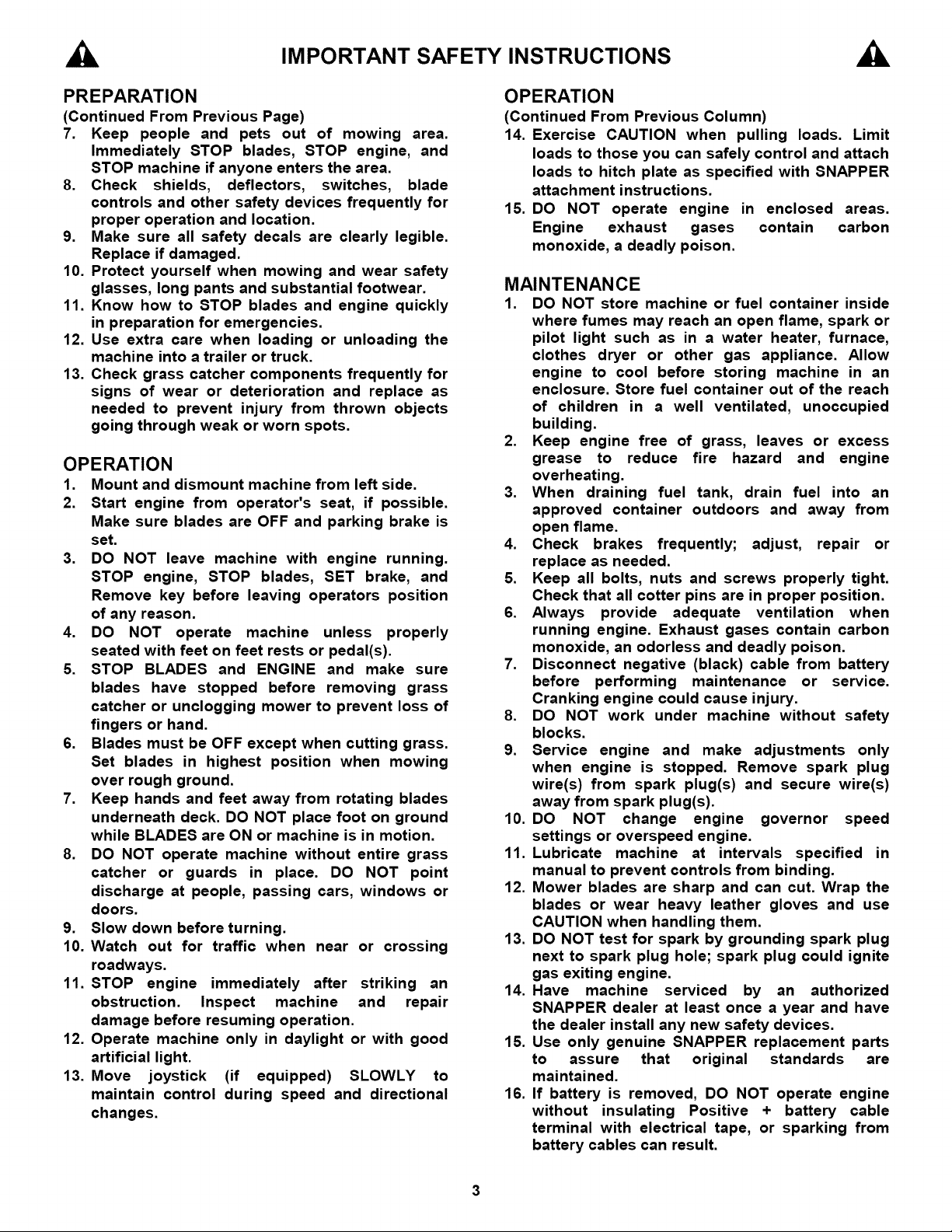

CLUTCH/BRAKE

PEDAL

FIGURE 2.14

FIGURE 2.13

2.4.2. WHEEL DRIVE

1. Stop motion of Rear Engine Rider by pushing

clutch/brake pedal all the way "DOWN" to apply

brake. See Figure 2.14.

WARNING

Once blade is disengaged, it should come to a

complete stop in 3 seconds or less. If the blade

continues to rotate after 3 seconds, the blade brake

must be adjusted. Refer to Section "BLADE BRAKE

ADJUSTMENT" for adjustment procedures or return

machine to an authorized SNAPPER dealer for

adjustment. DO NOT CONTINUE to operate machine

until blade brake is adjusted and functioning

properly.

2.4.3. MOWER BLADE

1. Stop mower blade by releasing blade pedals or

moving blade lever rearward to the "OFF" position.

See Figure 2.15.

BLADE LEVER IN "OFF"

POSITION

RELEASE BLADE

PEDALS

FIGURE 2.15

(Continued on Next Page)

10

Page 4

Section 2 - OPERATING INSTRUCTIONS

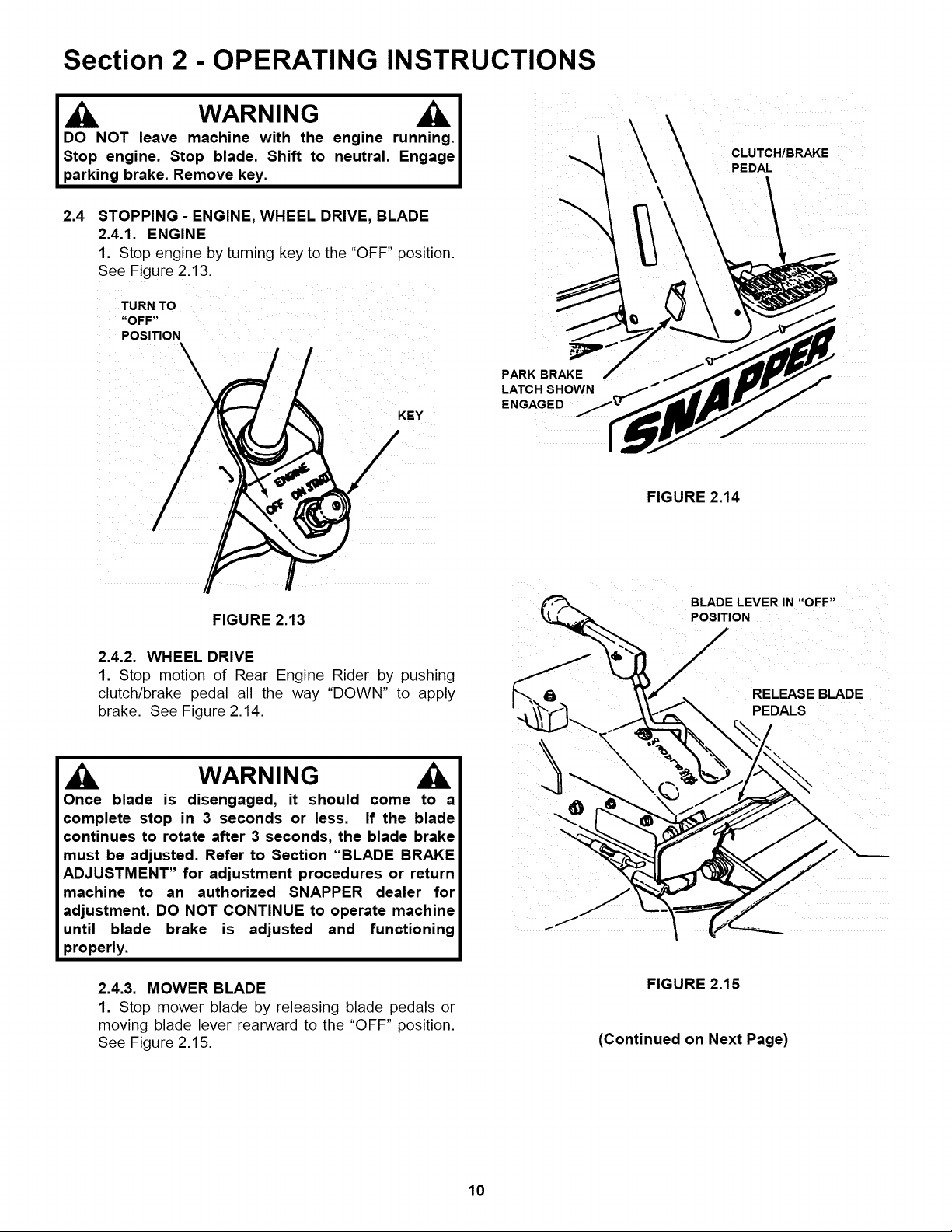

2.4

STOPPING - ENGINE, WHEEL DRIVE, BLADE

2.4.4. PARK BRAKE

1. Engage park brake by pushing clutch/brake pedal

"DOWN" and moving the park brake latch to the

"ENGAGED" position. While holding the park brake

latch "ENGAGED", release clutch/brake pedal to set

park brake. See Figure 2.16.

I,_ WARNING _I

DO NOT park the machine on slopes.

CLUTCH/BRAKE

PEDAL

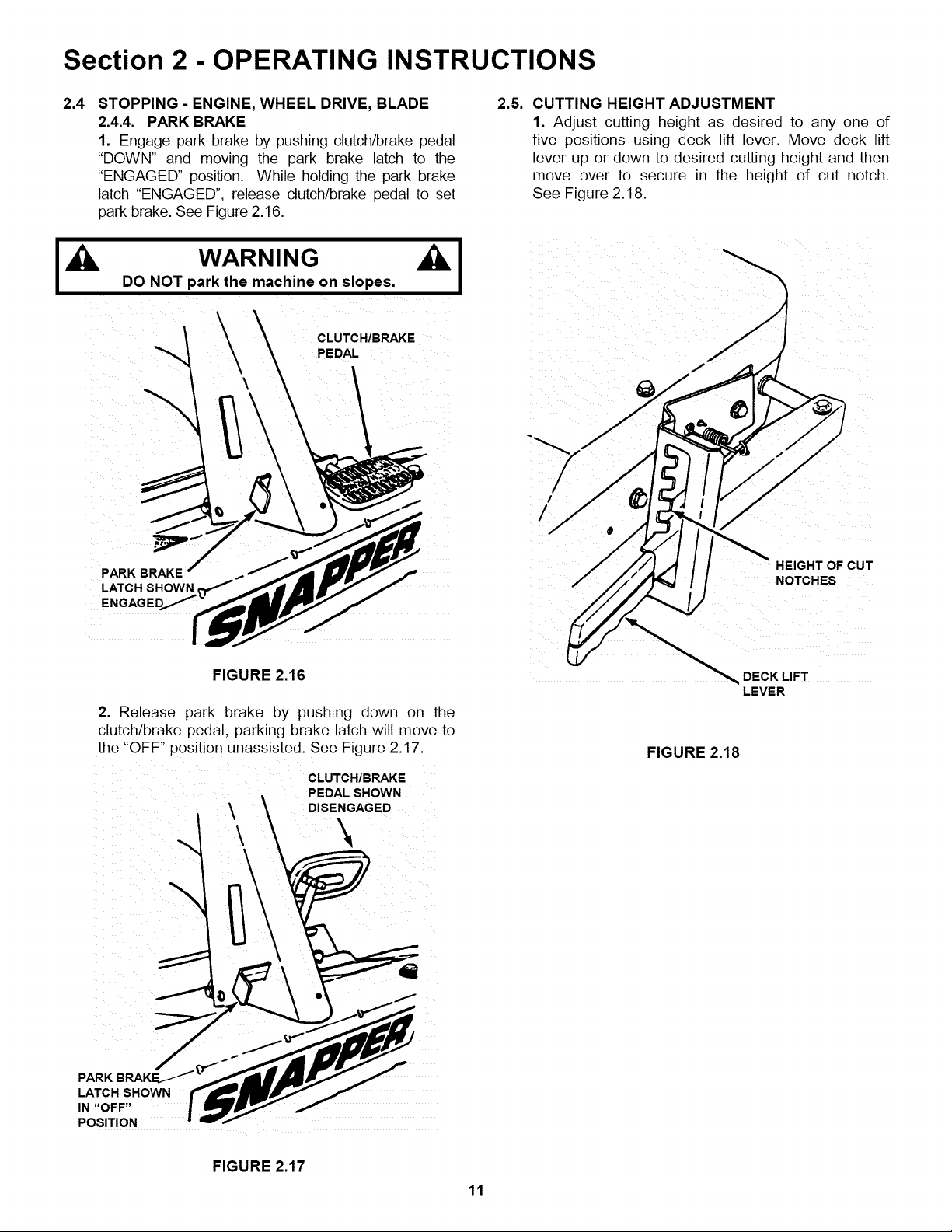

2.5. CUTTING HEIGHT ADJUSTMENT

1. Adjust cutting height as desired to any one of

five positions using deck lift lever. Move deck lift

lever up or down to desired cutting height and then

move over to secure in the height of cut notch.

See Figure 2.18.

/

/

PARK BRAKE

LATCH SHOWN

FIGURE 2.16

2. Release park brake by pushing down on the

clutch/brake pedal, parking brake latch will move to

the "OFF" position unassisted. See Figure 2.17.

CLUTCH/BRAKE

PEDAL SHOWN

\ DISENGAGED

HEIGHT OF CUT

DECK LIFT

LEVER

FIGURE 2.18

PARK BRAKE

LATCH SHOWN

IN "OFF"

POSITION

FIGURE 2.17

11

Page 5

Section 2 - OPERATING INSTRUCTIONS

2.6 REVERSE LOCKOUT MECHANISM

Data indicates that tragic back-over accidents occur

each year. These accidents usually involve

unsupervised children. Many times these children have

been given rides on the machine and have been trained

to view this potentially dangerous piece of machinery as

fun rather than being taught how to avoid danger.

This riding mower has a Reverse Lockout Mechanism.

This mechanism prevents the mower from being shifted

into reverse with the blade running. To shift into reverse

you must first stop the blade by releasing the blade

pedals and then shift to reverse. It is our

recommendation that this mechanism remain functional

and the operator of this equipment develop the habit of

never backing up with the blade running. As the Safety

Instructions Indicate, DO NOT operate blades in

reverse. STOP BLADES, LOOK AND SEE BEHIND

AND DOWN for children, pets and hazards before

and while backing.

We realize that this could cause a change to your

previous mowing method but we encourage you to

adjust to this new system. Do not defeat the Reverse

Lockout Mechanism.

2.6.1. Reverse Lockout Mechanism Override

1. Stop machine. Stop blade.

2. Depress and hold Override Lever.

3. Depress and hold Blade Pedals. Release

Override Lever.

4. Move blade lever forward to "ON" position.

LOOK and SEE behind and down for children,

and hazards before and while backing.

IMPORTANT: DO NOT use the Reverse Lockout

Mechanism Override as the normal operating mode. To

return to the Reverse Lockout Mechanism mode,

release blade pedals to turn blade off. The Override will

reset to Reverse Lockout. Check the Reverse Lockout

Mechanism frequently for proper function. With the

blade pedals depressed, the shift lever must not go into

reverse. DO NOT operate machine if Reverse Lockout

Mechanism is not functioning properly. Contact your

local Snapper dealer for assistance.

If you operate your mower near roadways or use

attachments that require quicker shifting to reverse,

there is an override lever provided. This lever can be

pushed and held before starting the blade and wilt allow

reverse operation until the blade pedals are released, at

which time the system will return to its Reverse Lockout

mode. This feature should never be selected unless you

are absolutely sure that no children or others are

present in the mowing area and that all children are

away and supervised by a responsible adult.

DANGER

LOOK and SEE behind and down for children, pets

and hazards before and while backing.

BLADES must be turned off before backing

machine.

DO NOT allow children on machine (even with

blades off) or in yard when mowing.

12

Page 6

Section 3 - MAINTENANCE

WARNING

DO NOT attempt any adjustments, maintenance,

service or repairs with the engine running. STOP

engine. STOP blade. Engage parking brake. Remove

key. Remove spark plug wire from spark plug and

secure away from plug. Engine and components are

HOT. Avoid serious burns, allow all parts to cool

before working on machine. Fuel Filler Cap and vent

must be closed securely to prevent fuel spillage.

3.1

INTRODUCTION

To retain the quality of the Rear Engine Rider, use

genuine SNAPPER replacement parts only. Contact a

local SNAPPER dealer for parts and service

assistance. For the correct part or information for a

particular Rear Engine Riding Mower, always mention

the model and serial number. SNAPPER recommends

returning the Rear Engine Rider to an authorized

SNAPPER dealer annually for inspection and addition

of any new devices which might upgrade the safety of

the Rear Engine Rider. For the nearest SNAPPER

dealer in your area, check the yellow pages under the

heading LAWN MOWERS. For engine parts and

service, look for the engine manufacturer's dealers

under the heading, ENGINES - gasoline.

3.2

SERVICE - AFTER FIRST 5 HOURS

Routine maintenance is important to the performance

and life of your Rear Engine Rider. Service performed

properly and at the recommended interval is essential.

Refer to Section "MAINTENANCE SCHEDULE" in this

manual and in the Engine Owner's Manual. Carefully

complete all of the recommended service procedures.

3.2.1. CHANGE ENGINE OIL

1. Place bricks or wooden blocks under the front

wheels to lower rear of engine.

2. Loosen or remove oil fill cap on engine.

3. Loosen oil drain plug.

4. Place a 2 quart minimum capacity container

under the end of the oil drain. Open oi drain. See

Figure 3.1 for oil drains used on the Rear Engine

Riders.

5. After all the oil has drained, close the drain and

wipe up any oil that may have spilled. See Figure 3.1.

Dispose of used oil properly.

6. Fill engine crankcase with new oil. Refer to your

engine owner's manual for oil specifications.

3.2.2. SERVICE ENGINE AIR CLEANER

The engine is equipped with a dual element air

cleaner. Both the foam pre-cleaner and cartridge

require service. Refer to Engine Owner's Manual for

recommended service procedures.

3.2.3. CHECK MOWER BLADE

1. Follow WARNING statement found on this page.

2. Check fuel level in tank. If over 3/4 full, remove

tank. Refer to Section "REMOVING FUEL TANK". If

3/4 or less, proceed to next step.

3. Carefully stand Rear Engine Rider on rear bumper.

WARNING

Remove the battery if the Rear Engine Rider will be

left standing on the rear bumper for longer than 2

hours. See Section on BATTERY REMOVAL. DO

NOT use a cutting blade that shows signs of

excessive wear or damage on the Rear Engine Rider.

Refer to Section on MOWER BLADE REPLACEMENT

for proper blade inspection and service procedures.

4. Check torque of blade mounting bolts. As

necessary, torque to 30 to 40 ft. Ibs. See Figure 3.2.

5. Check blade for sharpness, wear and damage.

See Section on BLADE WEAR LIMITS.

REMOVE OIL

PLUG TO ALLOW

OIL TO DRAIN

BOLTS TO 30 TO

40 FT, LB8,

\

FIGURE 3.2

6. Check blade for straightness.

"ADJUSTING MOWER BLADE".

FIGURE 3.1

13

Refer to Section

Page 7

Section 3 - MAINTENANCE

WARNING

DO NOT attempt any adjust_nents,maintenance, service or

repairswith the engine running. STOP engine. STOP blade.

Engage parking brake. Remove key. Remove spark plug

wire from spark plug and secure away from plug. Engine

and components are HOT. Avoid serious bums, allow all

partsto cool beforeworking on machine. FuelFillerCap and

vent must be closedsecurelyto prevent fuel spillage.

3.2 SERVICE - AFTER FIRST 5 HOURS

3.2.4. CHECK BLADE DRIVE BELT

The blade drive consists of a single belt from the

engine to the deck. Inspect for signs of deterioration

and proper tension.

1. Lower deck to lowest setting.

2. Remove four self-tapping screws, two on each

side of mower drive belt cover. See Figure 3.3.

3. Slide cover back and rotate out.

REMOVE FOUR (4)

SELF-TAPPING ......

REMOVE

3.2.5. BLADE BRAKE

1. Check blade brake for proper function. Blade should

stop rotating in 3 seconds or less after moving the blade

control lever to the "OFF" position or after releasing the

blade pedals.

I Blades must stop rotating in 3 seconds or less after I

the blade has been turned off. DO NOT operate l

machine until blade brake has been adjusted and l

functioning properly. I

2. If the blade continues to rotate longer than 3

seconds do not operate machine. Refer to Section

"BLADE BRAKE ADJUSTMENT" or contact your

SNAPPER dealer for assistance.

3.2.6. SERVICE BRAKE / PARK BRAKE

1. Check machine brake for proper function. Engage

park brake. Push machine. Rear tires should skid. Drive

machine forward and apply brake. Machine should come

to a complete stop in less than 5 ft.

2. If brakes are not functioning properly brake

adjustment must be completed before operating

machine. Refer to Section "SERVICE BRAKE - PARK

BRAKE ADJUSTMENT".

FIGURE 3.3

4. With engine "OFF" and deck in 3rd height of cut

position, move blade lever back to the "ON" position

and depress blade pedals.

5. Measure the belt spacing at idler pulley. See

Figure 3.4. The belt spacing should be 1 1/4" but

no less 1". If the measurement is less than 1", the belt

tension should be adjusted. Refer to Section "MOWER

DRIVE BELT ADJUSTMENT".

ENGINE

._t PULLEY

BELT SPACING -_

SHOULD BE

1-1/4"

IDLER

PULLEY

3.2.7. INTERLOCK SYSTEM

Check interlock controls for proper function:

The engine MUST NOT start if:

1. Blade Control is "ON" and/or clutch/brake pedal is

released.

The engine and blades MUST STOP if:

2. The operator leaves the operator position with Blade

Control "ON" and/or clutch/brake pedal is released.

DO NOT operate machine if interlock system t

functioning properly. Contact your SNAPPER r

WARNING I

immediately for assistance,

3.2.8. REVERSE LOCKOUT MECHANISM

Check function of Reverse Lockout Mechanism with

engine off.

1. Depress and hold blade pedals.

2. Depress and hold clutch/brake pedal.

3. Shift lever must not go into reverse.

WARNING

DO NOT operate machine if Reverse LockoutI

Mechanism is not functioning properly. Contact your l

SNAPPER dealer immediately for assistance. I

FIGURE 3.4

MOWER

DECK

PULLEY

14

Page 8

Section 4 - ADJUSTMENTS & REPAIR

Once blade is disengaged it should come to a stop

in 3 seconds or less. If the blade continues to rotate

after 3 seconds the blade brake must be adjusted.

DO NOT continue to operate the machine if the blade

brake is not operating properly.

4.2.2. BLADE BRAKE ADJUSTMENT

The automatic Blade Brake should stop the blades

within seconds anytime the blades are

disengaged by moving blade lever to the "OFF"

position or by releasing the Blade Pedals. When

the Blade Brake is properly adjusted there should

be 1/16" to 1/8" clearance between the Blade

Engagement Lever and the back of the Latch

Plate. Check this by disengaging the Blade Lever

and depressing the Blade Pedals as shown in

Figure 4.2. If clearance is greater than 1/4"

perform the following adjustment.

1. Remove Belt Cover. Refer to Section "BLADE

BELT COVER REMOVAL".

2. With the blade engagement lever disengaged,

hold the blade pedals down and measure the

distance between the front of the blade lever and the

rear of the latch plate. The dimension should be 1/16"

to 1/8" clearance between lever and plate. See Figure

4.5. If the dimension is incorrect go to step 3.

3. If dimension is greater than 1/8", rotate nut

clockwise to increase brake tension. If dimension is

less than 1/16", rotate nut counter-clockwise to

decrease brake tension. See Figure 4.4.

4. Reinstall spindle cover.

engag_ it shoL

ss. lft :bladec

WARNING i

he blaq , blake

toope tethern

ting pr )erly.

E BRA "A)JU_

c Blad_ _rat:e sh, :te,_

3

WARNING

DO NOT operate machine until blade brake is

adjusted and functioning properly. If blade stop time

can not be achieved with the adjustment procedure

described above, take machine immediately to an

authorized Snapper dealer.

FIGURE 4.5

DO NOT attempt any adjustments, maintenance, service

or repairs with the engine running. Stop engine. Stop

blade. Engage parking brake. Remove key. Remove

spark plug wire from spark plug and secure away from

plug. Engine and components are HOT. Avoid serious

burns, allow all parts to cool before working on machine.

Fuel Filler Cap and Vent must be closed securely to

prevent fuel spillage.

4.2.3. MOWER DECK ADJUSTMENT

(Side-To-Side Levelness)

Before making deck leveling adjustments, check the tire

pressure. Front tires 12 psi, rear tires 12 psi. If tires are

properly inflated and mowing is still uneven, adjust side-

to-side deck levelness.

1. Place Rider on a smooth level surface.

2. Follow WARNING statement found on this page.

3. Place a piece of angle iron, pipe, or similar object

under center of deck at the rear.

4. Remove rear hanger chains and allow center, rear of

deck to rest on angle iron.

5. Measure the distance from blade tips to floor. If the

measurement is within 1/8" from side-to-side, the deck

attitude is satisfactory. If difference from side-to-side is

greater than 1/8",continue with adjustment.

6. Loosen the carriage bolt and nut retaining the left

side of the front lift arm and adjuster. Only loosen the

bolt and nut to the point where some tension remains

but liftarm can be moved.

ROTATE NUT CLOCKWISE TO

INCREASE BRAKE TENSION

ROTATE NUT COUNTER CLOCKWISE TO

DECREASE BRAKE TENSION

FIGURE 4.4

BLADE PEDAL

FRONT LIFT ARM

FIGURE 4.6

19

Page 9

Section 4 - ADJUSTMENTS & REPAIR

WARNING

DO NOT attempt any adjustments, maintenance,

service or repairs with the engine running. Stop

engine. Stop blade. Engage parking brake. Remove

key. Remove spark plug wire from spark plug and

secure away from plug. Engine and components are

HOT. Avoid serious burns, allow all parts to cool

before working on machine. Fuel Filler Cap and

Vent must be closed securely to prevent fuel

spillage.

4.3 REAR ENGINE RIDER DRIVE COMPONENTS

Your Snapper rider is equipped with a patented

smooth start clutch. The clutch should operate

smoothly and provide ample traction. If problems are

experienced, contact your Snapper dealer for repair.

4.3.1. SERVICE BRAKE/PARK BRAKE

ADJUSTMENT

Test the wheel brake on a dry concrete surface.

When properly adjusted, the Rear Engine Rider will

stop within 5 feet from fastest speed. If stopping

distance is more than 5 feet, the wheel brake should

be adjusted as follows:

1. Follow WARNING statement found on this page.

2. Check fuel level in tank. If over 3/4 full, remove

tank. Refer to Section "REMOVING FUEL TANK". If

3/4 or less, proceed to next step.

3. Carefully stand Rear Engine Rider on rear

bumper.

4. Depress clutch/brake pedal all the way down.

Move and hold the park brake latch in the

"ENGAGED" position and release the clutch/brake

pedal to set the park brake. See Figure 4.8.

CABLE

HOUSING

CABLE END

COTTER

PIN

7. Adjust cable up or down using the jam-nuts to

obtain a distance 3/4" between end of clutch/brake

cable (adjustment shown in inset of Figure 4.9) and

bottom of housing. See Figure 4.9.

8. After adjustment is complete, securely tighten

cable jam-nuts.

9. Retest wheel brake function.

CHAIN

CASE I t I

COTTER PIN

FIGURE 4.9

CLUTCH/BRAKE

FIGURE 4.8

5. Measure the distance between end of

clutch/brake cable and bottom of housing.

Measurement should be 3/4". See inset of Figure

4.9.

6. If measurement is less than 314", loosen the two

jam-nuts. See Figure 4.10. Hold the clutch/brake

cable to the chain case bracket.

\

BRAKE CABLE

CHAIN CASE

FIGURE 4.10

21

Page 10

Section 4 - ADJUSTMENTS & REPAIR

WARNING

DO NOT attempt any adjustments, maintenance,

service or repairs with the engine running. STOP

engine. STOP blade. Engage parking brake. Remove

key. Remove spark plug wire from spark plug and

secure away from plug. Engine and components are

HOT. Avoid serious burns, allow all parts to cool

before working on machine. Fuel Filler Cap and vent

must be closed securely to prevent fuel spillage.

DO NOT use a cutting blade that shows signs of

excessive wear or damage on the Rear Engine Rider.

On Rear Engine Riders equipped with a grass

catcher attachment, the air lifts should be replaced

when the blade is replaced.

MOWER BLADE REPLACEMENT '___' /

4.4

4.4.1. BLADE WEAR LIMITS

1. Inspect blade frequently for signs of excessive

wear or damage See Figure 4.11.

5. Inspect condition of blade. See Figure 4.11.

6. If blade is in good condition, sharpen at 22 to 28

degrees. DO NOT sharpen beyond existing cutting

edge. See Figure 4.13.

7. Check blade balance after sharpening. If

necessary, correct blade balance by grinding the

heavy end of blade.

8. Reinstall blade. See Figure 4.12. Torque blade

mounting bolts to recommended range of 30 to 40

ft. Ibs.

NUT LOCKWASHER

DANGEROUS CONDITION!

NOT USE ON MOWER! .....................................

REPLACE WITH NEW BLADE, DO NOT SHARPEN

Do

FIGURE 4.11

WARNING AI

Blades are extremely sharp and can cause severe I

injuries. Wear heavy leather gloves when working on or I

handling blades. DO NOT use blades that show signs I

of wear or damage. I

4.4.2. BLADE SHARPENING

1. Follow WARNING statement found on this page.

2. Check fuel level in tank. If over 3/4 full, remove

tank. Refer to Section "REMOVING FUEL TANK". If

3/4 or less, proceed to next step.

3. Carefully stand Rear Engine Rider on rear bumper.

4. Remove blade. See Figure 4.12.

FIGURE 4.12

ORIGINALBEYOND 028o__ "--" _. \

22 T --

.....................................

/

ORIGINAL CUTTING EDGE

FIGURE 4.13

22

Page 11

MAINTENANCE SCHEDULE

SUBJECT

Engine

Engine

Engine

AirPre-Cleaner

AirCleaner

SparkPlug

FuelFilter

EngineCooling

System

Battery

Battery

Tires

DriveBelts

MowerBlades

MowerDeck

LubricationPoints

SERVICE

TO BE PERFORMED

Check Oil Level

Initial Oil Change

Periodic Oil Change

Service Sponge Pre-

Cleaner Element

Replace Element

Replace Plugs

Replace Filter

Clean Shrouds & Fins

Check Electrolyte

Charge Battery

Check Pressures

Check For Wear And

Tension

Check For Wear And

Damage

Clean Debris

Accumulation

Grease or Oil

REFERENCE

PAGES

Page 6

Page 13

Page 13

Engine Manual

Engine Manual

Engine Manual

Page 17

Engine Manual

Page 25

Page 24 & 25

Page 6

Pages 14,18,23

Pages 22

Page 15 X

Pages 15 & 16

EACH

USE

6

HOURS

X

X

X

26

HOURS

X

X

X

X

X

60

HOURS

X*

100

HOURS

X

X

X**

EACH

SEASON

X

X

X

X

X

LubricateChainCase

Check Grease Level

Pages 16

&Transmission

BladeBrake

StoppingTime

Clutch/BrakeSystem

ReverseLockout

Check blade stopping

for proper operation

Check Clutch/Brake for

proper operation

Check function

Pages 14 & 19 X

Page 14 & 21 X

Page 6 & 14 X X

Mechanism

InterlockSystem

*Change oil every 25 hours when operating under heavy load or high temperatures.

**Clean more often under dusty conditions or when air debris is present

Check function

Page 14 X

X

X

X

X

29

Page 12

Generally, wash foam-type filters

In a dlshwashlng detergent and

water solution. Rinse and wring

dry, then saturate with oil and

squeeze out excess. Failure to

re-oil this type filter will ruin the

engine.

Clean paper elements by tapping

lightly. Blowing with air will

rupture paper elements.

Use a flashlight to detect clogged

or torn paper elements - replace If

damaged in any way.

PRIMARY MAINTENANCE

Air Is also needed to keep

your engine cool. Dirt, dust

& debris build up to restrict

and clog cooling air Intake

screens and fins. Clean

screens and fins at frequent

Intervals. The engine blower

housing and shrouds should

be removed at least once

each season or more often

under dry, dusty conditions

for a thorough cleaning of

fins.

Failure to keep external

surfaces clean not only

presents fire hazards, but

"causes overheating and

resulting engine damages

such as:

1. distorted valve guides

2. sticking valves

t_°o. 3. scuffed, scored

.,,_. walls

4. overspeedlng

5. loss of power

6. complete failure of

engine.

Dirt can also be introduced

Into an engine In dirty fuel

from a contaminated

container. Always use clean

fresh fuel from a clean

container to guard against

dirt, sludge and water

contamination.

Be aware that fuel breaks

down in storage and forms

gummy compounds which

will block carburetor pass-

ages. Never use fuel more

than 3 months old. Drain

tank then run the engine out

of fuel before storing during

the off-season.

An engine must also have proper lubrication.

All engines use some oil. On 4-cycle engines,

CHECK OIL LEVEL BEFORE EACH START-UP.

Wipe area clean around the oll check plug or

dipstick opening to keep dirt from falling Into

the engine when checking the oil Always

check with the machine on a level surface.

On engines with dipstick, keep the level up to,

but not over, the FULL mark. When adding o11,

allow time for all of the oll to flow down the fill

tube to prevent a false full reading when the

level could actually be low and result In engine

damage.

34

Page 13

PRIMARY MAINTENANCE

On 4-cyle engines with an oil level plug,

don't be fooled into thinking the engine has

sufficient lubricating oii if you can see "some"

oil in the opening - the level should always be

brought up to the point of lg at the

top of the fill hole,

I

Change oil at regular Intervals using a a high

quality oil such as Snapper's small engine

formulated 4-cycle engine oil Refer to the

engine owner's manual for oil details.

On 2-cycle engines, lubrication must be

provided by an exact mixture of gasoline

and 2-cycle air-cooled engine oil A 2-cycle

engine that Is mistakenly run on straight

gasoline will be ruined in less than 5

minutesl If you keep straight gasoline In

addition to pre-mixed 2-cycle engine fuel,

be sure the containers are clearly marked

to avoid mix-up.

Snapper 2-cycle engines require a 32 to 1

mixture of gasoline and BIA certified TC-W

oil such as Snapper's 2-cycle engine oil

Many of the 2-cycle engine oils on the

market today make fantastic claims, but for

the best performance and long engine life,

always use Snapper 2-cycle oil Pre-mix

the fuel and always shake the container

before filling the tank.

STARTING CHECK LIST

1. Engine 011

2. Air Cleaner

3. Fuel Tank

4. Choke

5. Primer (on

some engines)

6, Safety Inter-

lock Switches

7. Switch &

Blade Control

8. Spark plug

g. Throttle

control

10. Blade

11. Muffler

• To full level (4-cycle)

• Properly mixed with gas

• Clean and properly serviced

• Full fresh clean gasoline

• Fuel valve open

• Cap vent open

• Inline filter clean

• Operating properly

• Used properly

• In proper position

• All wires properly connected

• Switch On

• Blade control properly

• Wire connected

• Good connecUon

• Start position

• Sharpened

• Good condition

• Not clogged

• Grass & leaves cleaned away

(2 cycle)

positioned on walk mower

ProperlyInstalled and

torqued

Read and follow all safety "_

Instructions in safety book-

lets and manuals.

Keep in mind that dirt Is your engine's enemy

#1 both Internally and externallyl Internally,

dirt will quickly ruin an engine and externally

It will cause overheating and resulting Internal

Damage caused by Improper lubri-

poor air cleaner service or overheating

due to dirt cannot be covered under warranty.

It only takes a few moments to service the

engine (and equipment) on a routine baals

but the rewards will be a quick starUng, re-

sponsive engine that will provide long

astisfactory service with minimum maintananca

cost. The prestart checklist In the next column

and Instructions In your Snapper Operator's

Manual are designated to help you keep your

Snapper In top operating condition with

minimum effortl

J

35

Loading...

Loading...